NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1911 of 2267

pA

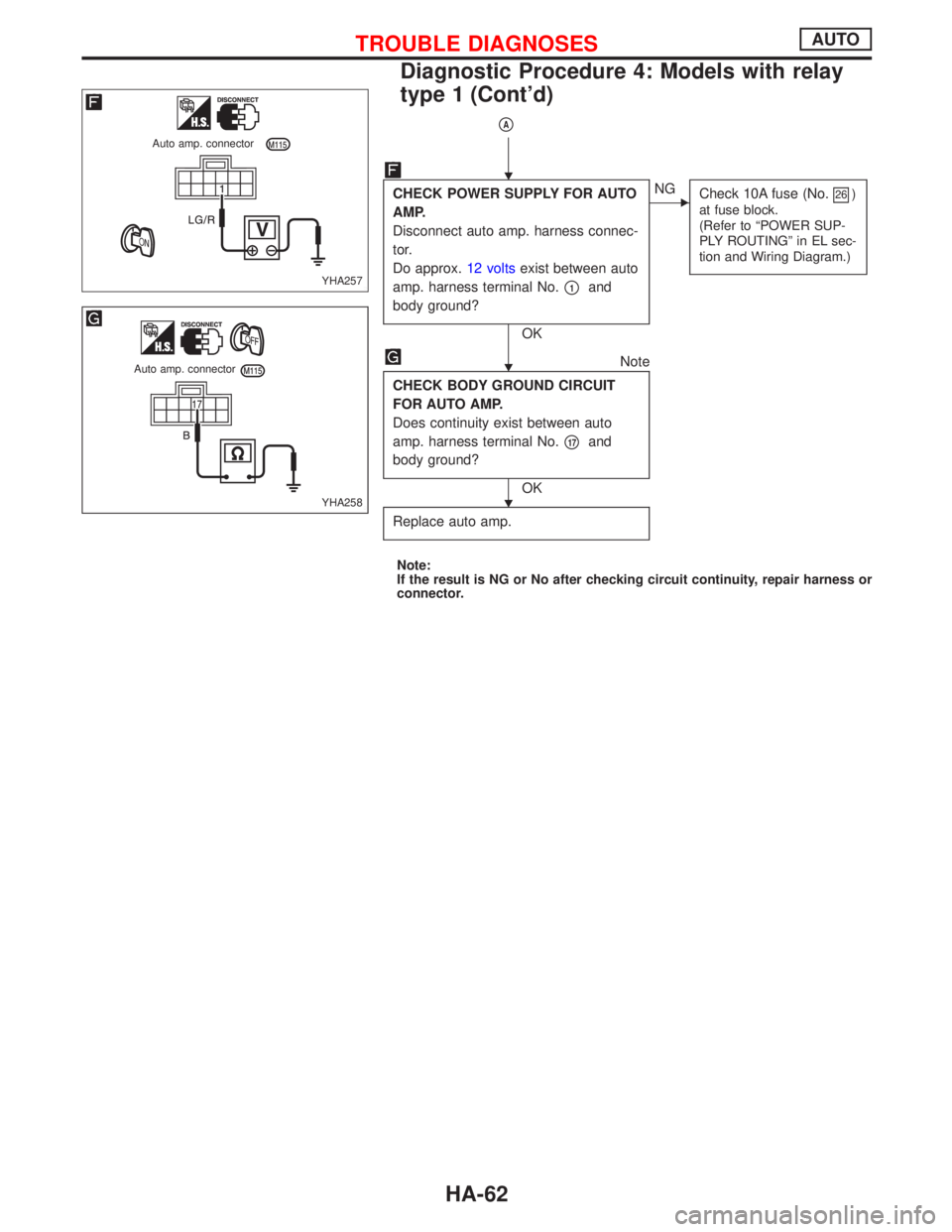

CHECK POWER SUPPLY FOR AUTO

AMP.

Disconnect auto amp. harness connec-

tor.

Do approx.12 voltsexist between auto

amp. harness terminal No.

p1and

body ground?

OK

ENG

Check 10A fuse (No.26)

at fuse block.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

Note

CHECK BODY GROUND CIRCUIT

FOR AUTO AMP.

Does continuity exist between auto

amp. harness terminal No.

p17and

body ground?

OK

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA257

Auto amp. connector

YHA258

Auto amp. connector

H

H

H

TROUBLE DIAGNOSESAUTO

Diagnostic Procedure 4: Models with relay

type 1 (Cont'd)

