low oil pressure NISSAN PRIMERA 1999 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 498 of 2267

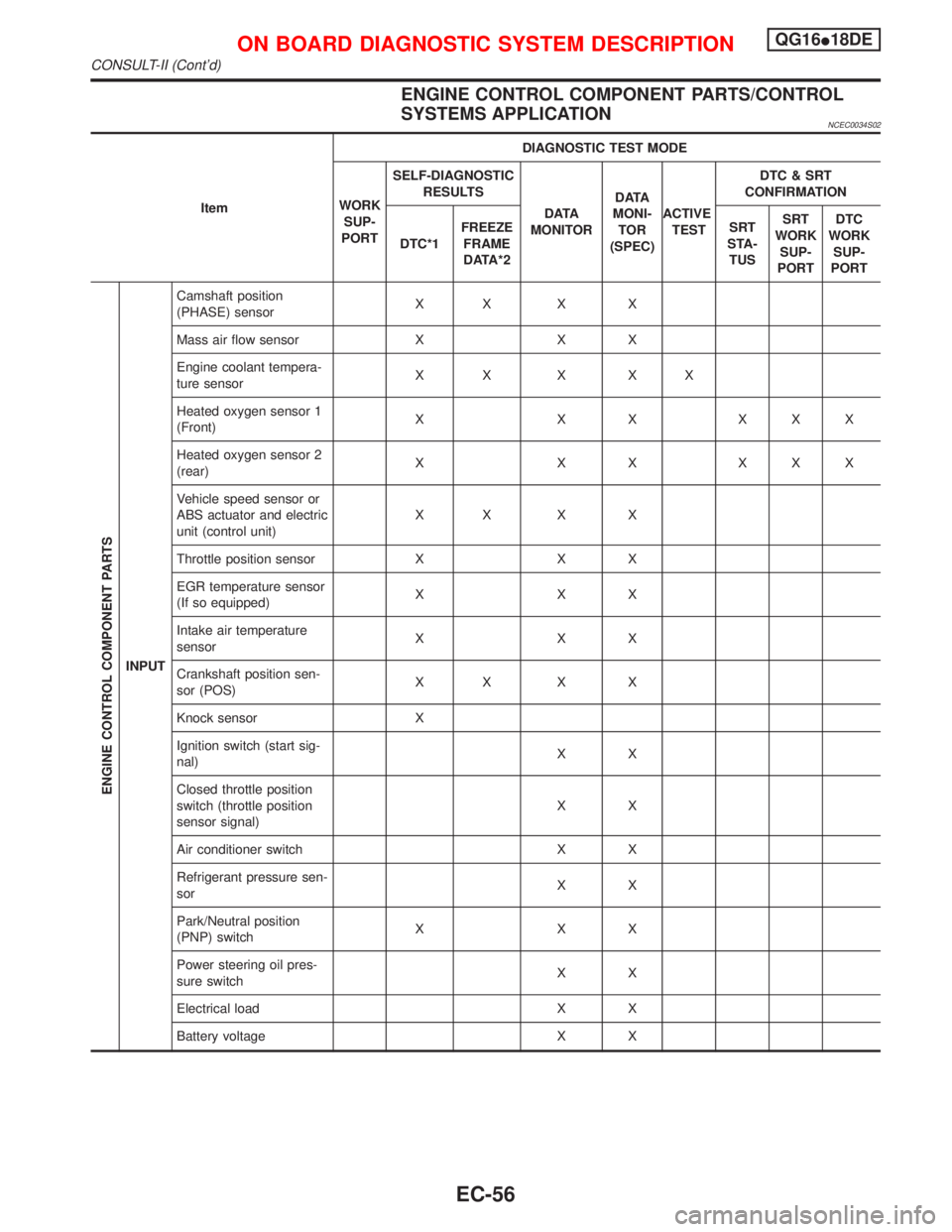

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NCEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONITORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSSRT

WORK

SUP-

PORTDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUTCamshaft position

(PHASE) sensorXX X X

Mass air flow sensor X X X

Engine coolant tempera-

ture sensorXX X XX

Heated oxygen sensor 1

(Front)X X X XXX

Heated oxygen sensor 2

(rear)X X X XXX

Vehicle speed sensor or

ABS actuator and electric

unit (control unit)XX X X

Throttle position sensor X X X

EGR temperature sensor

(If so equipped)XXX

Intake air temperature

sensorXXX

Crankshaft position sen-

sor (POS)XX X X

Knock sensor X

Ignition switch (start sig-

nal)XX

Closed throttle position

switch (throttle position

sensor signal)XX

Air conditioner switch X X

Refrigerant pressure sen-

sorXX

Park/Neutral position

(PNP) switchXXX

Power steering oil pres-

sure switchXX

Electrical load X X

Battery voltage X X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-56

Page 502 of 2267

![NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condition-

ing signa NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condition-

ing signa](/img/5/57377/w960_57377-501.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condition-

ing signal.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the PNP

switch signal.

