NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 301 of 1306

6 CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between distributor (camshaft position sensor) terminal 6 and engine ground. Refer to the

wiring diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-3

+Harness for open or short between camshaft position sensor and engine ground

©Repair open circuit or short to ground or short to power in harness or connectors.

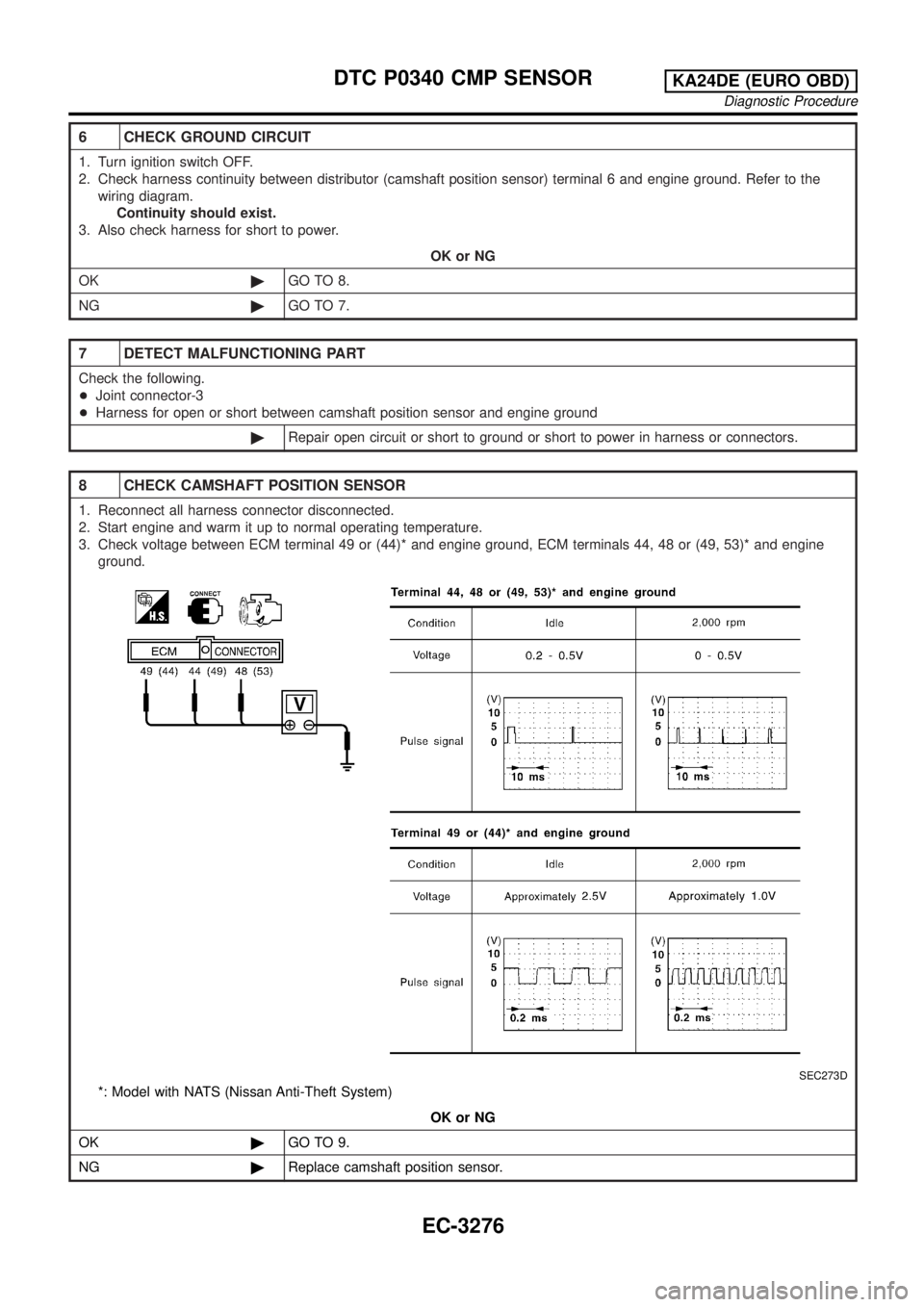

8 CHECK CAMSHAFT POSITION SENSOR

1. Reconnect all harness connector disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 49 or (44)* and engine ground, ECM terminals 44, 48 or (49, 53)* and engine

ground.

SEC273D

*: Model with NATS (Nissan Anti-Theft System)

OK or NG

OK©GO TO 9.

NG©Replace camshaft position sensor.

