NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 971 of 2267

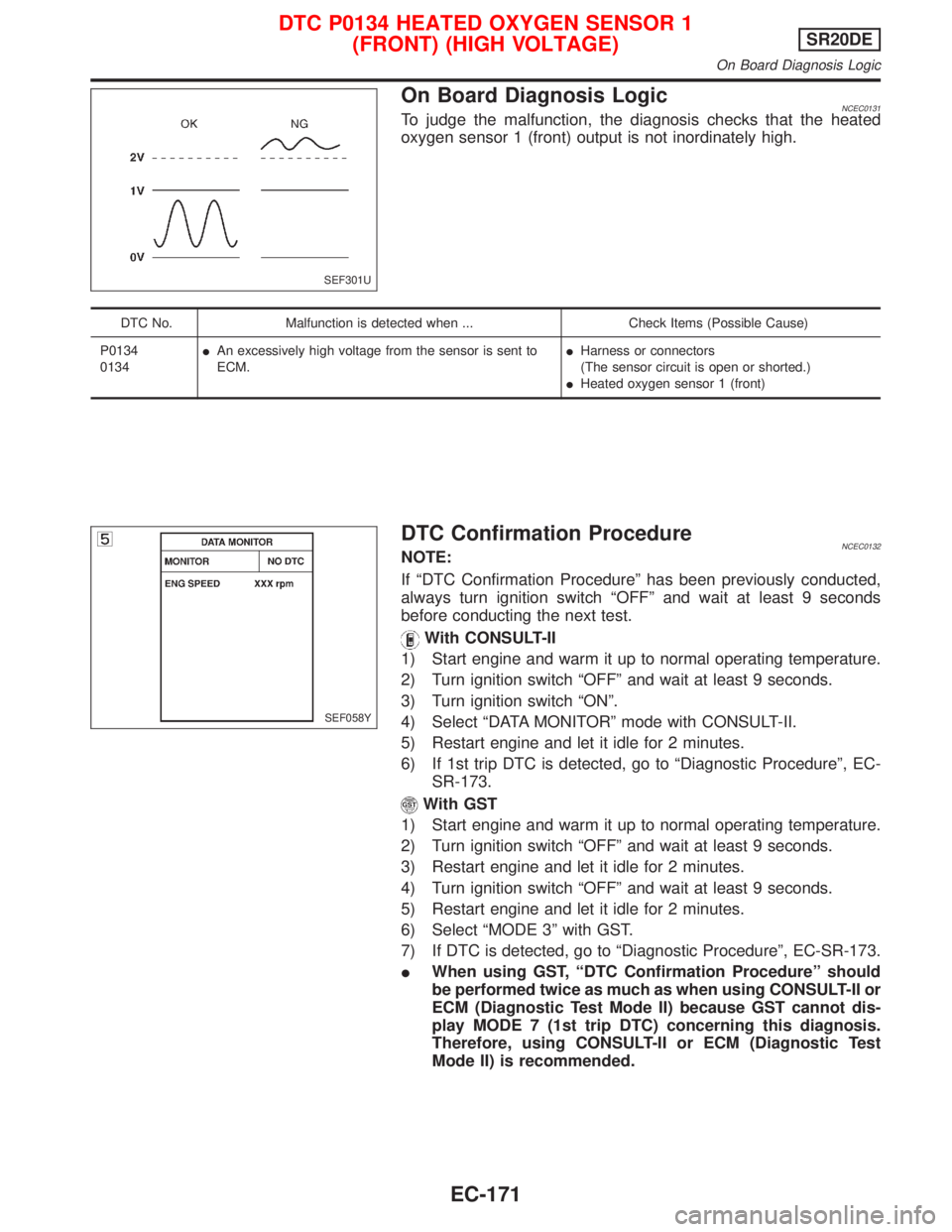

On Board Diagnosis LogicNCEC0131To judge the malfunction, the diagnosis checks that the heated

oxygen sensor 1 (front) output is not inordinately high.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0134

0134IAn excessively high voltage from the sensor is sent to

ECM.IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 1 (front)

DTC Confirmation ProcedureNCEC0132NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Turn ignition switch ªONº.

4) Select ªDATA MONITORº mode with CONSULT-II.

5) Restart engine and let it idle for 2 minutes.

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-173.

With GST

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Restart engine and let it idle for 2 minutes.

4) Turn ignition switch ªOFFº and wait at least 9 seconds.

5) Restart engine and let it idle for 2 minutes.

6) Select ªMODE 3º with GST.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-SR-173.

IWhen using GST, ªDTC Confirmation Procedureº should

be performed twice as much as when using CONSULT-II or

ECM (Diagnostic Test Mode II) because GST cannot dis-

play MODE 7 (1st trip DTC) concerning this diagnosis.

Therefore, using CONSULT-II or ECM (Diagnostic Test

Mode II) is recommended.

