NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1881 of 2267

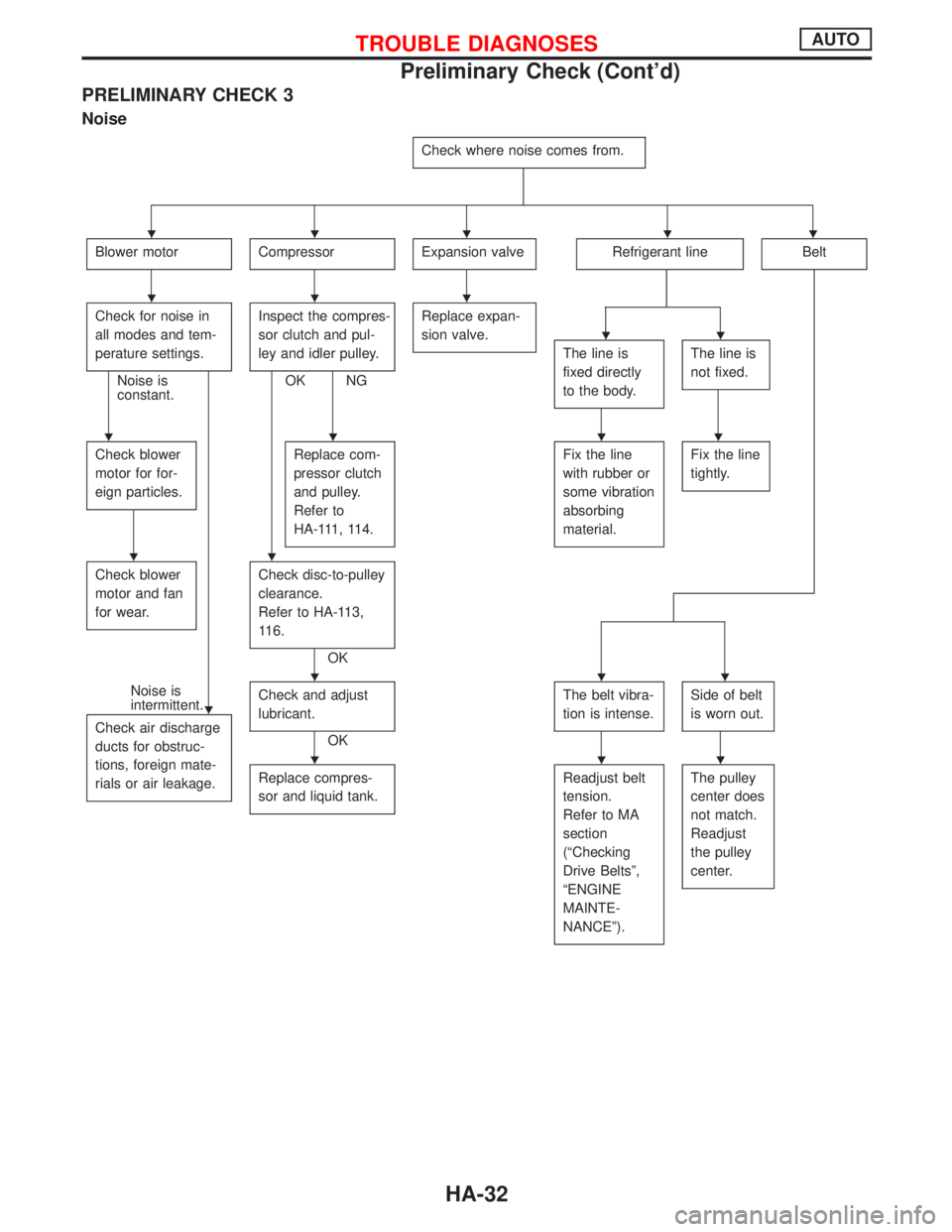

PRELIMINARY CHECK 3

Noise

Check where noise comes from.

Blower motorCompressorExpansion valveRefrigerant lineBelt

Check for noise in

all modes and tem-

perature settings.

Noise is

constant.Inspect the compres-

sor clutch and pul-

ley and idler pulley.OK NGReplace expan-

sion valve.

The line is

fixed directly

to the body.The line is

not fixed.

Check blower

motor for for-

eign particles.Replace com-

pressor clutch

and pulley.

Refer to

HA-111, 114.Fix the line

with rubber or

some vibration

absorbing

material.Fix the line

tightly.

Check blower

motor and fan

for wear.Check disc-to-pulley

clearance.

Refer to HA-113,

116.

OK

Noise is

intermittent.

Check air discharge

ducts for obstruc-

tions, foreign mate-

rials or air leakage.Check and adjust

lubricant.

OKThe belt vibra-

tion is intense.

Side of belt

is worn out.

Replace compres-

sor and liquid tank.Readjust belt

tension.

Refer to MA

section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº).The pulley

center does

not match.

Readjust

the pulley

center.

HHHHH

HHH

HH

HHHH

HH

H

HHH

HHH

TROUBLE DIAGNOSESAUTO

Preliminary Check (Cont'd)