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3276

Page 302 of 1306

9 CHECK SHIELD CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect joint connector-3.

3. Check the following.

+Continuity between joint connector-3 terminal 2 and ground

+Joint connector-3

(Refer to ªHARNESS LAYOUTº, EL section.)

Continuity should exist.

4. Also check harness for short to power.

5. Then reconnect joint connector-3.

OK or NG

OK©GO TO 10.

NG©Repair open circuit, short to power in harness or connectors.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3277

Page 303 of 1306

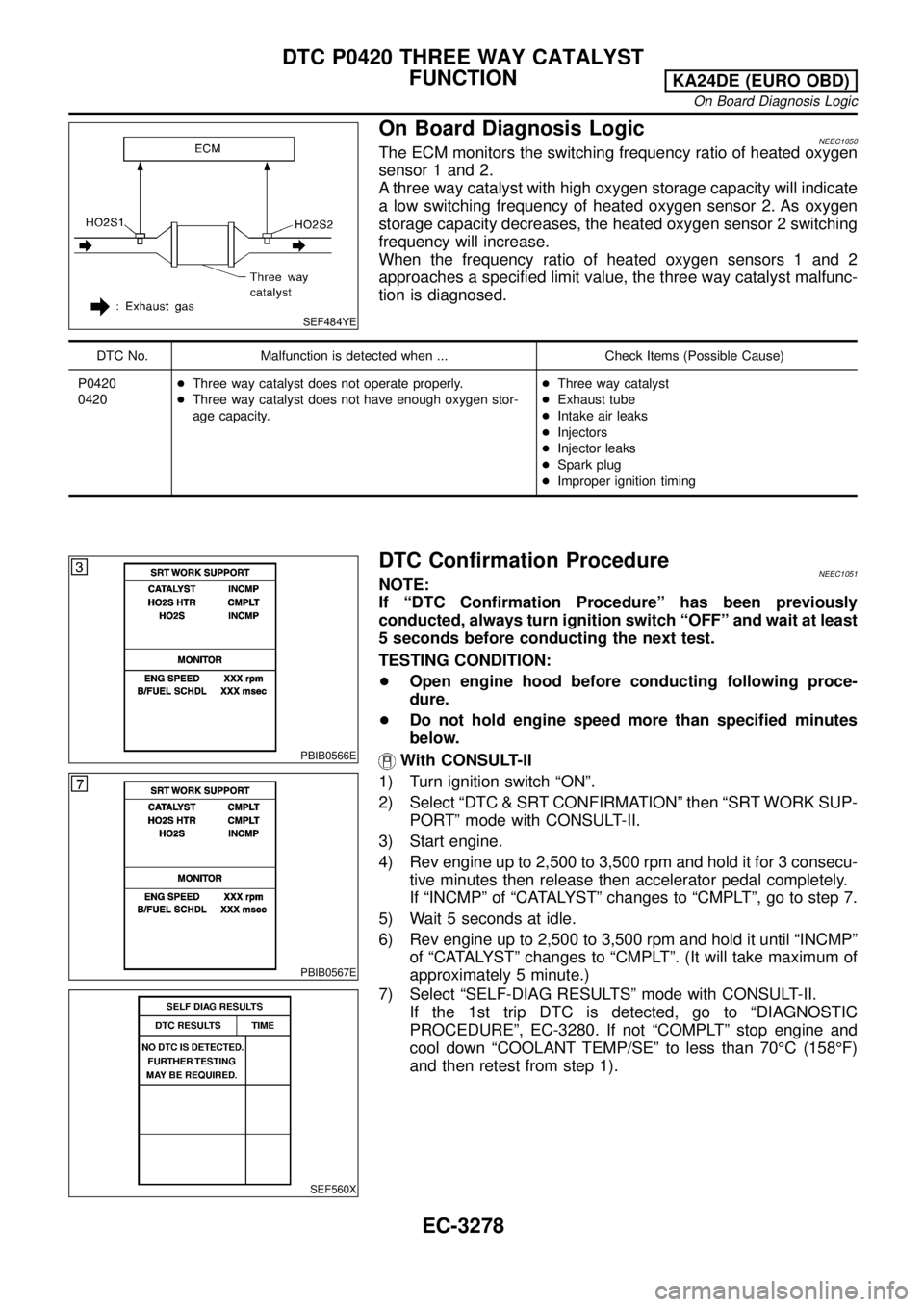

SEF484YE

On Board Diagnosis LogicNEEC1050The ECM monitors the switching frequency ratio of heated oxygen

sensor 1 and 2.

