sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 839 of 2267

4 ADJUST IGNITION TIMING

With CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

Without CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

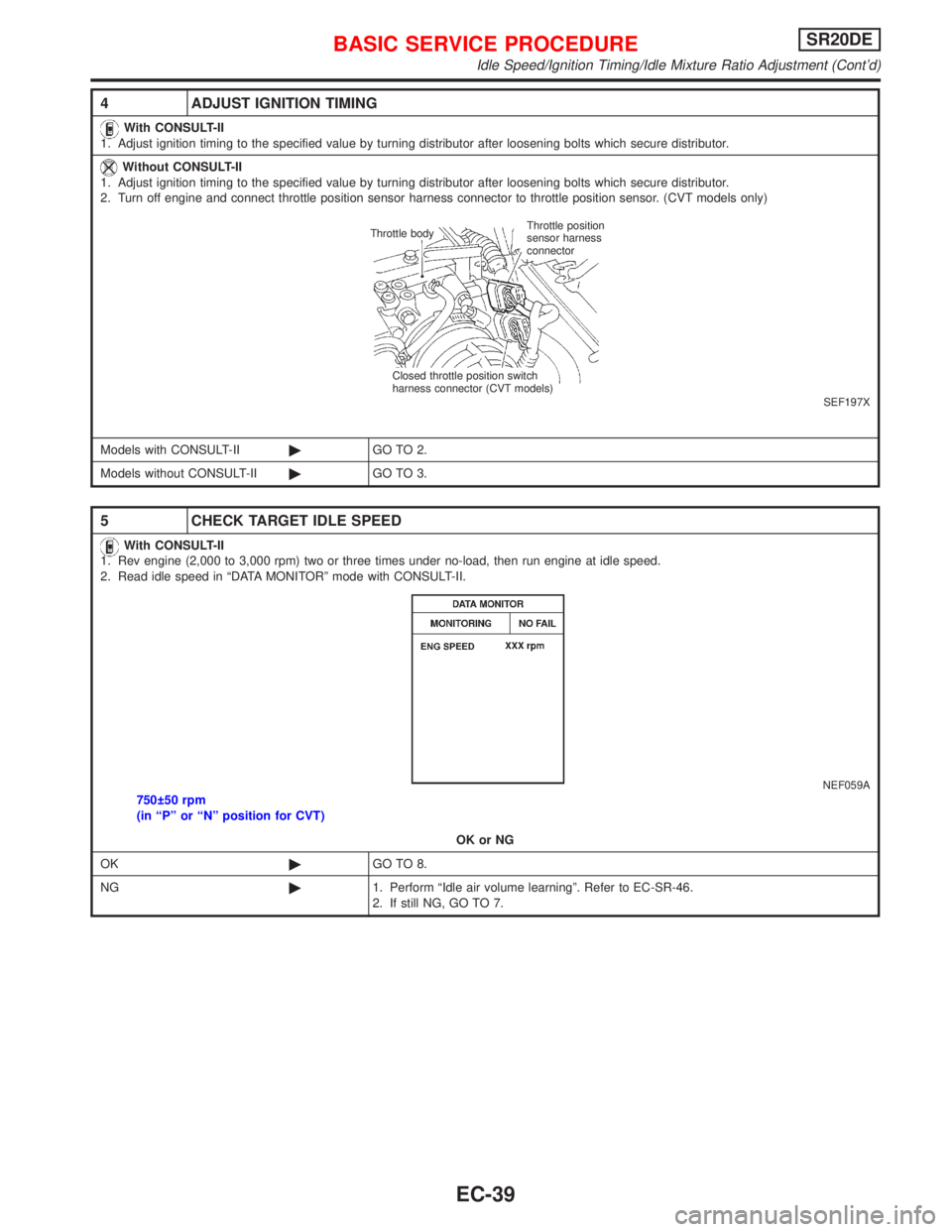

2. Turn off engine and connect throttle position sensor harness connector to throttle position sensor. (CVT models only)

SEF197X

Models with CONSULT-II©GO TO 2.

Models without CONSULT-II©GO TO 3.

