sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 441 of 2267

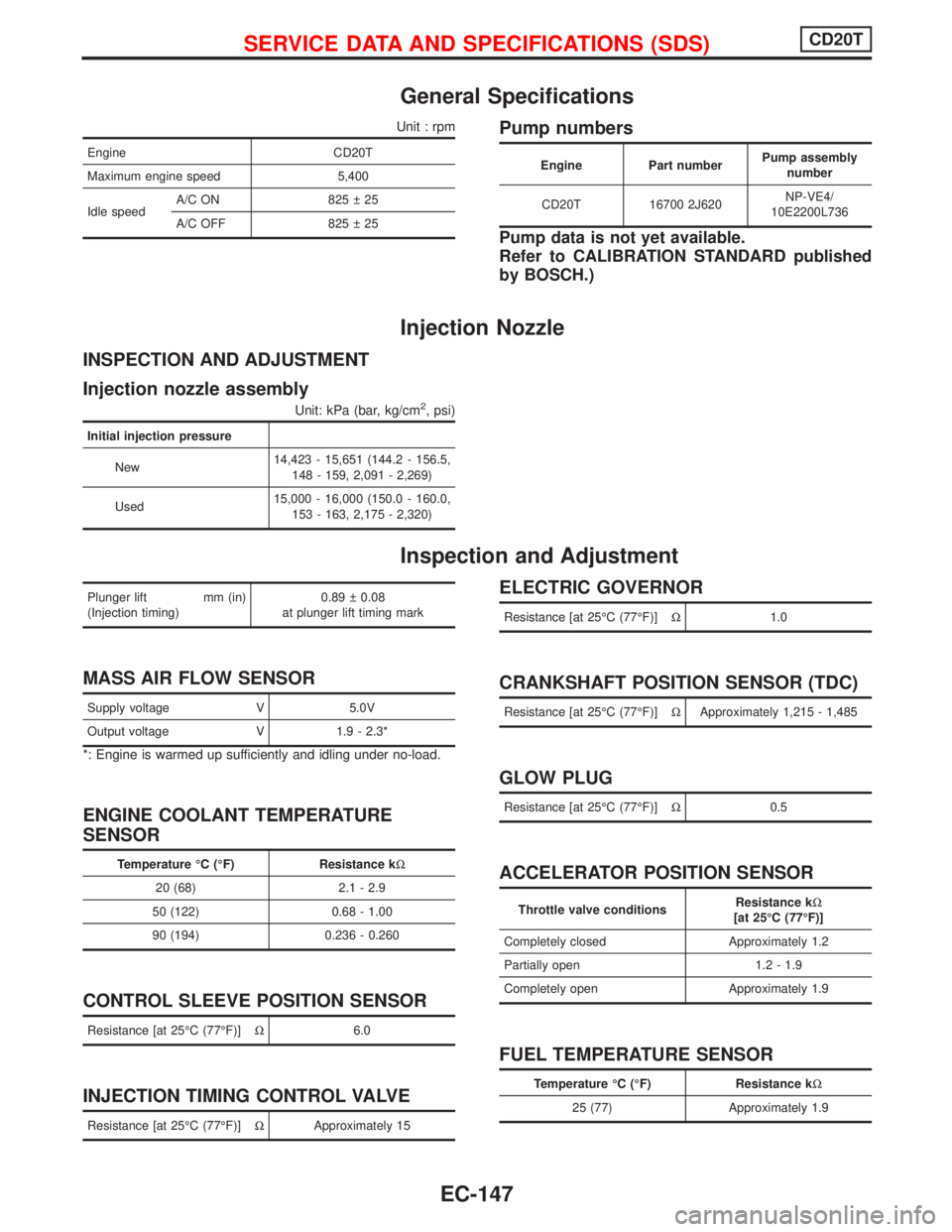

General Specifications

Unit : rpm

Engine CD20T

Maximum engine speed 5,400

Idle speedA/C ON 825 25

A/C OFF 825 25

Pump numbers

Engine Part numberPump assembly

number

CD20T 16700 2J620NP-VE4/

10E2200L736

Pump data is not yet available.

Refer to CALIBRATION STANDARD published

by BOSCH.)

Injection Nozzle

INSPECTION AND ADJUSTMENT

Injection nozzle assembly

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressure

New14,423 - 15,651 (144.2 - 156.5,

148 - 159, 2,091 - 2,269)

Used15,000 - 16,000 (150.0 - 160.0,

153 - 163, 2,175 - 2,320)

Inspection and Adjustment

Plunger lift mm (in)

(Injection timing)0.89 0.08

at plunger lift timing mark

MASS AIR FLOW SENSOR

Supply voltage V 5.0V

Output voltage V 1.9 - 2.3*

*: Engine is warmed up sufficiently and idling under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

CONTROL SLEEVE POSITION SENSOR

Resistance [at 25ÉC (77ÉF)]W6.0

INJECTION TIMING CONTROL VALVE

Resistance [at 25ÉC (77ÉF)]WApproximately 15

ELECTRIC GOVERNOR

Resistance [at 25ÉC (77ÉF)]W1.0

CRANKSHAFT POSITION SENSOR (TDC)

Resistance [at 25ÉC (77ÉF)]WApproximately 1,215 - 1,485

GLOW PLUG

Resistance [at 25ÉC (77ÉF)]W0.5

ACCELERATOR POSITION SENSOR

Throttle valve conditionsResistance kW

[at 25ÉC (77ÉF)]

