NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 831 of 2267

Fuel Pressure ReleaseNCEC0024Before disconnecting fuel line, release fuel pressure from fuel

line to eliminate danger.

WITH CONSULT-IINCEC0024S011. Start engine.

2. Perform ªFUEL PRES RELEASEº in ªWORK SUPPORTº

mode with CONSULT-II.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF.

WITHOUT CONSULT-IINCEC0024S021. Remove fuse for fuel pump. Refer to fuse block cover for fuse

location.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF and reconnect fuel pump fuse.

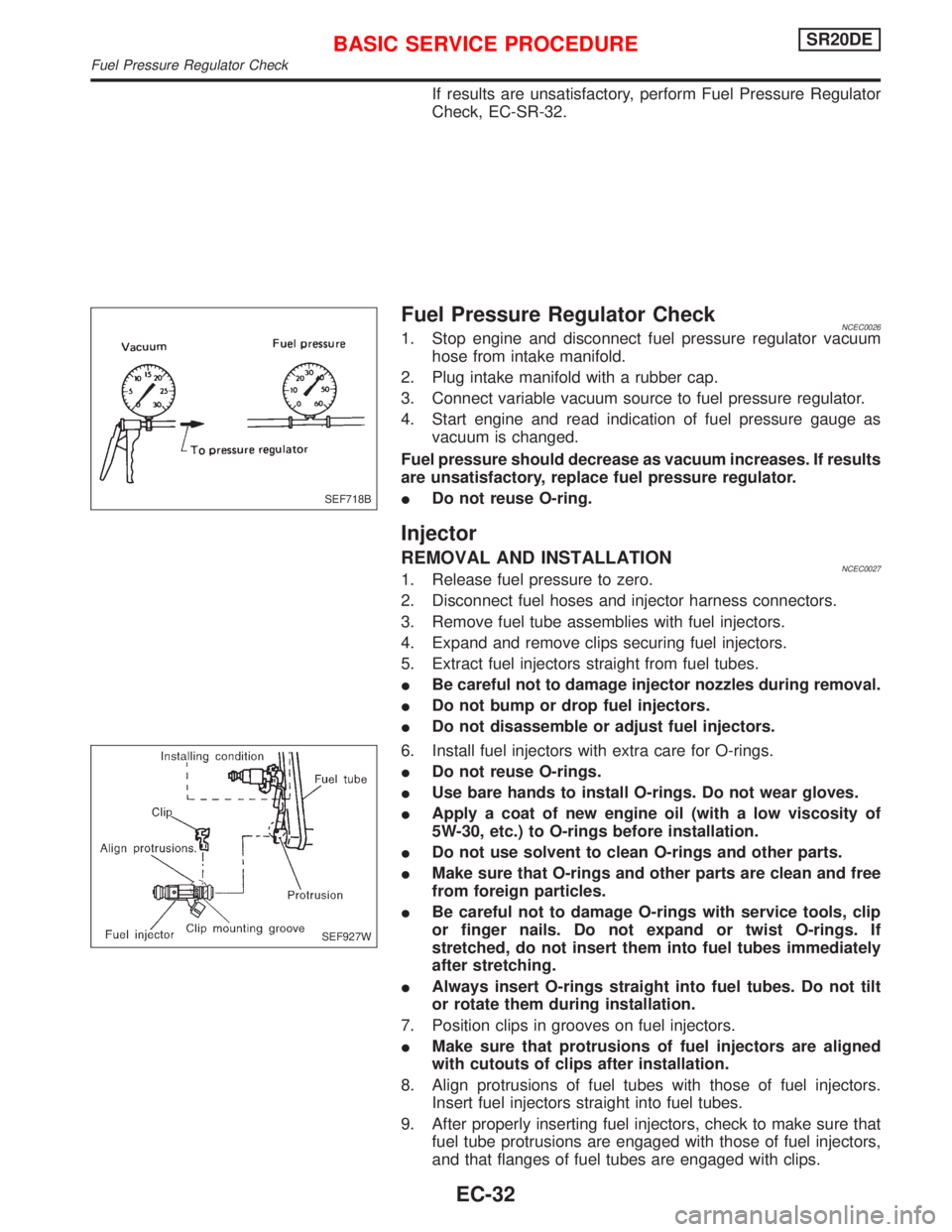

Fuel Pressure CheckNCEC0025IWhen reconnecting fuel line, always use new clamps.

IMake sure that clamp screw does not contact adjacent

parts.

IUse a torque driver to tighten clamps.

IUse Pressure Gauge to check fuel pressure.

IDo not perform fuel pressure check with system operat-

ing. Fuel pressure gauge may indicate false readings.

1. Release fuel pressure to zero.

2. Disconnect fuel hose between fuel filter and fuel tube (engine

side).

