check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 426 of 2267

DIAGNOSTIC PROCEDURE

INSPECTION START

(Circuit for EGRC-solenoid valve A)

CHECK MAIN POWER SUPPLY.

Refer to Trouble Diagnosis for main

power supply (EC-CD-59)

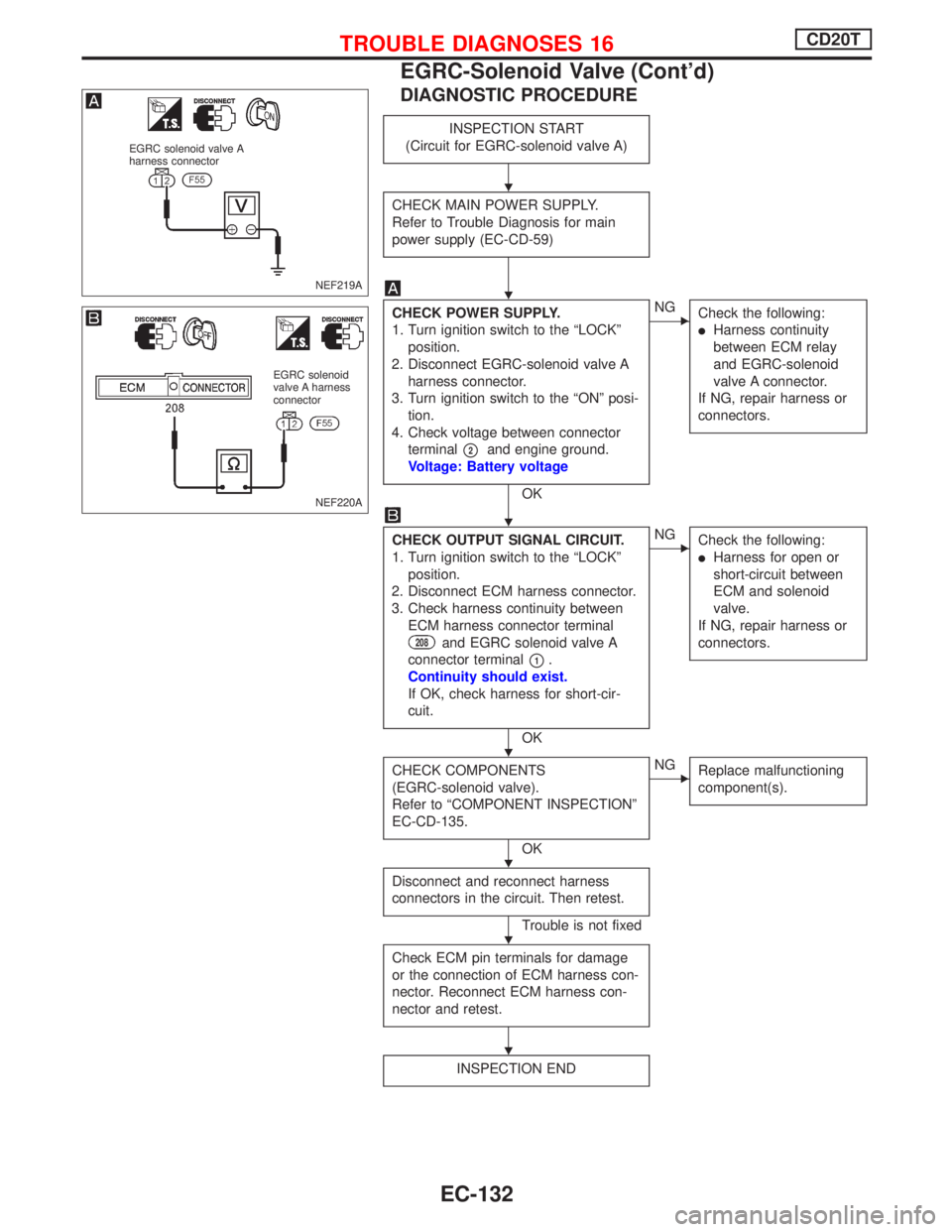

CHECK POWER SUPPLY.

1. Turn ignition switch to the ªLOCKº

position.

2. Disconnect EGRC-solenoid valve A

harness connector.

3. Turn ignition switch to the ªONº posi-

tion.

4. Check voltage between connector

terminal

p2and engine ground.

