NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 931 of 2267

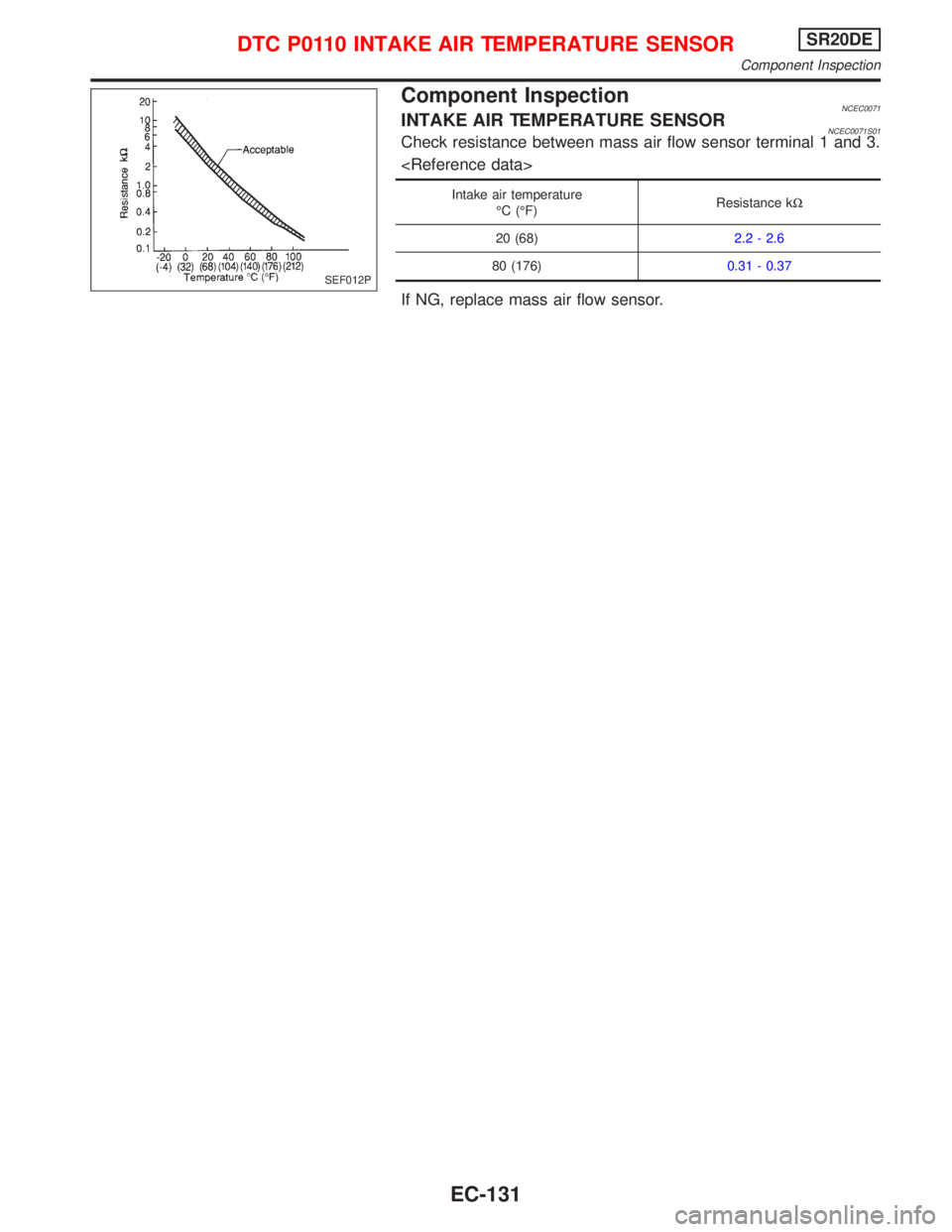

Component InspectionNCEC0071INTAKE AIR TEMPERATURE SENSORNCEC0071S01Check resistance between mass air flow sensor terminal 1 and 3.

Intake air temperature

ÉC (ÉF)Resistance kW

20 (68)2.2 - 2.6

80 (176)0.31 - 0.37

If NG, replace mass air flow sensor.

