low oil pressure NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 76 of 2267

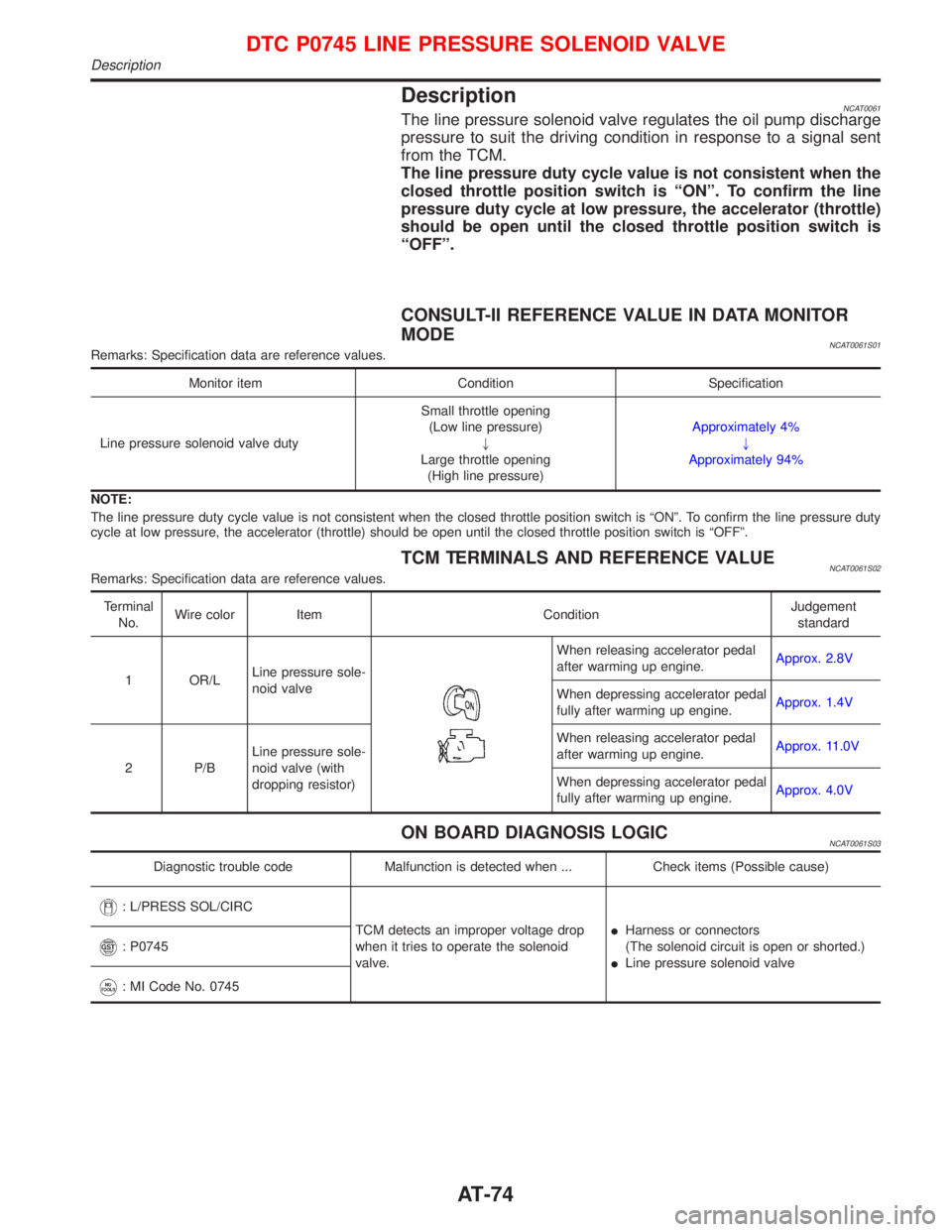

DescriptionNCAT0061The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0061S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

"

Large throttle opening

(High line pressure)Approximately 4%

"

Approximately 94%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENCAT0061S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

1 OR/LLine pressure sole-

noid valve

When releasing accelerator pedal

after warming up engine.Approx. 2.8V

When depressing accelerator pedal

fully after warming up engine.Approx. 1.4V

2 P/BLine pressure sole-

noid valve (with

dropping resistor)When releasing accelerator pedal

after warming up engine.Approx. 11.0V

When depressing accelerator pedal

fully after warming up engine.Approx. 4.0V

ON BOARD DIAGNOSIS LOGICNCAT0061S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: L/PRESS SOL/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