PW/ST SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition of the power steer-

ing oil pressure switch determined by the power

steering oil pressure switch signal.

LOAD SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the electrical

load signal and/or lighting switch.

ON ... rear defogger is operating and/or lighting

switch is on.

OFF ... rear defogger is not operating and light-

ing switch is not on.

IGNITION SW

[ON/OFF]qIIndicates [ON/OFF] condition from ignition

switch.

HEATER FAN SW

[ON/OFF]qIIndicates [ON/OFF] condition from the heater

fan switch.

INJ PULSE-B1

[msec]qIIndicates the actual fuel injection pulse width

compensated by ECM according to the input

signals.IWhen the engine is stopped, a

certain computed value is indi-

cated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel injection

pulse width programmed into ECM, prior to any

learned on board correction.

IGN TIMING [BTDC]qIIndicates the ignition timing computed by ECM

according to the input signals.

IACV-AAC/V [step]qIIndicates the IACV-AAC valve control value

computed by ECM according to the input sig-

nals.

A/F ALPHA-B1 [%]qIIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is stopped, a

certain value is indicated.

IThis data also includes the data

for the air-fuel ratio learning

control.

AIR COND RLY

[ON/OFF]qIIndicates the air conditioner relay control condi-

tion determined by ECM according to the input

signals.

FUEL PUMP RLY

[ON/OFF]qIIndicates the fuel pump relay control condition

determined by ECM according to the input sig-

nals.

INT/V SOL-B1

[ON/OFF]IThe control condition of the valve timing sole-

noid valve (determined by ECM according to the

input signal) is indicated.

ON ... Intake valve timing control operating

OFF ... Intake valve timing control not operating

COOLING FAN

[ON/OFF]qIIndicates the control condition of the cooling fan

determined by ECM according to the input sig-

nals.