Voltage: Battery voltage

OK

ENG

Check the following:

lHarness continuity

between ECM relay

and EGRC-solenoid

valve A connector.

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to the ªLOCKº

position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM harness connector terminal

208and EGRC solenoid valve A

connector terminal

p1.

Continuity should exist.

If OK, check harness for short-cir-

cuit.

OK

ENG

Check the following:

lHarness for open or

short-circuit between

ECM and solenoid

valve.

If NG, repair harness or

connectors.

CHECK COMPONENTS

(EGRC-solenoid valve).

Refer to ªCOMPONENT INSPECTIONº

EC-CD-135.

OK

ENG

Replace malfunctioning

component(s).

Disconnect and reconnect harness

connectors in the circuit. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage

or the connection of ECM harness con-

nector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

EGRC solenoid valve A

harness connector

NEF219A

EGRC solenoid

valve A harness

connector

NEF220A

H

H

H

H

H

H

H

TROUBLE DIAGNOSES 16CD20T

EGRC-Solenoid Valve (Cont'd)

EC-132

Page 427 of 2267

DIAGNOSTIC PROCEDURE

INSPECTION START

EGR CONTROL OPERATION

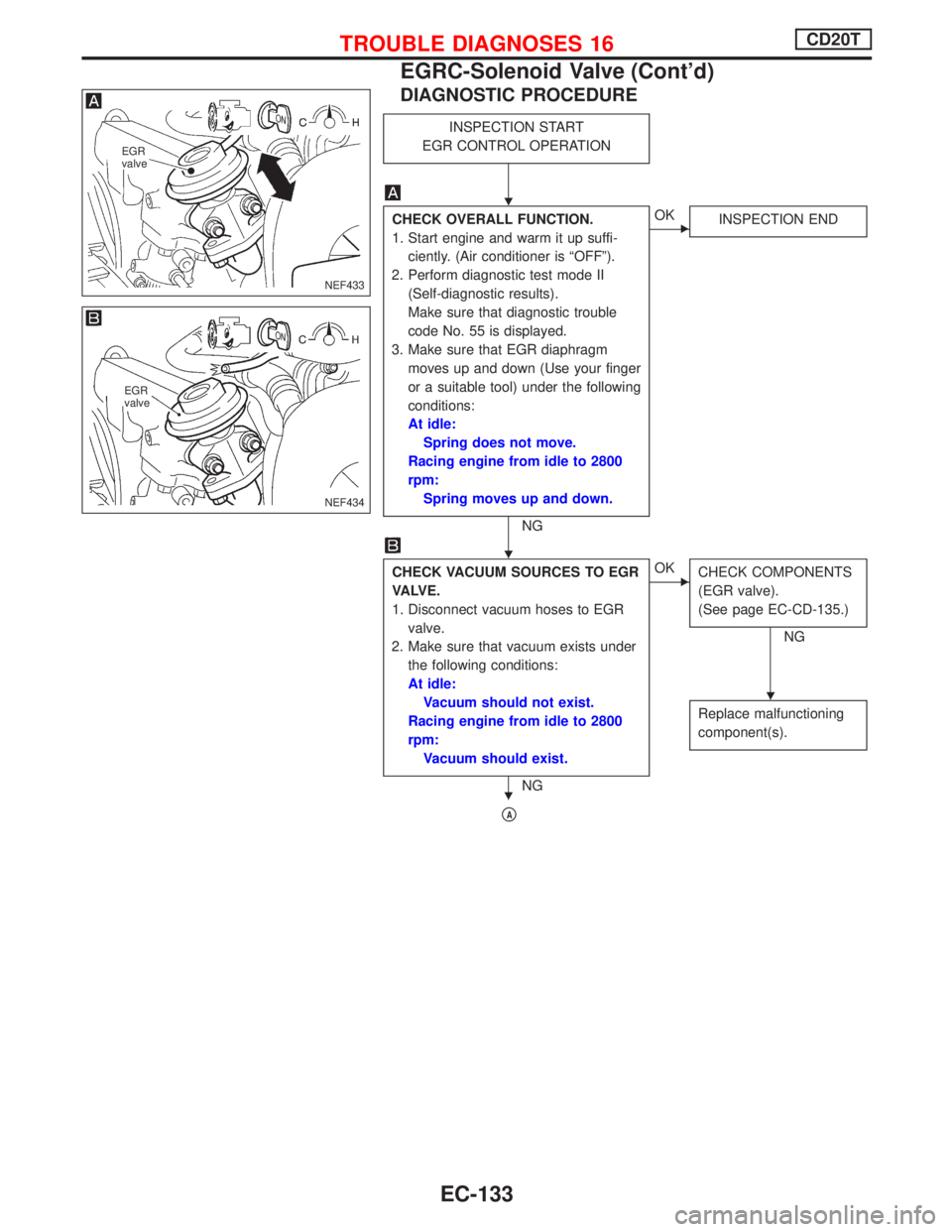

CHECK OVERALL FUNCTION.

