sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1607 of 2267

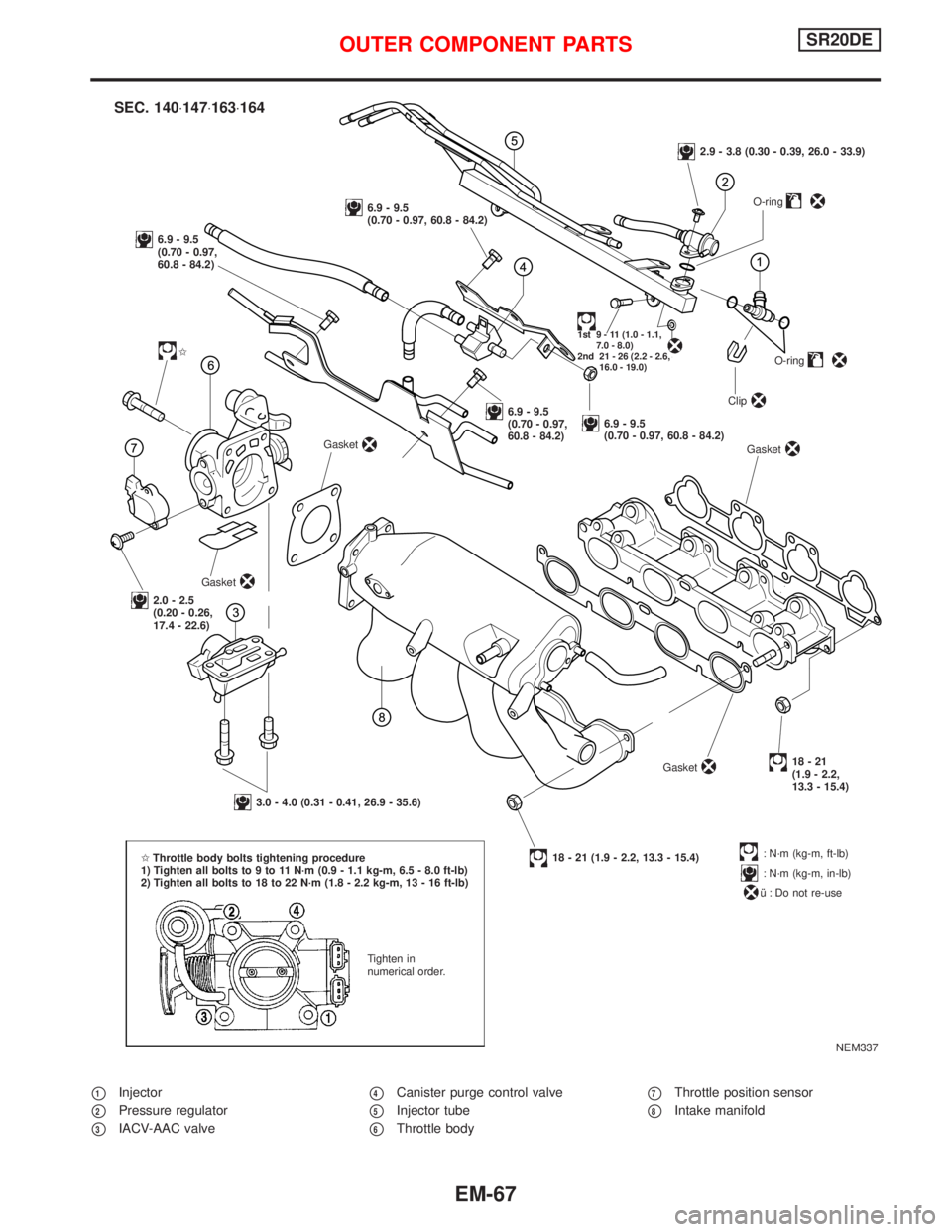

p1Injector

p2Pressure regulator

p3IACV-AAC valve

p4Canister purge control valve

p5Injector tube

p6Throttle body

p7Throttle position sensor

p8Intake manifold

NEM337

.

SEC. 140×147×163×164

6.9 - 9.5

(0.70 - 0.97,

60.8 - 84.2)

6.9 - 9.5

(0.70 - 0.97, 60.8 - 84.2)

2.9 - 3.8 (0.30 - 0.39, 26.0 - 33.9)

O-ring

1st 9 - 11 (1.0 - 1.1,

7.0 - 8.0)

2nd 21 - 26 (2.2 - 2.6,

16.0 - 19.0)

I

Gasket

6.9 - 9.5

(0.70 - 0.97,

60.8 - 84.2)6.9 - 9.5

(0.70 - 0.97, 60.8 - 84.2)O-ring

Clip

Gasket

2.0 - 2.5

(0.20 - 0.26,

17.4 - 22.6)Gasket

3.0 - 4.0 (0.31 - 0.41, 26.9 - 35.6)

18 - 21 (1.9 - 2.2, 13.3 - 15.4)Gasket

18-21

(1.9 - 2.2,

13.3 - 15.4)

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

î : Do not re-use IThrottle body bolts tightening procedure

1) Tighten all bolts to 9 to 11 N´m (0.9 - 1.1 kg-m, 6.5 - 8.0 ft-lb)

2) Tighten all bolts to 18 to 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

Tighten in

numerical order.