HA-62

Page 1912 of 2267

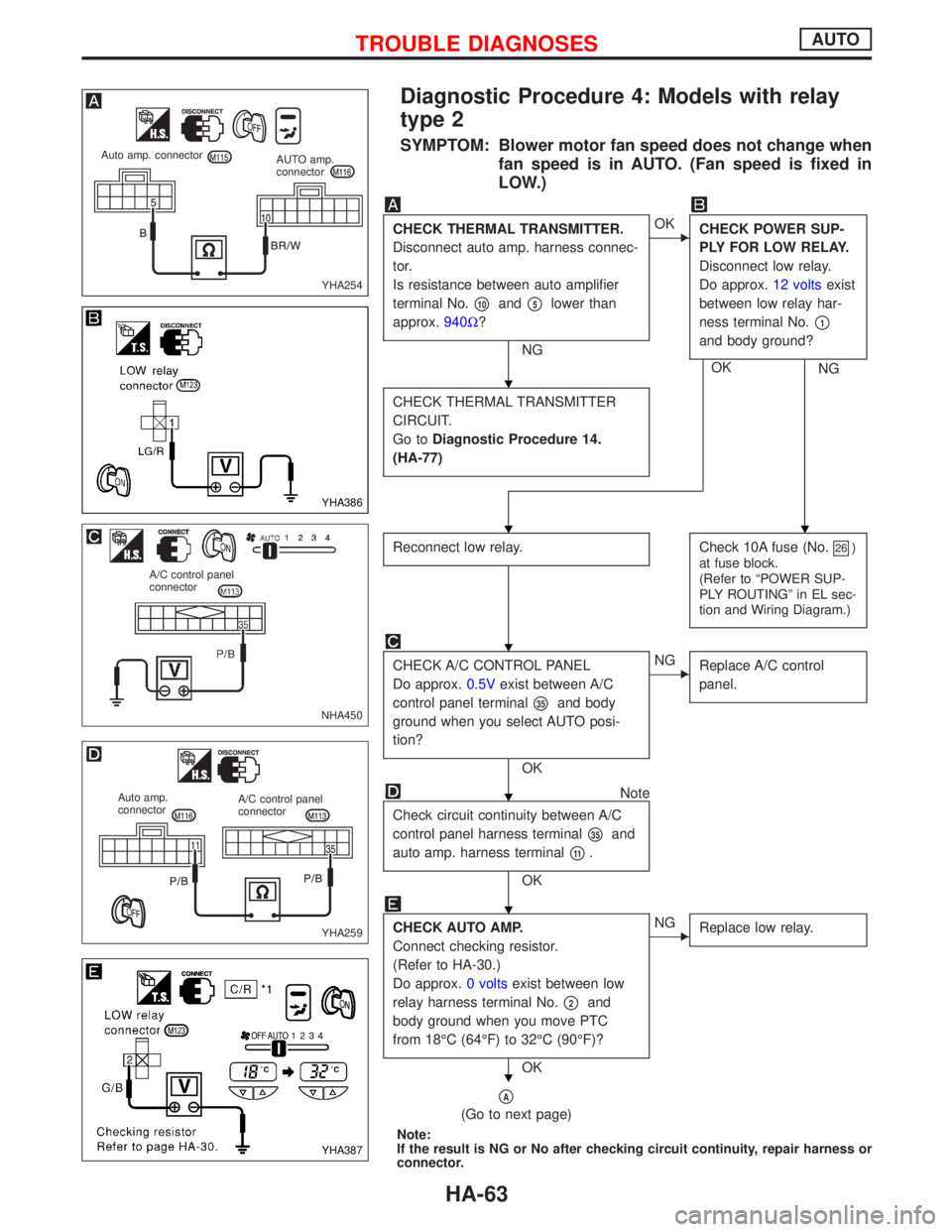

Diagnostic Procedure 4: Models with relay

type 2

SYMPTOM: Blower motor fan speed does not change when

fan speed is in AUTO. (Fan speed is fixed in

LOW.)

CHECK THERMAL TRANSMITTER.

Disconnect auto amp. harness connec-

tor.

Is resistance between auto amplifier

terminal No.

p10andp5lower than

approx.940W?

NG

EOK

CHECK POWER SUP-

PLY FOR LOW RELAY.

Disconnect low relay.

Do approx.12 voltsexist

between low relay har-

ness terminal No.

p1

and body ground?

OK

NG

CHECK THERMAL TRANSMITTER

CIRCUIT.

Go toDiagnostic Procedure 14.

(HA-77)

Reconnect low relay.Check 10A fuse (No.26)

at fuse block.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

CHECK A/C CONTROL PANEL

Do approx.0.5Vexist between A/C

control panel terminal

p35and body

ground when you select AUTO posi-

tion?

OK

ENG

Replace A/C control

panel.

Note

Check circuit continuity between A/C

control panel harness terminal

p35and

auto amp. harness terminal

p11.

OK

CHECK AUTO AMP.

Connect checking resistor.

(Refer to HA-30.)

Do approx.0 voltsexist between low

relay harness terminal No.

p2and

body ground when you move PTC

from 18ÉC (64ÉF) to 32ÉC (90ÉF)?

OK

ENG

Replace low relay.

pA

(Go to next page)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA254

Auto amp. connector

AUTO amp.

connector

YHA386

NHA450

A/C control panel

connector

YHA259

Auto amp.