SEF301U

SEF058Y

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)SR20DE

On Board Diagnosis Logic

EC-171

Page 972 of 2267

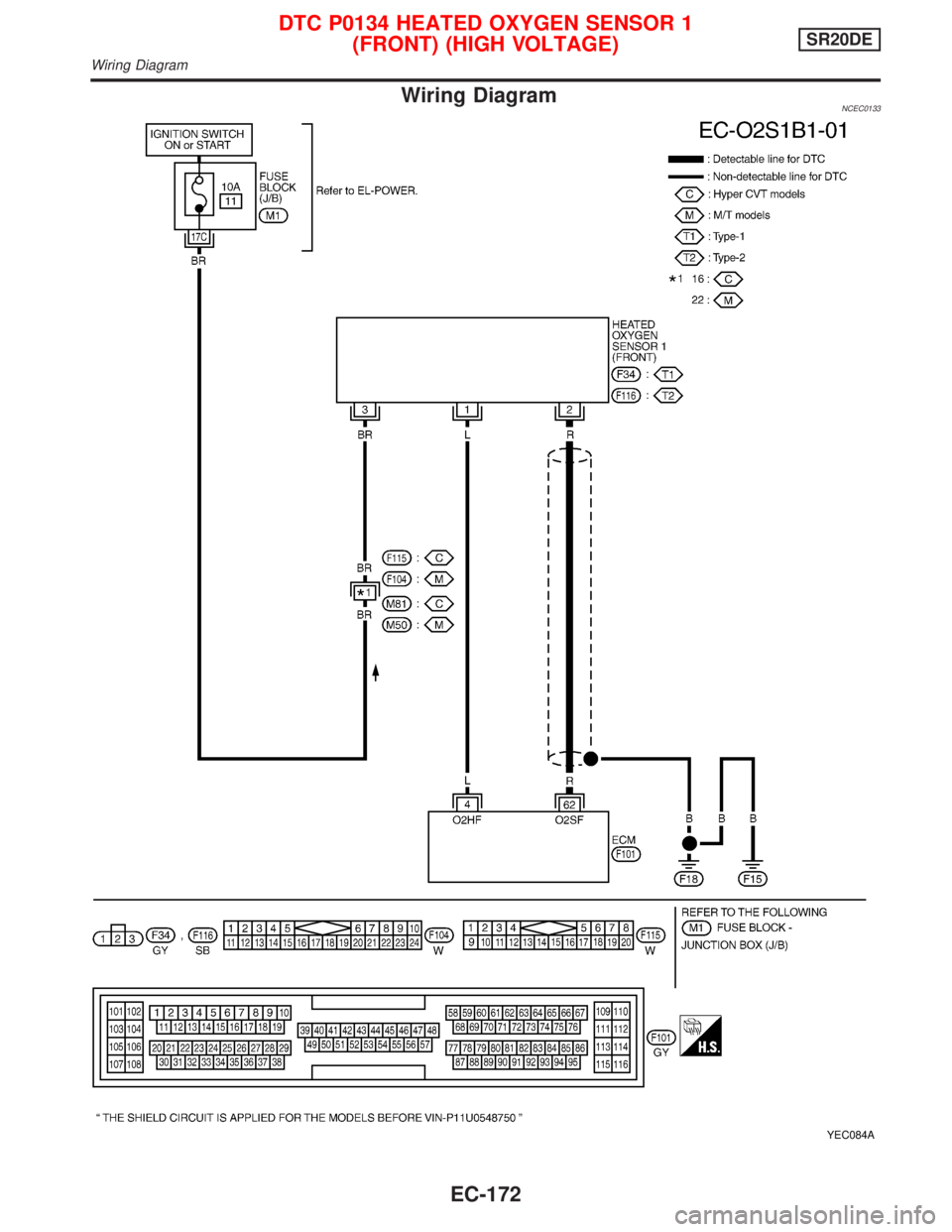

Wiring DiagramNCEC0133

YEC084A

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)SR20DE

Wiring Diagram

EC-172

Page 973 of 2267

Diagnostic ProcedureNCEC0134

1 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40-60N×m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 2.