OUTER COMPONENT PARTSSR20DE

EM-67

Page 1608 of 2267

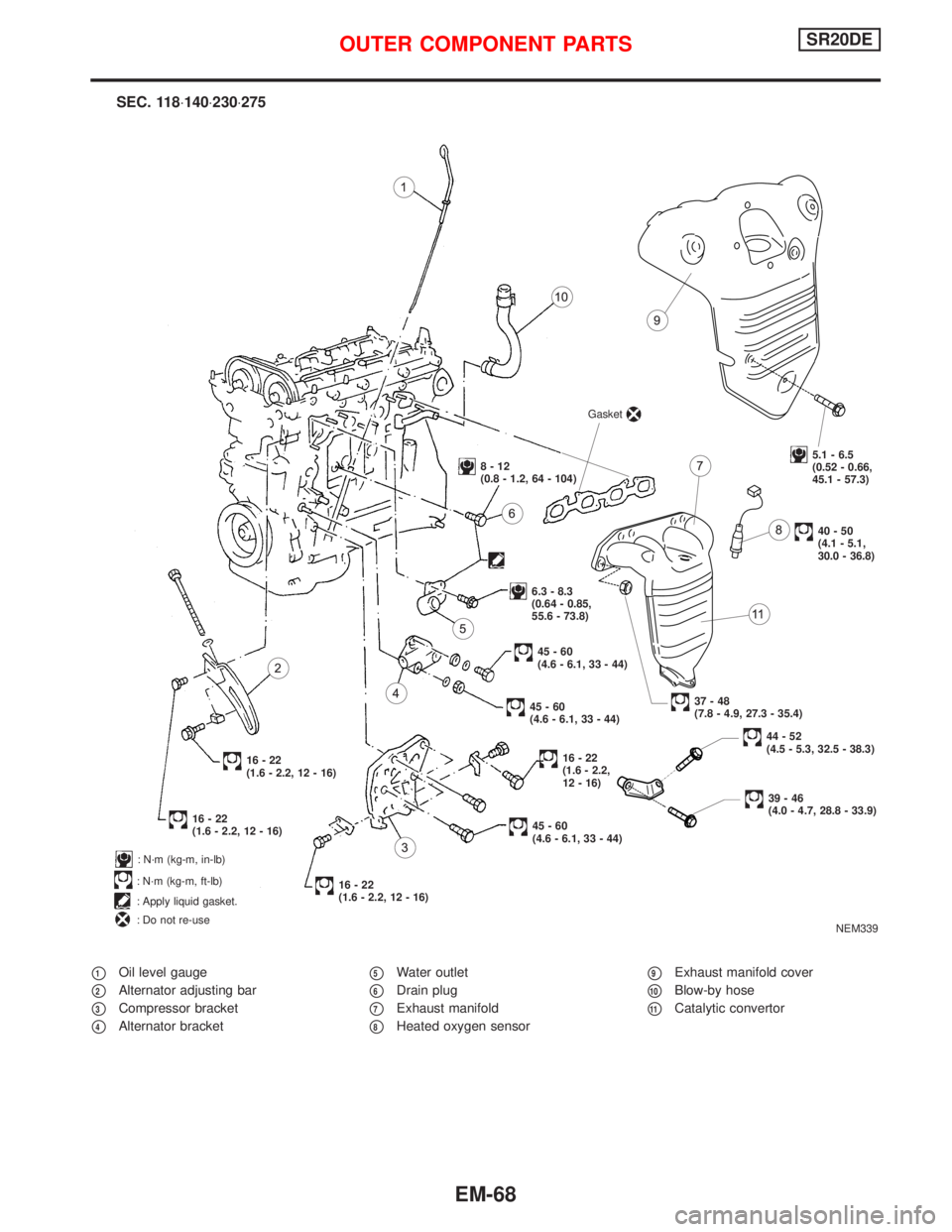

p1Oil level gauge

p2Alternator adjusting bar

p3Compressor bracket

p4Alternator bracket

p5Water outlet

p6Drain plug

p7Exhaust manifold

p8Heated oxygen sensor

p9Exhaust manifold cover

p10Blow-by hose

p11Catalytic convertor

NEM339

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: Apply liquid gasket.

: Do not re-use

SEC. 118×140×230×275

Gasket

5.1 - 6.5

(0.52 - 0.66,

45.1 - 57.3)

40-50

(4.1 - 5.1,

30.0 - 36.8)

8-12

(0.8 - 1.2, 64 - 104)

6.3 - 8.3

(0.64 - 0.85,

55.6 - 73.8)

37-48

(7.8 - 4.9, 27.3 - 35.4)

45-60

(4.6 - 6.1, 33 - 44)

45-60

(4.6 - 6.1, 33 - 44)

16-22

(1.6 - 2.2, 12 - 16)

16-22

(1.6 - 2.2, 12 - 16)

16-22

(1.6 - 2.2,

12 - 16)

45-60

(4.6 - 6.1, 33 - 44)

16-22

(1.6 - 2.2, 12 - 16)

44-52

(4.5 - 5.3, 32.5 - 38.3)

39-46

(4.0 - 4.7, 28.8 - 33.9)

