check engine NISSAN PRIMERA 1999 Electronic Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 372 of 2267

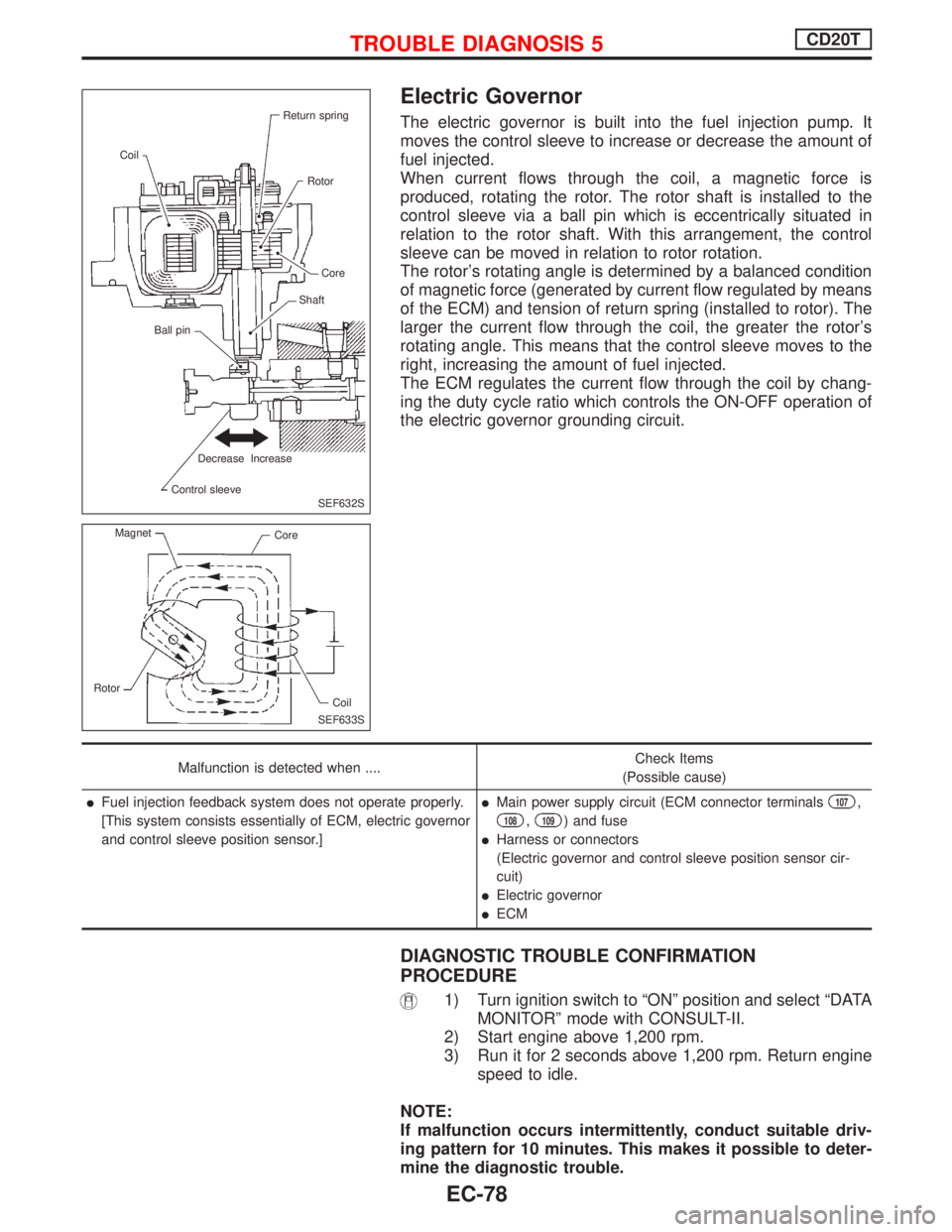

Electric Governor

The electric governor is built into the fuel injection pump. It

moves the control sleeve to increase or decrease the amount of

fuel injected.

When current flows through the coil, a magnetic force is

produced, rotating the rotor. The rotor shaft is installed to the

control sleeve via a ball pin which is eccentrically situated in

relation to the rotor shaft. With this arrangement, the control

sleeve can be moved in relation to rotor rotation.

The rotor's rotating angle is determined by a balanced condition

of magnetic force (generated by current flow regulated by means

of the ECM) and tension of return spring (installed to rotor). The

larger the current flow through the coil, the greater the rotor's

rotating angle. This means that the control sleeve moves to the

right, increasing the amount of fuel injected.

The ECM regulates the current flow through the coil by chang-

ing the duty cycle ratio which controls the ON-OFF operation of

the electric governor grounding circuit.

Malfunction is detected when ....Check Items

(Possible cause)

lFuel injection feedback system does not operate properly.

[This system consists essentially of ECM, electric governor

and control sleeve position sensor.]lMain power supply circuit (ECM connector terminals107,

108,109) and fuse

lHarness or connectors

(Electric governor and control sleeve position sensor cir-

cuit)

lElectric governor

lECM

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch to ªONº position and select ªDATA

MONITORº mode with CONSULT-II.

2) Start engine above 1,200 rpm.

3) Run it for 2 seconds above 1,200 rpm. Return engine

speed to idle.

NOTE:

If malfunction occurs intermittently, conduct suitable driv-

ing pattern for 10 minutes. This makes it possible to deter-

mine the diagnostic trouble.