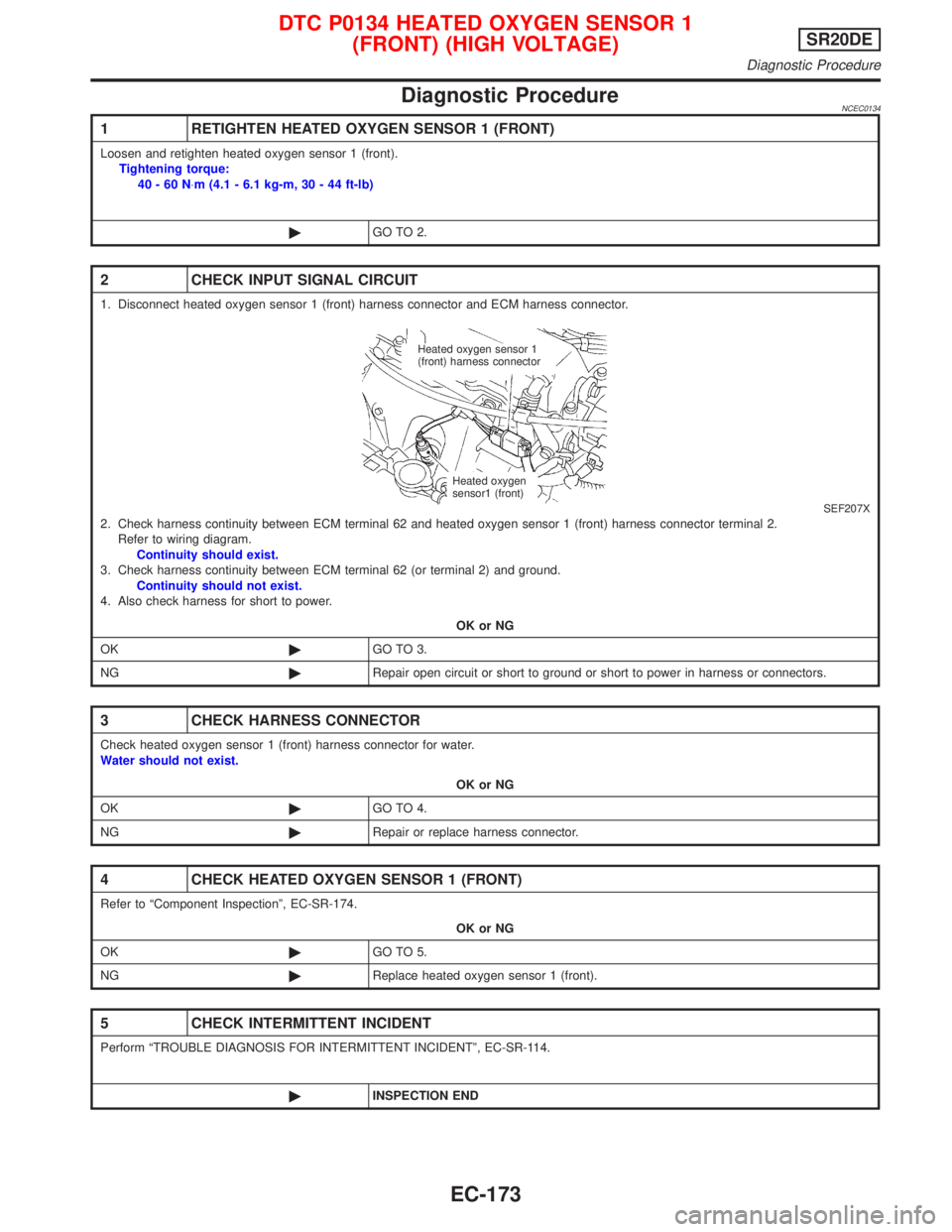

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF207X2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK HARNESS CONNECTOR

Check heated oxygen sensor 1 (front) harness connector for water.

Water should not exist.

OK or NG

OK©GO TO 4.

NG©Repair or replace harness connector.

4 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-SR-174.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

Heated oxygen sensor 1

(front) harness connector

Heated oxygen

sensor1 (front)

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)SR20DE

Diagnostic Procedure

EC-173

Page 974 of 2267

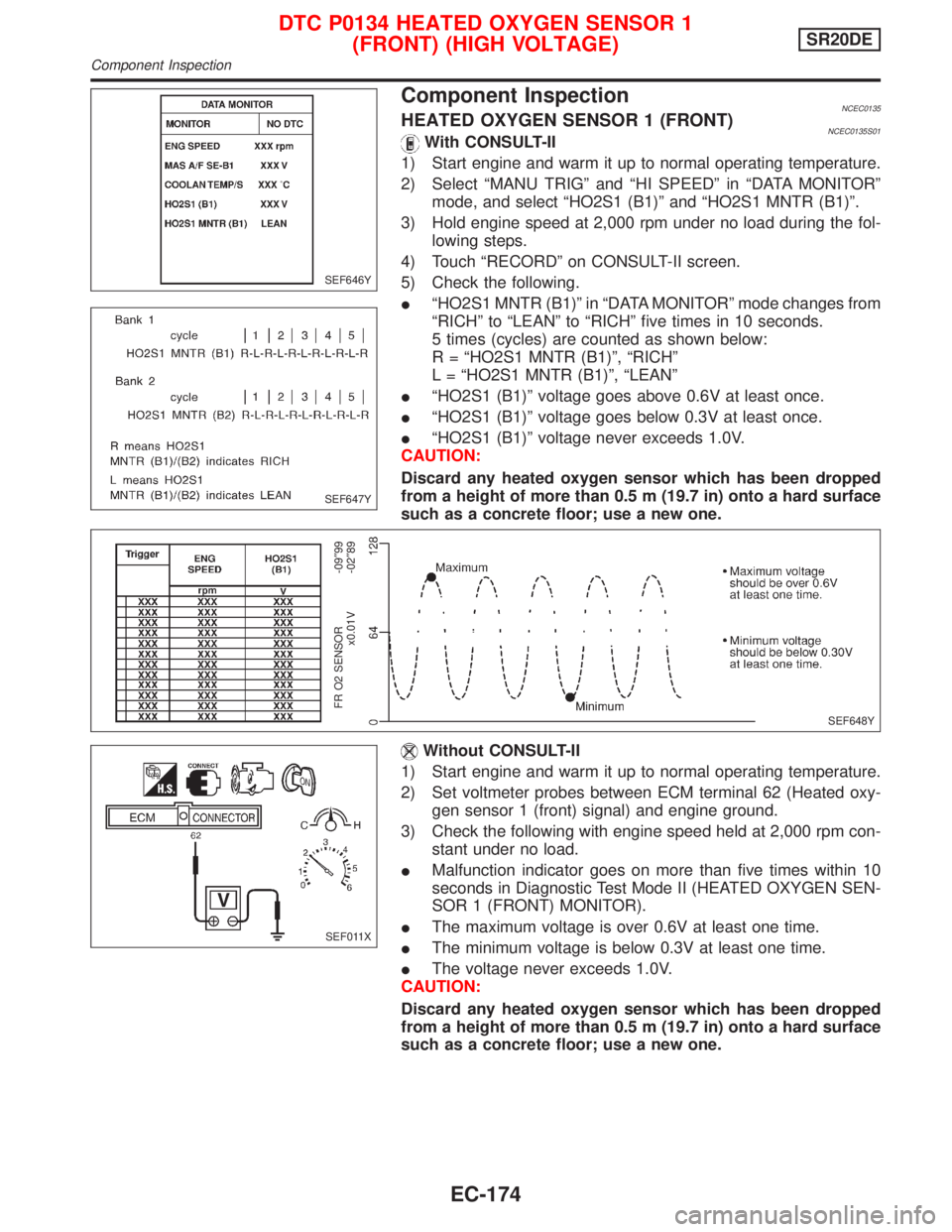

Component InspectionNCEC0135HEATED OXYGEN SENSOR 1 (FRONT)NCEC0135S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªMANU TRIGº and ªHI SPEEDº in ªDATA MONITORº

mode, and select ªHO2S1 (B1)º and ªHO2S1 MNTR (B1)º.