A three way catalyst with high oxygen storage capacity will indicate

a low switching frequency of heated oxygen sensor 2. As oxygen

storage capacity decreases, the heated oxygen sensor 2 switching

frequency will increase.

When the frequency ratio of heated oxygen sensors 1 and 2

approaches a specified limit value, the three way catalyst malfunc-

tion is diagnosed.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0420

0420+Three way catalyst does not operate properly.

+Three way catalyst does not have enough oxygen stor-

age capacity.+Three way catalyst

+Exhaust tube

+Intake air leaks

+Injectors

+Injector leaks

+Spark plug

+Improper ignition timing

PBIB0566E

PBIB0567E

DTC Confirmation ProcedureNEEC1051NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

5 seconds before conducting the next test.

TESTING CONDITION:

+Open engine hood before conducting following proce-

dure.

+Do not hold engine speed more than specified minutes

below.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDTC & SRT CONFIRMATIONº then ªSRT WORK SUP-

PORTº mode with CONSULT-II.

3) Start engine.

4) Rev engine up to 2,500 to 3,500 rpm and hold it for 3 consecu-

tive minutes then release then accelerator pedal completely.

If ªINCMPº of ªCATALYSTº changes to ªCMPLTº, go to step 7.

5) Wait 5 seconds at idle.

6) Rev engine up to 2,500 to 3,500 rpm and hold it until ªINCMPº

of ªCATALYSTº changes to ªCMPLTº. (It will take maximum of

approximately 5 minute.)

SEF560X

7) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

If the 1st trip DTC is detected, go to ªDIAGNOSTIC

PROCEDUREº, EC-3280. If not ªCOMPLTº stop engine and

cool down ªCOOLANT TEMP/SEº to less than 70ÉC (158ÉF)

and then retest from step 1).

DTC P0420 THREE WAY CATALYST

FUNCTION

KA24DE (EURO OBD)