SEF632S Return spring

Coil

Rotor

Core

Shaft

Ball pin

Decrease Increase

Control sleeve

SEF633S Magnet

Core

Rotor

Coil

TROUBLE DIAGNOSIS 5CD20T

EC-78

Page 376 of 2267

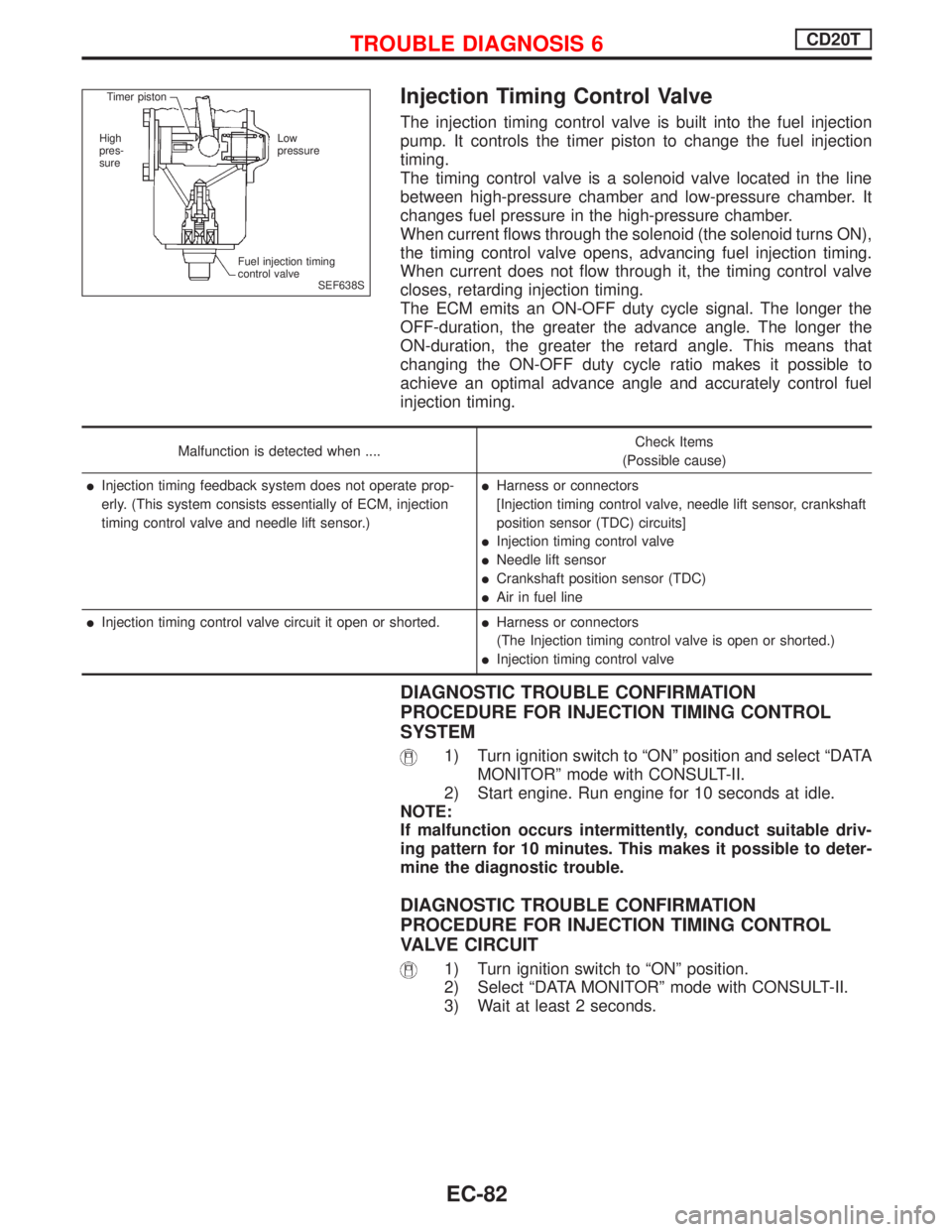

Injection Timing Control Valve

The injection timing control valve is built into the fuel injection

pump. It controls the timer piston to change the fuel injection

timing.

The timing control valve is a solenoid valve located in the line

between high-pressure chamber and low-pressure chamber. It

changes fuel pressure in the high-pressure chamber.

When current flows through the solenoid (the solenoid turns ON),

the timing control valve opens, advancing fuel injection timing.

When current does not flow through it, the timing control valve

closes, retarding injection timing.

The ECM emits an ON-OFF duty cycle signal. The longer the

OFF-duration, the greater the advance angle. The longer the

ON-duration, the greater the retard angle. This means that

changing the ON-OFF duty cycle ratio makes it possible to

achieve an optimal advance angle and accurately control fuel

injection timing.

Malfunction is detected when ....Check Items

(Possible cause)

lInjection timing feedback system does not operate prop-

erly. (This system consists essentially of ECM, injection

timing control valve and needle lift sensor.)lHarness or connectors

[Injection timing control valve, needle lift sensor, crankshaft

position sensor (TDC) circuits]

lInjection timing control valve

lNeedle lift sensor

lCrankshaft position sensor (TDC)

lAir in fuel line

lInjection timing control valve circuit it open or shorted.lHarness or connectors

(The Injection timing control valve is open or shorted.)

lInjection timing control valve

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE FOR INJECTION TIMING CONTROL

SYSTEM

1) Turn ignition switch to ªONº position and select ªDATA

MONITORº mode with CONSULT-II.

2) Start engine. Run engine for 10 seconds at idle.

NOTE:

If malfunction occurs intermittently, conduct suitable driv-

ing pattern for 10 minutes. This makes it possible to deter-

mine the diagnostic trouble.

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE FOR INJECTION TIMING CONTROL

VALVE CIRCUIT

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

SEF638S Timer piston

High

pres-

sureLow

pressure

Fuel injection timing

control valve

TROUBLE DIAGNOSIS 6CD20T

EC-82

Page 380 of 2267

Engine Control Module (ECM)

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The module monitors and

controls the engine operation.

Malfunction is detected when ....Check Item

(Possible Cause)

lECM calculation function is malfunctioning.lECM *

lAn excessively high or low voltage from the atmospheric

pressure sensor is detected by the ECM.lECM *

lECM reference voltage (2.5V) is excessively high or low.lECM *

lECM version number or switching function is not plausible.lECM *

lIgnition switch ªONº signal evaluation circuit in ECM is

malfunctioning.lECM *

* Actually inspecting the ECM inside circuit is impossible. Then, ECM may be replaced.