HA-32

Page 1882 of 2267

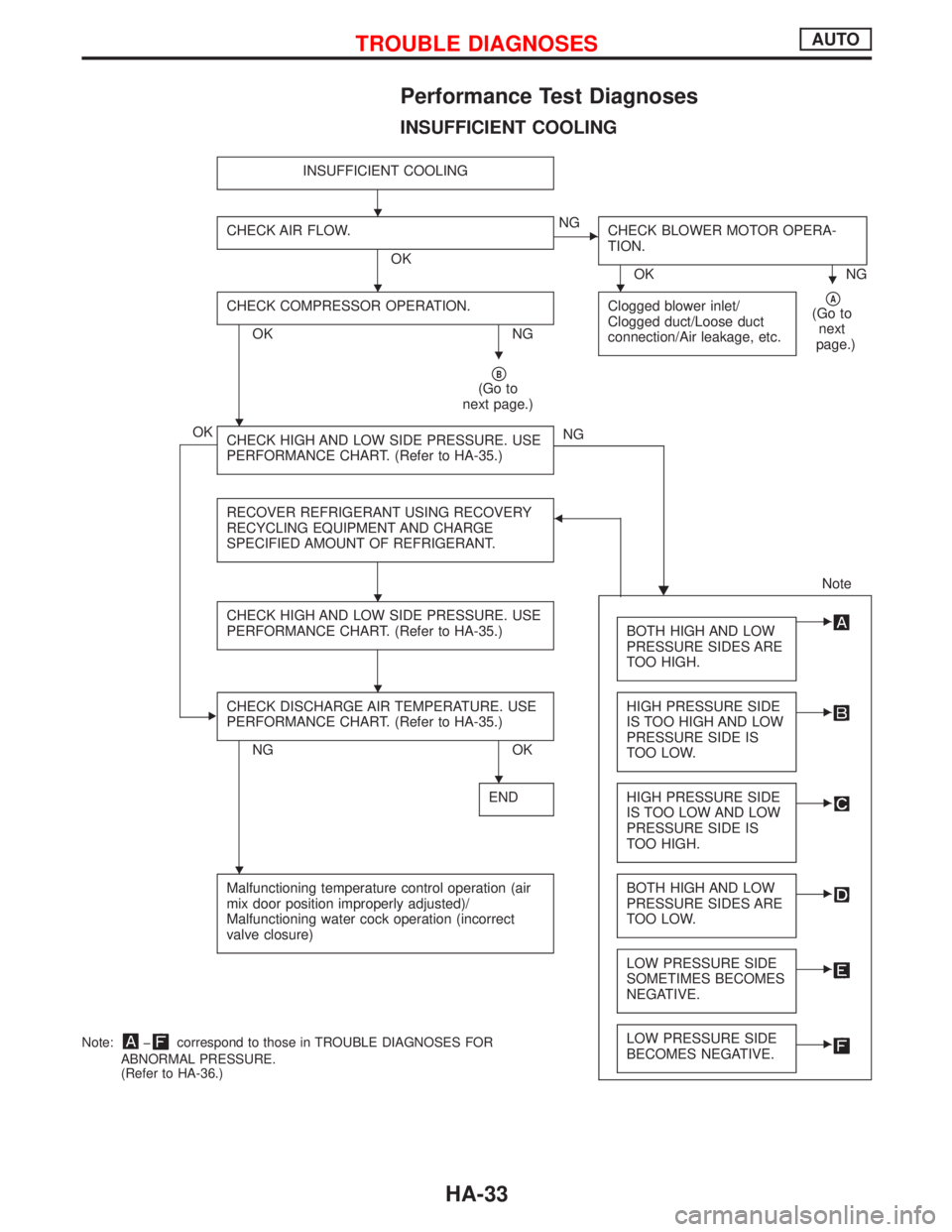

Performance Test Diagnoses

INSUFFICIENT COOLING

INSUFFICIENT COOLING

CHECK AIR FLOW.

OK

ENG

CHECK BLOWER MOTOR OPERA-

TION.

OK NG

CHECK COMPRESSOR OPERATION.

OK NGClogged blower inlet/

Clogged duct/Loose duct

connection/Air leakage, etc.

pA(Go to

next

page.)

pB(Go to

next page.)

OK

CHECK HIGH AND LOW SIDE PRESSURE. USE

PERFORMANCE CHART. (Refer to HA-35.)NG

H RECOVER REFRIGERANT USING RECOVERY

RECYCLING EQUIPMENT AND CHARGE

SPECIFIED AMOUNT OF REFRIGERANT.

F

Note

CHECK HIGH AND LOW SIDE PRESSURE. USE

PERFORMANCE CHART. (Refer to HA-35.)

BOTH HIGH AND LOW

PRESSURE SIDES ARE

TOO HIGH.E

ECHECK DISCHARGE AIR TEMPERATURE. USE

PERFORMANCE CHART. (Refer to HA-35.)

NG OKHIGH PRESSURE SIDE

IS TOO HIGH AND LOW

PRESSURE SIDE IS

TOO LOW.

E

ENDHIGH PRESSURE SIDE

IS TOO LOW AND LOW

PRESSURE SIDE IS

TOO HIGH.E

Malfunctioning temperature control operation (air

mix door position improperly adjusted)/

Malfunctioning water cock operation (incorrect

valve closure)BOTH HIGH AND LOW

PRESSURE SIDES ARE

TOO LOW.E

LOW PRESSURE SIDE

SOMETIMES BECOMES

NEGATIVE.E

LOW PRESSURE SIDE

BECOMES NEGATIVE.ENote:þcorrespond to those in TROUBLE DIAGNOSES FOR

ABNORMAL PRESSURE.

(Refer to HA-36.)

