light NISSAN PULSAR 1987 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 196 of 238

196 Electrical System

Check the specific gravity in each cell with a hydro-

meter.

Check the battery electrolyte level and re-

plenish as necessary. Remove the filler cap s from the battery.

Follow the battery charger manufacturers

instructions. (3) Should the battery fail to operate satisfacto-

rily after charging, it is recommended that it be taken

to a workshop with the necessary equipment to per-

form a load test. Load testing, when performed in

conjunction with the specific gravity tests described

above will give an accurate indication of the service-

ability of the battery.

7. ALTERNATOR

Special Equipment Required

To Test On Vehicle - Voltmeter, 100-0-100

amp ammeter, ohmmeter

To Dismantle — 200 watt soldering iron,

bearing

puller, press

To Assemble — 200 watt soldering iron

DESCRIPTION

Two types of alternator are installed to the range

of vehicles covered by this manual, either Hitachi or

Bosch. In the alternator, the field and pole shoe assembly

is the moving part and it is shaped to form the rotor.

Since only a low amperage current flows between the

slip rings on the rotor shaft and the brushes, wear on

the brushes and slip rings is very slight and mainte-

nance is reduced to a minimum. The output current is generated in the fixed stator

windings and is a three phase alternating current

(AC). The stator windings are wound on a laminated

soft iron former, star connected and installed between

the end brackets. As it is not possible to charge a storage battery

with alternating current, it is necessary to rectify the

output of the stator windings to direct current (DC). This is done by a bank of diodes mounted within the

alternator slip ring end bracket.

The output of the alternator is governed by the

regulator and the built in ch aracteristics of the alter-

nator.

The regulator and brush holder assembly on

Hitachi alternators is mounted within the alternator

on the slip ring end bracket side. On Bosch

alternators

the regulator and brush holder unit is mounted to the

outside of the slip ring end bracket. An electrical cut out unit is not necessary with the

alternator charging system as the diodes prevent a

reverse current flow through the alternator.

SERVICE PRECAUTIONS

Ensure that the battery is connected with the

correct polarity to earth. Refer to Specifications.

Do not short out or ground any terminals

common to the charging circuit. Always disconnect the battery before con-

necting a battery charger.

If a booster battery is used, always connect it

in a parallel circuit i.e. positive to positive ( + to + )

and negative to negative (- to -) to maintain a 12

volt supply. Never disconnect the battery or terminals in

the charging circuit while the engine is running. Regularly check that the alternator drive belt

tension is as specified. Refer to the Engine Tune-up

section.

Keep the battery terminals clean and all

electrical connections tight. Disconnect the battery and alternator when

electric welding on the vehicle.

TO TEST ON VEHICLE If the charge indicator lamp stays on after the

engine has been started and run at approximately

1 000 rpm, carry out the following tests. Stop the engine.

Check the condition and adjustment of the

alternator drive belt. Clean the battery terminals, tighten all elec-

trical connections, check the wiring for shorts to earth

and/or bridged circuits. Ensure that the battery is fully

charged. If the battery is discharged charge it or

replace it with one fully charged. Start the engine and allow it to run until

normal operating temperature is reached.

Stop the engine and disconnect the negative

battery terminal.

Remove the nut and washer from the alter-

nator output terminal (B +) and disconnect the alter-

nator output lead. Connect one lead of an ammeter to the

alternator output terminal and the other lead to the

lead removed from the output terminal. Connect the negative battery terminal and

connect a voltmeter across the battery terminals.