connectorA/C control panel

connector

YHA387

H

HH

H

H

H

H

TROUBLE DIAGNOSESAUTO

HA-63

Page 1913 of 2267

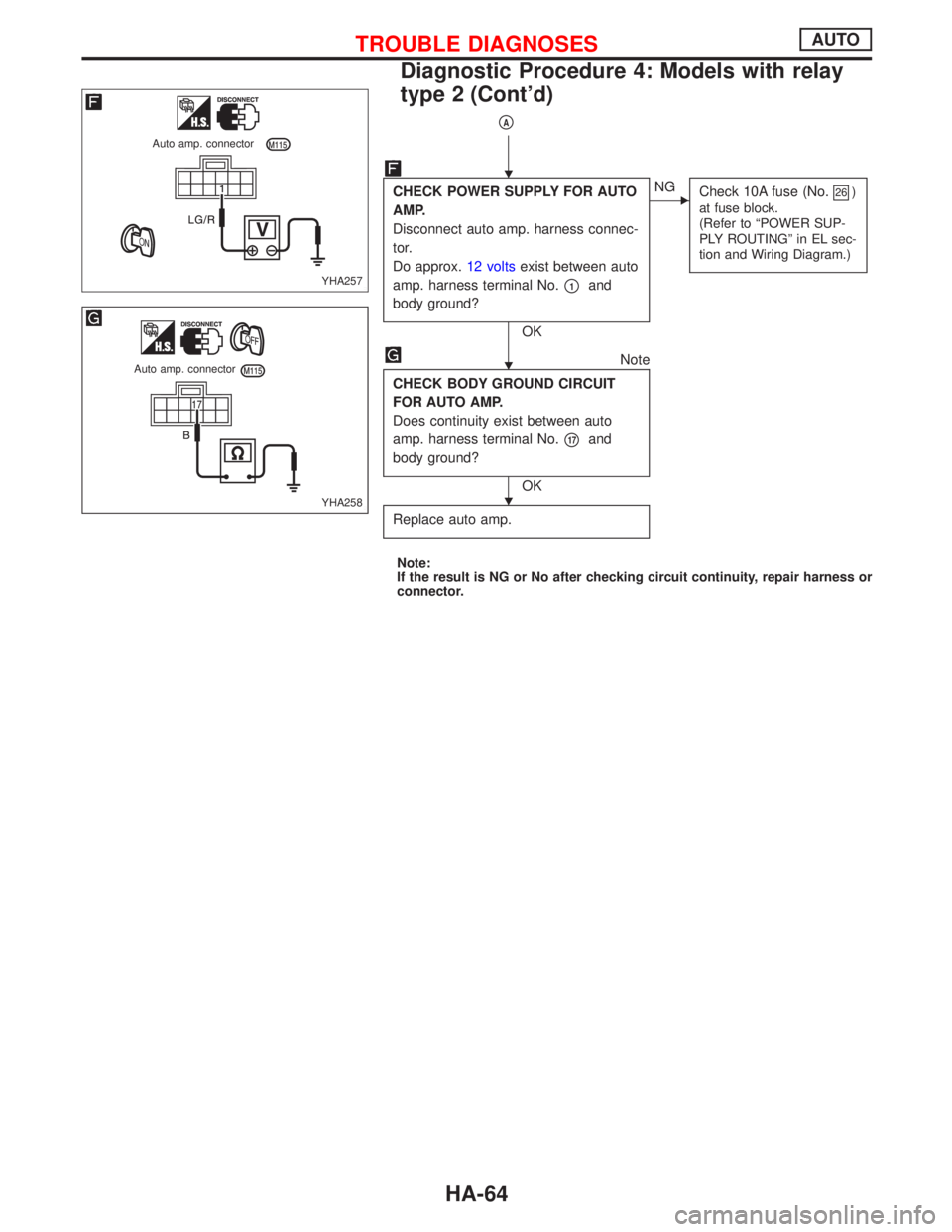

pA

CHECK POWER SUPPLY FOR AUTO

AMP.

Disconnect auto amp. harness connec-

tor.

Do approx.12 voltsexist between auto

amp. harness terminal No.

p1and

body ground?

OK

ENG

Check 10A fuse (No.26)

at fuse block.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL sec-

tion and Wiring Diagram.)

Note

CHECK BODY GROUND CIRCUIT

FOR AUTO AMP.

Does continuity exist between auto

amp. harness terminal No.

p17and

body ground?

OK

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA257

Auto amp. connector

YHA258

Auto amp. connector

H

H

H

TROUBLE DIAGNOSESAUTO

Diagnostic Procedure 4: Models with relay

type 2 (Cont'd)

HA-64

Page 1914 of 2267

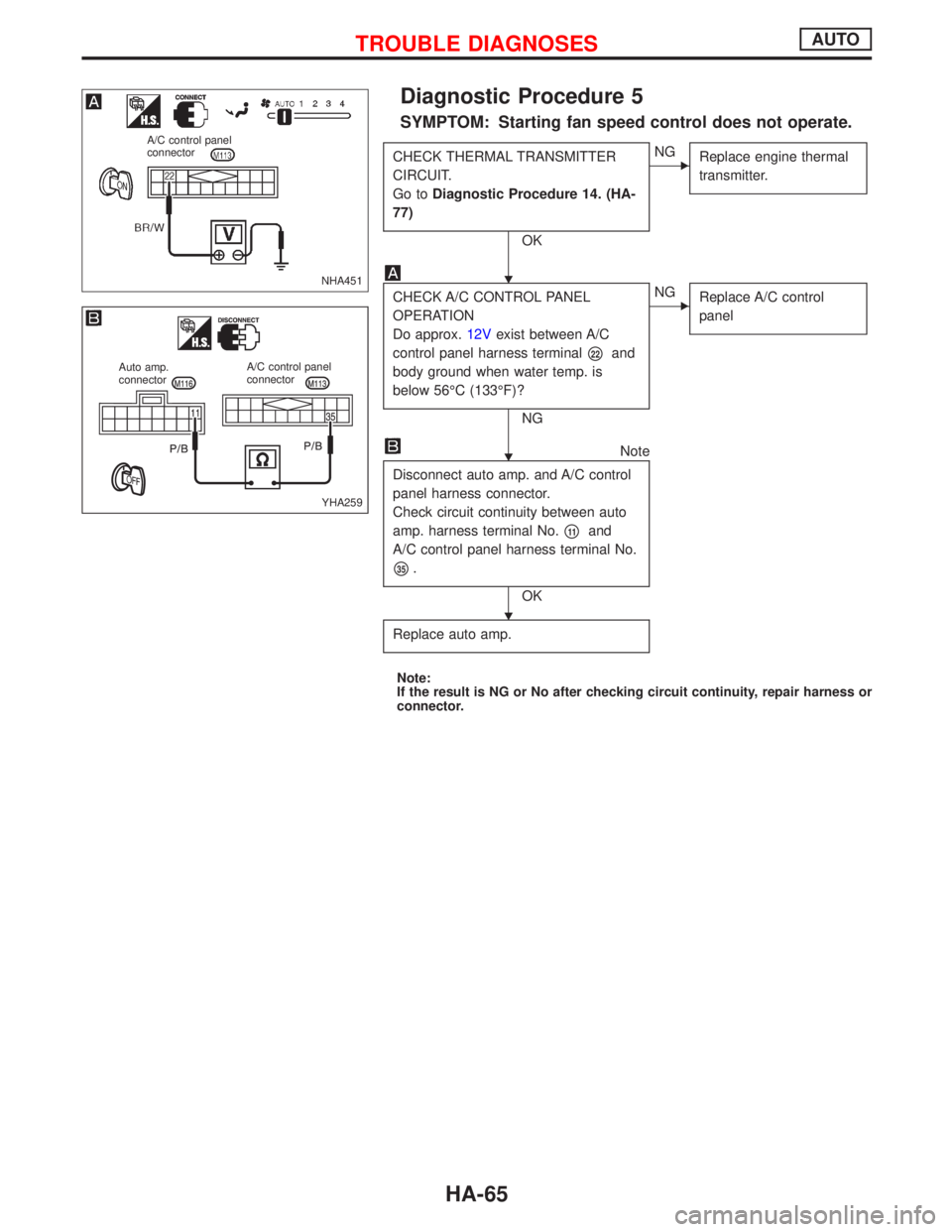

Diagnostic Procedure 5

SYMPTOM: Starting fan speed control does not operate.

CHECK THERMAL TRANSMITTER

CIRCUIT.

Go toDiagnostic Procedure 14. (HA-

77)

OK

ENG

Replace engine thermal

transmitter.

CHECK A/C CONTROL PANEL

OPERATION

Do approx.12Vexist between A/C

control panel harness terminal

p22and

body ground when water temp. is

below 56ÉC (133ÉF)?

NG

ENG

Replace A/C control

panel

Note

Disconnect auto amp. and A/C control

panel harness connector.