3. Install pressure gauge between fuel filter and fuel tube.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

At idle speed:

With vacuum hose connected

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2,34

psi)

With vacuum hose disconnected

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2,43

psi)

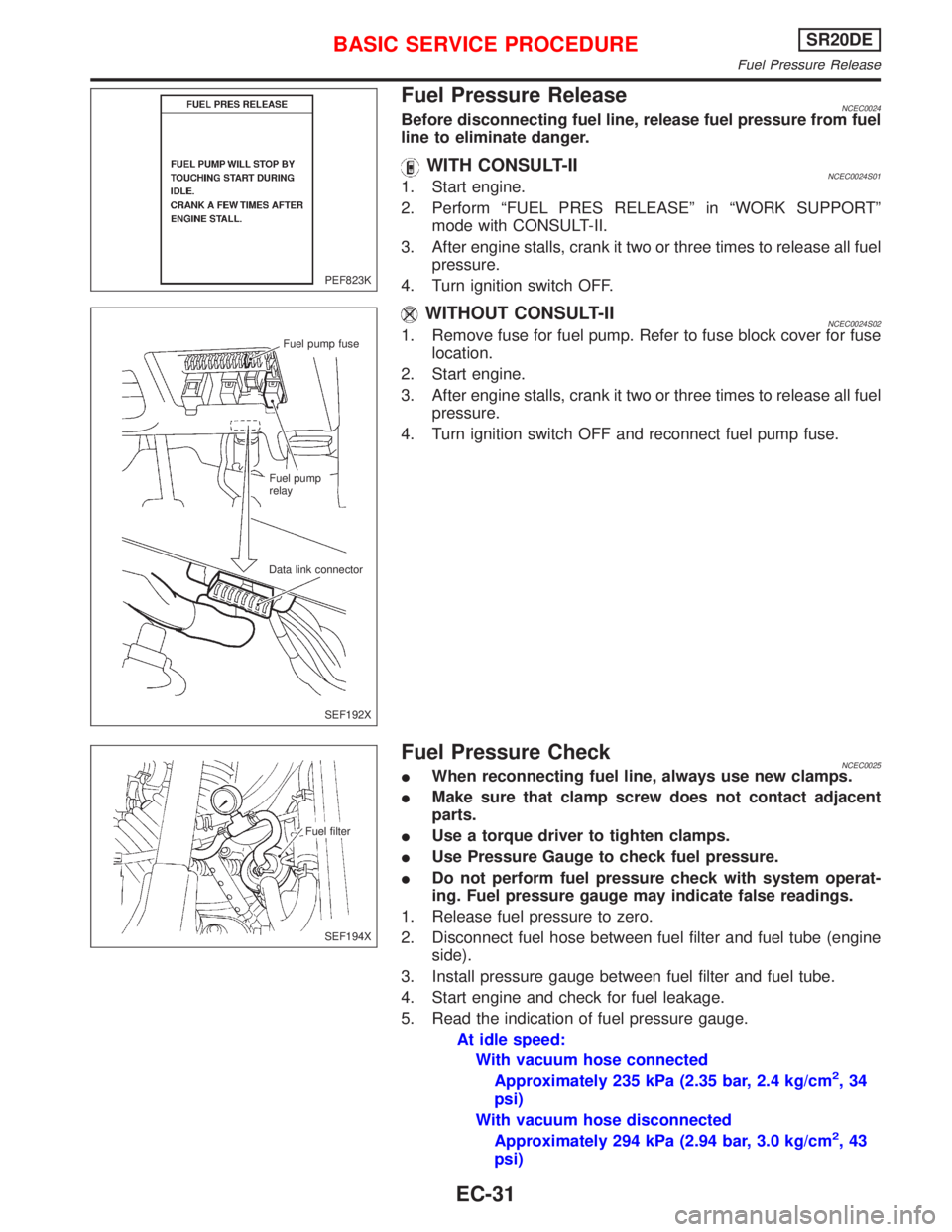

PEF823K

Fuel pump fuse

Fuel pump

relay

Data link connector

SEF192X

Fuel filter

SEF194X

BASIC SERVICE PROCEDURESR20DE

Fuel Pressure Release

EC-31

Page 832 of 2267

If results are unsatisfactory, perform Fuel Pressure Regulator

Check, EC-SR-32.

Fuel Pressure Regulator CheckNCEC00261. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

2. Plug intake manifold with a rubber cap.

3. Connect variable vacuum source to fuel pressure regulator.

4. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If results

are unsatisfactory, replace fuel pressure regulator.

IDo not reuse O-ring.