H

HHH

H

H

H

H

H

H

TROUBLE DIAGNOSESAUTO

HA-33

Page 1883 of 2267

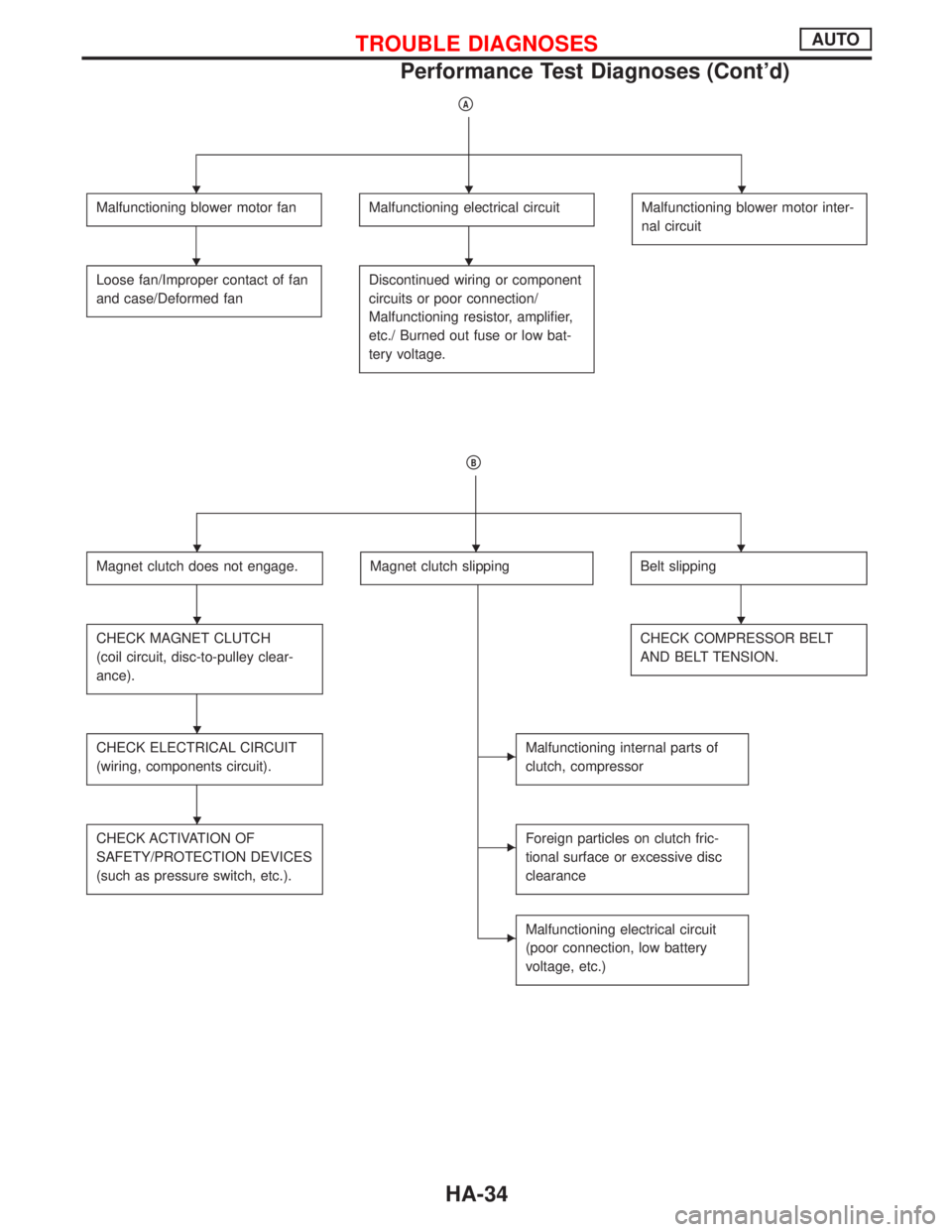

pA

Malfunctioning blower motor fanMalfunctioning electrical circuitMalfunctioning blower motor inter-

nal circuit

Loose fan/Improper contact of fan

and case/Deformed fanDiscontinued wiring or component

circuits or poor connection/

Malfunctioning resistor, amplifier,

etc./ Burned out fuse or low bat-

tery voltage.

pB

Magnet clutch does not engage.Magnet clutch slippingBelt slipping

CHECK MAGNET CLUTCH

(coil circuit, disc-to-pulley clear-

ance).CHECK COMPRESSOR BELT

AND BELT TENSION.

CHECK ELECTRICAL CIRCUIT

(wiring, components circuit).EMalfunctioning internal parts of

clutch, compressor

CHECK ACTIVATION OF

SAFETY/PROTECTION DEVICES

(such as pressure switch, etc.).EForeign particles on clutch fric-

tional surface or excessive disc

clearance

EMalfunctioning electrical circuit

(poor connection, low battery

voltage, etc.)

HHH

HH

HHH

HH

H

H

TROUBLE DIAGNOSESAUTO

Performance Test Diagnoses (Cont'd)

HA-34

Page 1884 of 2267

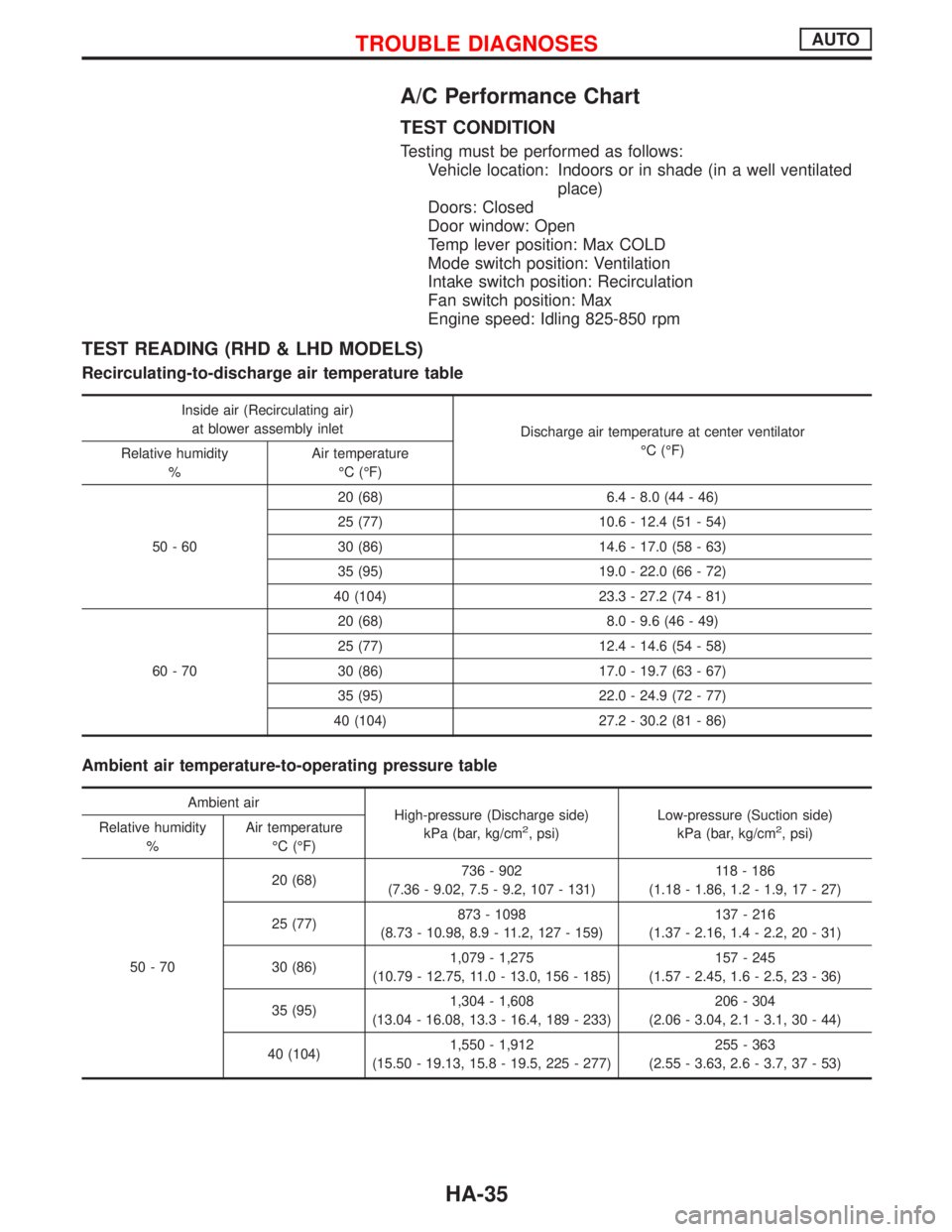

A/C Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location: Indoors or in shade (in a well ventilated

place)