Completely closed Approximately 1.2

Partially open 1.2 - 1.9

Completely open Approximately 1.9

FUEL TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance kW

25 (77) Approximately 1.9

SERVICE DATA AND SPECIFICATIONS (SDS)CD20T

EC-147

Page 443 of 2267

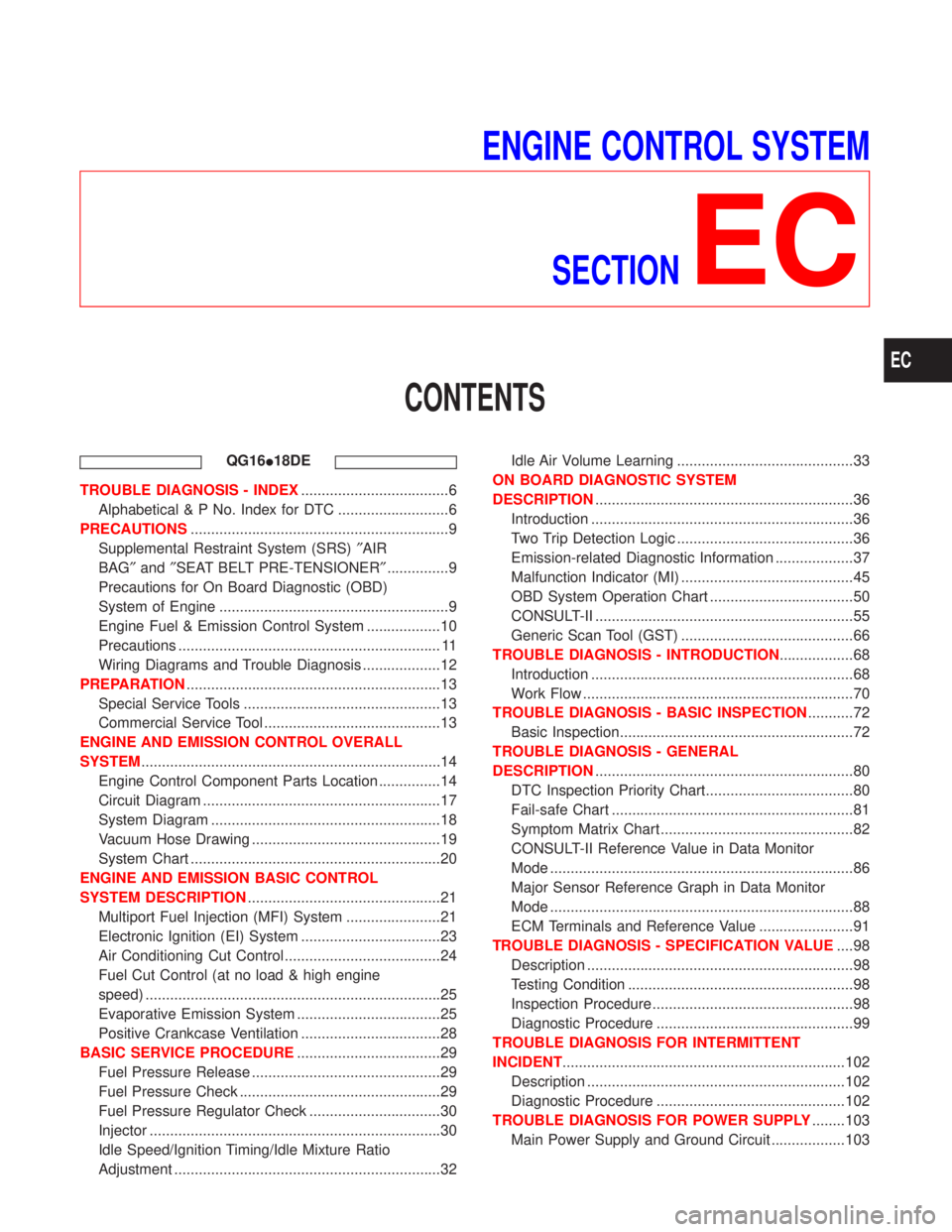

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG16I18DE

TROUBLE DIAGNOSIS - INDEX....................................6

Alphabetical & P No. Index for DTC ...........................6

PRECAUTIONS...............................................................9

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............9

Precautions for On Board Diagnostic (OBD)

System of Engine ........................................................9

Engine Fuel & Emission Control System ..................10

Precautions ................................................................ 11

Wiring Diagrams and Trouble Diagnosis ...................12

PREPARATION..............................................................13

Special Service Tools ................................................13

Commercial Service Tool ...........................................13

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................14

Engine Control Component Parts Location ...............14

Circuit Diagram ..........................................................17

System Diagram ........................................................18

Vacuum Hose Drawing ..............................................19

System Chart .............................................................20

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................21

Multiport Fuel Injection (MFI) System .......................21

Electronic Ignition (EI) System ..................................23

Air Conditioning Cut Control ......................................24

Fuel Cut Control (at no load & high engine

speed) ........................................................................25

Evaporative Emission System ...................................25

Positive Crankcase Ventilation ..................................28

BASIC SERVICE PROCEDURE...................................29

Fuel Pressure Release ..............................................29

Fuel Pressure Check .................................................29

Fuel Pressure Regulator Check ................................30

Injector .......................................................................30

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................32Idle Air Volume Learning ...........................................33

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................36

Introduction ................................................................36

Two Trip Detection Logic ...........................................36

Emission-related Diagnostic Information ...................37

Malfunction Indicator (MI) ..........................................45

OBD System Operation Chart ...................................50

CONSULT-II ...............................................................55

Generic Scan Tool (GST) ..........................................66

TROUBLE DIAGNOSIS - INTRODUCTION..................68

Introduction ................................................................68

Work Flow ..................................................................70

TROUBLE DIAGNOSIS - BASIC INSPECTION...........72

Basic Inspection.........................................................72

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................80

DTC Inspection Priority Chart....................................80

Fail-safe Chart ...........................................................81

Symptom Matrix Chart ...............................................82

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................86

Major Sensor Reference Graph in Data Monitor

Mode ..........................................................................88