1. Start engine and warm it up suffi-

ciently. (Air conditioner is ªOFFº).

2. Perform diagnostic test mode II

(Self-diagnostic results).

Make sure that diagnostic trouble

code No. 55 is displayed.

3. Make sure that EGR diaphragm

moves up and down (Use your finger

or a suitable tool) under the following

conditions:

At idle:

Spring does not move.

Racing engine from idle to 2800

rpm:

Spring moves up and down.

NG

EOK

INSPECTION END

CHECK VACUUM SOURCES TO EGR

VA LV E .

1. Disconnect vacuum hoses to EGR

valve.

2. Make sure that vacuum exists under

the following conditions:

At idle:

Vacuum should not exist.

Racing engine from idle to 2800

rpm:

Vacuum should exist.

NG

EOK

CHECK COMPONENTS

(EGR valve).

(See page EC-CD-135.)

NG

Replace malfunctioning

component(s).

pA

NEF433

EGR

valve

NEF434

EGR

valve

H

H

H

H

TROUBLE DIAGNOSES 16CD20T

EGRC-Solenoid Valve (Cont'd)

EC-133

Page 428 of 2267

pA

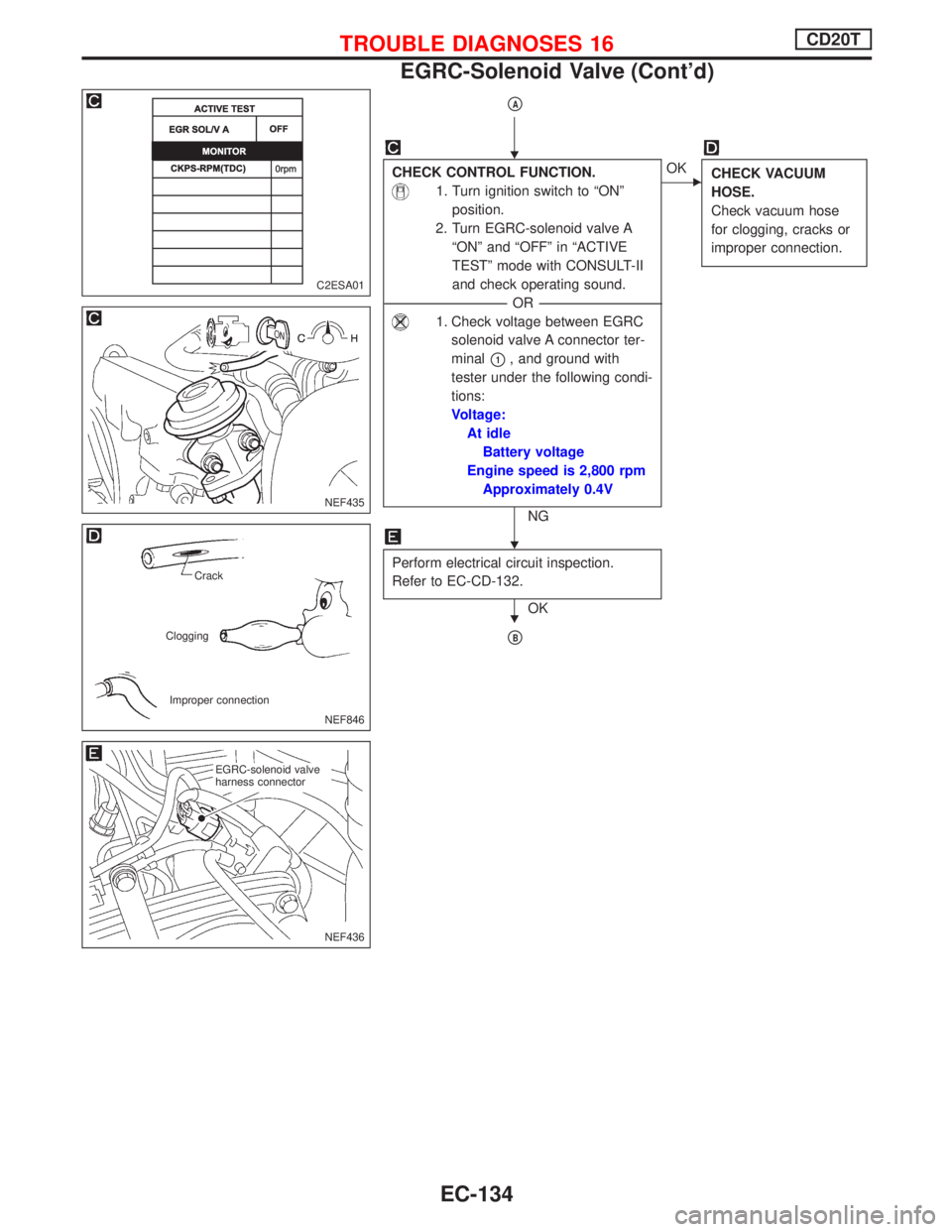

CHECK CONTROL FUNCTION.

1. Turn ignition switch to ªONº

position.

2. Turn EGRC-solenoid valve A

ªONº and ªOFFº in ªACTIVE

TESTº mode with CONSULT-II

and check operating sound.

----------------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------------

1. Check voltage between EGRC

solenoid valve A connector ter-

minal

p1, and ground with

tester under the following condi-

tions:

Voltage:

At idle

Battery voltage

Engine speed is 2,800 rpm

Approximately 0.4V

NG

EOK

CHECK VACUUM

HOSE.

Check vacuum hose

for clogging, cracks or

improper connection.

Perform electrical circuit inspection.

Refer to EC-CD-132.

OK

pB

C2ESA01

NEF435

NEF846

Crack

Clogging

Improper connection

.

NEF436

.EGRC-solenoid valve

harness connector

H

H

H

TROUBLE DIAGNOSES 16CD20T

EGRC-Solenoid Valve (Cont'd)

EC-134

Page 430 of 2267

Brake Switch

The ECM receives signals from two brake switches. One is a

conventional brake lamp switch, the other is referred to as a

redundant (RDNT) brake switch.

In case the accelerator pedal does not return to the idle position

(pedal sticks), the driver will react by depressing the brake. In

this (emergency) situation, the ECM will disregard the accelera-

tor pedal signal and bring back the engine speed to 1200 rpm.

Malfunction is detected when ...Check Items

(Possible Cause)

lBrake switch circuits are open or shorted.lHarness or connectors

(Brake switch circuits are open or shorted.)

lStop lamp switch

lRDNT brake switch

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch to ªONº position and select ªDATA