3) Hold engine speed at 2,000 rpm under no load during the fol-

lowing steps.

4) Touch ªRECORDº on CONSULT-II screen.

5) Check the following.

IªHO2S1 MNTR (B1)º in ªDATA MONITORº mode changes from

ªRICHº to ªLEANº to ªRICHº five times in 10 seconds.

5 times (cycles) are counted as shown below:

R = ªHO2S1 MNTR (B1)º, ªRICHº

L = ªHO2S1 MNTR (B1)º, ªLEANº

IªHO2S1 (B1)º voltage goes above 0.6V at least once.

IªHO2S1 (B1)º voltage goes below 0.3V at least once.

IªHO2S1 (B1)º voltage never exceeds 1.0V.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (Heated oxy-

gen sensor 1 (front) signal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IMalfunction indicator goes on more than five times within 10

seconds in Diagnostic Test Mode II (HEATED OXYGEN SEN-

SOR 1 (FRONT) MONITOR).

IThe maximum voltage is over 0.6V at least one time.

IThe minimum voltage is below 0.3V at least one time.

IThe voltage never exceeds 1.0V.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

SEF646Y

SEF647Y

SEF648Y

FR O2 SENSOR

x0.01V-09²99

-02²89

SEF011X

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)SR20DE

Component Inspection

EC-174

Page 975 of 2267

DescriptionNCEC0136SYSTEM DESCRIPTIONNCEC0136S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speedHeated oxy-

gen sensor

1 (front)

heater con-

trolHeated oxygen sensor 1 (front)

heater

The ECM performs ON/OFF control of the heated oxygen sensor 1 (front) heater corresponding to the engine

operating condition.

OPERATIONNCEC0136S02

Engine speed Heated oxygen sensor 1 (front) heater

Above 3,200 rpm OFF

More than 20 seconds after exceeding 3,200 rpm ON

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0137Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)IEngine speed: Below 3,200 rpm ON

IMore than 20 seconds after exceeding 3,200 rpm OFF

ECM Terminals and Reference ValueNCEC0138Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4LHeated oxygen sensor 1

(front) heater[Engine is running]

IEngine speed is below 3,200 rpm.Approximately 0V

[Engine is running]

IMore than 20 seconds after exceeding

3,200 rpm.BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNCEC0139

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0135

0135IThe current amperage in the heated oxygen sensor 1

(front) heater circuit is out of the normal range.

(An improper voltage drop signal is sent to ECM through

the heated oxygen sensor 1 (front) heater.)IHarness or connectors

(The heated oxygen sensor 1 (front) heater cir-

cuit is open or shorted.)

IHeated oxygen sensor 1 (front) heater

DTC Confirmation ProcedureNCEC0140NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is between 10.5V and 16V at idle.