Doors: Closed

Door window: Open

Temp lever position: Max COLD

Mode switch position: Ventilation

Intake switch position: Recirculation

Fan switch position: Max

Engine speed: Idling 825-850 rpm

TEST READING (RHD & LHD MODELS)

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet

Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

%Air temperature

ÉC (ÉF)

50-6020 (68) 6.4 - 8.0 (44 - 46)

25 (77) 10.6 - 12.4 (51 - 54)

30 (86) 14.6 - 17.0 (58 - 63)

35 (95) 19.0 - 22.0 (66 - 72)

40 (104) 23.3 - 27.2 (74 - 81)

60-7020 (68) 8.0 - 9.6 (46 - 49)

25 (77) 12.4 - 14.6 (54 - 58)

30 (86) 17.0 - 19.7 (63 - 67)

35 (95) 22.0 - 24.9 (72 - 77)

40 (104) 27.2 - 30.2 (81 - 86)

Ambient air temperature-to-operating pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

ÉC (ÉF)

50-7020 (68)736 - 902

(7.36 - 9.02, 7.5 - 9.2, 107 - 131)118 - 186

(1.18 - 1.86, 1.2 - 1.9, 17 - 27)

25 (77)873 - 1098

(8.73 - 10.98, 8.9 - 11.2, 127 - 159)137 - 216

(1.37 - 2.16, 1.4 - 2.2, 20 - 31)

30 (86)1,079 - 1,275

(10.79 - 12.75, 11.0 - 13.0, 156 - 185)157 - 245

(1.57 - 2.45, 1.6 - 2.5, 23 - 36)

35 (95)1,304 - 1,608

(13.04 - 16.08, 13.3 - 16.4, 189 - 233)206 - 304

(2.06 - 3.04, 2.1 - 3.1, 30 - 44)

40 (104)1,550 - 1,912

(15.50 - 19.13, 15.8 - 19.5, 225 - 277)255 - 363

(2.55 - 3.63, 2.6 - 3.7, 37 - 53)

TROUBLE DIAGNOSESAUTO

HA-35

Page 1885 of 2267

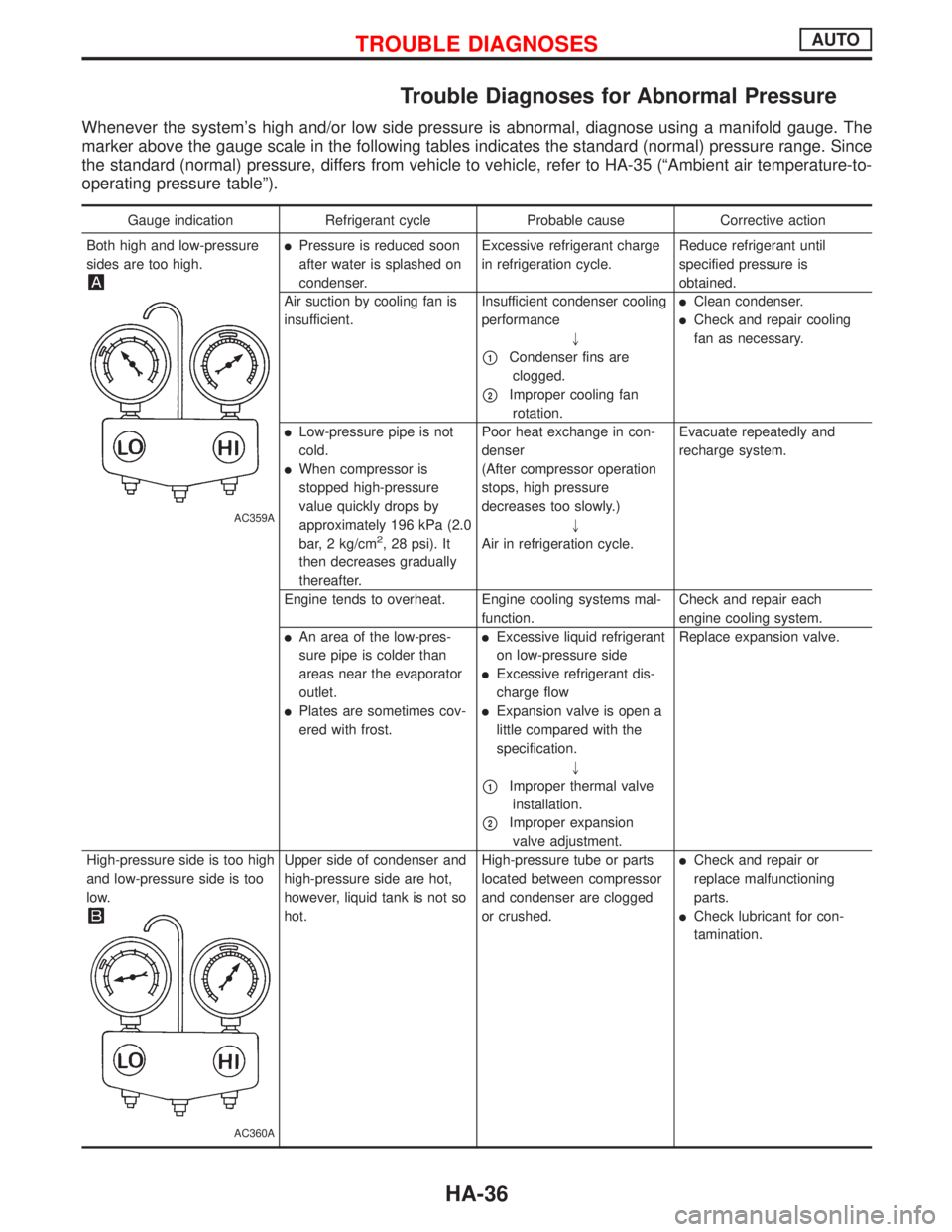

Trouble Diagnoses for Abnormal Pressure

Whenever the system's high and/or low side pressure is abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (normal) pressure range. Since

the standard (normal) pressure, differs from vehicle to vehicle, refer to HA-35 (ªAmbient air temperature-to-

operating pressure tableº).