ECM Terminals and Reference Value .......................91

TROUBLE DIAGNOSIS - SPECIFICATION VALUE....98

Description .................................................................98

Testing Condition .......................................................98

Inspection Procedure .................................................98

Diagnostic Procedure ................................................99

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................102

Description ...............................................................102

Diagnostic Procedure ..............................................102

TROUBLE DIAGNOSIS FOR POWER SUPPLY........103

Main Power Supply and Ground Circuit ..................103

EC

Page 444 of 2267

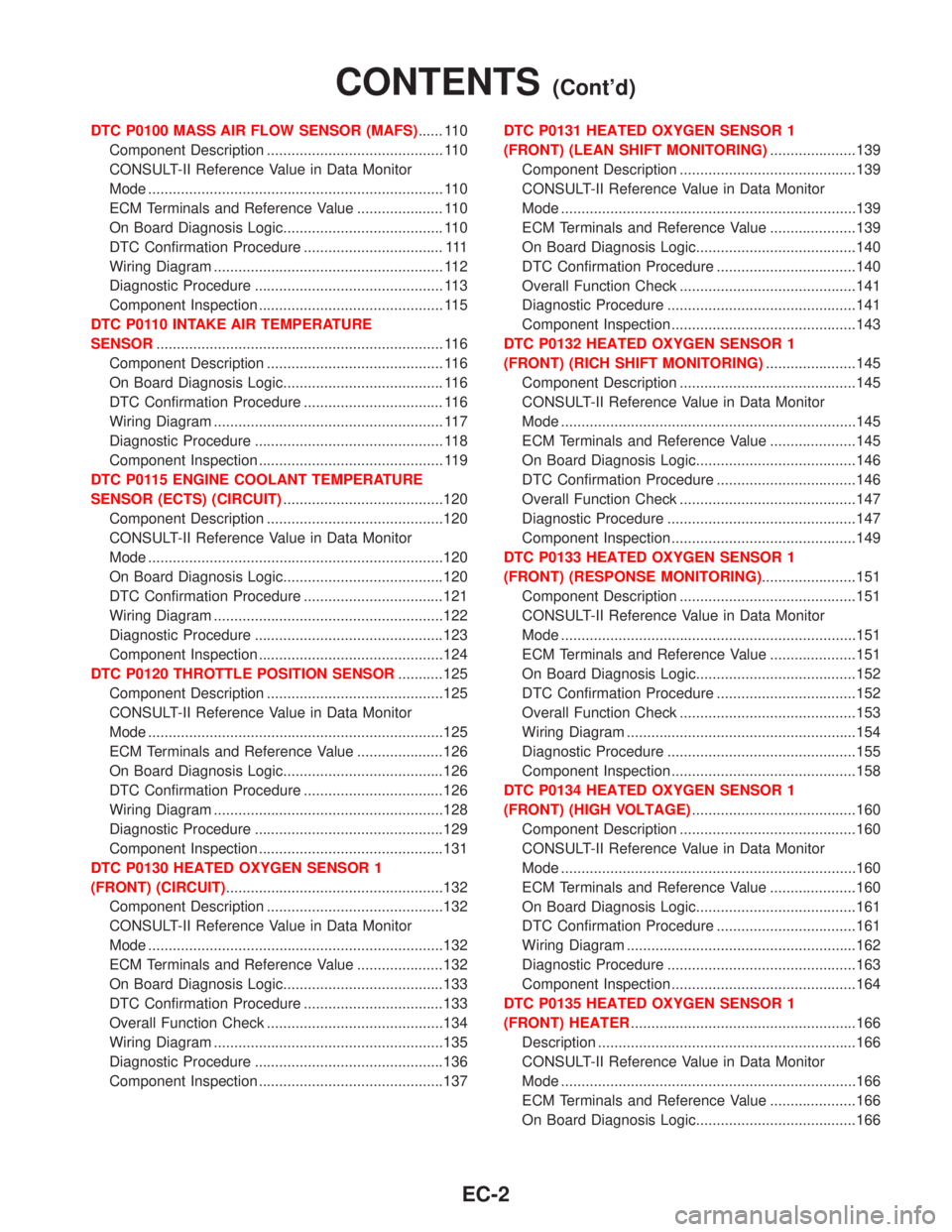

DTC P0100 MASS AIR FLOW SENSOR (MAFS)...... 110

Component Description ........................................... 110

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 110

ECM Terminals and Reference Value ..................... 110

On Board Diagnosis Logic....................................... 110

DTC Confirmation Procedure .................................. 111

Wiring Diagram ........................................................ 112

Diagnostic Procedure .............................................. 113

Component Inspection ............................................. 115

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR...................................................................... 116

Component Description ........................................... 116

On Board Diagnosis Logic....................................... 116

DTC Confirmation Procedure .................................. 116

Wiring Diagram ........................................................ 117

Diagnostic Procedure .............................................. 118

Component Inspection ............................................. 119

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS) (CIRCUIT).......................................120

Component Description ...........................................120

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................120

On Board Diagnosis Logic.......................................120

DTC Confirmation Procedure ..................................121

Wiring Diagram ........................................................122

Diagnostic Procedure ..............................................123

Component Inspection .............................................124

DTC P0120 THROTTLE POSITION SENSOR...........125

Component Description ...........................................125

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................125

ECM Terminals and Reference Value .....................126

On Board Diagnosis Logic.......................................126

DTC Confirmation Procedure ..................................126

Wiring Diagram ........................................................128

Diagnostic Procedure ..............................................129

Component Inspection .............................................131

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................132

Component Description ...........................................132

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................132

ECM Terminals and Reference Value .....................132

On Board Diagnosis Logic.......................................133

DTC Confirmation Procedure ..................................133

Overall Function Check ...........................................134

Wiring Diagram ........................................................135

Diagnostic Procedure ..............................................136

Component Inspection .............................................137DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................139