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Description

EC-175

Page 976 of 2267

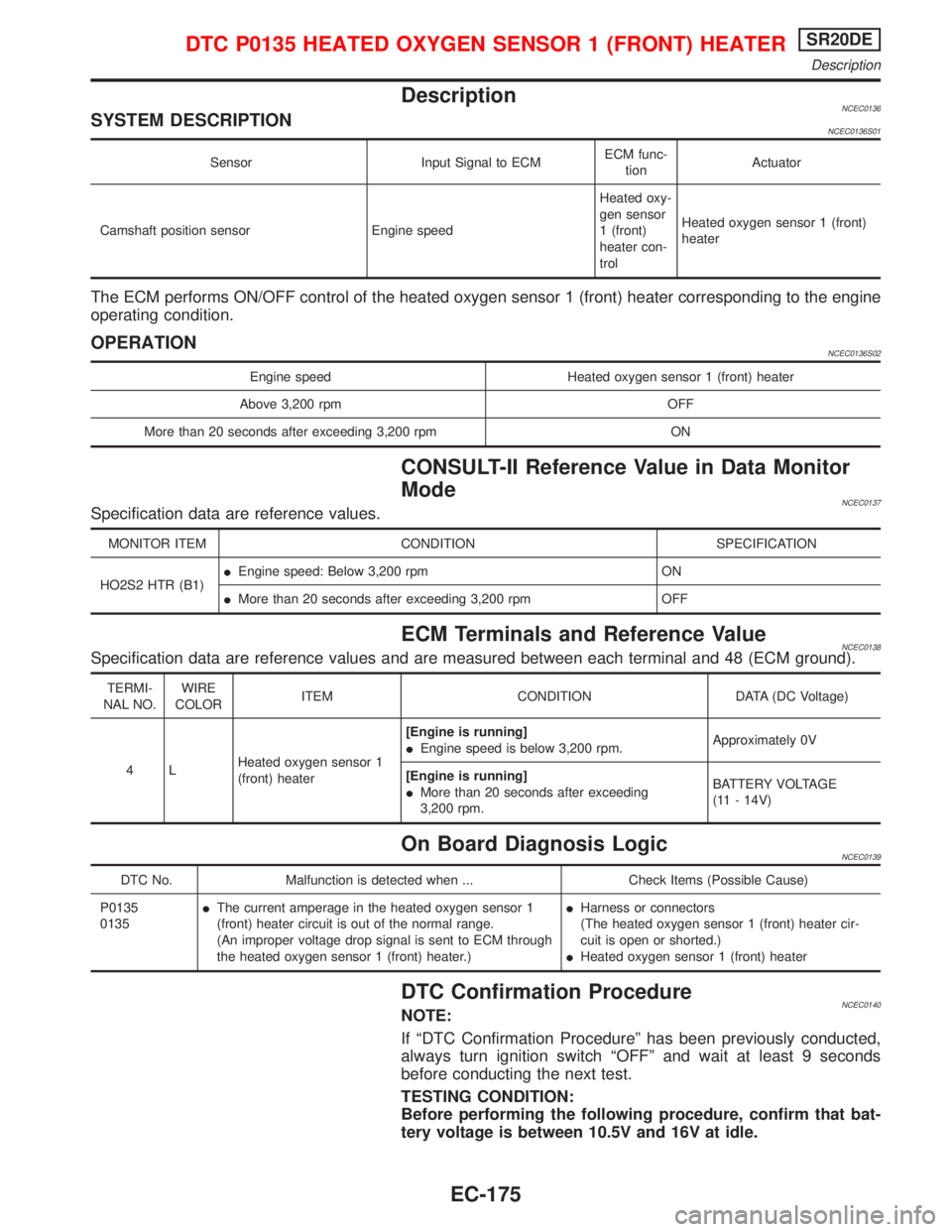

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and run it for at least 5 seconds at idle speed.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-178.

With GST

1) Start engine and run it for at least 5 seconds at idle speed.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Start engine and run it for at least 5 seconds at idle speed.

4) Select ªMODE 3º with GST.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-SR-178.

IWhen using GST, ªDTC Confirmation Procedureº should

be performed twice as much as when using CONSULT-II or

ECM (Diagnostic Test Mode II) because GST cannot dis-

play MODE 7 (1st trip DTC) concerning this diagnosis.

Therefore, using CONSULT-II or ECM (Diagnostic Test

Mode II) is recommended.

NEF068A

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

DTC Confirmation Procedure (Cont'd)