HI ... High speed operation

LOW ... Low speed operation

OFF ... Stop

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-60

Page 524 of 2267

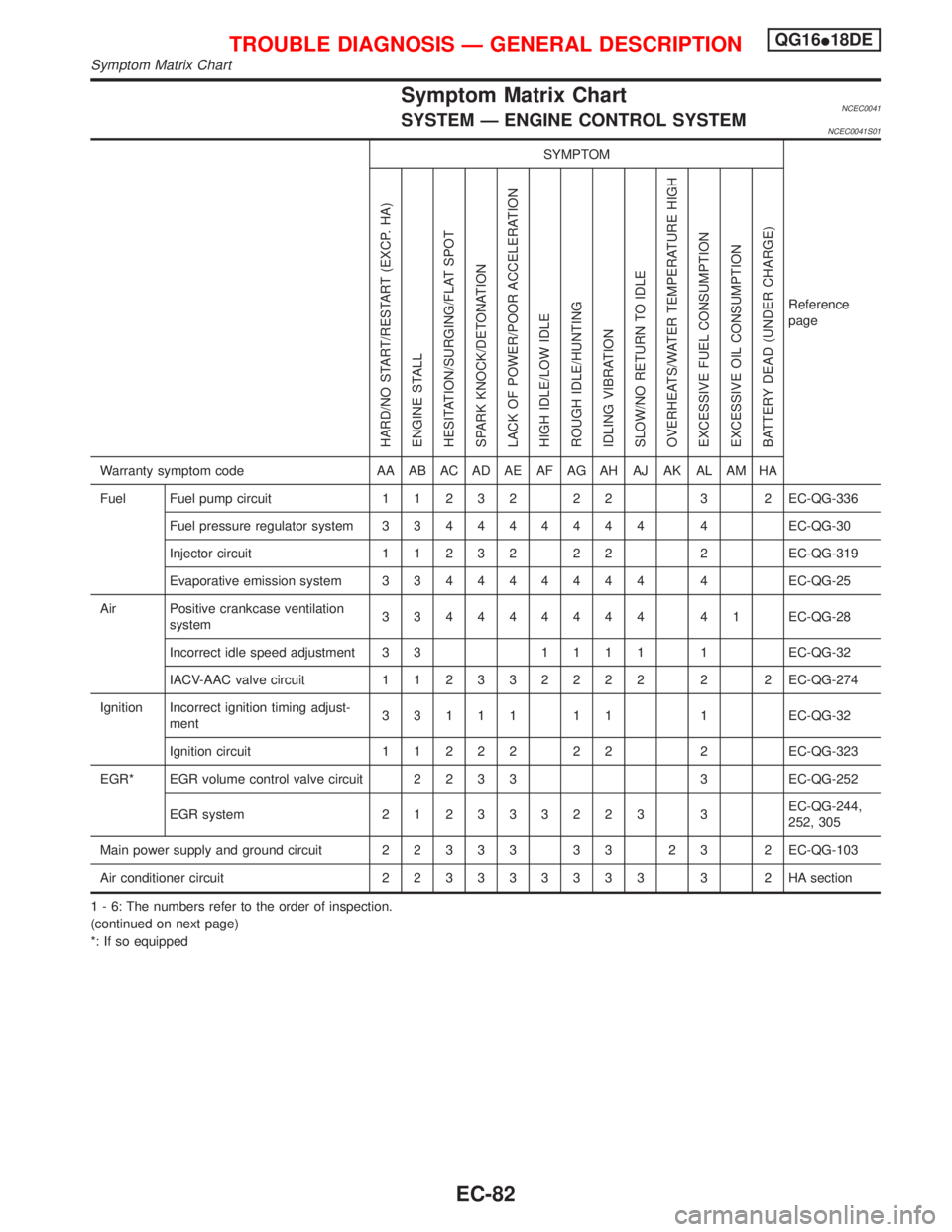

Symptom Matrix ChartNCEC0041SYSTEM Ð ENGINE CONTROL SYSTEMNCEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 22 3 2EC-QG-336

Fuel pressure regulator system334444444 4EC-QG-30

Injector circuit11232 22 2EC-QG-319

Evaporative emission system334444444 4EC-QG-25

Air Positive crankcase ventilation

system334444444 41EC-QG-28

Incorrect idle speed adjustment 3 31111 1EC-QG-32

IACV-AAC valve circuit112332222 2 2EC-QG-274

Ignition Incorrect ignition timing adjust-

ment33111 11 1EC-QG-32

Ignition circuit11222 22 2EC-QG-323

EGR* EGR volume control valve circuit2233 3EC-QG-252

EGR system212333223 3EC-QG-244,

252, 305

Main power supply and ground circuit22333 33 23 2EC-QG-103

Air conditioner circuit223333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

*: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Symptom Matrix Chart

EC-82

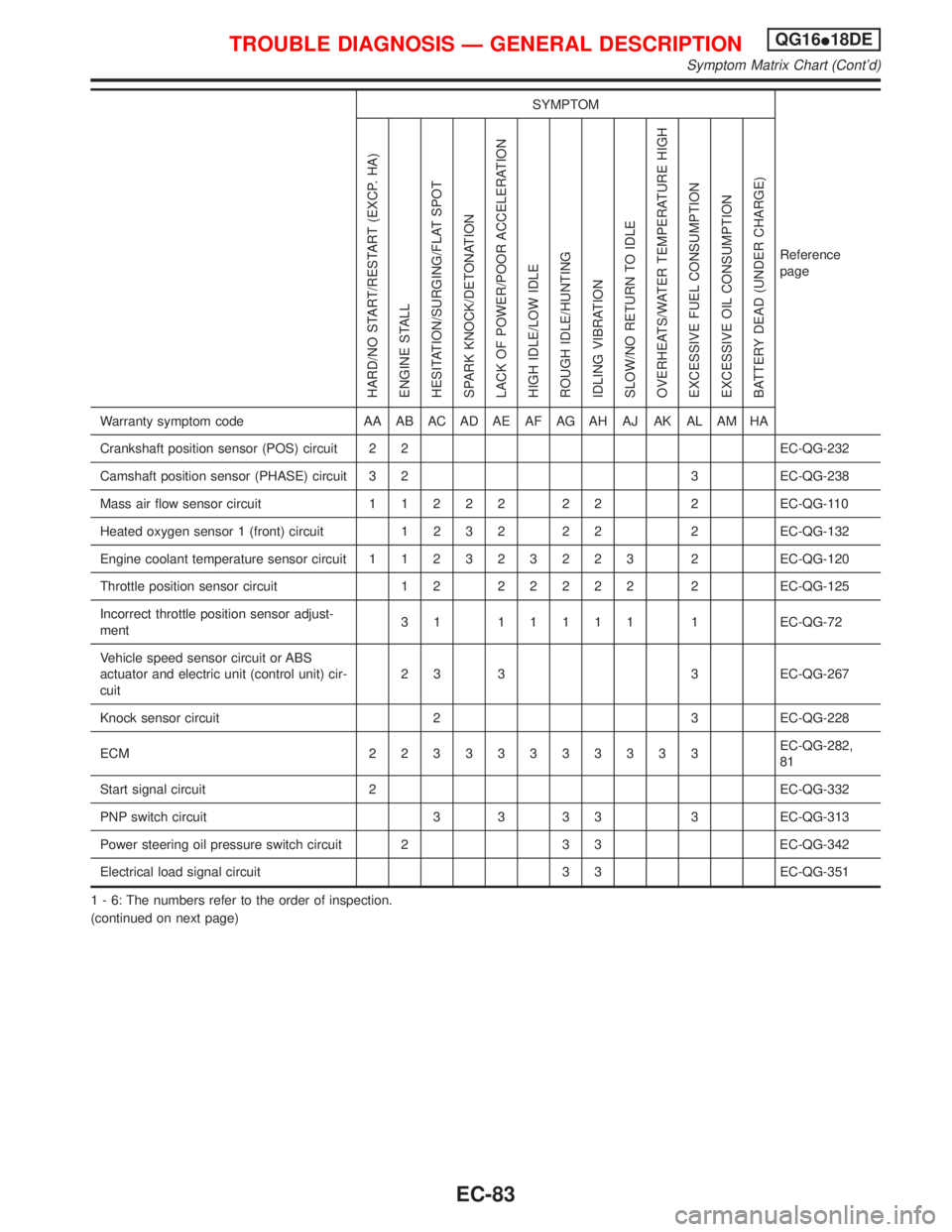

Page 525 of 2267

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Crankshaft position sensor (POS) circuit 2 2 EC-QG-232

