sensor NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 102 of 238

\(V2 Fuel and Engine Management

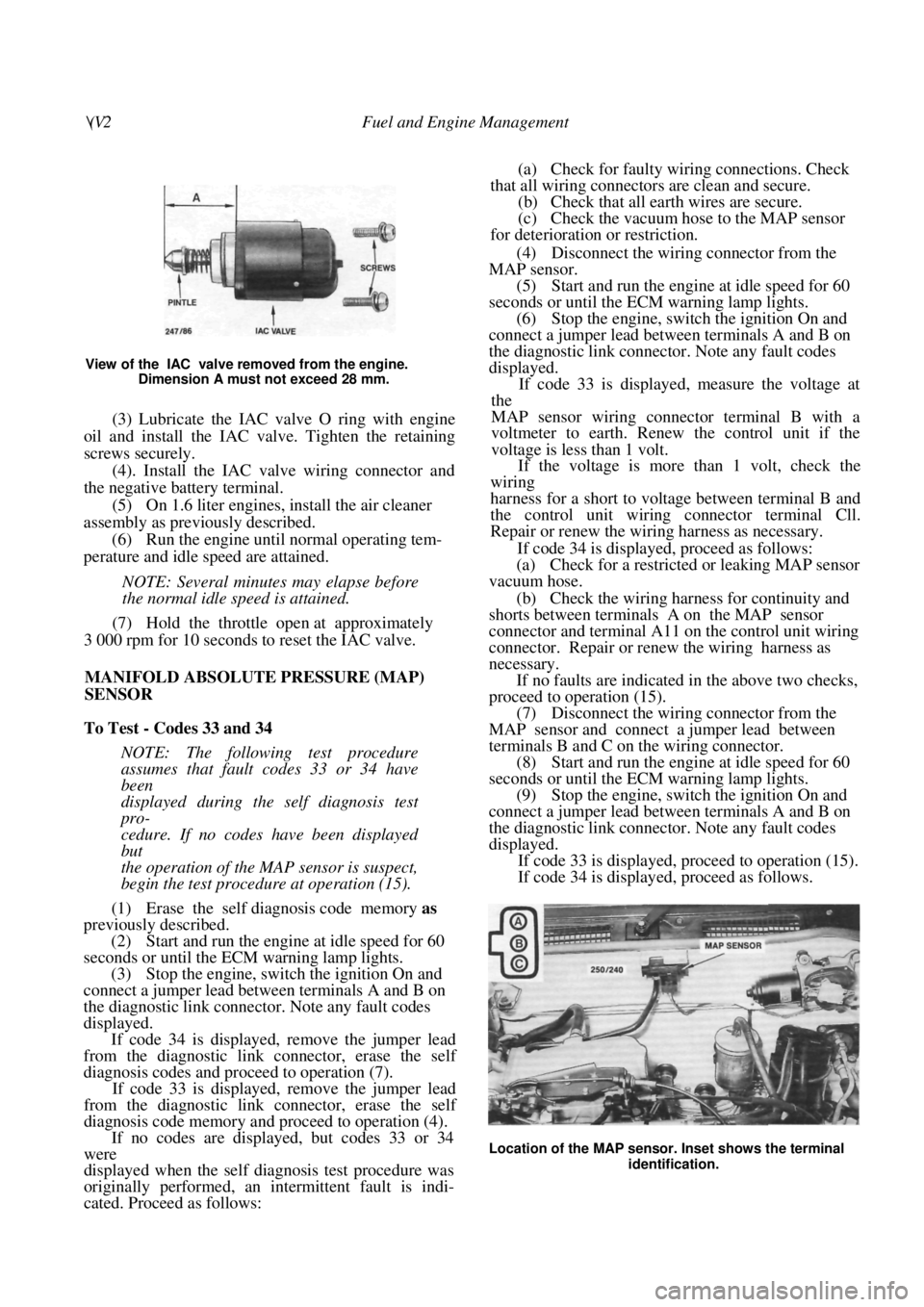

View of the IAC valve removed from the engine. Dimension A must not exceed 28 mm.

(3) Lubricate the IAC valve O ring with engine

oil and install the IAC valve. Tighten the retaining

screws securely.

(4). Install the IAC valve wiring connector and

the negative battery terminal.

(5) On 1.6 liter engines, install the air cleaner

assembly as previously described. (6) Run the engine until normal operating tem-

perature and idle speed are attained.

NOTE: Several minutes may elapse before

the normal idle speed is attained.

(7) Hold the throttle open at approximately

3 000 rpm for 10 seconds to reset the IAC valve.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR

To Test - Codes 33 and 34

NOTE: The following test procedure

assumes that fault codes 33 or 34 have

been

displayed during the self diagnosis test

pro-

cedure. If no codes have been displayed

but

the operation of the MAP sensor is suspect,

begin the test procedure at operation (15).

(1) Erase the self diagnosis code memory as

previously described.

(2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed. If code 34 is displayed, remove the jumper lead

from the diagnostic link connector, erase the self

diagnosis codes and proceed to operation (7).

If code 33 is displayed, remove the jumper lead

from the diagnostic link connector, erase the self

diagnosis code memory and proceed to operation (4).

If no codes are displayed, but codes 33 or 34

were

displayed when the self diagnosis test procedure was

originally performed, an intermittent fault is indi-

cated. Proceed as follows:

(a) Check for faulty wiring connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(c) Check the vacuum hose to the MAP sensor

for deterioration or restriction.

(4) Disconnect the wiring connector from the

MAP sensor. (5) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. (6) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed.

If code 33 is displayed, measure the voltage at

the

MAP sensor wiring connector terminal B with a

voltmeter to earth. Renew the control unit if the

voltage is less than 1 volt.

If the voltage is more than 1 volt, check the

wiring

harness for a short to voltage between terminal B and

the control unit wiring connector terminal Cll.

Repair or renew the wiring harness as necessary.

If code 34 is displayed, proceed as follows:

(a) Check for a restricted or leaking MAP sensor

vacuum hose.

(b) Check the wiring harness for continuity and

shorts between terminals A on the MAP sensor

connector and terminal A11 on the control unit wiring

connector. Repair or renew the wiring harness as

necessary.

If no faults are indicated in the above two checks,

proceed to operation (15).

(7) Disconnect the wiring connector from the

MAP sensor and connect a jumper lead between

terminals B and C on the wiring connector. (8) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. (9) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. Note any fault codes

displayed.

If code 33 is displayed, proceed to operation (15).

If code 34 is displayed, proceed as follows.