ILine pressure solenoid valve

: P0745

: MI Code No. 0745

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description

AT-74

Page 221 of 2267

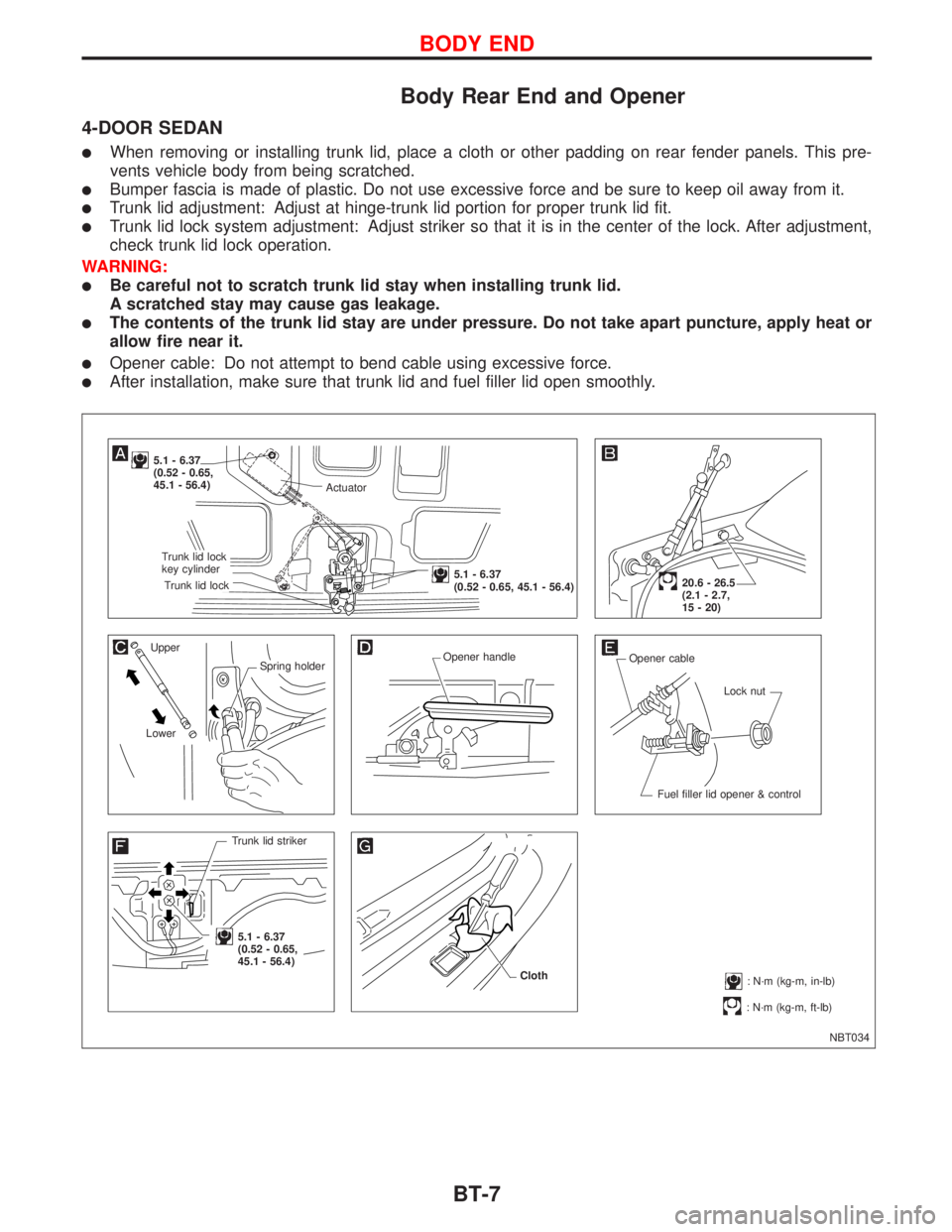

Body Rear End and Opener

4-DOOR SEDAN

lWhen removing or installing trunk lid, place a cloth or other padding on rear fender panels. This pre-

vents vehicle body from being scratched.

lBumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

lTrunk lid adjustment: Adjust at hinge-trunk lid portion for proper trunk lid fit.

lTrunk lid lock system adjustment: Adjust striker so that it is in the center of the lock. After adjustment,

check trunk lid lock operation.

WARNING:

lBe careful not to scratch trunk lid stay when installing trunk lid.

A scratched stay may cause gas leakage.

lThe contents of the trunk lid stay are under pressure. Do not take apart puncture, apply heat or

allow fire near it.

lOpener cable: Do not attempt to bend cable using excessive force.

lAfter installation, make sure that trunk lid and fuel filler lid open smoothly.

NBT034

5.1 - 6.37

(0.52 - 0.65,

45.1 - 56.4)

Upper

Spring holder

LowerOpener handle

Opener cable

Lock nut

Fuel filler lid opener & control

Trunk lid striker

.5.1 - 6.37

(0.52 - 0.65,

45.1 - 56.4)

: N´m (kg-m, ft-lb)

20.6 - 26.5

(2.1 - 2.7,

15 - 20)

: N´m (kg-m, in-lb) Cloth

Actuator

.Trunk lid lock

key cylinder

.Trunk lid lock

.5.1 - 6.37

(0.52 - 0.65, 45.1 - 56.4)