Camshaft position sensor (PHASE) circuit 3 2 3 EC-QG-238

Mass air flow sensor circuit11222 22 2EC-QG-110

Heated oxygen sensor 1 (front) circuit1232 22 2EC-QG-132

Engine coolant temperature sensor circuit112323223 2EC-QG-120

Throttle position sensor circuit 1 222222 2EC-QG-125

Incorrect throttle position sensor adjust-

ment31 11111 1EC-QG-72

Vehicle speed sensor circuit or ABS

actuator and electric unit (control unit) cir-

cuit2 3 3 3 EC-QG-267

Knock sensor circuit 2 3 EC-QG-228

ECM 22333333333EC-QG-282,

81

Start signal circuit 2 EC-QG-332

PNP switch circuit 3 3 3 3 3 EC-QG-313

Power steering oil pressure switch circuit 2 3 3 EC-QG-342

Electrical load signal circuit 3 3 EC-QG-351

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Symptom Matrix Chart (Cont'd)

EC-83

Page 716 of 2267

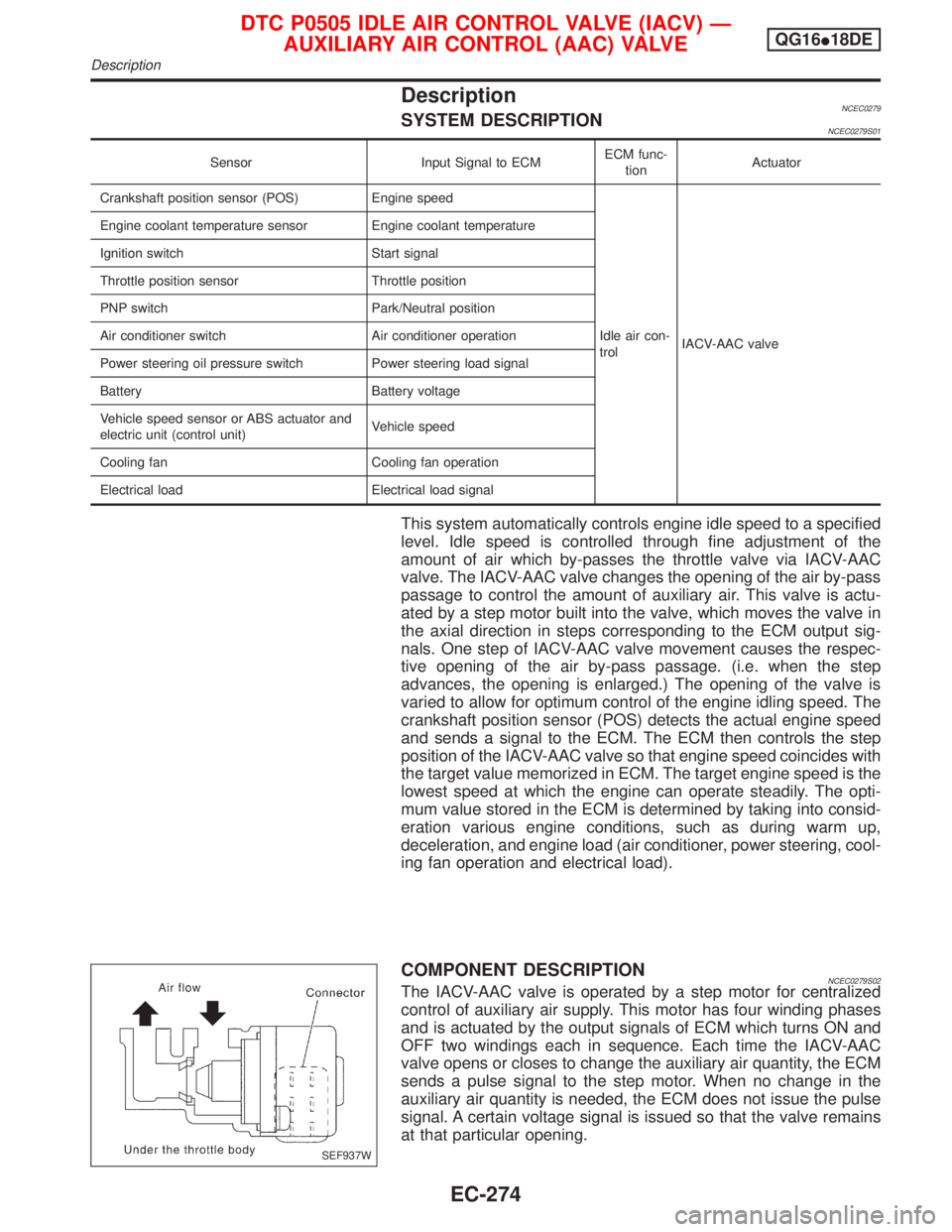

DescriptionNCEC0279SYSTEM DESCRIPTIONNCEC0279S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Idle air con-

trolIACV-AAC valve Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

PNP switch Park/Neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Cooling fan Cooling fan operation

Electrical load Electrical load signal

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by taking into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering, cool-

ing fan operation and electrical load).