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure

sides are too high.

AC359A

lPressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycle.Reduce refrigerant until

specified pressure is

obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

"

p1Condenser fins are

clogged.

p2Improper cooling fan

rotation.

lClean condenser.

lCheck and repair cooling

fan as necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2.0

bar, 2 kg/cm

2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal-

function.Check and repair each

engine cooling system.

lAn area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a

little compared with the

specification.

"

p1Improper thermal valve

installation.

p2Improper expansion

valve adjustment.Replace expansion valve.

High-pressure side is too high

and low-pressure side is too

low.

AC360A

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged

or crushed.lCheck and repair or

replace malfunctioning

parts.

lCheck lubricant for con-

tamination.

TROUBLE DIAGNOSESAUTO

HA-36

Page 1886 of 2267

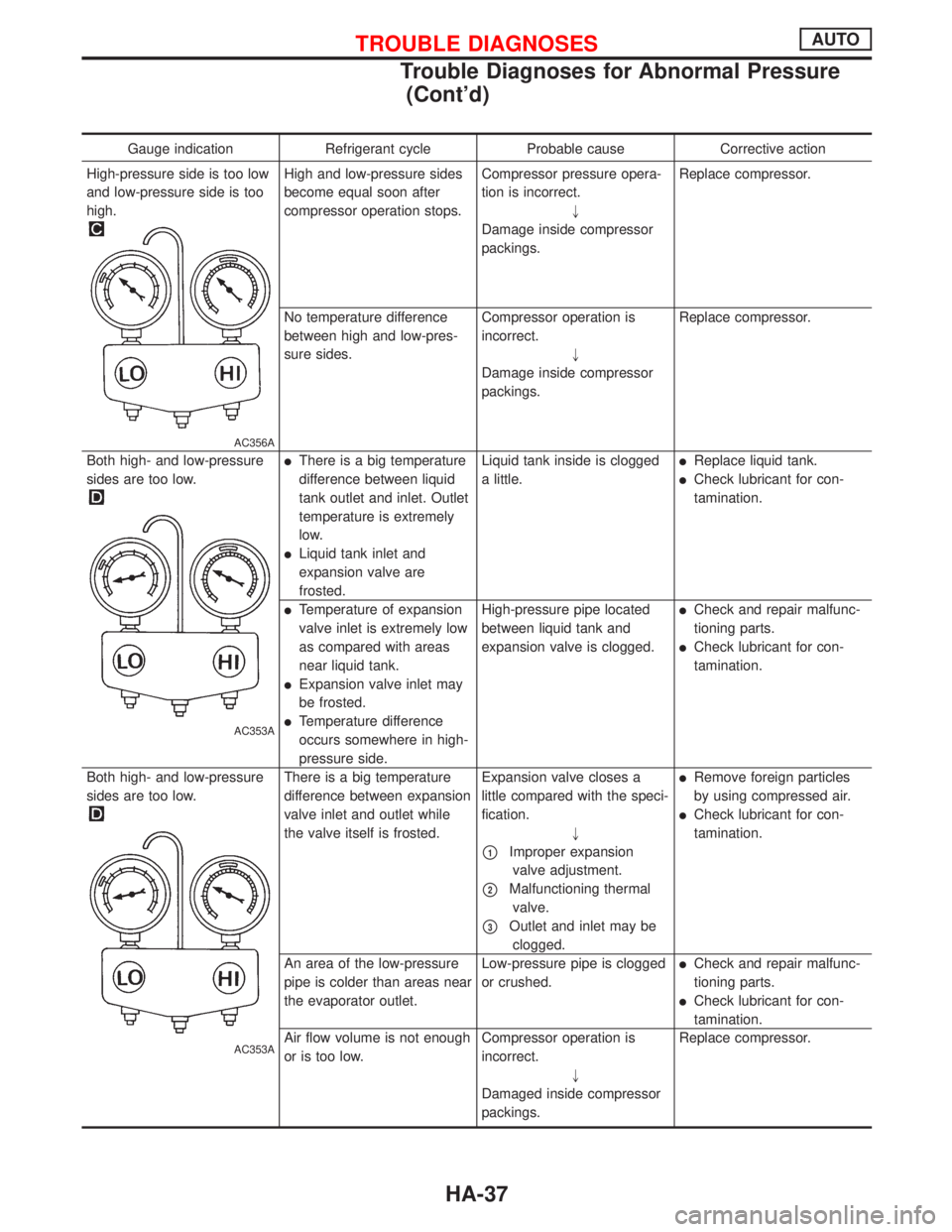

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low

and low-pressure side is too

high.

AC356A

High and low-pressure sides

become equal soon after

compressor operation stops.Compressor pressure opera-

tion is incorrect.

"

Damage inside compressor

packings.Replace compressor.

No temperature difference

between high and low-pres-

sure sides.Compressor operation is

incorrect.

"

Damage inside compressor

packings.Replace compressor.

Both high- and low-pressure

sides are too low.

AC353A

lThere is a big temperature

difference between liquid

tank outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and

expansion valve are

frosted.Liquid tank inside is clogged

a little.

lReplace liquid tank.

lCheck lubricant for con-

tamination.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure side.High-pressure pipe located

between liquid tank and

expansion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for con-

tamination.

Both high- and low-pressure

sides are too low.

AC353A

There is a big temperature

difference between expansion

valve inlet and outlet while

the valve itself is frosted.Expansion valve closes a

little compared with the speci-

fication.

"

p1Improper expansion

valve adjustment.

p2Malfunctioning thermal

valve.

p3Outlet and inlet may be

clogged.

lRemove foreign particles

by using compressed air.

lCheck lubricant for con-

tamination.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for con-

tamination.

Air flow volume is not enough

or is too low.Compressor operation is

incorrect.

"

Damaged inside compressor

packings.Replace compressor.