OUTER COMPONENT PARTSSR20DE

EM-68

Page 1614 of 2267

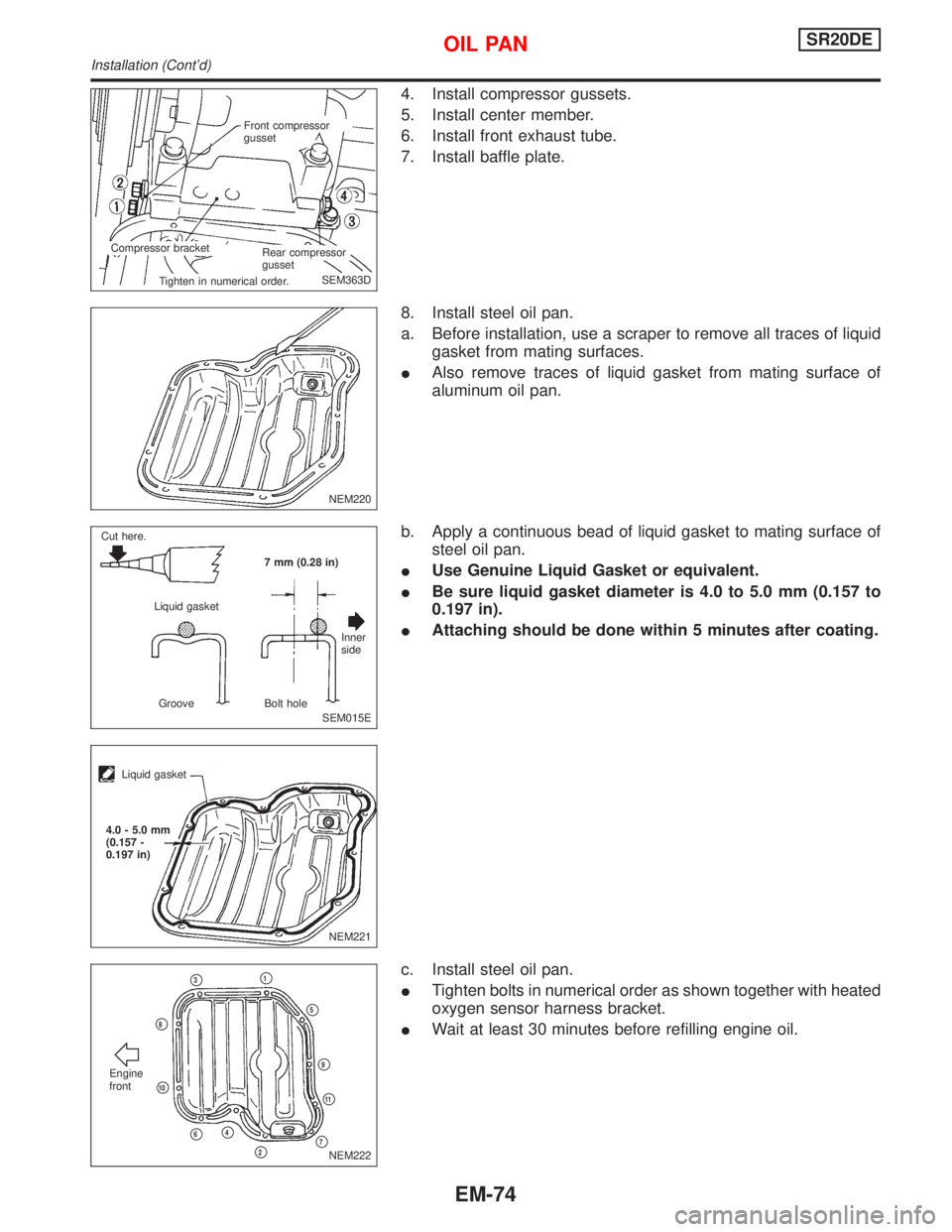

4. Install compressor gussets.

5. Install center member.

6. Install front exhaust tube.

7. Install baffle plate.

8. Install steel oil pan.

a. Before installation, use a scraper to remove all traces of liquid

gasket from mating surfaces.

IAlso remove traces of liquid gasket from mating surface of

aluminum oil pan.

b. Apply a continuous bead of liquid gasket to mating surface of

steel oil pan.

IUse Genuine Liquid Gasket or equivalent.

IBe sure liquid gasket diameter is 4.0 to 5.0 mm (0.157 to

0.197 in).

IAttaching should be done within 5 minutes after coating.

c. Install steel oil pan.

ITighten bolts in numerical order as shown together with heated

oxygen sensor harness bracket.

IWait at least 30 minutes before refilling engine oil.

SEM363D Front compressor

gusset

Compressor bracket

Rear compressor

gusset

Tighten in numerical order.

NEM220

SEM015E Cut here.

