ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1146 of 5121

WATER INLET AND THERMOSTAT ASSEMBLY

CO-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

WATER INLET AND THERMOSTAT ASSEMBLY

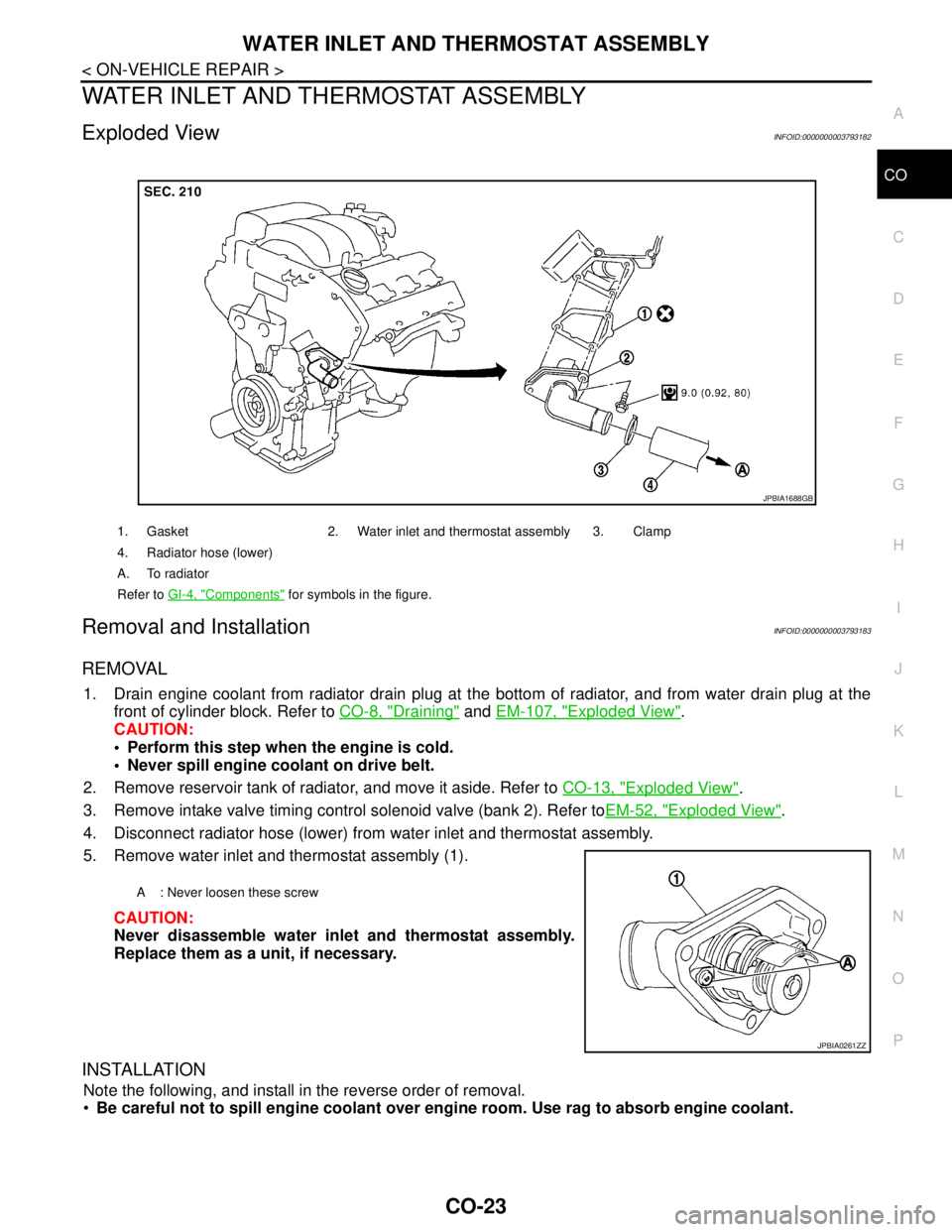

Exploded ViewINFOID:0000000003793182

Removal and InstallationINFOID:0000000003793183

REMOVAL

1. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-8, "

Draining" and EM-107, "Exploded View".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

2. Remove reservoir tank of radiator, and move it aside. Refer to CO-13, "

Exploded View".

3. Remove intake valve timing control solenoid valve (bank 2). Refer toEM-52, "

Exploded View".