COMPONENT DESCRIPTIONNCEC0279S02The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in sequence. Each time the IACV-AAC

valve opens or closes to change the auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

SEF937W

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð

AUXILIARY AIR CONTROL (AAC) VALVEQG16I18DE

Description

EC-274

Page 786 of 2267

Diagnostic Procedure=NCEC0454

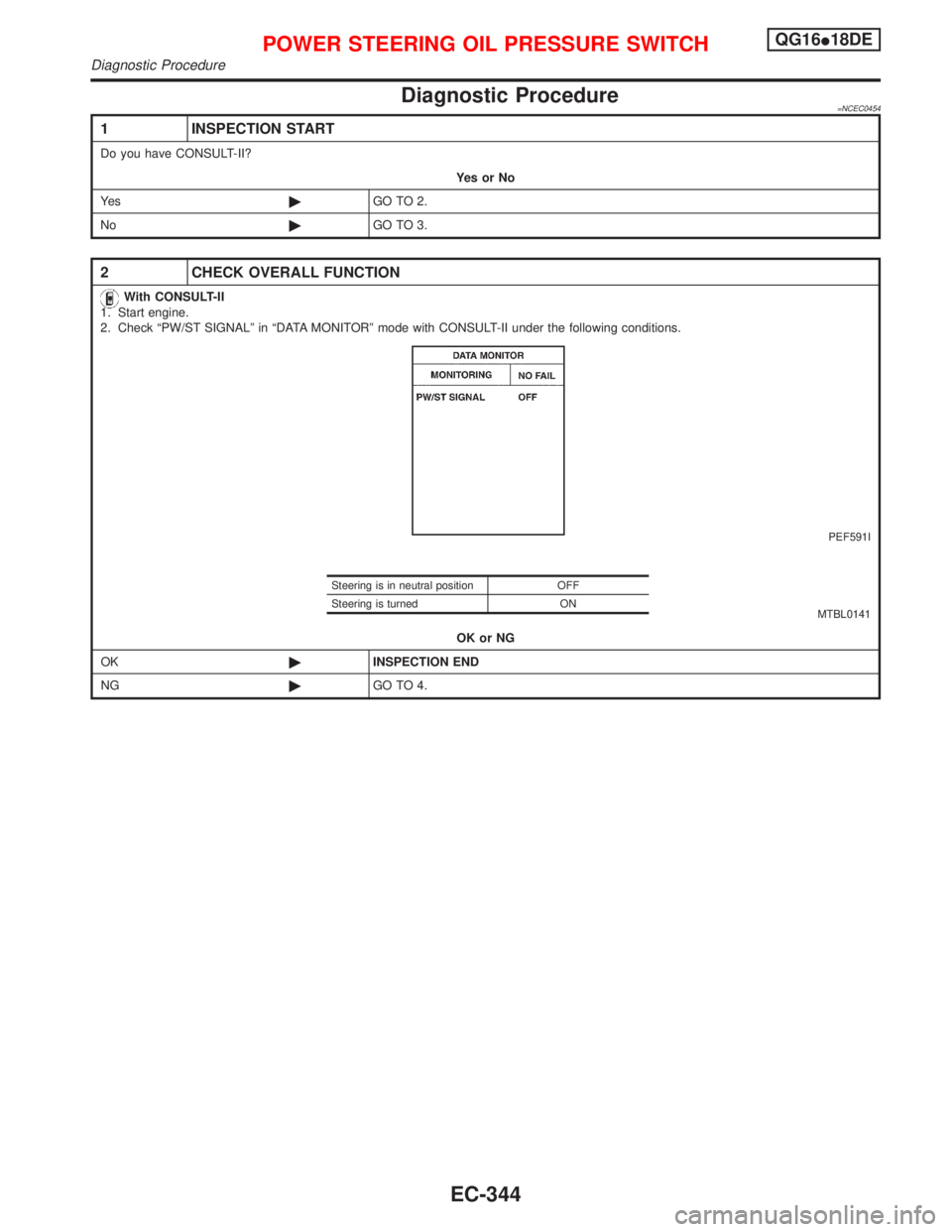

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

PEF591I

MTBL0141

OK or NG

OK©INSPECTION END

NG©GO TO 4.