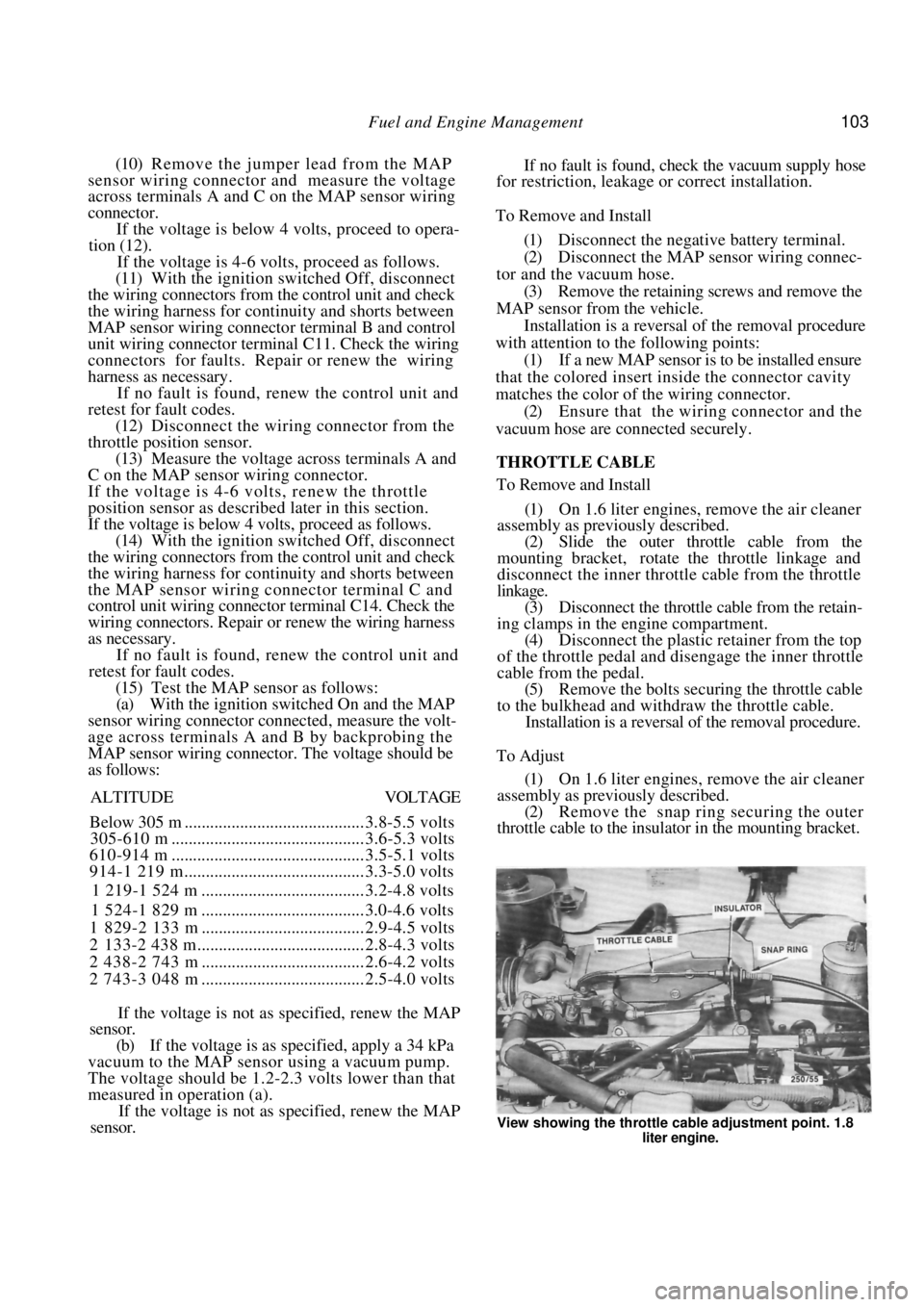

Location of the MAP sensor. Inset shows the terminal

identification.

Page 103 of 238

Fuel and Engine Management 103

(10) Remove the jumper lead from the MAP

sensor wiring connector and measure the voltage

across terminals A and C on the MAP sensor wiring

connector.

If the voltage is below 4 volts, proceed to opera-

tion (12).

If the voltage is 4-6 volts, proceed as follows.

(11) With the ignition switched Off, disconnect

the wiring connectors from the control unit and check

the wiring harness for contin uity and shorts between

MAP sensor wiring connector terminal B and control

unit wiring connector terminal C11. Check the wiring

connectors for faults. Repair or renew the wiring

harness as necessary.

If no fault is found, renew the control unit and

retest for fault codes.

(12) Disconnect the wiring connector from the

throttle position sensor. (13) Measure the voltage across terminals A and

C on the MAP sensor wiring connector.

If the voltage is 4-6 volts, renew the throttle

position sensor as describe d later in this section.

If the voltage is below 4 volts, proceed as follows.

(14) With the ignition switched Off, disconnect

the wiring connectors from the control unit and check

the wiring harness for contin uity and shorts between

the MAP sensor wiring connector terminal C and

control unit wiring connector terminal C14. Check the

wiring connectors. Repair or renew the wiring harness

as necessary.

If no fault is found, renew the control unit and

retest for fault codes.

(15) Test the MAP sensor as follows:

(a) With the ignition switched On and the MAP

sensor wiring connector connected, measure the volt-

age across terminals A an d B by backprobing the

MAP sensor wiring connector. The voltage should be

as follows:

ALTITUDE VOLTAGE

Below 305 m .......................................... 3.8-5.5 volts

305-610 m ............................................. 3.6-5.3 volts

610-914 m ............................................. 3.5-5.1 volts

914-1 219 m .......................................... 3.3-5.0 volts

1 219-1 524 m ...................................... 3.2-4.8 volts

1 524-1 829 m ...................................... 3.0-4.6 volts

1 829-2 133 m ...................................... 2.9-4.5 volts

2 133-2 438 m ....................................... 2.8-4.3 volts

2 438-2 743 m ...................................... 2.6-4.2 volts

2 743-3 048 m ...................................... 2.5-4.0 volts

If the voltage is not as specified, renew the MAP

sensor.

(b) If the voltage is as specified, apply a 34 kPa

vacuum to the MAP sensor using a vacuum pump.

The voltage should be 1.2-2.3 volts lower than that

measured in operation (a).

If the voltage is not as specified, renew the MAP

sensor.

If no fault is found, check the vacuum supply hose

for restriction, leakage or correct installation.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the MAP sensor wiring connec-

tor and the vacuum hose. (3) Remove the retaining sc rews and remove the

MAP sensor from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) If a new MAP sensor is to be installed ensure

that the colored insert inside the connector cavity

matches the color of the wiring connector.

(2) Ensure that the wiri ng connector and the

vacuum hose are connected securely.

THROTTLE CABLE

To Remove and Install

(1) On 1.6 liter engines, remove the air cleaner

assembly as previously described.

(2) Slide the outer throttle cable from the

mounting bracket, rotate the throttle linkage and

disconnect the inner throttle cable from the throttle

linkage. (3) Disconnect the throttle cable from the retain-

ing clamps in the engine compartment. (4) Disconnect the plastic re tainer from the top

of the throttle pedal and disengage the inner throttle

cable from the pedal. (5) Remove the bolts securing the throttle cable

to the bulkhead and withdraw the throttle cable. Installation is a reversal of the removal procedure.