On Board Diagnosis Logic

EC-3278

Page 304 of 1306

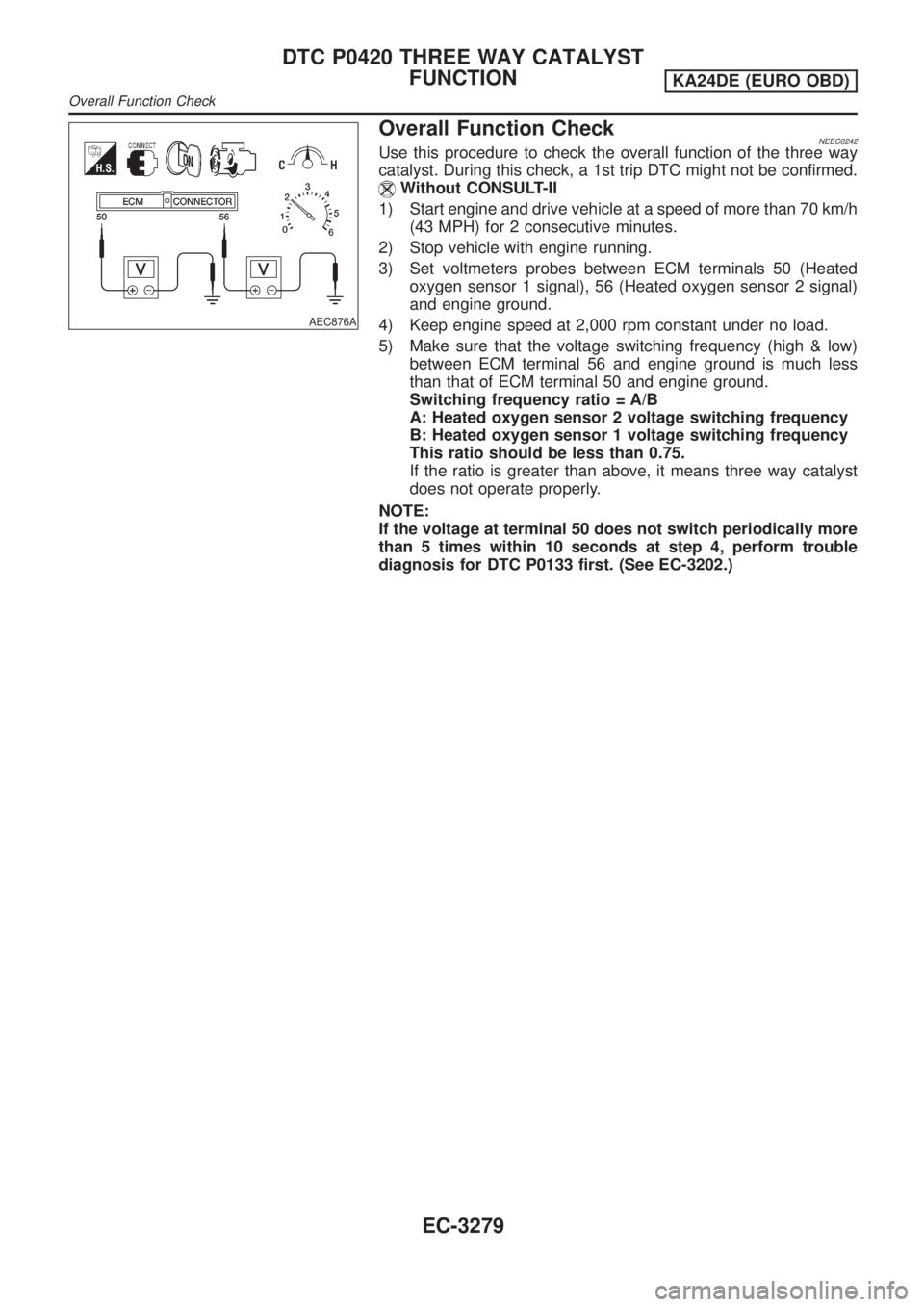

AEC876A

Overall Function CheckNEEC0242Use this procedure to check the overall function of the three way

catalyst. During this check, a 1st trip DTC might not be confirmed.

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeters probes between ECM terminals 50 (Heated

oxygen sensor 1 signal), 56 (Heated oxygen sensor 2 signal)

and engine ground.

4) Keep engine speed at 2,000 rpm constant under no load.

5) Make sure that the voltage switching frequency (high & low)

between ECM terminal 56 and engine ground is much less

than that of ECM terminal 50 and engine ground.

Switching frequency ratio = A/B

A: Heated oxygen sensor 2 voltage switching frequency

B: Heated oxygen sensor 1 voltage switching frequency

This ratio should be less than 0.75.

If the ratio is greater than above, it means three way catalyst

does not operate properly.

NOTE:

If the voltage at terminal 50 does not switch periodically more

than 5 times within 10 seconds at step 4, perform trouble

diagnosis for DTC P0133 first. (See EC-3202.)

DTC P0420 THREE WAY CATALYST

FUNCTION

KA24DE (EURO OBD)

Overall Function Check

EC-3279

Page 305 of 1306

Diagnostic Procedure=NEEC0243

1 CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before three way catalyst.

SEF099P

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 4.

NG©Repair or replace.

4 CHECK IGNITION TIMING

1. Check the following items. Refer to ªBasic Inspectionº, EC-3086.

MTBL1315

OK or NG

OK©GO TO 5.

NG©Adjust ignition timing.