Steering is in neutral position OFF

Steering is turned ON

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure

EC-344

Page 787 of 2267

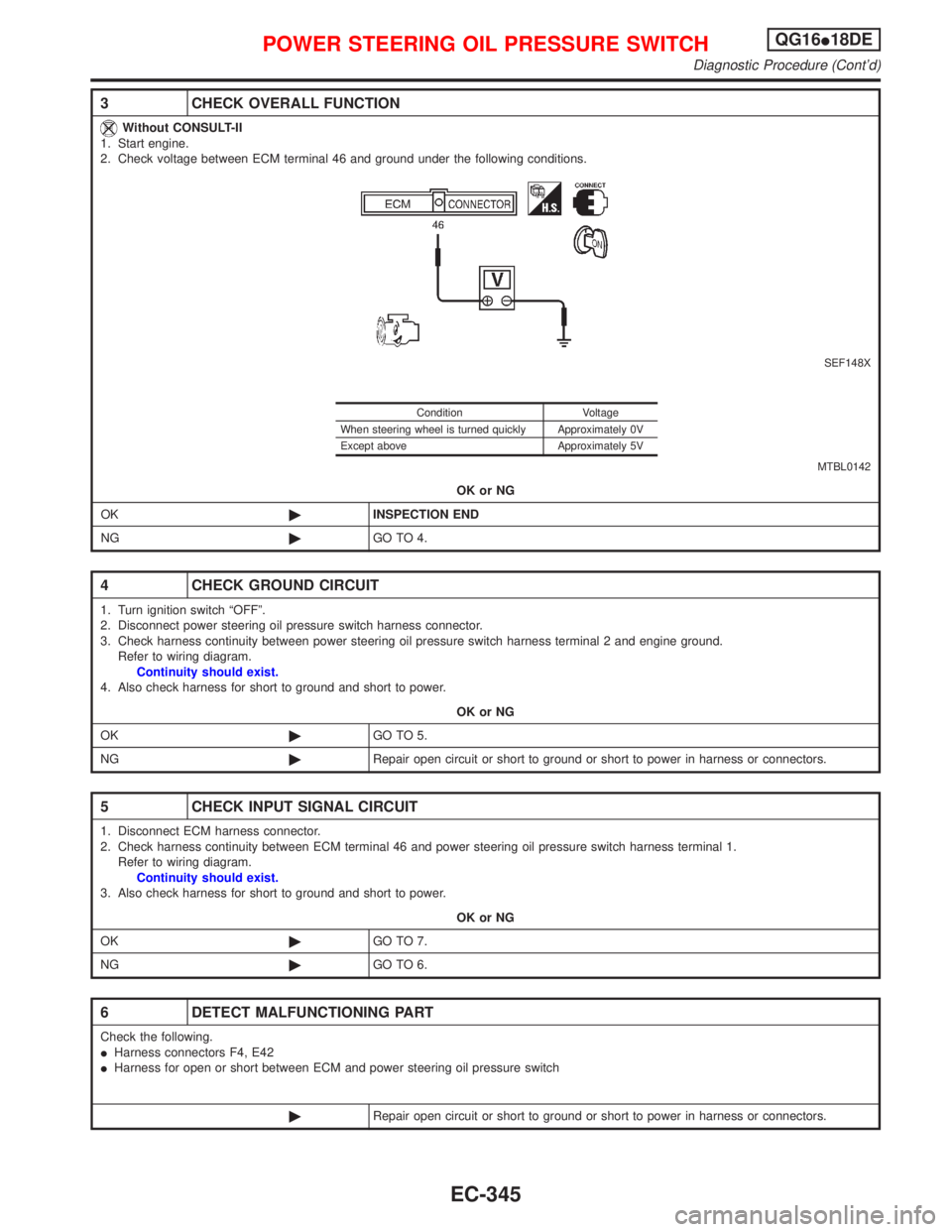

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 46 and ground under the following conditions.

SEF148X

MTBL0142

OK or NG

OK©INSPECTION END

NG©GO TO 4.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

3. Check harness continuity between power steering oil pressure switch harness terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and power steering oil pressure switch harness terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F4, E42

IHarness for open or short between ECM and power steering oil pressure switch

©Repair open circuit or short to ground or short to power in harness or connectors.

Condition Voltage

When steering wheel is turned quickly Approximately 0V

Except above Approximately 5V

POWER STEERING OIL PRESSURE SWITCHQG16I18DE

Diagnostic Procedure (Cont'd)

EC-345

Page 805 of 2267

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................306

ECM Terminals and Reference Value .....................306

Wiring Diagram ........................................................308

Diagnostic Procedure ..............................................309

Component Inspection .............................................310

START SIGNAL...........................................................312

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................312

ECM Terminals and Reference Value .....................312

Wiring Diagram ........................................................313

Diagnostic Procedure ..............................................314

FUEL PUMP.................................................................316

System Description ..................................................316

Component Description ...........................................316

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................316

ECM Terminals and Reference Value .....................316

Wiring Diagram ........................................................317

Diagnostic Procedure ..............................................318

Component Inspection .............................................320

POWER STEERING OIL PRESSURE SWITCH.........321

Component Description ...........................................321

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................321

ECM Terminals and Reference Value .....................321

Wiring Diagram ........................................................322Diagnostic Procedure ..............................................323