MONITORº mode with CONSULT-II.

2) Depress brake pedal for at least 1 minute.

TROUBLE DIAGNOSES 17CD20T

EC-136

Page 435 of 2267

MI & Data Link Connectors

Malfunction indicator (MI) circuit is monitored for open or short-

circuit. If the circuit is malfunctioning, MI can not report it but

CONSULT-II can.

Malfunction is detected when ....Check Items

(Possible cause)

lMI circuit is open or shorted.lHarness or connectors

(MI circuit is open or shorted).

lMI lamp

lECM

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch to ªONº position and select ªDATA

MONITORº mode with CONSULT-II.

2) Start engine and run it for at least 2 seconds at idle

speed.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

OVERALL FUNCTION CHECK

1) Turn ignition switch to ªONº position.

2) Check that MI lits on.

TROUBLE DIAGNOSES 19CD20T

EC-141

Page 443 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG16I18DE

TROUBLE DIAGNOSIS - INDEX....................................6

Alphabetical & P No. Index for DTC ...........................6

PRECAUTIONS...............................................................9

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............9

Precautions for On Board Diagnostic (OBD)

System of Engine ........................................................9

Engine Fuel & Emission Control System ..................10

Precautions ................................................................ 11

Wiring Diagrams and Trouble Diagnosis ...................12

PREPARATION..............................................................13

Special Service Tools ................................................13

Commercial Service Tool ...........................................13

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................14

Engine Control Component Parts Location ...............14

Circuit Diagram ..........................................................17

System Diagram ........................................................18

Vacuum Hose Drawing ..............................................19

System Chart .............................................................20

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................21

Multiport Fuel Injection (MFI) System .......................21

Electronic Ignition (EI) System ..................................23

Air Conditioning Cut Control ......................................24

Fuel Cut Control (at no load & high engine

speed) ........................................................................25

