sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 404 of 2267

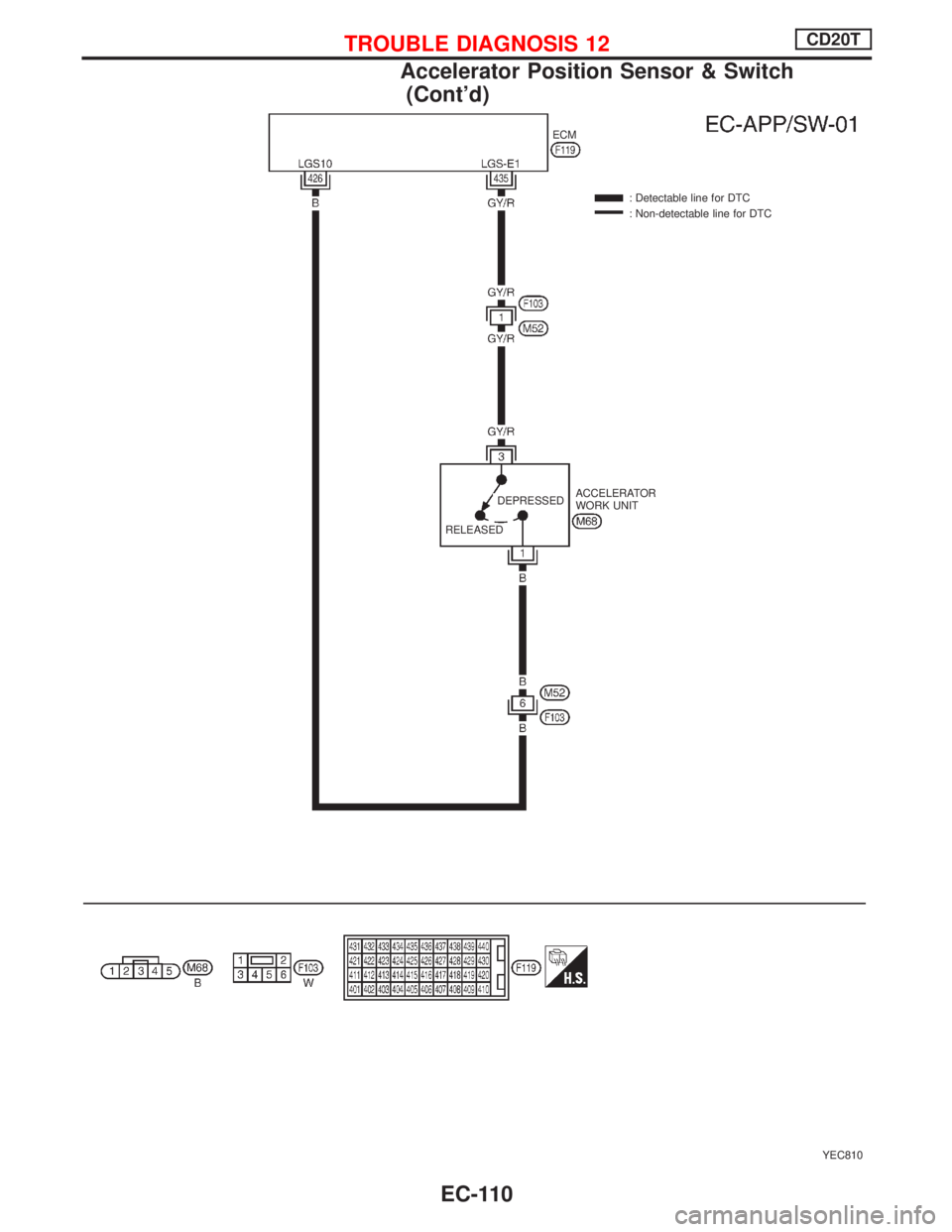

YEC810 : Detectable line for DTC

: Non-detectable line for DTC

ACCELERATOR

WORK UNIT ECM

RELEASEDDEPRESSED

TROUBLE DIAGNOSIS 12CD20T

Accelerator Position Sensor & Switch

(Cont'd)