4. Disconnect radiator hose (lower) from water inlet and thermostat assembly.

5. Remove water inlet and thermostat assembly (1).

CAUTION:

Never disassemble water inlet and thermostat assembly.

Replace them as a unit, if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

Be careful not to spill engine coolant over engine room. Use rag to absorb engine coolant.

1. Gasket 2. Water inlet and thermostat assembly 3. Clamp

4. Radiator hose (lower)

A. To radiator

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1688GB

A : Never loosen these screw

JPBIA0261ZZ

Page 1204 of 5121

DEF-54

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

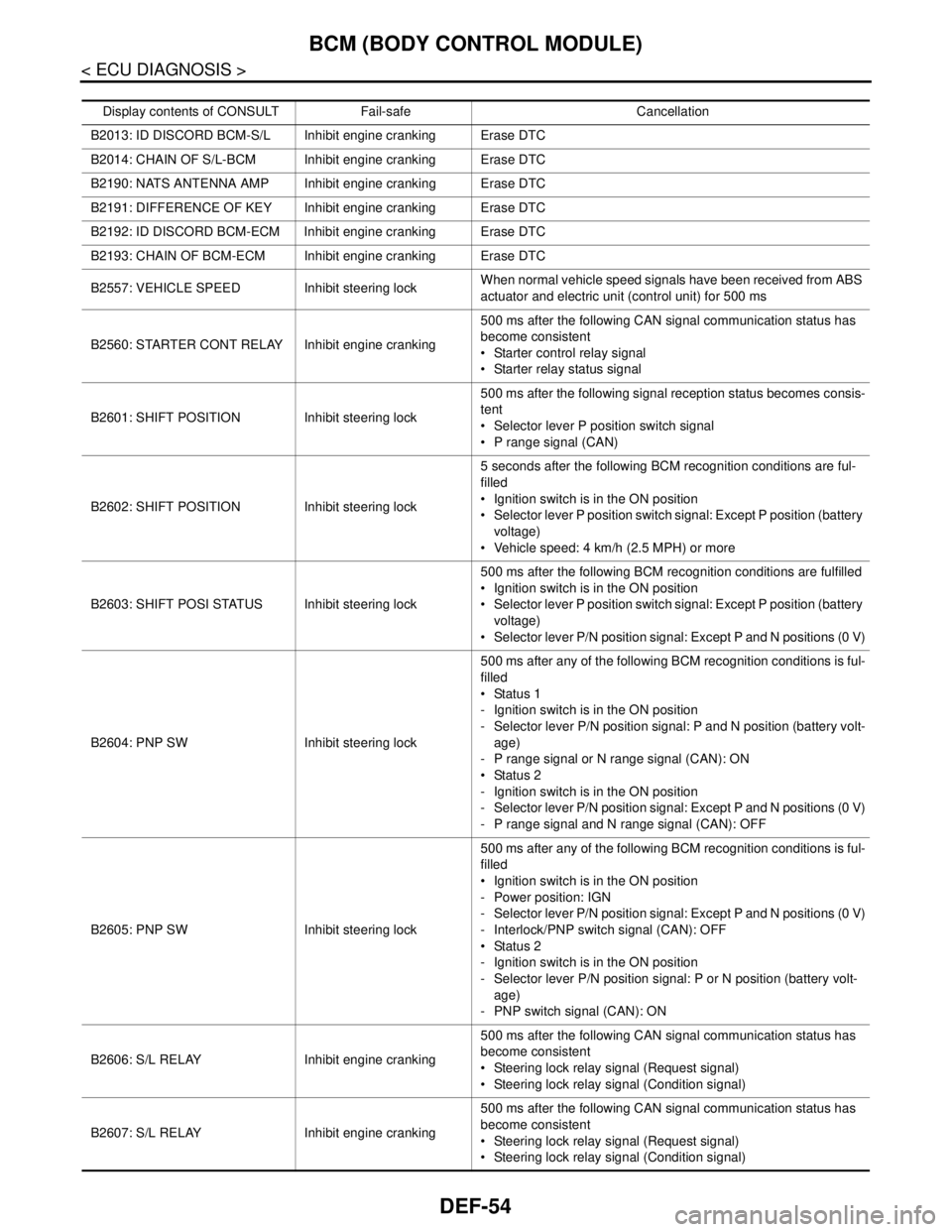

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 1261 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW](/img/5/57391/w960_57391-1260.png)

DIAGNOSIS SYSTEM (BCM)

DLK-45

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

ACTIVE TEST

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW 1 Indicates [ON/OFF] condition of brake switch.