Evaporative Emission System ...................................25

Positive Crankcase Ventilation ..................................28

BASIC SERVICE PROCEDURE...................................29

Fuel Pressure Release ..............................................29

Fuel Pressure Check .................................................29

Fuel Pressure Regulator Check ................................30

Injector .......................................................................30

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................32Idle Air Volume Learning ...........................................33

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................36

Introduction ................................................................36

Two Trip Detection Logic ...........................................36

Emission-related Diagnostic Information ...................37

Malfunction Indicator (MI) ..........................................45

OBD System Operation Chart ...................................50

CONSULT-II ...............................................................55

Generic Scan Tool (GST) ..........................................66

TROUBLE DIAGNOSIS - INTRODUCTION..................68

Introduction ................................................................68

Work Flow ..................................................................70

TROUBLE DIAGNOSIS - BASIC INSPECTION...........72

Basic Inspection.........................................................72

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................80

DTC Inspection Priority Chart....................................80

Fail-safe Chart ...........................................................81

Symptom Matrix Chart ...............................................82

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................86

Major Sensor Reference Graph in Data Monitor

Mode ..........................................................................88

ECM Terminals and Reference Value .......................91

TROUBLE DIAGNOSIS - SPECIFICATION VALUE....98

Description .................................................................98

Testing Condition .......................................................98

Inspection Procedure .................................................98

Diagnostic Procedure ................................................99

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................102

Description ...............................................................102

Diagnostic Procedure ..............................................102

TROUBLE DIAGNOSIS FOR POWER SUPPLY........103

Main Power Supply and Ground Circuit ..................103

EC

Page 444 of 2267

DTC P0100 MASS AIR FLOW SENSOR (MAFS)...... 110

Component Description ........................................... 110

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 110

ECM Terminals and Reference Value ..................... 110

On Board Diagnosis Logic....................................... 110

DTC Confirmation Procedure .................................. 111

Wiring Diagram ........................................................ 112

Diagnostic Procedure .............................................. 113

Component Inspection ............................................. 115

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR...................................................................... 116

Component Description ........................................... 116

On Board Diagnosis Logic....................................... 116

DTC Confirmation Procedure .................................. 116

Wiring Diagram ........................................................ 117

Diagnostic Procedure .............................................. 118

Component Inspection ............................................. 119

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS) (CIRCUIT).......................................120

Component Description ...........................................120

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................120

On Board Diagnosis Logic.......................................120

DTC Confirmation Procedure ..................................121

Wiring Diagram ........................................................122

Diagnostic Procedure ..............................................123

Component Inspection .............................................124

DTC P0120 THROTTLE POSITION SENSOR...........125

Component Description ...........................................125

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................125

ECM Terminals and Reference Value .....................126

On Board Diagnosis Logic.......................................126

DTC Confirmation Procedure ..................................126

Wiring Diagram ........................................................128

Diagnostic Procedure ..............................................129

Component Inspection .............................................131

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................132

Component Description ...........................................132

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................132

ECM Terminals and Reference Value .....................132

On Board Diagnosis Logic.......................................133

DTC Confirmation Procedure ..................................133

Overall Function Check ...........................................134

Wiring Diagram ........................................................135

Diagnostic Procedure ..............................................136

Component Inspection .............................................137DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................139

Component Description ...........................................139

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................139

ECM Terminals and Reference Value .....................139

On Board Diagnosis Logic.......................................140

DTC Confirmation Procedure ..................................140

Overall Function Check ...........................................141

Diagnostic Procedure ..............................................141

Component Inspection .............................................143

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................145

Component Description ...........................................145

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................145

ECM Terminals and Reference Value .....................145

On Board Diagnosis Logic.......................................146

DTC Confirmation Procedure ..................................146

Overall Function Check ...........................................147

Diagnostic Procedure ..............................................147

Component Inspection .............................................149

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT) (RESPONSE MONITORING).......................151

Component Description ...........................................151

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................151

ECM Terminals and Reference Value .....................151

On Board Diagnosis Logic.......................................152

DTC Confirmation Procedure ..................................152

Overall Function Check ...........................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................155