EC-110

Page 405 of 2267

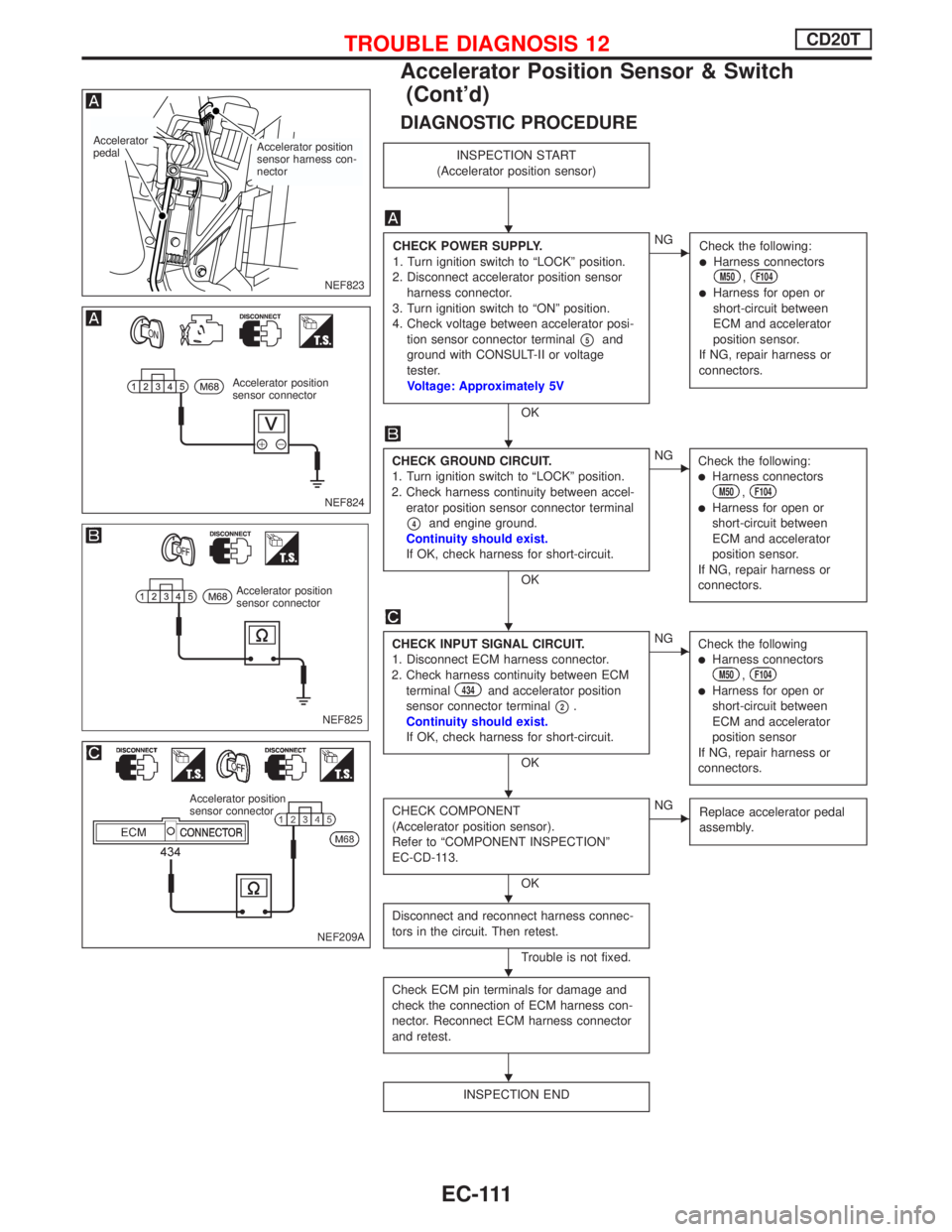

DIAGNOSTIC PROCEDURE

INSPECTION START

(Accelerator position sensor)

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect accelerator position sensor

harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between accelerator posi-

tion sensor connector terminal

p5and

ground with CONSULT-II or voltage

tester.

Voltage: Approximately 5V

OK

ENG

Check the following:

lHarness connectorsM50,F104

lHarness for open or

short-circuit between

ECM and accelerator

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between accel-

erator position sensor connector terminal

p4and engine ground.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

lHarness connectorsM50,F104

lHarness for open or

short-circuit between

ECM and accelerator

position sensor.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

434and accelerator position

sensor connector terminal

p2.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following

lHarness connectorsM50,F104

lHarness for open or

short-circuit between

ECM and accelerator

position sensor

If NG, repair harness or

connectors.

CHECK COMPONENT

(Accelerator position sensor).

Refer to ªCOMPONENT INSPECTIONº

EC-CD-113.

OK

ENG

Replace accelerator pedal

assembly.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

NEF823

Accelerator position

sensor harness con-

nector Accelerator

pedal

NEF824

Accelerator position

sensor connector

NEF825 Accelerator position

sensor connector

NEF209A

Accelerator position

sensor connector

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS 12CD20T

Accelerator Position Sensor & Switch

(Cont'd)