5 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

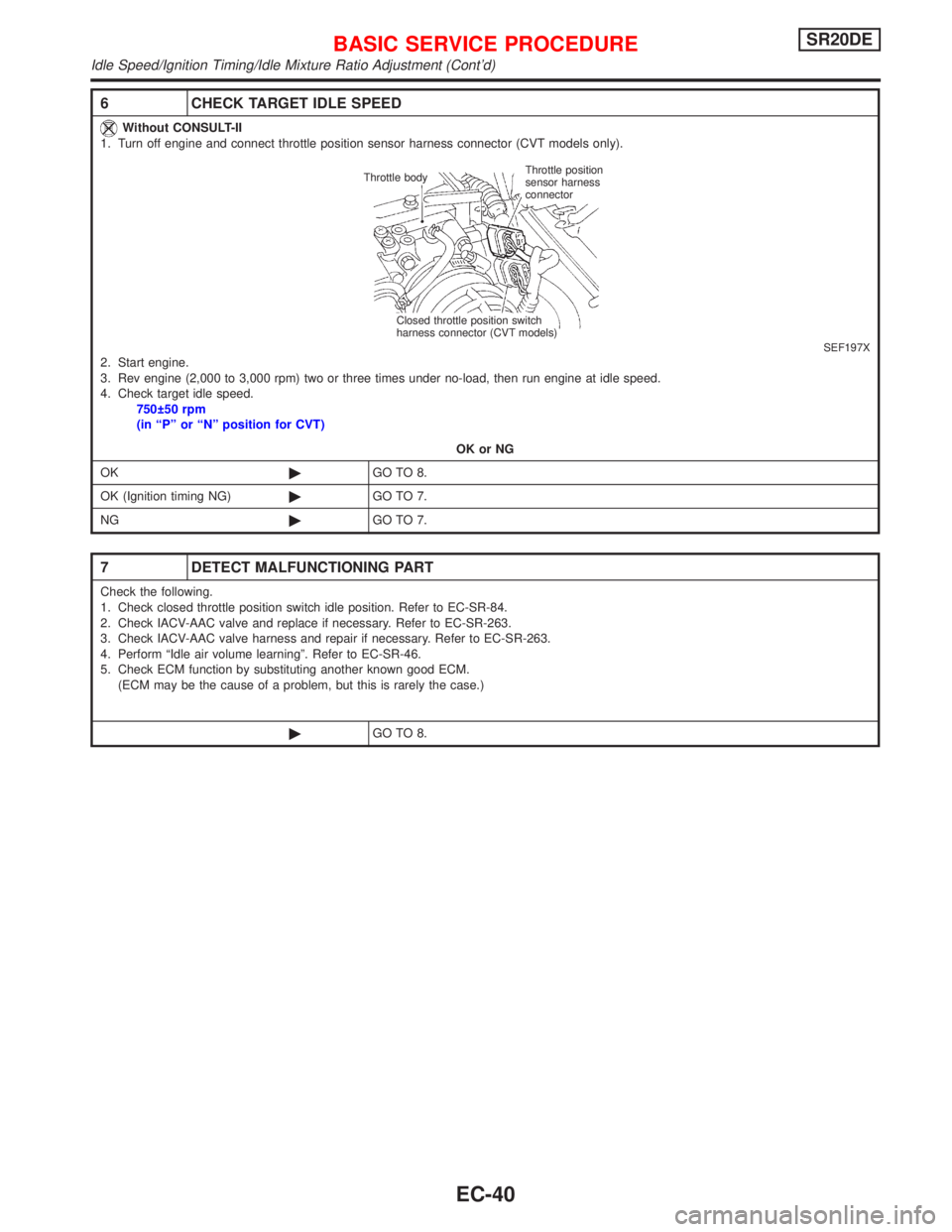

2. Read idle speed in ªDATA MONITORº mode with CONSULT-II.

NEF059A750 50 rpm

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 8.

NG©1. Perform ªIdle air volume learningº. Refer to EC-SR-46.

2. If still NG, GO TO 7.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-39

Page 840 of 2267

6 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Turn off engine and connect throttle position sensor harness connector (CVT models only).

SEF197X2. Start engine.

3. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

4. Check target idle speed.

750 50 rpm

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 8.

OK (Ignition timing NG)©GO TO 7.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Check closed throttle position switch idle position. Refer to EC-SR-84.

2. Check IACV-AAC valve and replace if necessary. Refer to EC-SR-263.

3. Check IACV-AAC valve harness and repair if necessary. Refer to EC-SR-263.

4. Perform ªIdle air volume learningº. Refer to EC-SR-46.

5. Check ECM function by substituting another known good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 8.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-40