Component Inspection .............................................158

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................160

Component Description ...........................................160

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................160

ECM Terminals and Reference Value .....................160

On Board Diagnosis Logic.......................................161

DTC Confirmation Procedure ..................................161

Wiring Diagram ........................................................162

Diagnostic Procedure ..............................................163

Component Inspection .............................................164

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................166

Description ...............................................................166

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................166

ECM Terminals and Reference Value .....................166

On Board Diagnosis Logic.......................................166

CONTENTS(Cont'd)

EC-2

Page 447 of 2267

Component Inspection ............................................. 311

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................313

Component Description ...........................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................313

ECM Terminals and Reference Value .....................313

On Board Diagnosis Logic.......................................313

DTC Confirmation Procedure ..................................313

Overall Function Check ...........................................314

Wiring Diagram ........................................................315

Diagnostic Procedure For M/T Models....................316

INJECTOR...................................................................318

Component Description ...........................................318

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................318

ECM Terminals and Reference Value .....................318

Wiring Diagram ........................................................319

Diagnostic Procedure ..............................................320

Component Inspection .............................................322

IGNITION SIGNAL.......................................................323

Component Description ...........................................323

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................323

ECM Terminals and Reference Value .....................323

Wiring Diagram ........................................................324

Diagnostic Procedure ..............................................326

Component Inspection .............................................331

START SIGNAL...........................................................332

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................332

ECM Terminals and Reference Value .....................332

Wiring Diagram ........................................................333

Diagnostic Procedure ..............................................334

FUEL PUMP.................................................................336

System Description ..................................................336

Component Description ...........................................336

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................336

ECM Terminals and Reference Value .....................337

Wiring Diagram ........................................................338

Diagnostic Procedure ..............................................339Component Inspection .............................................341

POWER STEERING OIL PRESSURE SWITCH.........342

Component Description ...........................................342

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................342

ECM Terminals and Reference Value .....................342

Wiring Diagram ........................................................343

Diagnostic Procedure ..............................................344

Component Inspection .............................................346

REFRIGERANT PRESSURE SENSOR......................347

Description ...............................................................347

ECM Terminals and Reference Value .....................347

Wiring Diagram ........................................................348

Diagnostic Procedure ..............................................349

ELECTRICAL LOAD SIGNAL.....................................351

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................351

ECM Terminals and Reference Value .....................351

Wiring Diagram ........................................................352

MI & DATA LINK CONNECTORS...............................354

Wiring Diagram ........................................................354

SERVICE DATA AND SPECIFICATIONS (SDS)........355

Fuel Pressure Regulator..........................................355

Idle Speed and Ignition Timing ................................355

Mass Air Flow Sensor..............................................355

Intake Air Temperature Sensor ................................355

Engine Coolant Temperature Sensor ......................355

Throttle Position Sensor ..........................................355

Heated Oxygen Sensor 1 Heater (Front) ................355

Heated Oxygen Sensor 2 Heater (Rear).................355

Crankshaft Position Sensor (POS) ..........................356

Camshaft Position Sensor (PHASE) .......................356

EGR Volume Control Valve (If so equipped)...........356

EGR Temperature Sensor (If so equipped).............356

EVAP Canister Purge Volume Control Valve ..........356

IACV-AAC Valve ......................................................356

Injector .....................................................................356

Ignition Coil with Power Transistor ..........................357

Fuel Pump ...............................................................357

CONTENTS(Cont'd)