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

SEC220B

TROUBLE DIAGNOSIS 7CD20T

EC-86

Page 381 of 2267

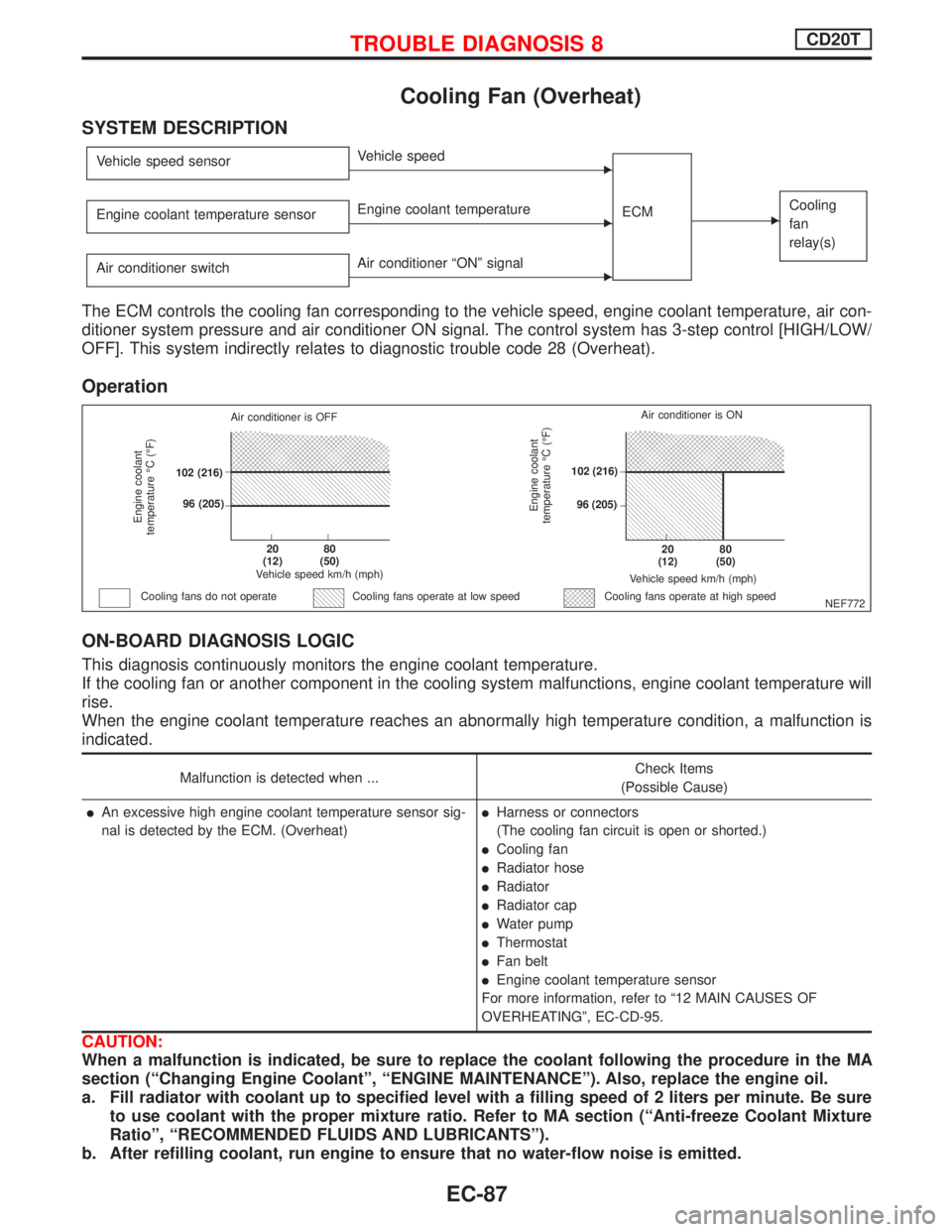

Cooling Fan (Overheat)

SYSTEM DESCRIPTION

Vehicle speed sensorEVehicle speed

ECM

ECooling

fan

relay(s)Engine coolant temperature sensorEEngine coolant temperature

Air conditioner switch

EAir conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air con-

ditioner system pressure and air conditioner ON signal. The control system has 3-step control [HIGH/LOW/

OFF]. This system indirectly relates to diagnostic trouble code 28 (Overheat).

Operation

ON-BOARD DIAGNOSIS LOGIC

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ...Check Items

(Possible Cause)

lAn excessive high engine coolant temperature sensor sig-

nal is detected by the ECM. (Overheat)lHarness or connectors

(The cooling fan circuit is open or shorted.)

lCooling fan

lRadiator hose

lRadiator

lRadiator cap

lWater pump

lThermostat

lFan belt

lEngine coolant temperature sensor

For more information, refer to ª12 MAIN CAUSES OF

OVERHEATINGº, EC-CD-95.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

a. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED FLUIDS AND LUBRICANTSº).

b. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

NEF772

Engine coolant

temperature ÉC (ÉF)

Air conditioner is OFF

.102 (216)

.96 (205)

.20

(12).80

(50)

Vehicle speed km/h (mph)

Cooling fans do not operateCooling fans operate at high speed

Engine coolant

temperature ÉC (ÉF)

Vehicle speed km/h (mph)

.20

(12).80

(50)

.102 (216)

