sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1560 of 2267

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing chain tensioner, oil seals, or other sliding

parts, lubricate contacting surfaces with new engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

IWhen removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

IBe careful not to damage sensor edges.

RemovalNCEM00121. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Release fuel pressure.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

3. Remove the following belts.

IPower steering pump drive belt

IAlternator drive belt

4. Remove power steering pulley and pump with bracket.

5. Remove front right-side wheel.

6. Remove front right-side splash cover.

7. Remove front undercovers.

8. Remove front exhaust tube.

9. Remove vacuum hoses, fuel hoses, and so on.

10. Remove ignition coils.

11. Remove cylinder head front mounting bracket.

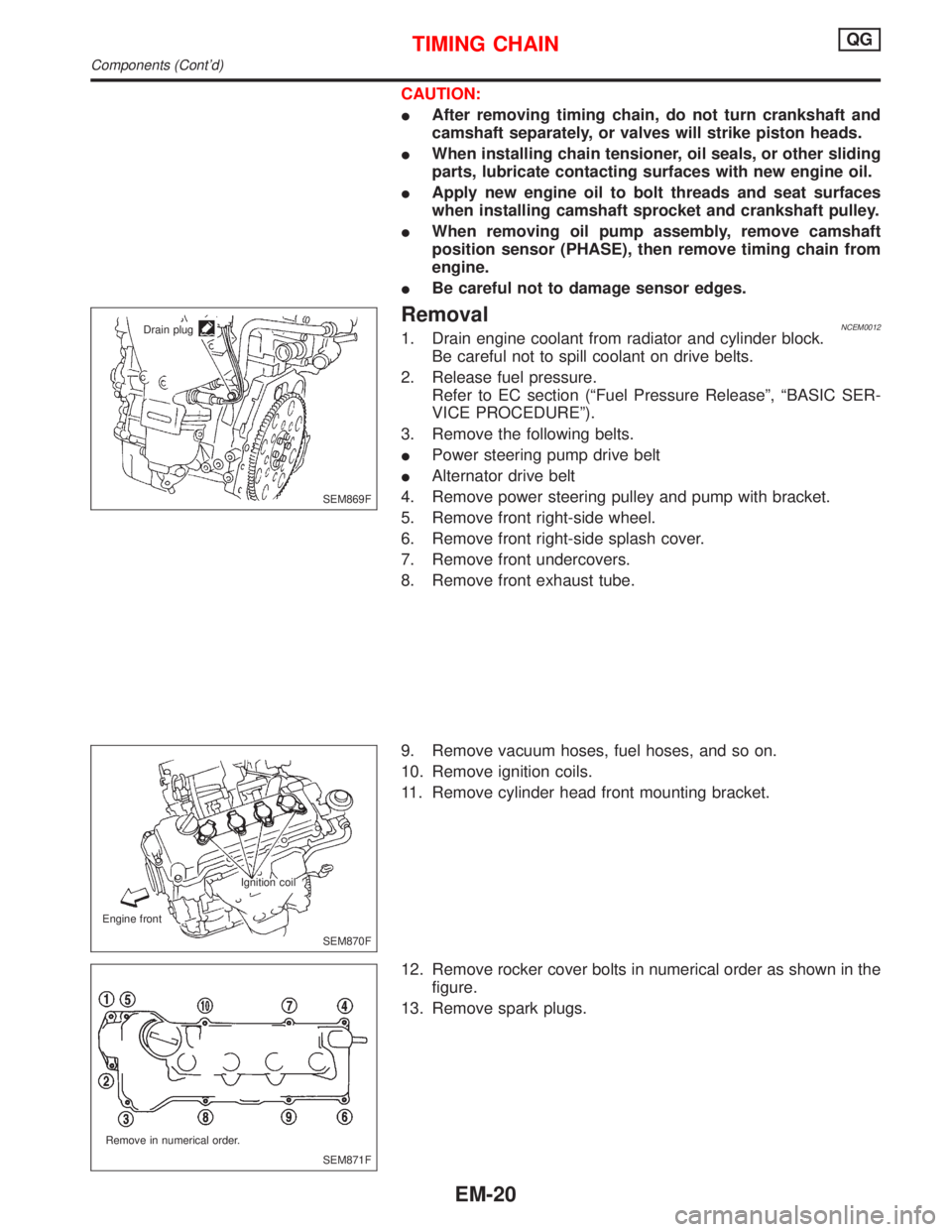

12. Remove rocker cover bolts in numerical order as shown in the

figure.

13. Remove spark plugs.

SEM869F Drain plug

SEM870F Ignition coil

Engine front

SEM871F Remove in numerical order.

TIMING CHAINQG

Components (Cont'd)