To Adjust

(1) On 1.6 liter engines, remove the air cleaner

assembly as previously described.

(2) Remove the snap ring securing the outer

throttle cable to the insulator in the mounting bracket.

View showing the throttle cable adjustment point. 1.8

liter engine.

Page 109 of 238

Fuel and Engine Management 109

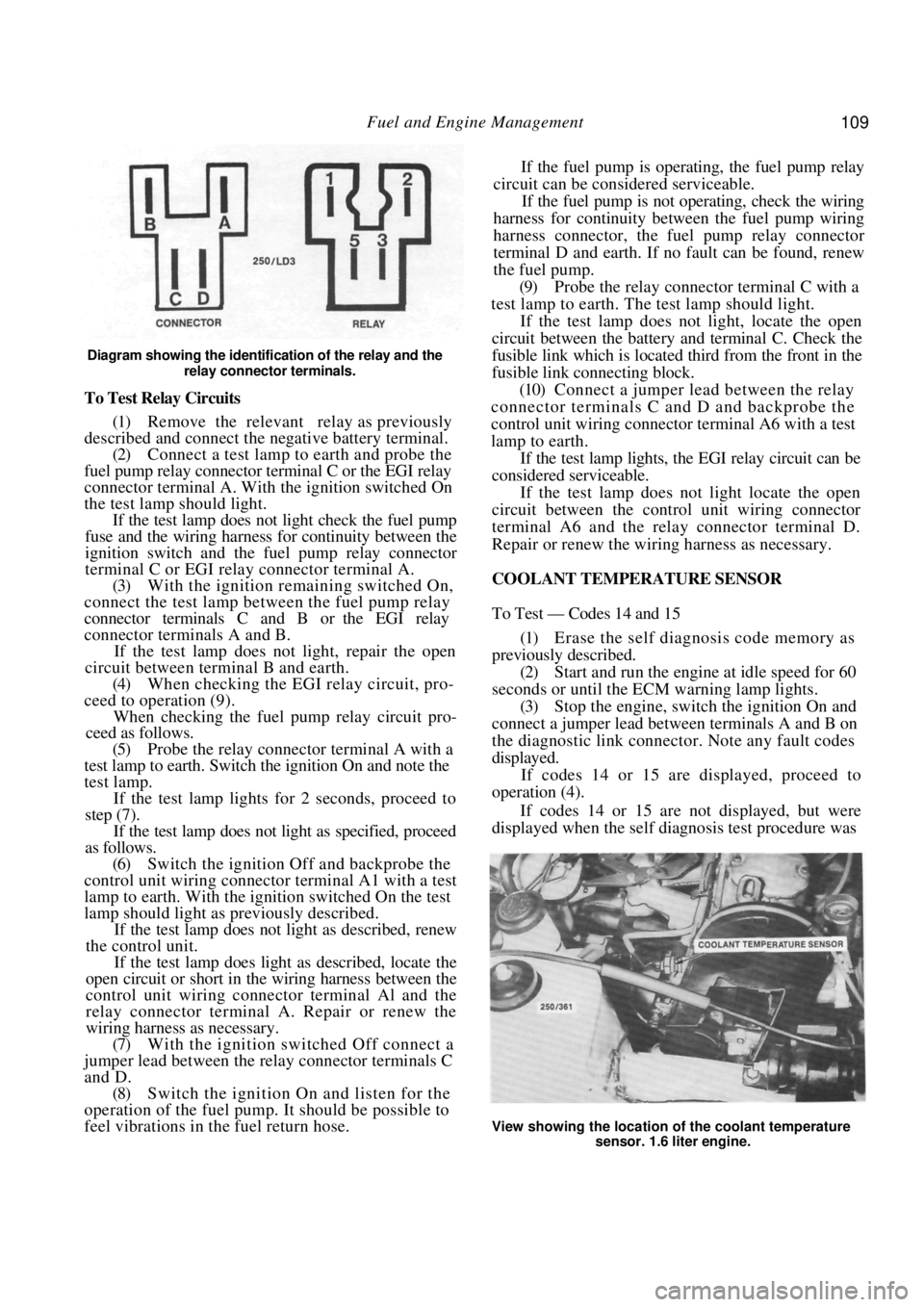

Diagram showing the identification of the relay and the relay connector terminals.

To Test Relay Circuits

(1) Remove the relevant relay as previously

described and connect the ne gative battery terminal.

(2) Connect a test lamp to earth and probe the

fuel pump relay connector terminal C or the EGI relay

connector terminal A. With the ignition switched On

the test lamp should light. If the test lamp does not light check the fuel pump

fuse and the wiring harness for continuity between the

ignition switch and the fuel pump relay connector

terminal C or EGI rela y connector terminal A.

(3) With the ignition remaining switched On,

connect the test lamp between the fuel pump relay

connector terminals C and B or the EGI relay

connector terminals A and B.

If the test lamp does not light, repair the open

circuit between terminal B and earth.

(4) When checking the EGI relay circuit, pro-

ceed to operation (9).

When checking the fuel pu mp relay circuit pro-

ceed as follows.

(5) Probe the relay connector terminal A with a

test lamp to earth. Switch the ignition On and note the

test lamp.

If the test lamp lights for 2 seconds, proceed to

step (7).

If the test lamp does not light as specified, proceed

as follows.

(6) Switch the ignition Off and backprobe the

control unit wiring connector terminal A1 with a test

lamp to earth. With the ignition switched On the test

lamp should light as previously described.

If the test lamp does not light as described, renew

the control unit.

If the test lamp does light as described, locate the

open circuit or short in the wiring harness between the

control unit wiring connector terminal Al and the

relay connector terminal A. Repair or renew the

wiring harness as necessary.

(7) With the ignition switched Off connect a

jumper lead between the relay connector terminals C

and D. (8) Switch the ignition On and listen for the

operation of the fuel pump. It should be possible to

feel vibrations in the fuel return hose. If the fuel pump is operating, the fuel pump relay

circuit can be considered serviceable.

If the fuel pump is not operating, check the wiring

harness for continuity between the fuel pump wiring

harness connector, the fuel pump relay connector

terminal D and earth. If no fault can be found, renew

the fuel pump.

(9) Probe the relay connector terminal C with a

test lamp to earth. The test lamp should light.

If the test lamp does not light, locate the open

circuit between the battery and terminal C. Check the

fusible link which is located third from the front in the

fusible link connecting block.

(10) Connect a jumper lead between the relay

connector terminals C and D and backprobe the

control unit wiring connector terminal A6 with a test

lamp to earth.

If the test lamp lights, the EGI relay circuit can be

considered serviceable.

If the test lamp does not light locate the open

circuit between the contro l unit wiring connector

terminal A6 and the relay connector terminal D.

Repair or renew the wiring harness as necessary.