Check circuit continuity between auto

amp. harness terminal No.

p11and

A/C control panel harness terminal No.

p35.

OK

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

NHA451

A/C control panel

connector

YHA259

Auto amp.

connectorA/C control panel

connector

H

H

H

TROUBLE DIAGNOSESAUTO

HA-65

Page 1915 of 2267

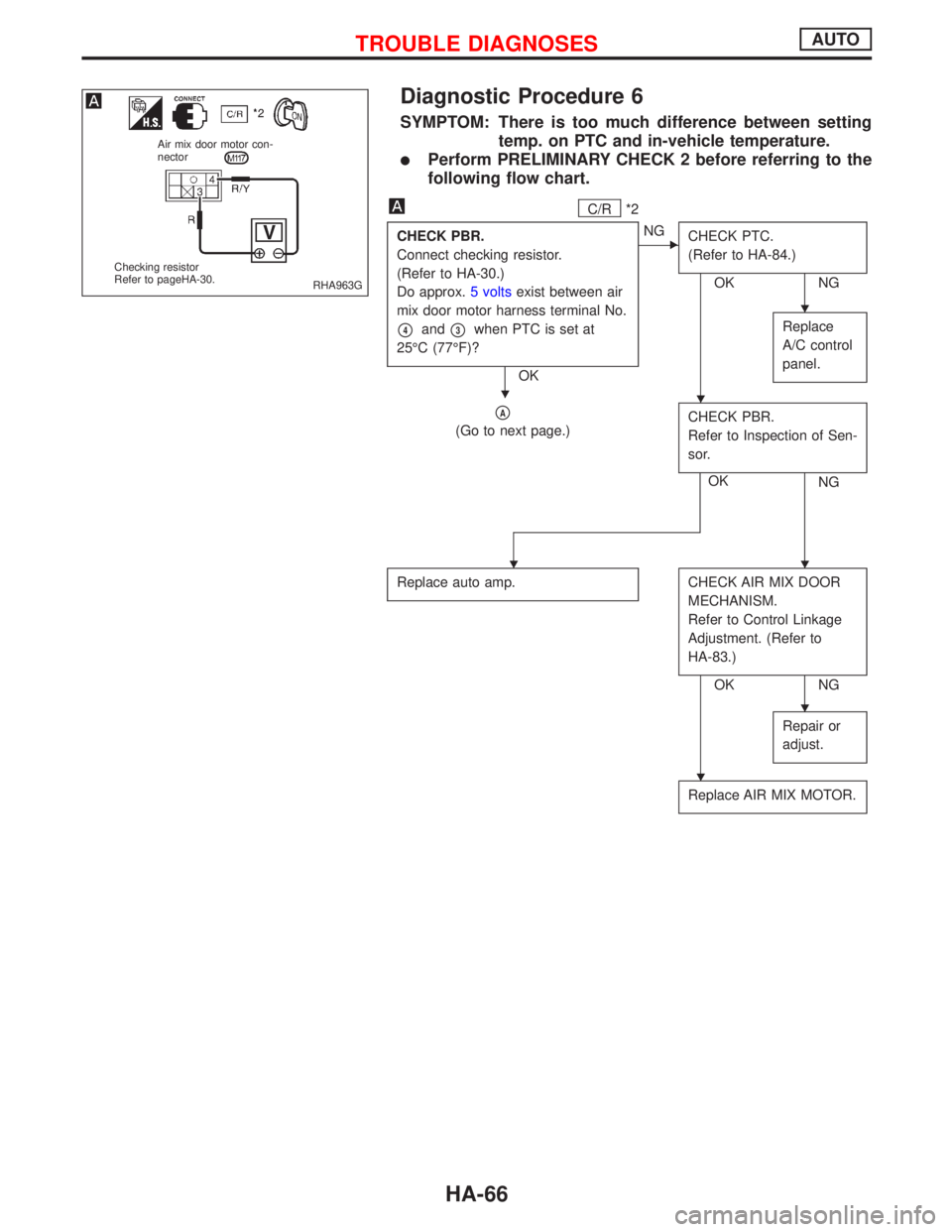

Diagnostic Procedure 6

SYMPTOM: There is too much difference between setting

temp. on PTC and in-vehicle temperature.

lPerform PRELIMINARY CHECK 2 before referring to the

following flow chart.

C/R*2

CHECK PBR.

Connect checking resistor.

(Refer to HA-30.)

Do approx.5 voltsexist between air

mix door motor harness terminal No.

p4andp3when PTC is set at

25ÉC (77ÉF)?

OK

ENG

CHECK PTC.

(Refer to HA-84.)

OK NG

Replace

A/C control

panel.

pA

(Go to next page.)CHECK PBR.

Refer to Inspection of Sen-

sor.

OK

NG

Replace auto amp.CHECK AIR MIX DOOR

MECHANISM.

Refer to Control Linkage

Adjustment. (Refer to

HA-83.)

OK NG

Repair or

adjust.

Replace AIR MIX MOTOR.

RHA963G

Air mix door motor con-

nector

Checking resistor

Refer to pageHA-30.