Page 841 of 2267

8 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

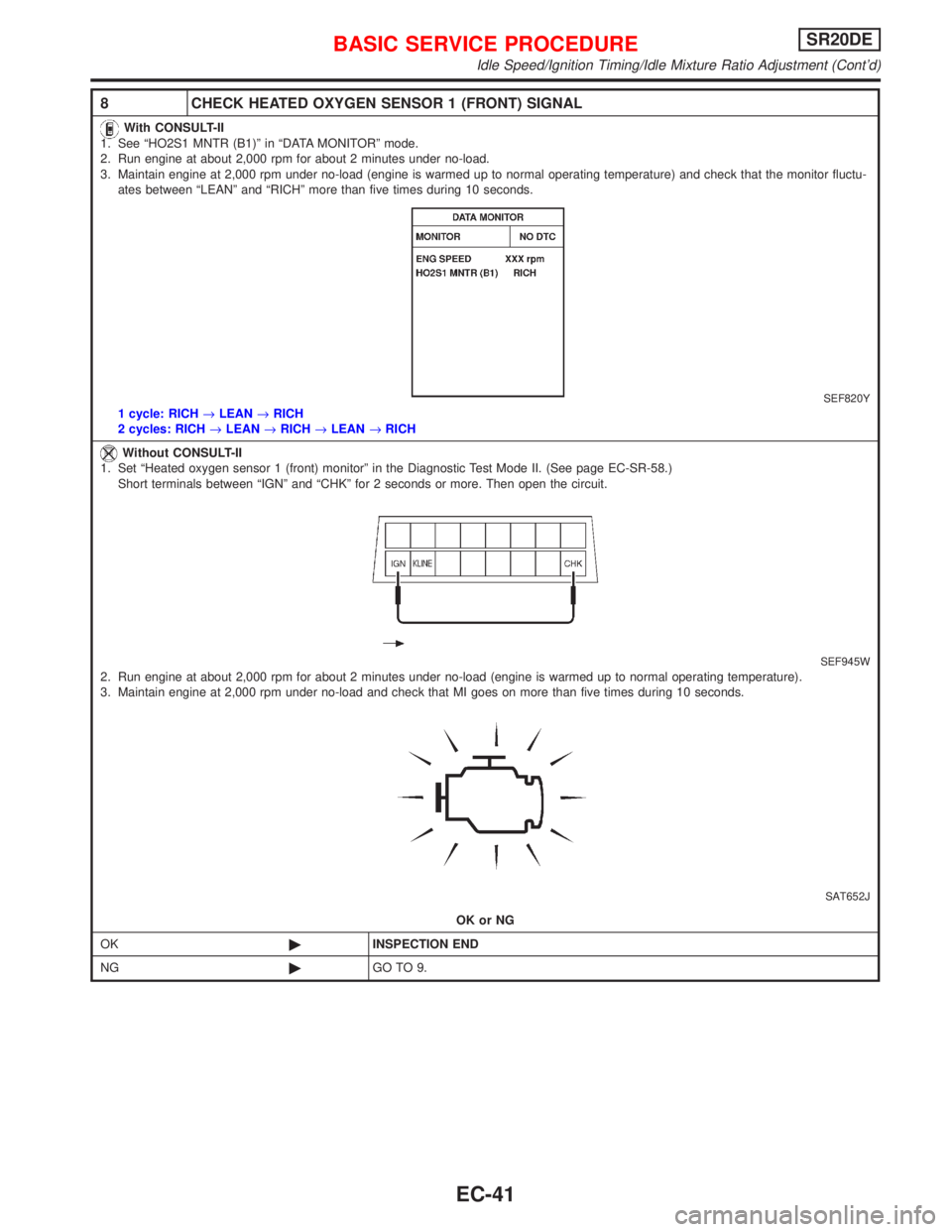

1. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

2. Run engine at about 2,000 rpm for about 2 minutes under no-load.

3. Maintain engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature) and check that the monitor fluctu-

ates between ªLEANº and ªRICHº more than five times during 10 seconds.

SEF820Y1 cycle: RICH®LEAN®RICH

2 cycles: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Set ªHeated oxygen sensor 1 (front) monitorº in the Diagnostic Test Mode II. (See page EC-SR-58.)

Short terminals between ªIGNº and ªCHKº for 2 seconds or more. Then open the circuit.

SEF945W2. Run engine at about 2,000 rpm for about 2 minutes under no-load (engine is warmed up to normal operating temperature).

3. Maintain engine at 2,000 rpm under no-load and check that MI goes on more than five times during 10 seconds.

SAT652J

OK or NG

OK©INSPECTION END

NG©GO TO 9.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-41

Page 842 of 2267

9 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HARNESS

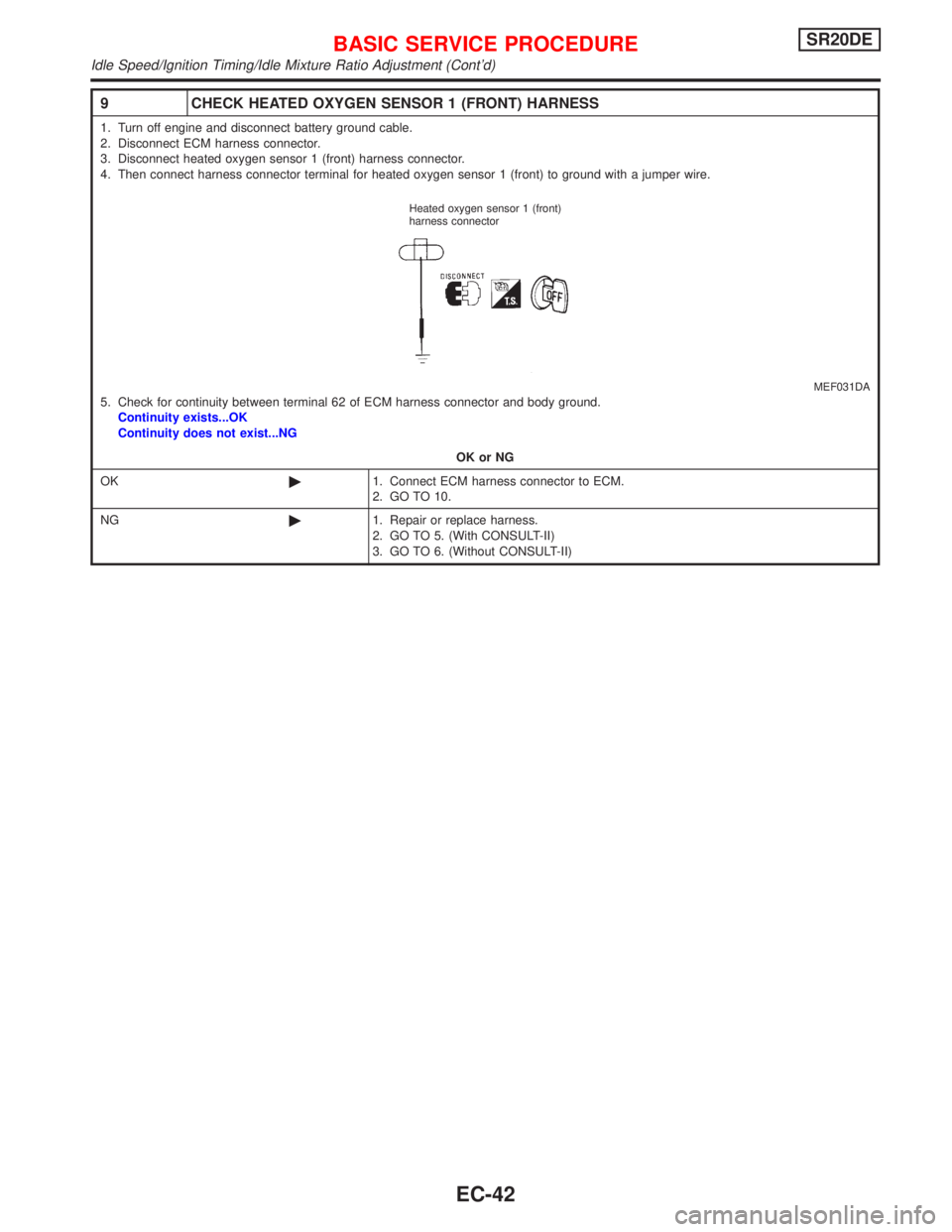

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) harness connector.

4. Then connect harness connector terminal for heated oxygen sensor 1 (front) to ground with a jumper wire.

MEF031DA5. Check for continuity between terminal 62 of ECM harness connector and body ground.