EC-111

Page 406 of 2267

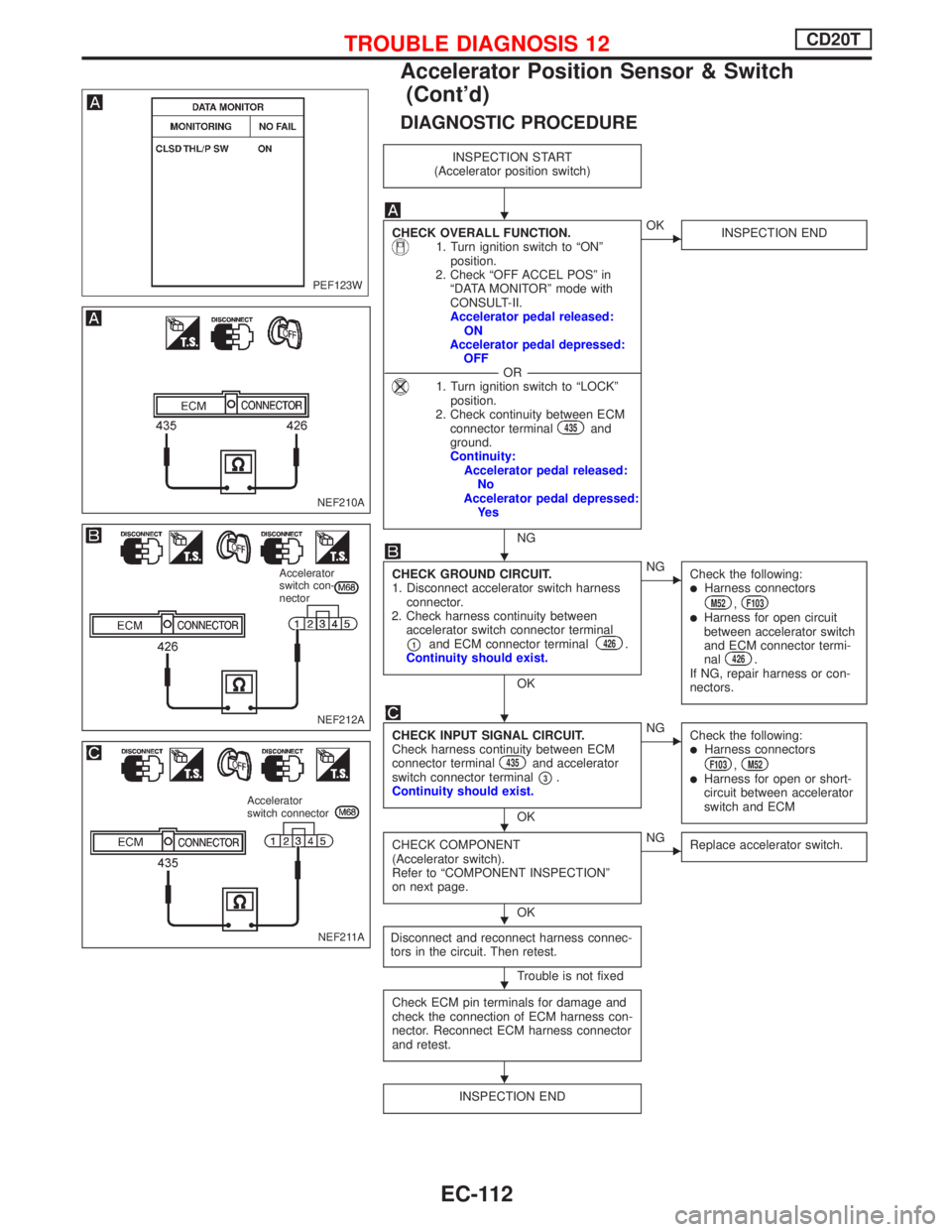

DIAGNOSTIC PROCEDURE

INSPECTION START

(Accelerator position switch)

CHECK OVERALL FUNCTION.1. Turn ignition switch to ªONº

position.

2. Check ªOFF ACCEL POSº in

ªDATA MONITORº mode with

CONSULT-II.

Accelerator pedal released:

ON

Accelerator pedal depressed:

OFF

-------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªLOCKº

position.

2. Check continuity between ECM

connector terminal

435and

ground.

Continuity:

Accelerator pedal released:

No

Accelerator pedal depressed:

Ye s

NG

EOK

INSPECTION END

CHECK GROUND CIRCUIT.

1. Disconnect accelerator switch harness

connector.

2. Check harness continuity between

accelerator switch connector terminal

p1and ECM connector terminal426.

Continuity should exist.

OK

ENG

Check the following:

lHarness connectorsM52,F103lHarness for open circuit

between accelerator switch

and ECM connector termi-

nal

426.

If NG, repair harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT.

Check harness continuity between ECM

connector terminal

435and accelerator

switch connector terminal

p3.

Continuity should exist.

OK

ENG

Check the following:

lHarness connectorsF103,M52lHarness for open or short-

circuit between accelerator

switch and ECM

CHECK COMPONENT

(Accelerator switch).

Refer to ªCOMPONENT INSPECTIONº

on next page.

OK

ENG

Replace accelerator switch.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

PEF123W

NEF210A

NEF212A

Accelerator

switch con-

nector

NEF211A

Accelerator

switch connector

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS 12CD20T

Accelerator Position Sensor & Switch

(Cont'd)