Page 203 of 238

Electrical System 203

BRUSH HOLDER

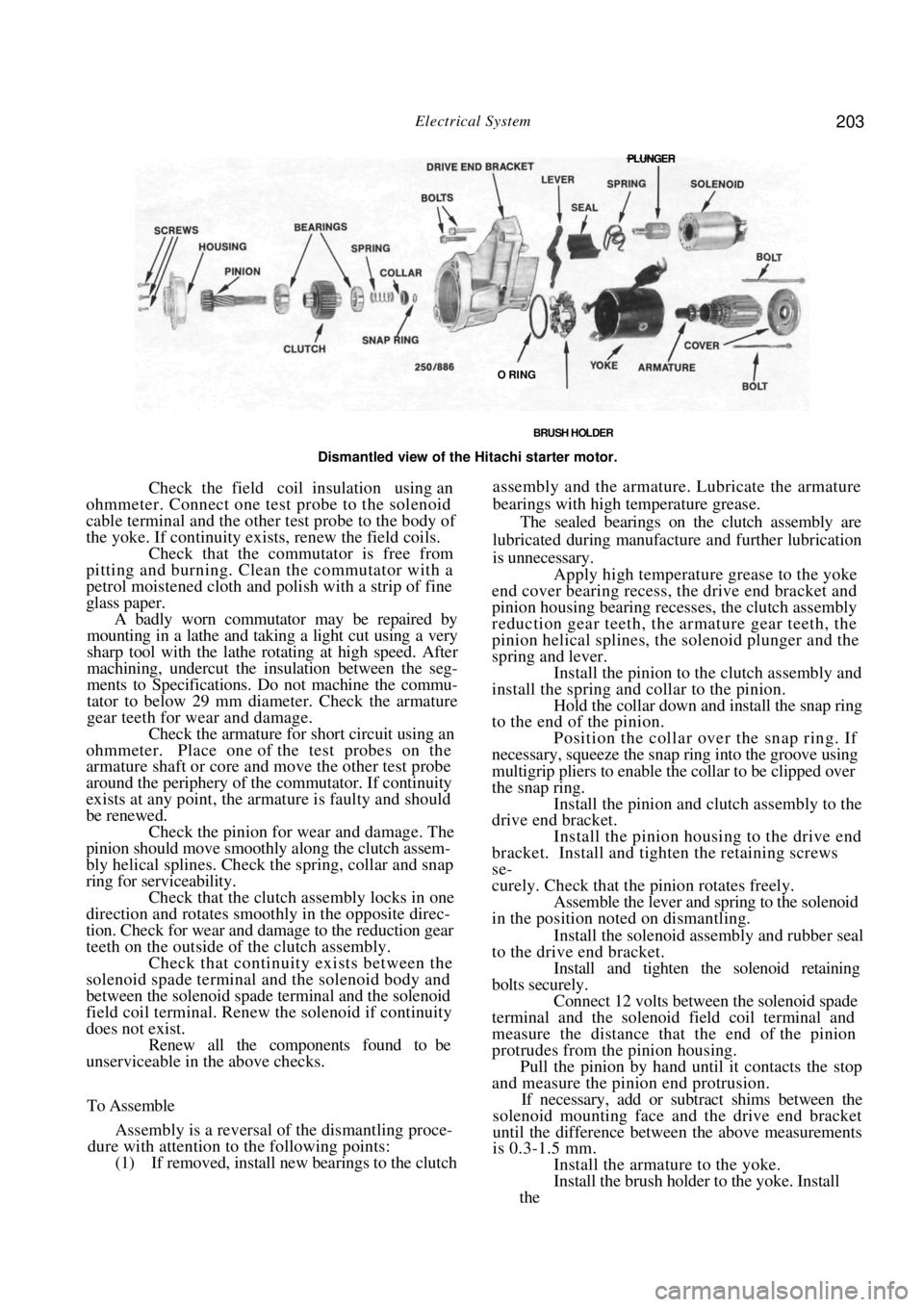

Dismantled view of the Hitachi starter motor.

Check the field coil insulation using an

ohmmeter. Connect one test probe to the solenoid

cable terminal and the other test probe to the body of

the yoke. If continuity exists, renew the field coils. Check that the commutator is free from

pitting and burning. Clean the commutator with a

petrol moistened cloth and polish with a strip of fine

glass paper.

A badly worn commutator may be repaired by

mounting in a lathe and taking a light cut using a very

sharp tool with the lathe rotating at high speed. After

machining, undercut the insulation between the seg-

ments to Specifications. Do not machine the commu-

tator to below 29 mm diameter. Check the armature

gear teeth for wear and damage.

Check the armature for short circuit using an

ohmmeter. Place one of the test probes on the

armature shaft or core and move the other test probe

around the periphery of the commutator. If continuity

exists at any point, the armature is faulty and should

be renewed. Check the pinion for wear and damage. The

pinion should move smoothl y along the clutch assem-

bly helical splines. Check the spring, collar and snap

ring for serviceability.

Check that the clutch assembly locks in one

direction and rotates smoothly in the opposite direc-

tion. Check for wear and damage to the reduction gear

teeth on the outside of the clutch assembly.

Check that continuity exists between the

solenoid spade terminal and the solenoid body and

between the solenoid spade terminal and the solenoid

field coil terminal. Renew the solenoid if continuity

does not exist. Renew all the components found to be

unserviceable in the above checks.

To Assemble

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) If removed, install new bearings to the clutch

assembly and the armature. Lubricate the armature

bearings with high temperature grease.

The sealed bearings on the clutch assembly are

lubricated during manufacture and further lubrication

is unnecessary.

Apply high temperature grease to the yoke

end cover bearing recess, the drive end bracket and

pinion housing bearing recesses, the clutch assembly

reduction gear teeth, the armature gear teeth, the

pinion helical splines, th e solenoid plunger and the

spring and lever. Install the pinion to the clutch assembly and

install the spring and collar to the pinion. Hold the collar down and install the snap ring

to the end of the pinion.

Position the collar over the snap ring. If

necessary, squeeze the snap ring into the groove using

multigrip pliers to enable the collar to be clipped over

the snap ring. Install the pinion and clutch assembly to the

drive end bracket.

Install the pinion housing to the drive end

bracket. Install and tighten the retaining screws

se-

curely. Check that the pinion rotates freely.

Assemble the lever and spring to the solenoid

in the position noted on dismantling.

Install the solenoid assembly and rubber seal

to the drive end bracket.

Install and tighten the solenoid retaining

bolts securely. Connect 12 volts between the solenoid spade

terminal and the solenoid field coil terminal and

measure the distance that the end of the pinion

protrudes from the pinion housing. Pull the pinion by hand until it contacts the stop

and measure the pinion end protrusion.

If necessary, add or subt ract shims between the

solenoid mounting face and the drive end bracket

until the difference between the above measurements

is 0.3-1.5 mm.

Install the armature to the yoke.