H

HH

HH

H

H

TROUBLE DIAGNOSESAUTO

HA-66

Page 1916 of 2267

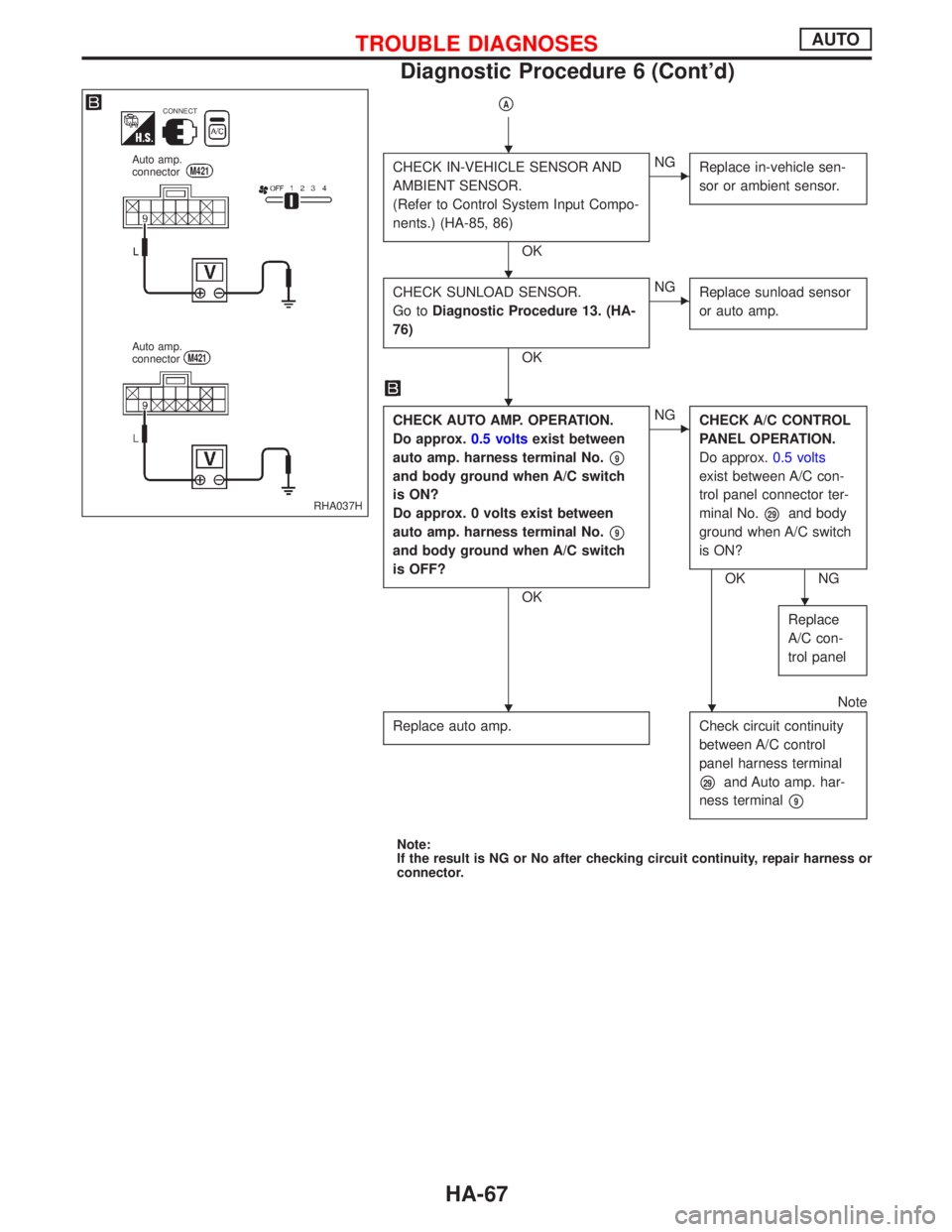

pA

CHECK IN-VEHICLE SENSOR AND

AMBIENT SENSOR.

(Refer to Control System Input Compo-

nents.) (HA-85, 86)

OK

ENG

Replace in-vehicle sen-

sor or ambient sensor.

CHECK SUNLOAD SENSOR.

Go toDiagnostic Procedure 13. (HA-

76)

OK

ENG

Replace sunload sensor

or auto amp.

CHECK AUTO AMP. OPERATION.

Do approx.0.5 voltsexist between

auto amp. harness terminal No.

p9

and body ground when A/C switch

is ON?

Do approx. 0 volts exist between

auto amp. harness terminal No.

p9

and body ground when A/C switch

is OFF?

OK

ENG

CHECK A/C CONTROL

PANEL OPERATION.

Do approx.0.5 volts

exist between A/C con-

trol panel connector ter-

minal No.

p29and body

ground when A/C switch

is ON?

OK NG

Replace

A/C con-

trol panel

Replace auto amp.

Note

Check circuit continuity

between A/C control

panel harness terminal

p29and Auto amp. har-

ness terminal

p9

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA037H

CONNECT

Auto amp.

connectorM421

Auto amp.

connectorM421

H

H

HH

H

HH

TROUBLE DIAGNOSESAUTO

Diagnostic Procedure 6 (Cont'd)