EC-112

Page 407 of 2267

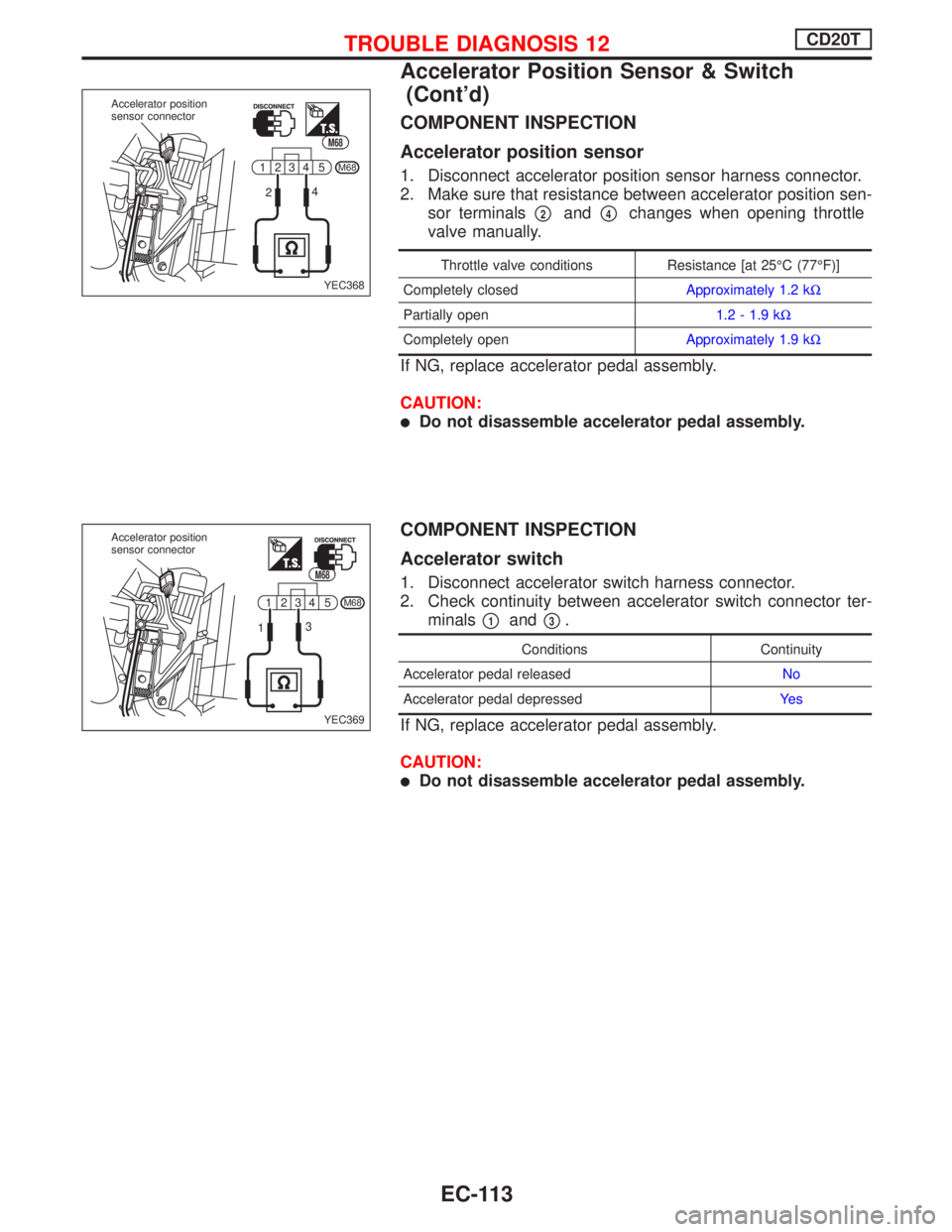

COMPONENT INSPECTION

Accelerator position sensor

1. Disconnect accelerator position sensor harness connector.

2. Make sure that resistance between accelerator position sen-

sor terminals

p2andp4changes when opening throttle

valve manually.

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closedApproximately 1.2 kW

Partially open1.2 - 1.9 kW

Completely openApproximately 1.9 kW

If NG, replace accelerator pedal assembly.

CAUTION:

lDo not disassemble accelerator pedal assembly.

COMPONENT INSPECTION

Accelerator switch

1. Disconnect accelerator switch harness connector.

2. Check continuity between accelerator switch connector ter-

minals

p1andp3.

Conditions Continuity

Accelerator pedal releasedNo

Accelerator pedal depressedYe s

If NG, replace accelerator pedal assembly.

CAUTION:

lDo not disassemble accelerator pedal assembly.

1

25 4 3M68

24

YEC368 Accelerator position

sensor connector

M68

1

25 4 3M68

13

YEC369 Accelerator position

sensor connector

M68

TROUBLE DIAGNOSIS 12CD20T

Accelerator Position Sensor & Switch

(Cont'd)