Continuity exists...OK

Continuity does not exist...NG

OK or NG

OK©1. Connect ECM harness connector to ECM.

2. GO TO 10.

NG©1. Repair or replace harness.

2. GO TO 5. (With CONSULT-II)

3. GO TO 6. (Without CONSULT-II)

Heated oxygen sensor 1 (front)

harness connector

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-42

Page 843 of 2267

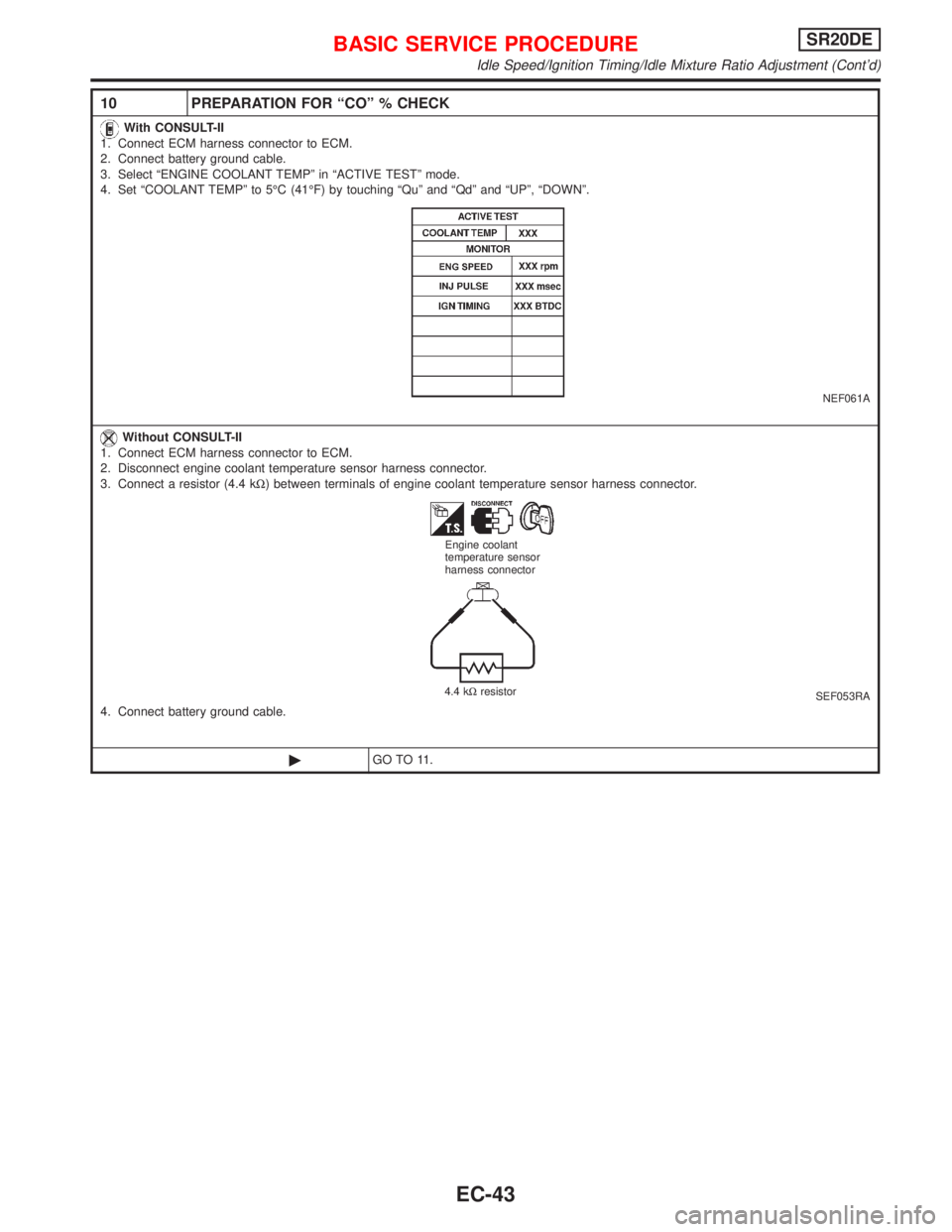

10 PREPARATION FOR ªCOº % CHECK

With CONSULT-II

1. Connect ECM harness connector to ECM.

2. Connect battery ground cable.

3. Select ªENGINE COOLANT TEMPº in ªACTIVE TESTº mode.

4. Set ªCOOLANT TEMPº to 5ÉC (41ÉF) by touching ªQuº and ªQdº and ªUPº, ªDOWNº.

NEF061A

Without CONSULT-II

1. Connect ECM harness connector to ECM.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect a resistor (4.4 kW) between terminals of engine coolant temperature sensor harness connector.

SEF053RA4. Connect battery ground cable.

©GO TO 11.