TROUBLE DIAGNOSESAUTO

Trouble Diagnoses for Abnormal Pressure

(Cont'd)

HA-37

Page 1887 of 2267

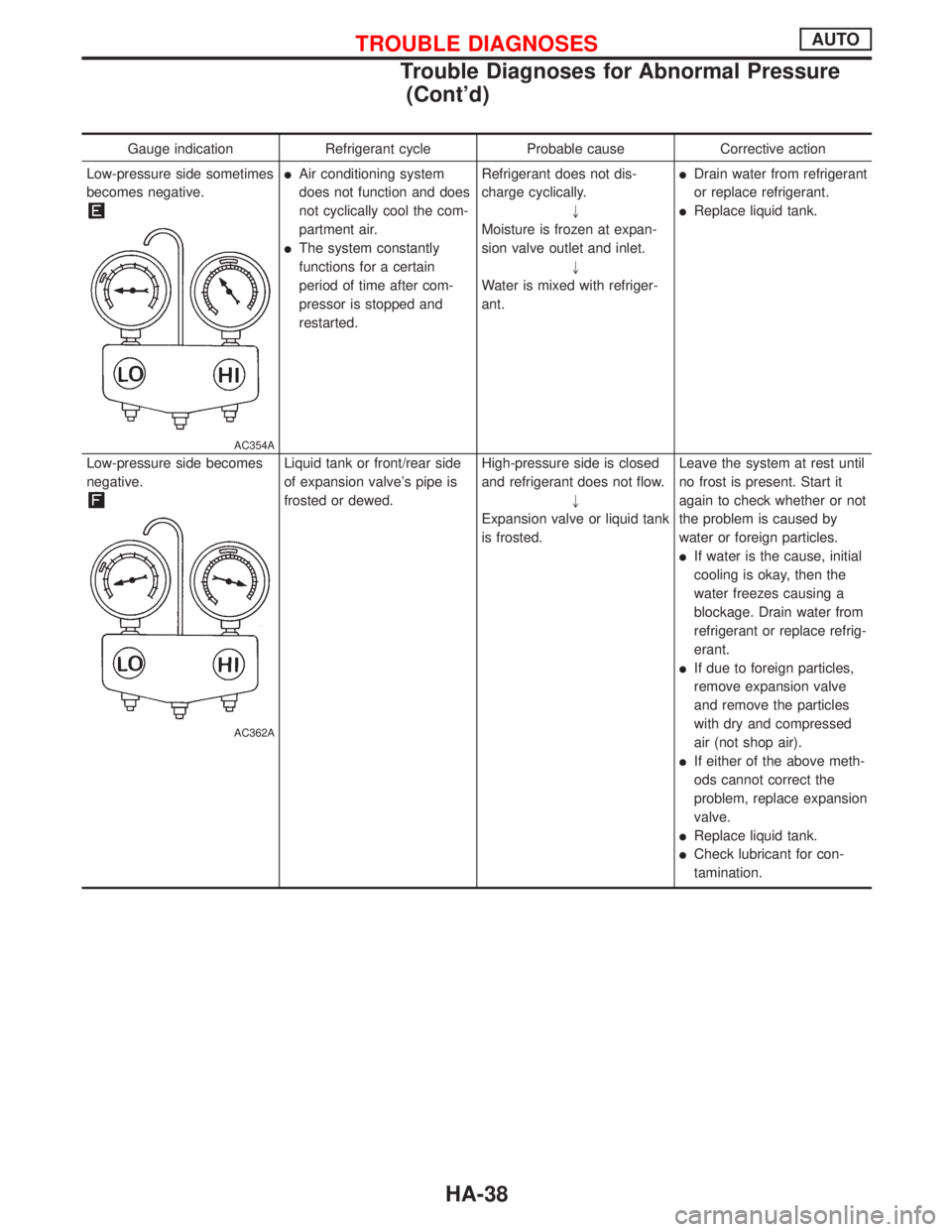

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

AC354A

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly

functions for a certain

period of time after com-

pressor is stopped and

restarted.Refrigerant does not dis-

charge cyclically.

"

Moisture is frozen at expan-

sion valve outlet and inlet.

"

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace liquid tank.

Low-pressure side becomes

negative.

AC362A

Liquid tank or front/rear side

of expansion valve's pipe is

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

"

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the problem is caused by

water or foreign particles.

lIf water is the cause, initial

cooling is okay, then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed

air (not shop air).

lIf either of the above meth-

ods cannot correct the

problem, replace expansion

valve.

lReplace liquid tank.

lCheck lubricant for con-

tamination.

TROUBLE DIAGNOSESAUTO

Trouble Diagnoses for Abnormal Pressure

(Cont'd)