EC-113

Page 408 of 2267

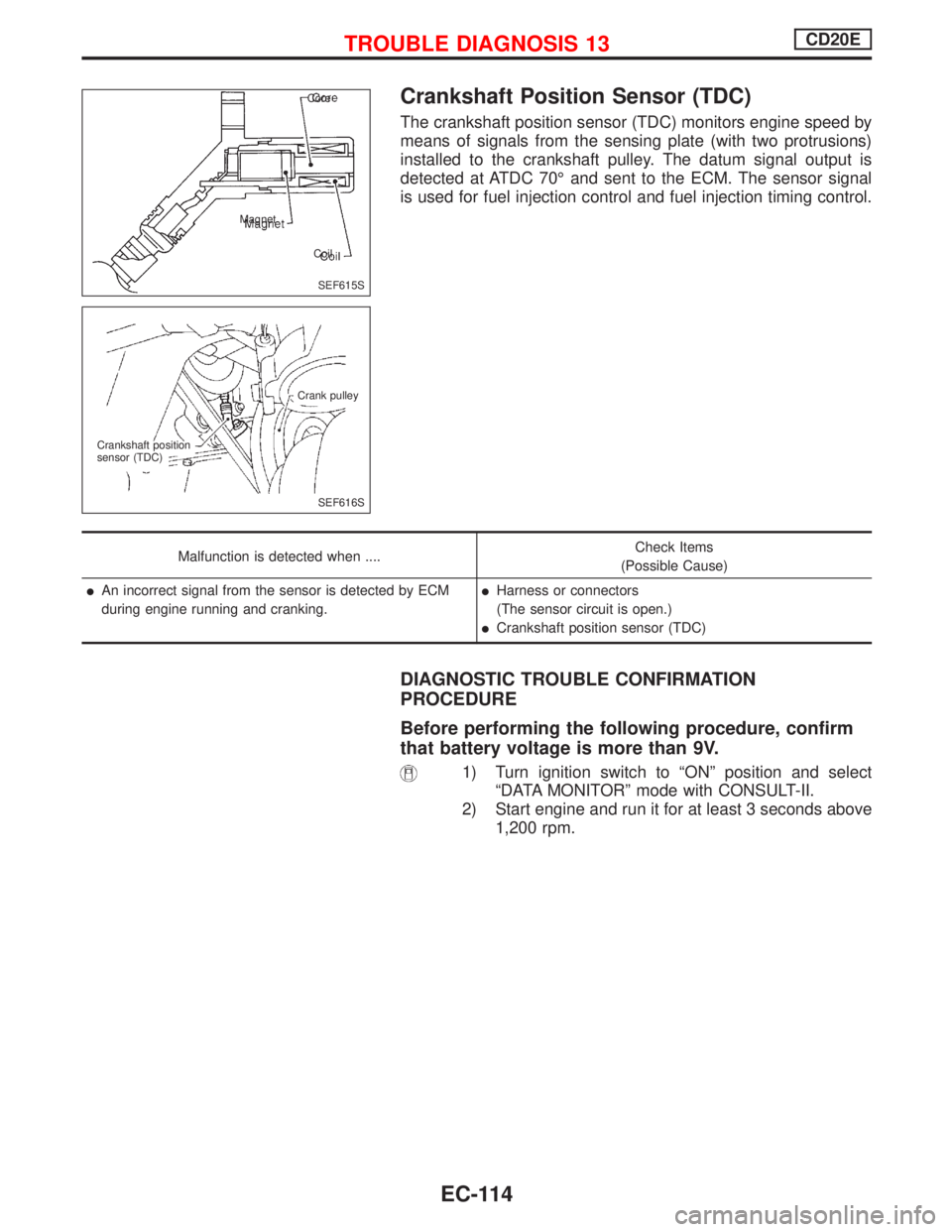

Crankshaft Position Sensor (TDC)

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with two protrusions)

installed to the crankshaft pulley. The datum signal output is

detected at ATDC 70É and sent to the ECM. The sensor signal

is used for fuel injection control and fuel injection timing control.

Malfunction is detected when ....Check Items

(Possible Cause)

lAn incorrect signal from the sensor is detected by ECM

during engine running and cranking.lHarness or connectors

(The sensor circuit is open.)

lCrankshaft position sensor (TDC)

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

Before performing the following procedure, confirm

that battery voltage is more than 9V.

1) Turn ignition switch to ªONº position and select

ªDATA MONITORº mode with CONSULT-II.

2) Start engine and run it for at least 3 seconds above

1,200 rpm.

SEF615S Core

Magnet

Coil

SEF616S Crank pulley

Crankshaft position

sensor (TDC)

TROUBLE DIAGNOSIS 13CD20E

EC-114

Page 409 of 2267

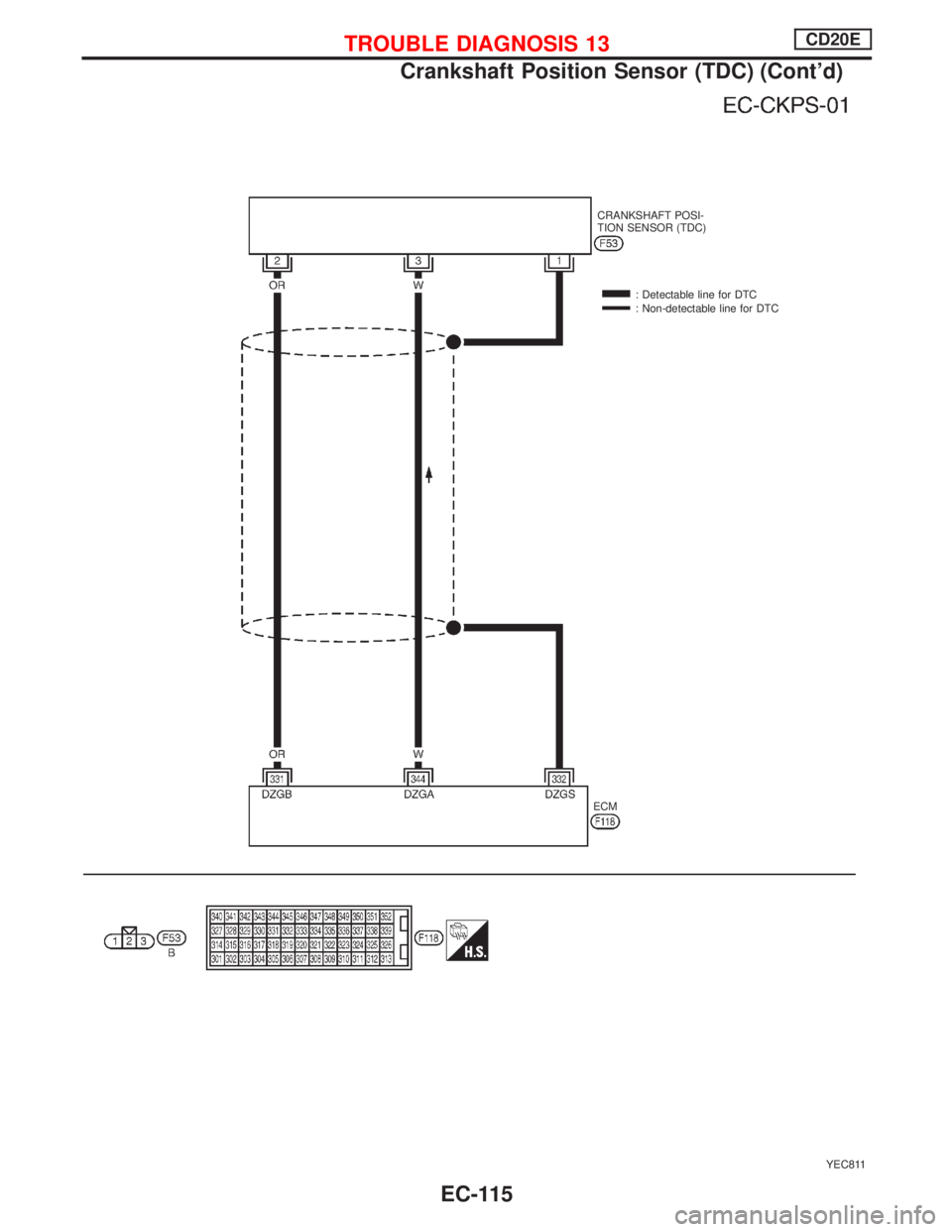

YEC811

CRANKSHAFT POSI-

TION SENSOR (TDC)

