NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 311 of 1306

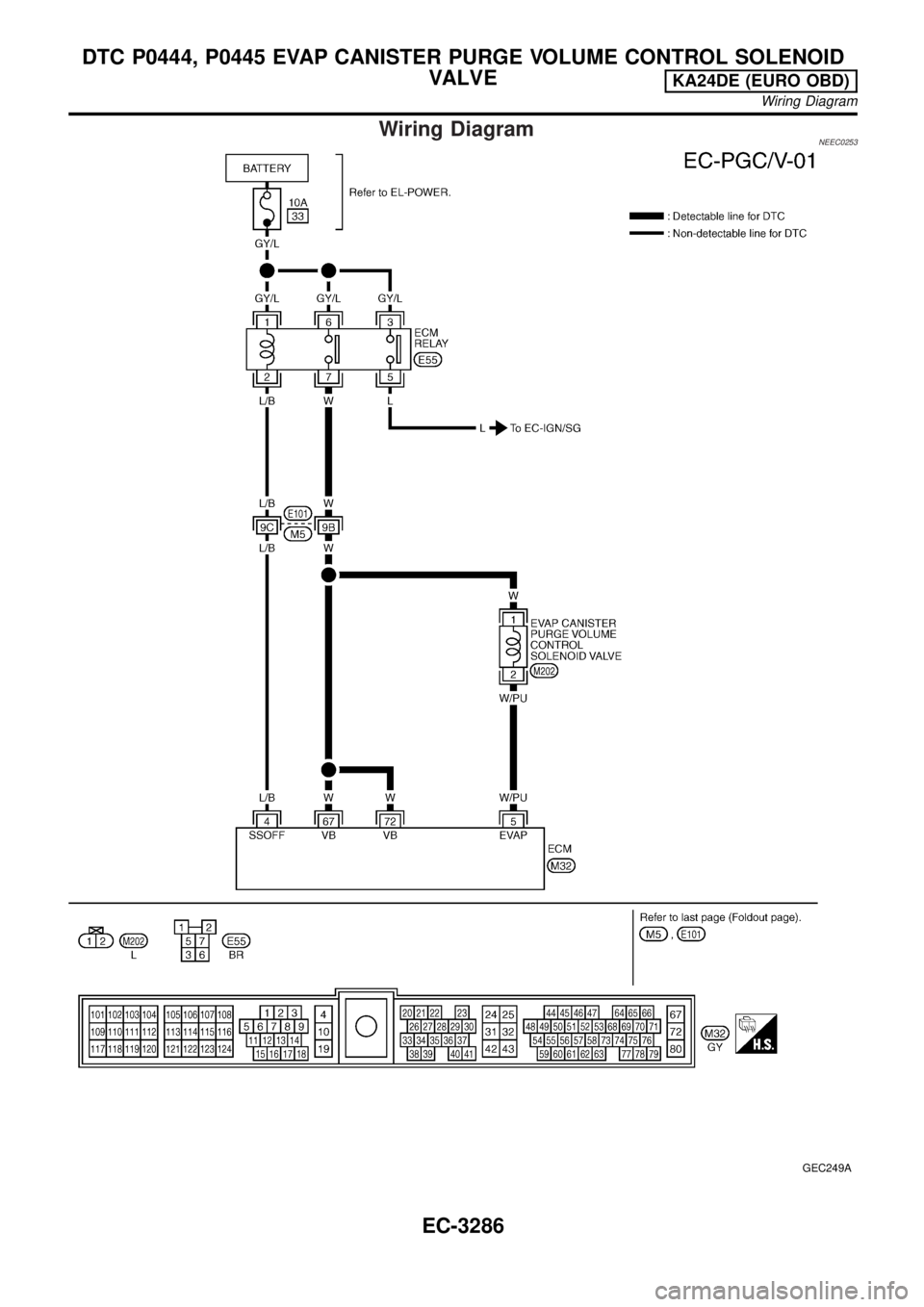

Wiring DiagramNEEC0253

GEC249A

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

Wiring Diagram

EC-3286

Page 312 of 1306

Diagnostic ProcedureNEEC0254

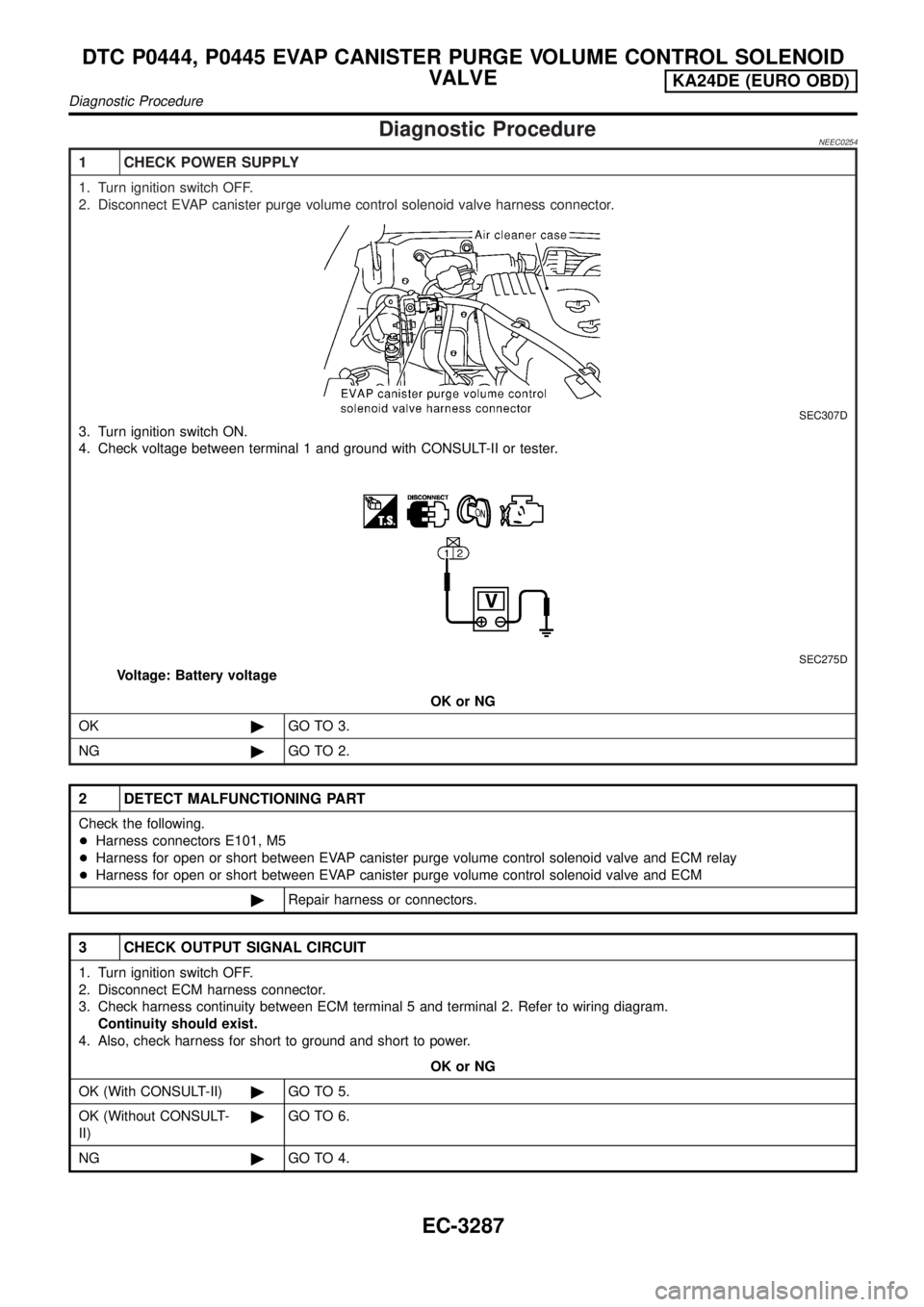

1 CHECK POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

SEC307D

3. Turn ignition switch ON.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEC275D

Voltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness for open or short between EVAP canister purge volume control solenoid valve and ECM relay

+Harness for open or short between EVAP canister purge volume control solenoid valve and ECM

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 5 and terminal 2. Refer to wiring diagram.

Continuity should exist.

4. Also, check harness for short to ground and short to power.

OK or NG

OK (With CONSULT-II)©GO TO 5.

OK (Without CONSULT-

II)©GO TO 6.

NG©GO TO 4.

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3287

Page 313 of 1306

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between EVAP canister purge volume control solenoid valve and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