DTC P0420 THREE WAY CATALYST

FUNCTION

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3280

Page 306 of 1306

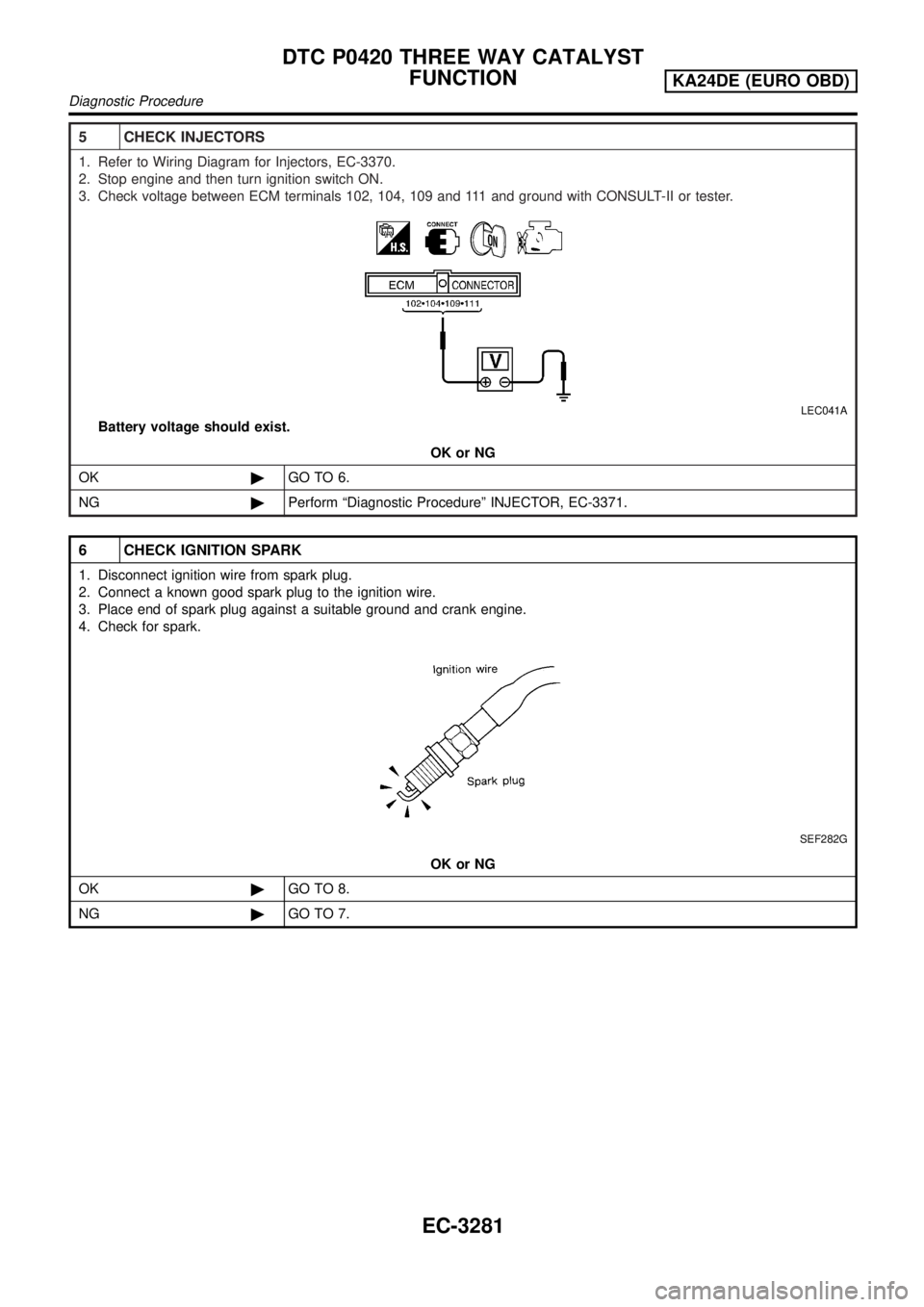

5 CHECK INJECTORS

1. Refer to Wiring Diagram for Injectors, EC-3370.

2. Stop engine and then turn ignition switch ON.

3. Check voltage between ECM terminals 102, 104, 109 and 111 and ground with CONSULT-II or tester.

LEC041A

Battery voltage should exist.

OK or NG

OK©GO TO 6.

NG©Perform ªDiagnostic Procedureº INJECTOR, EC-3371.

6 CHECK IGNITION SPARK

1. Disconnect ignition wire from spark plug.

2. Connect a known good spark plug to the ignition wire.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

SEF282G

OK or NG

OK©GO TO 8.

NG©GO TO 7.