Component Description ...........................................139

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................139

ECM Terminals and Reference Value .....................139

On Board Diagnosis Logic.......................................140

DTC Confirmation Procedure ..................................140

Overall Function Check ...........................................141

Diagnostic Procedure ..............................................141

Component Inspection .............................................143

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................145

Component Description ...........................................145

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................145

ECM Terminals and Reference Value .....................145

On Board Diagnosis Logic.......................................146

DTC Confirmation Procedure ..................................146

Overall Function Check ...........................................147

Diagnostic Procedure ..............................................147

Component Inspection .............................................149

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT) (RESPONSE MONITORING).......................151

Component Description ...........................................151

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................151

ECM Terminals and Reference Value .....................151

On Board Diagnosis Logic.......................................152

DTC Confirmation Procedure ..................................152

Overall Function Check ...........................................153

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................155

Component Inspection .............................................158

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................160

Component Description ...........................................160

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................160

ECM Terminals and Reference Value .....................160

On Board Diagnosis Logic.......................................161

DTC Confirmation Procedure ..................................161

Wiring Diagram ........................................................162

Diagnostic Procedure ..............................................163

Component Inspection .............................................164

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................166

Description ...............................................................166

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................166

ECM Terminals and Reference Value .....................166

On Board Diagnosis Logic.......................................166

CONTENTS(Cont'd)

EC-2

Page 445 of 2267

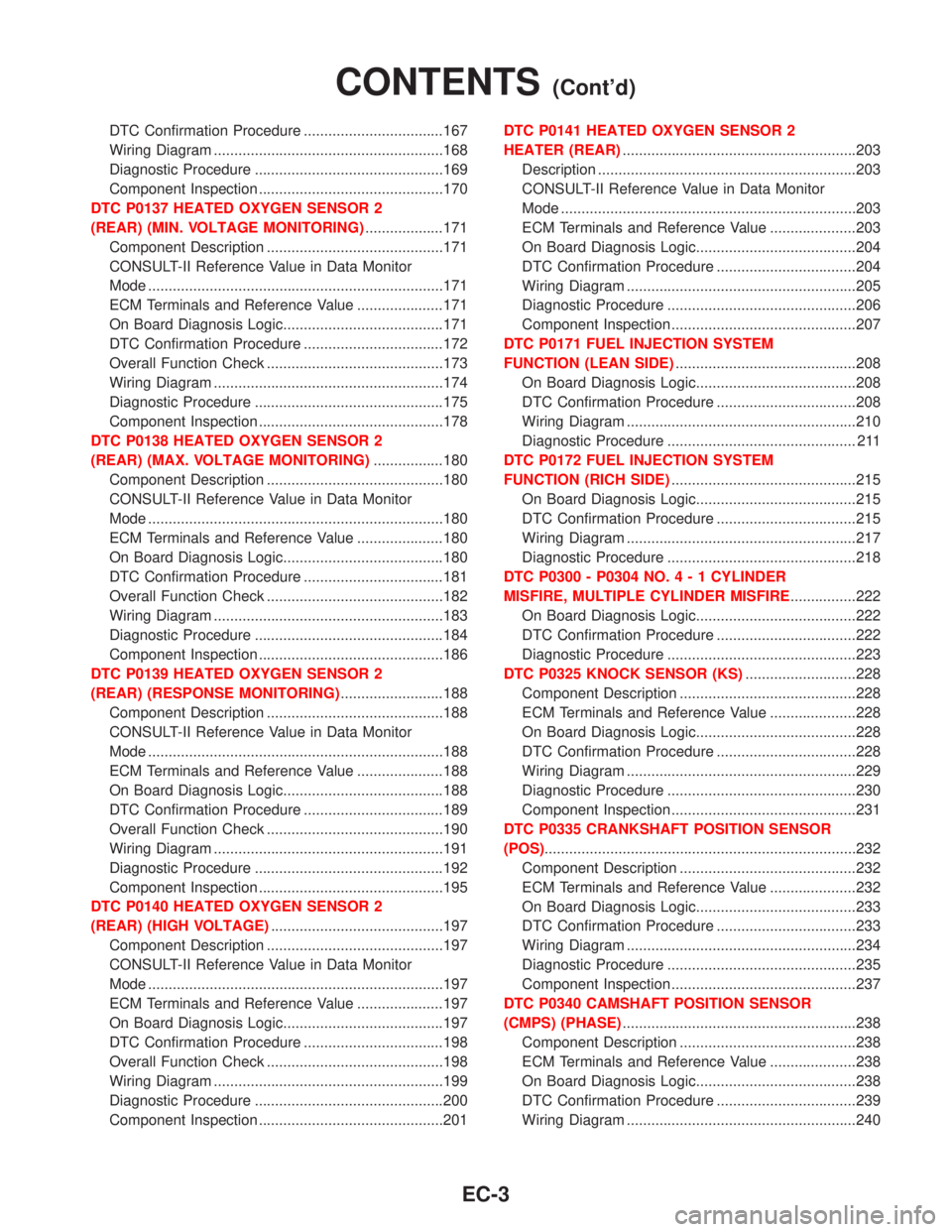

DTC Confirmation Procedure ..................................167

Wiring Diagram ........................................................168

Diagnostic Procedure ..............................................169

Component Inspection .............................................170

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................171

Component Description ...........................................171

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................171

ECM Terminals and Reference Value .....................171

On Board Diagnosis Logic.......................................171

DTC Confirmation Procedure ..................................172

Overall Function Check ...........................................173

Wiring Diagram ........................................................174

Diagnostic Procedure ..............................................175

Component Inspection .............................................178

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................180

Component Description ...........................................180

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................180

ECM Terminals and Reference Value .....................180

On Board Diagnosis Logic.......................................180

DTC Confirmation Procedure ..................................181

Overall Function Check ...........................................182

Wiring Diagram ........................................................183

Diagnostic Procedure ..............................................184

Component Inspection .............................................186

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING).........................188