BODY END

BT-7

Page 341 of 2267

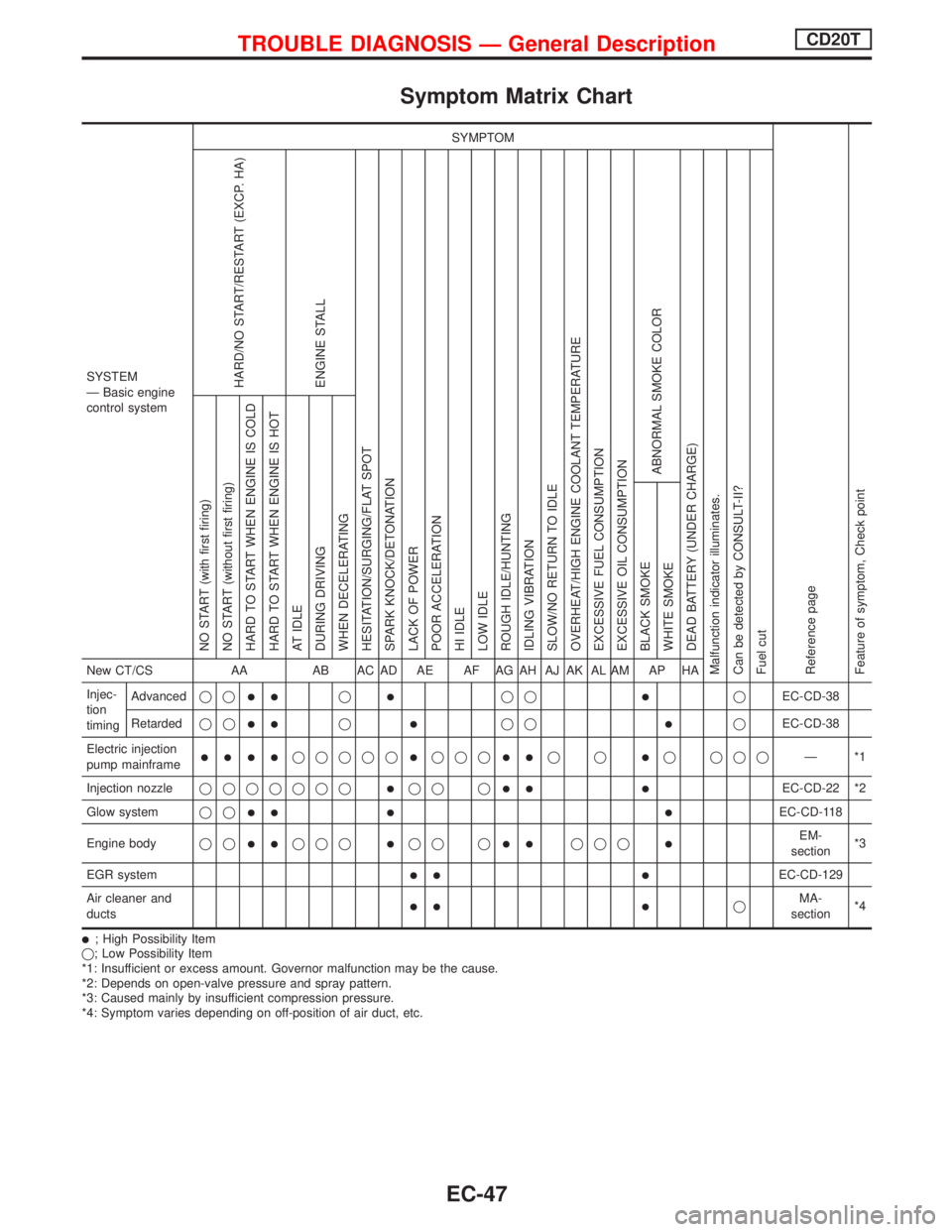

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?

Fuel cutNO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timingAdvancedqq

llqlqqlqEC-CD-38

Retardedqq

llqlqqlqEC-CD-38

Electric injection

pump mainframe

llllqqqqqlqqqllqqlq qqqÐ*1

Injection nozzleqqqqqqq

lqq qll lEC-CD-22 *2

Glow systemqq

ll l lEC-CD-118

Engine bodyqq

llqqqlqq qllqqqlEM-

section*3

EGR system

ll lEC-CD-129

Air cleaner and

ducts

ll lqMA-

section*4

l; High Possibility Item

q; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð General DescriptionCD20T

EC-47

Page 381 of 2267

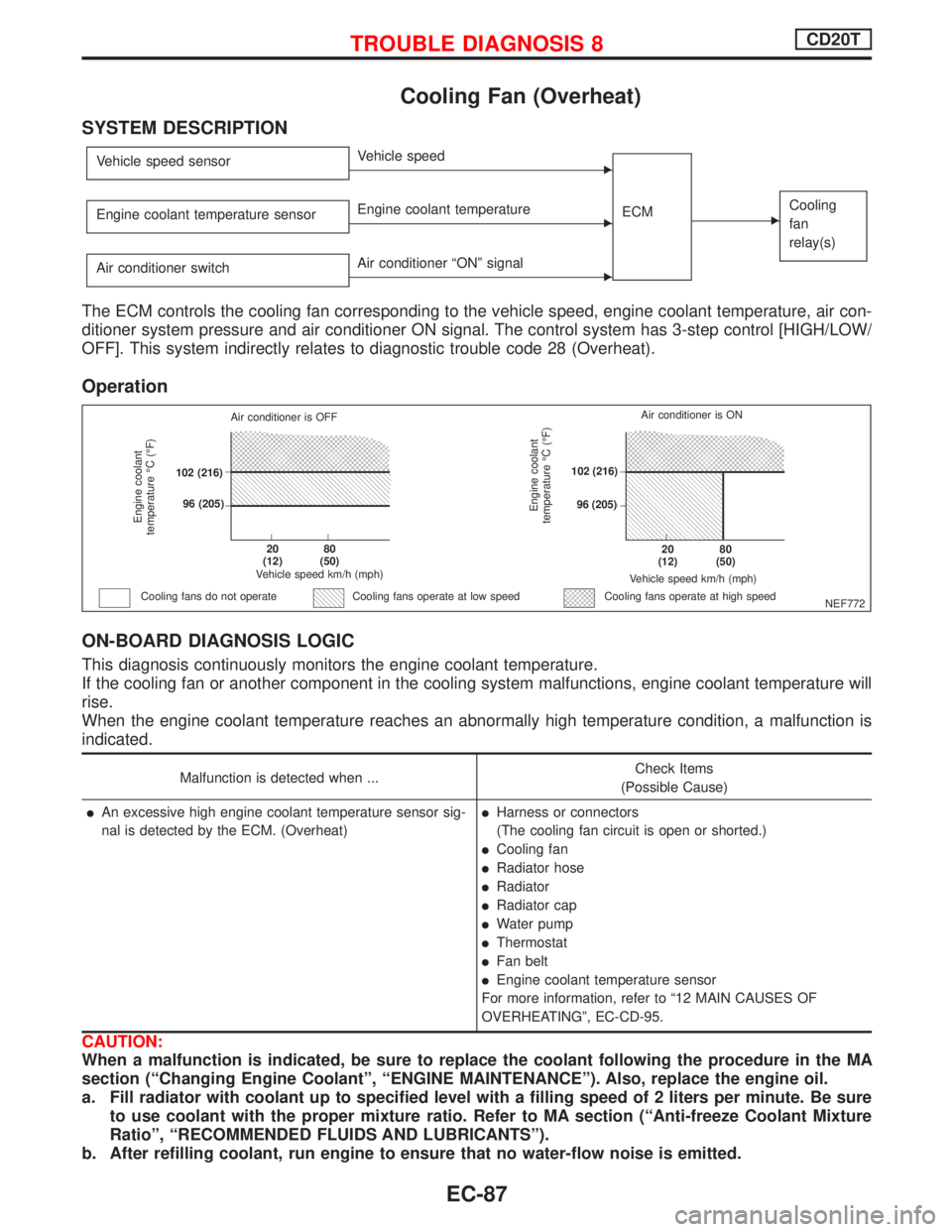

Cooling Fan (Overheat)

