sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 875 of 2267

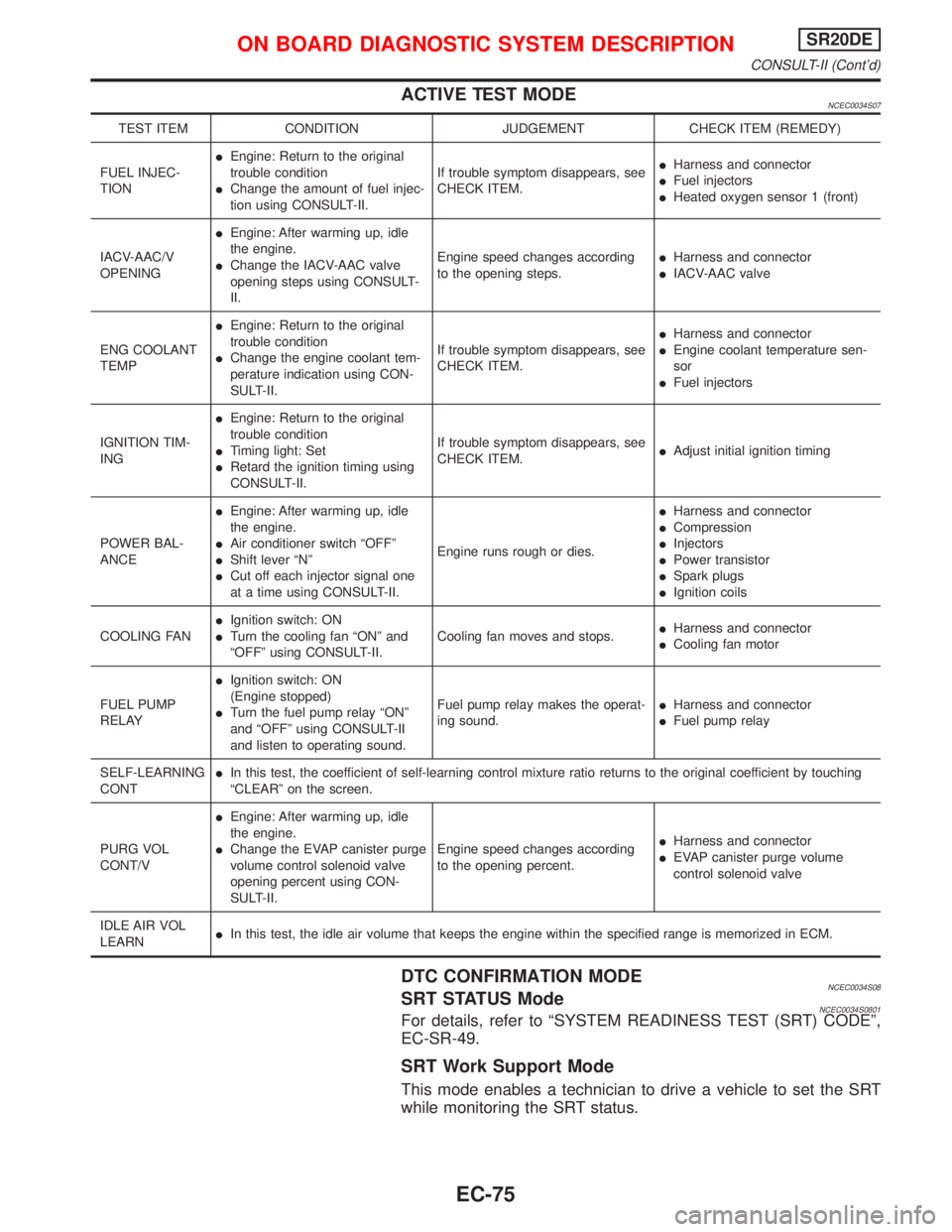

ACTIVE TEST MODENCEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor 1 (front)

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening steps using CONSULT-

II.Engine speed changes according

to the opening steps.IHarness and connector

IIACV-AAC valve

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature indication using CON-

SULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

IGNITION TIM-

INGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IAir conditioner switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

COOLING FANIIgnition switch: ON

ITurn the cooling fan ªONº and

ªOFFº using CONSULT-II.Cooling fan moves and stops.IHarness and connector

ICooling fan motor

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

SELF-LEARNING

CONTIIn this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching

ªCLEARº on the screen.

PURG VOL

CONT/VIEngine: After warming up, idle

the engine.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IEVAP canister purge volume

control solenoid valve

IDLE AIR VOL

LEARNIIn this test, the idle air volume that keeps the engine within the specified range is memorized in ECM.

DTC CONFIRMATION MODENCEC0034S08SRT STATUS ModeNCEC0034S0801For details, refer to ªSYSTEM READINESS TEST (SRT) CODEº,

EC-SR-49.