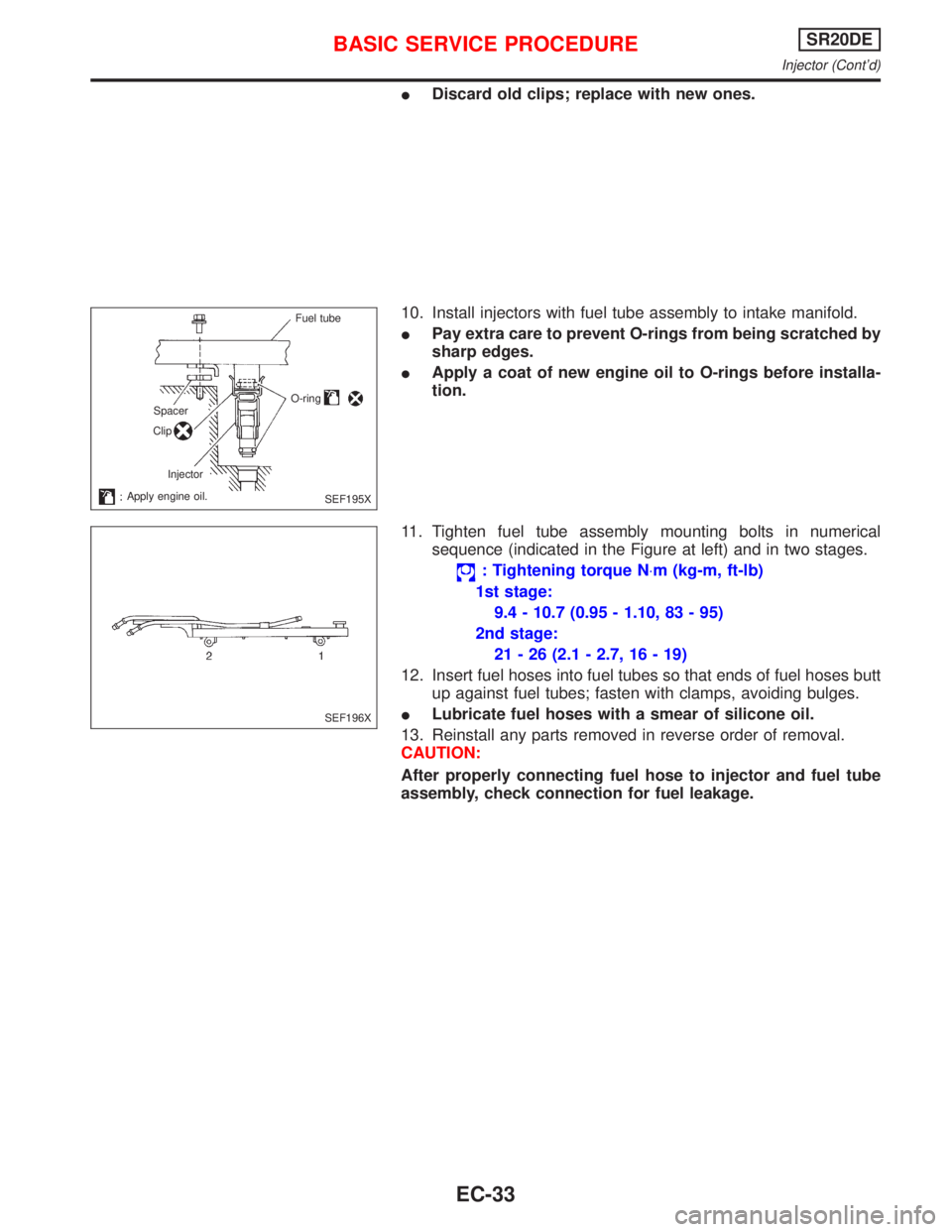

Injector

REMOVAL AND INSTALLATIONNCEC00271. Release fuel pressure to zero.

2. Disconnect fuel hoses and injector harness connectors.

3. Remove fuel tube assemblies with fuel injectors.

4. Expand and remove clips securing fuel injectors.

5. Extract fuel injectors straight from fuel tubes.

IBe careful not to damage injector nozzles during removal.

IDo not bump or drop fuel injectors.

IDo not disassemble or adjust fuel injectors.

6. Install fuel injectors with extra care for O-rings.

IDo not reuse O-rings.

IUse bare hands to install O-rings. Do not wear gloves.

IApply a coat of new engine oil (with a low viscosity of

5W-30, etc.) to O-rings before installation.

IDo not use solvent to clean O-rings and other parts.

IMake sure that O-rings and other parts are clean and free

from foreign particles.

IBe careful not to damage O-rings with service tools, clip

or finger nails. Do not expand or twist O-rings. If

stretched, do not insert them into fuel tubes immediately

after stretching.

IAlways insert O-rings straight into fuel tubes. Do not tilt

or rotate them during installation.

7. Position clips in grooves on fuel injectors.

IMake sure that protrusions of fuel injectors are aligned

with cutouts of clips after installation.

8. Align protrusions of fuel tubes with those of fuel injectors.

Insert fuel injectors straight into fuel tubes.

9. After properly inserting fuel injectors, check to make sure that

fuel tube protrusions are engaged with those of fuel injectors,

and that flanges of fuel tubes are engaged with clips.

SEF718B

SEF927W

BASIC SERVICE PROCEDURESR20DE

Fuel Pressure Regulator Check

EC-32

Page 833 of 2267

IDiscard old clips; replace with new ones.

10. Install injectors with fuel tube assembly to intake manifold.

IPay extra care to prevent O-rings from being scratched by

sharp edges.

IApply a coat of new engine oil to O-rings before installa-

tion.

11. Tighten fuel tube assembly mounting bolts in numerical

sequence (indicated in the Figure at left) and in two stages.

: Tightening torque N×m (kg-m, ft-lb)

1st stage:

9.4 - 10.7 (0.95 - 1.10, 83 - 95)

2nd stage:

21 - 26 (2.1 - 2.7, 16 - 19)

12. Insert fuel hoses into fuel tubes so that ends of fuel hoses butt

up against fuel tubes; fasten with clamps, avoiding bulges.

ILubricate fuel hoses with a smear of silicone oil.

13. Reinstall any parts removed in reverse order of removal.

CAUTION:

After properly connecting fuel hose to injector and fuel tube

assembly, check connection for fuel leakage.

Fuel tube

O-ring

Spacer

Clip

Injector

Apply engine oil.

SEF195X

SEF196X

BASIC SERVICE PROCEDURESR20DE

Injector (Cont'd)

EC-33

Page 834 of 2267

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

NCEC0028PREPARATIONNCEC0028S01IMake sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)Throttle valve

k)EVAP system

IOn models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

IWhen checking idle speed on models equipped with CVT,

ignition timing and mixture ratio, checks should be carried

out while shift lever is in ªPº or ªNº position.