SEF012P

DTC P0110 INTAKE AIR TEMPERATURE SENSORSR20DE

Component Inspection

EC-131

Page 932 of 2267

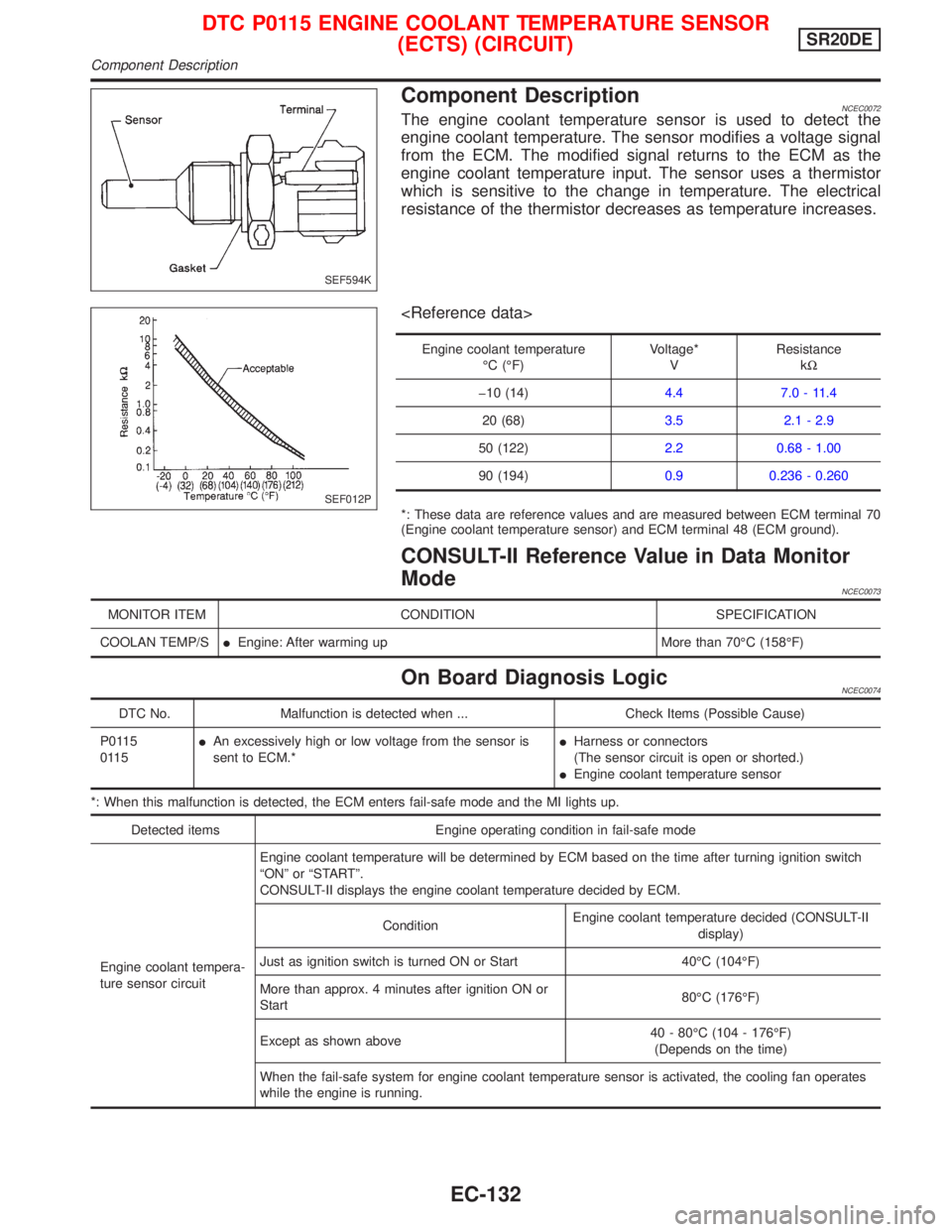

Component DescriptionNCEC0072The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

Engine coolant temperature

ÉC (ÉF)Voltage*

VResistance

kW

þ10 (14)4.4 7.0 - 11.4

20 (68)3.5 2.1 - 2.9

50 (122)2.2 0.68 - 1.00

90 (194)0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ECM terminal 48 (ECM ground).

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0073

MONITOR ITEM CONDITION SPECIFICATION

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

On Board Diagnosis LogicNCEC0074

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0115

0115IAn excessively high or low voltage from the sensor is

sent to ECM.*IHarness or connectors

(The sensor circuit is open or shorted.)

IEngine coolant temperature sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Detected items Engine operating condition in fail-safe mode

Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-II

display)

Just as ignition switch is turned ON or Start 40ÉC (104ÉF)

More than approx. 4 minutes after ignition ON or

Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates

while the engine is running.