SRT Work Support Mode

This mode enables a technician to drive a vehicle to set the SRT

while monitoring the SRT status.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

CONSULT-II (Cont'd)

EC-75

Page 876 of 2267

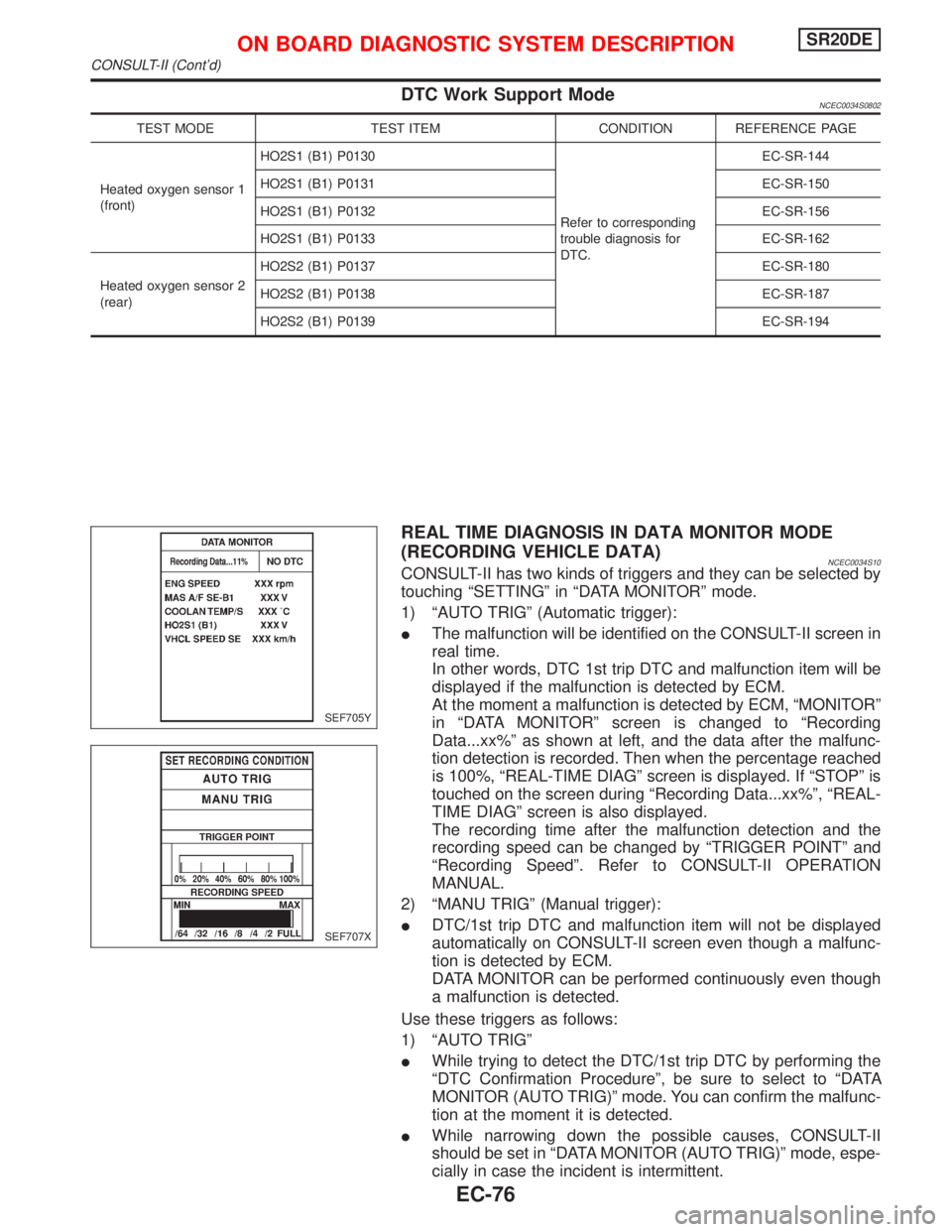

DTC Work Support ModeNCEC0034S0802

TEST MODE TEST ITEM CONDITION REFERENCE PAGE

Heated oxygen sensor 1

(front)HO2S1 (B1) P0130

Refer to corresponding

trouble diagnosis for

DTC.EC-SR-144

HO2S1 (B1) P0131 EC-SR-150

HO2S1 (B1) P0132 EC-SR-156

HO2S1 (B1) P0133 EC-SR-162

Heated oxygen sensor 2

(rear)HO2S2 (B1) P0137 EC-SR-180

HO2S2 (B1) P0138 EC-SR-187

HO2S2 (B1) P0139 EC-SR-194

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

(RECORDING VEHICLE DATA)

NCEC0034S10CONSULT-II has two kinds of triggers and they can be selected by

touching ªSETTINGº in ªDATA MONITORº mode.

1) ªAUTO TRIGº (Automatic trigger):

IThe malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC 1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, ªMONITORº

in ªDATA MONITORº screen is changed to ªRecording

Data...xx%º as shown at left, and the data after the malfunc-

tion detection is recorded. Then when the percentage reached

is 100%, ªREAL-TIME DIAGº screen is displayed. If ªSTOPº is

touched on the screen during ªRecording Data...xx%º, ªREAL-

TIME DIAGº screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by ªTRIGGER POINTº and

ªRecording Speedº. Refer to CONSULT-II OPERATION

MANUAL.

2) ªMANU TRIGº (Manual trigger):

IDTC/1st trip DTC and malfunction item will not be displayed

automatically on CONSULT-II screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Use these triggers as follows:

1) ªAUTO TRIGº

IWhile trying to detect the DTC/1st trip DTC by performing the

ªDTC Confirmation Procedureº, be sure to select to ªDATA

MONITOR (AUTO TRIG)º mode. You can confirm the malfunc-

tion at the moment it is detected.

IWhile narrowing down the possible causes, CONSULT-II

should be set in ªDATA MONITOR (AUTO TRIG)º mode, espe-

cially in case the incident is intermittent.