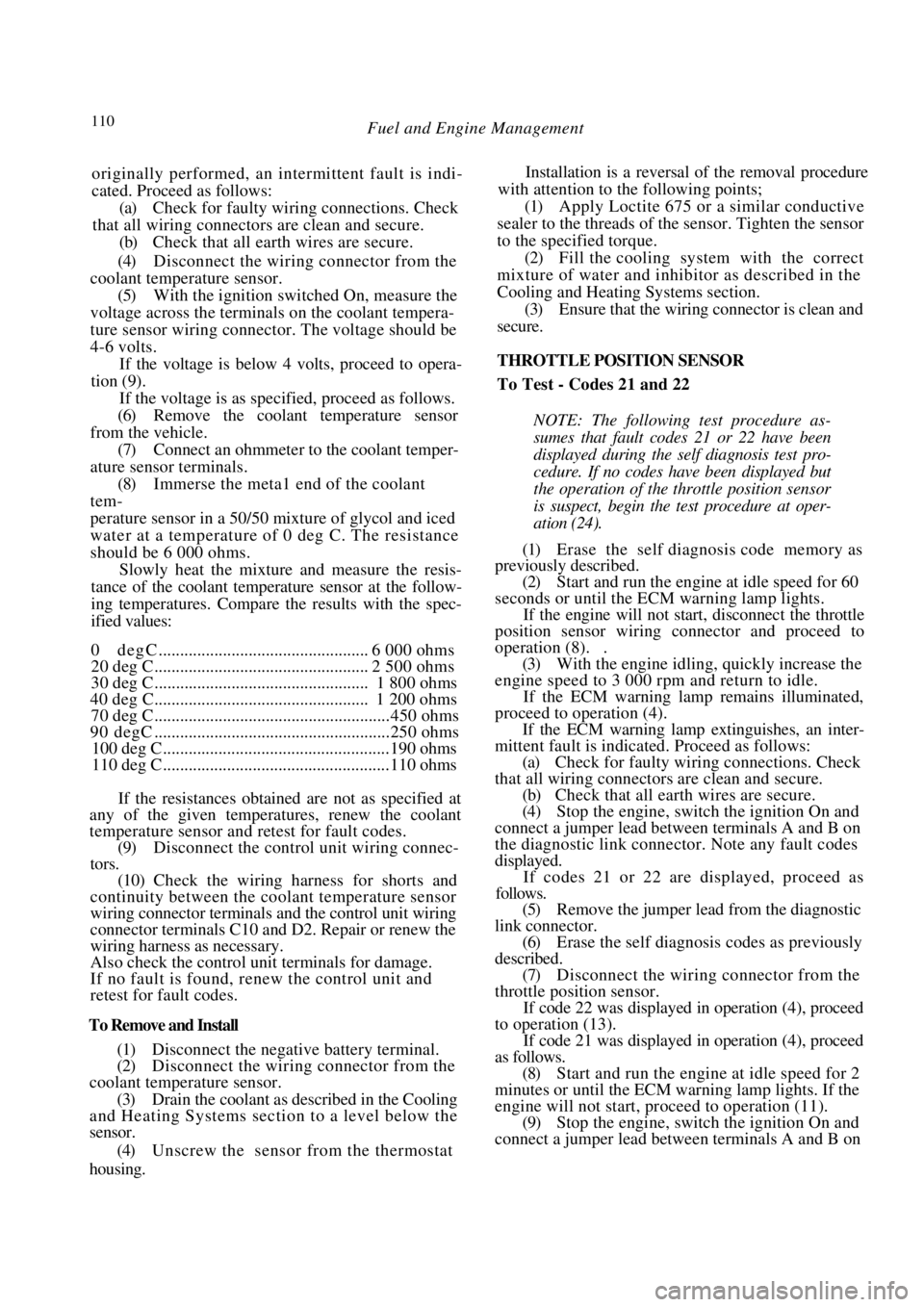

COOLANT TEMPERATURE SENSOR

To Test — Codes 14 and 15

(1) Erase the self diagnosis code memory as

previously described. (2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connect or. Note any fault codes

displayed. If codes 14 or 15 are displayed, proceed to

operation (4).

If codes 14 or 15 are not displayed, but were

displayed when the self diagnosis test procedure was

View showing the location of the coolant temperature

sensor. 1.6 liter engine.

Page 110 of 238

110 Fuel and Engine Management

originally performed, an intermittent fault is indi-

cated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Disconnect the wiring connector from the

coolant temperature sensor. (5) With the ignition switched On, measure the

voltage across the terminals on the coolant tempera-

ture sensor wiring connector. The voltage should be

4-6 volts.

If the voltage is below 4 volts, proceed to opera-

tion (9).

If the voltage is as specified, proceed as follows.

(6) Remove the coolant temperature sensor

from the vehicle. (7) Connect an ohmmeter to the coolant temper-

ature sensor terminals. (8) Immerse the meta1 end of the coolant

tem-

perature sensor in a 50/50 mixture of glycol and iced

water at a temperature of 0 deg C. The resistance

should be 6 000 ohms. Slowly heat the mixture and measure the resis-

tance of the coolant temperature sensor at the follow-

ing temperatures. Compare the results with the spec-

ified values:

0 d e g C ................................................. 6 000 ohms

20 deg C .................................................. 2 500 ohms

30 deg C .................................................. 1 800 ohms

40 deg C.................................................. 1 200 ohms

70 deg C .......................................................450 ohms

90 degC .......................................................250 ohms

100 deg C.....................................................190 ohms

110 deg C.....................................................110 ohms

If the resistances obtained are not as specified at

any of the given temperatures, renew the coolant

temperature sensor and retest for fault codes.

(9) Disconnect the control unit wiring connec-

tors.

(10) Check the wiring harness for shorts and

continuity between the coolant temperature sensor

wiring connector terminals and the control unit wiring

connector terminals C10 and D2. Repair or renew the

wiring harness as necessary.

Also check the control unit terminals for damage.

If no fault is found, renew the control unit and

retest for fault codes.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the wiring connector from the

coolant temperature sensor.

(3) Drain the coolant as described in the Cooling

and Heating Systems section to a level below the

sensor.

(4) Unscrew the sensor from the thermostat

housing. Installation is a reversal of the removal procedure

with attention to the following points;

(1) Apply Loctite 675 or a similar conductive

sealer to the threads of th e sensor. Tighten the sensor

to the specified torque.

(2) Fill the cooling system with the correct

mixture of water and inhibitor as described in the

Cooling and Heating Systems section. (3) Ensure that the wiring connector is clean and

secure.

THROTTLE POSITION SENSOR

To Test - Codes 21 and 22

NOTE: The following test procedure as-

sumes that fault codes 21 or 22 have been

displayed during the se lf diagnosis test pro-

cedure. If no codes have been displayed but

the operation of the throttle position sensor

is suspect, begin the test procedure at oper-

ation (24).

(1) Erase the self diagnosis code memory as

previously described.

(2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. If the engine will not start, disconnect the throttle

position sensor wiring co nnector and proceed to

operation (8). .

(3) With the engine id ling, quickly increase the

engine speed to 3 000 rpm and return to idle.

If the ECM warning lamp remains illuminated,

proceed to operation (4).