IWhen measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

ITurn off headlamps, heater blower, rear window defogger.

IOn vehicles equipped with daytime running light systems,

set lighting switch to the 1st position to light only small

lamps.

IKeep front wheels pointed straight ahead.

IIf engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

IMake the check after the cooling fan has stopped.

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-34

Page 835 of 2267

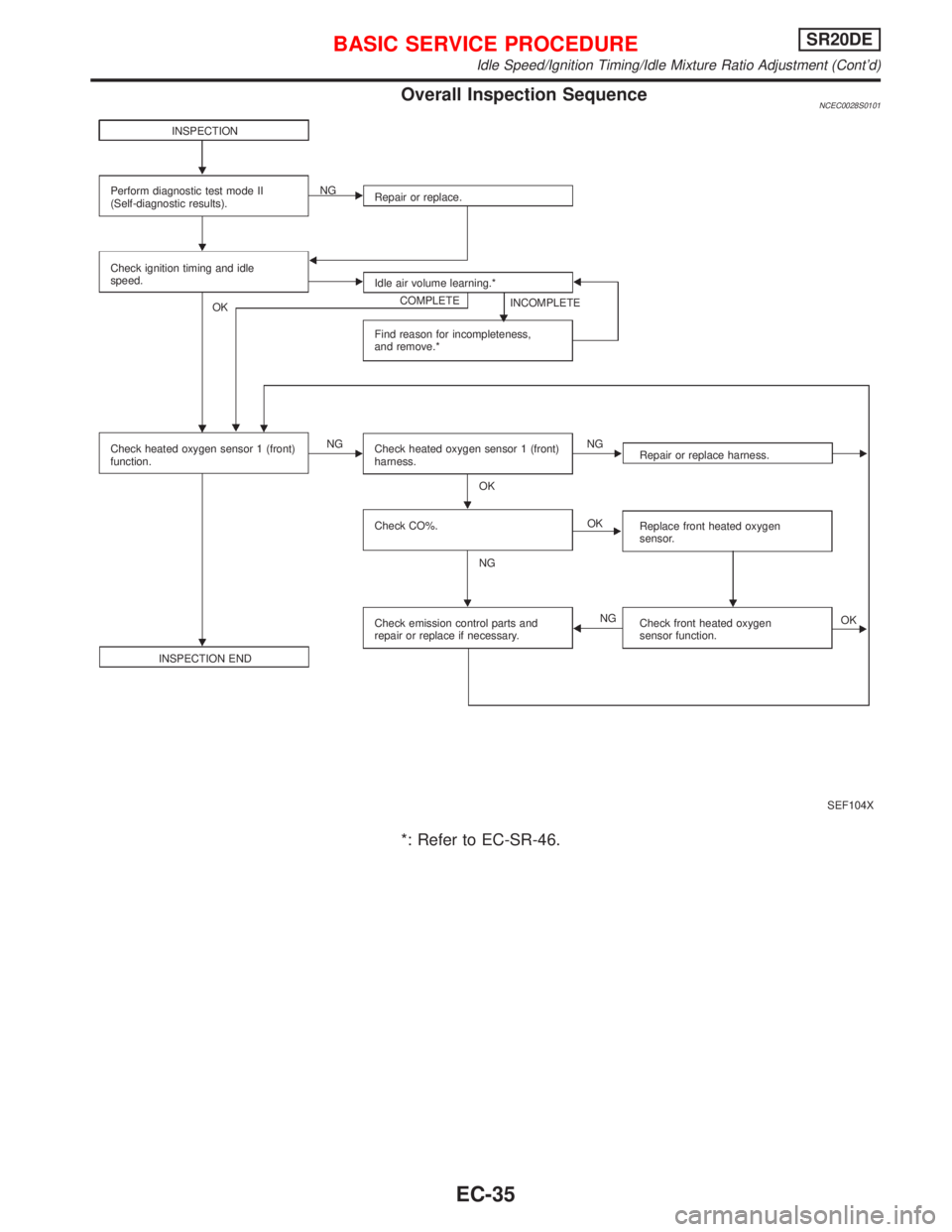

Overall Inspection SequenceNCEC0028S0101

*: Refer to EC-SR-46.

SEF104X INSPECTION

Perform diagnostic test mode II

(Self-diagnostic results).Repair or replace. NG

Check ignition timing and idle

speed.

Idle air volume learning.*

COMPLETE

INCOMPLETE

Find reason for incompleteness,

and remove.* OK

Check heated oxygen sensor 1 (front)

function.NG

Check heated oxygen sensor 1 (front)

harness.NG

OK

Check CO%.

NGOK

INSPECTION ENDCheck emission control parts and

repair or replace if necessary.NGRepair or replace harness.

Replace front heated oxygen

sensor.