EM-20

Page 1561 of 2267

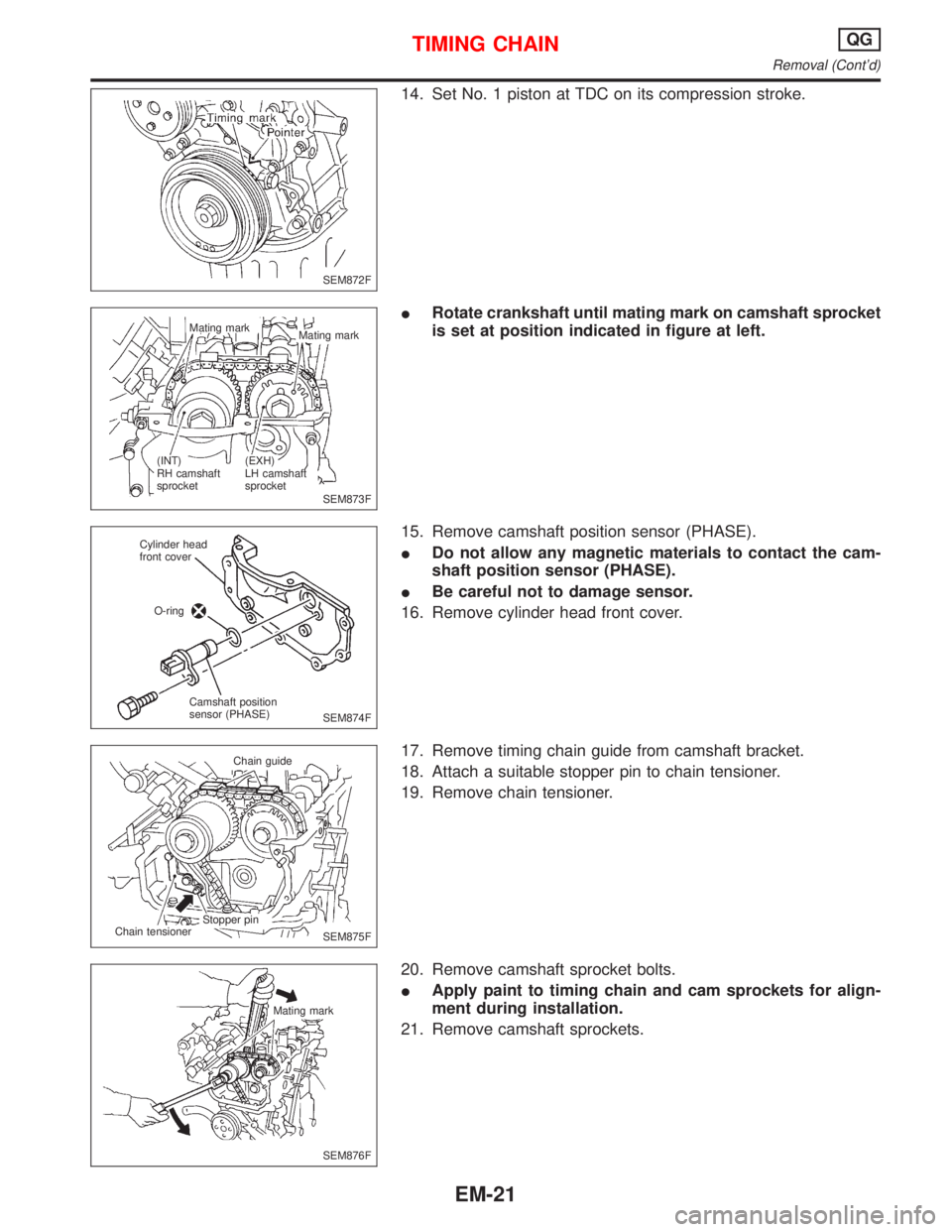

14. Set No. 1 piston at TDC on its compression stroke.

IRotate crankshaft until mating mark on camshaft sprocket

is set at position indicated in figure at left.

15. Remove camshaft position sensor (PHASE).

IDo not allow any magnetic materials to contact the cam-

shaft position sensor (PHASE).

IBe careful not to damage sensor.

16. Remove cylinder head front cover.

17. Remove timing chain guide from camshaft bracket.

18. Attach a suitable stopper pin to chain tensioner.

19. Remove chain tensioner.

20. Remove camshaft sprocket bolts.

IApply paint to timing chain and cam sprockets for align-

ment during installation.

21. Remove camshaft sprockets.

SEM872F

SEM873F Mating mark

Mating mark

(INT)

RH camshaft

sprocket(EXH)

LH camshaft

sprocket

SEM874F Cylinder head

front cover

O-ring

Camshaft position

sensor (PHASE)

SEM875F Chain guide

Stopper pin

Chain tensioner

SEM876F Mating mark

TIMING CHAINQG

Removal (Cont'd)

EM-21

Page 1567 of 2267

21. Install camshaft sprocket bolts to correct torque.

IApply new engine oil to bolt threads and seat surface.