SYSTEM DESCRIPTION

Vehicle speed sensorEVehicle speed

ECM

ECooling

fan

relay(s)Engine coolant temperature sensorEEngine coolant temperature

Air conditioner switch

EAir conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, air con-

ditioner system pressure and air conditioner ON signal. The control system has 3-step control [HIGH/LOW/

OFF]. This system indirectly relates to diagnostic trouble code 28 (Overheat).

Operation

ON-BOARD DIAGNOSIS LOGIC

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ...Check Items

(Possible Cause)

lAn excessive high engine coolant temperature sensor sig-

nal is detected by the ECM. (Overheat)lHarness or connectors

(The cooling fan circuit is open or shorted.)

lCooling fan

lRadiator hose

lRadiator

lRadiator cap

lWater pump

lThermostat

lFan belt

lEngine coolant temperature sensor

For more information, refer to ª12 MAIN CAUSES OF

OVERHEATINGº, EC-CD-95.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

a. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED FLUIDS AND LUBRICANTSº).

b. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

NEF772

Engine coolant

temperature ÉC (ÉF)

Air conditioner is OFF

.102 (216)

.96 (205)

.20

(12).80

(50)

Vehicle speed km/h (mph)

Cooling fans do not operateCooling fans operate at high speed

Engine coolant

temperature ÉC (ÉF)

Vehicle speed km/h (mph)

.20

(12).80

(50)

.102 (216)

.96 (205)Air conditioner is ON

Cooling fans operate at low speed

TROUBLE DIAGNOSIS 8CD20T

EC-87

Page 388 of 2267

pB

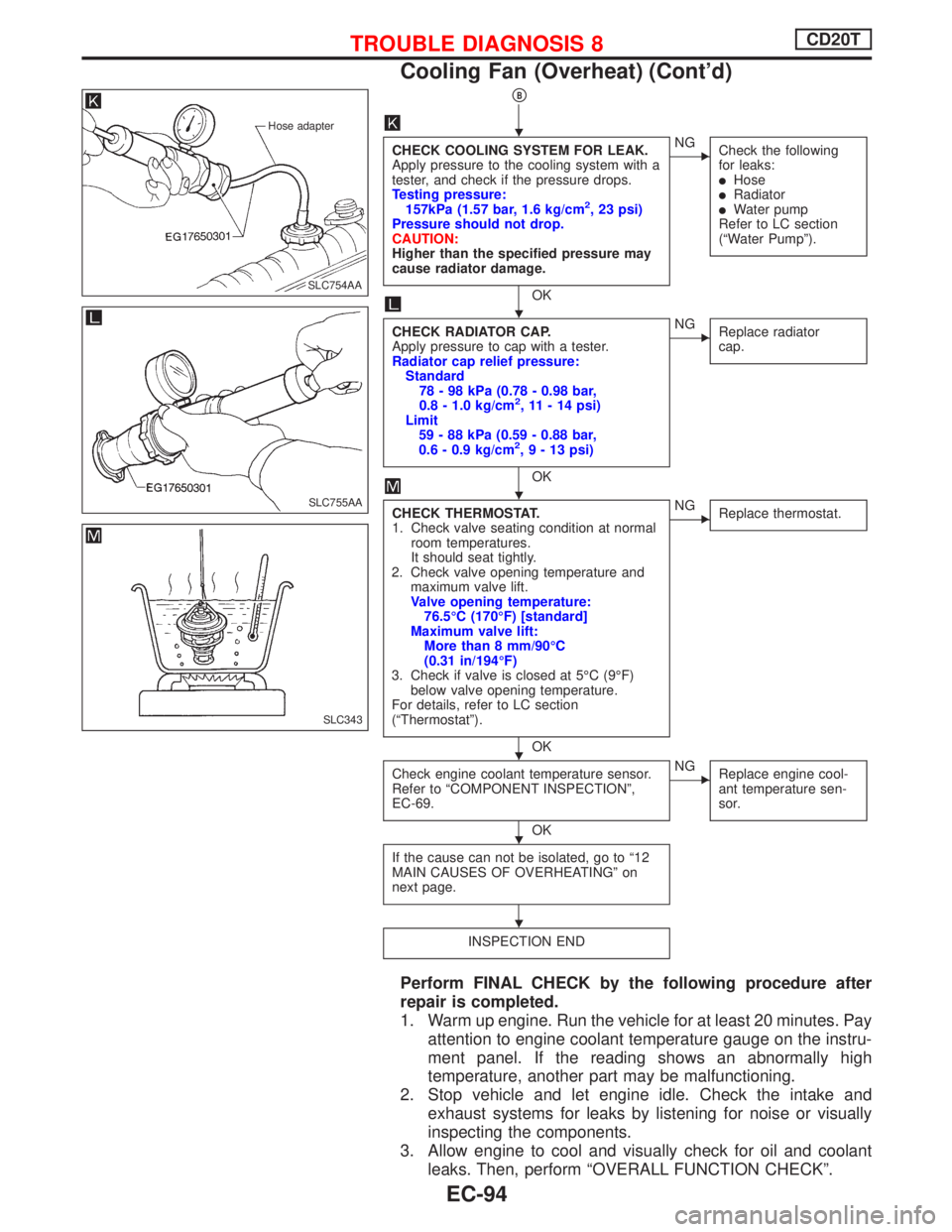

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with a

tester, and check if the pressure drops.