SEF594K

SEF012P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Component Description

EC-132

Page 933 of 2267

DTC Confirmation ProcedureNCEC0075NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-135.

With GST

Follow the procedure ªWith CONSULT-IIº above.

PEF002P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

DTC Confirmation Procedure

EC-133

Page 934 of 2267

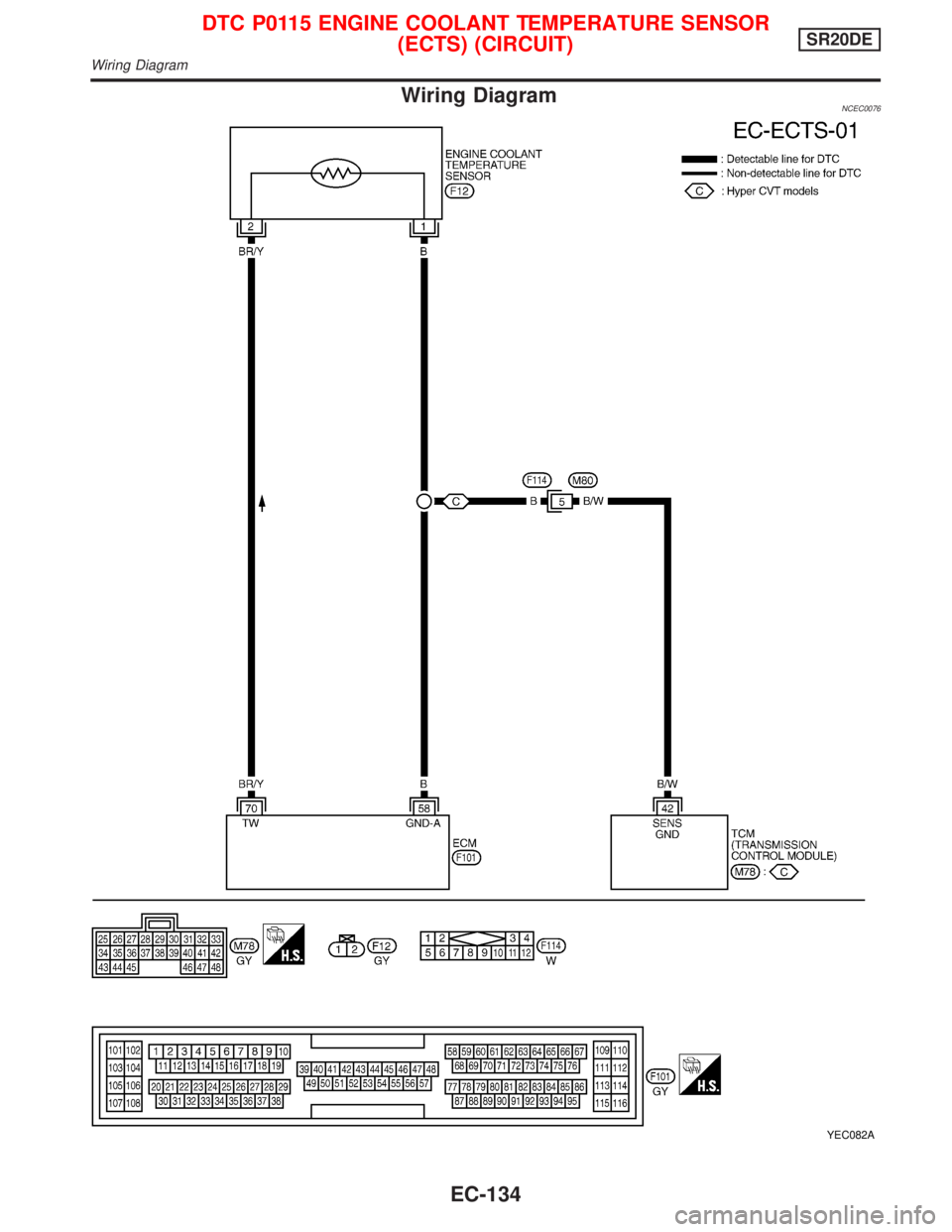

Wiring DiagramNCEC0076

YEC082A

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Wiring Diagram