Install the brush holder to the yoke. Install

the

PLUNGER

O RING

Page 205 of 238

Electrical System 205

Dismantled view of the brush holder assembly. Bosch

starter motor.

side and the other lead to the negative side. If there is

any indication of leakage the ohmmeter will show a

reading other than infinity. Repair or renew the brush

holder if leakage is evident.

(2) Check the brushes for adequate length.

Brushes should be renewed when their length is below

Specifications. They should be a free sliding fit in the

brush holders.

NOTE: Due to the difficulty involved in

removing and installing the brushes in the

Bosch starter motor, it is recommended that

the brush holder be renewed as an assembly.

(3) Check that the commutator is free from

pitting and burning. Clean with a petrol moistened

cloth and polish with a strip of fine glass paper.

A badly worn commutator may be repaired by

mounting in a lathe, spi nning at high speed, and

taking a light cut with a very sharp tool. After turning,

undercut the insulation between the segments.

(4) Check the armature for short circuit using an

ohmmeter.

Place one of the test lead s on the armature shaft

or core and move the other lead around the circum-

ference of the commutator. If the ohmmeter shows a

reading at any point the armature is faulty and should

be renewed.

Check the drive assembly clutch pinion teeth

for wear, scoring or chipping. A clutch in good

condition should take up the drive in one direction

only. It should rotate easily and smoothly in the

non-drive direction and the assembly should move

smoothly along the armature or drive shaft helical

splines.

Check the armature shaft bushes for wear

and renew as necessary. The old bushes must be

removed and the new ones pressed into the end

brackets using a polished mandrel of the exact diam-

eter of the armature shaft. NOTE: The new bushes must not be reamed

to size, as reaming will impair the porosity

of the bushes and cause early failure. New

bushes should be allowed to stand immersed

in clean light engine oil for one hour before

installation.

To Assemble

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Lubricate the helix of the drive shaft lightly

with graphite grease and install the drive assembly

to

the drive shaft. Install the stop collar and snap ring, slide the

stop collar over the snap ring to lock the snap ring in

position.

Lubricate the bushes in both end brackets

sparingly with engine oil. Install the engaging lever and gear set into the

drive end bracket. Install the centre rear bracket and the engag-

ing lever seal into the drive end bracket.

Slide the brush holder assembly into position

on the commutator ensuring that the brush holders

are correctly positioned in the anchor points. Install the commutator end bracket to

the

armature, install the shims and C clip. Check that the armature end float is satisfac-

tory and adjust as necessary using shims of the correct

thickness.

Align the slot in the commutator end bracket

with the cut out on the wiring seal and install the

armature end cover to the commutator end bracket.

Install the cover retaini ng screws but do not tighten.

Ensure that the permanent magnets in the

yoke have not picked up any debris and slide the yoke

over the armature ensuring that the wiring seal locates

correctly in the slot in the yoke.

View showing the planetary gear set. Bosch starter

motor.

Page 206 of 238

206 Electrical System

Install the armature and yoke to the drive end

bracket rotating the drive to align the reduction gears.

Do not use force.

Install the retaining through bolts to the

commutator end bracket and lighten the through bolts

and armature end cover retaining screws securely. Install the solenoid to the drive end bracket,

install the retaining screws and tighten them securely.

Install the brush connector strap and

install

the retaining nut and washer and tighten securely.

9 . IGNITION SYSTEM

The testing and repair procedures for the ignition

system are fully covered in the Fuel and Engine

Management section.

10. STEERING WHEEL

The removal and installation procedures for the

steering wheel and horn pad are fully covered in the

Steering section.