Testing pressure:

157kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

ENG

Check the following

for leaks:

lHoselRadiatorlWater pump

Refer to LC section

(ªWater Pumpº).

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78 - 98 kPa (0.78 - 0.98 bar,

0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59 - 88 kPa (0.59 - 0.88 bar,

0.6 - 0.9 kg/cm

2,9-13psi)

OK

ENG

Replace radiator

cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and

maximum valve lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Maximum valve lift:

More than 8 mm/90ÉC

(0.31 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF)

below valve opening temperature.

For details, refer to LC section

(ªThermostatº).

OK

ENG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ªCOMPONENT INSPECTIONº,

EC-69.

OK

ENG

Replace engine cool-

ant temperature sen-

sor.

If the cause can not be isolated, go to ª12

MAIN CAUSES OF OVERHEATINGº on

next page.

INSPECTION END

Perform FINAL CHECK by the following procedure after

repair is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instru-

ment panel. If the reading shows an abnormally high

temperature, another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and

exhaust systems for leaks by listening for noise or visually

inspecting the components.

3. Allow engine to cool and visually check for oil and coolant

leaks. Then, perform ªOVERALL FUNCTION CHECKº.

Hose adapter

.SLC754AA

SLC755AA

SLC343

H

H

H

H

H

H

TROUBLE DIAGNOSIS 8CD20T

Cooling Fan (Overheat) (Cont'd)

EC-94

Page 447 of 2267

Component Inspection ............................................. 311

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................313

Component Description ...........................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................313

ECM Terminals and Reference Value .....................313

On Board Diagnosis Logic.......................................313

DTC Confirmation Procedure ..................................313

Overall Function Check ...........................................314

Wiring Diagram ........................................................315

Diagnostic Procedure For M/T Models....................316

INJECTOR...................................................................318

Component Description ...........................................318

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................318

ECM Terminals and Reference Value .....................318

Wiring Diagram ........................................................319

Diagnostic Procedure ..............................................320

Component Inspection .............................................322

IGNITION SIGNAL.......................................................323

Component Description ...........................................323

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................323

ECM Terminals and Reference Value .....................323

Wiring Diagram ........................................................324

Diagnostic Procedure ..............................................326

Component Inspection .............................................331

START SIGNAL...........................................................332

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................332

ECM Terminals and Reference Value .....................332

Wiring Diagram ........................................................333

Diagnostic Procedure ..............................................334

FUEL PUMP.................................................................336

System Description ..................................................336

Component Description ...........................................336

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................336

ECM Terminals and Reference Value .....................337

Wiring Diagram ........................................................338

Diagnostic Procedure ..............................................339Component Inspection .............................................341

POWER STEERING OIL PRESSURE SWITCH.........342

Component Description ...........................................342

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................342

ECM Terminals and Reference Value .....................342

Wiring Diagram ........................................................343

Diagnostic Procedure ..............................................344

Component Inspection .............................................346

REFRIGERANT PRESSURE SENSOR......................347

Description ...............................................................347

ECM Terminals and Reference Value .....................347

Wiring Diagram ........................................................348

Diagnostic Procedure ..............................................349

ELECTRICAL LOAD SIGNAL.....................................351

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................351

ECM Terminals and Reference Value .....................351

Wiring Diagram ........................................................352

MI & DATA LINK CONNECTORS...............................354

Wiring Diagram ........................................................354

SERVICE DATA AND SPECIFICATIONS (SDS)........355

Fuel Pressure Regulator..........................................355

Idle Speed and Ignition Timing ................................355

Mass Air Flow Sensor..............................................355

Intake Air Temperature Sensor ................................355

Engine Coolant Temperature Sensor ......................355

Throttle Position Sensor ..........................................355

Heated Oxygen Sensor 1 Heater (Front) ................355

Heated Oxygen Sensor 2 Heater (Rear).................355

Crankshaft Position Sensor (POS) ..........................356

Camshaft Position Sensor (PHASE) .......................356

EGR Volume Control Valve (If so equipped)...........356

EGR Temperature Sensor (If so equipped).............356

EVAP Canister Purge Volume Control Valve ..........356

IACV-AAC Valve ......................................................356

Injector .....................................................................356

Ignition Coil with Power Transistor ..........................357

Fuel Pump ...............................................................357

CONTENTS(Cont'd)