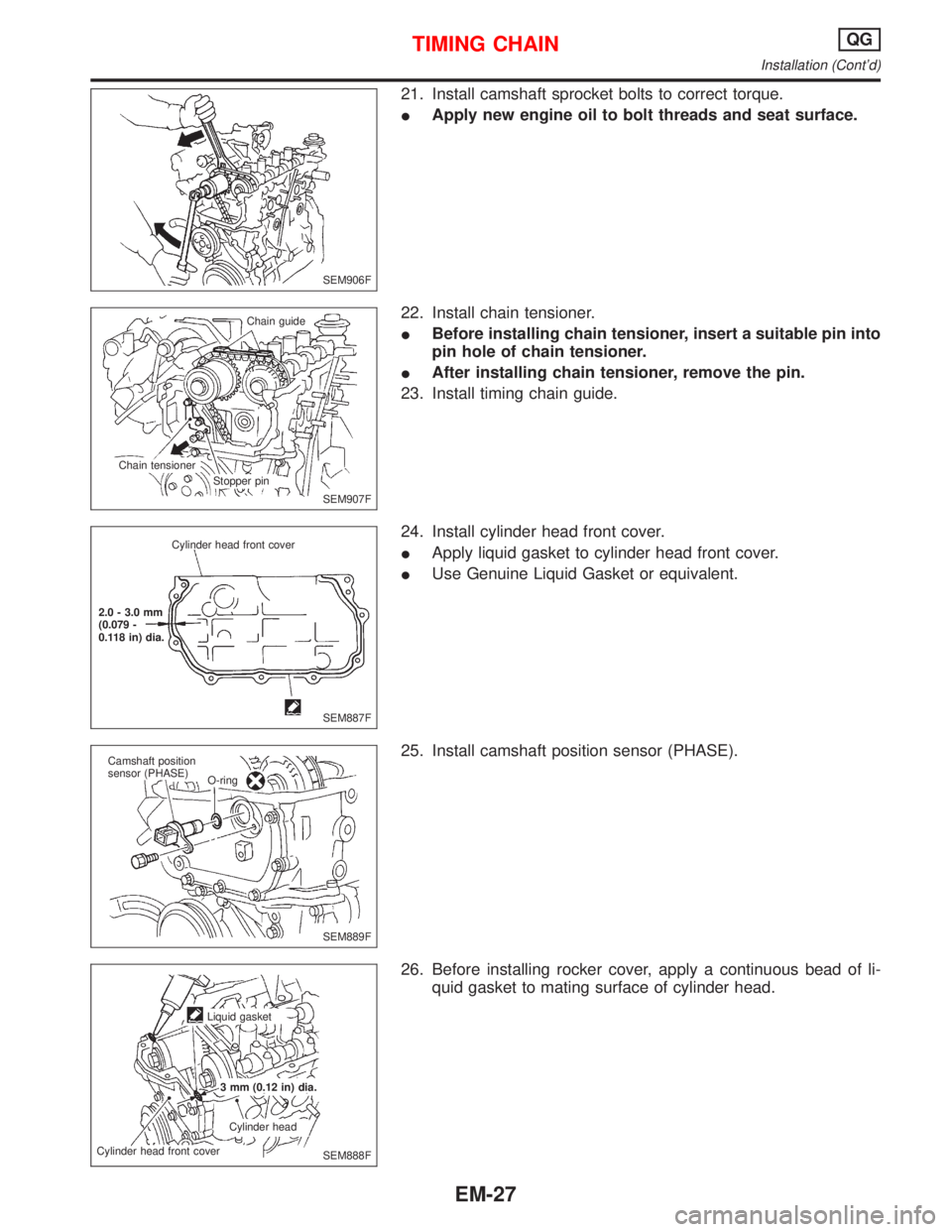

22. Install chain tensioner.

IBefore installing chain tensioner, insert a suitable pin into

pin hole of chain tensioner.

IAfter installing chain tensioner, remove the pin.

23. Install timing chain guide.

24. Install cylinder head front cover.

IApply liquid gasket to cylinder head front cover.

IUse Genuine Liquid Gasket or equivalent.

25. Install camshaft position sensor (PHASE).

26. Before installing rocker cover, apply a continuous bead of li-

quid gasket to mating surface of cylinder head.

SEM906F

SEM907F Chain guide

Chain tensioner

Stopper pin

SEM887F Cylinder head front cover

2.0 - 3.0 mm

(0.079 -

0.118 in) dia.

SEM889F Camshaft position

sensor (PHASE)

O-ring

SEM888F Liquid gasket

3 mm (0.12 in) dia.

Cylinder head

Cylinder head front cover

TIMING CHAINQG

Installation (Cont'd)

EM-27

Page 1573 of 2267

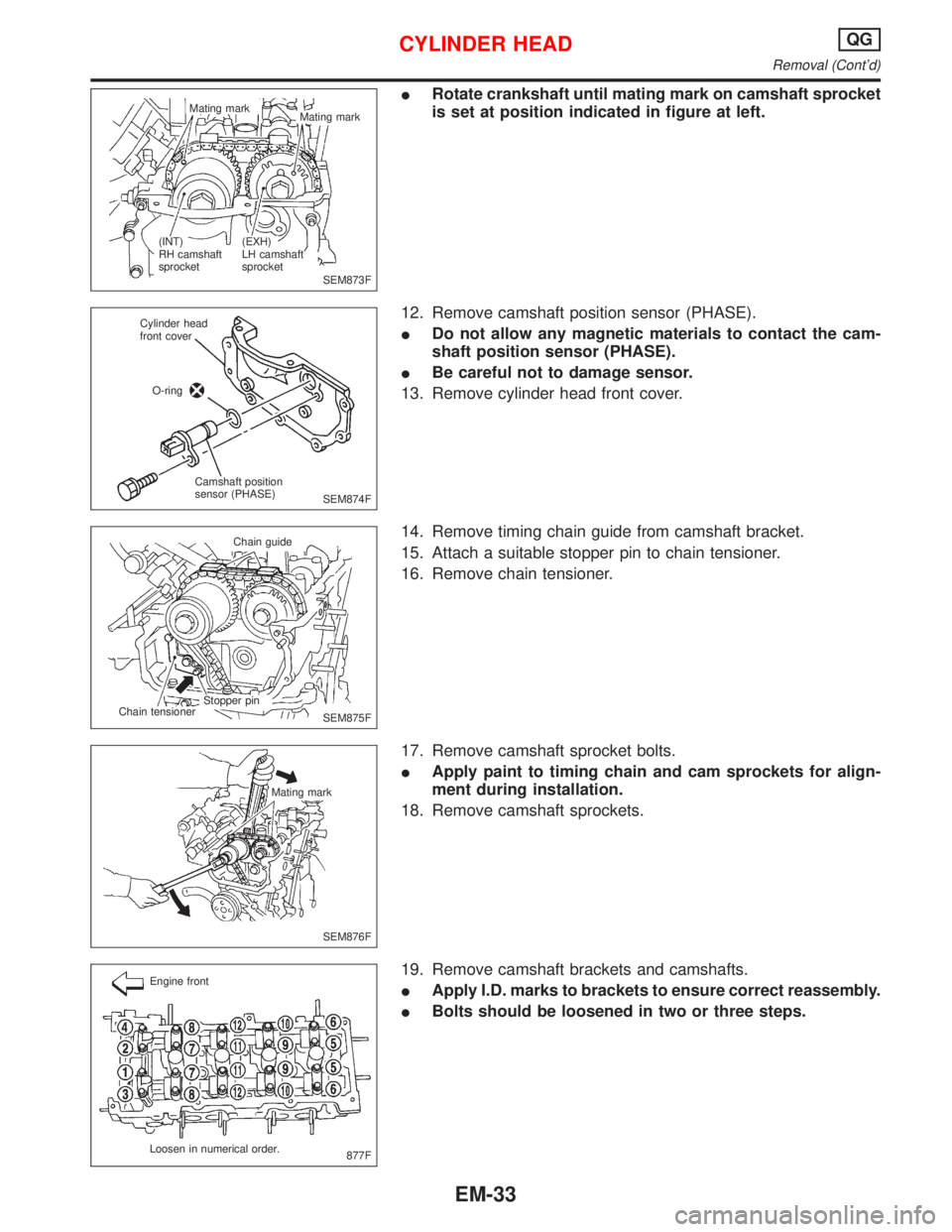

IRotate crankshaft until mating mark on camshaft sprocket

is set at position indicated in figure at left.

12. Remove camshaft position sensor (PHASE).

IDo not allow any magnetic materials to contact the cam-

shaft position sensor (PHASE).

IBe careful not to damage sensor.

13. Remove cylinder head front cover.

14. Remove timing chain guide from camshaft bracket.

15. Attach a suitable stopper pin to chain tensioner.

16. Remove chain tensioner.

17. Remove camshaft sprocket bolts.

IApply paint to timing chain and cam sprockets for align-

ment during installation.

18. Remove camshaft sprockets.

19. Remove camshaft brackets and camshafts.

IApply I.D. marks to brackets to ensure correct reassembly.