SEF705Y

SEF707X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

CONSULT-II (Cont'd)

EC-76

Page 880 of 2267

IntroductionNCEC0036The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-SR-82.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

DIAGNOSTIC WORKSHEETNCEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the malfunction indicator to come on

steady or blink and DTC to be detected.

Example:

Vehicle ran out of fuel, which caused the engine to misfire.

MEF036D

SEF233G

SEF234G

SEF907L

KEY POINTS

WHAT..... Vehicle & engine model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions,

Weather conditions,

Symptoms

TROUBLE DIAGNOSIS Ð INTRODUCTIONSR20DE

Introduction

EC-80

Page 883 of 2267

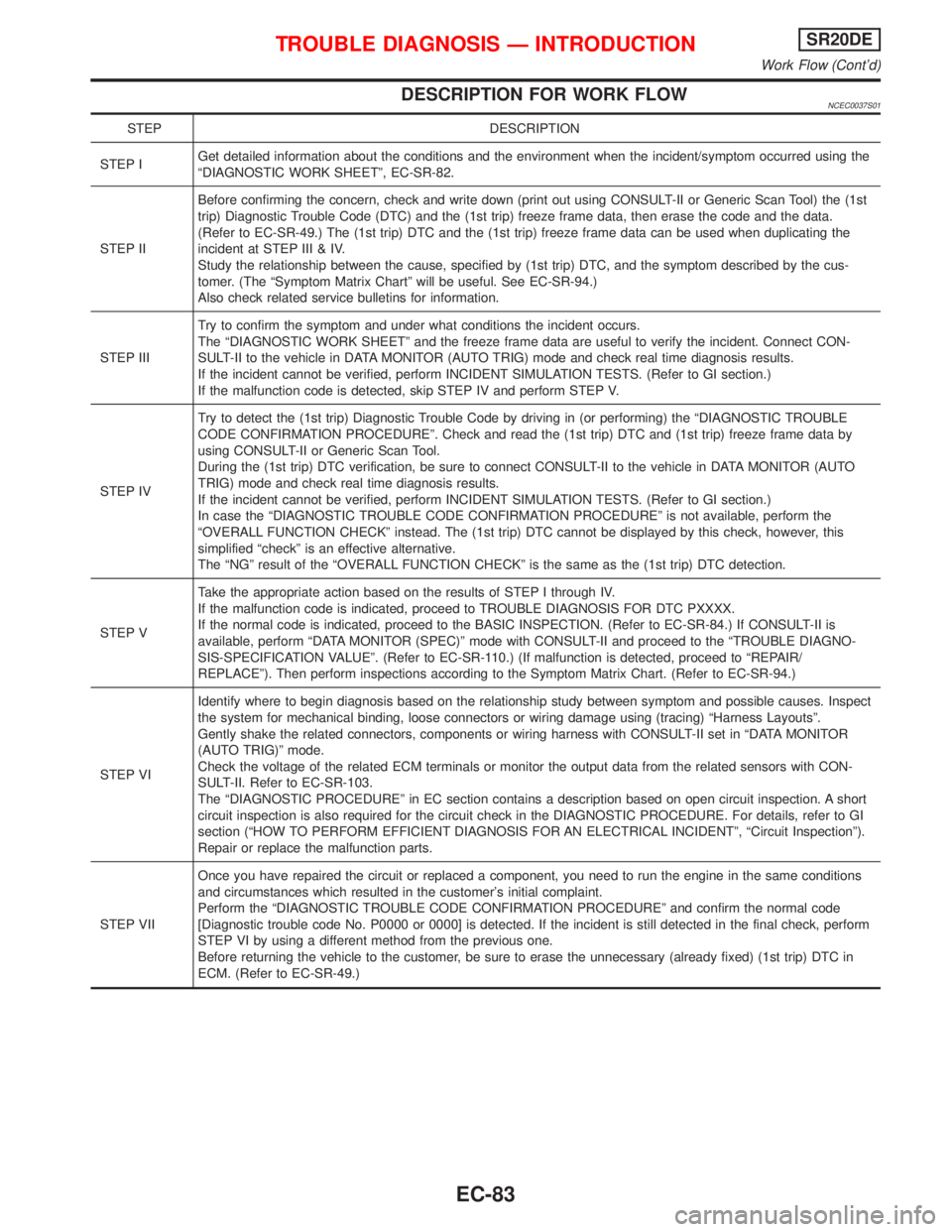

DESCRIPTION FOR WORK FLOWNCEC0037S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

ªDIAGNOSTIC WORK SHEETº, EC-SR-82.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or Generic Scan Tool) the (1st

trip) Diagnostic Trouble Code (DTC) and the (1st trip) freeze frame data, then erase the code and the data.

(Refer to EC-SR-49.) The (1st trip) DTC and the (1st trip) freeze frame data can be used when duplicating the

incident at STEP III & IV.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-SR-94.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) Diagnostic Trouble Code by driving in (or performing) the ªDIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCEDUREº. Check and read the (1st trip) DTC and (1st trip) freeze frame data by

using CONSULT-II or Generic Scan Tool.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

In case the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº is not available, perform the

ªOVERALL FUNCTION CHECKº instead. The (1st trip) DTC cannot be displayed by this check, however, this

simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOVERALL FUNCTION CHECKº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-SR-84.) If CONSULT-II is

available, perform ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNO-

SIS-SPECIFICATION VALUEº. (Refer to EC-SR-110.) (If malfunction is detected, proceed to ªREPAIR/

REPLACEº). Then perform inspections according to the Symptom Matrix Chart. (Refer to EC-SR-94.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect

the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-SR-103.