EC-5

Page 462 of 2267

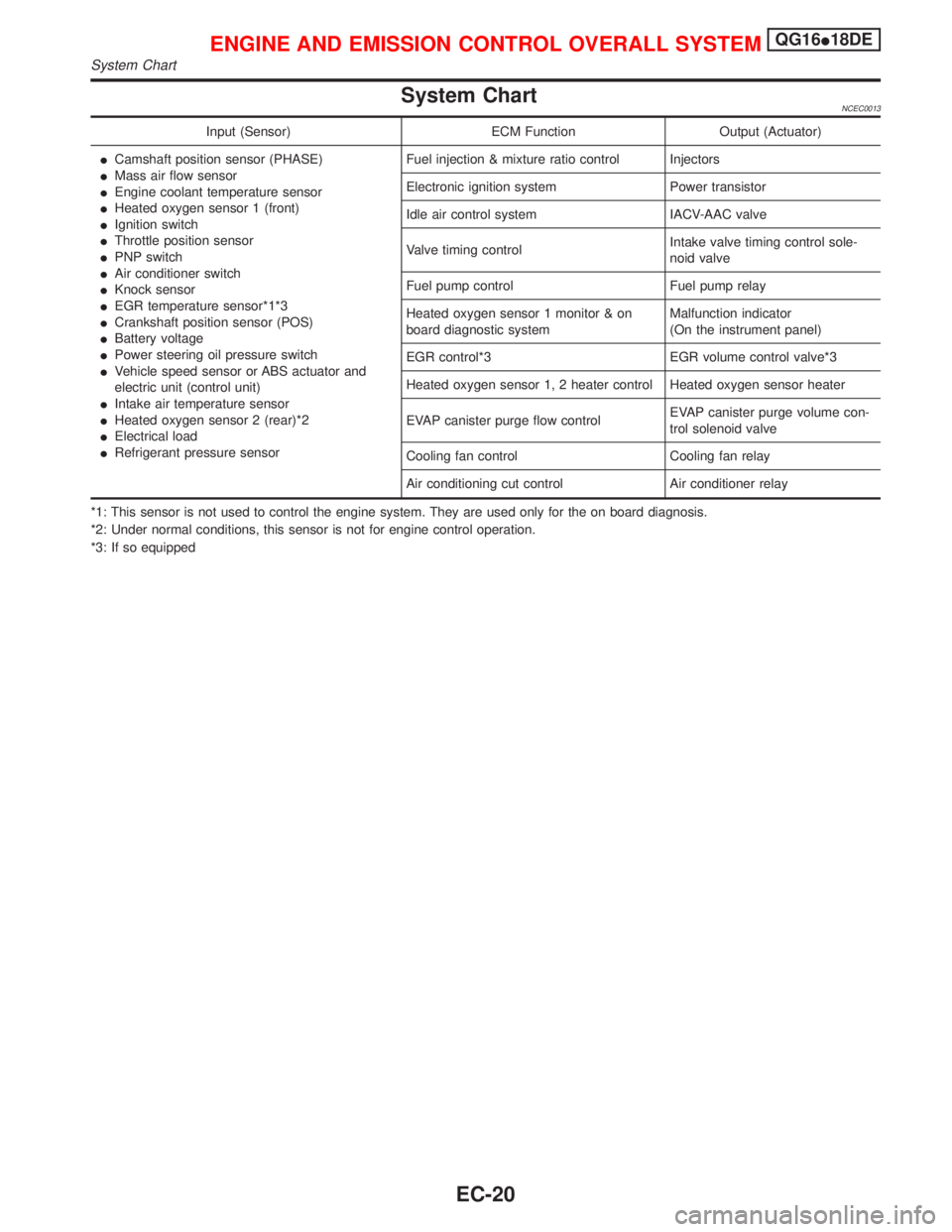

System ChartNCEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor (PHASE)

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IPNP switch

IAir conditioner switch

IKnock sensor

IEGR temperature sensor*1*3

ICrankshaft position sensor (POS)

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor or ABS actuator and

electric unit (control unit)

IIntake air temperature sensor

IHeated oxygen sensor 2 (rear)*2

IElectrical load

IRefrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

Heated oxygen sensor 1 monitor & on

board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control*3 EGR volume control valve*3

Heated oxygen sensor 1, 2 heater control Heated oxygen sensor heater

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

*1: This sensor is not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: If so equipped