IBolts should be loosened in two or three steps.

SEM873F Mating mark

Mating mark

(EXH)

LH camshaft

sprocket (INT)

RH camshaft

sprocket

SEM874F Cylinder head

front cover

O-ring

Camshaft position

sensor (PHASE)

SEM875F Chain guide

Stopper pin

Chain tensioner

SEM876F Mating mark

877F Engine front

Loosen in numerical order.

CYLINDER HEADQG

Removal (Cont'd)

EM-33

Page 1586 of 2267

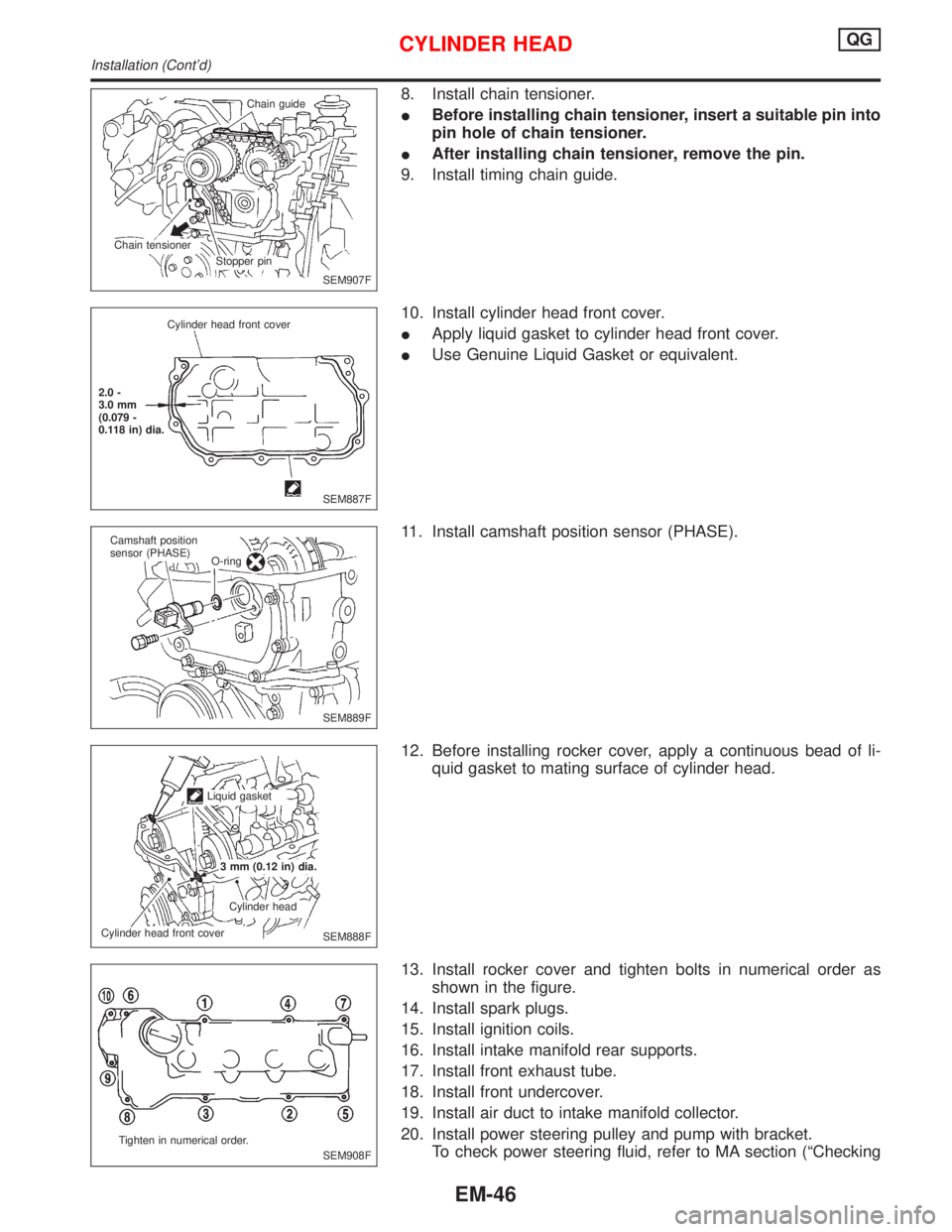

8. Install chain tensioner.

IBefore installing chain tensioner, insert a suitable pin into

pin hole of chain tensioner.

IAfter installing chain tensioner, remove the pin.