.96 (205)Air conditioner is ON

Cooling fans operate at low speed

TROUBLE DIAGNOSIS 8CD20T

EC-87

Page 382 of 2267

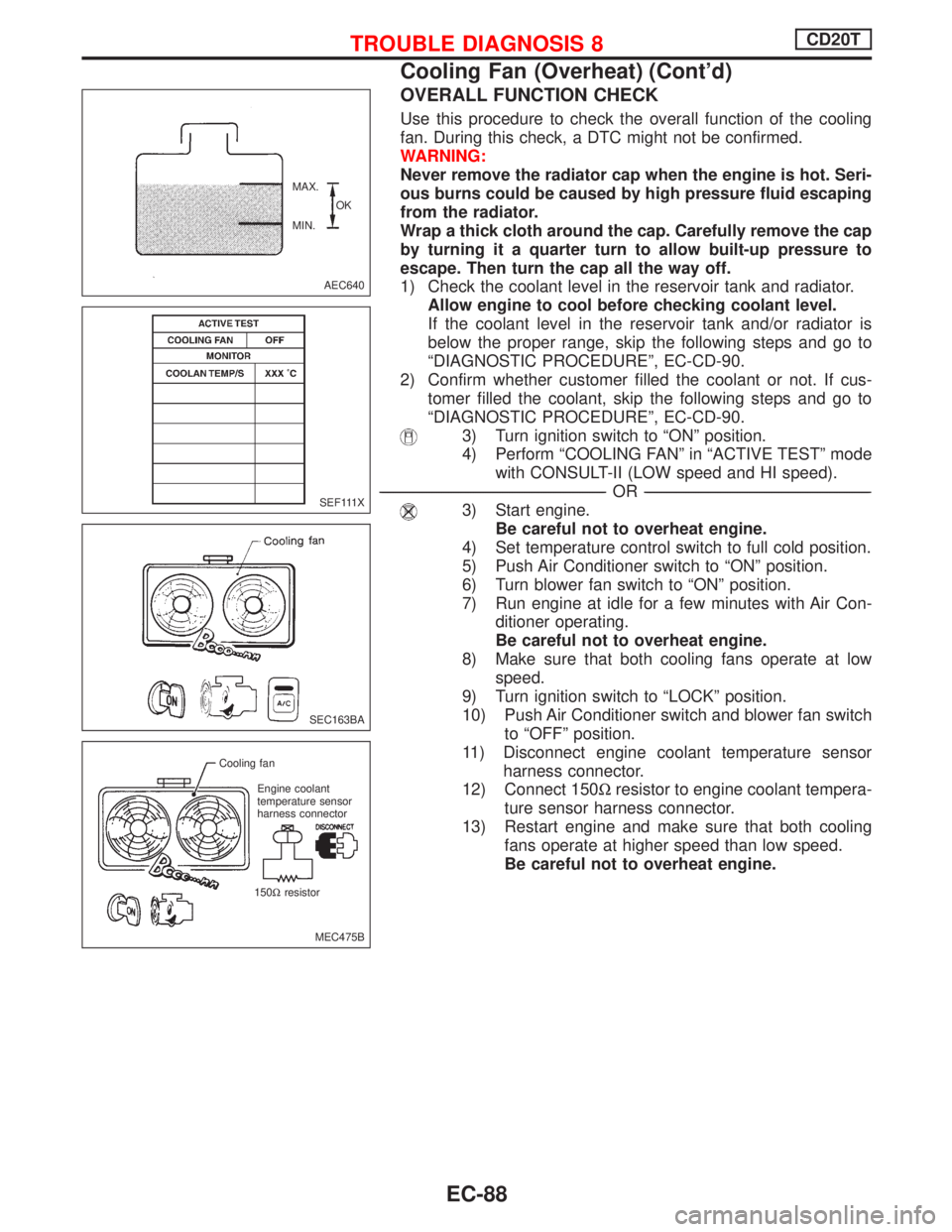

OVERALL FUNCTION CHECK

Use this procedure to check the overall function of the cooling

fan. During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following steps and go to

ªDIAGNOSTIC PROCEDUREº, EC-CD-90.

2) Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, skip the following steps and go to

ªDIAGNOSTIC PROCEDUREº, EC-CD-90.

3) Turn ignition switch to ªONº position.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode

with CONSULT-II (LOW speed and HI speed).

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

3) Start engine.

Be careful not to overheat engine.

4) Set temperature control switch to full cold position.

5) Push Air Conditioner switch to ªONº position.

6) Turn blower fan switch to ªONº position.

7) Run engine at idle for a few minutes with Air Con-

ditioner operating.

Be careful not to overheat engine.

8) Make sure that both cooling fans operate at low

speed.

9) Turn ignition switch to ªLOCKº position.

10) Push Air Conditioner switch and blower fan switch

to ªOFFº position.

11) Disconnect engine coolant temperature sensor

harness connector.

12) Connect 150Wresistor to engine coolant tempera-

ture sensor harness connector.

13) Restart engine and make sure that both cooling

fans operate at higher speed than low speed.

Be careful not to overheat engine.

AEC640 MAX.

MIN.OK

SEF111X

SEC163BA

MEC475B Cooling fan

Engine coolant

temperature sensor

harness connector

150Wresistor

TROUBLE DIAGNOSIS 8CD20T

Cooling Fan (Overheat) (Cont'd)