DETE/CANCL SW Indicates [ON/OFF] condition of the P position.

SFT PN/N SW Indicates [ON/OFF] condition of the P or N position.

S/L -LOCK Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L -UNLOCK Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY -F/B Indicates [ON/OFF] condition of steering lock relay.

UNLK SEN -DR Indicates [ON/OFF] condition of driver door UNLOCK status.

PUSH SW -IPDM Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY1 -F/B Indicates [ON/OFF] condition of ignition relay 1.

DETE SW -IPDM Indicates [ON/OFF] condition of the P position.

SFT PN -IPDM Indicates [ON/OFF] condition of the P or N position.

SFT P -MET Indicates [ON/OFF] condition of the P position.

SFT N -MET Indicates [ON/OFF] condition of the N position.

ENGINE STATE Indicates [STOP/STALL/CRANK/RUN] condition of engine states.

S/L LOCK-IPDM Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L UNLK-IPDM Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY-REQ Indicates [ON/OFF] condition of steering lock relay.

VEH SPEED 1 Displays the vehicle speed signal received from combination meter by numerical value [Km/h].

VEH SPEED 2 Displays the vehicle speed signal received from ABS, VDC or CVT by numerical value [Km/h].

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of driver side door status.

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status.

ID OK FLAG Indicates [SET/RESET] condition of key ID.

PRMT ENG STRT Indicates [SET/RESET] condition of engine start possibility.

PRMT RKE STRTNOTE:

This item is displayed, but cannot be monitored.

KEY SW -SLOT Indicates [ON/OFF] condition of key slot.

TRNK/HAT MNTR Indicates [ON/OFF] condition of trunk lid.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD Indicates [ON/OFF] condition of TRUNK OPEN signal from Intelligent Key.

RKE-PANICNOTE:

This item is displayed, but cannot be monitored.

RKE-P/W OPENNOTE:

This item is displayed, but cannot be monitored.

RKE-MODE CHG Indicates [ON/OFF] condition of MODE CHANGE signal from Intelligent Key.

RKE OPE COUN1When remote keyless entry receiver receives the signal transmitted while operating on Intelligent Key, the

numerical values start changing.

RKE OPE COUN2NOTE:

This item is displayed, but cannot be monitored. Monitor Item Condition

Page 1367 of 5121

![NISSAN TEANA 2008 Service Manual BCM (BODY CONTROL MODULE)

DLK-151

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit e NISSAN TEANA 2008 Service Manual BCM (BODY CONTROL MODULE)

DLK-151

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit e](/img/5/57391/w960_57391-1366.png)

BCM (BODY CONTROL MODULE)

DLK-151

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITIONInhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITIONInhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 1412 of 5121

![NISSAN TEANA 2008 Service Manual DLK-196

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

Exploded ViewINFOID:0000000003795070

Removal and InstallationINFOID:0000000003795071

REMOVAL

1. U NISSAN TEANA 2008 Service Manual DLK-196

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

Exploded ViewINFOID:0000000003795070

Removal and InstallationINFOID:0000000003795071

REMOVAL

1. U](/img/5/57391/w960_57391-1411.png)

DLK-196

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

Exploded ViewINFOID:0000000003795070

Removal and InstallationINFOID:0000000003795071

REMOVAL

1. Use refrigerant collecting equipment to discharge the refrigerant. Refer to HA-24, "Collection and

Charge".

2. Remove front under cover. Refer to EXT-28, "

Removal and Installation".

3. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

4. Remove front bumper fascia, energy absorber and bumper reinforcement. Refer to EXT-12, "

Removal

and Installation".

5. Remove mounting clips and remove air duct cover.

6. Remove hood lock opener and hood lock. Refer to DLK-220, "

Removal and Installation".

7. Disconnect connector of horn (HIGH/LOW), and then remove horn (HIGH/LOW). Refer to HRN-6,

"Removal and Installation".

8. Disconnect connector of gas sensor, and then remove gas sensor (with intelligent air conditioner system).

Refer to VTL-82, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Removal and Installation".

9. Remove bumper retainer assembly. Refer to EXT-12, "

Removal and Installation".

10. Remove air guide (RH/LH).

11. Remove front combination lamp (RH/LH). Refer to EXL-181, "

Removal and Installation" (XENON TYPE)

or EXL-343, "

Removal and Installation" (HALOGEN TYPE).