11. SWITCHES AND CONTROLS

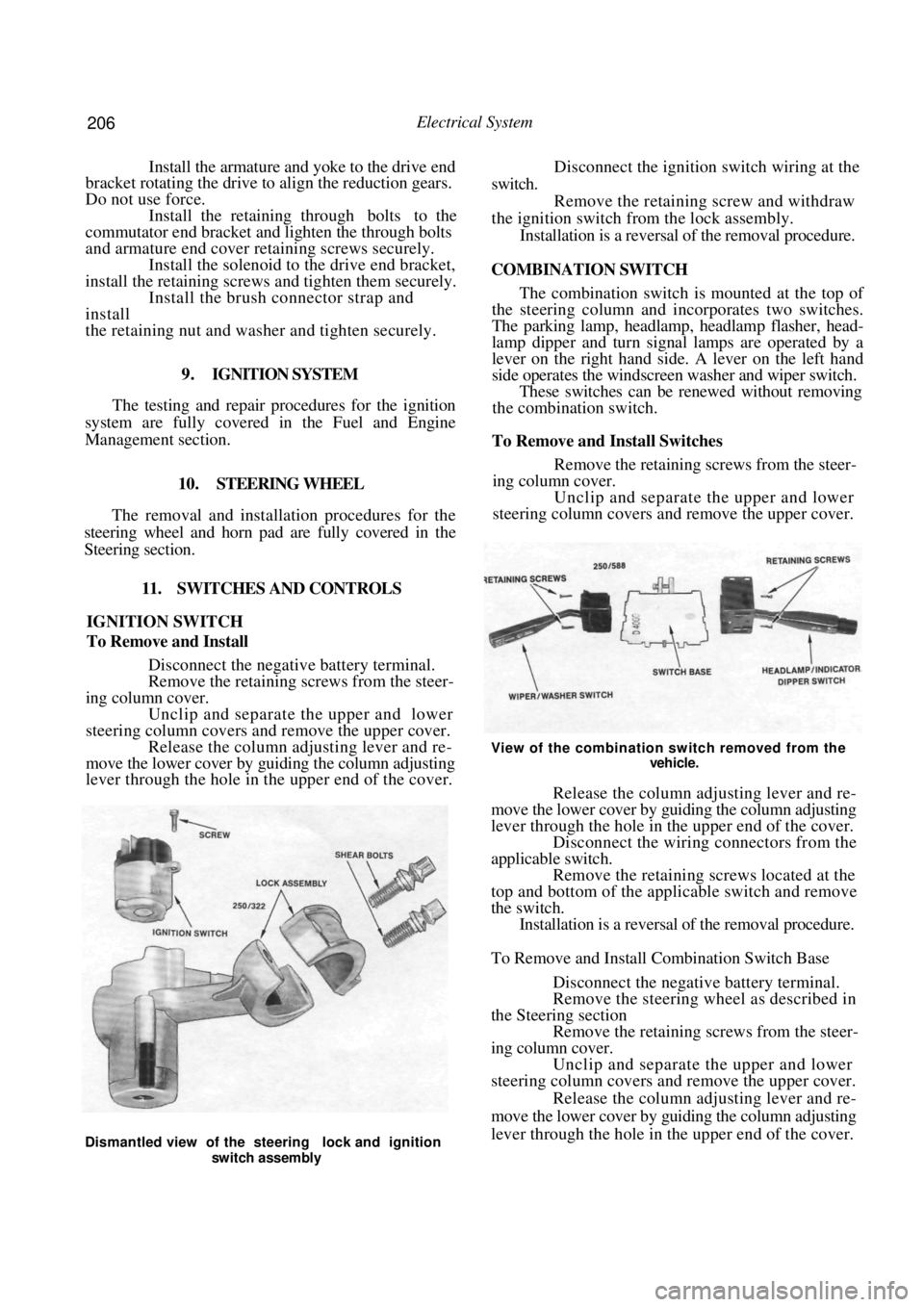

IGNITION SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover. Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Disconnect the ignition switch wiring at the

switch. Remove the retaining screw and withdraw

the ignition switch fr om the lock assembly.

Installation is a reversal of the removal procedure.

COMBINATION SWITCH

The combination switch is mounted at the top of

the steering column and incorporates two switches.

The parking lamp, headlamp, headlamp flasher, head-

lamp dipper and turn signal lamps are operated by a

lever on the right hand side. A lever on the left hand

side operates the windscreen washer and wiper switch.

These switches can be re newed without removing

the combination switch.

To Remove and Install Switches

Remove the retaining screws from the steer-

ing column cover.

Unclip and separate the upper and lower

steering column covers and remove the upper cover.

View of the combination switch removed from the

vehicle.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover. Disconnect the wiring connectors from the

applicable switch. Remove the retaining screws located at the

top and bottom of the applicable switch and remove

the switch. Installation is a reversal of the removal procedure.

To Remove and Install Combination Switch Base

Disconnect the negative battery terminal.

Remove the steering wheel as described in

the Steering section Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Dismantled view of the steering lock and ignition