Engine coolant

temperature sensor

harness connector

4.4 kWresistor

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-43

Page 844 of 2267

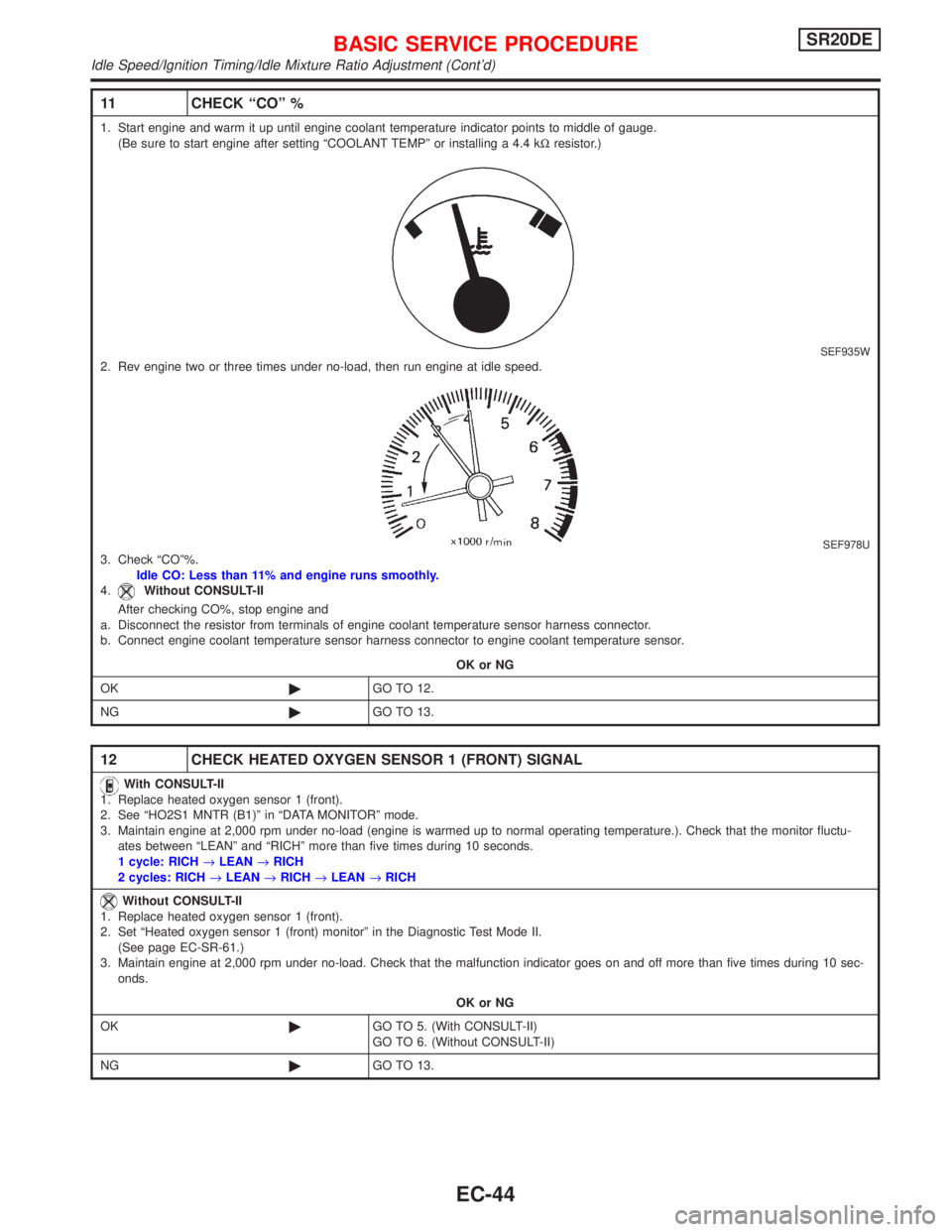

11 CHECK ªCOº %

1. Start engine and warm it up until engine coolant temperature indicator points to middle of gauge.

(Be sure to start engine after setting ªCOOLANT TEMPº or installing a 4.4 kWresistor.)

SEF935W2. Rev engine two or three times under no-load, then run engine at idle speed.

SEF978U3. Check ªCOº%.

Idle CO: Less than 11% and engine runs smoothly.

4.

Without CONSULT-II

After checking CO%, stop engine and

a. Disconnect the resistor from terminals of engine coolant temperature sensor harness connector.

b. Connect engine coolant temperature sensor harness connector to engine coolant temperature sensor.

OK or NG

OK©GO TO 12.

NG©GO TO 13.

12 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Replace heated oxygen sensor 1 (front).

2. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

3. Maintain engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.). Check that the monitor fluctu-

ates between ªLEANº and ªRICHº more than five times during 10 seconds.

1 cycle: RICH®LEAN®RICH

2 cycles: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Replace heated oxygen sensor 1 (front).

2. Set ªHeated oxygen sensor 1 (front) monitorº in the Diagnostic Test Mode II.

(See page EC-SR-61.)

3. Maintain engine at 2,000 rpm under no-load. Check that the malfunction indicator goes on and off more than five times during 10 sec-

onds.

OK or NG

OK©GO TO 5. (With CONSULT-II)

GO TO 6. (Without CONSULT-II)

NG©GO TO 13.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-44

Page 845 of 2267

13 DETECT MALFUNCTIONING PART

1. Connect heated oxygen sensor 1 (front) harness connector to heated oxygen sensor 1 (front).

2. Check fuel pressure regulator. Refer to EC-SR-32.

3. Check mass air flow sensor and its circuit.

Refer to EC-SR-120.

4. Check injector and its circuit.

Refer to EC-SR-302.

Clean or replace if necessary.

5. Check engine coolant temperature sensor and its circuit. Refer to EC-SR-132.

6. Check ECM function by substituting another known good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 5. (With CONSULT-II)

GO TO 6. (Without CONSULT-II)