12. Disconnect connector of ambient sensor. Refer to VTL-24, "

Removal and Installation" (WITHOUT 7 INCH

DISPLAY) or VTL-81, "

Removal and Installation" (WITH 7 INCH DISPLAY).

1. Radiator upper hose bracket 2. Hood switch bracket 3. Air duct cover

4. Air guide (RH/LH) 5. Radiator core support

: Pawl

JMKIA2382ZZ

Page 1489 of 5121

![NISSAN TEANA 2008 Service Manual EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM throug NISSAN TEANA 2008 Service Manual EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM throug](/img/5/57391/w960_57391-1488.png)

EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from the crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

During warm-up

When starting the engine

During acceleration

Hot-engine operation

When selector lever is changed from N to D

High-load, high-speed operation

During high engine speed operation

Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Intake air temperature sensor Intake air temperature

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)Gear position

Battery

Battery voltage*

3

Knock sensor Engine knocking condition

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

BCM

Air conditioner operation*2

ABS actuator and electric unit (control unit)

Vehicle speed*2

Page 1498 of 5121

![NISSAN TEANA 2008 Service Manual ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003 NISSAN TEANA 2008 Service Manual ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003](/img/5/57391/w960_57391-1497.png)

ELECTRIC IGNITION SYSTEM

EC-37

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ELECTRIC IGNITION SYSTEM

System DiagramINFOID:0000000003856469

System DescriptionINFOID:0000000003856470

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Ignition order: 1 - 2 - 3 - 4 - 5 - 6

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in

the ECM.

At starting

During warm-up

At idle

At low battery voltage

During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

JMBIA1493GB

Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

2

Piston position

Ignition timing

controlIgnition coil

(with power transistor) Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Battery

Battery voltage*

2

Knock sensor Engine knocking

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)Gear position

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Page 1505 of 5121

![NISSAN TEANA 2008 Service Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN NISSAN TEANA 2008 Service Manual EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGN](/img/5/57391/w960_57391-1504.png)

EC-44

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AIR CONDITIONING CUT CONTROL

AIR CONDITIONING CUT CONTROL

System DiagramINFOID:0000000003856473

System DescriptionINFOID:0000000003856474

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

When the accelerator pedal is fully depressed.

When cranking the engine.

At high engine speeds.

When the engine coolant temperature becomes excessively high.

When operating power steering during low engine speed or low vehicle speed.

When engine speed is excessively low.

When refrigerant pressure is excessively low or high.

JMBIA1414GB

Sensor Input Signal to ECM ECM function Actuator

BCM

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

ABS actuator and electric unit (control unit)

Vehicle speed*

1

Page 1512 of 5121

![NISSAN TEANA 2008 Service Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System De NISSAN TEANA 2008 Service Manual AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System De](/img/5/57391/w960_57391-1511.png)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

EC-51

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DiagramINFOID:0000000003856477

System DescriptionINFOID:0000000003856478

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric throttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE lamp and SET lamp in combination meter. If any malfunc-

tion occurs in the ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in a safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE lamp in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET lamp in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is pressed during cruise control driving, increase the vehicle speed until

the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will maintain the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

CANCEL switch is pressed

More than 2 switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

JMBIA1494GB

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed

controlElectric throttle control

actuator Stop lamp switch Brake pedal operation

ASCD steering switch ASCD steering switch operation

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE

engine)Gear position

Powertrain revolution*

ABS actuator and electric unit (control unit) Vehicle speed*

Page 1521 of 5121

![NISSAN TEANA 2008 Service Manual EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The E NISSAN TEANA 2008 Service Manual EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The E](/img/5/57391/w960_57391-1520.png)

EC-60

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN CONTROL

COOLING FAN CONTROL

System DiagramINFOID:0000000003856482

System DescriptionINFOID:0000000003856483

INPUT/OUTPUT SIGNAL CHART

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

SYSTEM DESCRIPTION

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 4-step control [HIGH/MIDDLE/LOW/OFF].

JMBIA1324GB

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

1

Cooling fan

controlIPDM E/R

↓

Cooling fan relay

↓

Cooling fan motor Battery

Battery voltage*

1

ABS actuator and electric unit (control unit)

Vehicle speed*2

Engine coolant temperature sensor Engine coolant temperature

BCM

Air conditioner ON signal*

2

Refrigerant pressure sensor Refrigerant pressure