switch assembly

Page 210 of 238

210 Electrical System

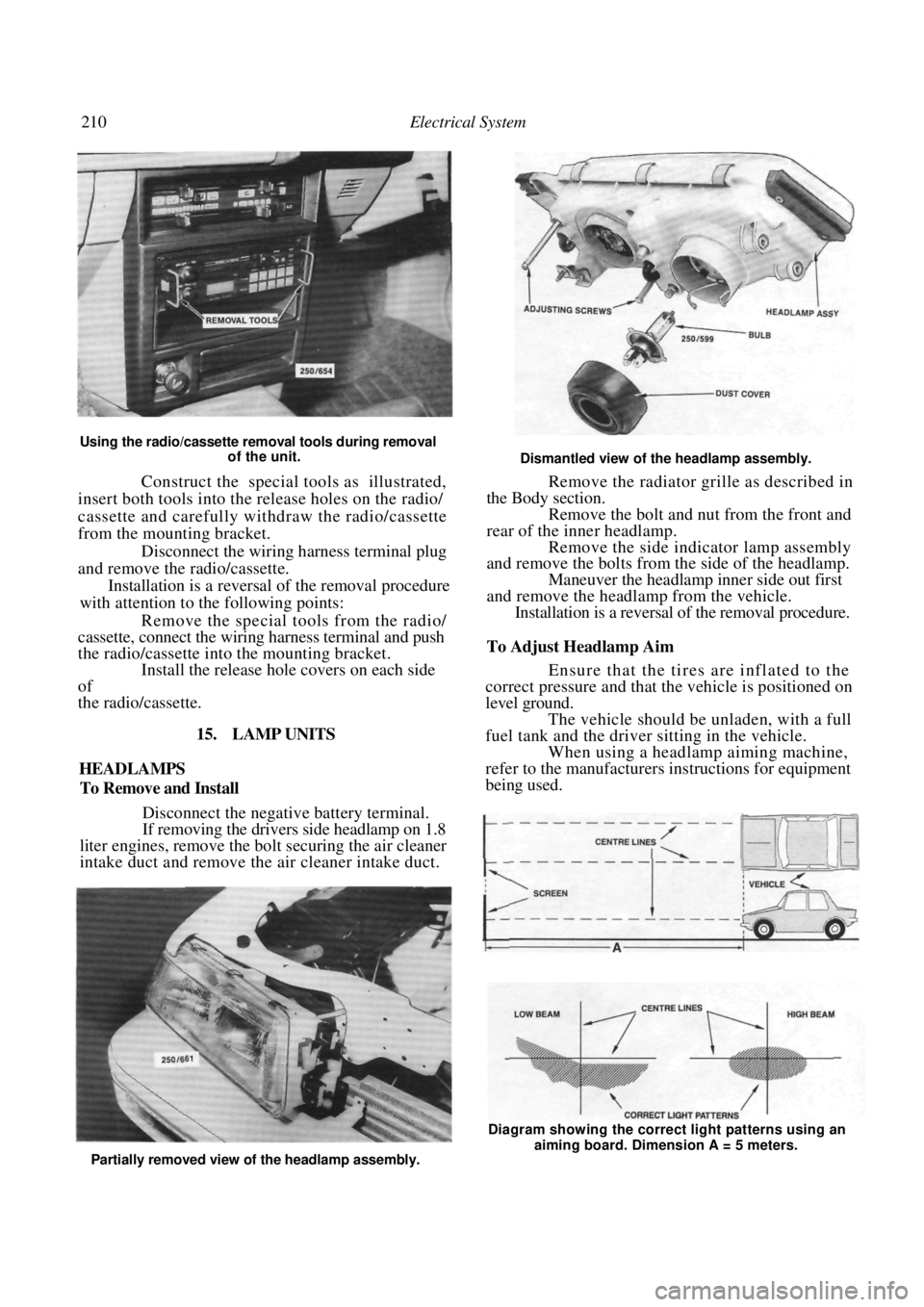

Using the radio/cassette removal tools during removal of the unit.

Construct the special tools as illustrated,

insert both tools into the release holes on the radio/

cassette and carefully withdraw the radio/cassette

from the mounting bracket.

Disconnect the wiring harness terminal plug

and remove the radio/cassette.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the special tools from the radio/

cassette, connect the wiring harness terminal and push

the radio/cassette into the mounting bracket. Install the release hole covers on each side

of

the radio/cassette.

15. LAMP UNITS

HEADLAMPS

To Remove and Install

Disconnect the negative battery terminal.

If removing the drivers side headlamp on 1.8

liter engines, remove the bo lt securing the air cleaner

intake duct and remove the air cleaner intake duct.

Dismantled view of the headlamp assembly.

Remove the radiator grille as described in

the Body section. Remove the bolt and nut from the front and

rear of the inner headlamp. Remove the side indicator lamp assembly

and remove the bolts from the side of the headlamp.

Maneuver the headlamp inner side out first

and remove the headlamp from the vehicle. Installation is a reversal of the removal procedure.

To Adjust Headlamp Aim

Ensure that the tires are inflated to the

correct pressure and that the vehicle is positioned on

level ground.

The vehicle should be unladen, with a full

fuel tank and the driver sitting in the vehicle. When using a headlamp aiming machine,

refer to the manufacturers instructions for equipment

being used.

Partially removed view of the headlamp assembly. Diagram showing the correct light patterns using an

aiming board. Dimension A = 5 meters.