EC-134

Page 935 of 2267

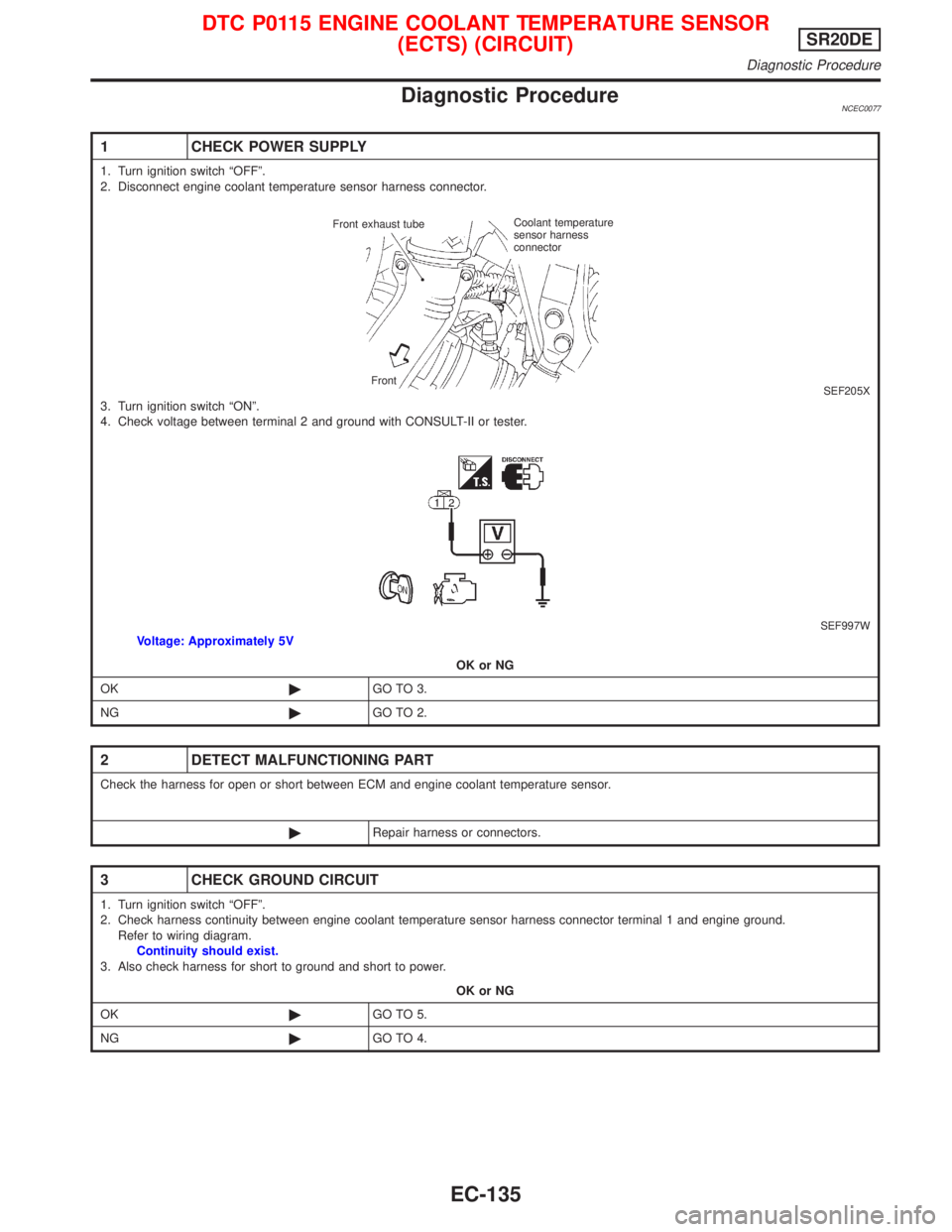

Diagnostic ProcedureNCEC0077

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

SEF205X3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF997WVoltage: Approximately 5V

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and engine coolant temperature sensor.

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between engine coolant temperature sensor harness connector terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Front exhaust tube

