ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1744 of 5121

![NISSAN TEANA 2008 Service Manual P1720 VSS

EC-283

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1720 VSS

DescriptionINFOID:0000000003856765

ECM receives two vehicle speed signals via the CAN communication l NISSAN TEANA 2008 Service Manual P1720 VSS

EC-283

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1720 VSS

DescriptionINFOID:0000000003856765

ECM receives two vehicle speed signals via the CAN communication l](/img/5/57391/w960_57391-1743.png)

P1720 VSS

EC-283

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1720 VSS

DescriptionINFOID:0000000003856765

ECM receives two vehicle speed signals via the CAN communication line. One is sent from âABS actuator and

electric unit (control unit)â via combination meter, and the other is from TCM (Transmission control module).

ECM uses these signals for engine control.

DTC LogicINFOID:0000000003856766

DTC DETECTION LOGIC

NOTE:

If DTC P1720 is displayed with DTC U1000, U1001 first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-135, "

DTC Logic".

If DTC P1720 is displayed with DTC P0607, first perform the trouble diagnosis for DTC P0607. Refer

to EC-242, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine.

2. Drive vehicle at a speed of 20 km/h (12 MPH) or more for at least 5 seconds without depressing the brake

pedal.

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-283, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003856767

1.CHECK DTC WITH TCM

Check DTC with TCM. Refer to TM-121, "

DTC Index".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform trouble shooting relevant to DTC indicated.

2.CHECK DTC WITH âABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)â

Refer to BRC-140, "

DTC No. Index".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Perform trouble shooting relevant to DTC indicated.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1720Vehicle speed sensor

(TCM output)The difference between two vehicle speed

signals is out of the specified range. Harness or connectors

(Secondary speed sensor circuit is open or

shorted.)

Harness or connectors

(Wheel sensor circuit is open or shorted.)

TCM

Secondary speed sensor

ABS actuator and electric unit (control unit)

Wheel sensor

Combination meter

Page 1862 of 5121

![NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM â NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM â](/img/5/57391/w960_57391-1861.png)

ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM â ENGINE MECHANICAL & OTHER

Crankshaft position sensor (POS) circuit 2 2EC-218

Camshaft position sensor (PHASE) circuit 3 2EC-222

Vehicle speed signal circuit 2 3 3 3EC-234

Power steering pressure sensor circuit 2 3 3EC-236

ECM 22333333333EC-238,

EC-240

Intake valve timing control solenoid valve cir-

cuit32 13223 3EC-146

PNP signal circuit 3 3 3 3 3EC-245

VIAS control solenoid valve 1 circuit 1EC-285

VIAS control solenoid valve 2 circuit 1EC-288

Refrigerant pressure sensor circuit 2 3 3 4EC-348

Electrical load signal circuit 3EC-329

Air conditioner circuit 223333333 3 2HAC-159

ABS actuator and electric unit (control unit) 4BRC-80

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 1920 of 5121

FUEL INJECTOR AND FUEL TUBE

EM-45

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

5. Drain engine coolant, or when water hoses are disconnected, attach plug to prevent engine coolant leak-

age. Refer to CO-8, "

Draining" or EM-28, "Exploded View".

CAUTION:

Perform this step when the engine is cold.

6. Remove intake manifold collector. Refer to EM-28, "

Exploded View".

7. When separating fuel feed hose and fuel tube connection, disconnect quick connector as follows:

a. Remove quick connector cap from quick connector.

b. Disconnect quick connector from fuel tube as follows:

CAUTION:

Disconnect quick connector by using the quick connector release [SST: â (J-45488)], not by pick-

ing out retainer tabs.

i. With the sleeve side of quick connector release facing to quick connector, install the quick connector

release onto fuel tube.