If the ECM warning lamp extinguishes, an inter-

mittent fault is indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connect or. Note any fault codes

displayed.

If codes 21 or 22 are displayed, proceed as

follows.

(5) Remove the jumper lead from the diagnostic

link connector. (6) Erase the self diagnosis codes as previously

described. (7) Disconnect the wiring connector from the

throttle position sensor. If code 22 was displayed in operation (4), proceed

to operation (13).

If code 21 was displayed in operation (4), proceed

as follows.

(8) Start and run the engine at idle speed for 2

minutes or until the ECM warning lamp lights. If the

engine will not start, pr oceed to operation (11).

(9) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

Page 111 of 238

Fuel and Engine Management 111

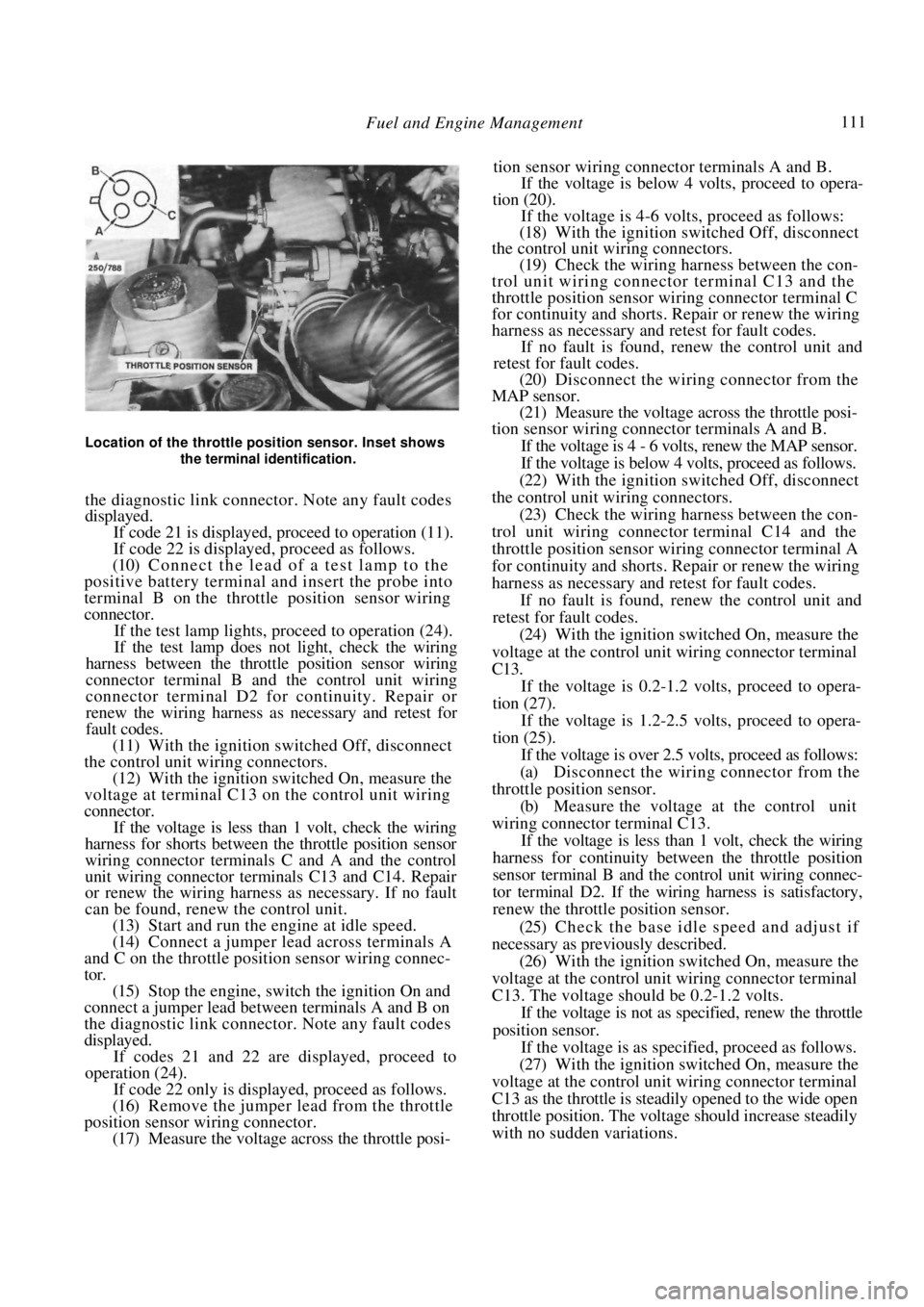

Location of the throttle position sensor. Inset shows the terminal identification.

the diagnostic link connector. Note any fault codes

displayed.

If code 21 is displayed, proceed to operation (11).

If code 22 is displayed, proceed as follows.

(10) Connect the lead of a test lamp to the

positive battery terminal and insert the probe into

terminal B on the throttle position sensor wiring

connector.

If the test lamp lights, pr oceed to operation (24).

If the test lamp does not light, check the wiring

harness between the throt tle position sensor wiring

connector terminal B and the control unit wiring

connector terminal D2 fo r continuity. Repair or

renew the wiring harness as necessary and retest for

fault codes.

(11) With the ignition switched Off, disconnect

the control unit wiring connectors. (12) With the ignition switched On, measure the

voltage at terminal C13 on the control unit wiring

connector.

If the voltage is less than 1 volt, check the wiring

harness for shorts between the throttle position sensor

wiring connector terminals C and A and the control

unit wiring connector terminals C13 and C14. Repair

or renew the wiring harness as necessary. If no fault

can be found, renew the control unit.

(13) Start and run the engine at idle speed.

(14) Connect a jumper lead across terminals A

and C on the throttle position sensor wiring connec-

tor. (15) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector . Note any fault codes

displayed. If codes 21 and 22 are displayed, proceed to

operation (24).

If code 22 only is displayed, proceed as follows.

(16) Remove the jumper lead from the throttle

position sensor wiring connector. (17) Measure the voltage across the throttle posi- tion sensor wiring connector terminals A and B.

If the voltage is below 4 volts, proceed to opera-

tion (20).

If the voltage is 4-6 volts, proceed as follows:

(18) With the ignition switched Off, disconnect

the control unit wiring connectors.

(19) Check the wiring harness between the con-

trol unit wiring connector terminal C13 and the

throttle position sensor wiring connector terminal C

for continuity and shorts. Repair or renew the wiring

harness as necessary and retest for fault codes. If no fault is found, renew the control unit and

retest for fault codes.

(20) Disconnect the wiring connector from the

MAP sensor. (21) Measure the voltage across the throttle posi-

tion sensor wiring connector terminals A and B.

If the voltage is 4 - 6 volts, renew the MAP sensor.

If the voltage is below 4 volts, proceed as follows.

(22) With the ignition switched Off, disconnect

the control unit wiring connectors. (23) Check the wiring harness between the con-

trol unit wiring connecto r terminal C14 and the

throttle position sensor wiring connector terminal A

for continuity and shorts. Repair or renew the wiring

harness as necessary and retest for fault codes. If no fault is found, renew the control unit and

retest for fault codes.