FrontCoolant temperature

sensor harness

connector

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Diagnostic Procedure

EC-135

Page 936 of 2267

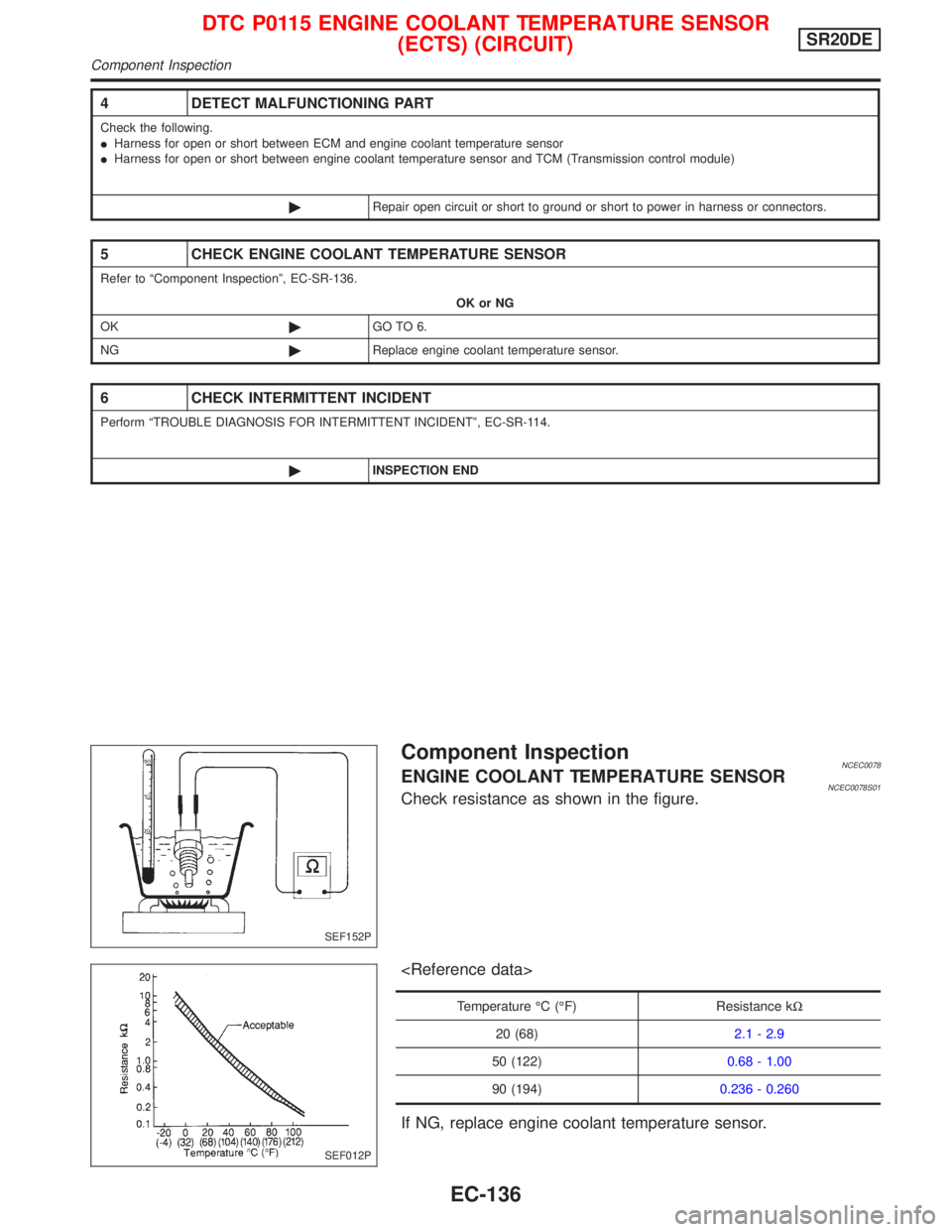

Component InspectionNCEC0078ENGINE COOLANT TEMPERATURE SENSORNCEC0078S01Check resistance as shown in the figure.

Temperature ÉC (ÉF) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

If NG, replace engine coolant temperature sensor.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and engine coolant temperature sensor

IHarness for open or short between engine coolant temperature sensor and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-SR-136.

OK or NG

OK©GO TO 6.

NG©Replace engine coolant temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF152P