EC-176

Page 977 of 2267

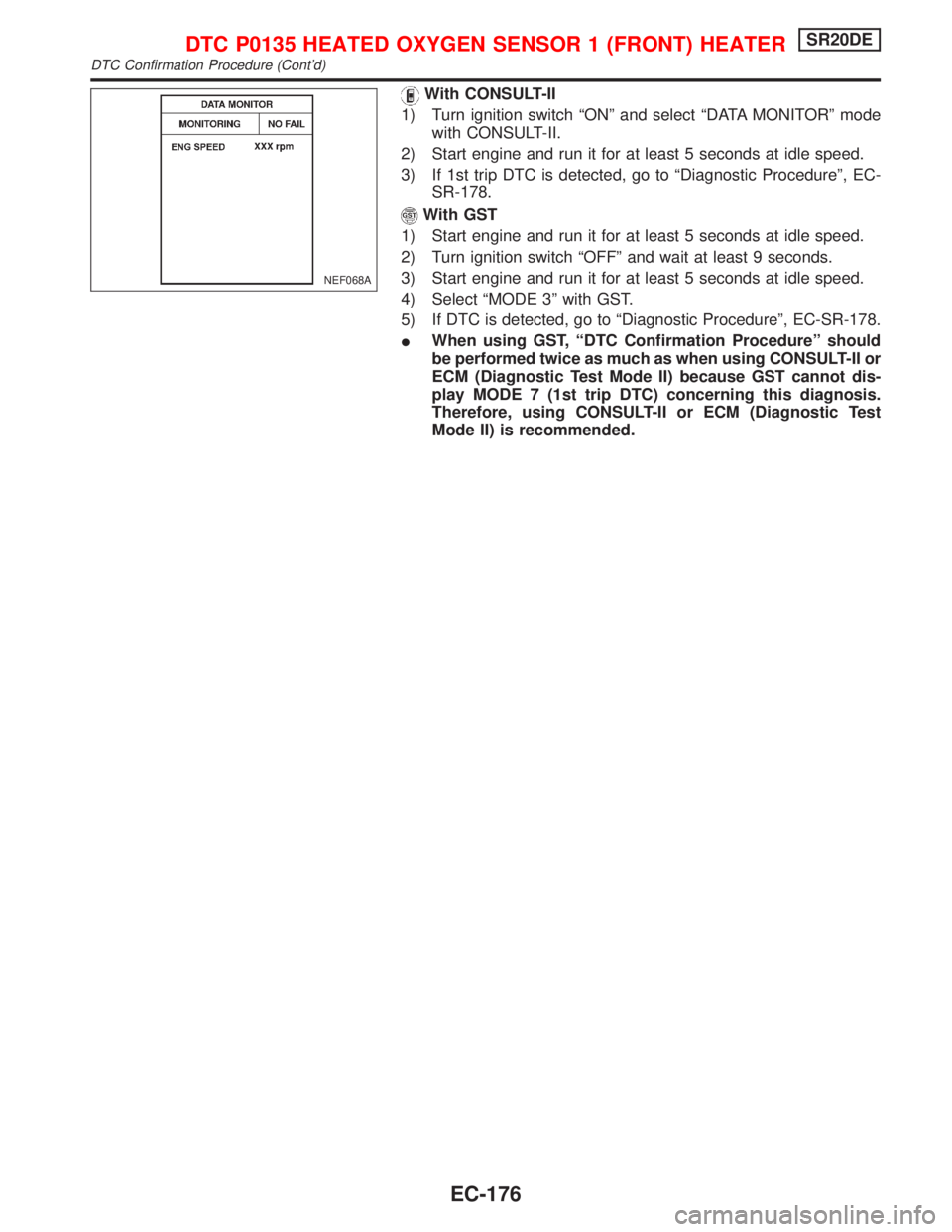

Wiring DiagramNCEC0141

YEC085A

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Wiring Diagram

EC-177

Page 978 of 2267

Diagnostic ProcedureNCEC0142

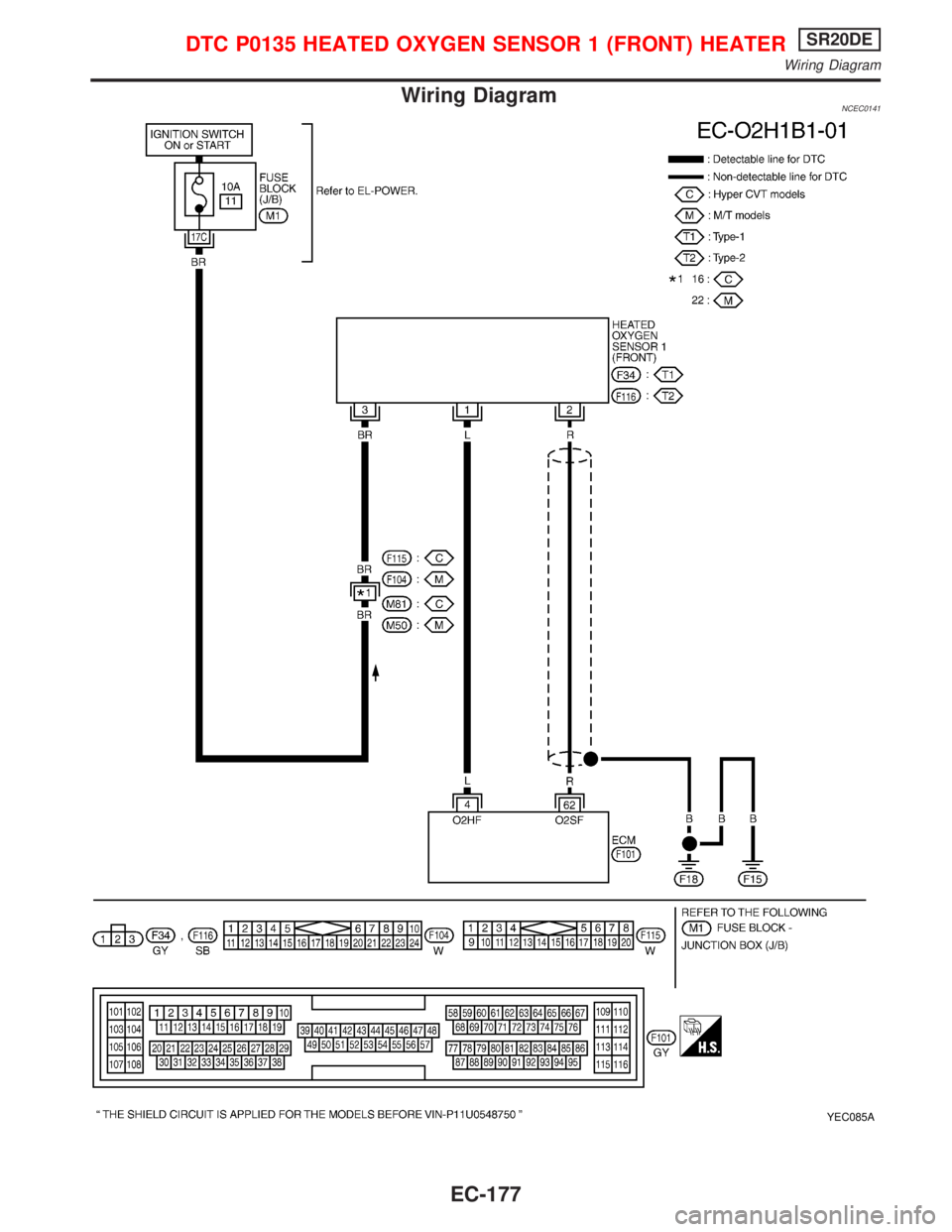

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF207X3. Turn ignition switch ªONº.

4. Check voltage between terminal 3 and ground with CONSULT or tester.

SEF025XVoltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M50, F104 (M81, F115 for CVT models)

I10A fuse

IHarness for open or short between heated oxygen sensor 1 (front) and fuse

©Repair harness or connectors.