Component Description ...........................................188

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................188

ECM Terminals and Reference Value .....................188

On Board Diagnosis Logic.......................................188

DTC Confirmation Procedure ..................................189

Overall Function Check ...........................................190

Wiring Diagram ........................................................191

Diagnostic Procedure ..............................................192

Component Inspection .............................................195

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................197

Component Description ...........................................197

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................197

ECM Terminals and Reference Value .....................197

On Board Diagnosis Logic.......................................197

DTC Confirmation Procedure ..................................198

Overall Function Check ...........................................198

Wiring Diagram ........................................................199

Diagnostic Procedure ..............................................200

Component Inspection .............................................201DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................203

Description ...............................................................203

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................203

ECM Terminals and Reference Value .....................203

On Board Diagnosis Logic.......................................204

DTC Confirmation Procedure ..................................204

Wiring Diagram ........................................................205

Diagnostic Procedure ..............................................206

Component Inspection .............................................207

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................208

On Board Diagnosis Logic.......................................208

DTC Confirmation Procedure ..................................208

Wiring Diagram ........................................................210

Diagnostic Procedure .............................................. 211

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................215

On Board Diagnosis Logic.......................................215

DTC Confirmation Procedure ..................................215

Wiring Diagram ........................................................217

Diagnostic Procedure ..............................................218

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE................222

On Board Diagnosis Logic.......................................222

DTC Confirmation Procedure ..................................222

Diagnostic Procedure ..............................................223

DTC P0325 KNOCK SENSOR (KS)...........................228

Component Description ...........................................228

ECM Terminals and Reference Value .....................228

On Board Diagnosis Logic.......................................228

DTC Confirmation Procedure ..................................228

Wiring Diagram ........................................................229

Diagnostic Procedure ..............................................230

Component Inspection .............................................231

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................232

Component Description ...........................................232

ECM Terminals and Reference Value .....................232

On Board Diagnosis Logic.......................................233

DTC Confirmation Procedure ..................................233

Wiring Diagram ........................................................234

Diagnostic Procedure ..............................................235

Component Inspection .............................................237

DTC P0340 CAMSHAFT POSITION SENSOR

(CMPS) (PHASE).........................................................238

Component Description ...........................................238

ECM Terminals and Reference Value .....................238

On Board Diagnosis Logic.......................................238

DTC Confirmation Procedure ..................................239

Wiring Diagram ........................................................240

CONTENTS(Cont'd)

EC-3

Page 446 of 2267

Diagnostic Procedure ..............................................241

Component Inspection .............................................243

DTC P0400 EGR FUNCTION (CLOSE) (IF SO

EQUIPPED)..................................................................244

Description ...............................................................244

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................245

ECM Terminals and Reference Value .....................245

On Board Diagnosis Logic.......................................245

DTC Confirmation Procedure ..................................246

Wiring Diagram ........................................................248

Diagnostic Procedure ..............................................249

Component Inspection .............................................251

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT) (IF SO EQUIPPED)....................................252

Description ...............................................................252

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................253

ECM Terminals and Reference Value .....................253

On Board Diagnosis Logic.......................................253

DTC Confirmation Procedure ..................................253

Wiring Diagram ........................................................255

Diagnostic Procedure ..............................................256

Component Inspection .............................................257

DTC P0420 THREE WAY CATALYST FUNCTION...258

On Board Diagnosis Logic.......................................258

DTC Confirmation Procedure ..................................258

Overall Function Check ...........................................259

Diagnostic Procedure ..............................................259

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................262

Description ...............................................................262

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................262

ECM Terminals and Reference Value .....................263

On Board Diagnosis Logic.......................................263

DTC Confirmation Procedure ..................................263

Wiring Diagram ........................................................264

Diagnostic Procedure ..............................................265

Component Inspection .............................................266

DTC P0500 VEHICLE SPEED SENSOR (VSS).........267

Component Description ...........................................267

ECM Terminals and Reference Value .....................267

On Board Diagnosis Logic.......................................267

DTC Confirmation Procedure ..................................267

Wiring Diagram ........................................................269

Diagnostic Procedure ..............................................271

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE................274

Description ...............................................................274

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................275ECM Terminals and Reference Value .....................275

On Board Diagnosis Logic.......................................275

DTC Confirmation Procedure ..................................275

Wiring Diagram ........................................................276

Diagnostic Procedure ..............................................277

Component Inspection .............................................281

DTC P0605 ECM.........................................................282

Component Description ...........................................282

On Board Diagnosis Logic.......................................282

DTC Confirmation Procedure ..................................282

Diagnostic Procedure ..............................................282

D T C P 1111 I N TA K E VA LV ETIMING CONTROL

SOLENOID VALVE......................................................284

Component Description ...........................................284

Operation .................................................................284

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................284

ECM Terminals and Reference Value .....................284

On Board Diagnosis Logic.......................................284

DTC Confirmation Procedure ..................................285

Wiring Diagram ........................................................286

Diagnostic Procedure ..............................................287

Component Inspection .............................................288

DTC P1217 OVERHEAT (COOLING SYSTEM).........289

System Description ..................................................289

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................289

ECM Terminals and Reference Value .....................290

On Board Diagnosis Logic.......................................290

Overall Function Check ...........................................291

Wiring Diagram ........................................................292

Diagnostic Procedure ..............................................294

Main 12 Causes of Overheating..............................298

Component Inspection .............................................299

DTC P1401 EGR TEMPERATURE SENSOR (IF

SO EQUIPPED)...........................................................300

Component Description ...........................................300

On Board Diagnosis Logic.......................................300

DTC Confirmation Procedure ..................................300

Wiring Diagram ........................................................302

Diagnostic Procedure ..............................................303

Component Inspection .............................................304

DTC P1402 EGR FUNCTION (OPEN) (IF SO

EQUIPPED)..................................................................305

Description ...............................................................305

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................306

ECM Terminals and Reference Value .....................306

On Board Diagnosis Logic.......................................306

DTC Confirmation Procedure ..................................307

Wiring Diagram ........................................................309

Diagnostic Procedure ..............................................310

CONTENTS(Cont'd)