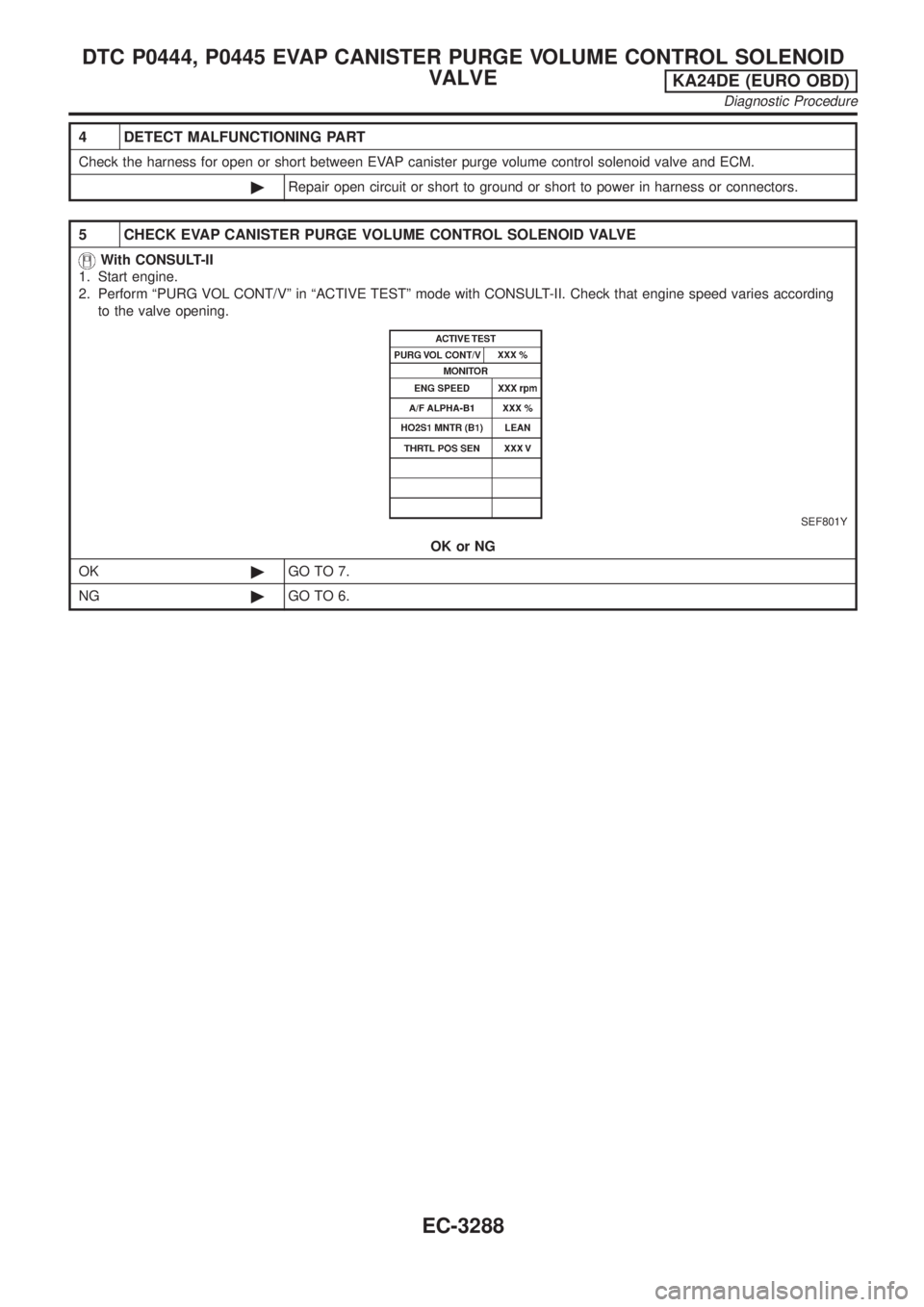

5 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

1. Start engine.

2. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II. Check that engine speed varies according

to the valve opening.

SEF801Y

OK or NG

OK©GO TO 7.

NG©GO TO 6.

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3288

Page 314 of 1306

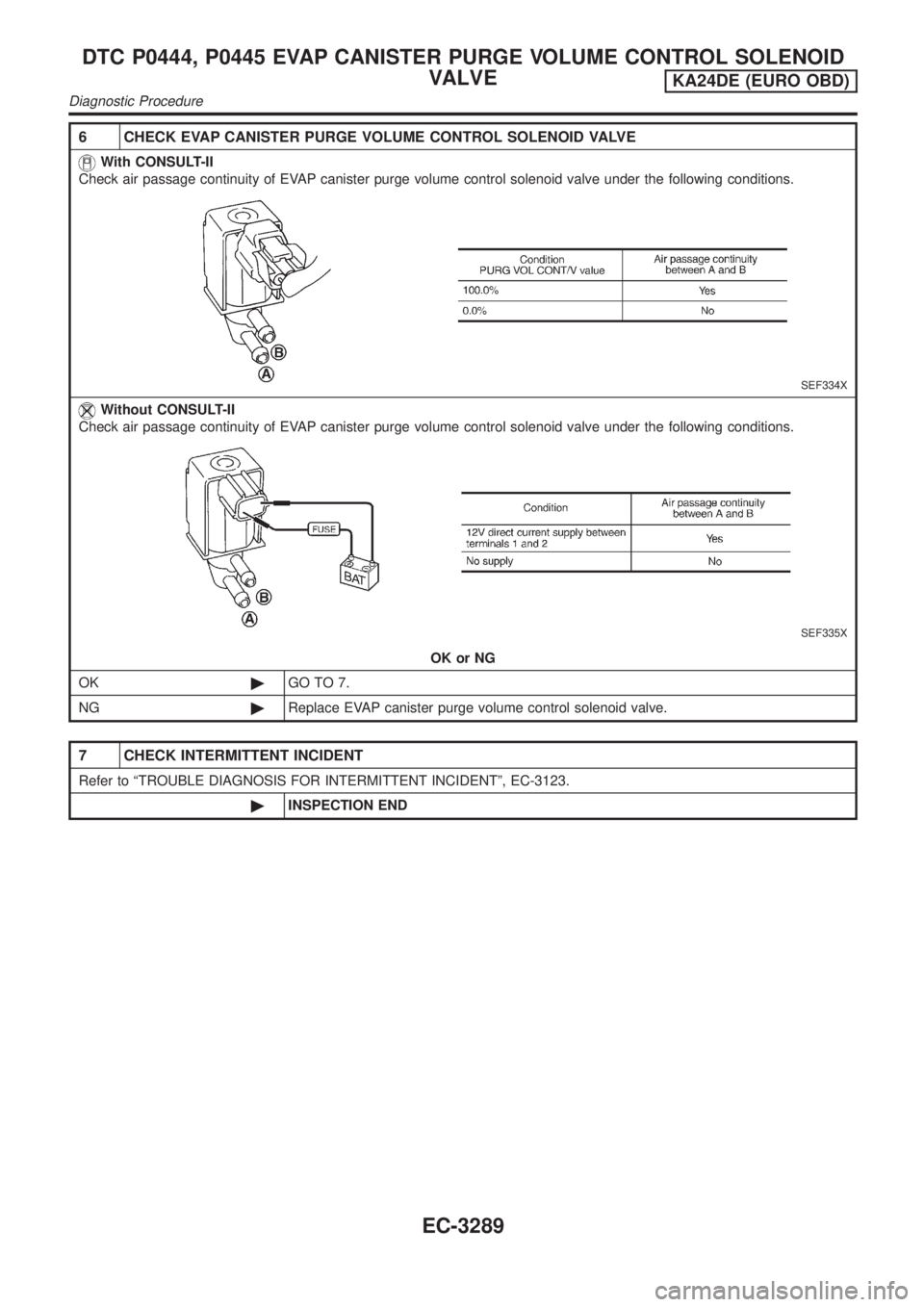

6 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF334X

Without CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF335X

OK or NG

OK©GO TO 7.