9. Install timing chain guide.

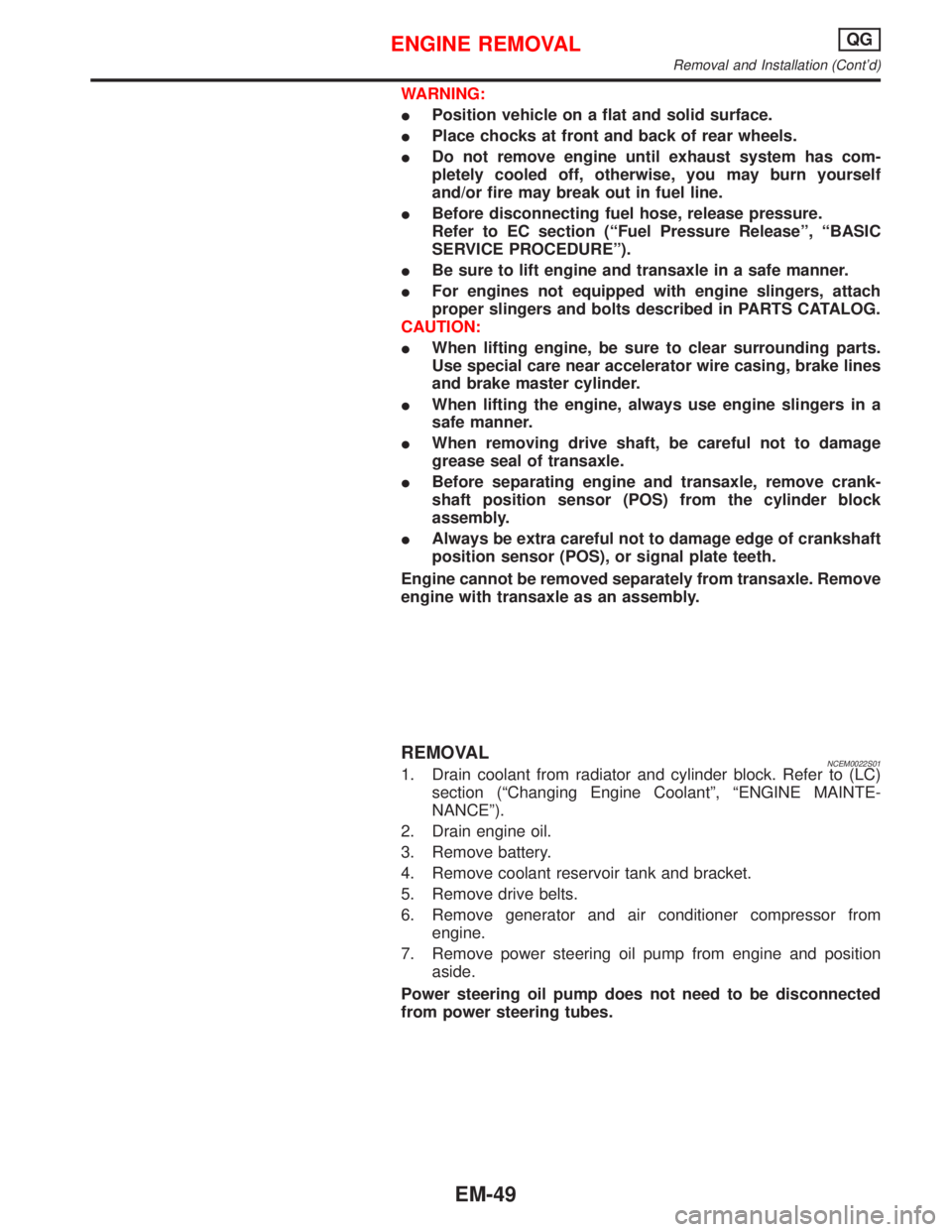

10. Install cylinder head front cover.

IApply liquid gasket to cylinder head front cover.

IUse Genuine Liquid Gasket or equivalent.

11. Install camshaft position sensor (PHASE).

12. Before installing rocker cover, apply a continuous bead of li-

quid gasket to mating surface of cylinder head.

13. Install rocker cover and tighten bolts in numerical order as

shown in the figure.

14. Install spark plugs.

15. Install ignition coils.

16. Install intake manifold rear supports.

17. Install front exhaust tube.

18. Install front undercover.

19. Install air duct to intake manifold collector.

20. Install power steering pulley and pump with bracket.

To check power steering fluid, refer to MA section (ªChecking

SEM907F Chain guide

Stopper pin Chain tensioner

SEM887F Cylinder head front cover

2.0 -

3.0 mm

(0.079 -

0.118 in) dia.

SEM889F Camshaft position

sensor (PHASE)

O-ring

SEM888F Liquid gasket

3 mm (0.12 in) dia.

Cylinder head

Cylinder head front cover

SEM908F Tighten in numerical order.

CYLINDER HEADQG

Installation (Cont'd)

EM-46

Page 1589 of 2267

WARNING:

IPosition vehicle on a flat and solid surface.

IPlace chocks at front and back of rear wheels.

IDo not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

IBefore disconnecting fuel hose, release pressure.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC

SERVICE PROCEDUREº).

IBe sure to lift engine and transaxle in a safe manner.

IFor engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

IWhen lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

IWhen lifting the engine, always use engine slingers in a

safe manner.

IWhen removing drive shaft, be careful not to damage

grease seal of transaxle.

IBefore separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

IAlways be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNCEM0022S011. Drain coolant from radiator and cylinder block. Refer to (LC)

section (ªChanging Engine Coolantº, ªENGINE MAINTE-

NANCEº).

2. Drain engine oil.

3. Remove battery.

4. Remove coolant reservoir tank and bracket.

5. Remove drive belts.

6. Remove generator and air conditioner compressor from

engine.

7. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE REMOVALQG

Removal and Installation (Cont'd)