The ªDIAGNOSTIC PROCEDUREº in EC section contains a description based on open circuit inspection. A short

circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE. For details, refer to GI

section (ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº, ªCircuit Inspectionº).

Repair or replace the malfunction parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº and confirm the normal code

[Diagnostic trouble code No. P0000 or 0000] is detected. If the incident is still detected in the final check, perform

STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM. (Refer to EC-SR-49.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONSR20DE

Work Flow (Cont'd)

EC-83

Page 885 of 2267

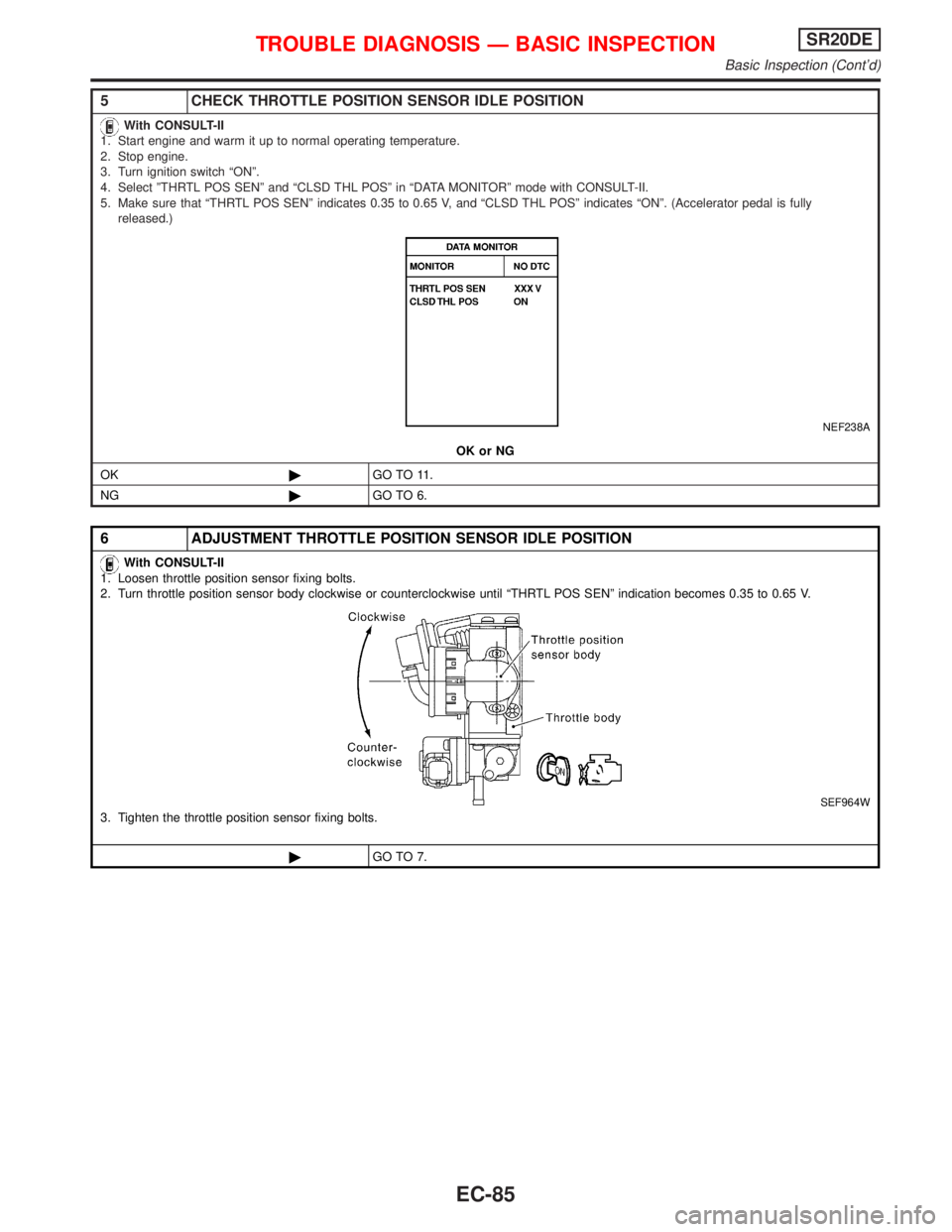

5 CHECK THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ºTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65 V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is fully

released.)