EC-88

Page 384 of 2267

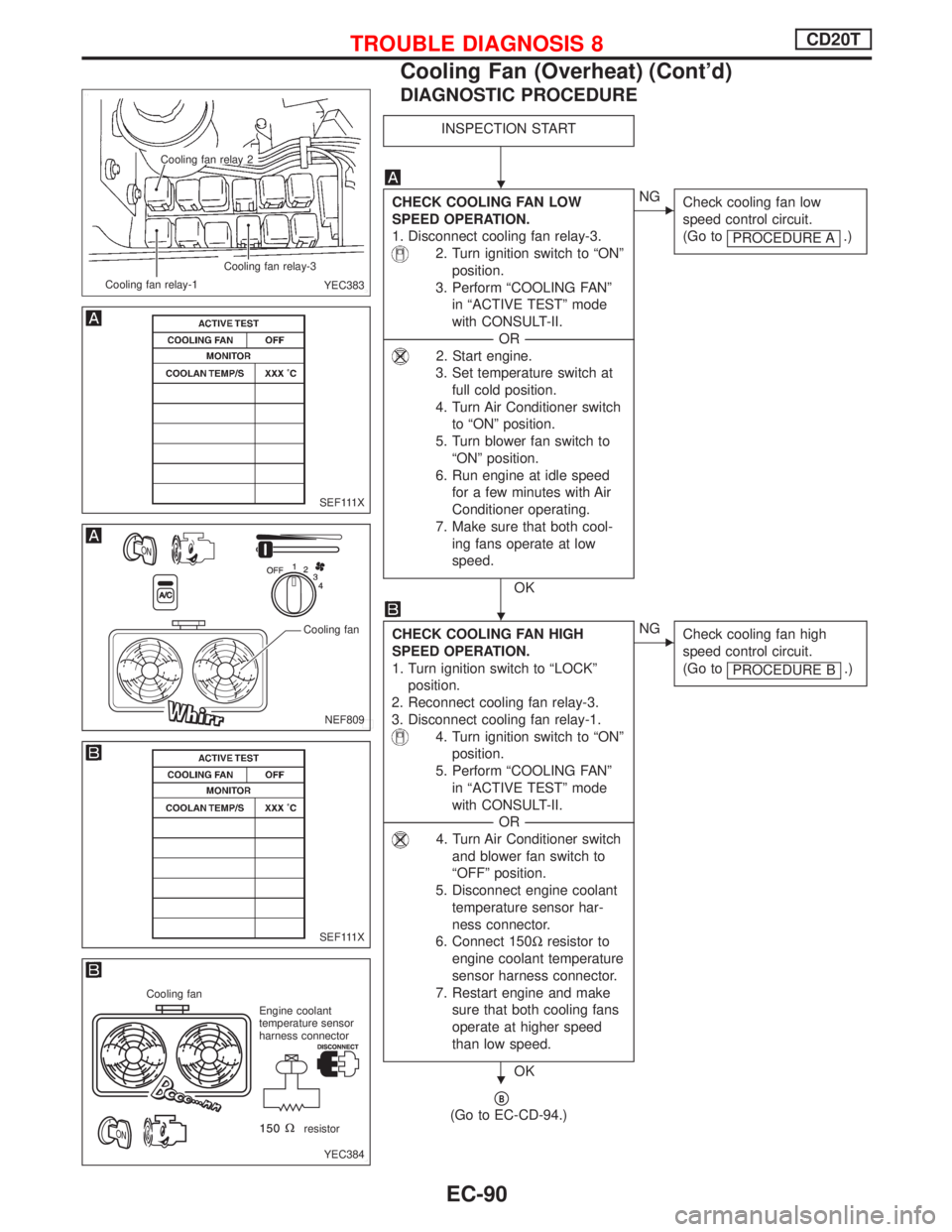

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK COOLING FAN LOW

SPEED OPERATION.

1. Disconnect cooling fan relay-3.

2. Turn ignition switch to ªONº

position.

3. Perform ªCOOLING FANº

in ªACTIVE TESTº mode

with CONSULT-II.

-------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------

2. Start engine.

3. Set temperature switch at

full cold position.

4. Turn Air Conditioner switch

to ªONº position.

5. Turn blower fan switch to

ªONº position.

6. Run engine at idle speed

for a few minutes with Air

Conditioner operating.

7. Make sure that both cool-

ing fans operate at low

speed.

OK

ENG

Check cooling fan low

speed control circuit.

(Go to

PROCEDURE A

.)

CHECK COOLING FAN HIGH

SPEED OPERATION.

1. Turn ignition switch to ªLOCKº

position.

2. Reconnect cooling fan relay-3.

3. Disconnect cooling fan relay-1.

4. Turn ignition switch to ªONº

position.

5. Perform ªCOOLING FANº

in ªACTIVE TESTº mode

with CONSULT-II.

-------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------

4. Turn Air Conditioner switch

and blower fan switch to

ªOFFº position.

5. Disconnect engine coolant

temperature sensor har-

ness connector.

6. Connect 150Wresistor to

engine coolant temperature

sensor harness connector.

7. Restart engine and make

sure that both cooling fans

operate at higher speed

than low speed.

OK

ENG

Check cooling fan high

speed control circuit.

(Go to

PROCEDURE B

.)

pB

(Go to EC-CD-94.)

.Cooling fan relay 2

Cooling fan relay-1Cooling fan relay-3

YEC383

SEF111X

NEF809

Cooling fan

SEF111X

YEC384

Cooling fan

Engine coolant

temperature sensor

harness connector

resistor

H

H

H

TROUBLE DIAGNOSIS 8CD20T

Cooling Fan (Overheat) (Cont'd)