Check front heated oxygen

sensor function.OK H

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-35

Page 836 of 2267

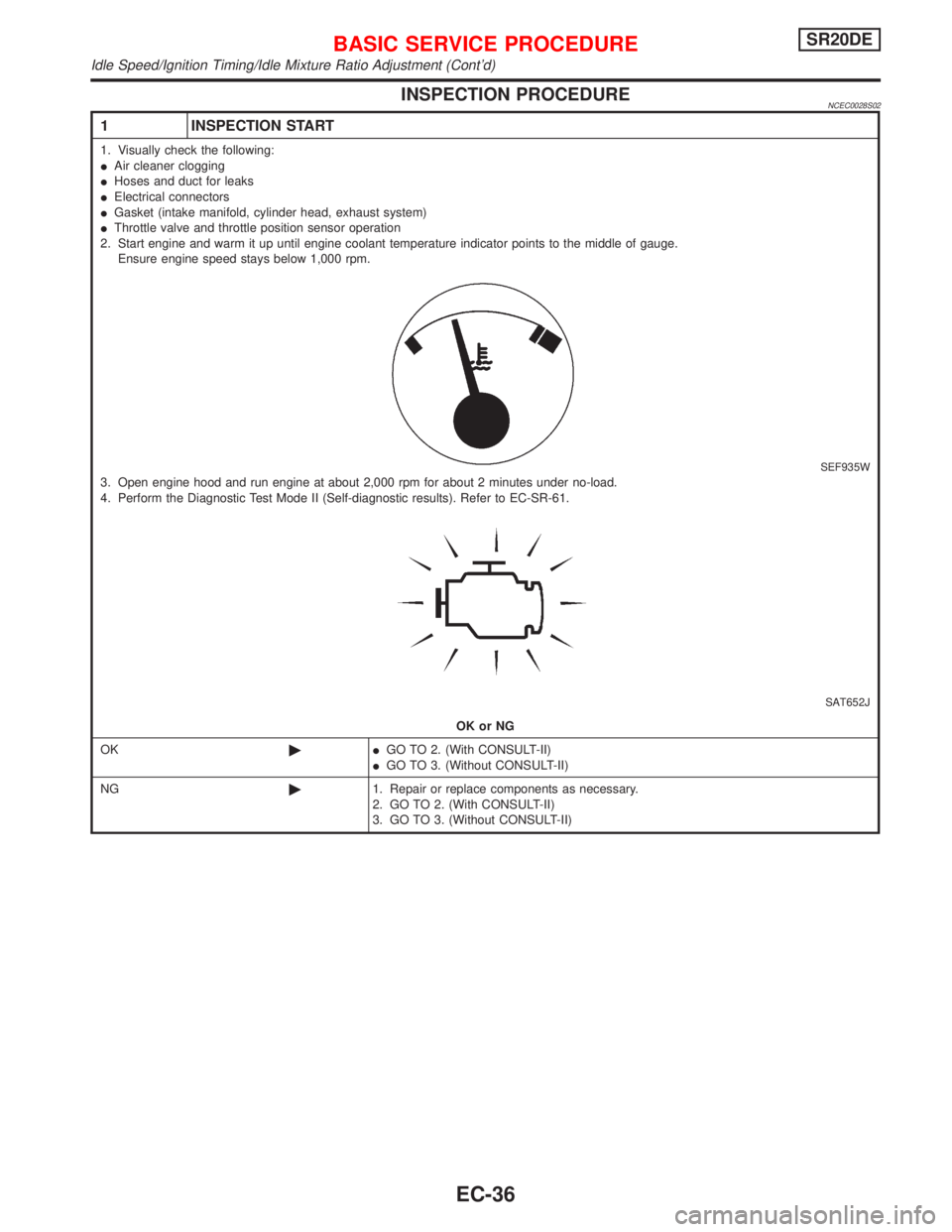

INSPECTION PROCEDURENCEC0028S02

1 INSPECTION START

1. Visually check the following:

IAir cleaner clogging

IHoses and duct for leaks

IElectrical connectors

IGasket (intake manifold, cylinder head, exhaust system)

IThrottle valve and throttle position sensor operation

2. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

Ensure engine speed stays below 1,000 rpm.

SEF935W3. Open engine hood and run engine at about 2,000 rpm for about 2 minutes under no-load.

4. Perform the Diagnostic Test Mode II (Self-diagnostic results). Refer to EC-SR-61.

SAT652J

OK or NG

OK©IGO TO 2. (With CONSULT-II)

IGO TO 3. (Without CONSULT-II)

NG©1. Repair or replace components as necessary.