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

6 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-85

Page 886 of 2267

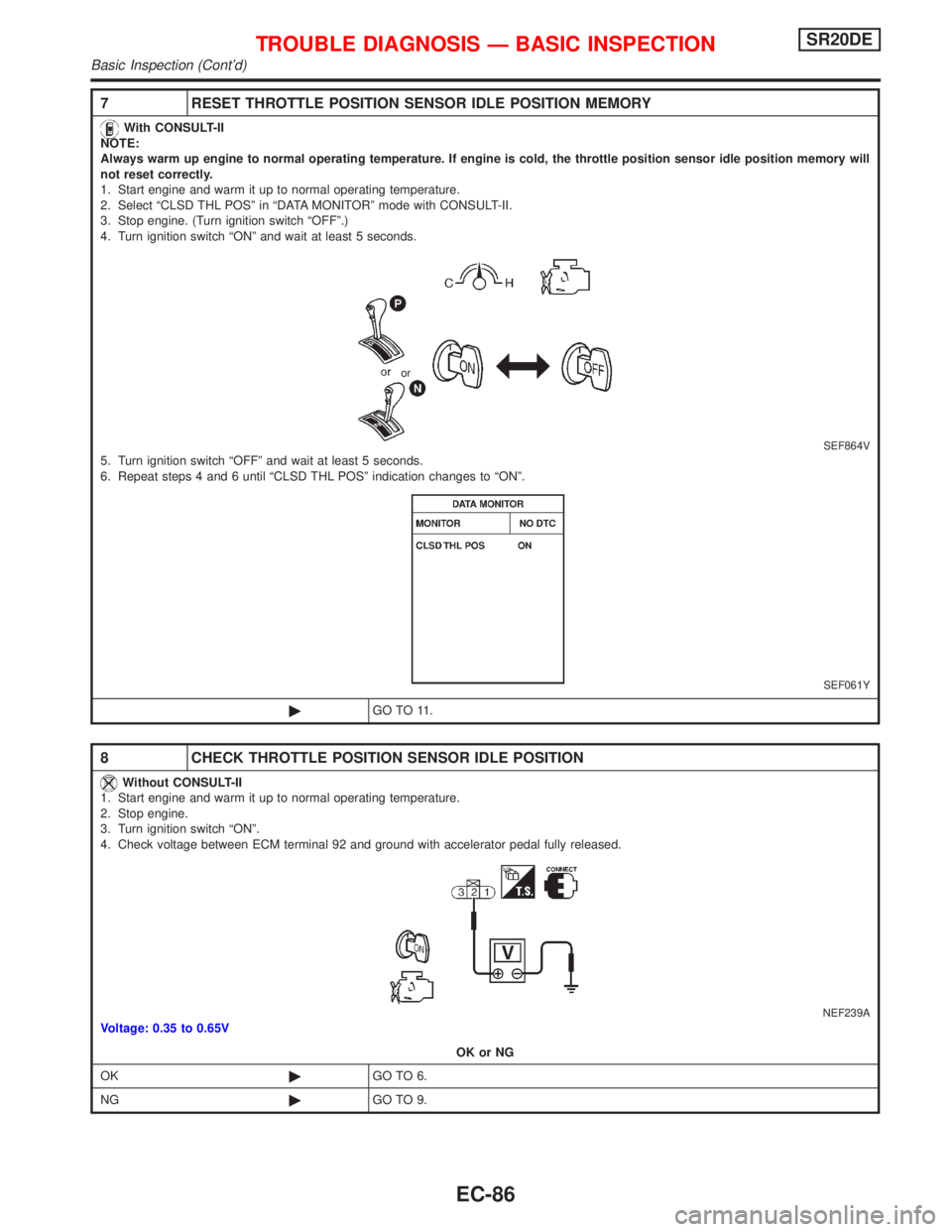

7 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cold, the throttle position sensor idle position memory will

not reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Select ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V5. Turn ignition switch ªOFFº and wait at least 5 seconds.

6. Repeat steps 4 and 6 until ªCLSD THL POSº indication changes to ªONº.

SEF061Y

©GO TO 11.

8 CHECK THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 92 and ground with accelerator pedal fully released.

NEF239AVoltage: 0.35 to 0.65V

OK or NG

OK©GO TO 6.

NG©GO TO 9.