(24) With the ignition switched On, measure the

voltage at the control unit wiring connector terminal

C13.

If the voltage is 0.2-1.2 volts, proceed to opera-

tion (27).

If the voltage is 1.2-2.5 volts, proceed to opera-

tion (25).

If the voltage is over 2.5 volts, proceed as follows:

(a) Disconnect the wiring connector from the

throttle position sensor. (b) Measure the voltage at the control unit

wiring connector terminal C13. If the voltage is less than 1 volt, check the wiring

harness for continuity between the throttle position

sensor terminal B and the control unit wiring connec-

tor terminal D2. If the wiring harness is satisfactory,

renew the throttle position sensor.

(25) Check the base idle sp eed and adjust if

necessary as previously described. (26) With the ignition switched On, measure the

voltage at the control unit wiring connector terminal

C13. The voltage should be 0.2-1.2 volts. If the voltage is not as specified, renew the throttle

position sensor.

If the voltage is as specified, proceed as follows.

(27) With the ignition switched On, measure the

voltage at the control unit wiring connector terminal

C13 as the throttle is steadily opened to the wide open

throttle position. The voltage should increase steadily

with no sudden variations.

Page 112 of 238

112 Fuel and Engine Management

If the voltage does not increase as specified, renew

the throttle position sensor.

If the voltage is as specified, proceed as follows.

(28) With the ignition switched On and the

throttle valve held fully open, measure the voltage at

control unit wiring connector terminal C13. The

voltage should be above 4 volts.

If the voltage is below 4 volts, renew the throttle

position sensor.

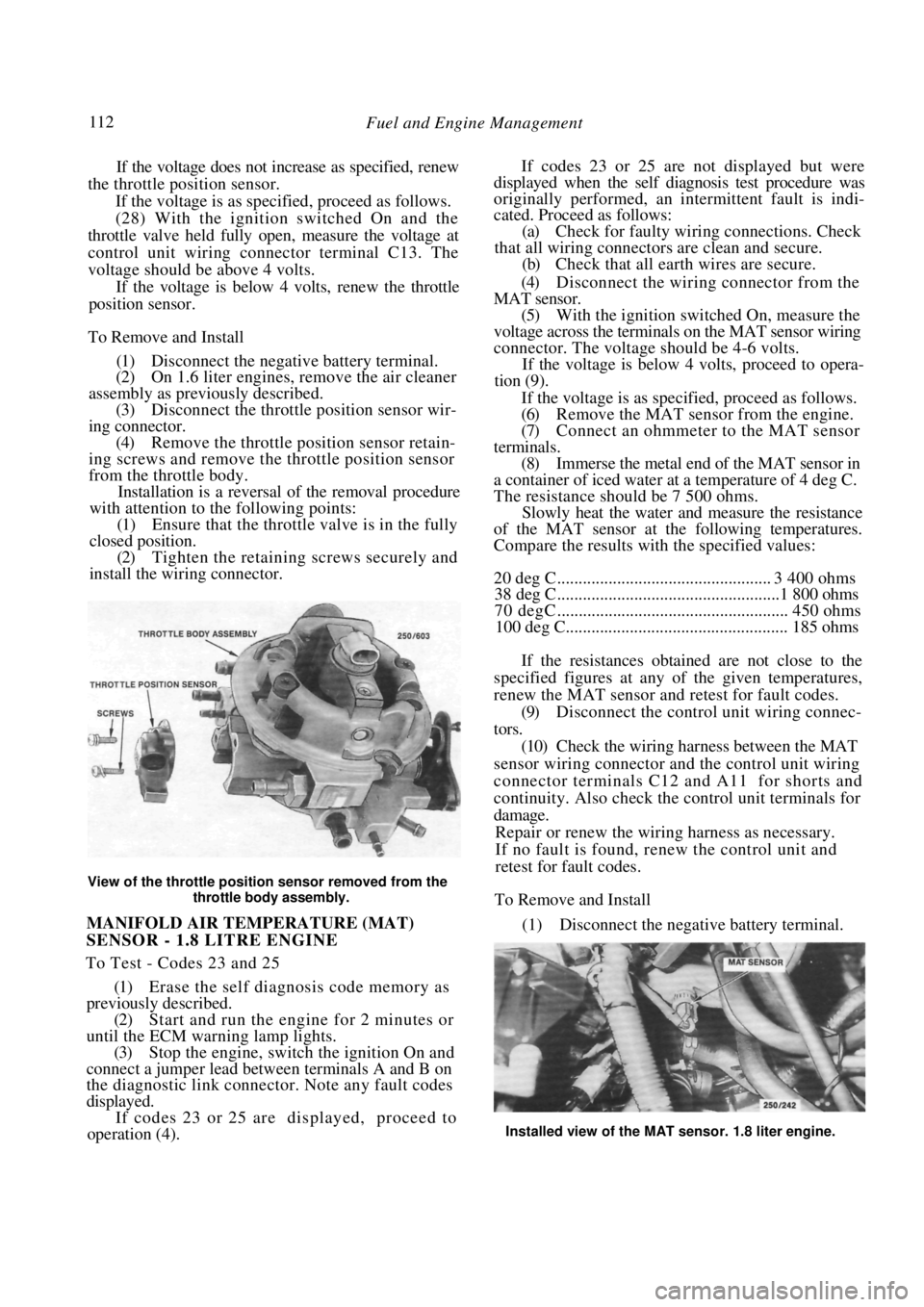

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter engines, remove the air cleaner

assembly as previously described. (3) Disconnect the throttle position sensor wir-

ing connector. (4) Remove the throttle position sensor retain-

ing screws and remove the throttle position sensor

from the throttle body. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the throttle valve is in the fully

closed position. (2) Tighten the retaining screws securely and

install the wiring connector.

View of the throttle positi on sensor removed from the

throttle body assembly.

MANIFOLD AIR TEMPERATURE (MAT)

SENSOR - 1.8 LITRE ENGINE

To Test - Codes 23 and 25

(1) Erase the self diagnosis code memory as

previously described.

(2) Start and run the engine for 2 minutes or

until the ECM warning lamp lights. (3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector . Note any fault codes

displayed. If codes 23 or 25 are displayed, proceed to

operation (4).

If codes 23 or 25 are not displayed but were

displayed when the self diagnosis test procedure was

originally performed, an intermittent fault is indi-

cated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Disconnect the wiring connector from the

MAT sensor. (5) With the ignition switched On, measure the

voltage across the terminals on the MAT sensor wiring

connector. The voltage s hould be 4-6 volts.

If the voltage is below 4 volts, proceed to opera-

tion (9).

If the voltage is as specified, proceed as follows.

(6) Remove the MAT sensor from the engine.

(7) Connect an ohmmeter to the MAT sensor

terminals. (8) Immerse the metal end of the MAT sensor in

a container of iced water at a temperature of 4 deg C.