NG©Replace EVAP canister purge volume control solenoid valve.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

KA24DE (EURO OBD)

Diagnostic Procedure

EC-3289

Page 315 of 1306

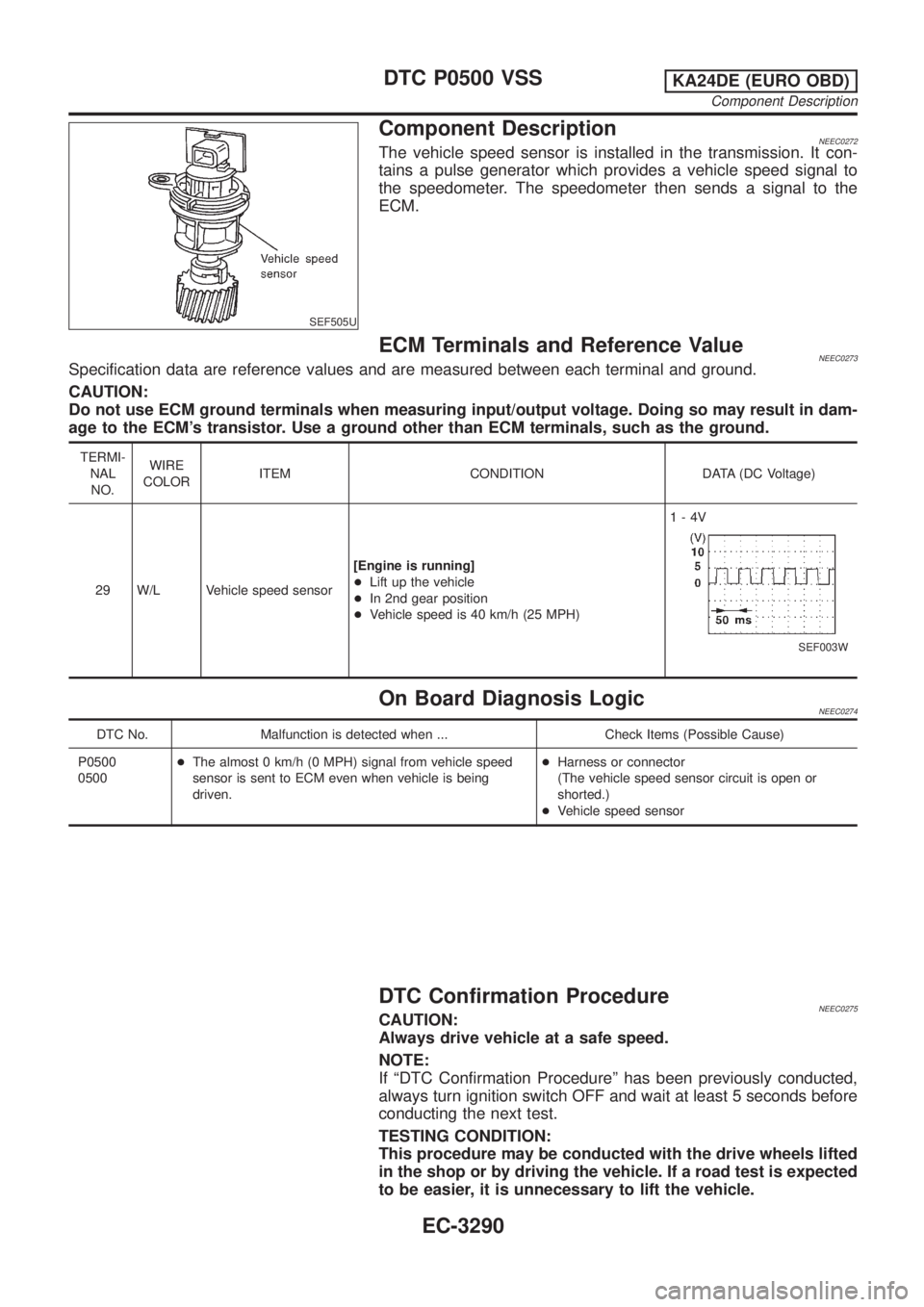

SEF505U

Component DescriptionNEEC0272The vehicle speed sensor is installed in the transmission. It con-

tains a pulse generator which provides a vehicle speed signal to

the speedometer. The speedometer then sends a signal to the

ECM.

ECM Terminals and Reference ValueNEEC0273Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 W/L Vehicle speed sensor[Engine is running]

+Lift up the vehicle

+In 2nd gear position

+Vehicle speed is 40 km/h (25 MPH)1-4V

SEF003W

On Board Diagnosis LogicNEEC0274

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0500

0500+The almost 0 km/h (0 MPH) signal from vehicle speed

sensor is sent to ECM even when vehicle is being

driven.+Harness or connector

(The vehicle speed sensor circuit is open or

shorted.)

+Vehicle speed sensor

DTC Confirmation ProcedureNEEC0275CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch OFF and wait at least 5 seconds before

conducting the next test.

TESTING CONDITION:

This procedure may be conducted with the drive wheels lifted

in the shop or by driving the vehicle. If a road test is expected

to be easier, it is unnecessary to lift the vehicle.