or

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-86

Page 887 of 2267

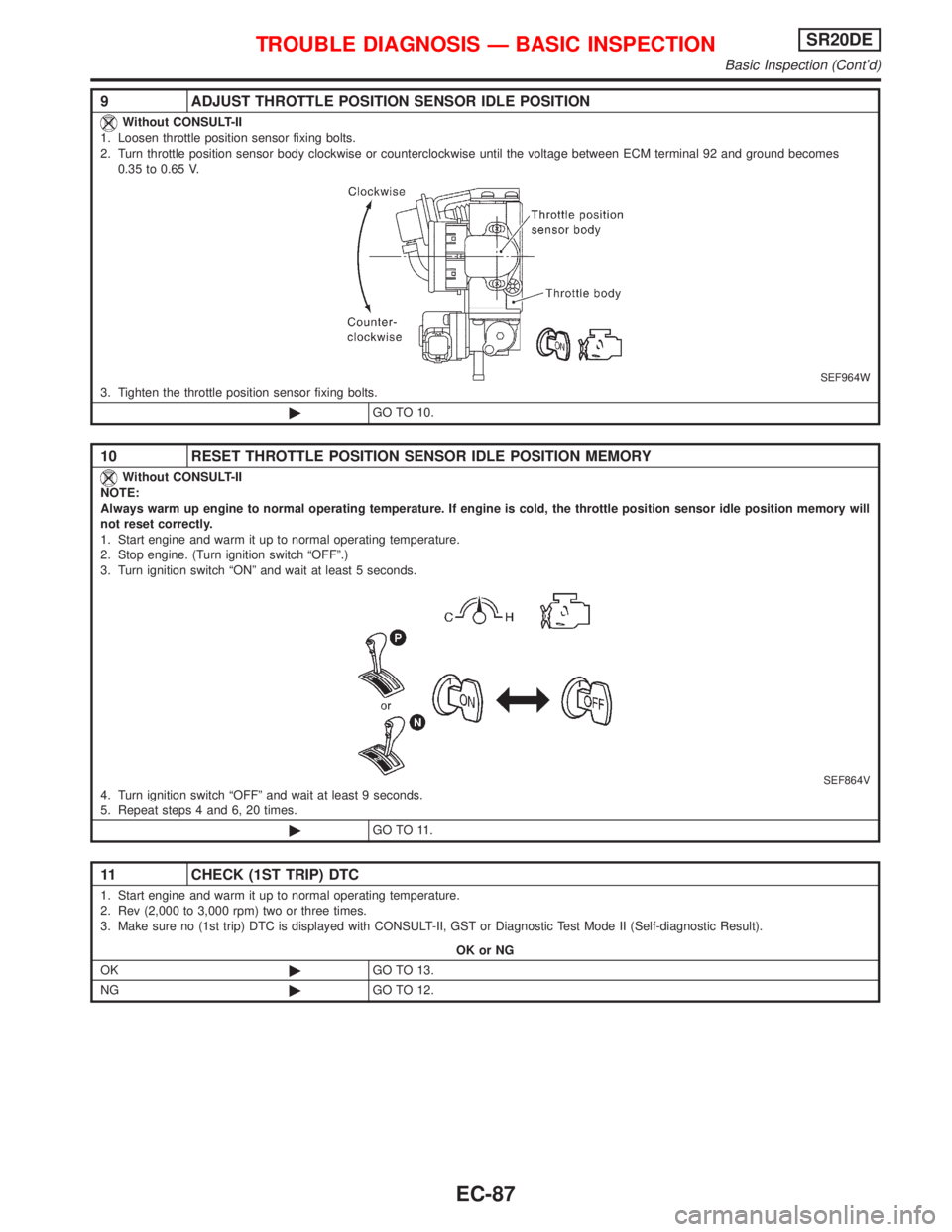

9 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground becomes

0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cold, the throttle position sensor idle position memory will

not reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº.)

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II, GST or Diagnostic Test Mode II (Self-diagnostic Result).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-87

Page 892 of 2267

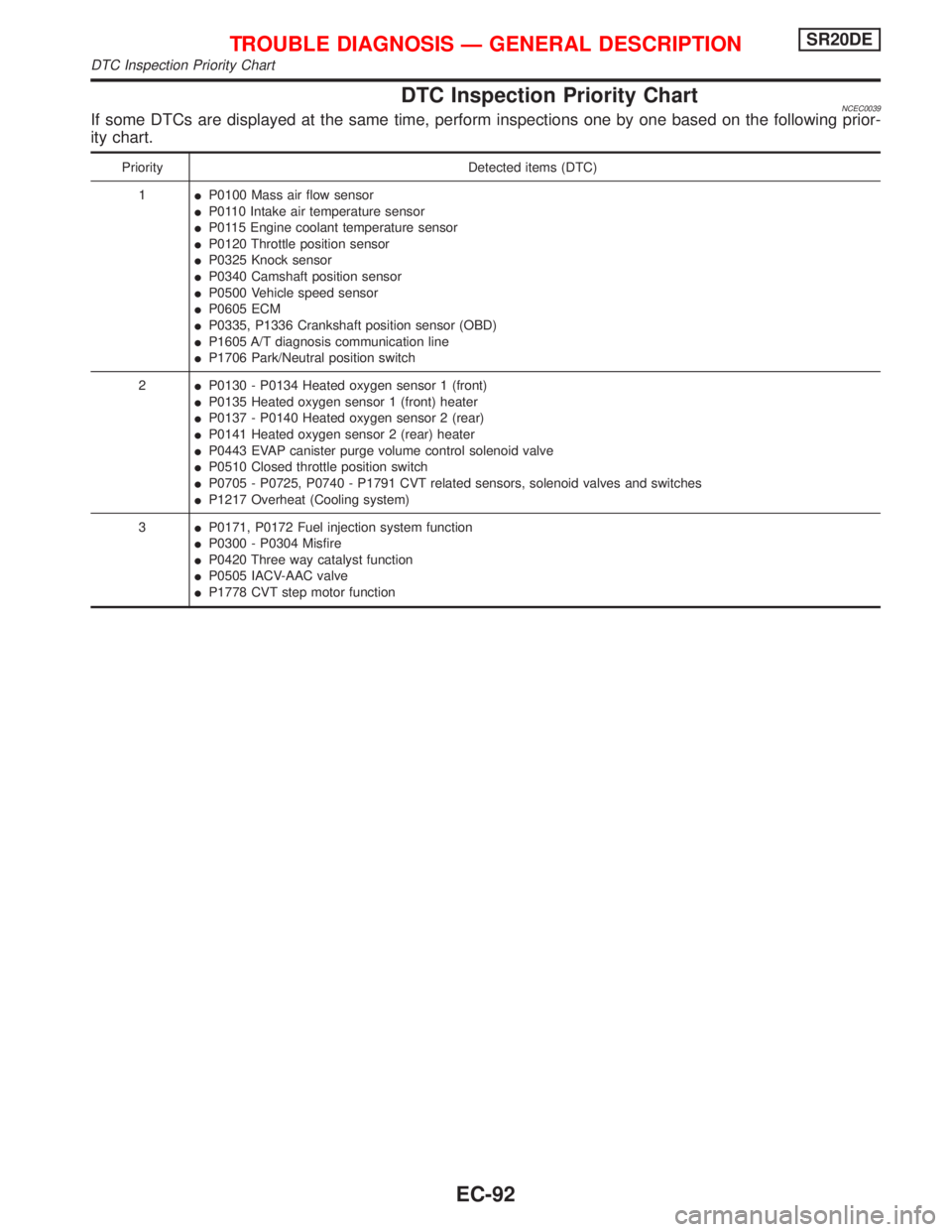

DTC Inspection Priority ChartNCEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0325 Knock sensor