EC-4

Page 447 of 2267

Component Inspection ............................................. 311

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................313

Component Description ...........................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................313

ECM Terminals and Reference Value .....................313

On Board Diagnosis Logic.......................................313

DTC Confirmation Procedure ..................................313

Overall Function Check ...........................................314

Wiring Diagram ........................................................315

Diagnostic Procedure For M/T Models....................316

INJECTOR...................................................................318

Component Description ...........................................318

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................318

ECM Terminals and Reference Value .....................318

Wiring Diagram ........................................................319

Diagnostic Procedure ..............................................320

Component Inspection .............................................322

IGNITION SIGNAL.......................................................323

Component Description ...........................................323

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................323

ECM Terminals and Reference Value .....................323

Wiring Diagram ........................................................324

Diagnostic Procedure ..............................................326

Component Inspection .............................................331

START SIGNAL...........................................................332

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................332

ECM Terminals and Reference Value .....................332

Wiring Diagram ........................................................333

Diagnostic Procedure ..............................................334

FUEL PUMP.................................................................336

System Description ..................................................336

Component Description ...........................................336

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................336

ECM Terminals and Reference Value .....................337

Wiring Diagram ........................................................338

Diagnostic Procedure ..............................................339Component Inspection .............................................341

POWER STEERING OIL PRESSURE SWITCH.........342

Component Description ...........................................342

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................342

ECM Terminals and Reference Value .....................342

Wiring Diagram ........................................................343

Diagnostic Procedure ..............................................344

Component Inspection .............................................346

REFRIGERANT PRESSURE SENSOR......................347

Description ...............................................................347

ECM Terminals and Reference Value .....................347

Wiring Diagram ........................................................348

Diagnostic Procedure ..............................................349

ELECTRICAL LOAD SIGNAL.....................................351

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................351

ECM Terminals and Reference Value .....................351

Wiring Diagram ........................................................352

MI & DATA LINK CONNECTORS...............................354

Wiring Diagram ........................................................354

SERVICE DATA AND SPECIFICATIONS (SDS)........355

Fuel Pressure Regulator..........................................355

Idle Speed and Ignition Timing ................................355

Mass Air Flow Sensor..............................................355

Intake Air Temperature Sensor ................................355

Engine Coolant Temperature Sensor ......................355

Throttle Position Sensor ..........................................355

Heated Oxygen Sensor 1 Heater (Front) ................355

Heated Oxygen Sensor 2 Heater (Rear).................355

Crankshaft Position Sensor (POS) ..........................356

Camshaft Position Sensor (PHASE) .......................356

EGR Volume Control Valve (If so equipped)...........356

EGR Temperature Sensor (If so equipped).............356

EVAP Canister Purge Volume Control Valve ..........356

IACV-AAC Valve ......................................................356

Injector .....................................................................356

Ignition Coil with Power Transistor ..........................357

Fuel Pump ...............................................................357

CONTENTS(Cont'd)

EC-5

Page 451 of 2267

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NCEC0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT PRE-TENSIONERº connector) can be

identified with yellow harness connector (and with yellow harness protector or yellow insulation

tape before the harness connectors).

Precautions for On Board Diagnostic (OBD)

System of Engine

NCEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

IBe sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

IBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

ICertain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

IBe sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

IBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the EGR system or fuel injection system,

etc.