Component Inspection .............................................324

ELECTRICAL LOAD SIGNAL.....................................325

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................325

ECM Terminals and Reference Value .....................325

Wiring Diagram ........................................................326

MI & DATA LINK CONNECTORS..............................329

Wiring Diagram ........................................................329

SERVICE DATA AND SPECIFICATIONS (SDS).......330

Fuel Pressure Regulator..........................................330

Idle Speed and Ignition Timing ................................330

Ignition Coil ..............................................................330

Mass Air Flow Sensor..............................................330

Engine Coolant Temperature Sensor ......................330

Fuel Pump ...............................................................330

IACV-AAC Valve ......................................................330

Injector .....................................................................330

Throttle Position Sensor ..........................................331

Heated Oxygen Sensor 1 (Front) Heater ................331

Intake Air Temperature Sensor ................................331

EVAP Canister Purge Volume Control Valve ..........331

Heated Oxygen Sensor 1 (Rear) Heater.................331

Crankshaft Position Sensor (OBD)..........................331

CONTENTS(Cont'd)

EC-5

Page 815 of 2267

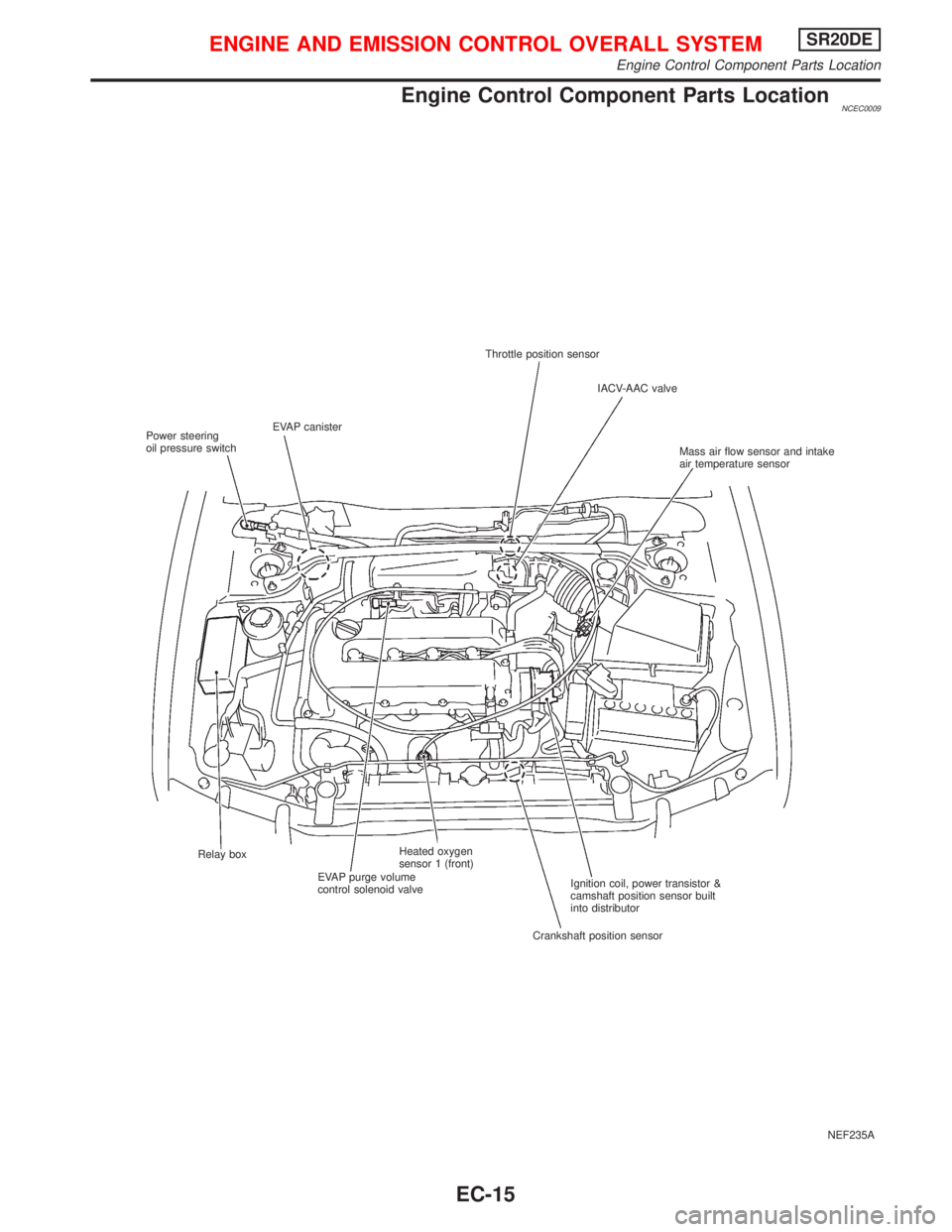