HA-67

Page 1917 of 2267

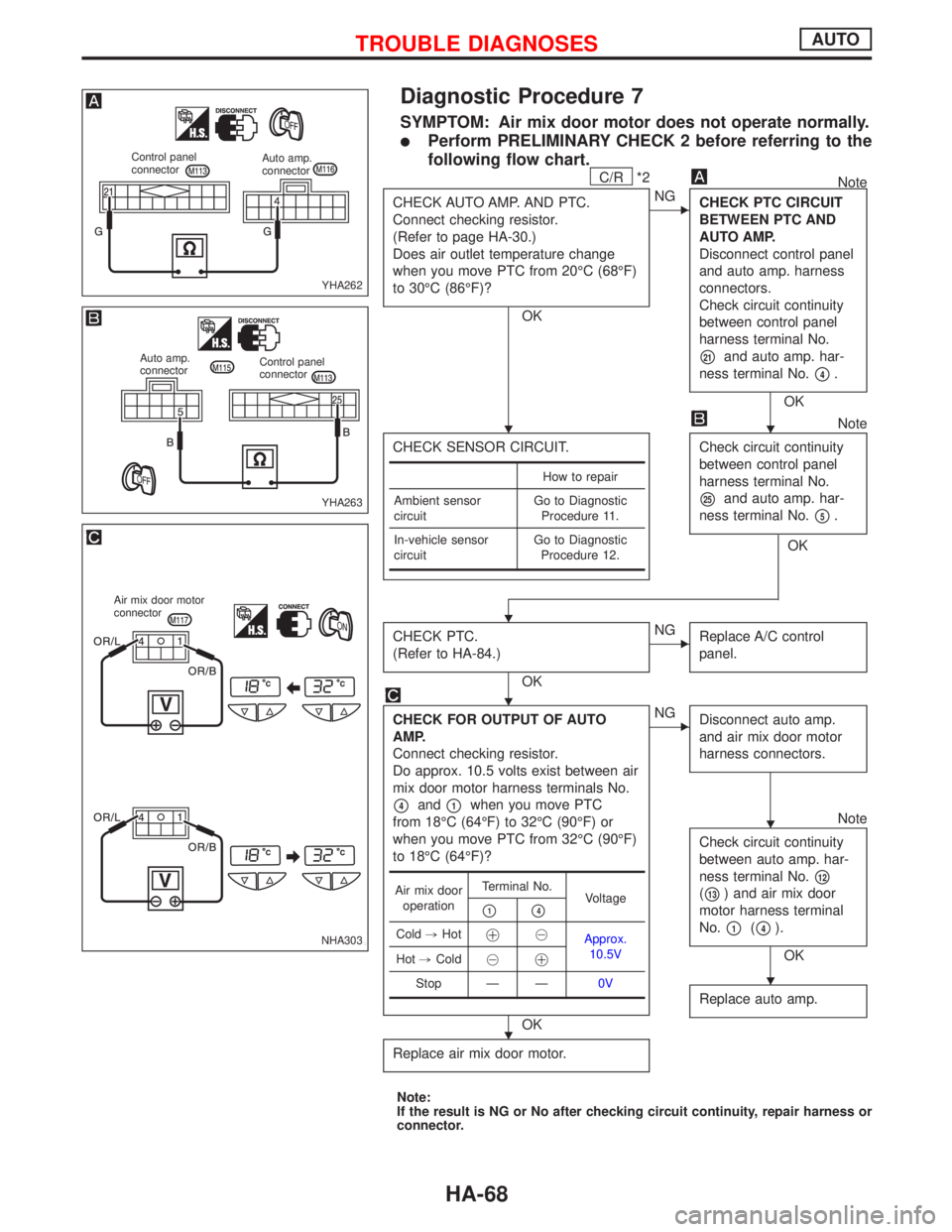

Diagnostic Procedure 7

SYMPTOM: Air mix door motor does not operate normally.

lPerform PRELIMINARY CHECK 2 before referring to the

following flow chart.

C/R*2Note

CHECK AUTO AMP. AND PTC.

Connect checking resistor.

(Refer to page HA-30.)

Does air outlet temperature change

when you move PTC from 20ÉC (68ÉF)

to 30ÉC (86ÉF)?

OK

ENG

CHECK PTC CIRCUIT

BETWEEN PTC AND

AUTO AMP.

Disconnect control panel

and auto amp. harness

connectors.

Check circuit continuity

between control panel

harness terminal No.

p21and auto amp. har-

ness terminal No.

p4.

OK

CHECK SENSOR CIRCUIT.

Note

Check circuit continuity

between control panel

harness terminal No.

p25and auto amp. har-

ness terminal No.

p5.

OK

CHECK PTC.

(Refer to HA-84.)

OK

ENG

Replace A/C control

panel.

CHECK FOR OUTPUT OF AUTO

AMP.

Connect checking resistor.

Do approx. 10.5 volts exist between air

mix door motor harness terminals No.

p4andp1when you move PTC

from 18ÉC (64ÉF) to 32ÉC (90ÉF) or

when you move PTC from 32ÉC (90ÉF)

to 18ÉC (64ÉF)?

OK

ENG

Disconnect auto amp.

and air mix door motor

harness connectors.

Note

Check circuit continuity

between auto amp. har-

ness terminal No.

p12

(p13) and air mix door

motor harness terminal

No.

p1(p4).

OK

Replace auto amp.

Replace air mix door motor.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

How to repair

Ambient sensor

circuitGo to Diagnostic

Procedure 11.

In-vehicle sensor

circuitGo to Diagnostic

Procedure 12.

Air mix door

operationTerminal No.

Voltage

p1p4

Cold,Hot!@

Approx.

10.5V

Hot,Cold@

!

Stop Ð Ð0V

YHA262

Control panel

connectorAuto amp.

connector

YHA263

Auto amp.