SEF012P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)SR20DE

Component Inspection

EC-136

Page 937 of 2267

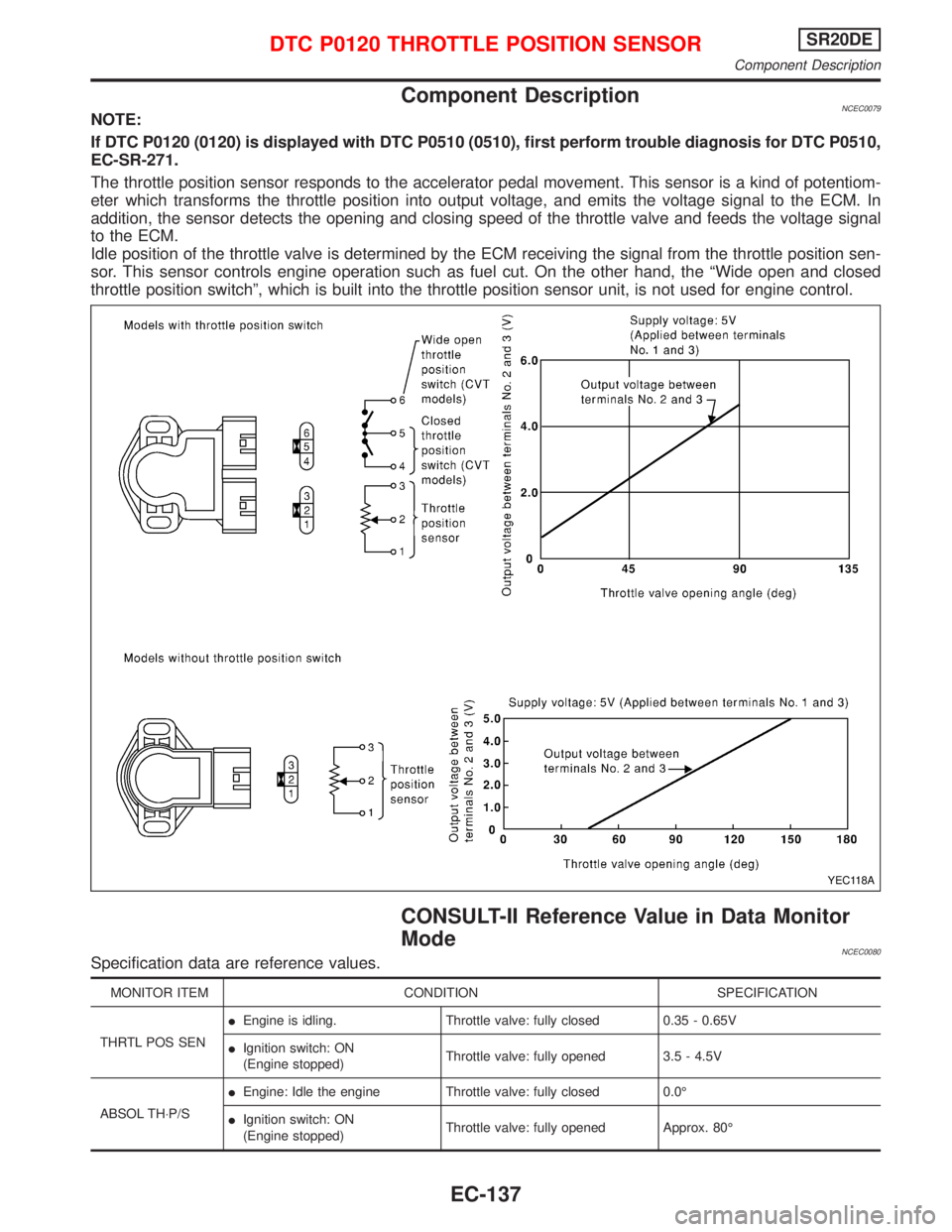

Component DescriptionNCEC0079NOTE:

If DTC P0120 (0120) is displayed with DTC P0510 (0510), first perform trouble diagnosis for DTC P0510,

EC-SR-271.

The throttle position sensor responds to the accelerator pedal movement. This sensor is a kind of potentiom-

eter which transforms the throttle position into output voltage, and emits the voltage signal to the ECM. In

addition, the sensor detects the opening and closing speed of the throttle valve and feeds the voltage signal

to the ECM.

Idle position of the throttle valve is determined by the ECM receiving the signal from the throttle position sen-

sor. This sensor controls engine operation such as fuel cut. On the other hand, the ªWide open and closed

throttle position switchº, which is built into the throttle position sensor unit, is not used for engine control.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0080Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