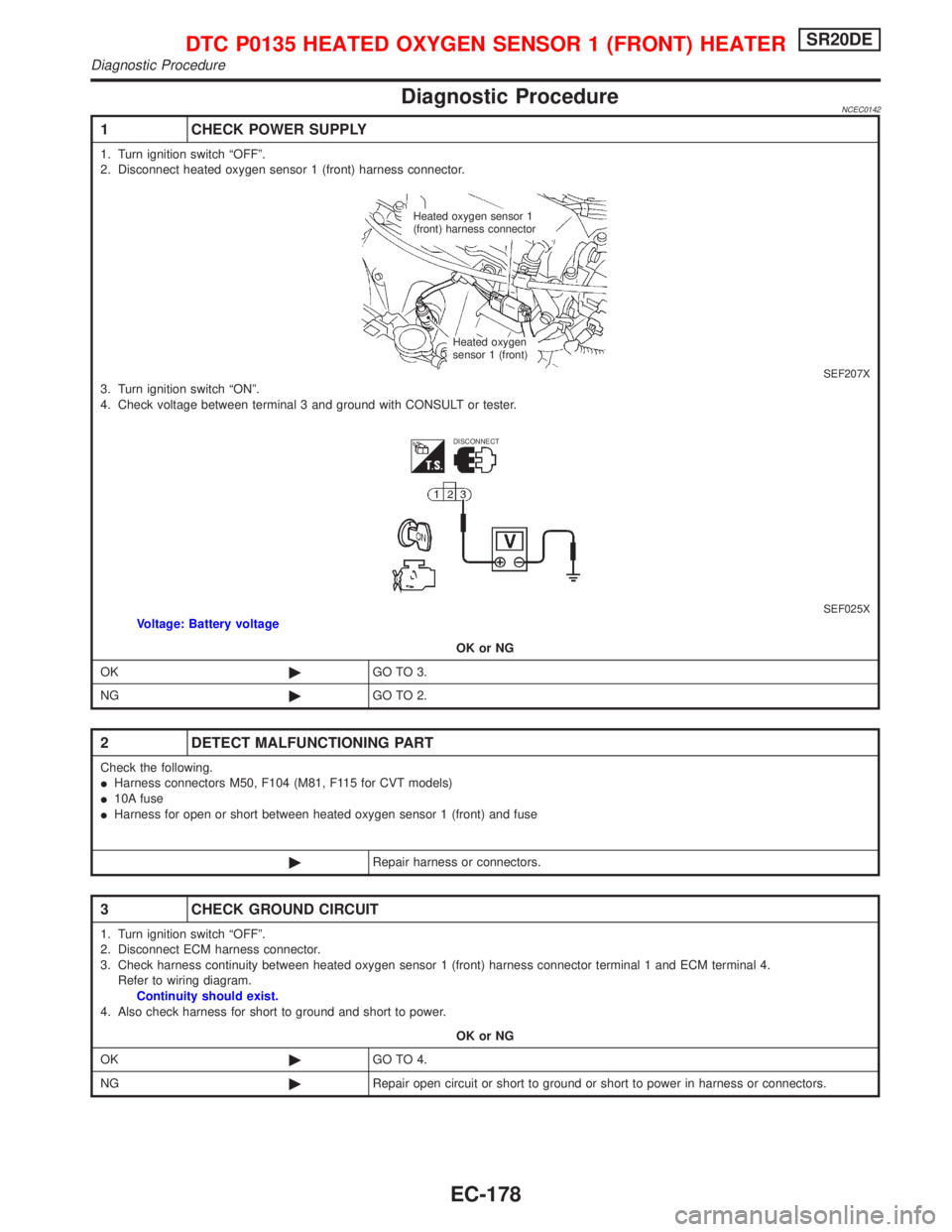

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 1 (front) harness connector terminal 1 and ECM terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

Heated oxygen sensor 1

(front) harness connector

Heated oxygen

sensor 1 (front)

DISCONNECT

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Diagnostic Procedure

EC-178

Page 979 of 2267

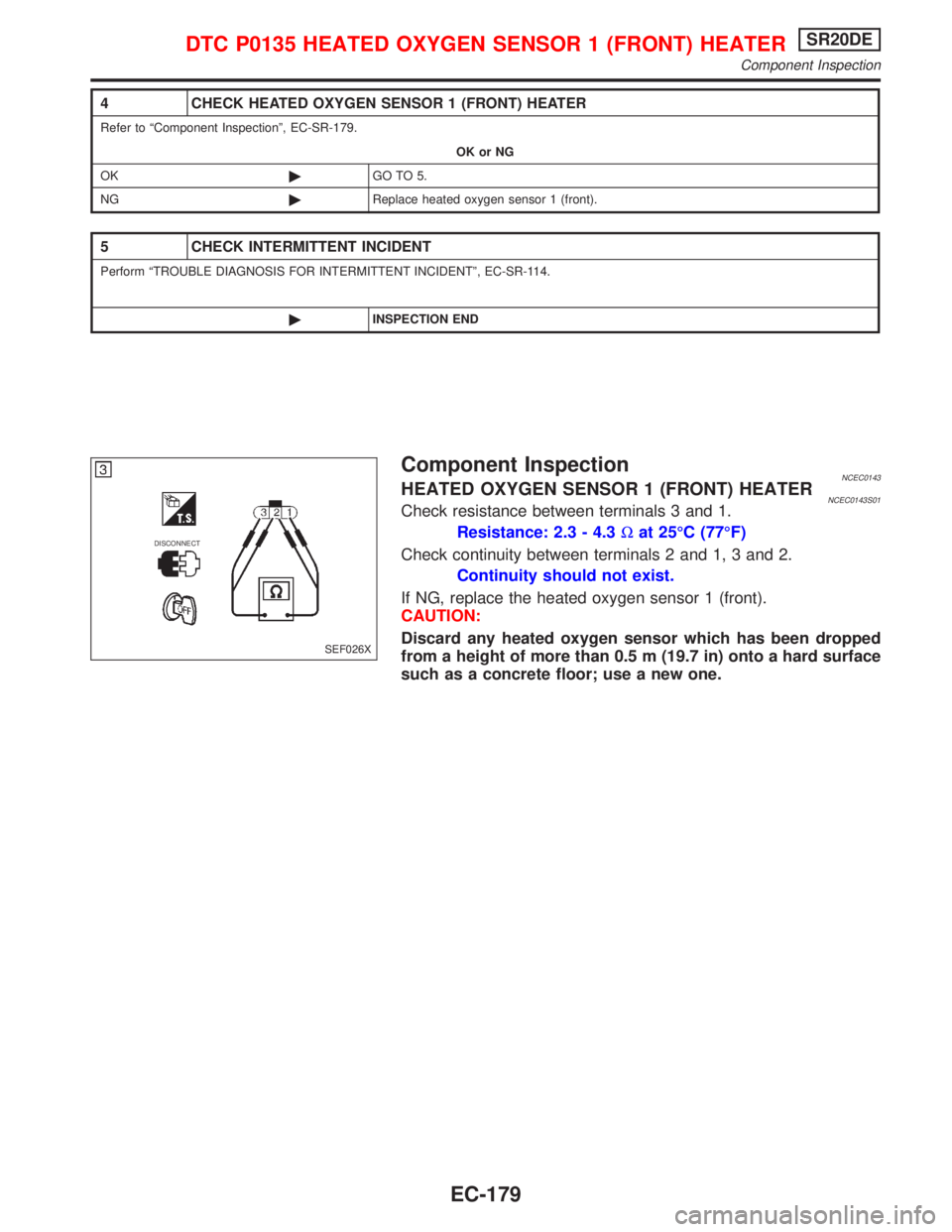

Component InspectionNCEC0143HEATED OXYGEN SENSOR 1 (FRONT) HEATERNCEC0143S01Check resistance between terminals 3 and 1.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

Check continuity between terminals 2 and 1, 3 and 2.