Liquid gasket7 mm (0.28 in)

Inner

side

Groove Bolt hole

NEM221

Liquid gasket

4.0 - 5.0 mm

(0.157 -

0.197 in)

NEM222p7

Engine

front

p3p1

p5

p9

p11

p2

p4p6

p10

p8

OIL PANSR20DE

Installation (Cont'd)

EM-74

Page 1751 of 2267

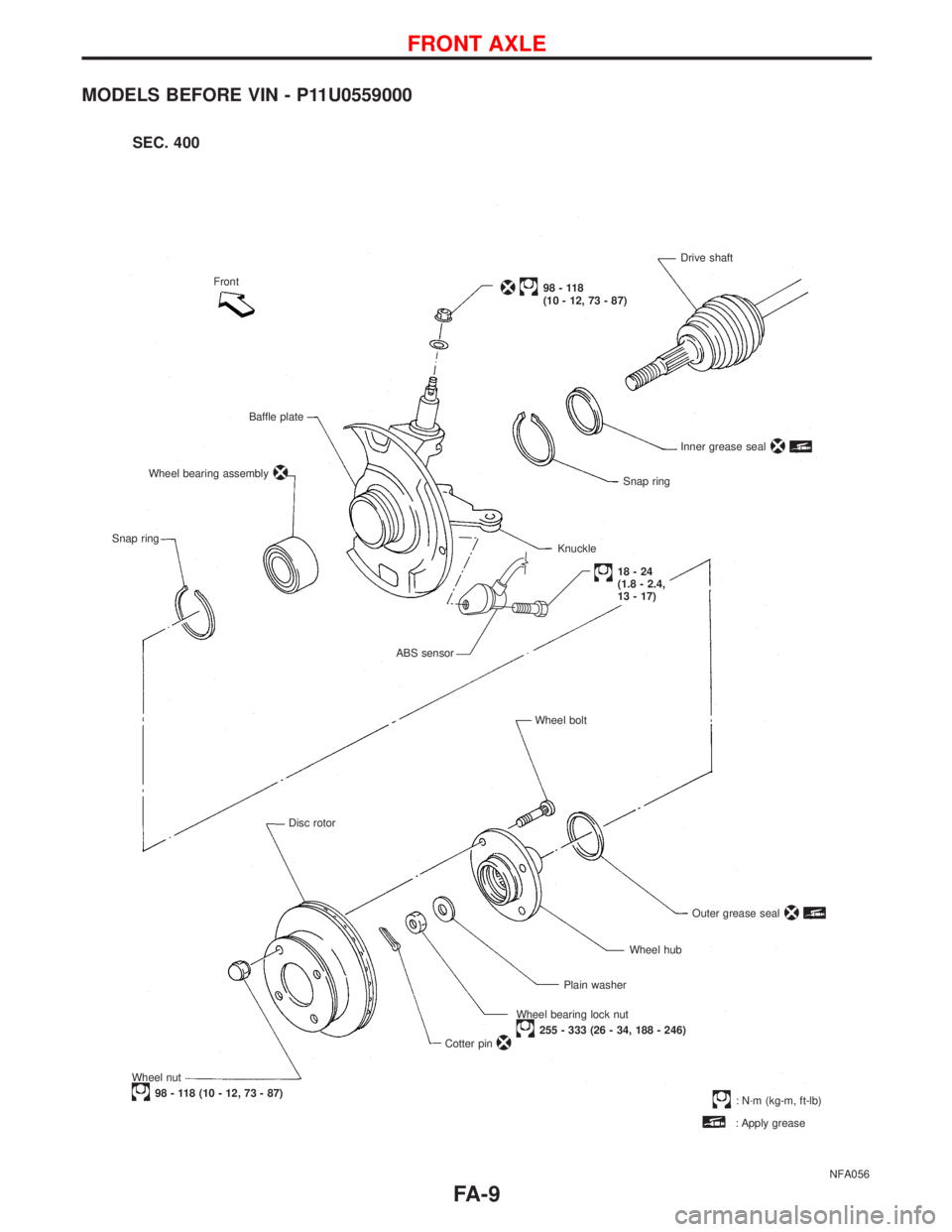

MODELS BEFORE VIN - P11U0559000

NFA056 Front

98-118

(10 - 12, 73 - 87)Drive shaft

Baffle plate

Wheel bearing assembly

Snap ringInner grease seal

Snap ring

Knuckle

Wheel bolt

Disc rotor

Outer grease seal

Wheel hub

Plain washer

Wheel bearing lock nut

255 - 333 (26 - 34, 188 - 246)

Cotter pin

Wheel nut

98 - 118 (10 - 12, 73 - 87): N´m (kg-m, ft-lb)

: Apply grease

SEC. 400

.18-24

(1.8 - 2.4,

13 - 17)