IIf a vehicle contains a part which is operating outside of

design specifications with no MI illumination, the part

shall not be replaced prior to emission testing unless it is

determined that the part has been tampered with or

abused in such a way that the diagnostic system cannot

reasonably be expected to detect the resulting malfunc-

tion.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-45

Page 847 of 2267

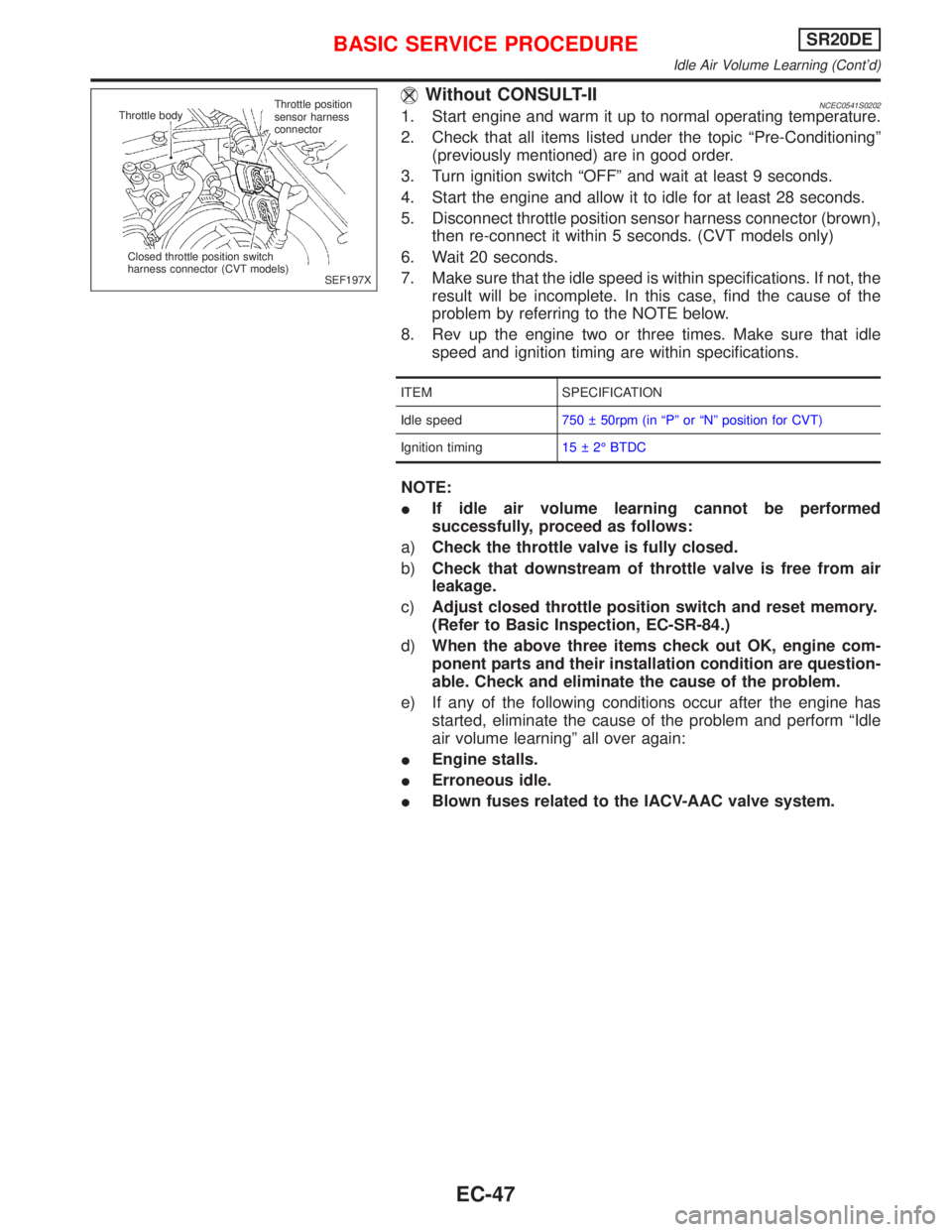

Without CONSULT-IINCEC0541S02021. Start engine and warm it up to normal operating temperature.

2. Check that all items listed under the topic ªPre-Conditioningº

(previously mentioned) are in good order.

3. Turn ignition switch ªOFFº and wait at least 9 seconds.

4. Start the engine and allow it to idle for at least 28 seconds.

5. Disconnect throttle position sensor harness connector (brown),

then re-connect it within 5 seconds. (CVT models only)

6. Wait 20 seconds.

7. Make sure that the idle speed is within specifications. If not, the

result will be incomplete. In this case, find the cause of the

problem by referring to the NOTE below.

8. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed750 50rpm (in ªPº or ªNº position for CVT)

Ignition timing15 2É BTDC

NOTE:

IIf idle air volume learning cannot be performed

successfully, proceed as follows:

a)Check the throttle valve is fully closed.

b)Check that downstream of throttle valve is free from air

leakage.

c)Adjust closed throttle position switch and reset memory.

(Refer to Basic Inspection, EC-SR-84.)

d)When the above three items check out OK, engine com-

ponent parts and their installation condition are question-

able. Check and eliminate the cause of the problem.

e) If any of the following conditions occur after the engine has

started, eliminate the cause of the problem and perform ªIdle

air volume learningº all over again:

IEngine stalls.

IErroneous idle.

IBlown fuses related to the IACV-AAC valve system.

SEF197X

Throttle bodyThrottle position

sensor harness

connector

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Air Volume Learning (Cont'd)