The resistance should be 7 500 ohms. Slowly heat the water and measure the resistance

of the MAT sensor at the following temperatures.

Compare the results with the specified values:

20 deg C .................................................. 3 400 ohms

38 deg C....................................................1 800 ohms

70 degC ...................................................... 450 ohms

100 deg C.................................................... 185 ohms

If the resistances obtained are not close to the

specified figures at any of the given temperatures,

renew the MAT sensor and retest for fault codes.

(9) Disconnect the control unit wiring connec-

tors. (10) Check the wiring harness between the MAT

sensor wiring connector and the control unit wiring

connector terminals C12 and A11 for shorts and

continuity. Also check the control unit terminals for

damage. Repair or renew the wiring harness as necessary.

If no fault is found, renew the control unit and

retest for fault codes.

To Remove and Install

(1) Disconnect the negative battery terminal.

Installed view of the MAT sensor. 1.8 liter engine.

Page 113 of 238

Fuel and Engine Management 113

(2) Disconnect the wiring connector from the

MAT sensor.

(3) Unscrew the sensor from the inlet manifold.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Apply Loctite 567 or a similar conductive

sealer to the threads of th e sensor. Tighten the sensor

to the specified torque. (2) Ensure that the wiring connector is clean and

tight.

OXYGEN SENSOR

To Test - Code 13

(1) Run the engine until the normal operating

temperature is obtained. (2) With the ignition switched Off, connect a

jumper lead between terminals A and B on the

diagnostic link connector.

(3) Start and run the engi ne at approximately

1 600-1 800 rpm for 2 minutes and note the ECM

warning lamp.

If the ECM warning lamp flashes at the rate of

twice per second, proceed to operation (5).

If the ECM warning lamp flashes at the rate of

once per second or slower, proceed as follows.

(4) Remove the jumper lead from the diagnostic

link connector and run th e engine above 2 000 rpm

for 2 minutes, noting the ECM warning lamp.

If the ECM warning lamp lights, stop the engine,

switch the ignition On and connect a jumper lead

between terminals A and B on the diagnostic link

connector. If code 13 is displayed proceed to opera-

tion (5).

If the ECM warning lamp does not light, an

intermittent fault is indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure.

(b) Check that all earth wires are secure.

(5) Switch the ignition Off and disconnect the

oxygen sensor wiring connector. Using a jumper lead

connect the oxygen sensor wiring connector to a

suitable engine earth. (6) Start and run the engi ne at approximately

1 600-1 800 rpm and note the ECM warning lamp.

The lamp may flash for a few seconds but should then

extinguish for at least 30 seconds.

If the ECM warning lamp functions as described,

proceed to operation (7).

If the ECM warning lamp does not function as

described proceed as follows:

(a) Check the wiring harness between the oxygen

sensor wiring connector and the control unit wiring

connector D7 for open circuits. Repair or renew the

wiring harness as necessary.

{b) Check the earth circuit between the control

unit wiring connect D6 and the right rear cylinder

head bolts. Repair or renew the wiring harness as

necessary.

(c) If no fault is found in (a) and (b) renew the

control unit and retest for fault codes.

(7) Check the wiring harness earth circuit be-

tween the control unit wiring connector D6 and the

right rear cylinder head bolts. Repair or renew the

wiring harness as necessary.

If no fault is found, thoroughly check the oxygen

sensor connector. If the conne ctor is not faulty, renew

the oxygen sensor.

To Test - Code 44

(1) Run the engine until normal operating tem-

perature is attained.

(2) With the ignition switched Off, connect a

jumper lead between terminals A and B on the

diagnostic link connector. (3) Start and run the engi ne at approximately

1 600-1 800 rpm for 2 minutes and note the ECM

warning lamp. If the ECM warning lamp is off more than on or

flashes at the rate of twice per second, proceed to

operation (4).

If the ECM warning lamp flashes evenly at the

rate of once per second an intermittent fault is

indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Switch the engine Off and disconnect the

oxygen sensor wiring connector.

(5) Start and run the engine at 1 600-1 800 rpm

for at least 30 seconds and note the ECM warning

lamp. If the ECM warning lamp flashes at the rate of

twice per second procee d to operation (6).

If the ECM warning lamp extinguishes for at least

30 seconds, check the wiring harness between the

oxygen sensor wiring connector and the control unit

wiring connector terminal D7 for shorts to earth.

Repair or renew the wiring harness as necessary.

If no fault can be found in the wiring harness, renew

the control unit.

Installed view of the oxygen sensor.

Page 114 of 238

114 Fuel and Engine Management

(6) Check the vehicle for the following:

(a) Low fuel pressure.

(b) Contaminated fuel.

(c) Vacuum leaks at the inlet manifold, engine

vacuum hoses and engine ventilation hoses. (d) Exhaust manifold leaks before the oxygen

sensor. (e) Correct MAP sensor operation.

(f) Blocked oxygen sensor metal vent cover eg.

plugged with mud etc. (g) Fuel injectors) partially blocked. Refer to a

fuel injection specialis t or a Nissan dealer.

If the above items have been checked and no

faults have been found, a faulty oxygen sensor is

indicated. Renew the oxygen sensor, run the engine

and ensure that no fault codes are set.

To Test — Code 45

(1) Run the engine until normal operating tem-

perature is attained. (2) With the ignition switched Off, connect a

jumper lead between terminals B and A on the

diagnostic link connector. (3) Start and run the engine at approximately

1 600-1 800 rpm for 2 minutes and note the ECM

warning lamp. If the ECM warning lamp is on more than off or

flashes at the rate of twice per second, proceed to the

following operation.

If the ECM warning lamp flashes evenly at the

rate of once per second an intermittent fault is

indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Switch the engine Off and disconnect the

oxygen sensor wiring connector. (5) Using a jumper lead, connect the oxygen

sensor wiring connector to a suitable engine earth. (6) Start and run the engine at 1 600-1 800 rpm

and note the ECM warning lamp.

If the ECM warning lamp extinguishes for at least

30 seconds, proceed to operation (7).

If the ECM warning lamp flashes on more than off

or flashes at the rate of twice per second, switch the

engine Off and disconnect the control unit wiring

connectors. Using an ohmmeter, check that there is no

resistance between the co ntrol unit wiring connector

terminal D6 and earth. Repair or renew the wiring as

necessary.

If no fault can be found in the wiring harness,

renew the control unit.

NOTE: The wiring harness for terminal D6

earths through the righ t hand rear cylinder

head bolt.

(7) Check the vehicl e for the following:

(a) High fuel pressure.

(b) Leaking injector(s).

(c) Faulty ignition wiring.

(d) Charcoal canister purge system blocked or

restricted.

(e) Faulty coolant temper ature sensor circuit.

(f) Faulty MAT sensor circuit (1.8 liter engine).

(g) MAP sensor operation.

(h) Throttle position sensor operation.

If the above items have been checked and no

faults have been found, a faulty oxygen sensor is

indicated.

Renew the oxygen sensor, run the engine and

ensure that no fault codes are set.