Continuity should not exist.

If NG, replace the heated oxygen sensor 1 (front).

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

4 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HEATER

Refer to ªComponent Inspectionº, EC-SR-179.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF026X

DISCONNECT

DTC P0135 HEATED OXYGEN SENSOR 1 (FRONT) HEATERSR20DE

Component Inspection

EC-179

Page 980 of 2267

Component DescriptionNCEC0144The heated oxygen sensor 2 (rear) (Rear HO2S), after three way

catalyst, monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0145Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B)

IEngine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V+,Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN+,RICH

ECM Terminals and Reference ValueNCEC0146Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

IAfter warming up to normal operating temperature

and engine speed is 3,000 rpm0 - Approximately 1.0V

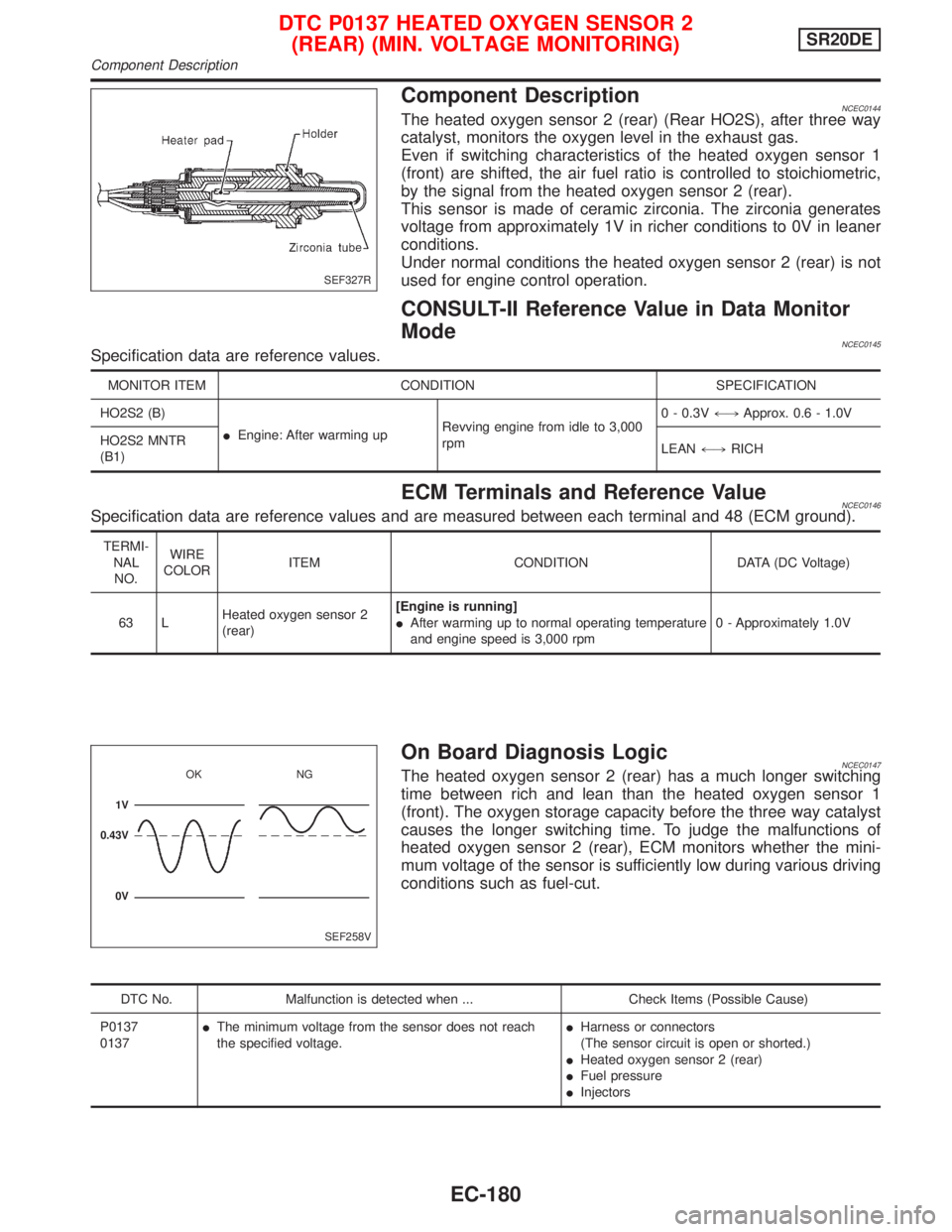

On Board Diagnosis LogicNCEC0147The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether the mini-

mum voltage of the sensor is sufficiently low during various driving

conditions such as fuel-cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0137

0137IThe minimum voltage from the sensor does not reach

the specified voltage.IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 2 (rear)

IFuel pressure

IInjectors

SEF327R

SEF258V OK NG

1V

0.43V

0V

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)SR20DE

Component Description

EC-180