2. GO TO 2. (With CONSULT-II)

3. GO TO 3. (Without CONSULT-II)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-36

Page 837 of 2267

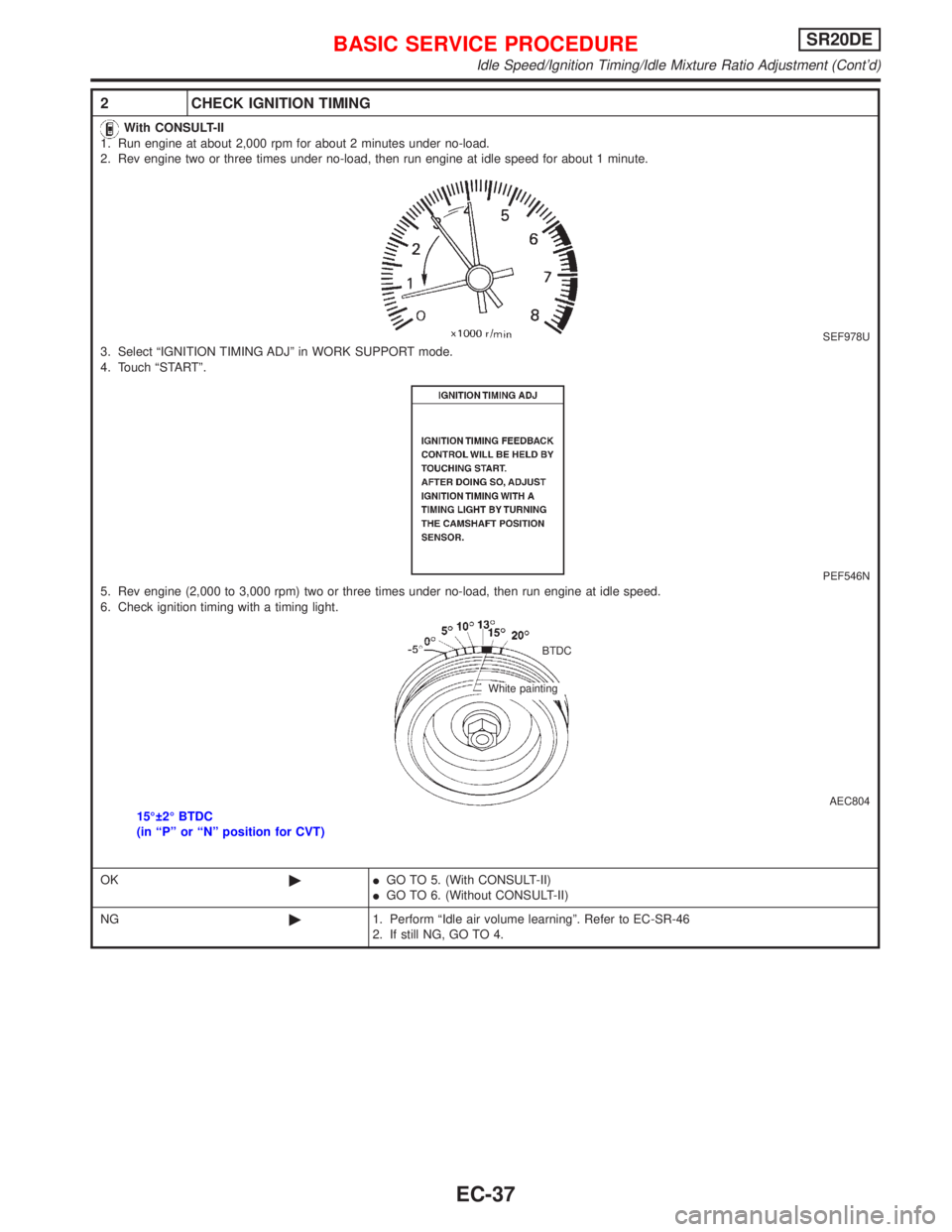

2 CHECK IGNITION TIMING

With CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Rev engine two or three times under no-load, then run engine at idle speed for about 1 minute.

SEF978U3. Select ªIGNITION TIMING ADJº in WORK SUPPORT mode.

4. Touch ªSTARTº.

PEF546N5. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

6. Check ignition timing with a timing light.

AEC80415É 2É BTDC

(in ªPº or ªNº position for CVT)

OK©IGO TO 5. (With CONSULT-II)

IGO TO 6. (Without CONSULT-II)