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG16I18DE

System Chart

EC-20

Page 463 of 2267

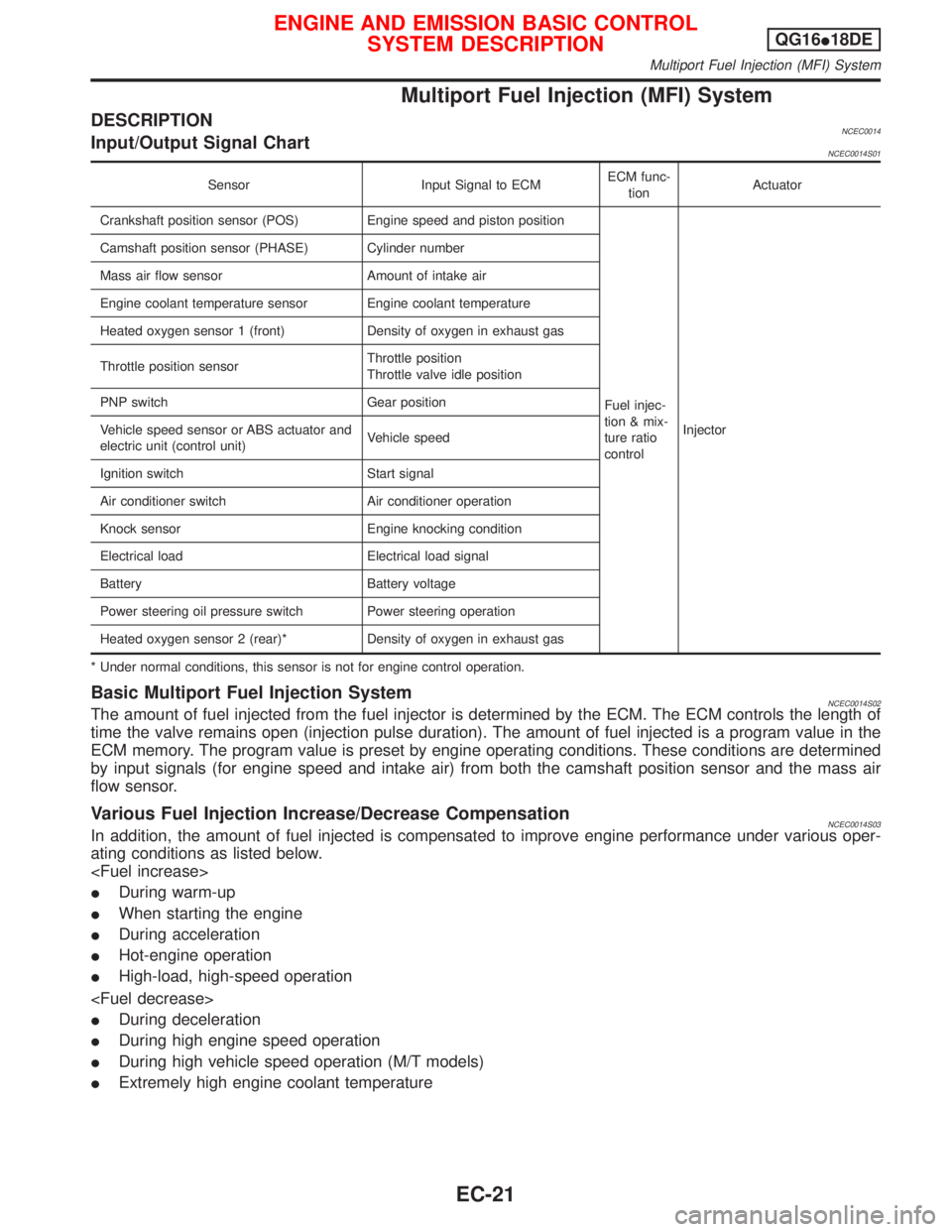

Multiport Fuel Injection (MFI) System

DESCRIPTIONNCEC0014Input/Output Signal ChartNCEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed and piston position

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNCEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNCEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

IDuring warm-up

IWhen starting the engine

IDuring acceleration

IHot-engine operation

IHigh-load, high-speed operation

IDuring deceleration

IDuring high engine speed operation

IDuring high vehicle speed operation (M/T models)

IExtremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONQG16I18DE

Multiport Fuel Injection (MFI) System

EC-21

Page 466 of 2267

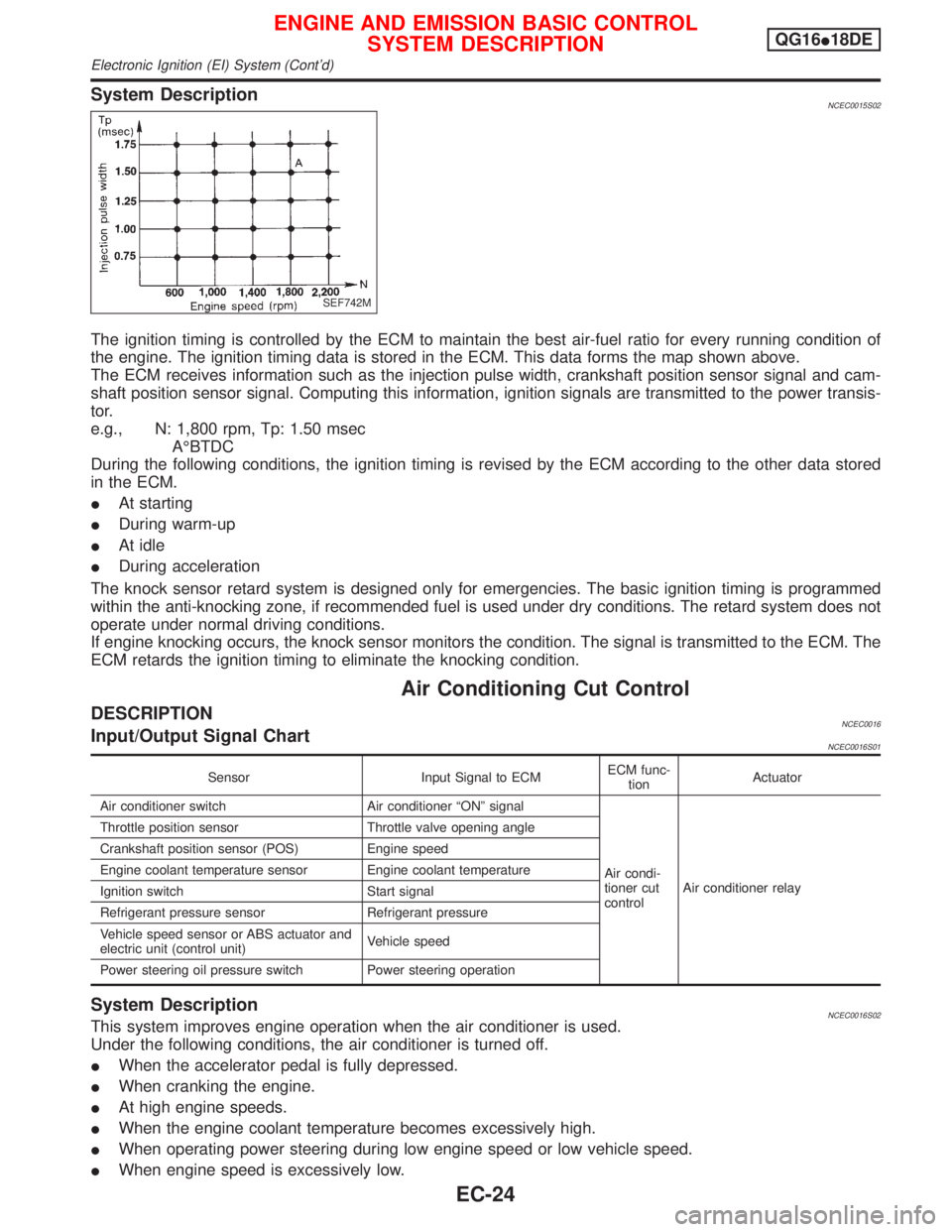

System DescriptionNCEC0015S02

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width, crankshaft position sensor signal and cam-

shaft position sensor signal. Computing this information, ignition signals are transmitted to the power transis-

tor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

IAt starting

IDuring warm-up

IAt idle

IDuring acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNCEC0016Input/Output Signal ChartNCEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNCEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

IWhen the accelerator pedal is fully depressed.