IBe sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PRECAUTIONSQG16I18DE

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-9

Page 455 of 2267

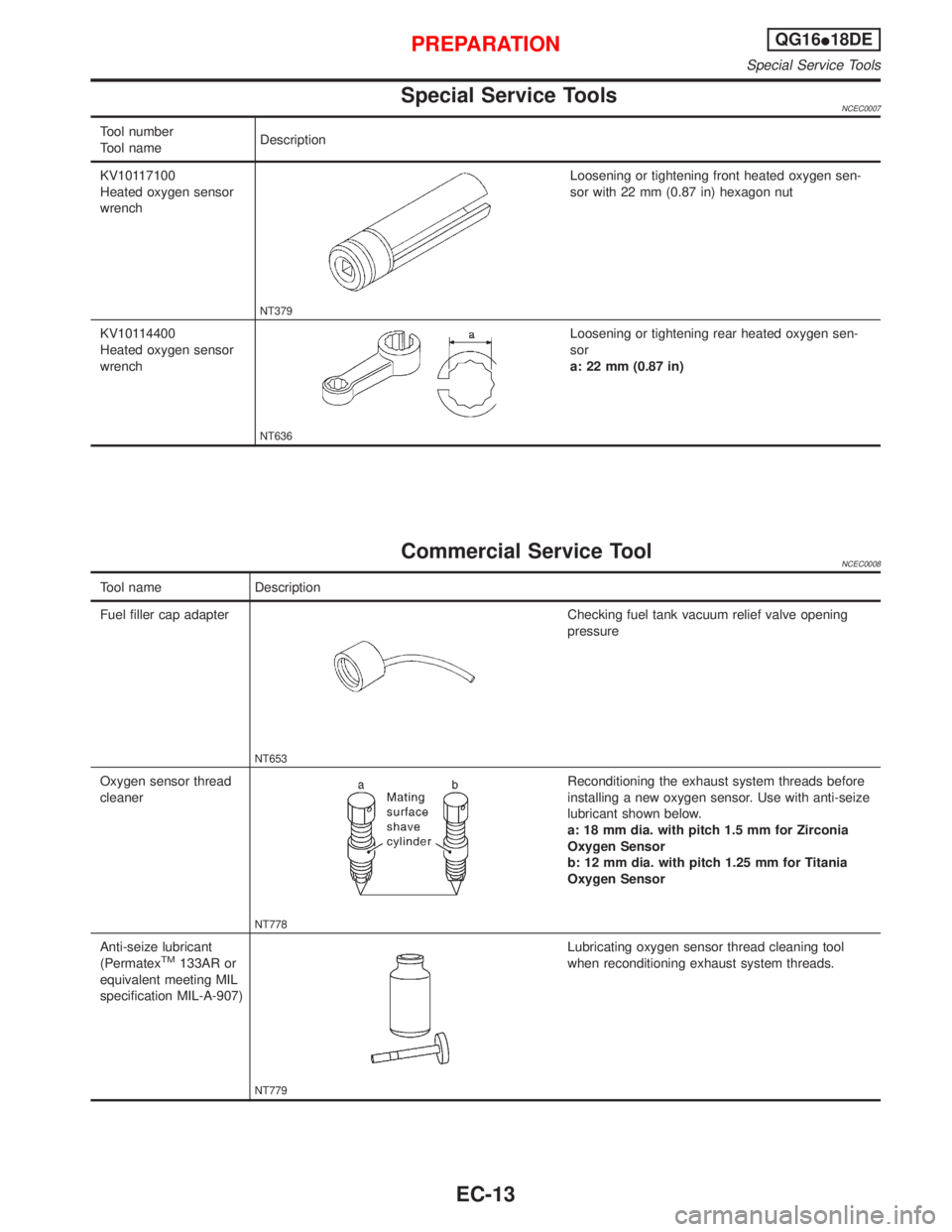

Special Service ToolsNCEC0007

Tool number

Tool nameDescription

KV10117100

Heated oxygen sensor

wrench

NT379

Loosening or tightening front heated oxygen sen-

sor with 22 mm (0.87 in) hexagon nut

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening rear heated oxygen sen-

sor

a: 22 mm (0.87 in)

Commercial Service ToolNCEC0008

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Oxygen sensor thread

cleaner

NT778

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-seize

lubricant shown below.

a: 18 mm dia. with pitch 1.5 mm for Zirconia

Oxygen Sensor

b: 12 mm dia. with pitch 1.25 mm for Titania

Oxygen Sensor

Anti-seize lubricant

(Permatex

TM133AR or

equivalent meeting MIL

specification MIL-A-907)