EM-49

Page 1592 of 2267

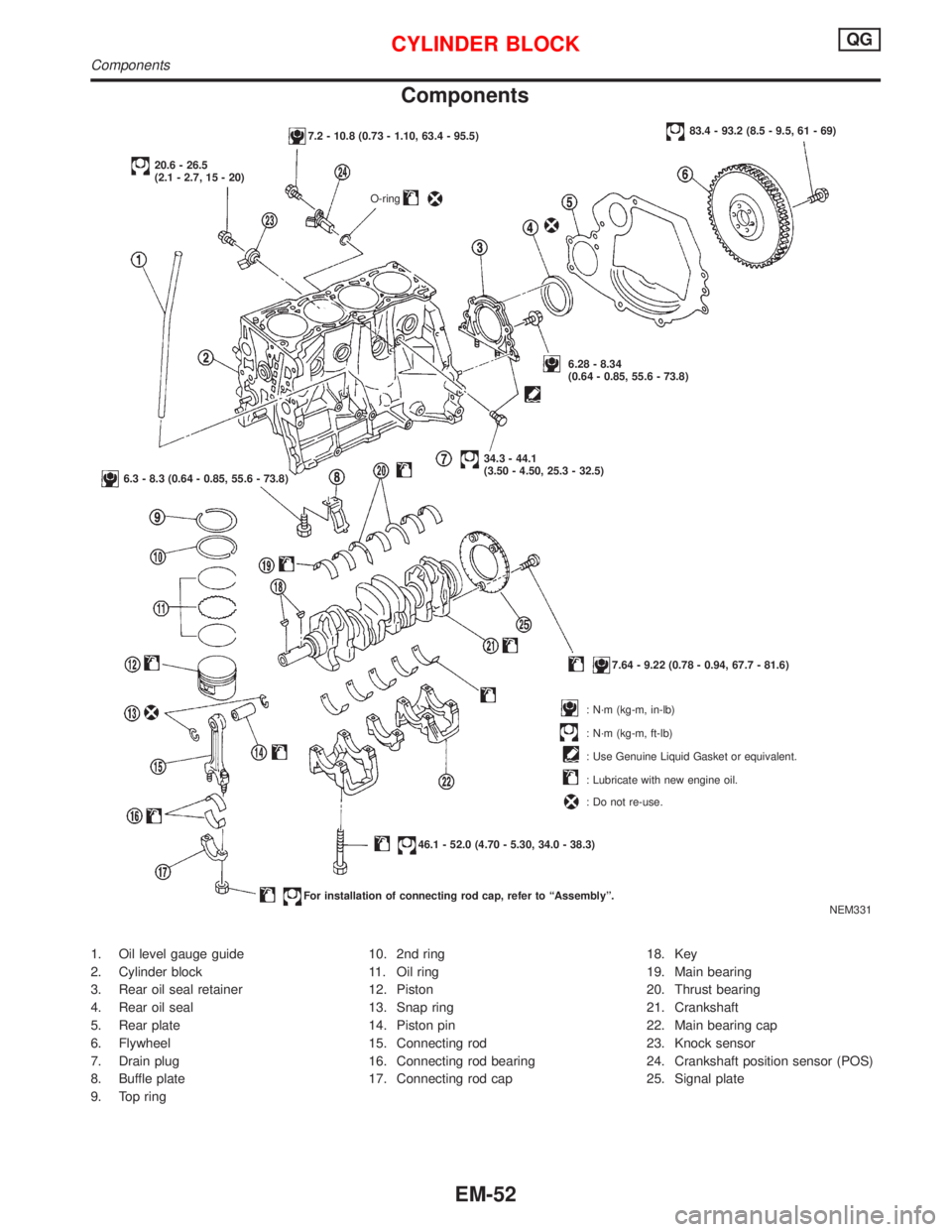

Components

1. Oil level gauge guide

2. Cylinder block

3. Rear oil seal retainer

4. Rear oil seal

5. Rear plate

6. Flywheel

7. Drain plug

8. Buffle plate

9. Top ring10. 2nd ring

11. Oil ring

12. Piston

13. Snap ring

14. Piston pin

15. Connecting rod

16. Connecting rod bearing

17. Connecting rod cap18. Key

19. Main bearing

20. Thrust bearing

21. Crankshaft

22. Main bearing cap

23. Knock sensor

24. Crankshaft position sensor (POS)

25. Signal plate

NEM331

7.2 - 10.8 (0.73 - 1.10, 63.4 - 95.5)

20.6 - 26.5

(2.1 - 2.7, 15 - 20)

O-ring

83.4 - 93.2 (8.5 - 9.5, 61 - 69)

6.28 - 8.34

(0.64 - 0.85, 55.6 - 73.8)

34.3 - 44.1

(3.50 - 4.50, 25.3 - 32.5)

6.3 - 8.3 (0.64 - 0.85, 55.6 - 73.8)

7.64 - 9.22 (0.78 - 0.94, 67.7 - 81.6)

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Use Genuine Liquid Gasket or equivalent.

: Lubricate with new engine oil.

: Do not re-use.

46.1 - 52.0 (4.70 - 5.30, 34.0 - 38.3)

For installation of connecting rod cap, refer to ªAssemblyº.

CYLINDER BLOCKQG

Components

EM-52

Page 1593 of 2267

Removal and InstallationNCEM0024CAUTION:

IWhen installing sliding parts such as bearings and

pistons, apply engine oil on the sliding surfaces.

IPlace removed parts, such as bearings and bearing caps,

in their proper order and direction.

IWhen installing connecting rod nuts and main bearing cap

bolts, apply new engine oil to threads and seating sur-

faces.

IDo not allow any magnetic materials to contact the signal

plate teeth of flywheel or drive plate, and rear plate.

IRemove the crankshaft position sensor (POS).

IBe careful not to damage sensor edges and single plate

teeth.