DTC P0420 THREE WAY CATALYST

FUNCTION

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3281

Page 307 of 1306

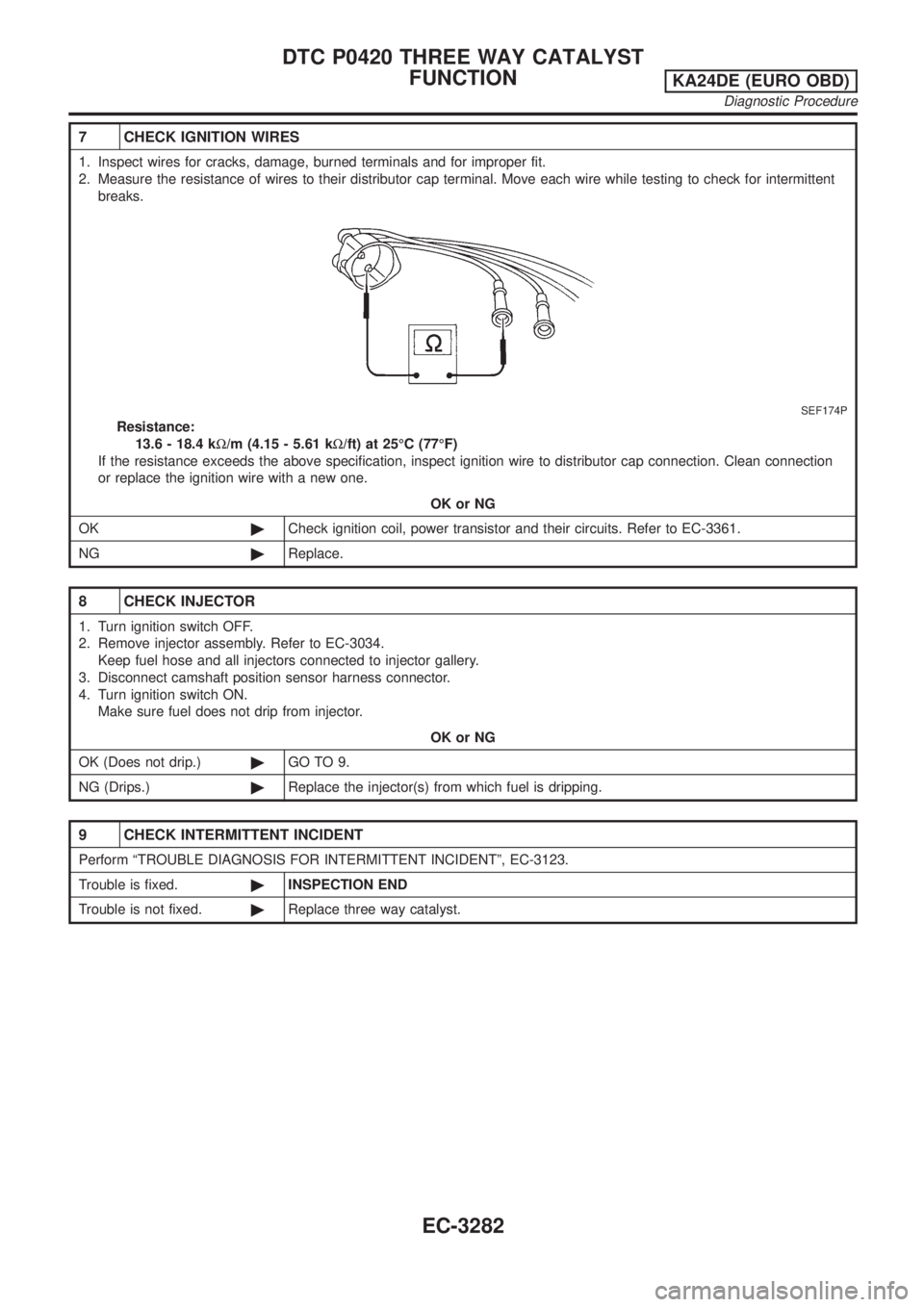

7 CHECK IGNITION WIRES

1. Inspect wires for cracks, damage, burned terminals and for improper fit.

2. Measure the resistance of wires to their distributor cap terminal. Move each wire while testing to check for intermittent

breaks.

SEF174P

Resistance:

13.6 - 18.4 kW/m (4.15 - 5.61 kW/ft) at 25ÉC (77ÉF)

If the resistance exceeds the above specification, inspect ignition wire to distributor cap connection. Clean connection

or replace the ignition wire with a new one.

OK or NG

OK©Check ignition coil, power transistor and their circuits. Refer to EC-3361.

NG©Replace.

8 CHECK INJECTOR

1. Turn ignition switch OFF.

2. Remove injector assembly. Refer to EC-3034.

Keep fuel hose and all injectors connected to injector gallery.

3. Disconnect camshaft position sensor harness connector.

4. Turn ignition switch ON.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip.)©GO TO 9.

NG (Drips.)©Replace the injector(s) from which fuel is dripping.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

Trouble is fixed.©INSPECTION END

Trouble is not fixed.©Replace three way catalyst.