DTC P0500 VSSKA24DE (EURO OBD)

Component Description

EC-3290

Page 316 of 1306

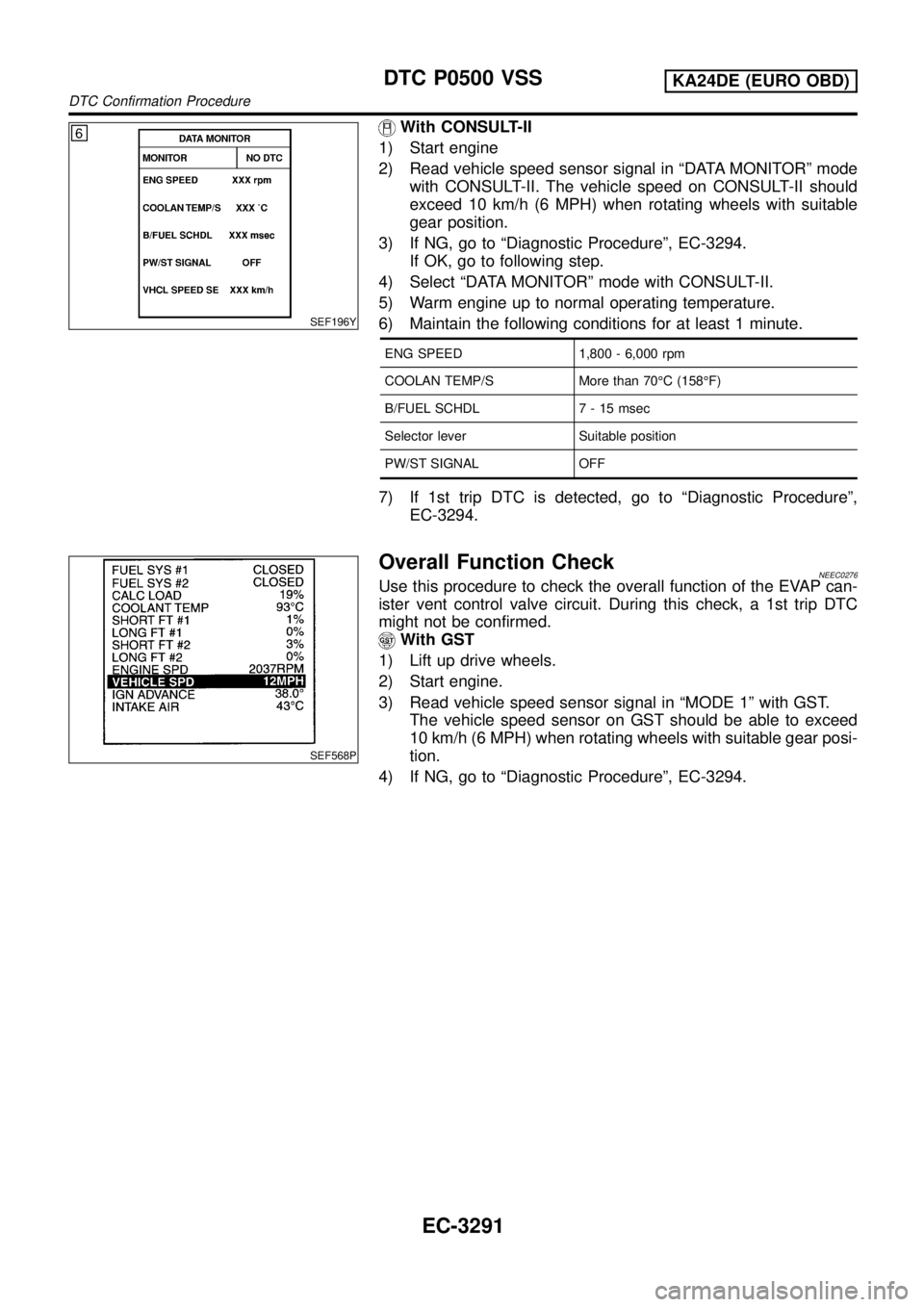

SEF196Y

With CONSULT-II

1) Start engine

2) Read vehicle speed sensor signal in ªDATA MONITORº mode

with CONSULT-II. The vehicle speed on CONSULT-II should

exceed 10 km/h (6 MPH) when rotating wheels with suitable

gear position.

3) If NG, go to ªDiagnostic Procedureº, EC-3294.

If OK, go to following step.

4) Select ªDATA MONITORº mode with CONSULT-II.

5) Warm engine up to normal operating temperature.

6) Maintain the following conditions for at least 1 minute.

ENG SPEED 1,800 - 6,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 7 - 15 msec

Selector lever Suitable position

PW/ST SIGNAL OFF

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-3294.

SEF568P

Overall Function CheckNEEC0276Use this procedure to check the overall function of the EVAP can-

ister vent control valve circuit. During this check, a 1st trip DTC

might not be confirmed.

With GST

1) Lift up drive wheels.

2) Start engine.

3) Read vehicle speed sensor signal in ªMODE 1º with GST.

The vehicle speed sensor on GST should be able to exceed

10 km/h (6 MPH) when rotating wheels with suitable gear posi-

tion.

4) If NG, go to ªDiagnostic Procedureº, EC-3294.

DTC P0500 VSSKA24DE (EURO OBD)