ABS sensor

FRONT AXLE

FA-9

Page 1753 of 2267

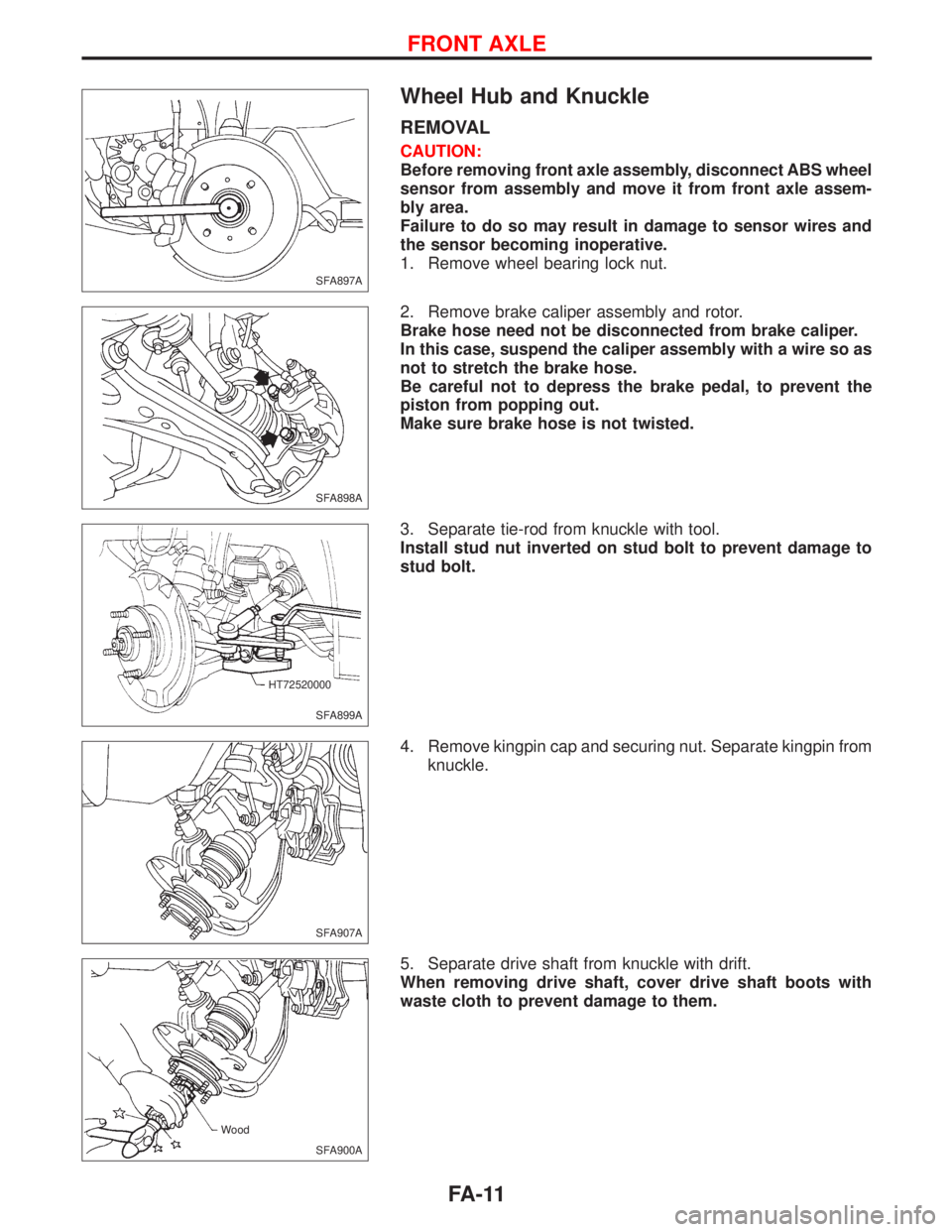

Wheel Hub and Knuckle

REMOVAL

CAUTION:

Before removing front axle assembly, disconnect ABS wheel

sensor from assembly and move it from front axle assem-

bly area.

Failure to do so may result in damage to sensor wires and

the sensor becoming inoperative.

1. Remove wheel bearing lock nut.

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper.

In this case, suspend the caliper assembly with a wire so as

not to stretch the brake hose.

Be careful not to depress the brake pedal, to prevent the

piston from popping out.

Make sure brake hose is not twisted.

3. Separate tie-rod from knuckle with tool.

Install stud nut inverted on stud bolt to prevent damage to

stud bolt.

4. Remove kingpin cap and securing nut. Separate kingpin from

knuckle.

5. Separate drive shaft from knuckle with drift.

When removing drive shaft, cover drive shaft boots with

waste cloth to prevent damage to them.