HA-38

Page 1888 of 2267

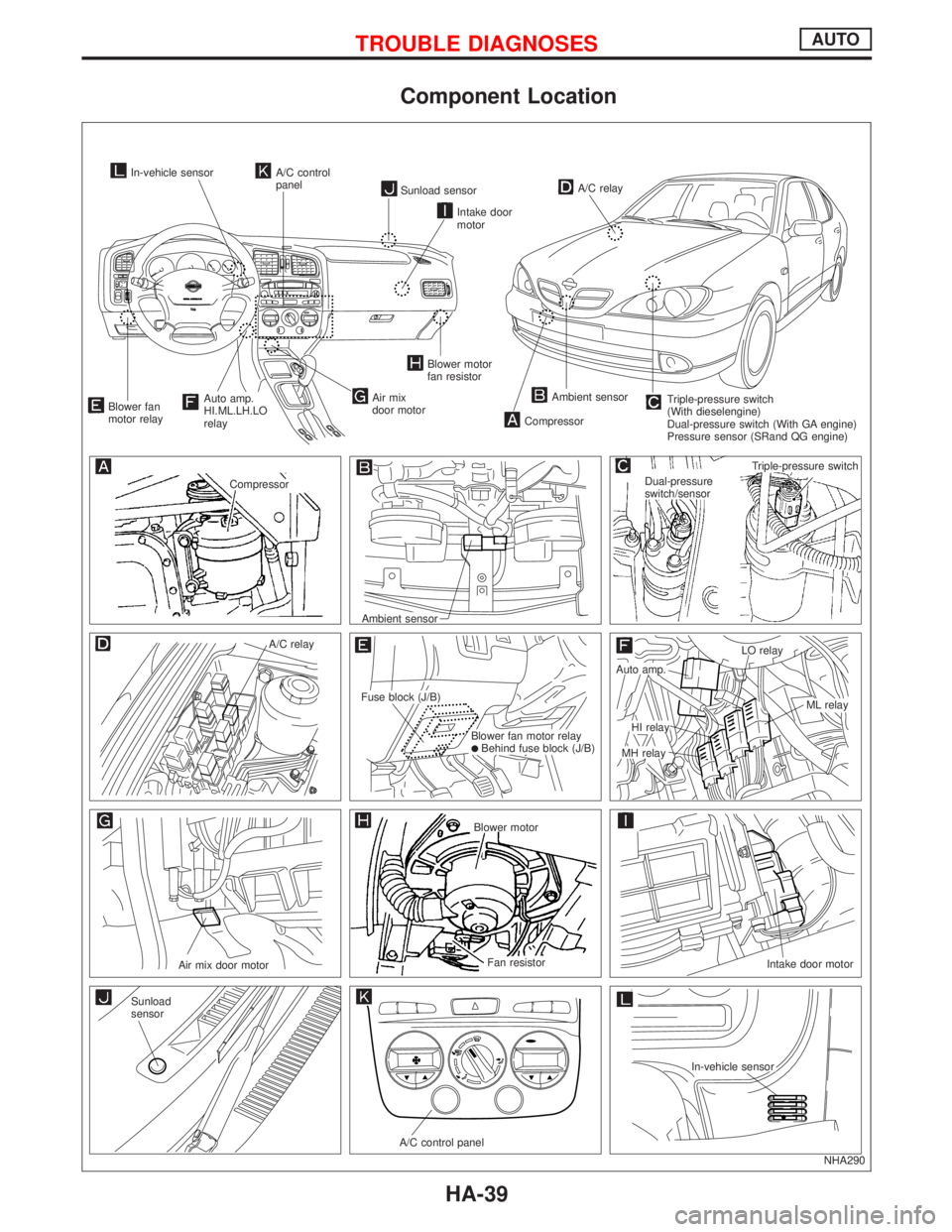

Component Location

NHA290

In-vehicle sensorA/C control

panel

Sunload sensorA/C relay

.Triple-pressure switch

(With dieselengine)

Dual-pressure switch (With GA engine)

Pressure sensor (SRand QG engine)Ambient sensor

Compressor

Blower motor

fan resistor

.Auto amp.

HI.ML.LH.LO

relayBlower fan

motor relay

Compressor

.Ambient sensor

.

A/C relay

.Fuse block (J/B)

.Blower fan motor relaylBehind fuse block (J/B)

.

.Auto amp.

.MH relayLO relay

.ML relay.HI relay

Air mix door motor

Blower motor

Fan resistor.

Intake door motor

Sunload

sensor.

A/C control panel

.

.In-vehicle sensor

.Dual-pressure

switch/sensor

.Triple-pressure switch

Intake door

motor

Air mix

door motor

TROUBLE DIAGNOSESAUTO

HA-39

Page 1889 of 2267

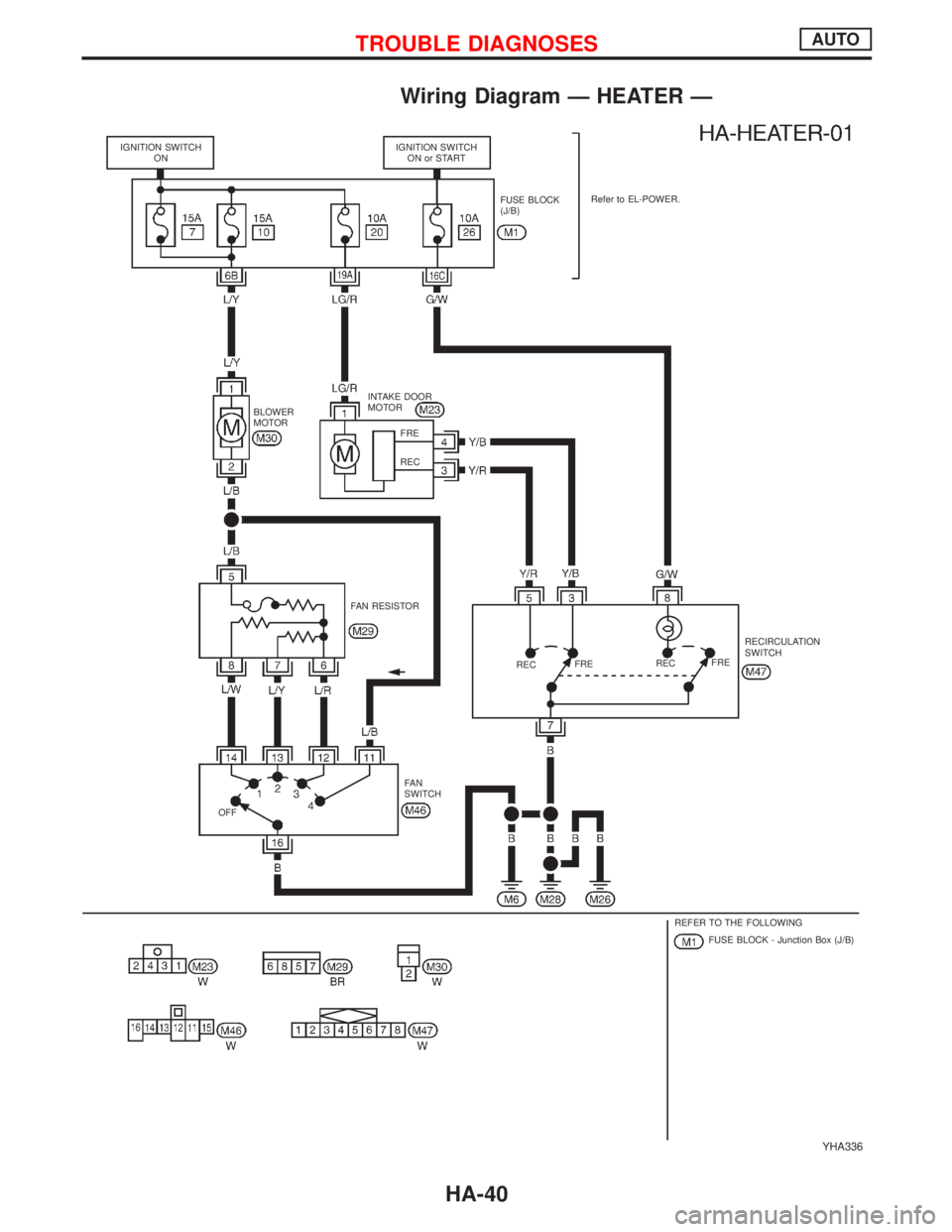

Wiring Diagram Ð HEATER Ð

YHA336

IGNITION SWITCH

ONIGNITION SWITCH

ON or START

FUSE BLOCK

(J/B)Refer to EL-POWER.