DTC Confirmation Procedure

EC-3291

Page 317 of 1306

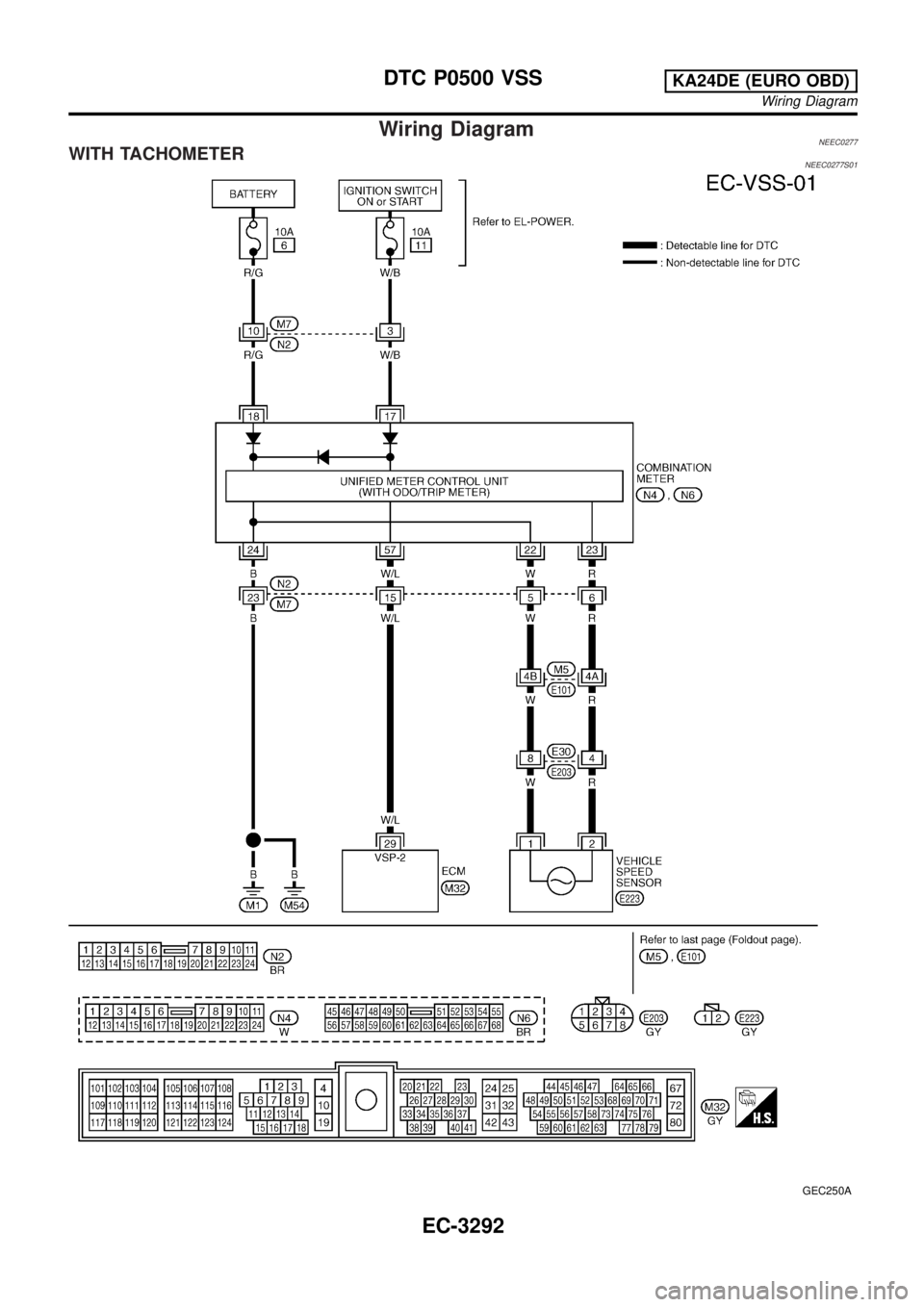

Wiring DiagramNEEC0277WITH TACHOMETERNEEC0277S01

GEC250A

DTC P0500 VSSKA24DE (EURO OBD)