SFA897A

SFA898A

SFA899A HT72520000

SFA907A

SFA900A Wood

FRONT AXLE

FA-11

Page 1774 of 2267

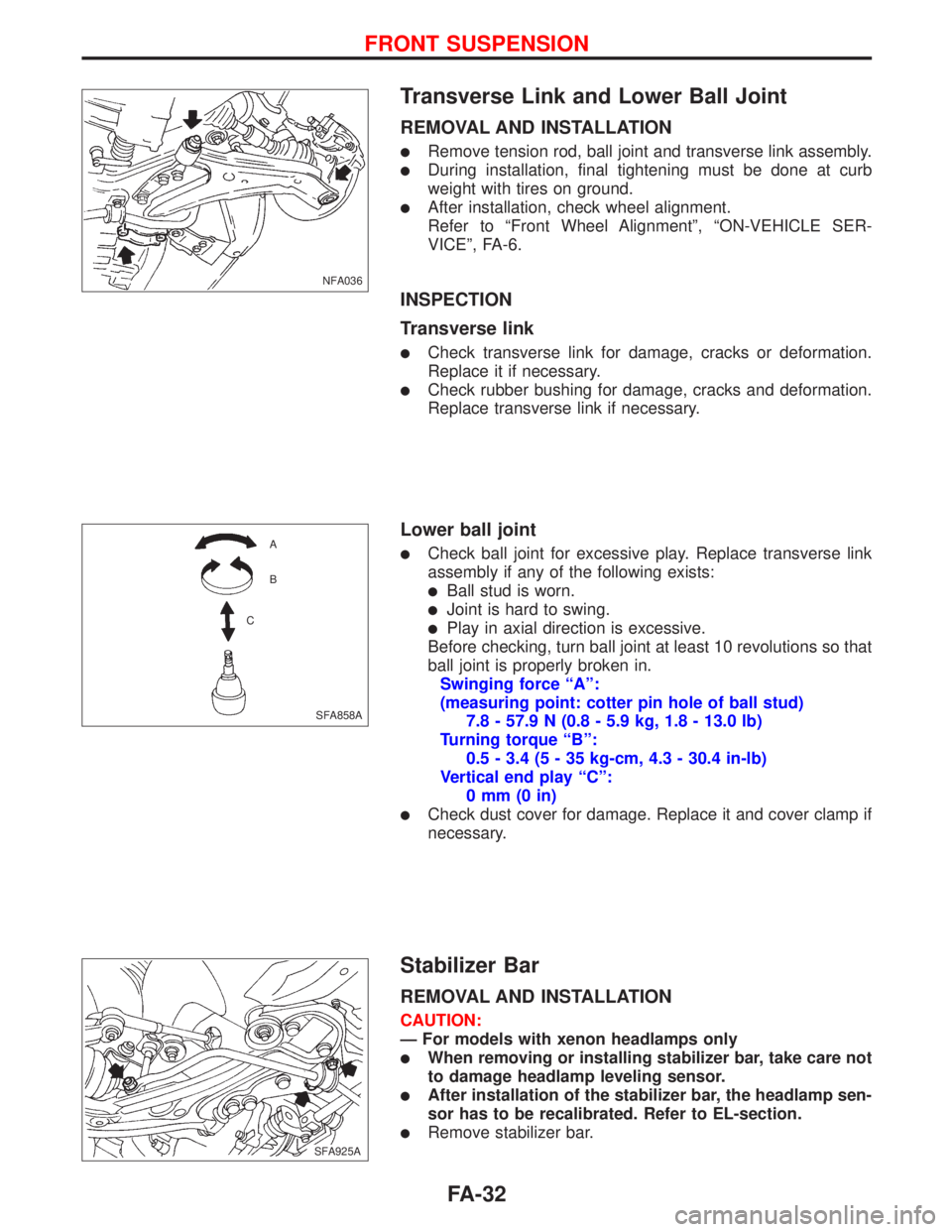

Transverse Link and Lower Ball Joint

REMOVAL AND INSTALLATION

lRemove tension rod, ball joint and transverse link assembly.

lDuring installation, final tightening must be done at curb

weight with tires on ground.

lAfter installation, check wheel alignment.

Refer to ªFront Wheel Alignmentº, ªON-VEHICLE SER-

VICEº, FA-6.

INSPECTION

Transverse link

lCheck transverse link for damage, cracks or deformation.

Replace it if necessary.

lCheck rubber bushing for damage, cracks and deformation.

Replace transverse link if necessary.

Lower ball joint

lCheck ball joint for excessive play. Replace transverse link

assembly if any of the following exists:

lBall stud is worn.

lJoint is hard to swing.

lPlay in axial direction is excessive.

Before checking, turn ball joint at least 10 revolutions so that

ball joint is properly broken in.

Swinging force ªAº:

(measuring point: cotter pin hole of ball stud)

7.8 - 57.9 N (0.8 - 5.9 kg, 1.8 - 13.0 lb)

Turning torque ªBº:

0.5 - 3.4 (5 - 35 kg-cm, 4.3 - 30.4 in-lb)

Vertical end play ªCº:

0mm(0in)

lCheck dust cover for damage. Replace it and cover clamp if

necessary.

Stabilizer Bar

REMOVAL AND INSTALLATION

CAUTION:

Ð For models with xenon headlamps only

lWhen removing or installing stabilizer bar, take care not

to damage headlamp leveling sensor.

lAfter installation of the stabilizer bar, the headlamp sen-

sor has to be recalibrated. Refer to EL-section.

lRemove stabilizer bar.