EC-90

Page 388 of 2267

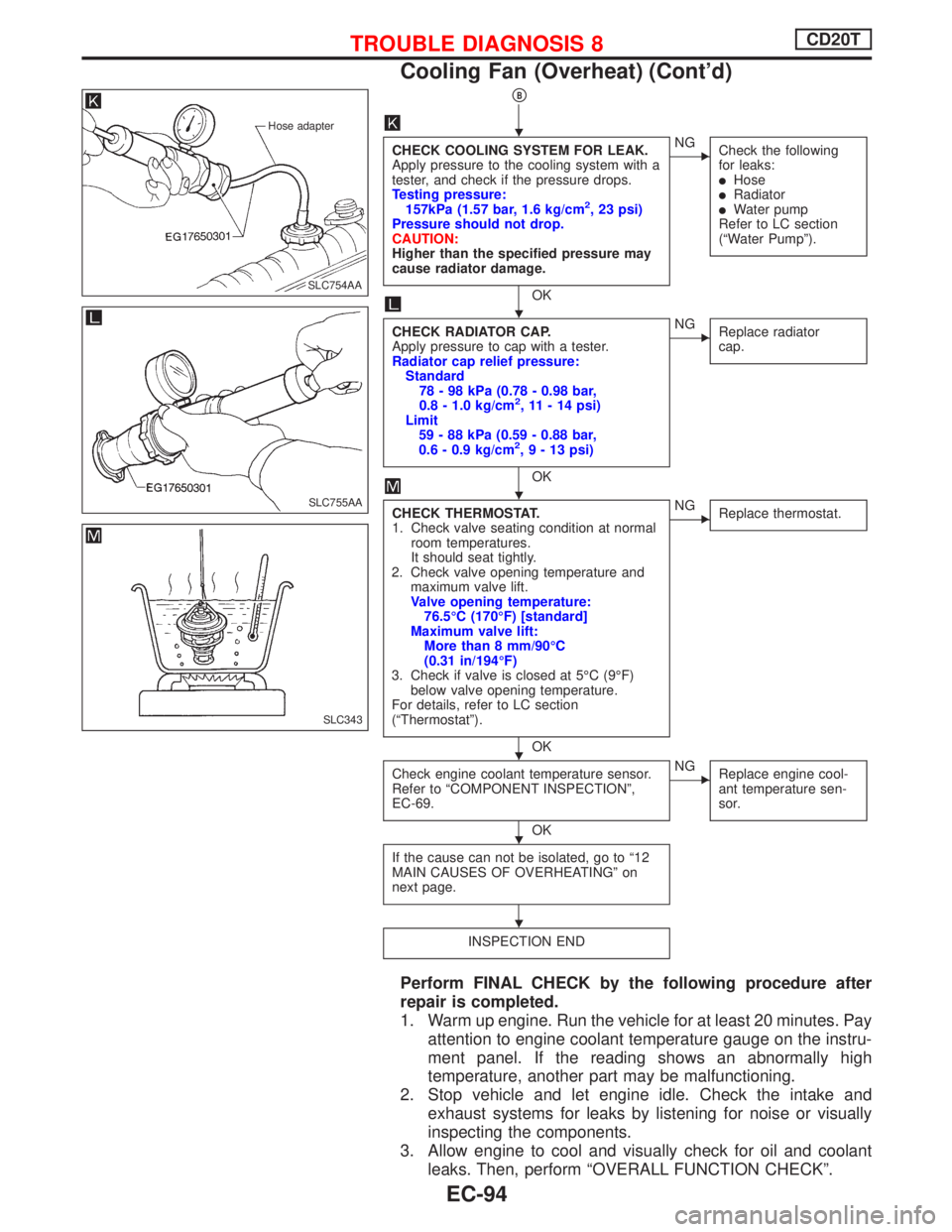

pB

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with a

tester, and check if the pressure drops.

Testing pressure:

157kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

ENG

Check the following

for leaks:

lHoselRadiatorlWater pump

Refer to LC section

(ªWater Pumpº).

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78 - 98 kPa (0.78 - 0.98 bar,

0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59 - 88 kPa (0.59 - 0.88 bar,

0.6 - 0.9 kg/cm

2,9-13psi)

OK

ENG

Replace radiator

cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and

maximum valve lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Maximum valve lift:

More than 8 mm/90ÉC

(0.31 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF)

below valve opening temperature.

For details, refer to LC section

(ªThermostatº).

OK

ENG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ªCOMPONENT INSPECTIONº,

EC-69.

OK

ENG

Replace engine cool-

ant temperature sen-

sor.

If the cause can not be isolated, go to ª12

MAIN CAUSES OF OVERHEATINGº on

next page.

INSPECTION END

Perform FINAL CHECK by the following procedure after

repair is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instru-

ment panel. If the reading shows an abnormally high

temperature, another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and

exhaust systems for leaks by listening for noise or visually

inspecting the components.

3. Allow engine to cool and visually check for oil and coolant

leaks. Then, perform ªOVERALL FUNCTION CHECKº.

Hose adapter

.SLC754AA

SLC755AA

SLC343

H

H

H

H

H

H

TROUBLE DIAGNOSIS 8CD20T

Cooling Fan (Overheat) (Cont'd)