Page 219 of 238

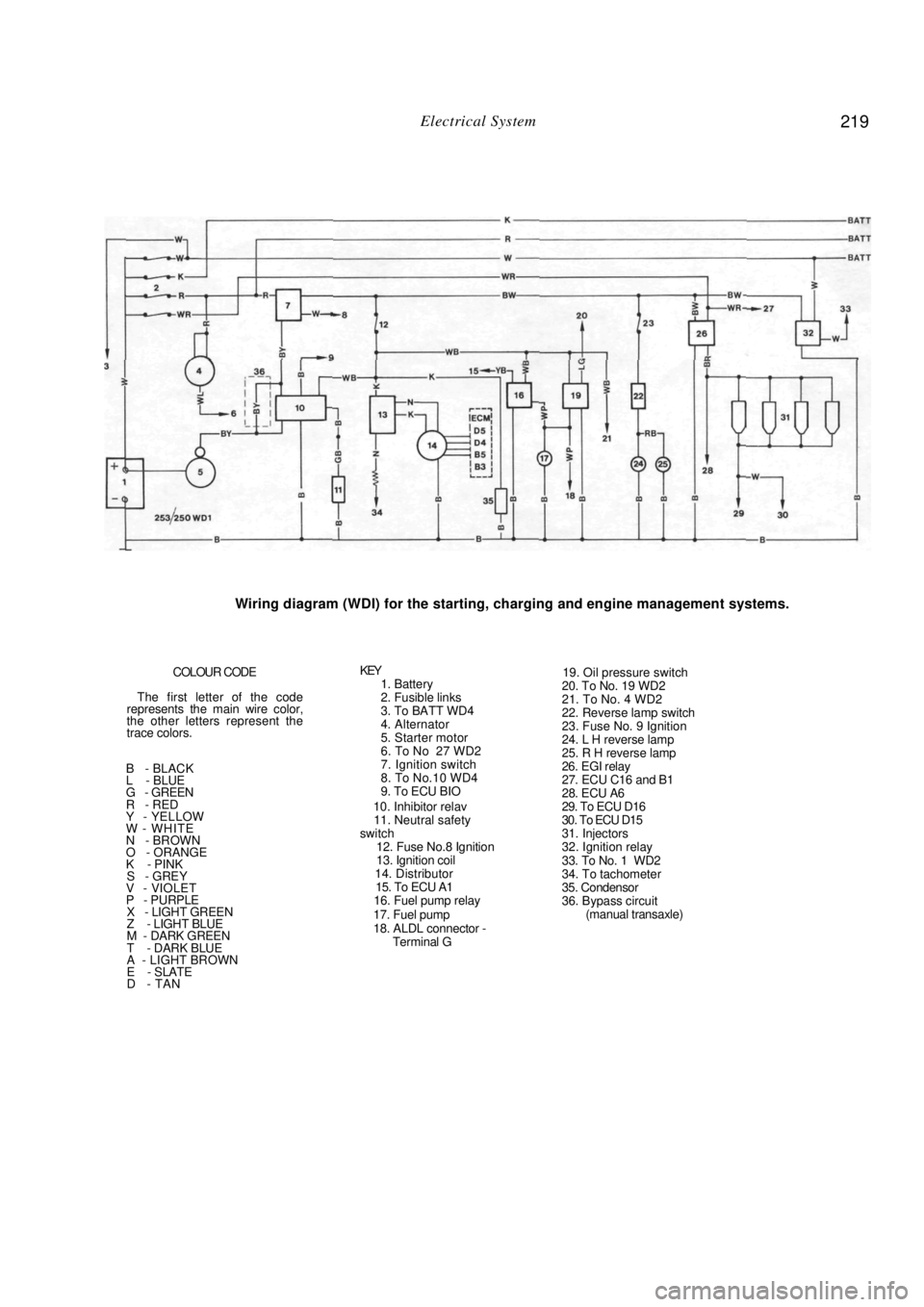

Electrical System 219

Wiring diagram (WDI) for the starting, charging and engine management systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Battery