EC-5

Page 468 of 2267

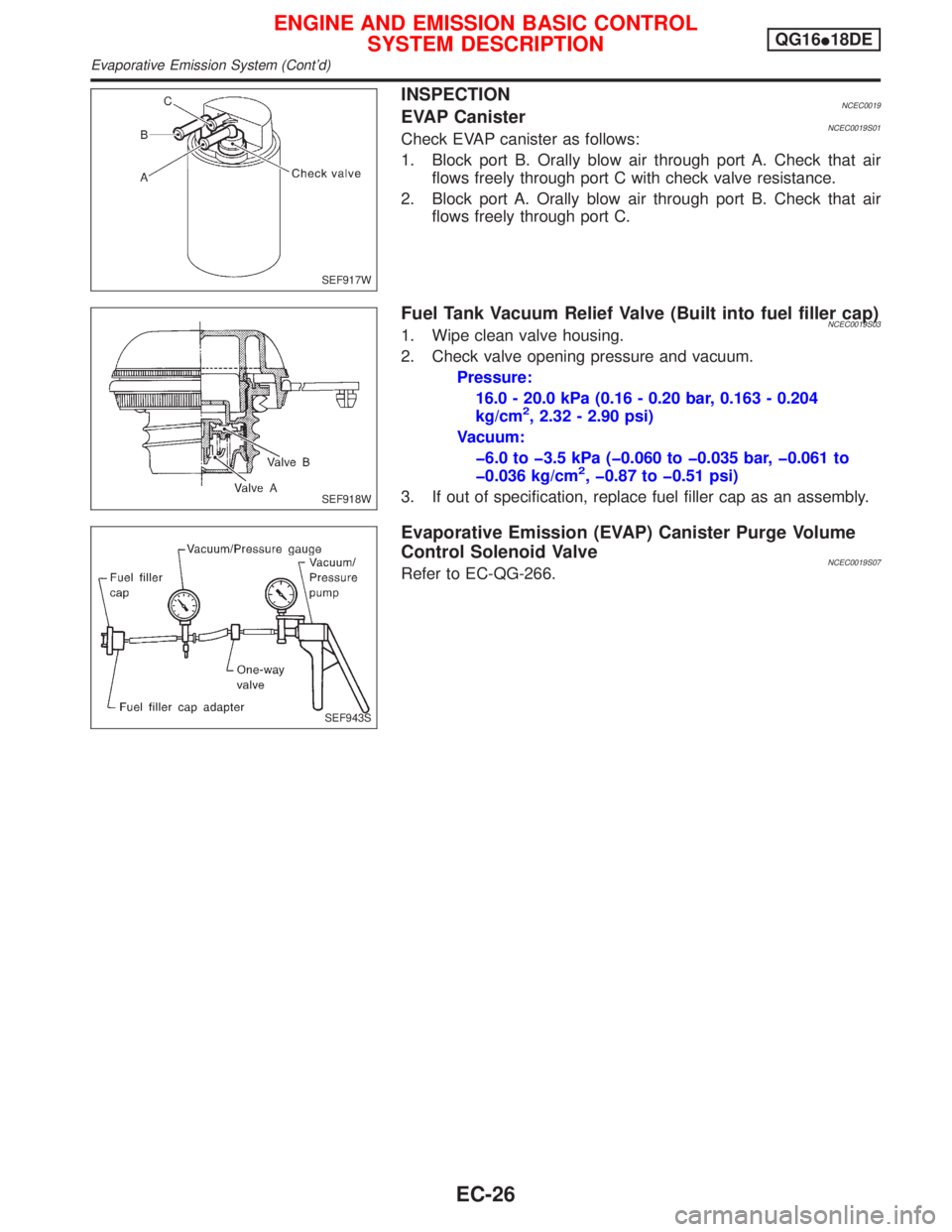

INSPECTIONNCEC0019EVAP CanisterNCEC0019S01Check EVAP canister as follows:

1. Block port B. Orally blow air through port A. Check that air

flows freely through port C with check valve resistance.

2. Block port A. Orally blow air through port B. Check that air

flows freely through port C.

Fuel Tank Vacuum Relief Valve (Built into fuel filler cap)NCEC0019S031. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

Pressure:

16.0 - 20.0 kPa (0.16 - 0.20 bar, 0.163 - 0.204

kg/cm

2, 2.32 - 2.90 psi)

Vacuum:

þ6.0 to þ3.5 kPa (þ0.060 to þ0.035 bar, þ0.061 to

þ0.036 kg/cm

2, þ0.87 to þ0.51 psi)

3. If out of specification, replace fuel filler cap as an assembly.

Evaporative Emission (EVAP) Canister Purge Volume

Control Solenoid Valve

NCEC0019S07Refer to EC-QG-266.