IP0340 Camshaft position sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP0335, P1336 Crankshaft position sensor (OBD)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position switch

2IP0130 - P0134 Heated oxygen sensor 1 (front)

IP0135 Heated oxygen sensor 1 (front) heater

IP0137 - P0140 Heated oxygen sensor 2 (rear)

IP0141 Heated oxygen sensor 2 (rear) heater

IP0443 EVAP canister purge volume control solenoid valve

IP0510 Closed throttle position switch

IP0705 - P0725, P0740 - P1791 CVT related sensors, solenoid valves and switches

IP1217 Overheat (Cooling system)

3IP0171, P0172 Fuel injection system function

IP0300 - P0304 Misfire

IP0420 Three way catalyst function

IP0505 IACV-AAC valve

IP1778 CVT step motor function

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

DTC Inspection Priority Chart

EC-92

Page 893 of 2267

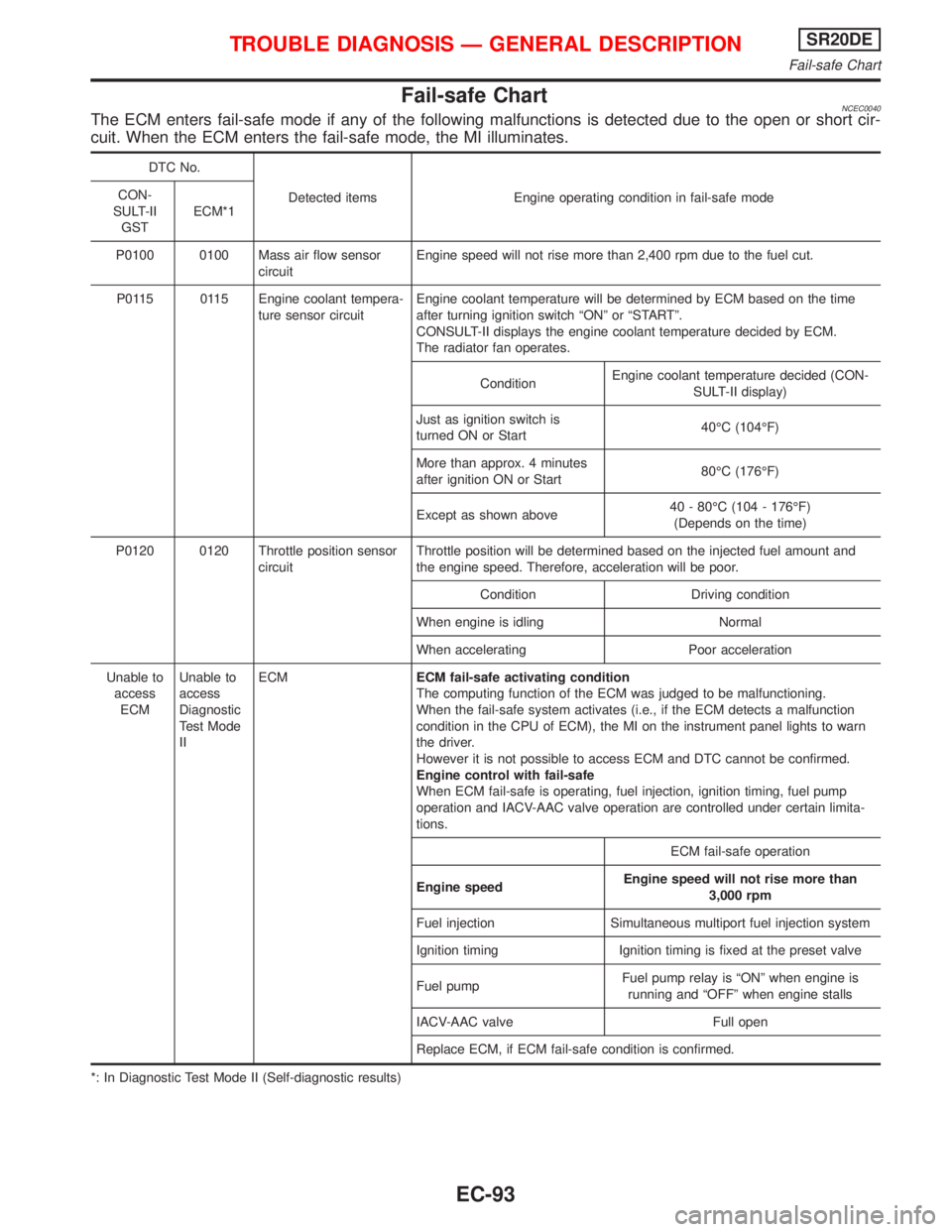

Fail-safe ChartNCEC0040The ECM enters fail-safe mode if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MI illuminates.

DTC No.

Detected items Engine operating condition in fail-safe mode CON-

SULT-II

GSTECM*1

P0100 0100 Mass air flow sensor

circuitEngine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 0115 Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time

after turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

The radiator fan operates.