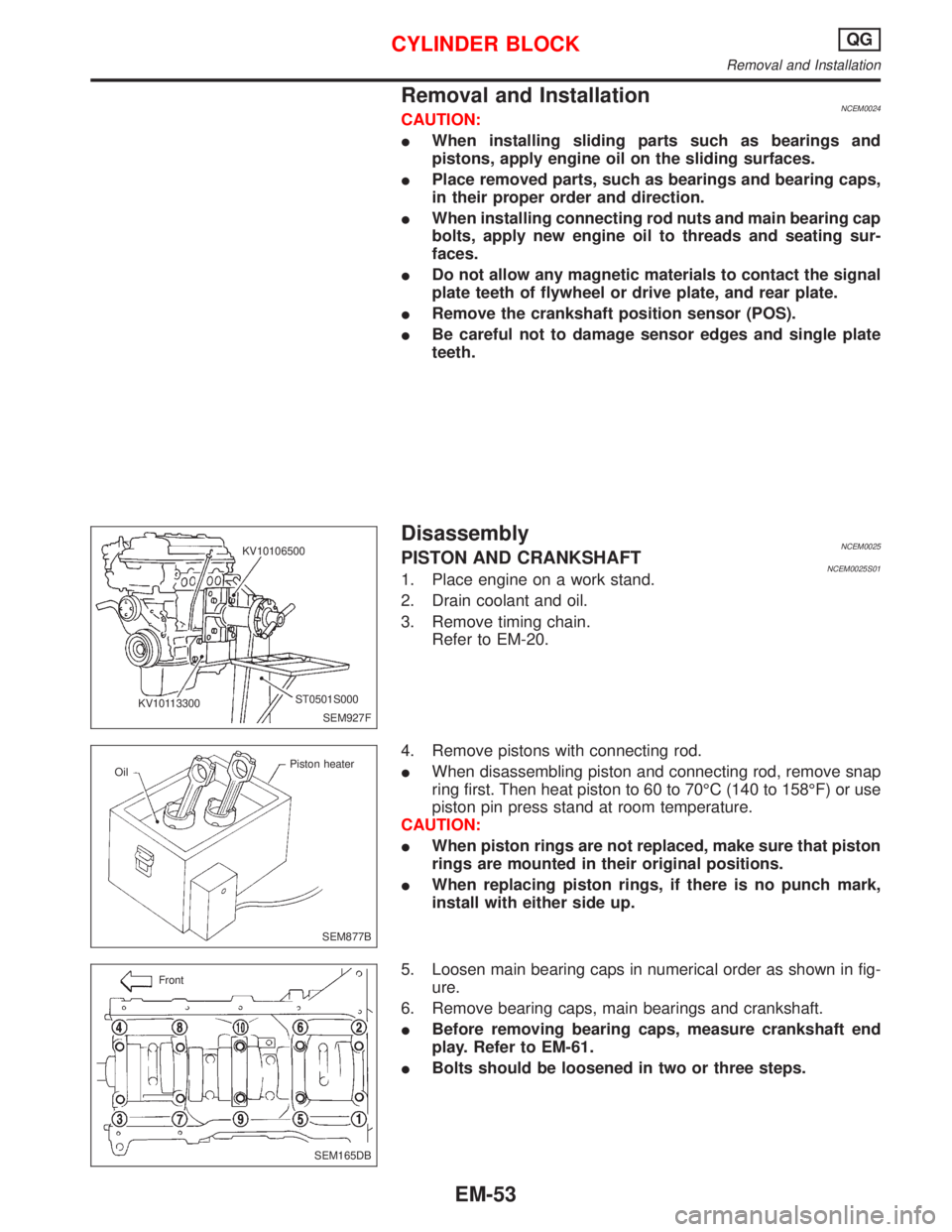

DisassemblyNCEM0025PISTON AND CRANKSHAFTNCEM0025S011. Place engine on a work stand.

2. Drain coolant and oil.

3. Remove timing chain.

Refer to EM-20.

4. Remove pistons with connecting rod.

IWhen disassembling piston and connecting rod, remove snap

ring first. Then heat piston to 60 to 70ÉC (140 to 158ÉF) or use

piston pin press stand at room temperature.

CAUTION:

IWhen piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

IWhen replacing piston rings, if there is no punch mark,

install with either side up.

5. Loosen main bearing caps in numerical order as shown in fig-

ure.

6. Remove bearing caps, main bearings and crankshaft.

IBefore removing bearing caps, measure crankshaft end

play. Refer to EM-61.

IBolts should be loosened in two or three steps.

SEM927F KV10106500

ST0501S000

KV10113300

SEM877B OilPiston heater

SEM165DB Front

CYLINDER BLOCKQG

Removal and Installation

EM-53

Page 1603 of 2267

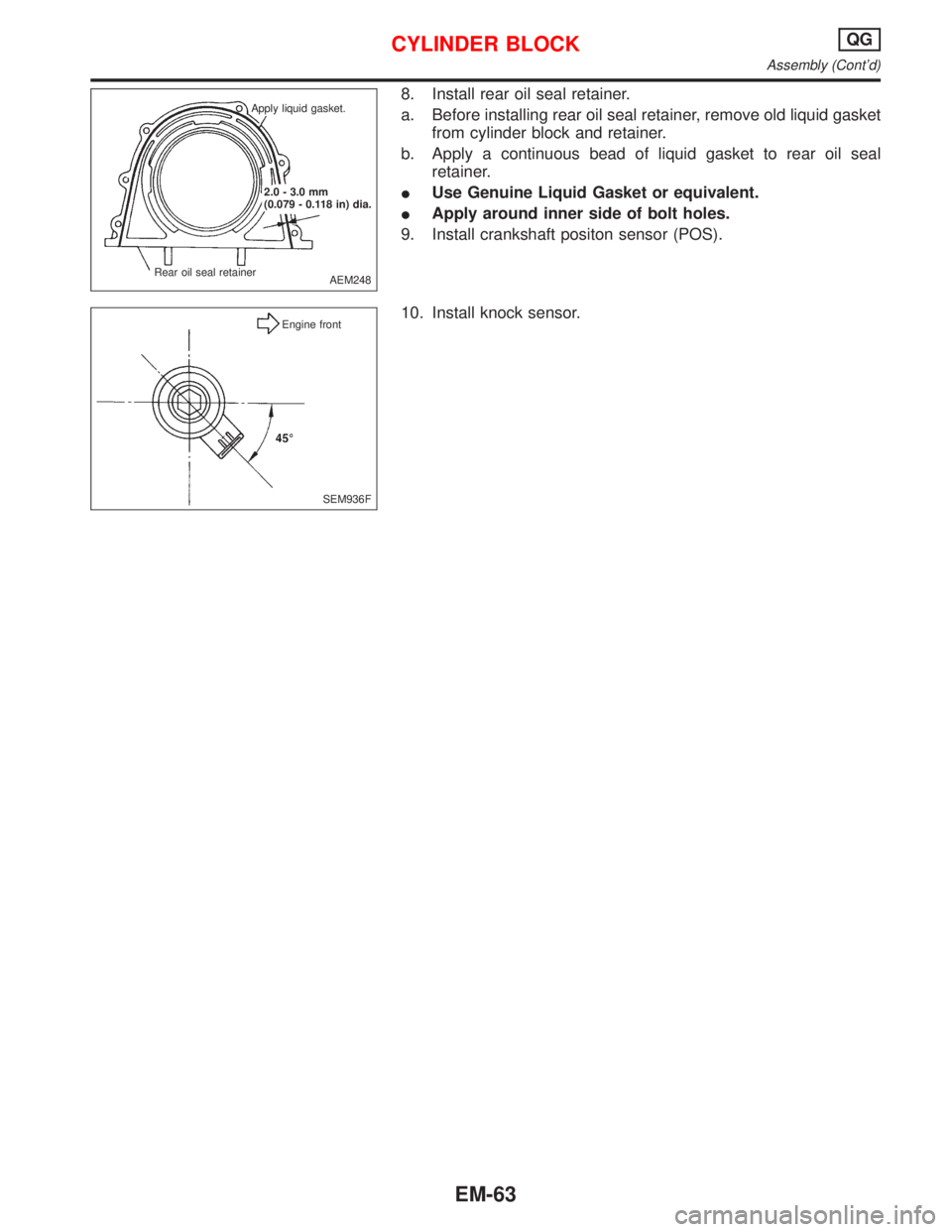

8. Install rear oil seal retainer.

a. Before installing rear oil seal retainer, remove old liquid gasket

from cylinder block and retainer.

b. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

IUse Genuine Liquid Gasket or equivalent.

IApply around inner side of bolt holes.

9. Install crankshaft positon sensor (POS).

10. Install knock sensor.

AEM248 Apply liquid gasket.