INTAKE DOOR

MOTOR

BLOWER

MOTOR

FAN RESISTOR

RECFRERECFRERECIRCULATION

SWITCH

FA N

SWITCH

OFF

REFER TO THE FOLLOWING

FUSE BLOCK - Junction Box (J/B) FRE

REC

TROUBLE DIAGNOSESAUTO

HA-40

Page 1890 of 2267

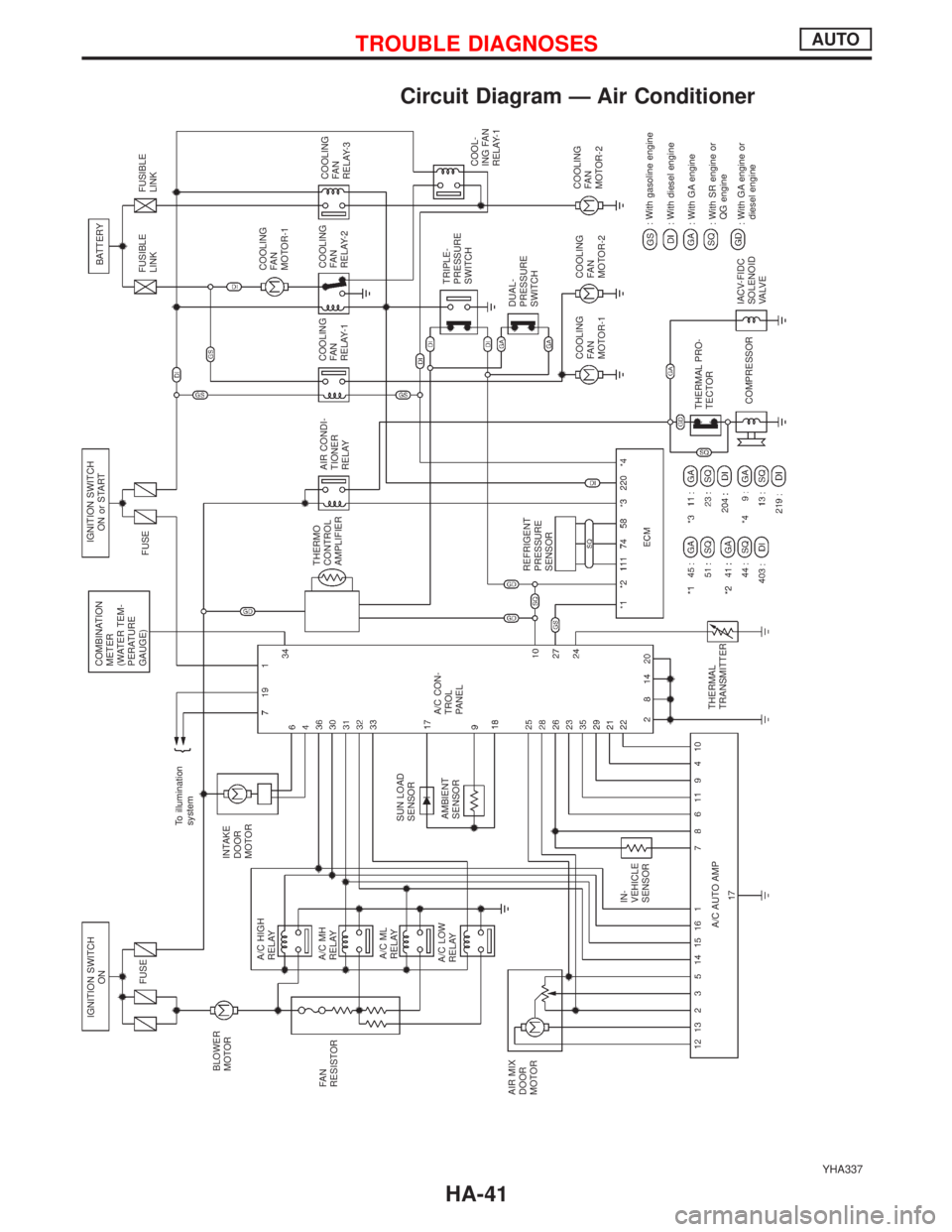

Circuit Diagram Ð Air Conditioner

YHA337

IGNITION SWITCH

ON

FUSE

BLOWER

MOTORINTAKE

DOOR

MOTORTo illumination

systemCOMBINATION

METER

(WATER TEM-

PERATURE

GAUGE)IGNITION SWITCH

ON or START

FUSEFUSIBLE

LINKBATTERY

FUSIBLE

LINK

COOLING

FA N

MOTOR-1

THERMO

CONTROL

AMPLIFIERAIR CONDI-

TIONER

RELAYCOOLING

FA N

RELAY-1COOLING

FA N

RELAY-2COOLING

FA N

RELAY-3

TRIPLE-

PRESSURE

SWITCH

COOL-

ING FAN

RELAY-1

DUAL-

PRESSURE

SWITCH

COOLING

FA N

MOTOR-1COOLING

FA N

MOTOR-2COOLING

FA N

MOTOR-2

: With gasoline engine

: With diesel engine

: With GA engine

: With SR engine or

QG engine

: With GA engine or

diesel engine IACV-FIDC

SOLENOID

VA LV E THERMAL PRO-

TECTOR

COMPRESSOR THERMAL

TRANSMITTER A/C AUTO AMPIN-

VEHICLE

SENSORA/C CON-

TROL

PANEL

REFRIGENT

PRESSURE

SENSOR AMBIENT

SENSOR SUN LOAD

SENSOR A/C HIGH

RELAY

A/C MH

RELAY

A/C ML

RELAY

A/C LOW

RELAY FA N

RESISTOR

AIR MIX

DOOR

MOTOR

TROUBLE DIAGNOSESAUTO

HA-41