: Detectable line for DTC

: Non-detectable line for DTC

ECM

TROUBLE DIAGNOSIS 13CD20E

Crankshaft Position Sensor (TDC) (Cont'd)

EC-115

Page 410 of 2267

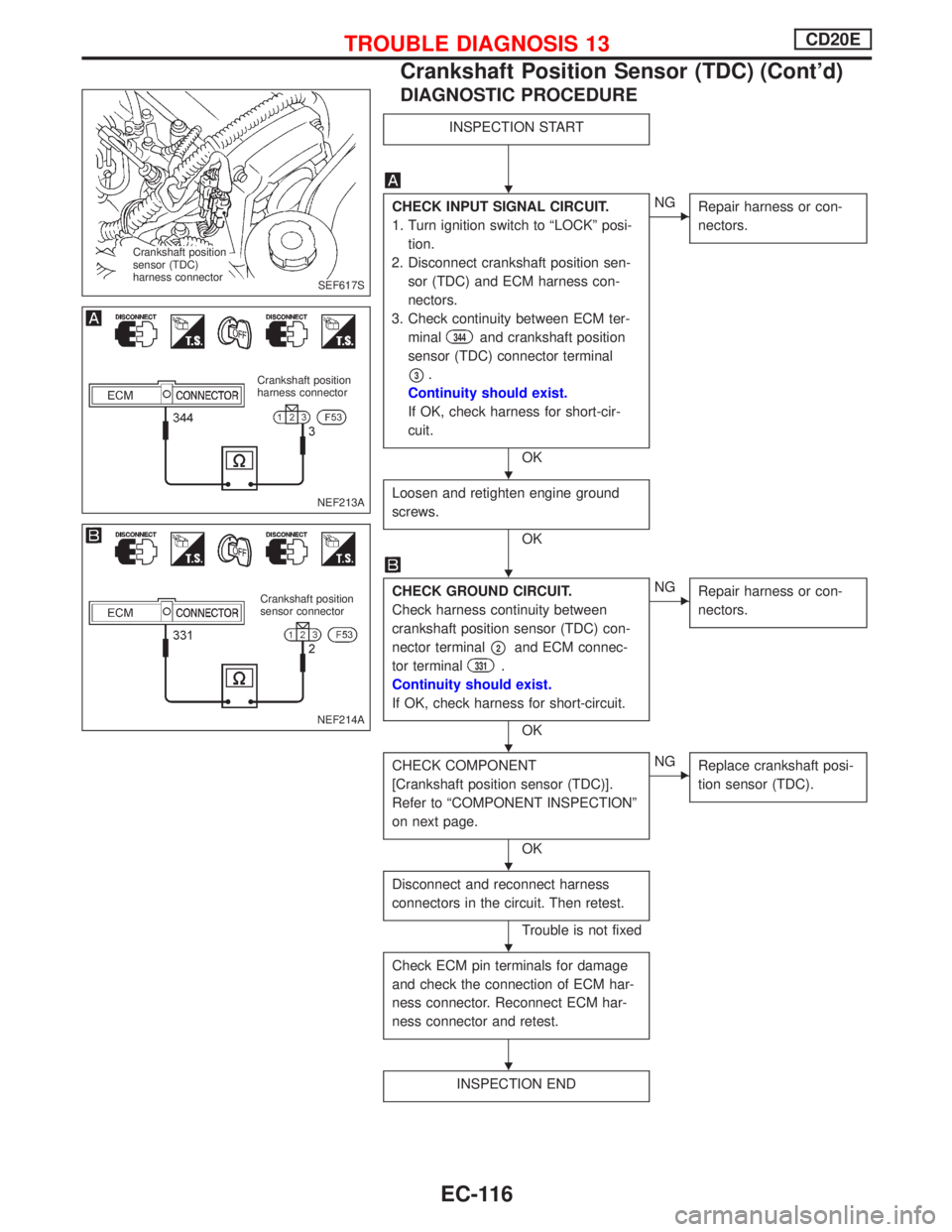

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº posi-

tion.

2. Disconnect crankshaft position sen-

sor (TDC) and ECM harness con-

nectors.

3. Check continuity between ECM ter-

minal

344and crankshaft position

sensor (TDC) connector terminal

p3.

Continuity should exist.

If OK, check harness for short-cir-

cuit.

OK

ENG

Repair harness or con-

nectors.

Loosen and retighten engine ground

screws.

OK

CHECK GROUND CIRCUIT.

Check harness continuity between

crankshaft position sensor (TDC) con-

nector terminal

p2and ECM connec-

tor terminal

331.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or con-

nectors.

CHECK COMPONENT

[Crankshaft position sensor (TDC)].

Refer to ªCOMPONENT INSPECTIONº

on next page.

OK

ENG

Replace crankshaft posi-

tion sensor (TDC).

Disconnect and reconnect harness

connectors in the circuit. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage

and check the connection of ECM har-

ness connector. Reconnect ECM har-

ness connector and retest.