.2.0 - 3.0 mm

(0.079 - 0.118 in) dia.

Rear oil seal retainer

SEM936F Engine front

CYLINDER BLOCKQG

Assembly (Cont'd)

EM-63

Page 1606 of 2267

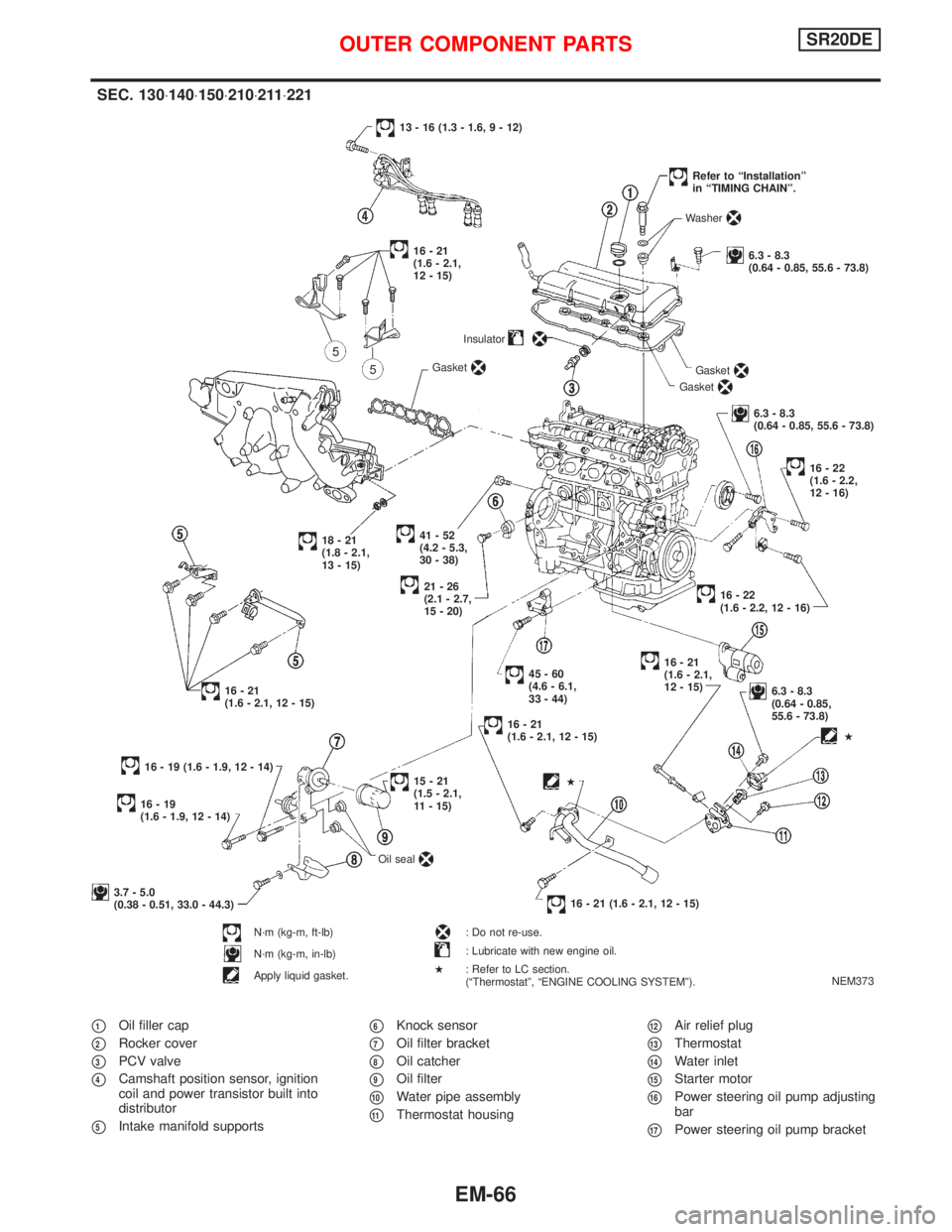

p1Oil filler cap

p2Rocker cover

p3PCV valve

p4Camshaft position sensor, ignition

coil and power transistor built into

distributor

p5Intake manifold supports

p6Knock sensor

p7Oil filter bracket

p8Oil catcher

p9Oil filter

p10Water pipe assembly

p11Thermostat housing

p12Air relief plug

p13Thermostat

p14Water inlet

p15Starter motor

p16Power steering oil pump adjusting

bar

p17Power steering oil pump bracket

NEM373

SEC. 130×140×150×210×211×221

.41-52

(4.2 - 5.3,

30 - 38)Insulator

21-26

(2.1 - 2.7,

15 - 20)

18-21

(1.8 - 2.1,

13 - 15)

16-21

(1.6 - 2.1, 12 - 15)

45-60

(4.6 - 6.1,

33 - 44)

16-21

(1.6 - 2.1, 12 - 15)

16 - 19 (1.6 - 1.9, 12 - 14)Gasket

13 - 16 (1.3 - 1.6, 9 - 12)

Gasket

Gasket

Washer

6.3 - 8.3

(0.64 - 0.85, 55.6 - 73.8)

Refer to ªInstallationº

in ªTIMING CHAINº.

6.3 - 8.3

(0.64 - 0.85, 55.6 - 73.8)

16-22

(1.6 - 2.2,

12 - 16)

.16-22

(1.6 - 2.2, 12 - 16)

16-21

(1.6 - 2.1,

12 - 15)

6.3 - 8.3

(0.64 - 0.85,

55.6 - 73.8)

16 - 21 (1.6 - 2.1, 12 - 15)

16-19

(1.6 - 1.9, 12 - 14)

15-21

(1.5 - 2.1,

11 - 15)

3.7 - 5.0

(0.38 - 0.51, 33.0 - 44.3)

N´m (kg-m, ft-lb)

N´m (kg-m, in-lb)

Apply liquid gasket.Oil seal

: Do not re-use.

: Lubricate with new engine oil.

: Refer to LC section.

(ªThermostatº, ªENGINE COOLING SYSTEMº).

H

H

H

16-21

(1.6 - 2.1,

12 - 15)

OUTER COMPONENT PARTSSR20DE

EM-66