THRTL POS SENIEngine is idling. Throttle valve: fully closed 0.35 - 0.65V

IIgnition switch: ON

(Engine stopped)Throttle valve: fully opened 3.5 - 4.5V

ABSOL TH×P/SIEngine: Idle the engine Throttle valve: fully closed 0.0É

IIgnition switch: ON

(Engine stopped)Throttle valve: fully opened Approx. 80É

YEC118A

DTC P0120 THROTTLE POSITION SENSORSR20DE

Component Description

EC-137

Page 938 of 2267

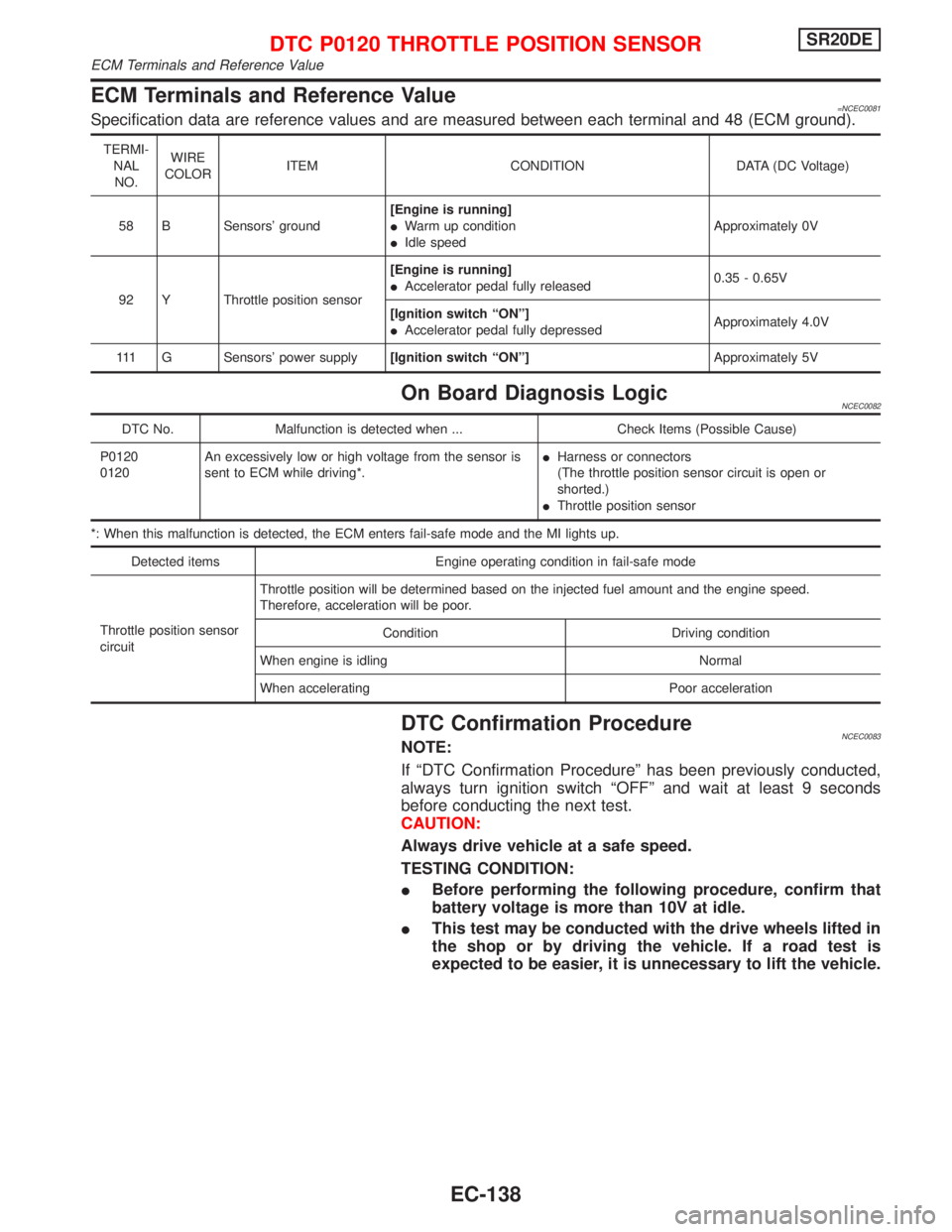

ECM Terminals and Reference Value=NCEC0081Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B Sensors' ground[Engine is running]

IWarm up condition

IIdle speedApproximately 0V

92 Y Throttle position sensor[Engine is running]

IAccelerator pedal fully released0.35 - 0.65V

[Ignition switch ªONº]

IAccelerator pedal fully depressedApproximately 4.0V

111 G Sensors' power supply[Ignition switch ªONº]Approximately 5V

On Board Diagnosis LogicNCEC0082

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0120

0120An excessively low or high voltage from the sensor is

sent to ECM while driving*.IHarness or connectors

(The throttle position sensor circuit is open or

shorted.)

IThrottle position sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Detected items Engine operating condition in fail-safe mode

Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and the engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

DTC Confirmation ProcedureNCEC0083NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle.

IThis test may be conducted with the drive wheels lifted in

the shop or by driving the vehicle. If a road test is

expected to be easier, it is unnecessary to lift the vehicle.