2. Fusible links

3. To BATT WD4

4. Alternator

5. Starter motor

6. To No 27 WD2

7. Ignition switch

8. To No.10 WD4

9. To ECU BIO

10. Inhibitor relav

11. Neutral safety

switch

12. Fuse No.8 Ignition

13. Ignition coil

14. Distributor

15. To ECU A1

16. Fuel pump relay

17. Fuel pump

18. ALDL connector - Terminal G

19. Oil pressure switch

20. To No. 19 WD2

21. To No. 4 WD2

22. Reverse lamp switch

23. Fuse No. 9 Ignition

24. L H reverse lamp

25. R H reverse lamp

26. EGI relay

27. ECU C16 and B1

28. ECU A6

29. To ECU D16

30. To ECU D15

31. Injectors

32. Ignition relay

33. To No. 1 WD2

34. To tachometer

35. Condensor

36. Bypass circuit (manual transaxle)

Page 220 of 238

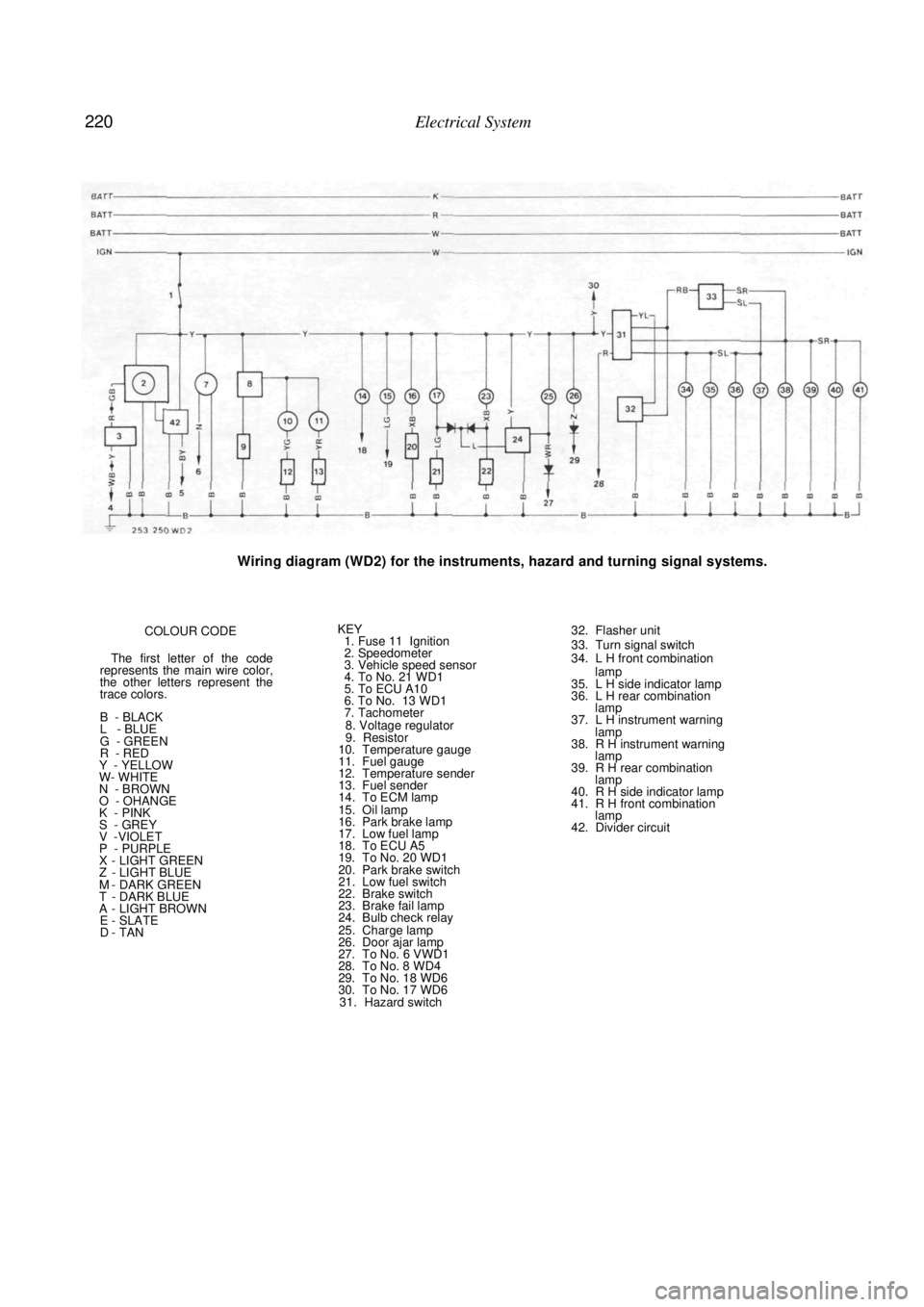

220 Electrical System

Wiring diagram (WD2) for the instruments, hazard and turning signal systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W- WHITE