NT779

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

PREPARATIONQG16I18DE

Special Service Tools

EC-13

Page 462 of 2267

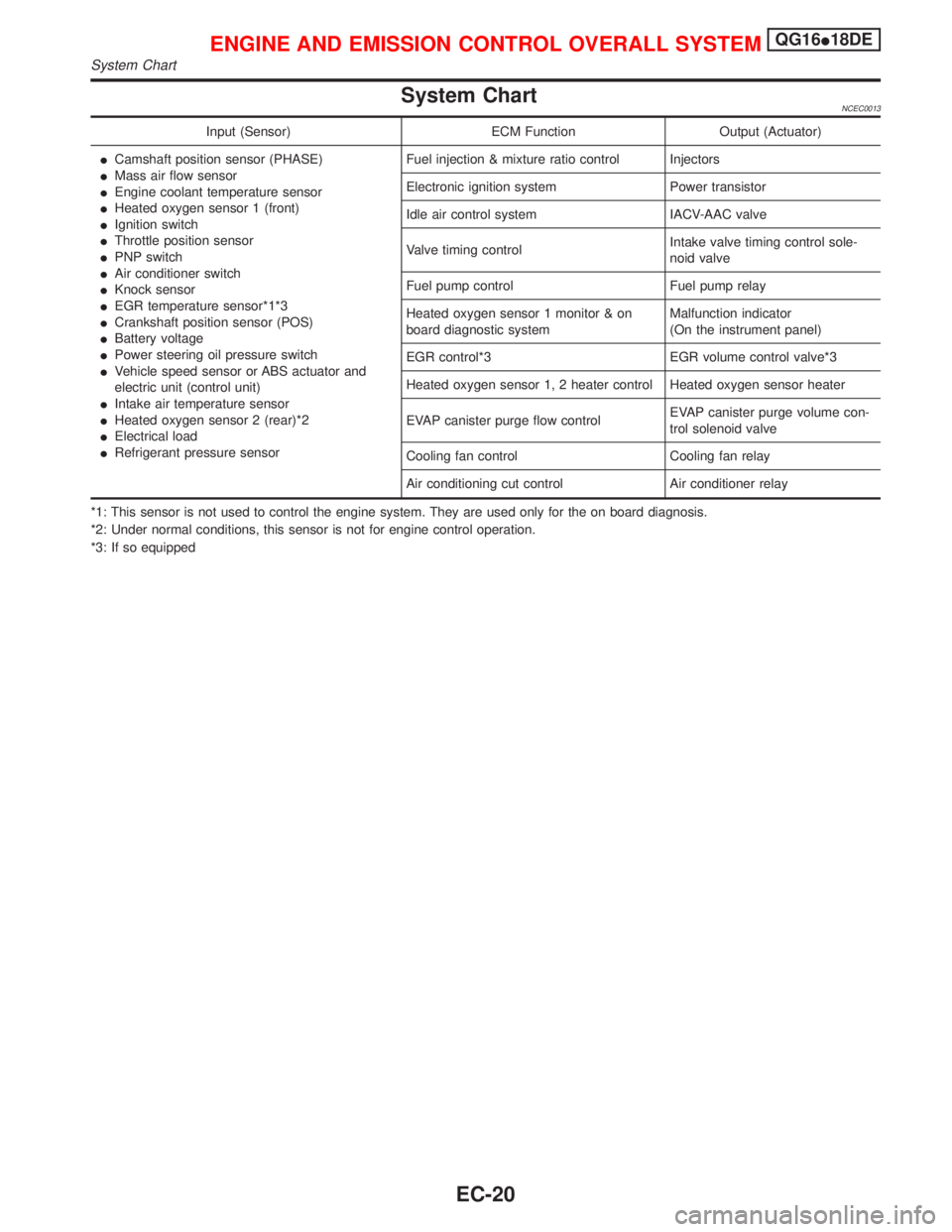

System ChartNCEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor (PHASE)

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IPNP switch

IAir conditioner switch

IKnock sensor

IEGR temperature sensor*1*3

ICrankshaft position sensor (POS)

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor or ABS actuator and

electric unit (control unit)

IIntake air temperature sensor

IHeated oxygen sensor 2 (rear)*2

IElectrical load

IRefrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

Heated oxygen sensor 1 monitor & on

board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control*3 EGR volume control valve*3

Heated oxygen sensor 1, 2 heater control Heated oxygen sensor heater

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

*1: This sensor is not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: If so equipped

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG16I18DE

System Chart

EC-20

Page 463 of 2267

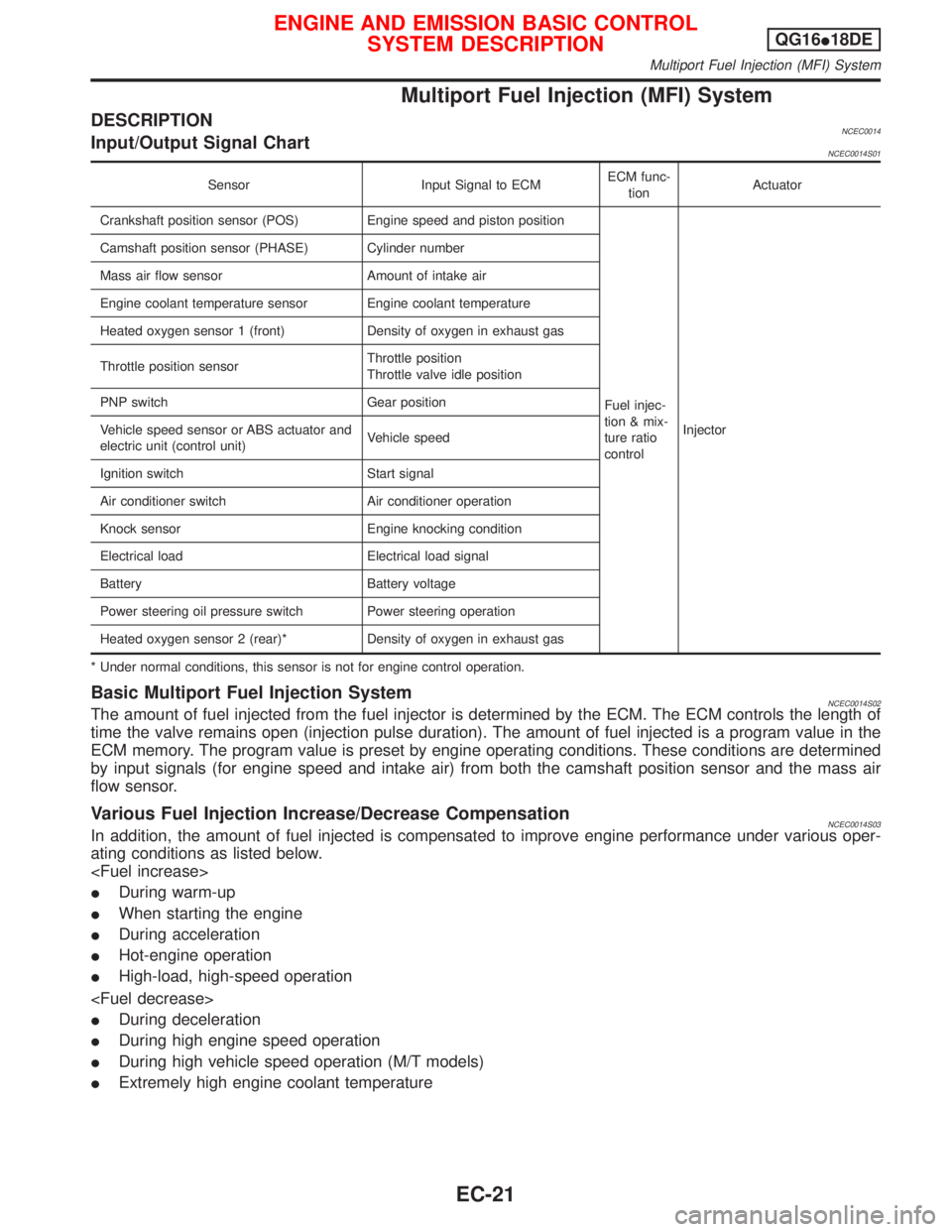

Multiport Fuel Injection (MFI) System

DESCRIPTIONNCEC0014Input/Output Signal ChartNCEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed and piston position

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNCEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNCEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

IDuring warm-up

IWhen starting the engine

IDuring acceleration

IHot-engine operation

IHigh-load, high-speed operation

IDuring deceleration

IDuring high engine speed operation

IDuring high vehicle speed operation (M/T models)

IExtremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONQG16I18DE

Multiport Fuel Injection (MFI) System

EC-21