NFA036

SFA858A A

B

C

.SFA925A

FRONT SUSPENSION

FA-32

Page 1783 of 2267

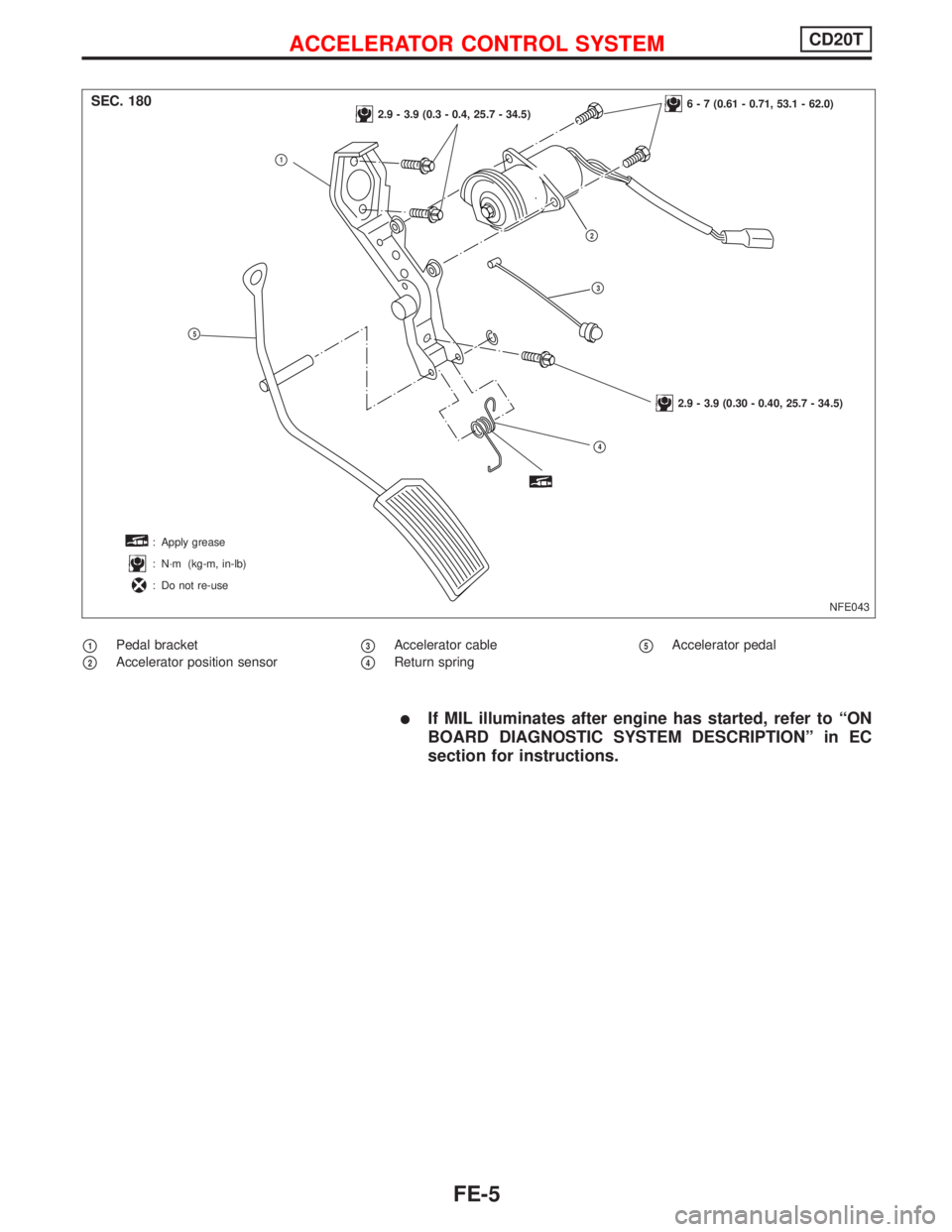

p1Pedal bracket

p2Accelerator position sensorp3Accelerator cable

p4Return springp5Accelerator pedal

lIf MIL illuminates after engine has started, refer to ªON

BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº in EC

section for instructions.

NFE043

p1

p5

6 - 7 (0.61 - 0.71, 53.1 - 62.0)

p4

p3

p2

2.9 - 3.9 (0.30 - 0.40, 25.7 - 34.5)

SEC. 180

: Apply grease

: N´m (kg-m, in-lb)

: Do not re-use

2.9 - 3.9 (0.3 - 0.4, 25.7 - 34.5)

ACCELERATOR CONTROL SYSTEMCD20T

FE-5

Page 1798 of 2267

Observe the following precautions to ensure safe and

proper servicing.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt

Pre-tensionerº, used along with a seat belt, help to reduce the

risk or severity of injury to the driver and front passenger in a

frontal collision. The Supplemental Restraint System consists of

air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-

tensioners, a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable.

If the vehicle is equipped with side air bag as the Supplemental

Restraint System, the side air bag used along with the seat belt

helps to reduce the risk or severity of injury to the driver and front

passenger in a side collision. The side air bag consists of air bag

modules (located in the outer side of front seats), satellite sensor,

diagnosis sensor unit (which is one of components of air bags for

a frontal collision), wiring harness, warning lamp (which is one of

components of air bags for a frontal collision).

WARNING:

lTo avoid rendering the SRS inoperative, (which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation) all

maintenance must be performed by an authorized

NISSAN dealer.

lImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury

caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit

related to the SRS unless instructed to do so in this

Service Manual. SRS wiring harnesses are covered with

yellow insulation (either just before the harness connec-

tors or for the complete harness), for easy identification.

Precautions for NATS

NATS (Nissan Anti-Theft System)

NATS will immobilize the engine if someone tries to start it with-

out the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The NATS security indicator is located on the instrument panel.

The indicator flashes when the ignition switch is in ªLOCKº or

ªAccº position. Therefore, NATS warns outsiders that the vehicle

is equipped with the anti-theft system.

lWhen NATS detects trouble, the malfunction indicator (MI)

flashes.

This flashing indicates that the anti-theft is not functioning, so

prompt service is required.

lWhen servicing NATS (trouble diagnoses, system initialisa-

tion and additional registration of other NATS ignition key

IDs), CONSULT-II hardware and CONSULT-II NATS soft-

ware is necessary.