DTC P0120 THROTTLE POSITION SENSORSR20DE

ECM Terminals and Reference Value

EC-138

Page 939 of 2267

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and maintain the following conditions for at least

5 consecutive seconds.

VHCL SPEED SE More than 4 km/h (2 MPH)

Selector lever Suitable position except ªPº or ªNº

position

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-141.

With GST

Follow the procedure ªWith CONSULT-IIº above.

PEF651U

DTC P0120 THROTTLE POSITION SENSORSR20DE

DTC Confirmation Procedure (Cont'd)

EC-139

Page 940 of 2267

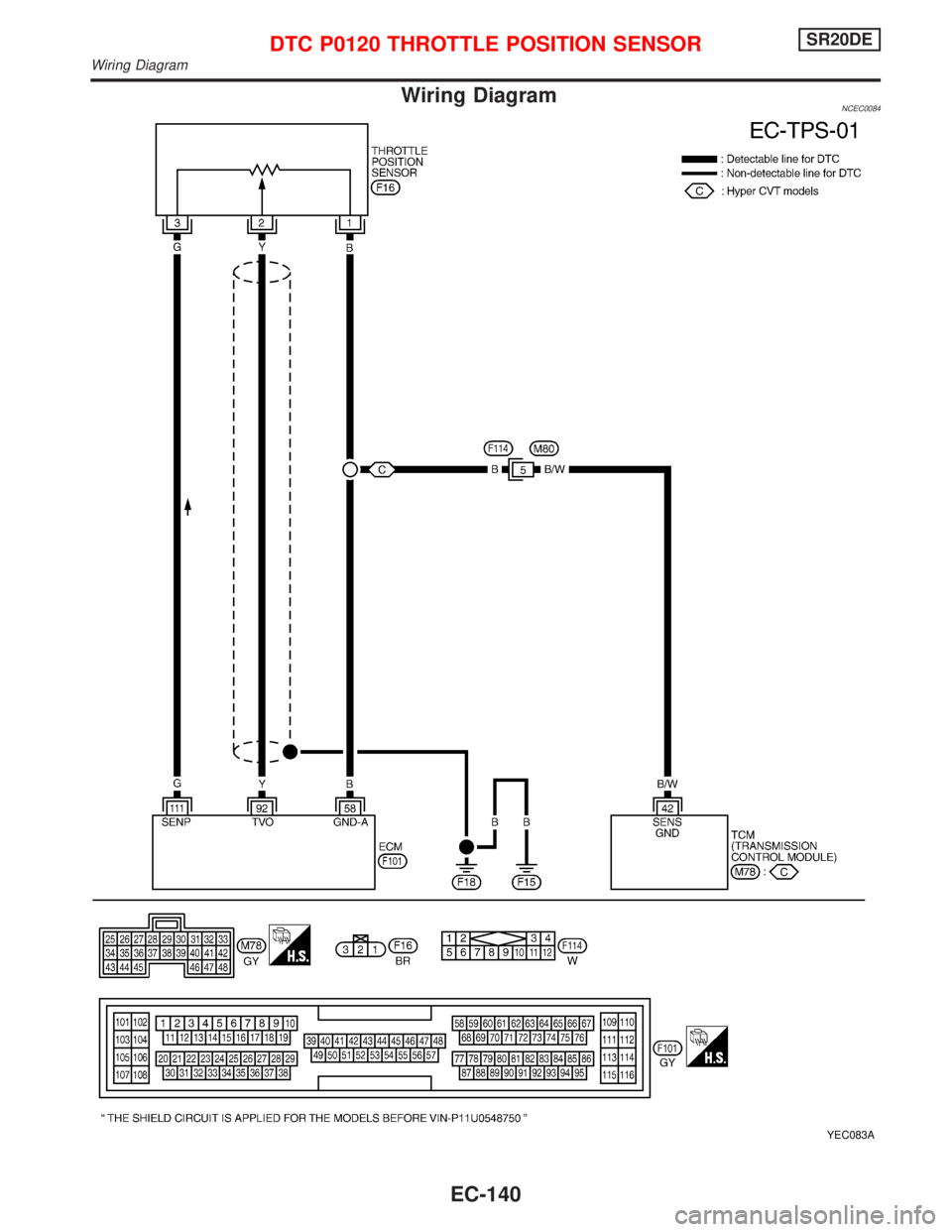

Wiring DiagramNCEC0084

YEC083A

DTC P0120 THROTTLE POSITION SENSORSR20DE

Wiring Diagram

EC-140