Wiring Diagram

EC-3292

Page 318 of 1306

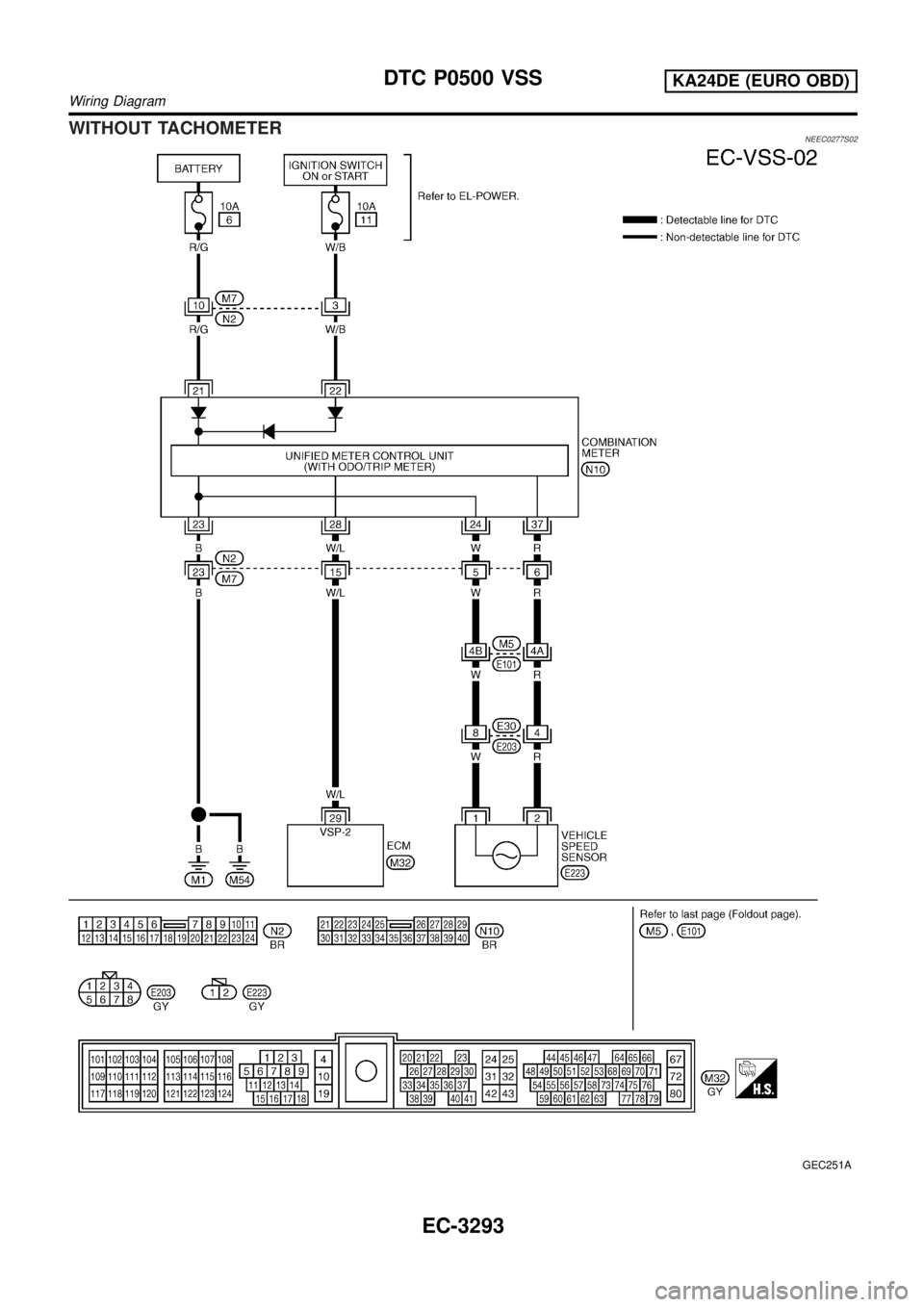

WITHOUT TACHOMETERNEEC0277S02

GEC251A

DTC P0500 VSSKA24DE (EURO OBD)

Wiring Diagram

EC-3293

Page 319 of 1306

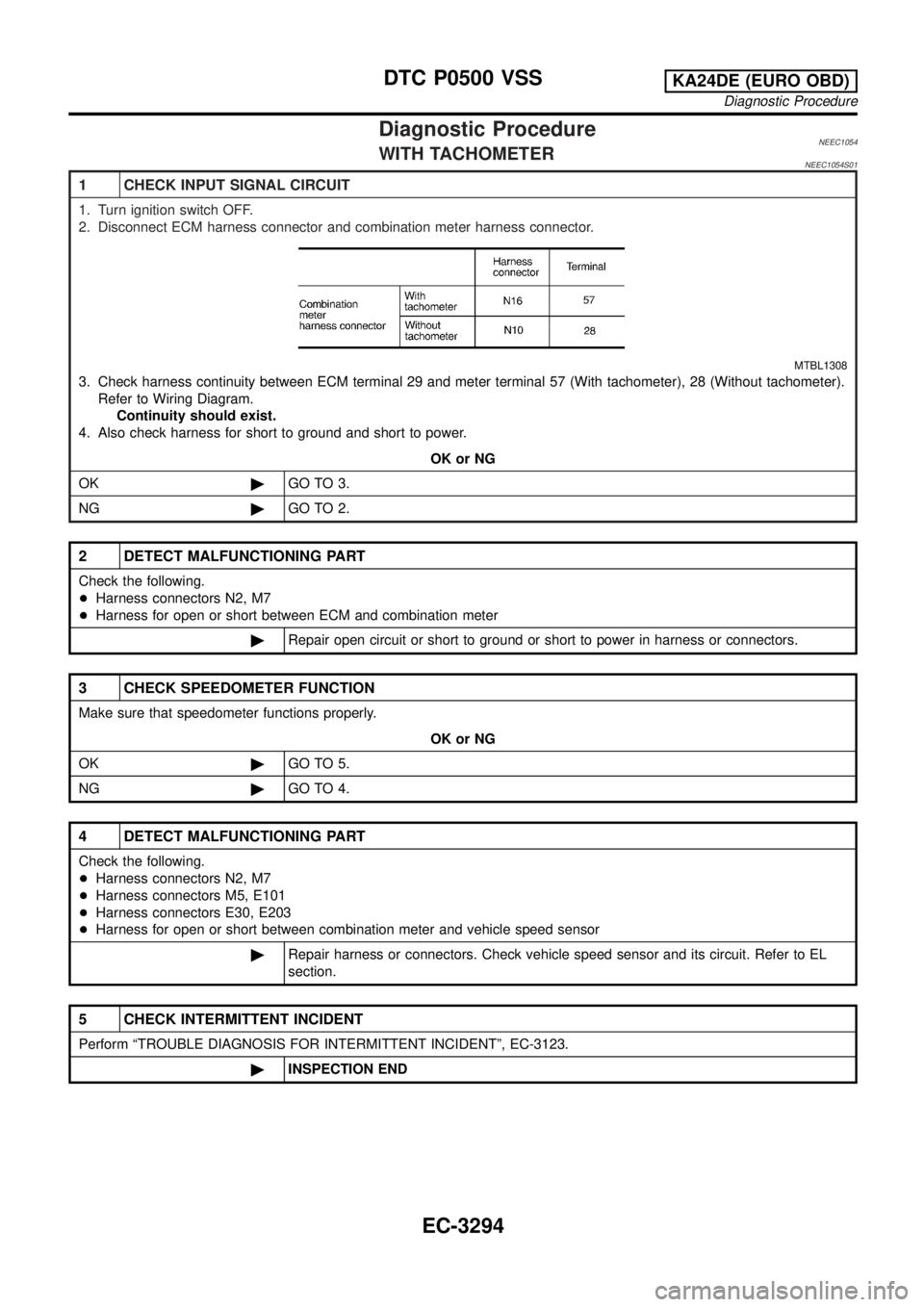

Diagnostic ProcedureNEEC1054WITH TACHOMETERNEEC1054S01

1 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector and combination meter harness connector.