connectorControl panel

connector

NHA303

Air mix door motor

connector

HH

H

H

H

H

H

TROUBLE DIAGNOSESAUTO

HA-68

Page 1918 of 2267

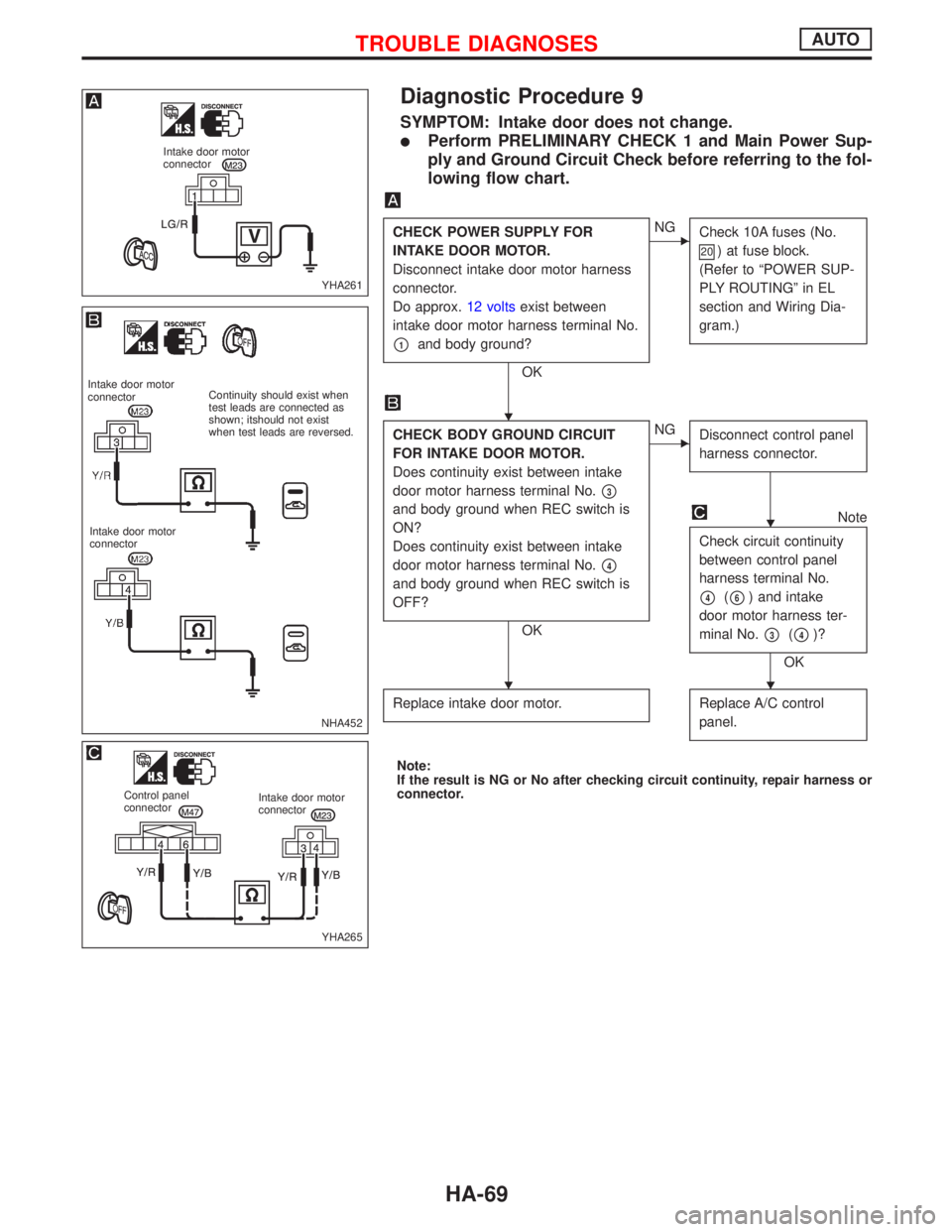

Diagnostic Procedure 9

SYMPTOM: Intake door does not change.

lPerform PRELIMINARY CHECK 1 and Main Power Sup-

ply and Ground Circuit Check before referring to the fol-

lowing flow chart.

CHECK POWER SUPPLY FOR

INTAKE DOOR MOTOR.

Disconnect intake door motor harness

connector.

Do approx.12 voltsexist between

intake door motor harness terminal No.

p1and body ground?

OK

ENG

Check 10A fuses (No.

20) at fuse block.

(Refer to ªPOWER SUP-

PLY ROUTINGº in EL

section and Wiring Dia-

gram.)

CHECK BODY GROUND CIRCUIT

FOR INTAKE DOOR MOTOR.

Does continuity exist between intake

door motor harness terminal No.

p3

and body ground when REC switch is

ON?

Does continuity exist between intake

door motor harness terminal No.

p4

and body ground when REC switch is

OFF?

OK

ENG

Disconnect control panel

harness connector.

Note

Check circuit continuity

between control panel

harness terminal No.

p4(p6) and intake

door motor harness ter-

minal No.

p3(p4)?

OK

Replace intake door motor.

Replace A/C control

panel.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA261

Intake door motor

connector

NHA452

Intake door motor

connectorContinuity should exist when

test leads are connected as

shown; itshould not exist

when test leads are reversed.

Intake door motor

connector

YHA265

Control panel

connectorIntake door motor

connector

H

H

HH

TROUBLE DIAGNOSESAUTO

HA-69

Page 1919 of 2267

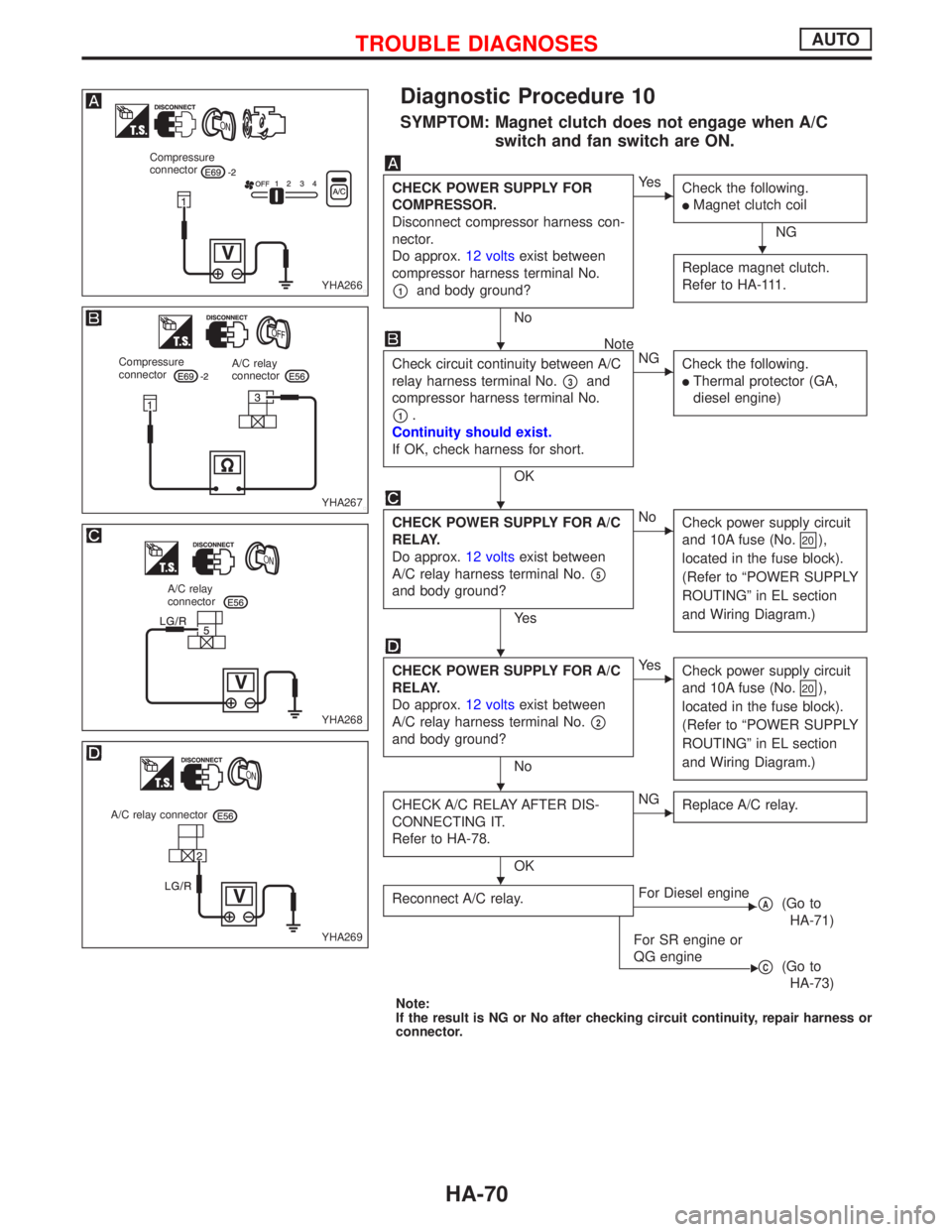

Diagnostic Procedure 10

SYMPTOM: Magnet clutch does not engage when A/C

switch and fan switch are ON.