To Remove and Install

(1) If the engine is cold, run the engine for

approximately two minutes to allow easy oxygen

sensor removal. (2) Disconnect the negative battery terminal and

the oxygen sensor connector.

View of the oxygen sensor removed from the exhaust

manifold.

(3) Remove the exhaust manifold heat shield

retaining bolts and remove the heat shield from the

engine.

(4) Remove the oxygen sensor with a short ring

spanner using care not to damage the sensor wire. Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing a sensor that has previously

been removed, coat the sen sor threads with anti-seize

compound. Nissan recommend a mixture of liquid

graphite and glass beads. (2) Install the sensor and tighten to the specified

torque. (3) Connect the electrical connector ensuring

that the wiring is secured away from the exhaust. (4) Install the heat shield and tighten the retain-

ing bolts securely. On 1.6 liter engines, ensure that the hot air inlet

tube is located correctly be tween the heat shield and

the air cleaner housing.

(5) Start the engine and check for leaks.

VEHICLE SPEED SENSOR

To Test - Code 24

(1) Check the fuel pump and meter fuses. If the

fuses are serviceable, proceed to operation (5). If a

fuse is blown, rectify the cause and renew the fuse.

Page 115 of 238

Fuel and Engine Management 115

Erase the fault codes and retest for fault codes as

follows:

(2) Start and run the engine until normal oper-

ating temperature is attained. (3) Drive the vehicle at a speed of at least 80

km/h and, with the throttle closed, allow the vehicle to

decelerate until the engine speed is below 1 500 rpm.

NOTE: After rectifying any fault it will be

necessary to retest for fault codes. To test for

Code 24 the vehicle must be driven as

previously described.

(4) Switch the engine Off and connect a jumper

lead between terminals A and B on the diagnostic link

connector. Switch the ignition On and note the fault

codes. If code 24 is displayed proceed as follows. (5) Check the operation of the speedometer and

the instrument cluster warning lamps. If the speed-

ometer only is not functioning, proceed to operation

(13).

If the speedometer and the instrument cluster

warning lamps are not functioning, a fault in the

instrument cluster wiring harness is indicated. Refer

the fault to an auto electrical workshop or a Nissan

dealer.

If the speedometer is functioning, proceed as

follows:

(6) Raise the front of the vehicle and support it

on chassis stands. (7) Place the transaxle in Neutral and switch the

ignition On. (8) With the aid of assistants, slowly spin the

front wheels by hand while backprobing the control

unit wiring connector terminal A10 with a digital

voltmeter to earth. The voltage should alternate from under 1 volt to

over 10 volts.

If the voltmeter readi ng is not as specified,

proceed to operation (9).

If the voltmeter reading is as specified, the vehicle

speed sensor is operating satisfactorily, indicating an

intermittent fault was the cause of the fault code.

Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth c onnections are secure.

(9) Remove the instrument cluster as described

in the Electrical System section. (10) With the ignition switched On, backprobe

the control unit wiring connector terminal A10 with a

voltmeter to earth. The voltage should be over 10

volts. If the voltage is less than specified, check the

wiring harness for shorts to earth between the black

and yellow wire terminal on the instrument cluster

wiring connector and the control unit connector

terminal A10. Repair or renew the wiring harness as

necessary. If no fault can be found, renew the control

unit.

(11) With the ignition switched On, backprobe

the black and yellow wire terminal on the instrument

cluster wiring connector with a voltmeter to earth.

The voltage should be over 10 volts.

If the voltage is less than specified, locate the open

circuit between the instrument cluster black and

yellow wire terminal and the control unit wiring

connector terminal A10. Repair or renew the wiring

harness as necessary.

(12) With a test lamp connected to 12 volts,

backprobe the black wire terminals on the instrument

cluster wiring connectors. The test lamp should light.

If the test lamp does not light locate the open

circuit between the black wire terminals and earth.

Repair or renew the wiring harness as necessary.

If the test lamp does light, renew the signal

divider circuit board which is located in the instru-

ment cluster.

(13) With the ignition switched On and the

engine not running, disconnect the vehicle speed

sensor wiring connector from the harness connector.

(14) With a test lamp connected to earth, probe

the yellow wire terminal on the harness wiring con-

nector. The test lamp should light. If the test lamp does not light, locate the open

circuit between the yellow wi re terminal and the Fuel

Pump fuse. Repair or renew the wiring harness as

necessary.

(15) With a test lamp connected to 12 volts,

probe the black wire terminal on the harness wiring

connector. The test lamp should light.

If the test lamp does not light, locate the open

circuit between the black wire terminal and earth.

Repair or renew the wiring harness as necessary.

(16) Using a voltmeter measure the voltage at the

red wire terminal on the harness wiring connector.

If the voltage is 5-9 volts proceed to operation

(19).

If the voltage is over 9 vol ts proceed to operation

(18).

Installed view of the vehicle speed sensor.

Page 116 of 238

116 Fuel and Engine Management

Rear view of the instrument cluster showing the flexible printed circuit.

If the voltage is under 5 volts proceed as follows.

(17) Check the wiring harness for continuity or

shorts to earth between th e red wire terminal on the

speed sensor harness connector and the green and

black wire terminal on th e instrument cluster wiring

connector.

If no fault can be found check the instrument

cluster printed circuit for continuity or shorts. If no

fault can be found, renew the speedometer and the

signal divider circuit board.

(18) Remove the instrument cluster as described

in the Electrical System se ction and repeat operation

(16).

If the voltage is under 1 volt, check the flexible

printed circuit on the rear of the instrument cluster for

continuity or shorts and re new as necessary. If no fault

can be found, renew the speedometer and the signal

divider circuit board.

(19) Connect the harness connector to the vehicle

speed sensor wiring connector. (20) Raise the front of the vehicle and support it on chassis stands. Place the transaxle in Neutral.

(21) With the aid of assistants, slowly spin the

front wheels by hand while backprobing the brown

wire terminal on the vehicle speed sensor wiring

connector with a voltmeter to earth.

The voltage should alternate between approxi-

mately 1 and 7 volts.

If the voltage is as specif ied, check the flexible

printed circuit on the rear of the instrument cluster for

continuity or shorts. If no fault can be found, renew

the speedometer and the signal divider circuit board.

If the voltage is not as specified, proceed as

follows.

(22) Disconnect the vehicle speed sensor wiring

connector and unscrew the sensor from the speedom-

eter drive housing. (23) Rotate both front wheels in the same direc-

tion and check that the speedometer drive shaft is

turning and does not slip. If the drive shaft does not operate as described,

renew the drive assembly as described in the Manual

or Automatic Transaxle section.

If the drive shaft operates satisfactorily, renew the

vehicle speed sensor.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the vehicle speed sensor wiring

connector. (3) Unscrew the vehicle speed sensor from the

speedometer drive housing.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Align the cut-out in the speedometer drive

shaft with the notch in the vehicle speed sensor shaft.

(2) Tighten the vehicle speed sensor securely.