INSPECTION END

SEF617S Crankshaft position

sensor (TDC)

harness connector

NEF213A

Crankshaft position

harness connector

NEF214A

Crankshaft position

sensor connector

H

H

H

H

H

H

H

TROUBLE DIAGNOSIS 13CD20E

Crankshaft Position Sensor (TDC) (Cont'd)

EC-116

Page 411 of 2267

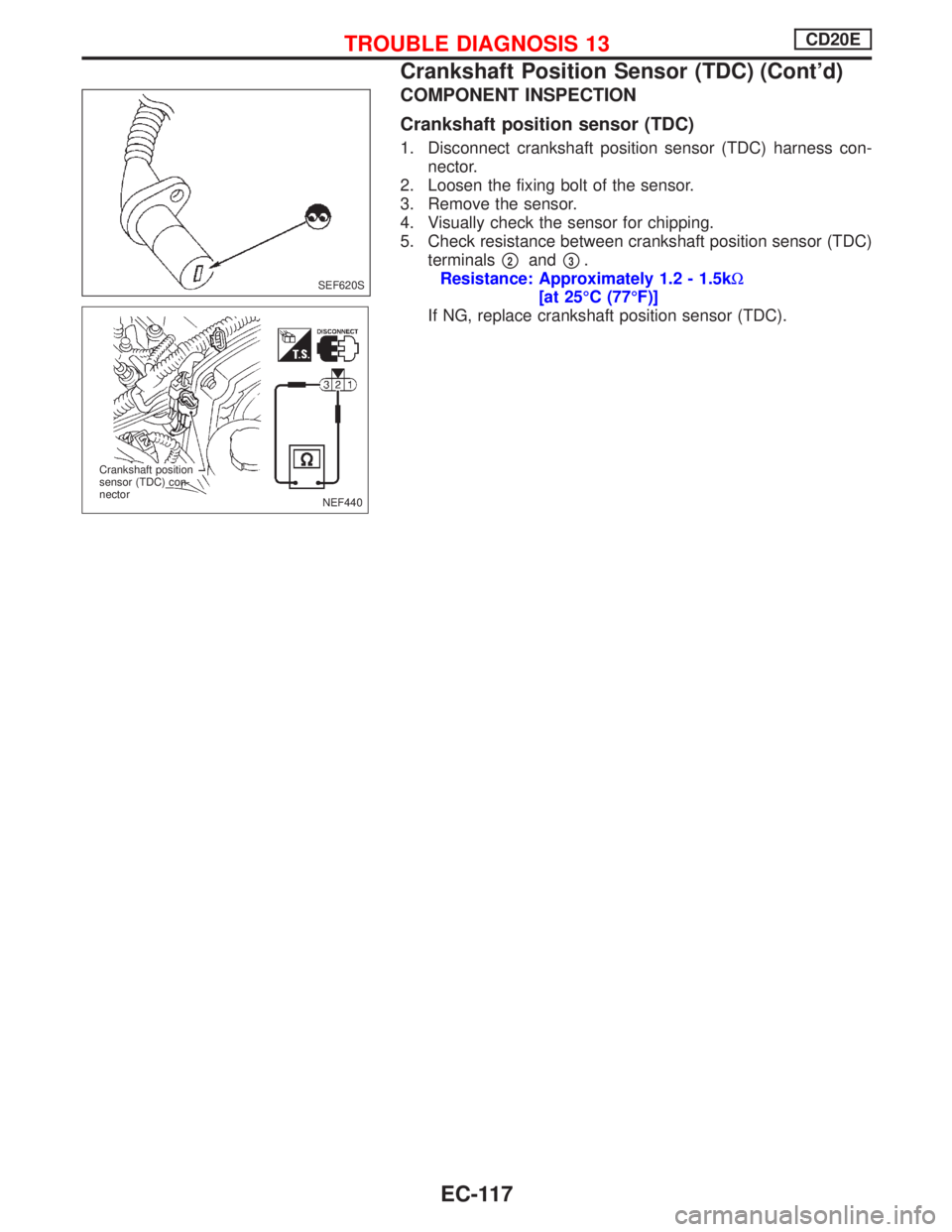

COMPONENT INSPECTION

Crankshaft position sensor (TDC)

1. Disconnect crankshaft position sensor (TDC) harness con-

nector.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

5. Check resistance between crankshaft position sensor (TDC)

terminals

p2andp3.

Resistance: Approximately 1.2 - 1.5kW

[at 25ÉC (77ÉF)]

If NG, replace crankshaft position sensor (TDC).

SEF620S

NEF440 Crankshaft position

sensor (TDC) con-

nector

TROUBLE DIAGNOSIS 13CD20E

Crankshaft Position Sensor (TDC) (Cont'd)

EC-117

Page 420 of 2267

Air Conditioner Cut Control

The Air Conditioner relay is controlled by the ECM. During the

following conditions, the ECM will cut the power supply towards

the air conditioner relay:

lStarting engine

lQuick acceleration from low speed

lUndershooting of idle speed

lHigh engine coolant temperature [above 107ÉC (225ÉF)].

lMalfunctioning of engine speed sensor, accelerator position

sensor or vehicle speed sensor when engine speed is below

2,100 rpm.

Malfunction is detected when ....Check Items

(Possible cause)

lAir conditioner relay signal circuit is shorted.lHarness or connectors

(The air conditioner relay signal circuit is shorted).

lAir conditioner relay

DIAGNOSTIC TROUBLE CONFIRMATION

PROCEDURE

1) Turn ignition switch and air conditioner switch to the

ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 2 seconds.