Engine Control Component Parts LocationNCEC0009

NEF235A Throttle position sensor

IACV-AAC valve

Mass air flow sensor and intake

air temperature sensor

Ignition coil, power transistor &

camshaft position sensor built

into distributor

Crankshaft position sensor Relay box

EVAP purge volume

control solenoid valveHeated oxygen

sensor 1 (front) EVAP canister

Power steering

oil pressure switch

ENGINE AND EMISSION CONTROL OVERALL SYSTEMSR20DE

Engine Control Component Parts Location

EC-15

Page 822 of 2267

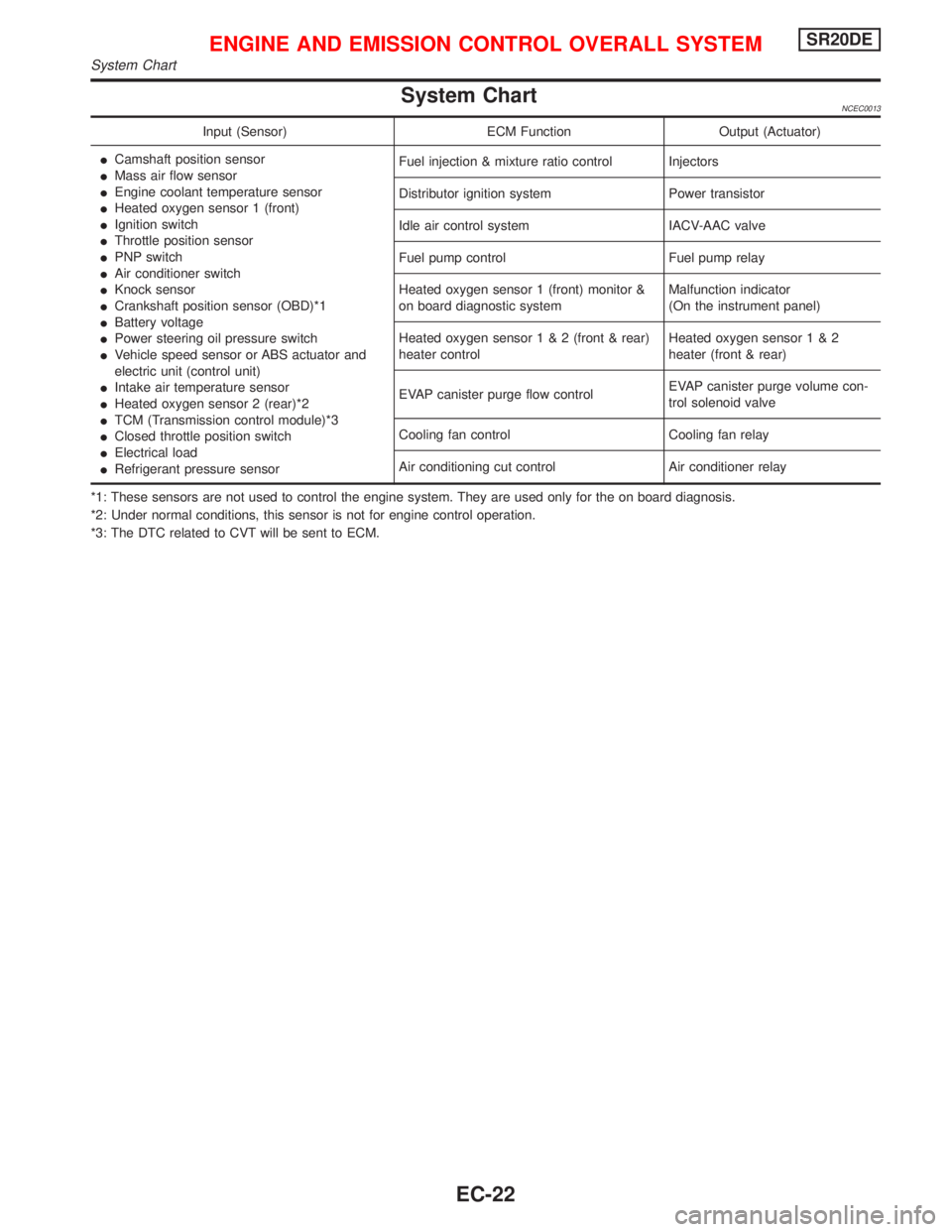

System ChartNCEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IPNP switch

IAir conditioner switch

IKnock sensor

ICrankshaft position sensor (OBD)*1

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor or ABS actuator and

electric unit (control unit)

IIntake air temperature sensor

IHeated oxygen sensor 2 (rear)*2

ITCM (Transmission control module)*3

IClosed throttle position switch

IElectrical load

IRefrigerant pressure sensorFuel injection & mixture ratio control Injectors

Distributor ignition system Power transistor

Idle air control system IACV-AAC valve

Fuel pump control Fuel pump relay

Heated oxygen sensor 1 (front) monitor &

on board diagnostic systemMalfunction indicator

(On the instrument panel)

Heated oxygen sensor1&2(front & rear)

heater controlHeated oxygen sensor1&2

heater (front & rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: The DTC related to CVT will be sent to ECM.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMSR20DE

System Chart

EC-22