SGI916

PRECAUTIONS

GI-3

Page 1801 of 2267

Precautions for Multiport Fuel Injection

System or Engine Control Module

lBefore connecting or disconnecting any harness connector

for the multiport fuel injection system or ECM (Engine Con-

trol Module):

Turn ignition switch to ªLOCKº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Three Way Catalyst

If a large amount of unburned fuel flows into the catalyst, the

catalyst temperature will be excessively high. To prevent this,

follow the instructions below:

lUse unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

lWhen checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

lDo not run engine when the fuel tank level is low, otherwise

the engine may misfire causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after

starting.

lIf engine had been operating at high rpm for an extended

period of time, let it idle for a few minutes prior to shutting it

off.

Precautions for Engine Oils

Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

lAvoid prolonged and repeated contact with oils, particularly

used engine oils.

SGI787

SGI292 Cold engine

PRECAUTIONS

GI-6

Page 1812 of 2267

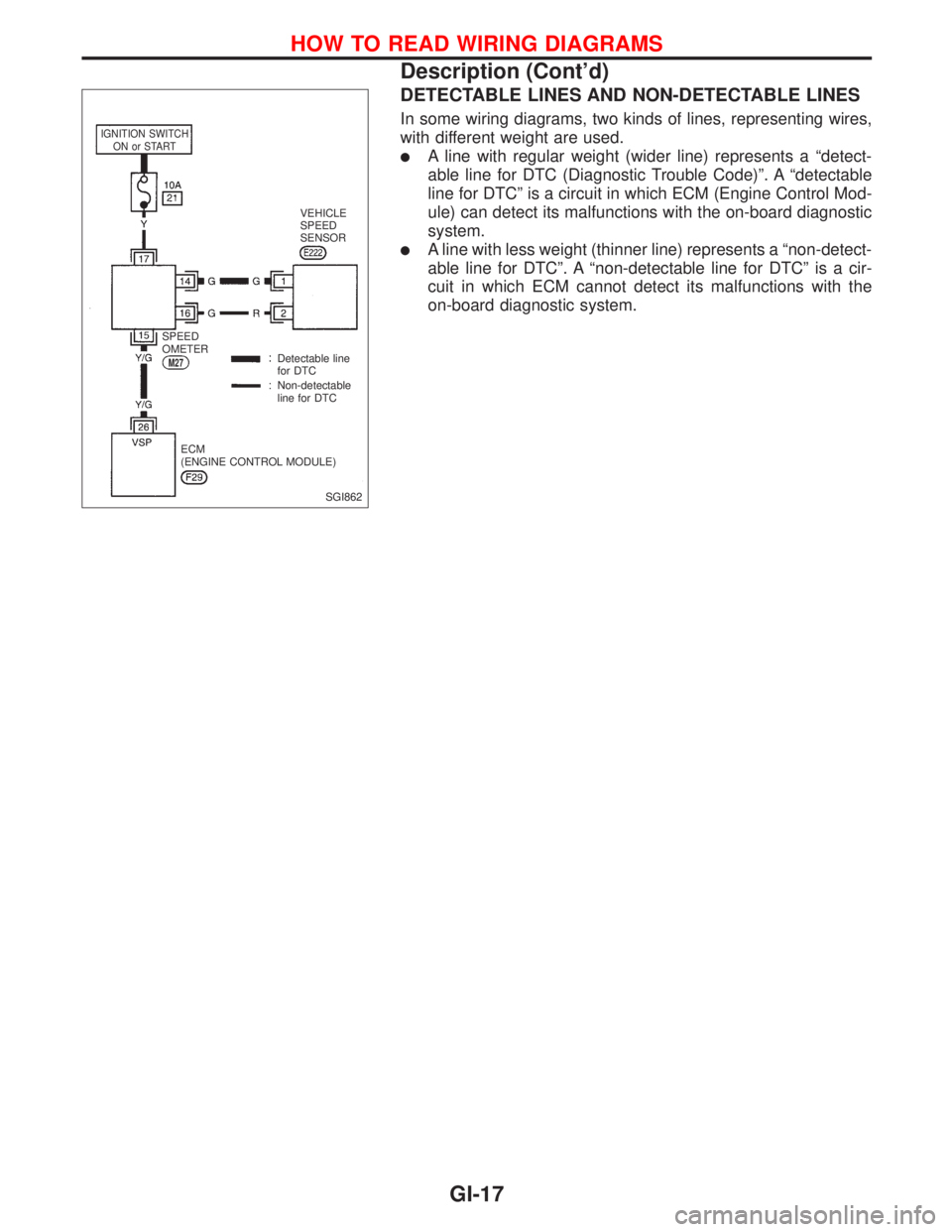

DETECTABLE LINES AND NON-DETECTABLE LINES

In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

lA line with regular weight (wider line) represents a ªdetect-

able line for DTC (Diagnostic Trouble Code)º. A ªdetectable

line for DTCº is a circuit in which ECM (Engine Control Mod-

ule) can detect its malfunctions with the on-board diagnostic

system.

lA line with less weight (thinner line) represents a ªnon-detect-

able line for DTCº. A ªnon-detectable line for DTCº is a cir-

cuit in which ECM cannot detect its malfunctions with the

on-board diagnostic system.

SGI862

IGNITION SWITCH

ON or START

VEHICLE

SPEED

SENSOR

SPEED

OMETER

M27Detectable line

for DTC

Non-detectable

line for DTC

ECM

(ENGINE CONTROL MODULE)

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-17