NG©1. Perform ªIdle air volume learningº. Refer to EC-SR-46

2. If still NG, GO TO 4.

BTDC

White painting

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-37

Page 838 of 2267

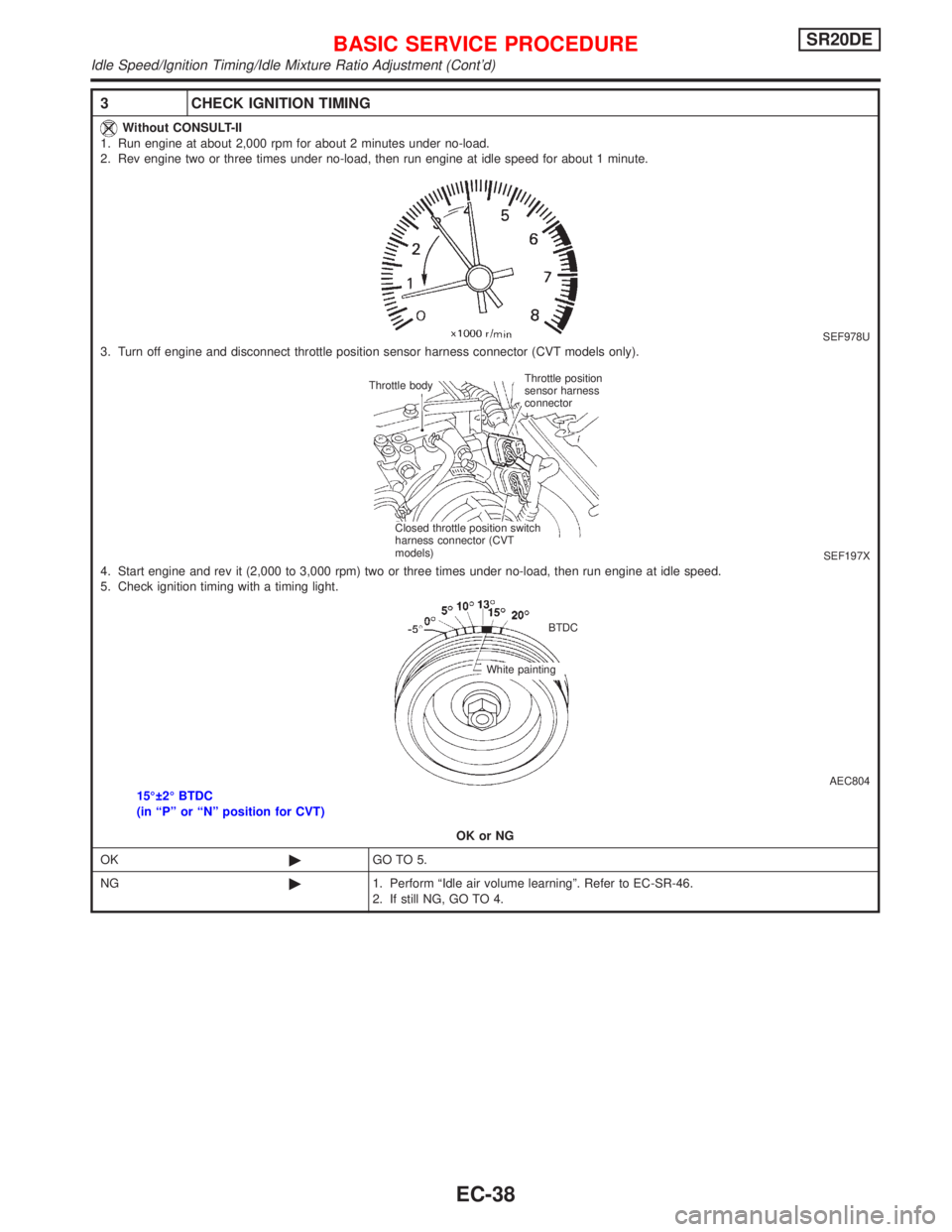

3 CHECK IGNITION TIMING

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Rev engine two or three times under no-load, then run engine at idle speed for about 1 minute.

SEF978U3. Turn off engine and disconnect throttle position sensor harness connector (CVT models only).

SEF197X4. Start engine and rev it (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

5. Check ignition timing with a timing light.

AEC80415É 2É BTDC

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 5.

NG©1. Perform ªIdle air volume learningº. Refer to EC-SR-46.

2. If still NG, GO TO 4.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT

models)

BTDC

White painting

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-38

Page 839 of 2267

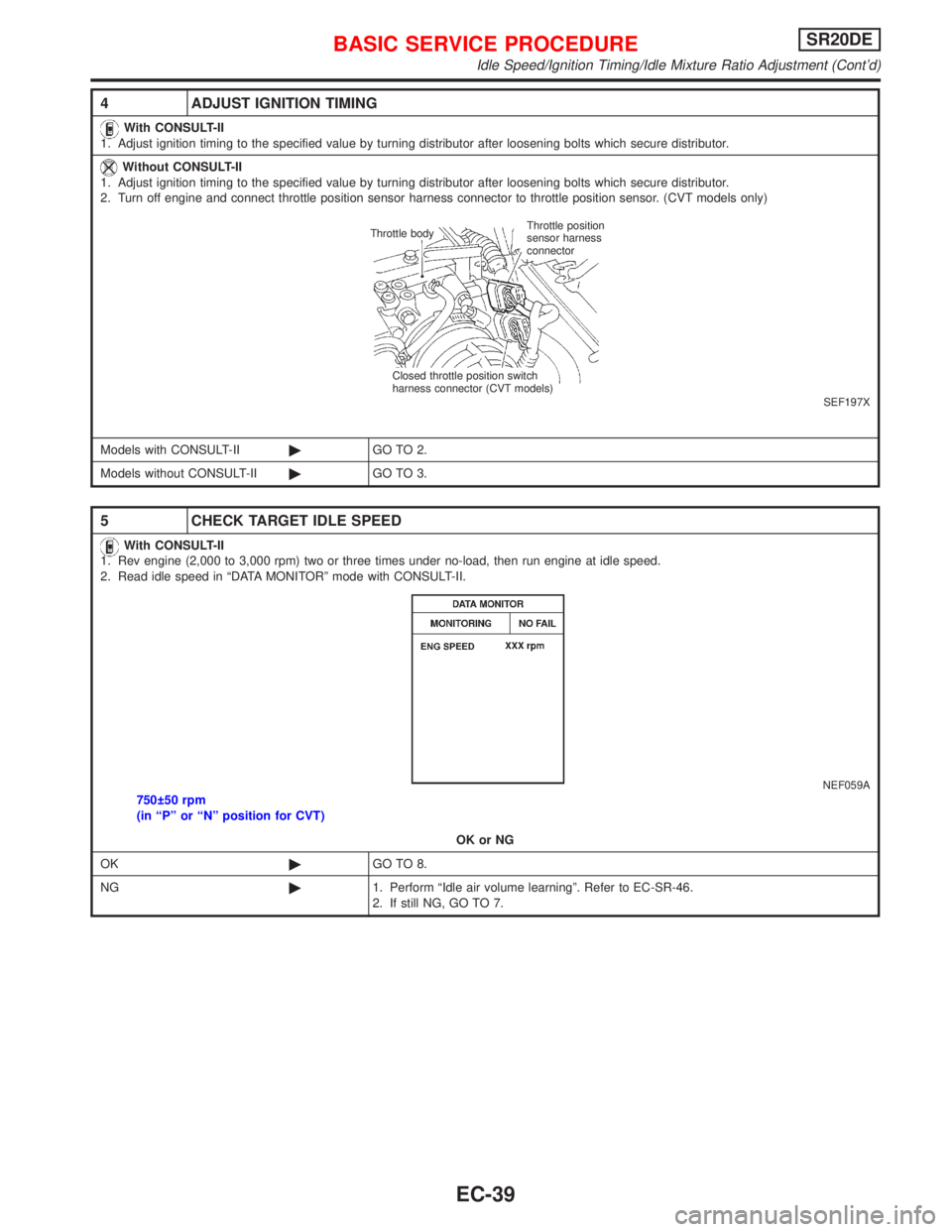

4 ADJUST IGNITION TIMING

With CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

Without CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

2. Turn off engine and connect throttle position sensor harness connector to throttle position sensor. (CVT models only)

SEF197X

Models with CONSULT-II©GO TO 2.