TROUBLE DIAGNOSES 15CD20T

EC-126

Page 423 of 2267

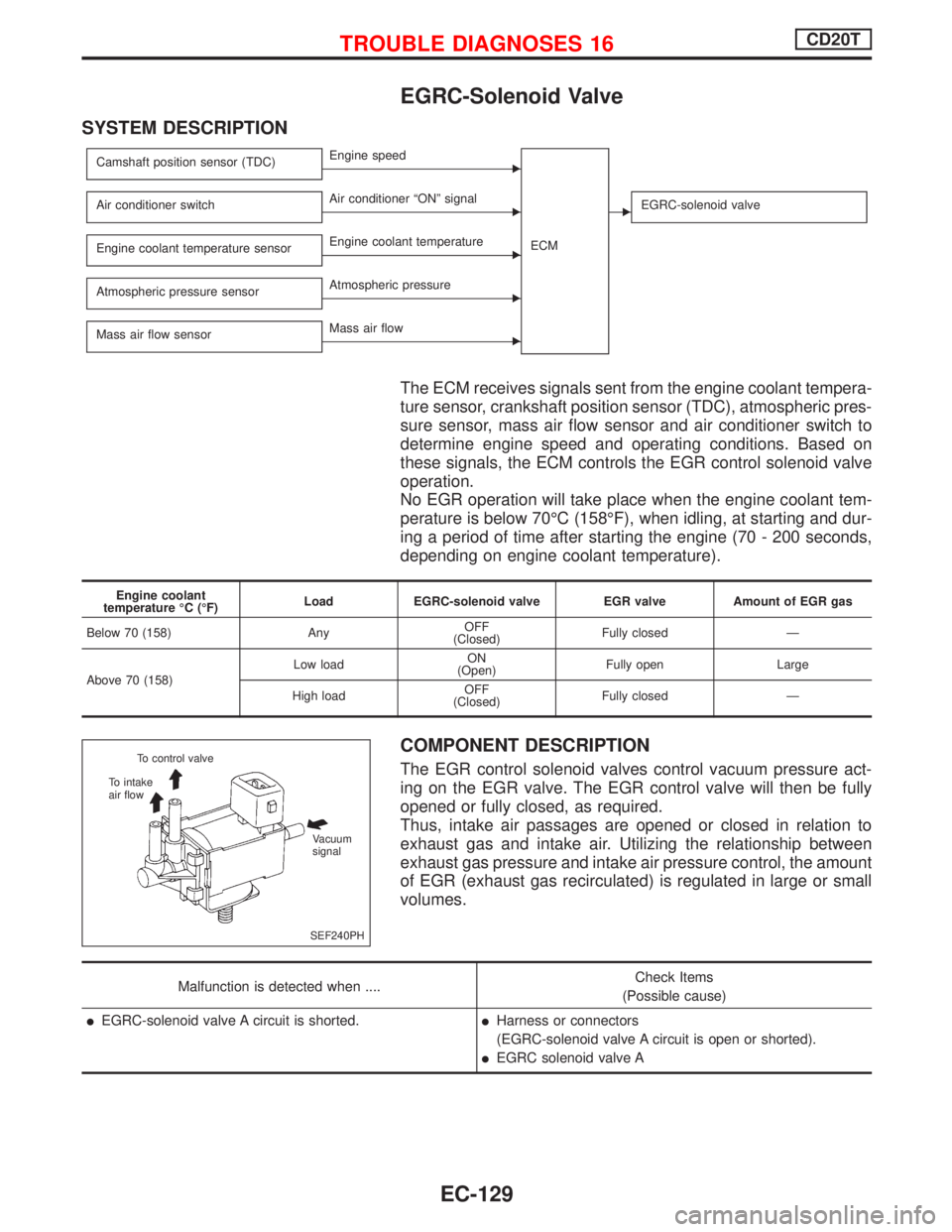

EGRC-Solenoid Valve

SYSTEM DESCRIPTION

Camshaft position sensor (TDC)EEngine speed

ECM

Air conditioner switchEAir conditioner ªONº signalEEGRC-solenoid valve

Engine coolant temperature sensorEEngine coolant temperature

Atmospheric pressure sensor

EAtmospheric pressure

Mass air flow sensor

EMass air flow

The ECM receives signals sent from the engine coolant tempera-

ture sensor, crankshaft position sensor (TDC), atmospheric pres-

sure sensor, mass air flow sensor and air conditioner switch to

determine engine speed and operating conditions. Based on

these signals, the ECM controls the EGR control solenoid valve

operation.

No EGR operation will take place when the engine coolant tem-

perature is below 70ÉC (158ÉF), when idling, at starting and dur-

ing a period of time after starting the engine (70 - 200 seconds,

depending on engine coolant temperature).

Engine coolant

temperature ÉC (ÉF)Load EGRC-solenoid valve EGR valve Amount of EGR gas

Below 70 (158) AnyOFF

(Closed)Fully closed Ð

Above 70 (158)Low loadON

(Open)Fully open Large

High loadOFF

(Closed)Fully closed Ð

COMPONENT DESCRIPTION

The EGR control solenoid valves control vacuum pressure act-

ing on the EGR valve. The EGR control valve will then be fully

opened or fully closed, as required.

Thus, intake air passages are opened or closed in relation to

exhaust gas and intake air. Utilizing the relationship between

exhaust gas pressure and intake air pressure control, the amount

of EGR (exhaust gas recirculated) is regulated in large or small

volumes.

Malfunction is detected when ....Check Items

(Possible cause)

lEGRC-solenoid valve A circuit is shorted.lHarness or connectors

(EGRC-solenoid valve A circuit is open or shorted).

lEGRC solenoid valve A

SEF240PH To control valve

To intake

air flow

Vacuum

signal

TROUBLE DIAGNOSES 16CD20T

EC-129