EC-47

Page 848 of 2267

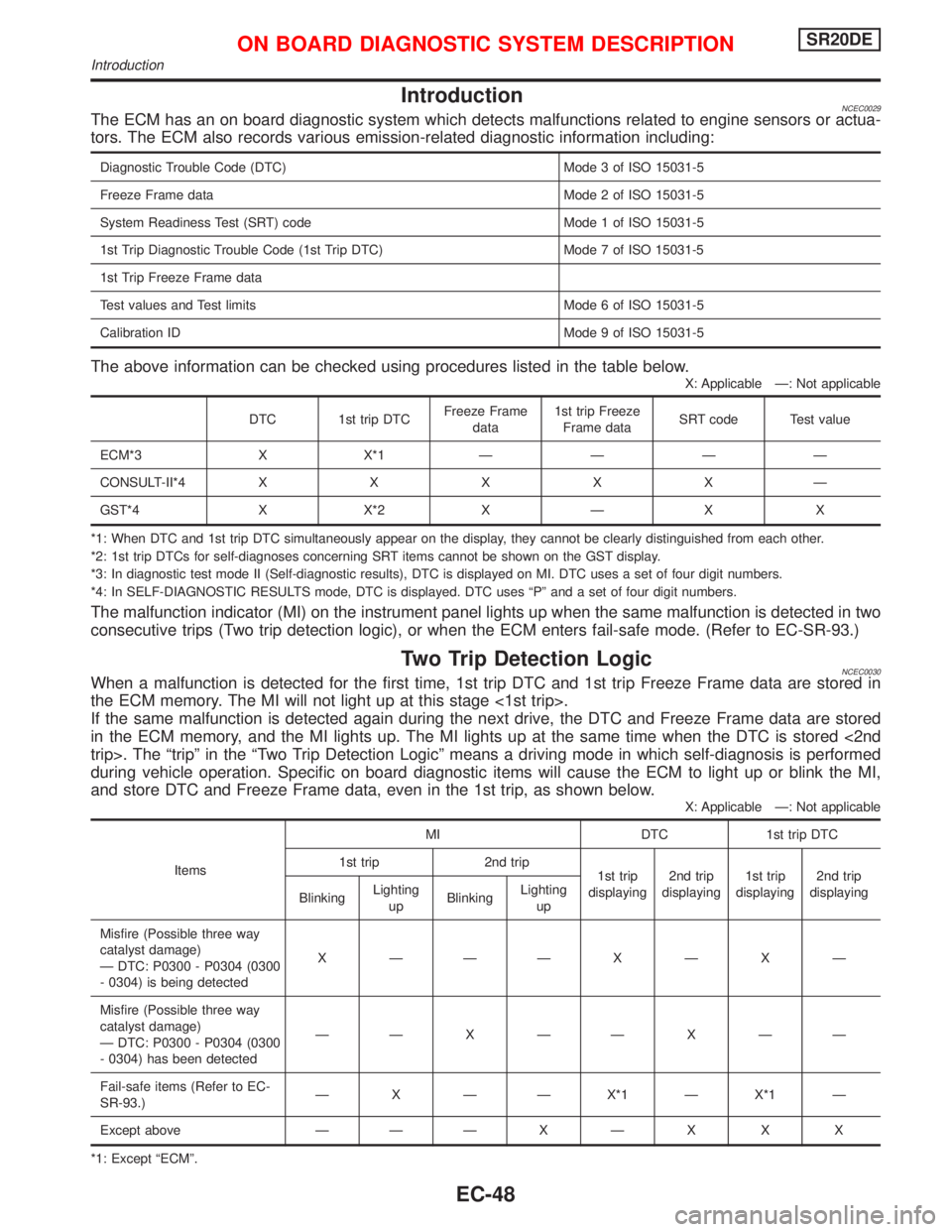

IntroductionNCEC0029The ECM has an on board diagnostic system which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

Diagnostic Trouble Code (DTC) Mode 3 of ISO 15031-5

Freeze Frame data Mode 2 of ISO 15031-5

System Readiness Test (SRT) code Mode 1 of ISO 15031-5

1st Trip Diagnostic Trouble Code (1st Trip DTC) Mode 7 of ISO 15031-5

1st Trip Freeze Frame data

Test values and Test limits Mode 6 of ISO 15031-5

Calibration ID Mode 9 of ISO 15031-5

The above information can be checked using procedures listed in the table below.

X: Applicable Ð: Not applicable

DTC 1st trip DTCFreeze Frame

data1st trip Freeze

Frame dataSRT code Test value

ECM*3 X X*1ÐÐÐÐ

CONSULT-II*4XXXXXÐ

GST*4 X X*2 X Ð X X

*1: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

*2: 1st trip DTCs for self-diagnoses concerning SRT items cannot be shown on the GST display.

*3: In diagnostic test mode II (Self-diagnostic results), DTC is displayed on MI. DTC uses a set of four digit numbers.

*4: In SELF-DIAGNOSTIC RESULTS mode, DTC is displayed. DTC uses ªPº and a set of four digit numbers.

The malfunction indicator (MI) on the instrument panel lights up when the same malfunction is detected in two

consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode. (Refer to EC-SR-93.)

Two Trip Detection LogicNCEC0030When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in

the ECM memory. The MI will not light up at this stage <1st trip>.

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored

in the ECM memory, and the MI lights up. The MI lights up at the same time when the DTC is stored <2nd

trip>. The ªtripº in the ªTwo Trip Detection Logicº means a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic items will cause the ECM to light up or blink the MI,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

X: Applicable Ð: Not applicable

ItemsMI DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

displaying

BlinkingLighting

upBlinkingLighting

up

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 (0300

- 0304) is being detectedXÐÐÐXÐXÐ

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 (0300

- 0304) has been detectedÐÐXÐÐXÐÐ

Fail-safe items (Refer to EC-

SR-93.)Ð X Ð Ð X*1 Ð X*1 Ð

Except above Ð ÐÐXÐX X X

*1: Except ªECMº.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Introduction