IWhen cranking the engine.

IAt high engine speeds.

IWhen the engine coolant temperature becomes excessively high.

IWhen operating power steering during low engine speed or low vehicle speed.

IWhen engine speed is excessively low.

SEF742M

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONQG16I18DE

Electronic Ignition (EI) System (Cont'd)

EC-24

Page 472 of 2267

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-QG-30.

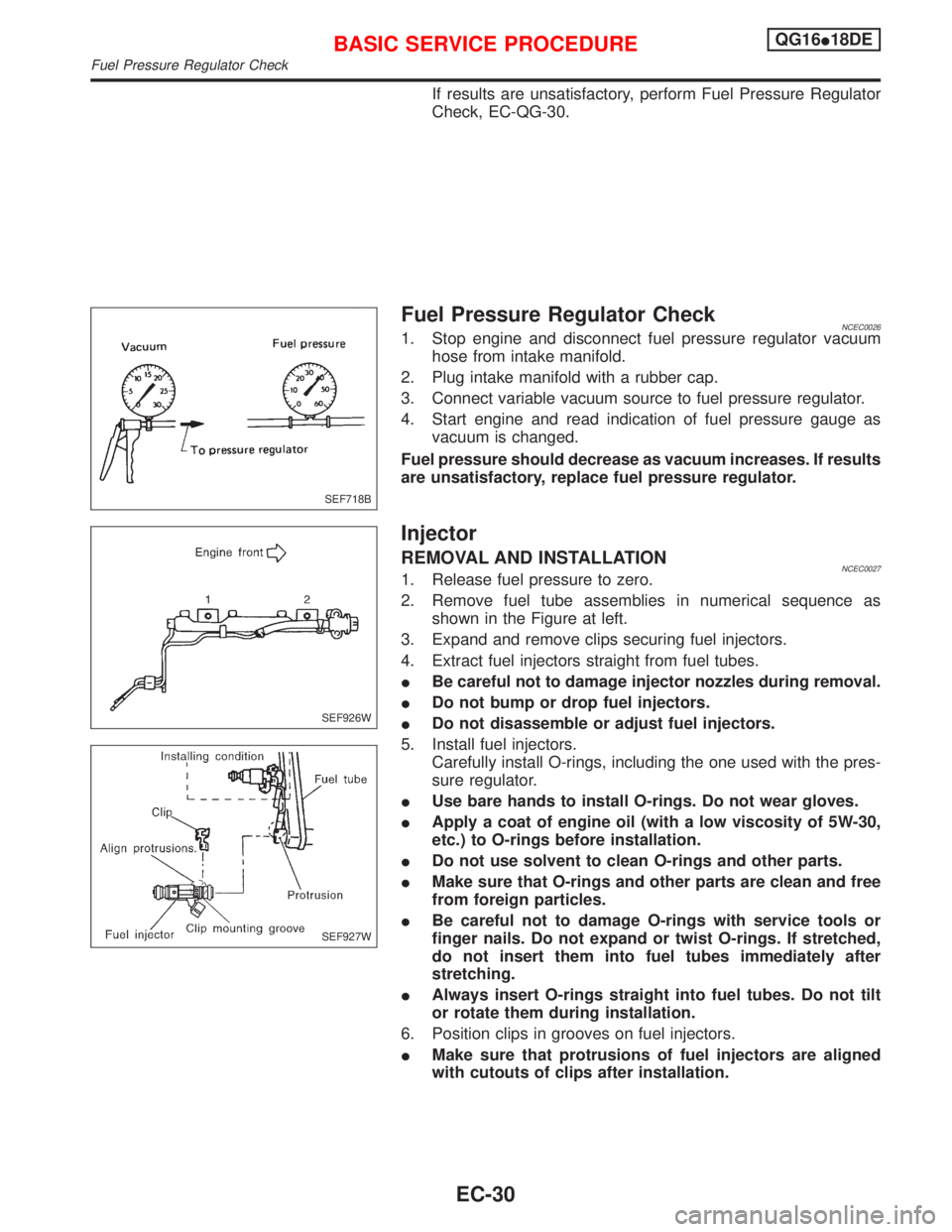

Fuel Pressure Regulator CheckNCEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

Injector

REMOVAL AND INSTALLATIONNCEC00271. Release fuel pressure to zero.

2. Remove fuel tube assemblies in numerical sequence as

shown in the Figure at left.

3. Expand and remove clips securing fuel injectors.

4. Extract fuel injectors straight from fuel tubes.

IBe careful not to damage injector nozzles during removal.

IDo not bump or drop fuel injectors.

IDo not disassemble or adjust fuel injectors.

5. Install fuel injectors.

Carefully install O-rings, including the one used with the pres-

sure regulator.

IUse bare hands to install O-rings. Do not wear gloves.

IApply a coat of engine oil (with a low viscosity of 5W-30,

etc.) to O-rings before installation.

IDo not use solvent to clean O-rings and other parts.

IMake sure that O-rings and other parts are clean and free

from foreign particles.

IBe careful not to damage O-rings with service tools or

finger nails. Do not expand or twist O-rings. If stretched,

do not insert them into fuel tubes immediately after

stretching.

IAlways insert O-rings straight into fuel tubes. Do not tilt

or rotate them during installation.

6. Position clips in grooves on fuel injectors.

IMake sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

SEF718B

SEF926W

SEF927W

BASIC SERVICE PROCEDUREQG16I18DE

Fuel Pressure Regulator Check

EC-30