EC-94

Page 389 of 2267

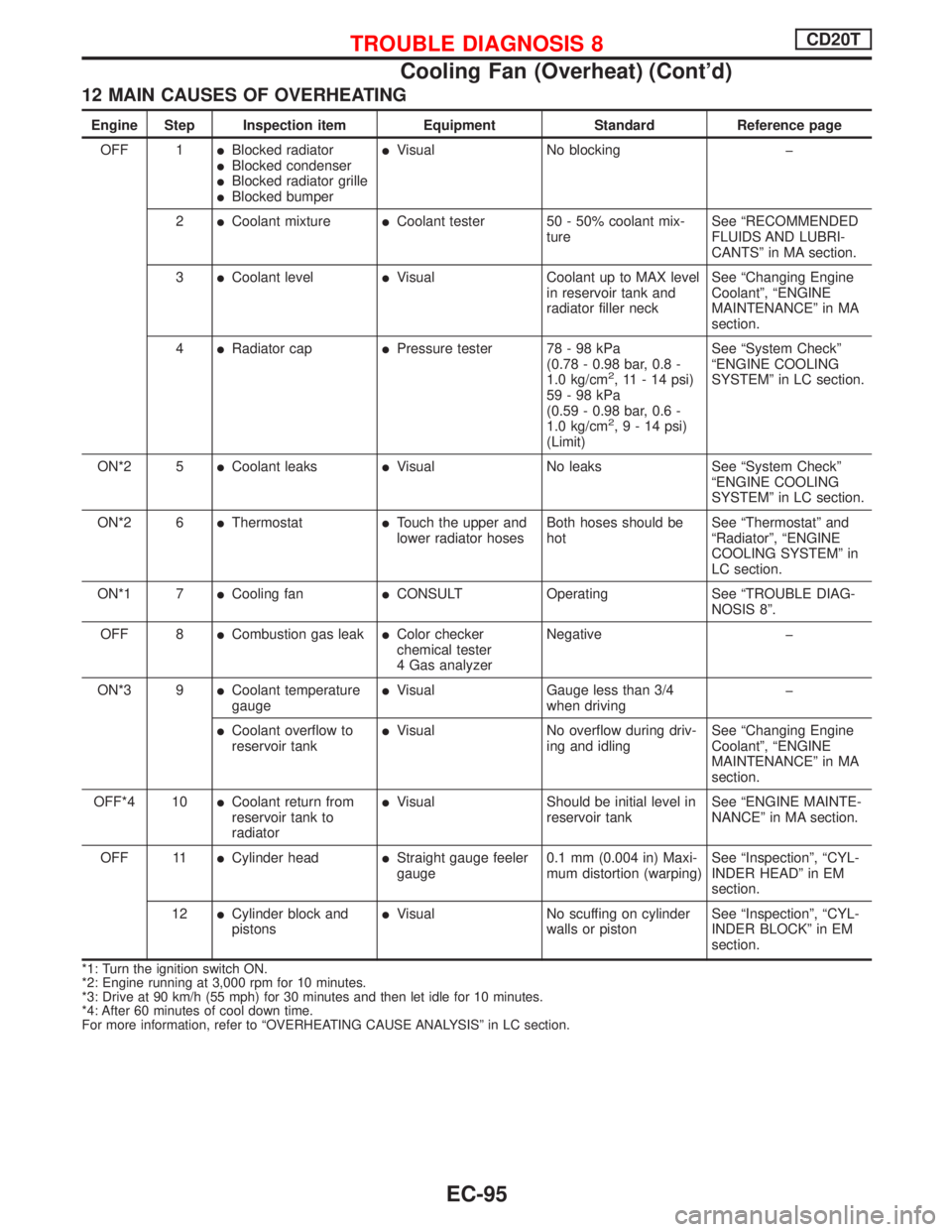

12 MAIN CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Standard Reference page

OFF 1

lBlocked radiatorlBlocked condenserlBlocked radiator grillelBlocked bumper

lVisual No blocking þ

2

lCoolant mixturelCoolant tester 50 - 50% coolant mix-

tureSee ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE

MAINTENANCEº in MA

section.

4

lRadiator caplPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 -

1.0 kg/cm

2, 11 - 14 psi)

59-98kPa

(0.59 - 0.98 bar, 0.6 -

1.0 kg/cm

2,9-14psi)

(Limit)See ªSystem Checkº

ªENGINE COOLING

SYSTEMº in LC section.

ON*2 5

lCoolant leakslVisual No leaks See ªSystem Checkº

ªENGINE COOLING

SYSTEMº in LC section.

ON*2 6

lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be

hotSee ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7

lCooling fanlCONSULT Operating See ªTROUBLE DIAG-

NOSIS 8º.

OFF 8

lCombustion gas leaklColor checker

chemical tester

4 Gas analyzerNegative þ

ON*3 9

lCoolant temperature

gaugelVisual Gauge less than 3/4

when drivingþ

lCoolant overflow to

reservoir tanklVisual No overflow during driv-

ing and idlingSee ªChanging Engine

Coolantº, ªENGINE

MAINTENANCEº in MA

section.

OFF*4 10

lCoolant return from

reservoir tank to

radiatorlVisual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11

lCylinder headlStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYL-

INDER HEADº in EM

section.

12

lCylinder block and

pistonslVisual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYL-

INDER BLOCKº in EM

section.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 mph) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

TROUBLE DIAGNOSIS 8CD20T

Cooling Fan (Overheat) (Cont'd)

EC-95

Page 391 of 2267

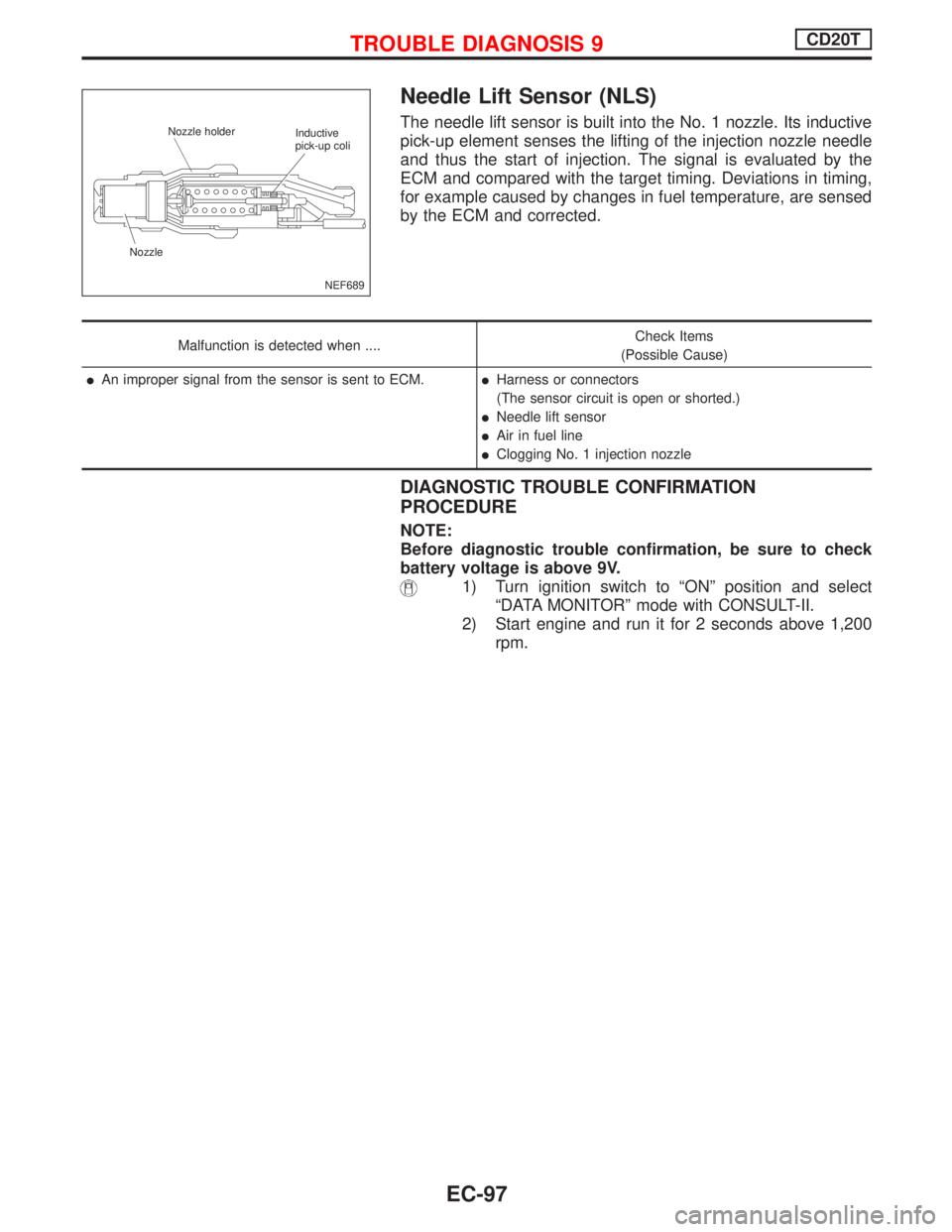

Needle Lift Sensor (NLS)

The needle lift sensor is built into the No. 1 nozzle. Its inductive

pick-up element senses the lifting of the injection nozzle needle

and thus the start of injection. The signal is evaluated by the

ECM and compared with the target timing. Deviations in timing,

for example caused by changes in fuel temperature, are sensed

by the ECM and corrected.