MTBL1308

3. Check harness continuity between ECM terminal 29 and meter terminal 57 (With tachometer), 28 (Without tachometer).

Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors N2, M7

+Harness for open or short between ECM and combination meter

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors N2, M7

+Harness connectors M5, E101

+Harness connectors E30, E203

+Harness for open or short between combination meter and vehicle speed sensor

©Repair harness or connectors. Check vehicle speed sensor and its circuit. Refer to EL

section.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

DTC P0500 VSSKA24DE (EURO OBD)

Diagnostic Procedure

EC-3294

Page 320 of 1306

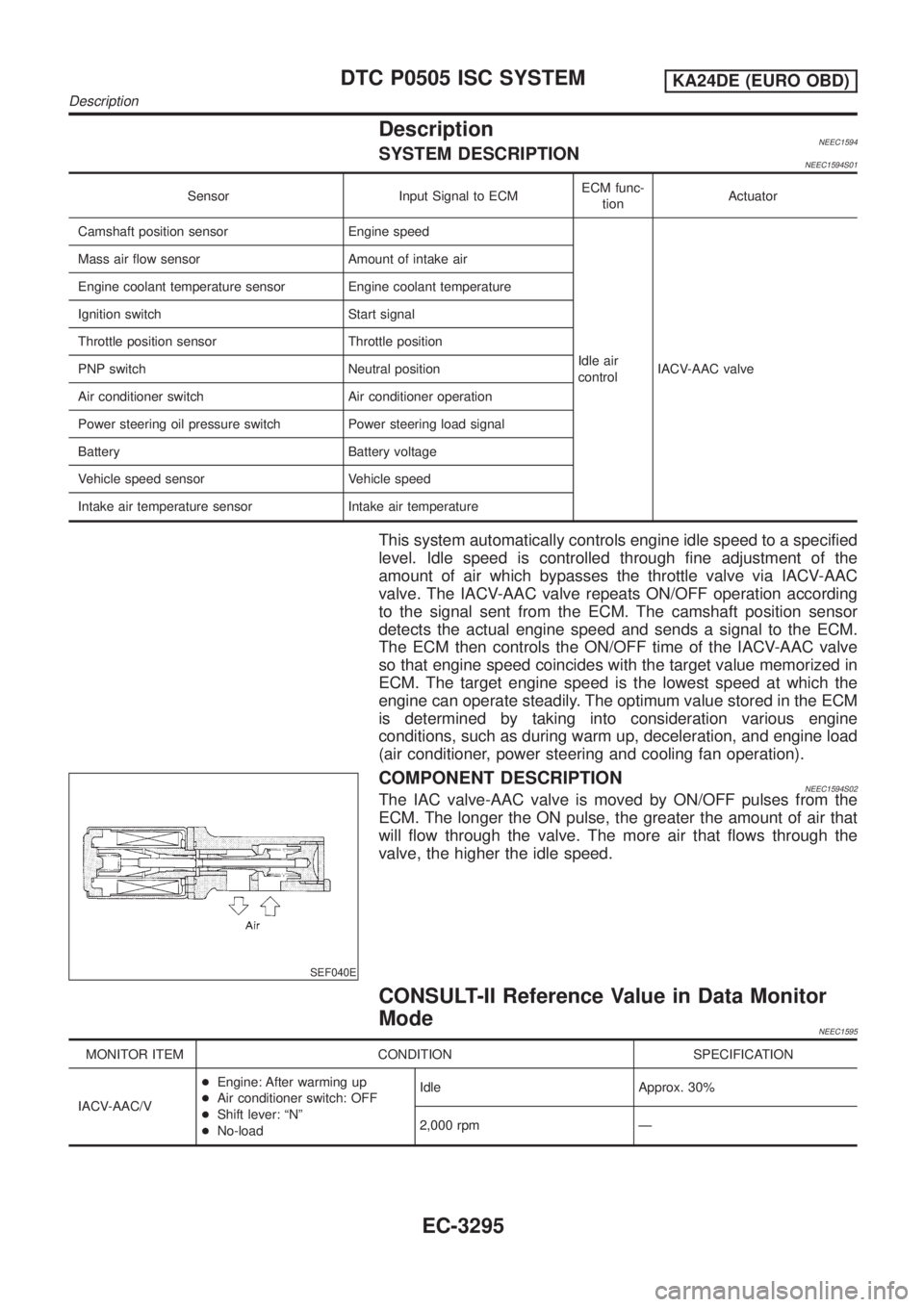

DescriptionNEEC1594SYSTEM DESCRIPTIONNEEC1594S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed

Idle air

controlIACV-AAC valve Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

PNP switch Neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Intake air temperature sensor Intake air temperature

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which bypasses the throttle valve via IACV-AAC

valve. The IACV-AAC valve repeats ON/OFF operation according

to the signal sent from the ECM. The camshaft position sensor

detects the actual engine speed and sends a signal to the ECM.

The ECM then controls the ON/OFF time of the IACV-AAC valve

so that engine speed coincides with the target value memorized in

ECM. The target engine speed is the lowest speed at which the

engine can operate steadily. The optimum value stored in the ECM

is determined by taking into consideration various engine

conditions, such as during warm up, deceleration, and engine load

(air conditioner, power steering and cooling fan operation).

SEF040E

COMPONENT DESCRIPTIONNEEC1594S02The IAC valve-AAC valve is moved by ON/OFF pulses from the

ECM. The longer the ON pulse, the greater the amount of air that

will flow through the valve. The more air that flows through the

valve, the higher the idle speed.

CONSULT-II Reference Value in Data Monitor

Mode

NEEC1595

MONITOR ITEM CONDITION SPECIFICATION

IACV-AAC/V+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle Approx. 30%

2,000 rpm Ð

DTC P0505 ISC SYSTEMKA24DE (EURO OBD)

Description

EC-3295