CHECK POWER SUPPLY FOR

COMPRESSOR.

Disconnect compressor harness con-

nector.

Do approx.12 voltsexist between

compressor harness terminal No.

p1and body ground?

No

EYe s

Check the following.

lMagnet clutch coil

NG

Replace magnet clutch.

Refer to HA-111.

Note

Check circuit continuity between A/C

relay harness terminal No.

p3and

compressor harness terminal No.

p1.

Continuity should exist.

If OK, check harness for short.

OK

ENG

Check the following.

lThermal protector (GA,

diesel engine)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx.12 voltsexist between

A/C relay harness terminal No.

p5

and body ground?

Ye s

ENo

Check power supply circuit

and 10A fuse (No.

20),

located in the fuse block).

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section

and Wiring Diagram.)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx.12 voltsexist between

A/C relay harness terminal No.

p2

and body ground?

No

EYe s

Check power supply circuit

and 10A fuse (No.

20),

located in the fuse block).

(Refer to ªPOWER SUPPLY

ROUTINGº in EL section

and Wiring Diagram.)

CHECK A/C RELAY AFTER DIS-

CONNECTING IT.

Refer to HA-78.

OK

ENG

Replace A/C relay.

Reconnect A/C relay.EFor Diesel enginepA(Go to

HA-71)

E

For SR engine or

QG engine

pC(Go to

HA-73)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

YHA266

Compressure

connector

YHA267

Compressure

connectorA/C relay

connector

YHA268

A/C relay

connector

YHA269

A/C relay connector

H

H

H

H

H

H

TROUBLE DIAGNOSESAUTO

HA-70

Page 1920 of 2267

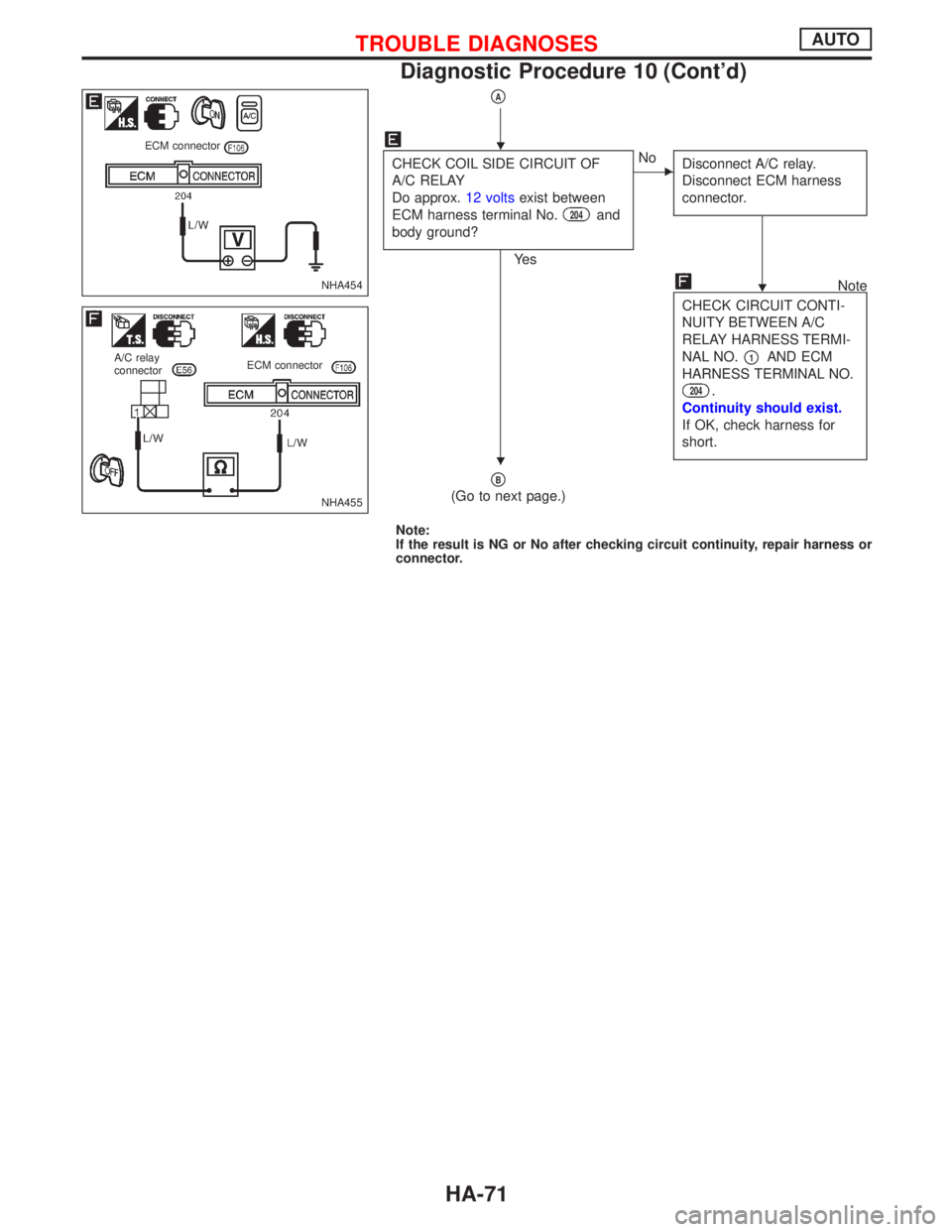

pA

CHECK COIL SIDE CIRCUIT OF

A/C RELAY

Do approx.12 voltsexist between

ECM harness terminal No.

204and

body ground?

Ye s

ENo

Disconnect A/C relay.

Disconnect ECM harness

connector.

Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN A/C

RELAY HARNESS TERMI-

NAL NO.

p1AND ECM

HARNESS TERMINAL NO.

204.

Continuity should exist.

If OK, check harness for

short.

pB

(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

NHA454

ECM connector

NHA455

A/C relay

connectorECM connector

H

H

H

TROUBLE DIAGNOSESAUTO

Diagnostic Procedure 10 (Cont'd)

HA-71