ConditionEngine coolant temperature decided (CON-

SULT-II display)

Just as ignition switch is

turned ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 0120 Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and

the engine speed. Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

Unable to

access

ECMUnable to

access

Diagnostic

Test Mode

IIECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction

condition in the CPU of ECM), the MI on the instrument panel lights to warn

the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump

operation and IACV-AAC valve operation are controlled under certain limita-

tions.

ECM fail-safe operation

Engine speedEngine speed will not rise more than

3,000 rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is

running and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

*: In Diagnostic Test Mode II (Self-diagnostic results)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

Fail-safe Chart

EC-93

Page 895 of 2267

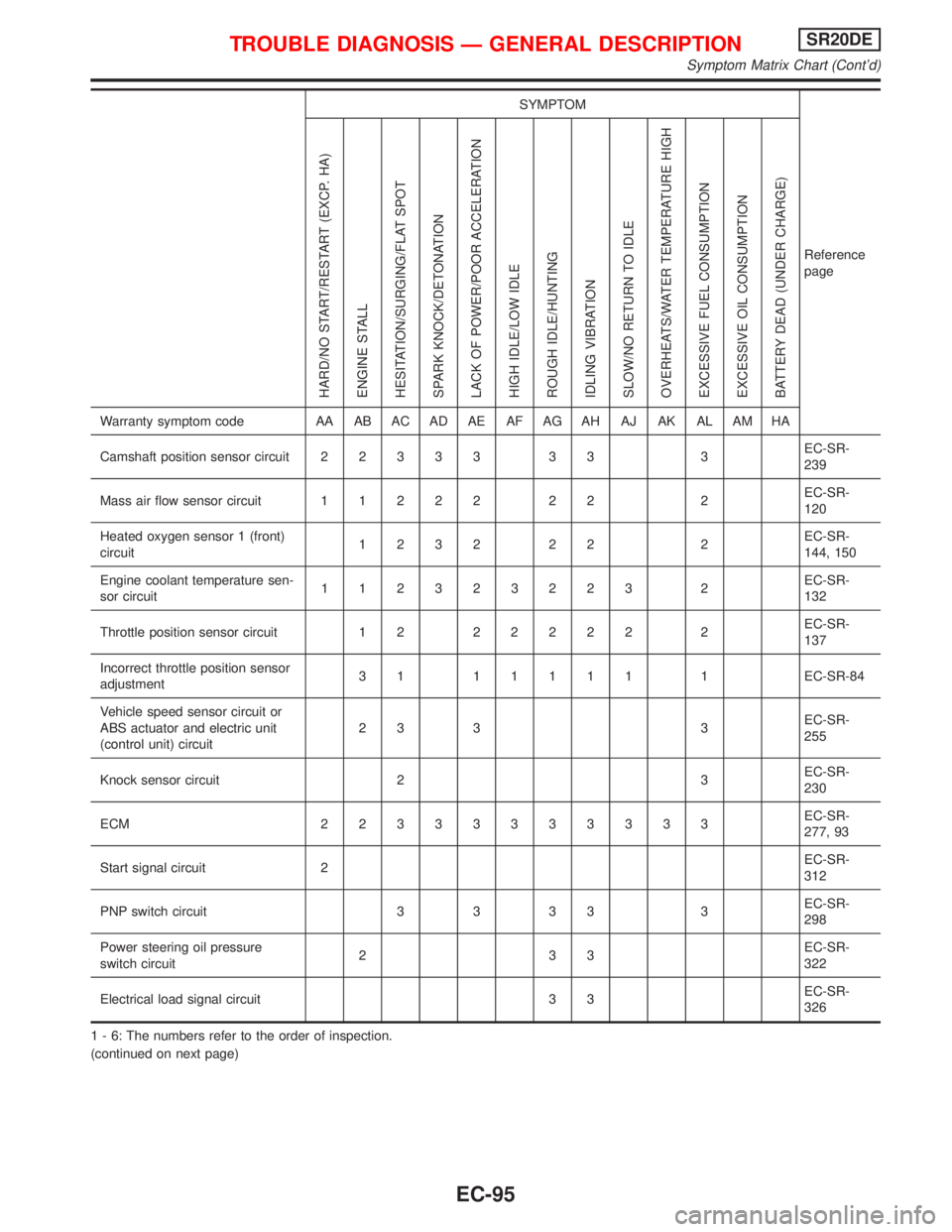

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Camshaft position sensor circuit22333 33 3EC-SR-

239

Mass air flow sensor circuit11222 22 2EC-SR-

120

Heated oxygen sensor 1 (front)

circuit1232 22 2EC-SR-

144, 150

Engine coolant temperature sen-

sor circuit112323223 2EC-SR-

132

Throttle position sensor circuit 1 222222 2EC-SR-

137

Incorrect throttle position sensor

adjustment31 11111 1EC-SR-84

Vehicle speed sensor circuit or

ABS actuator and electric unit

(control unit) circuit23 3 3EC-SR-

255

Knock sensor circuit 2 3EC-SR-

230

ECM 22333333333EC-SR-

277, 93

Start signal circuit 2EC-SR-

312

PNP switch circuit 3 3 3 3 3EC-SR-

298

Power steering oil pressure

switch circuit233EC-SR-

322

Electrical load signal circuit 3 3EC-SR-

326

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

Symptom Matrix Chart (Cont'd)

EC-95