N - BROWN

O - OHANGE

K - PINK

S - GREY V -VIOLET

P - PURPLE X - LIGHT GREEN Z - LIGHT BLUE M - DARK GREEN T - DARK BLUE A - LIGHT BROWN E - SLATE D - TAN

KEY 1. Fuse 11 Ignition

2. Speedometer

3. Vehicle speed sensor

4. To No. 21 WD1

5. To ECU A10

6. To No. 13 WD1

7. Tachometer

8. Voltage regulator

9. Resistor

10. Temperature gauge

11. Fuel gauge

12. Temperature sender

13. Fuel sender

14. To ECM lamp

15. Oil lamp

16. Park brake lamp

17. Low fuel lamp

18. To ECU A5

19. To No. 20 WD1

20. Park brake switch

21. Low fuel switch

22. Brake switch

23. Brake fail lamp

24. Bulb check relay

25. Charge lamp

26. Door ajar lamp

27. To No. 6 VWD1

28. To No. 8 WD4

29. To No. 18 WD6

30. To No. 17 WD6 31. Hazard switch

32. Flasher unit

33. Turn signal switch

34. L H front combination

lamp

35. L H side indicator lamp

36. L H rear combination lamp

37. L H instrument warning

lamp

38. R H instrument warning lamp

39. R H rear combination lamp

40. R H side indicator lamp

41. R H front combination lamp

42. Divider circuit

Page 221 of 238

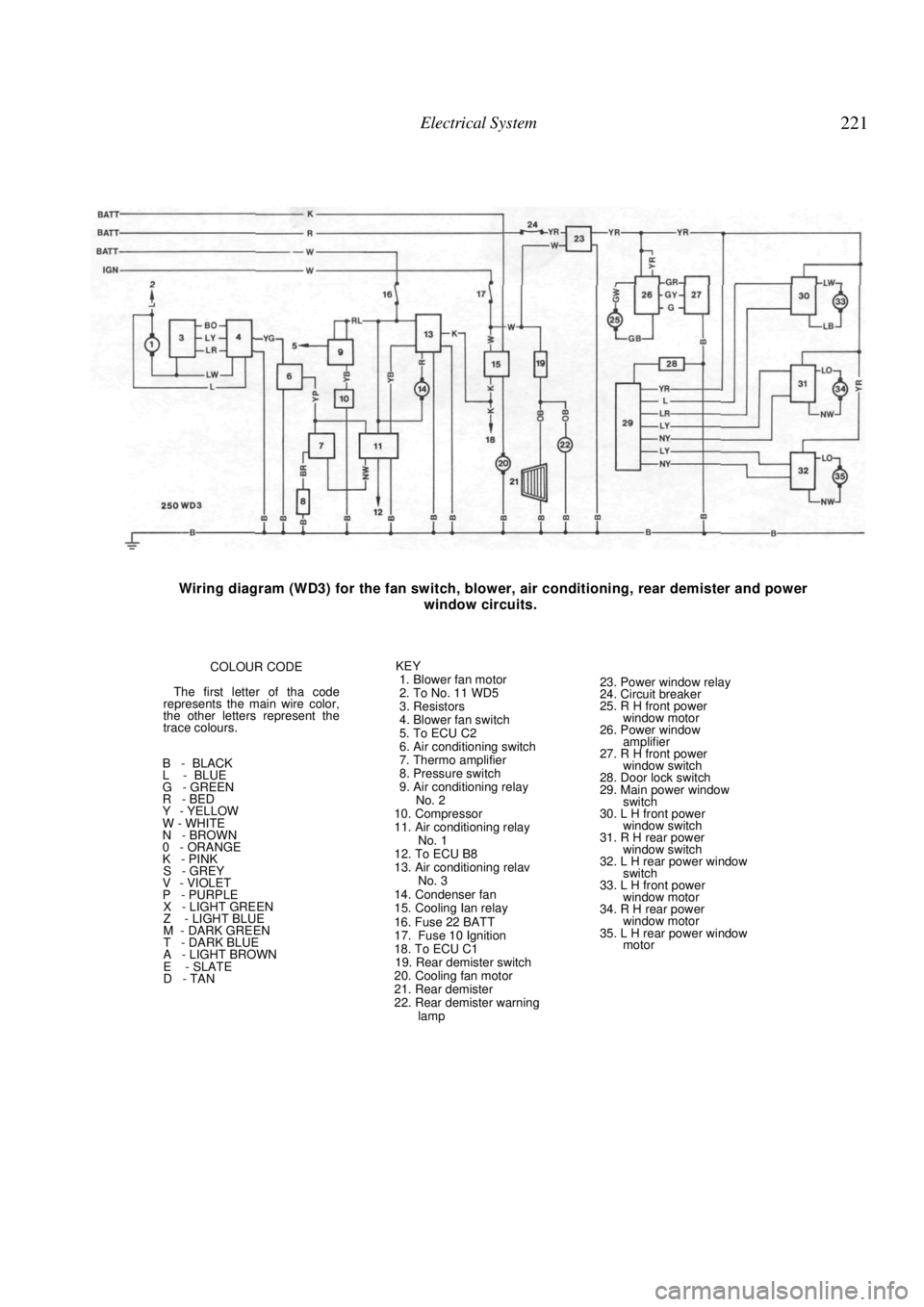

Electrical System 221

Wiring diagram (WD3) for the fan switch, blower, air conditioning, rear demister and power

window circuits.

COLOUR CODE

The first letter of tha code

represents the main wire color,

the other letters represent the

trace colours.

B - BLACK

L - BLUE

G - GREEN

R - BED

Y - YELLOW

W - WHITE

N - BROWN

0 - ORANGE

K - PINK

S - GREY

V - VIOLET

P - PURPLE

X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN KEY

1. Blower fan motor

2. To No. 11 WD5

3. Resistors

4. Blower fan switch

5. To ECU C2

6. Air conditioning switch

7. Thermo amplifier

8. Pressure switch

9. Air conditioning relay No. 2

10. Compressor

11. Air conditioning relay No. 1

12. To ECU B8

13. Air conditioning relav No. 3

14. Condenser fan

15. Cooling Ian relay

16. Fuse 22 BATT

17. Fuse 10 Ignition

18. To ECU C1

19. Rear demister switch

20. Cooling fan motor

21. Rear demister

22. Rear demister warning lamp

23. Power window relay

24. Circuit breaker

25. R H front power

window motor

26. Power window amplifier

27. R H front power window switch

28. Door lock switch

29. Main power window switch

30. L H front power

window switch

31. R H rear power window switch

32. L H rear power window switch

33. L H front power

window motor

34. R H rear power window motor

35. L H rear power window motor

Page 222 of 238

222 Electrical System

Wiring diagram (WD4) for the horn, audio, front wiper/washer and rear wiper/washer circuits.

COLOUR CODE

The first letter of the code

represents the main wire color.

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Fuse No. 18 Batt

2. Horn relay

3. Horn switch

4. Horn

5. Stop lamp switch

6. L H stop lamp

7. R H stop lamp

8. To No. 28 WD2

9. To No. 14 WD6

10. To No. 8 WD1

11. Radio cassette and clock

12. L H front speaker

13. L H rear speaker

14. R H front speaker

15. R H rear speaker

16. Fuse No. 19 Batt

17. Fuse No. 20 Batt

18. Fuse No. 6 ACC

19. Rear washer motor

20. Rear wiper/washer

motor

21. Rear wiper motor

22. Fuse No. 7 ACC

23. Front wiper motor

24. Front washer motor

25. Intermittent wiper relay

26. Front wiper/washer

switch

27. Variable intermittent

switch

Page 223 of 238

Electrical System 223

Wiring diagram (WD5) for the mirrors, cigarette lighter and door lock circuits.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Accessories relay

2. R H power mirror 3. L H power mirror

4. Power mirror switch

5. Fuse No. 3 ACC

6. Fuse No. 4 ACC

7. Fuse No. 5 ACC

8. Fuse No 21 B

9. Cigarette lighter

10. To No. 13 WD6

11. To No. 2 WD3

12. Door lock timer

13. Front door lock switch

14. Key lock switch

15. Door lock switch

16. L H front door lock solenoid

17. R H rear door lock solenoid

18. L H rear door lock

solenoid