SEF917W

SEF918W

SEF943S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONQG16I18DE

Evaporative Emission System (Cont'd)

EC-26

Page 470 of 2267

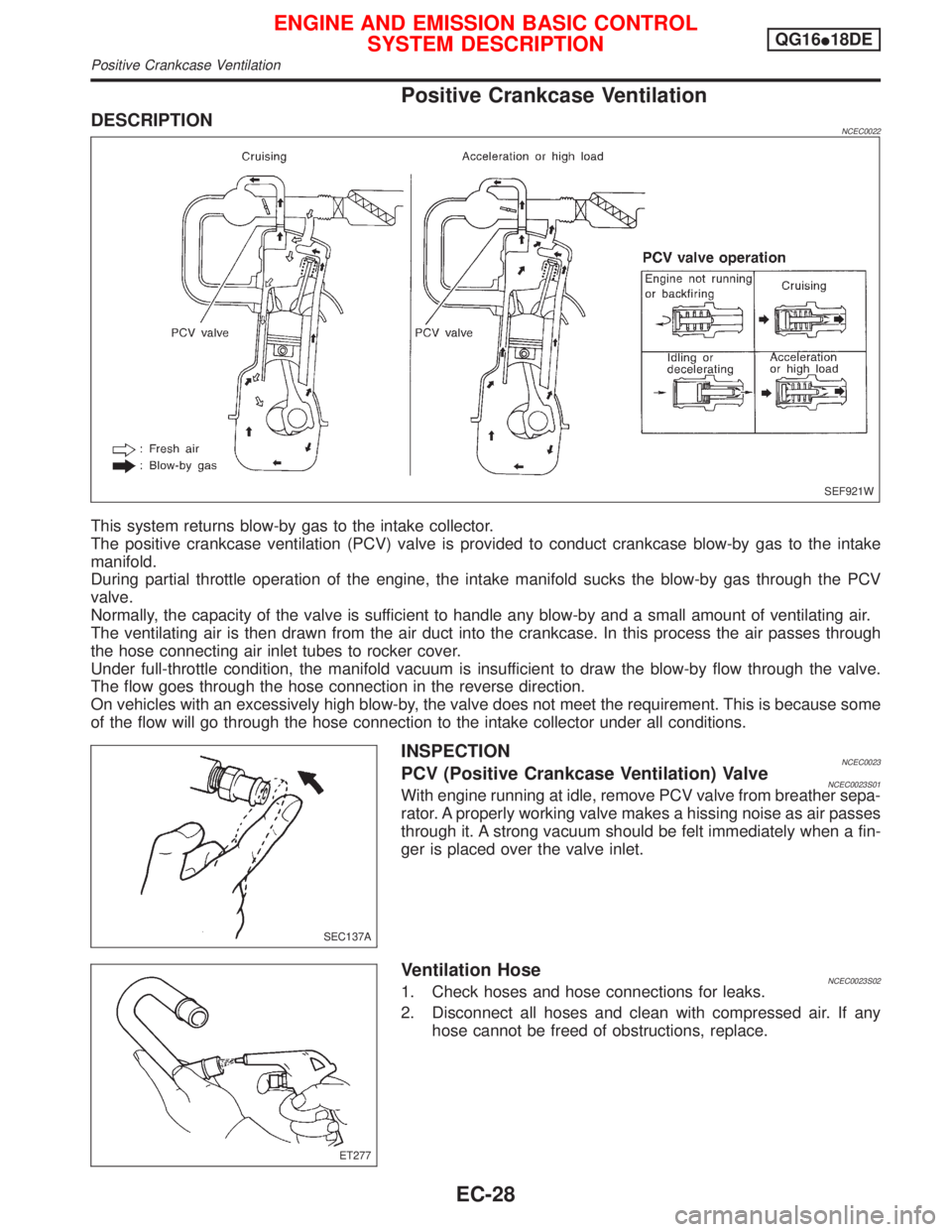

Positive Crankcase Ventilation

DESCRIPTIONNCEC0022

This system returns blow-by gas to the intake collector.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake

manifold.

During partial throttle operation of the engine, the intake manifold sucks the blow-by gas through the PCV

valve.

Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of ventilating air.

The ventilating air is then drawn from the air duct into the crankcase. In this process the air passes through

the hose connecting air inlet tubes to rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient to draw the blow-by flow through the valve.

The flow goes through the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not meet the requirement. This is because some

of the flow will go through the hose connection to the intake collector under all conditions.

INSPECTIONNCEC0023PCV (Positive Crankcase Ventilation) ValveNCEC0023S01With engine running at idle, remove PCV valve from breather sepa-

rator. A properly working valve makes a hissing noise as air passes

through it. A strong vacuum should be felt immediately when a fin-

ger is placed over the valve inlet.

Ventilation HoseNCEC0023S021. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any

hose cannot be freed of obstructions, replace.

SEF921W

SEC137A

ET277

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONQG16I18DE

Positive Crankcase Ventilation

EC-28