DTC P0420 THREE WAY CATALYST

FUNCTION

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3282

Page 308 of 1306

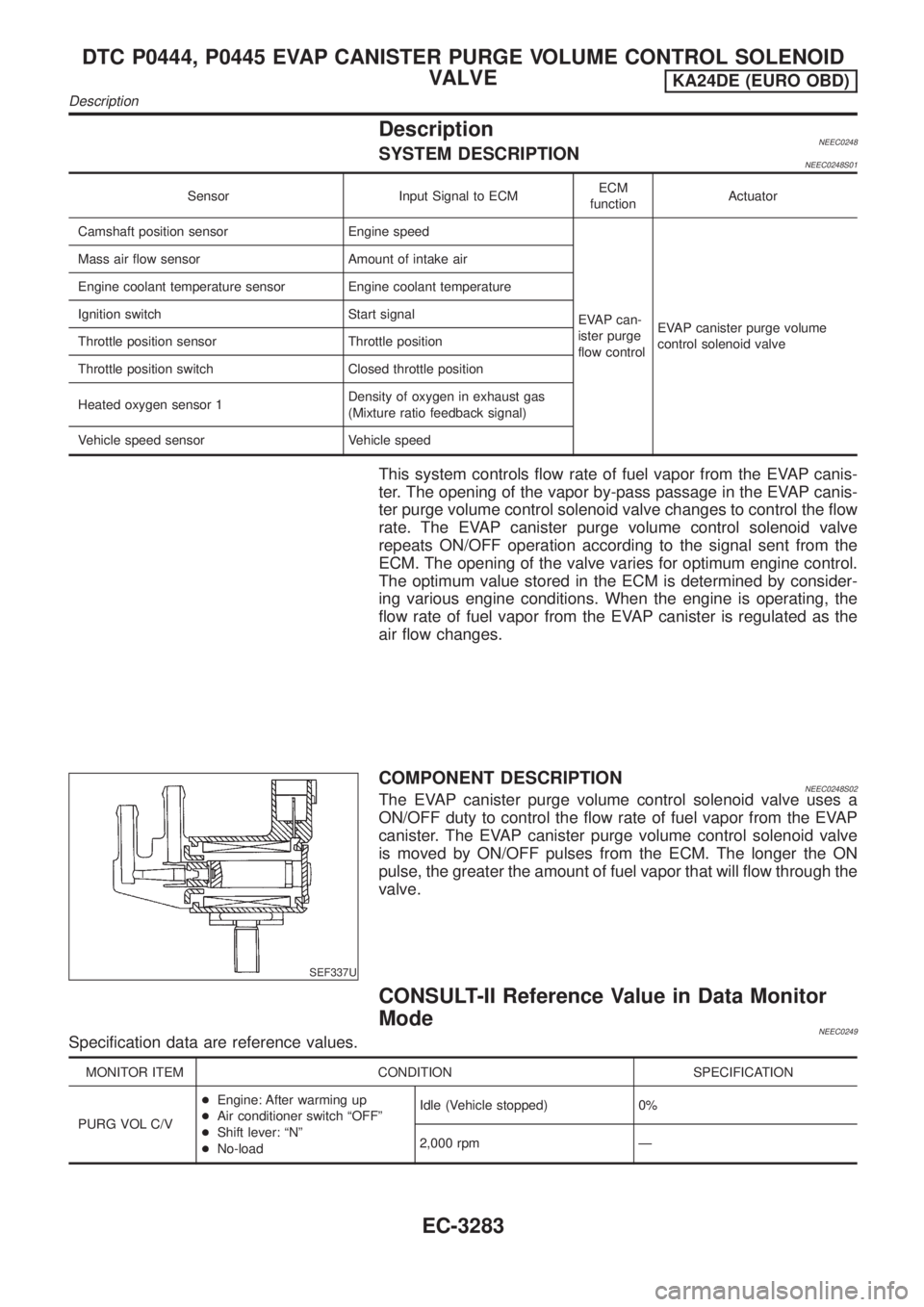

DescriptionNEEC0248SYSTEM DESCRIPTIONNEEC0248S01

Sensor Input Signal to ECMECM

functionActuator

Camshaft position sensor Engine speed

EVAP can-

ister purge

flow controlEVAP canister purge volume

control solenoid valve Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Throttle position switch Closed throttle position

Heated oxygen sensor 1Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Vehicle speed sensor Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

SEF337U

COMPONENT DESCRIPTIONNEEC0248S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NEEC0249Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/V+Engine: After warming up