Models without CONSULT-II©GO TO 3.

5 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

2. Read idle speed in ªDATA MONITORº mode with CONSULT-II.

NEF059A750 50 rpm

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 8.

NG©1. Perform ªIdle air volume learningº. Refer to EC-SR-46.

2. If still NG, GO TO 7.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-39

Page 840 of 2267

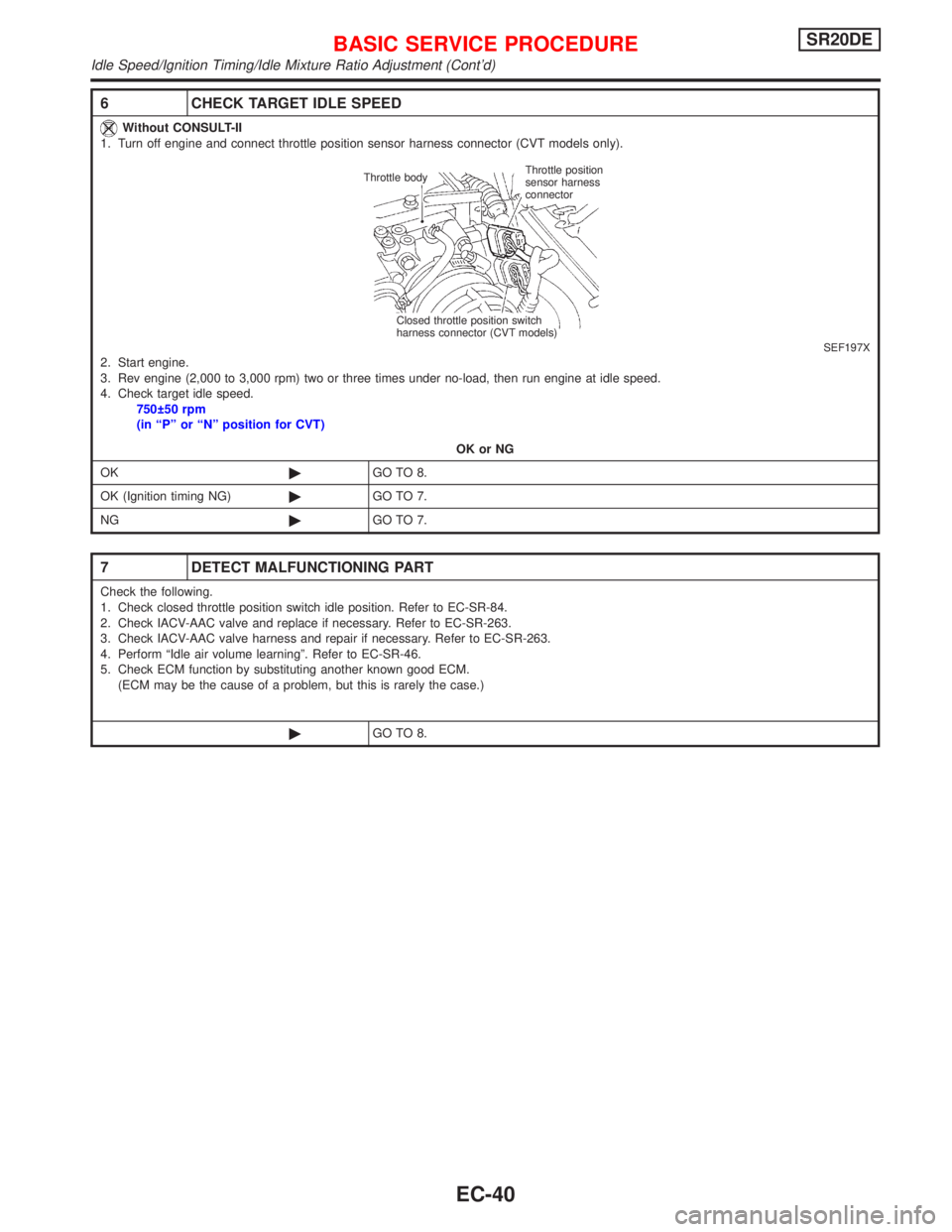

6 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Turn off engine and connect throttle position sensor harness connector (CVT models only).

SEF197X2. Start engine.

3. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

4. Check target idle speed.

750 50 rpm

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 8.

OK (Ignition timing NG)©GO TO 7.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Check closed throttle position switch idle position. Refer to EC-SR-84.

2. Check IACV-AAC valve and replace if necessary. Refer to EC-SR-263.

3. Check IACV-AAC valve harness and repair if necessary. Refer to EC-SR-263.

4. Perform ªIdle air volume learningº. Refer to EC-SR-46.

5. Check ECM function by substituting another known good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 8.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-40