Malfunction is detected when ....Check Items

(Possible Cause)

lAn improper signal from the sensor is sent to ECM.lHarness or connectors

(The sensor circuit is open or shorted.)

lNeedle lift sensor

lAir in fuel line

lClogging No. 1 injection nozzle

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

NOTE:

Before diagnostic trouble confirmation, be sure to check

battery voltage is above 9V.

1) Turn ignition switch to ªONº position and select

ªDATA MONITORº mode with CONSULT-II.

2) Start engine and run it for 2 seconds above 1,200

rpm.

NEF689 Nozzle holder

NozzleInductive

pick-up coli

TROUBLE DIAGNOSIS 9CD20T

EC-97

Page 394 of 2267

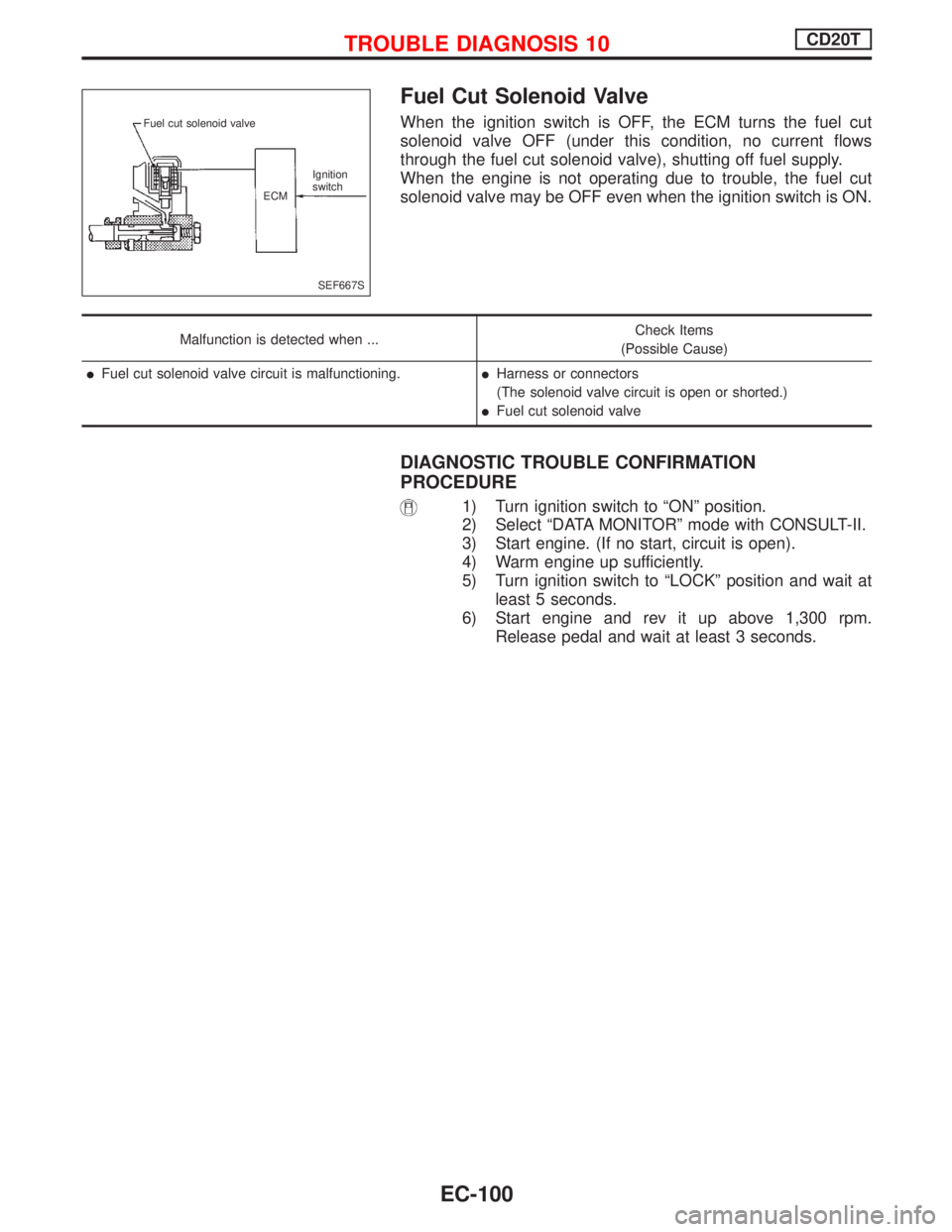

Fuel Cut Solenoid Valve

When the ignition switch is OFF, the ECM turns the fuel cut

solenoid valve OFF (under this condition, no current flows

through the fuel cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut

solenoid valve may be OFF even when the ignition switch is ON.

Malfunction is detected when ...Check Items

(Possible Cause)

lFuel cut solenoid valve circuit is malfunctioning.lHarness or connectors

(The solenoid valve circuit is open or shorted.)

lFuel cut solenoid valve

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine. (If no start, circuit is open).

4) Warm engine up sufficiently.

5) Turn ignition switch to ªLOCKº position and wait at

least 5 seconds.

6) Start engine and rev it up above 1,300 rpm.

Release pedal and wait at least 3 seconds.

SEF667S Fuel cut solenoid valve

ECMIgnition

switch

TROUBLE DIAGNOSIS 10CD20T

EC-100