+Air conditioner switch ªOFFº

+Shift lever: ªNº

+No-loadIdle (Vehicle stopped) 0%

2,000 rpm Ð

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

Description

EC-3283

Page 309 of 1306

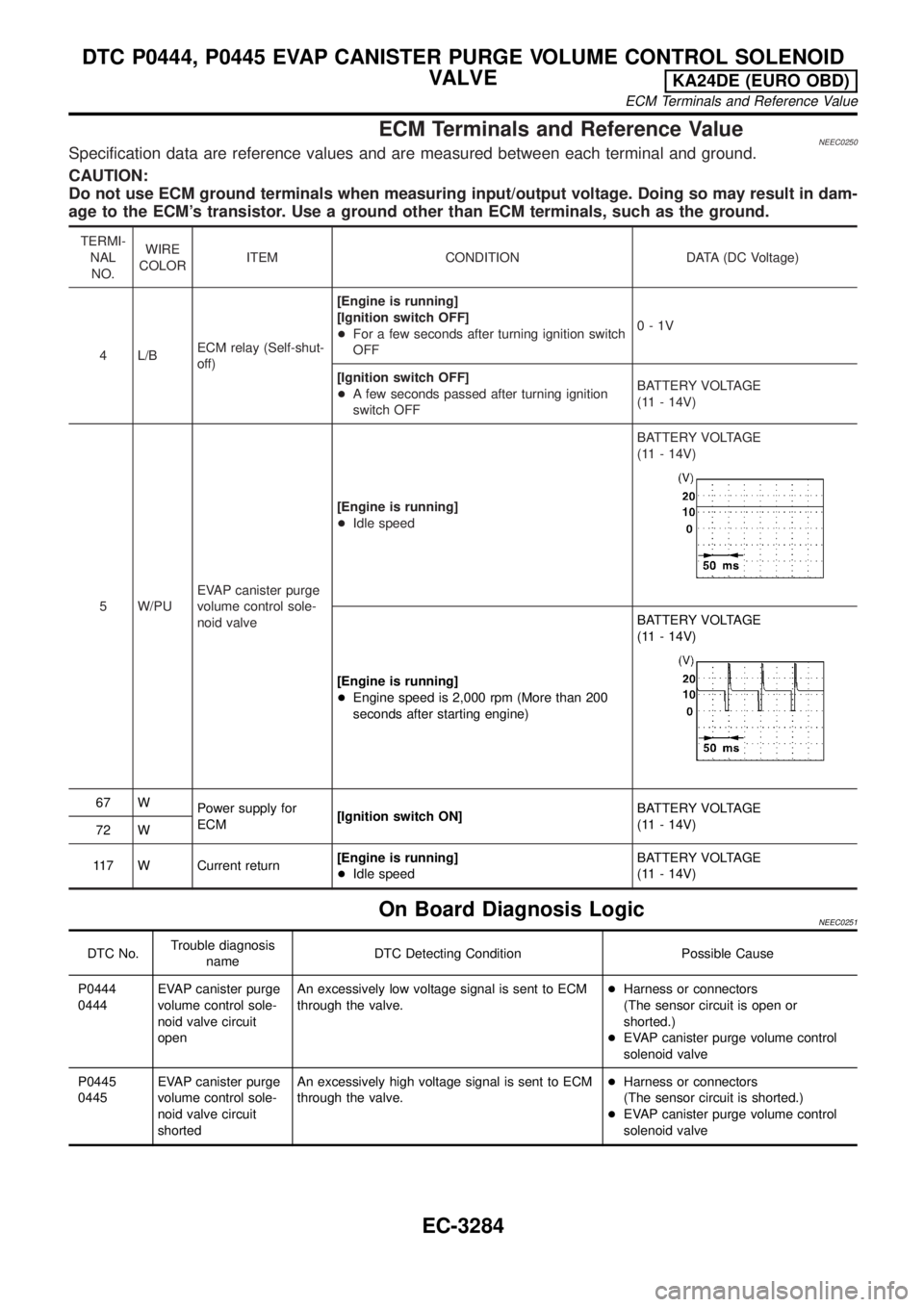

ECM Terminals and Reference ValueNEEC0250Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4 L/BECM relay (Self-shut-

off)[Engine is running]

[Ignition switch OFF]

+For a few seconds after turning ignition switch

OFF0-1V

[Ignition switch OFF]

+A few seconds passed after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

5 W/PUEVAP canister purge

volume control sole-

noid valve[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Engine speed is 2,000 rpm (More than 200

seconds after starting engine)BATTERY VOLTAGE

(11 - 14V)

67 W

Power supply for

ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

72 W

117 W Current return[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNEEC0251

DTC No.Trouble diagnosis

nameDTC Detecting Condition Possible Cause

P0444

0444EVAP canister purge

volume control sole-

noid valve circuit

openAn excessively low voltage signal is sent to ECM

through the valve.+Harness or connectors

(The sensor circuit is open or

shorted.)

+EVAP canister purge volume control

solenoid valve

P0445

0445EVAP canister purge

volume control sole-

noid valve circuit

shortedAn excessively high voltage signal is sent to ECM

through the valve.+Harness or connectors

(The sensor circuit is shorted.)

+EVAP canister purge volume control

solenoid valve

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

ECM Terminals and Reference Value

EC-3284

Page 310 of 1306

SEF058Y

DTC Confirmation Procedure=NEEC0252NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 5 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm battery

voltage is more than 11V at idle.

With CONSULT-II

1) Turn ignition switch ON.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and let it idle for at least 30 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-3287

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

DTC Confirmation Procedure

EC-3285