EC-48

Page 850 of 2267

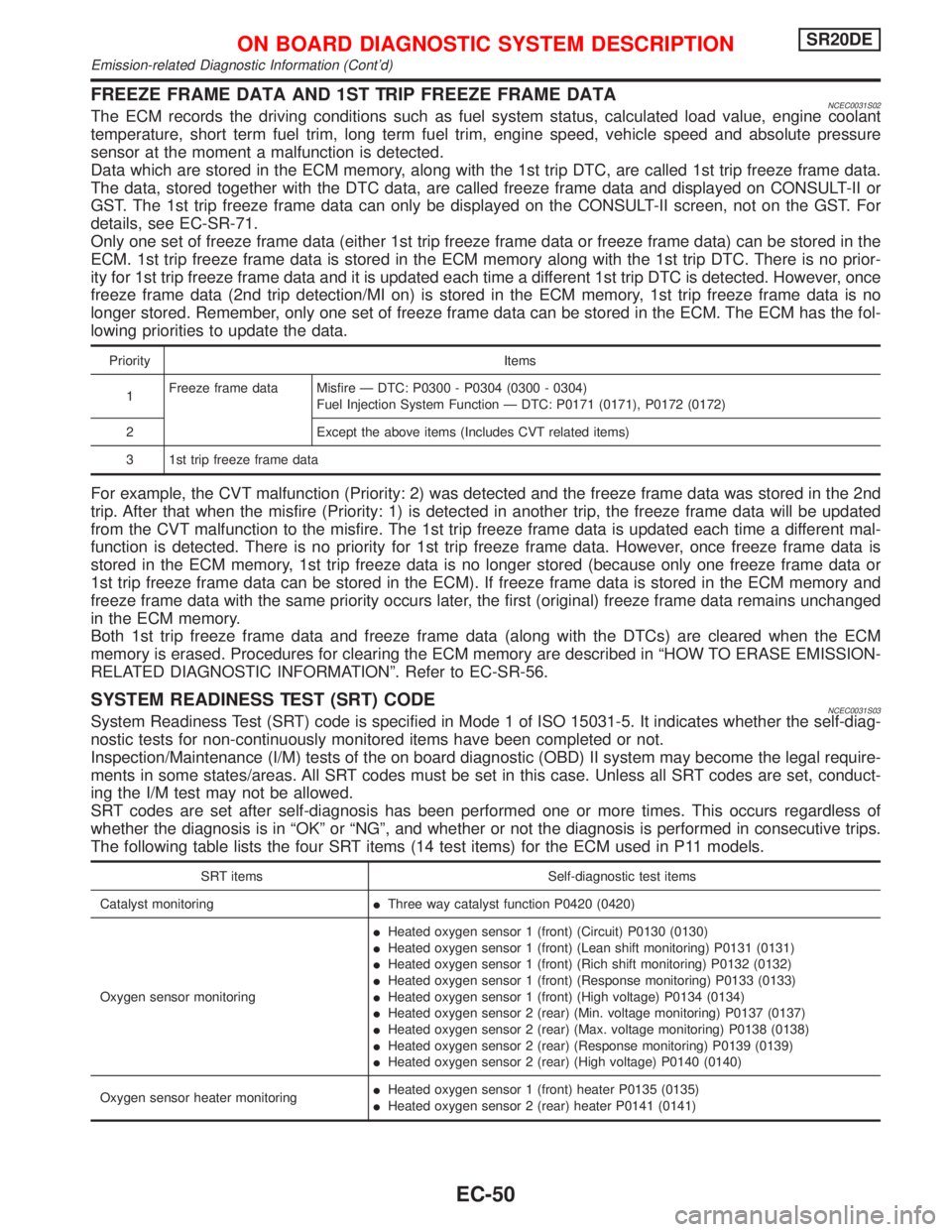

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATANCEC0031S02The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant

temperature, short term fuel trim, long term fuel trim, engine speed, vehicle speed and absolute pressure

sensor at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II or

GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

details, see EC-SR-71.

Only one set of freeze frame data (either 1st trip freeze frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no prior-

ity for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Priority Items

1Freeze frame data Misfire Ð DTC: P0300 - P0304 (0300 - 0304)

Fuel Injection System Function Ð DTC: P0171 (0171), P0172 (0172)

2 Except the above items (Includes CVT related items)

3 1st trip freeze frame data

For example, the CVT malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the CVT malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or

1st trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and

freeze frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged

in the ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM

memory is erased. Procedures for clearing the ECM memory are described in ªHOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATIONº. Refer to EC-SR-56.

SYSTEM READINESS TEST (SRT) CODENCEC0031S03System Readiness Test (SRT) code is specified in Mode 1 of ISO 15031-5. It indicates whether the self-diag-

nostic tests for non-continuously monitored items have been completed or not.

Inspection/Maintenance (I/M) tests of the on board diagnostic (OBD) II system may become the legal require-

ments in some states/areas. All SRT codes must be set in this case. Unless all SRT codes are set, conduct-

ing the I/M test may not be allowed.

SRT codes are set after self-diagnosis has been performed one or more times. This occurs regardless of

whether the diagnosis is in ªOKº or ªNGº, and whether or not the diagnosis is performed in consecutive trips.

The following table lists the four SRT items (14 test items) for the ECM used in P11 models.

SRT items Self-diagnostic test items

Catalyst monitoringIThree way catalyst function P0420 (0420)

Oxygen sensor monitoringIHeated oxygen sensor 1 (front) (Circuit) P0130 (0130)

IHeated oxygen sensor 1 (front) (Lean shift monitoring) P0131 (0131)

IHeated oxygen sensor 1 (front) (Rich shift monitoring) P0132 (0132)

IHeated oxygen sensor 1 (front) (Response monitoring) P0133 (0133)

IHeated oxygen sensor 1 (front) (High voltage) P0134 (0134)

IHeated oxygen sensor 2 (rear) (Min. voltage monitoring) P0137 (0137)

IHeated oxygen sensor 2 (rear) (Max. voltage monitoring) P0138 (0138)

IHeated oxygen sensor 2 (rear) (Response monitoring) P0139 (0139)

IHeated oxygen sensor 2 (rear) (High voltage) P0140 (0140)

Oxygen sensor heater monitoringIHeated oxygen sensor 1 (front) heater P0135 (0135)

IHeated oxygen sensor 2 (rear) heater P0141 (0141)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

Emission-related Diagnostic Information (Cont'd)

EC-50