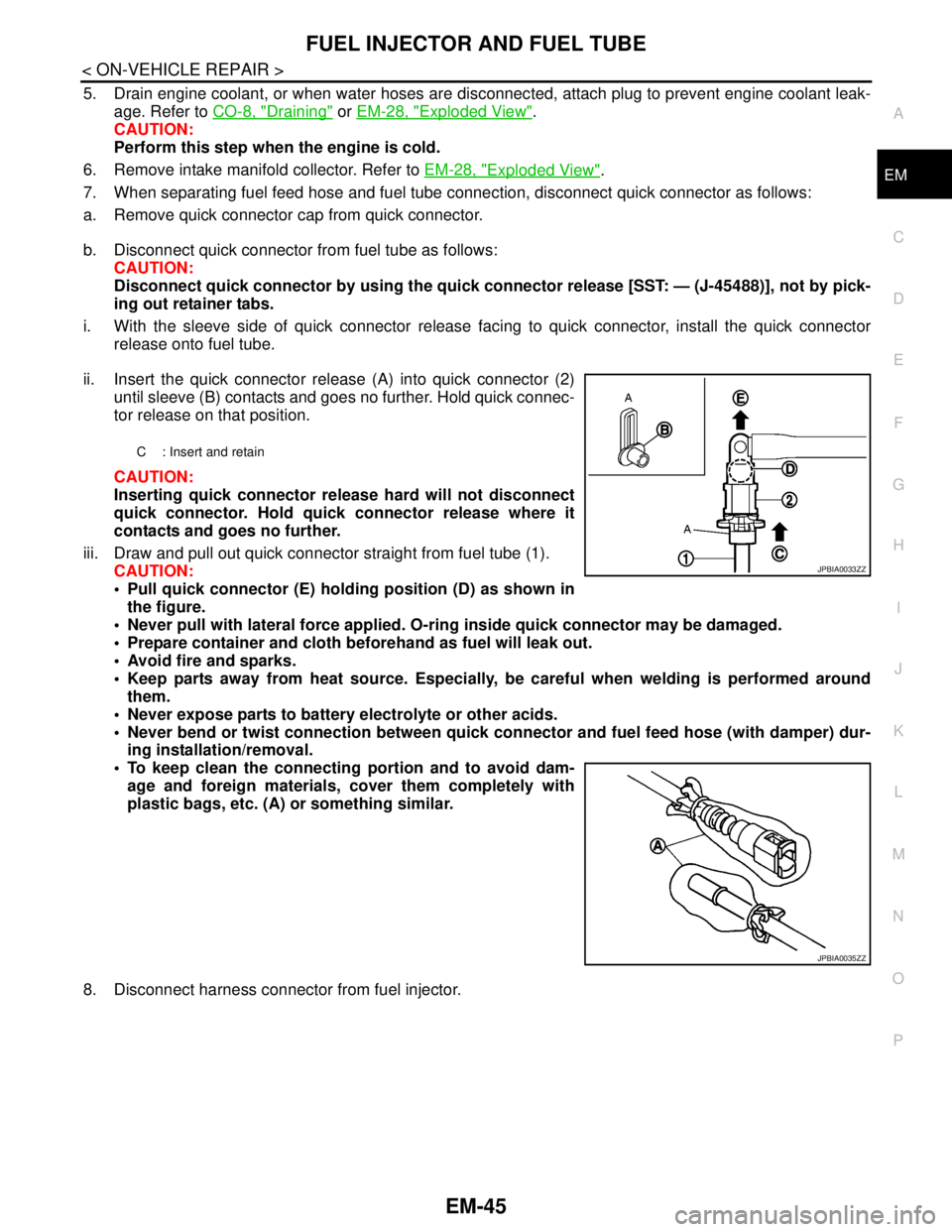

ii. Insert the quick connector release (A) into quick connector (2)

until sleeve (B) contacts and goes no further. Hold quick connec-

tor release on that position.

CAUTION:

Inserting quick connector release hard will not disconnect

quick connector. Hold quick connector release where it

contacts and goes no further.

iii. Draw and pull out quick connector straight from fuel tube (1).

CAUTION:

Pull quick connector (E) holding position (D) as shown in

the figure.

Never pull with lateral force applied. O-ring inside quick connector may be damaged.

Prepare container and cloth beforehand as fuel will leak out.

Avoid fire and sparks.

Keep parts away from heat source. Especially, be careful when welding is performed around

them.

Never expose parts to battery electrolyte or other acids.

Never bend or twist connection between quick connector and fuel feed hose (with damper) dur-

ing installation/removal.

To keep clean the connecting portion and to avoid dam-

age and foreign materials, cover them completely with

plastic bags, etc. (A) or something similar.

8. Disconnect harness connector from fuel injector.

C : Insert and retain

JPBIA0033ZZ

JPBIA0035ZZ

Page 1944 of 5121

ENGINE ASSEMBLY

EM-69

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove starter motor. Refer to STR-15, "VQ25DE : Exploded View" (VQ25DE) or STR-20, "VQ35DE :

Exploded View" (VQ35DE).

Vehicle Underbody

1. Remove front drive shafts (RH and LH). Refer to FAX-16, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove heat insulator.

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to ST-16, "

Exploded View".

5. Disconnect front stabilizer connecting rod. Refer to FSU-14, "

Exploded View".

6. Remove strut assembly and steering knuckle fixing nuts and bolts. Refer to FSU-9, "

Exploded View" and

FA X - 8 , "

Exploded View".

7. Remove front wheel sensor (RH and LH) for ABS from steering knuckle. Refer to BRC-57, "

FRONT

WHEEL SENSOR : Exploded View".

8. Remove front brake caliper assembly with piping connected, and temporarily secure it to aside for vehicle

side. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

9. Disconnect power steering piping at a point between vehicle and engine. Refer to ST-34, "

Exploded

View".

Install plug to avoid leakage of power steering fluid.

10. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-38, "

Exploded View" and TM-332, "Removal and Installation" (VQ25DE) or TM-168,

"Removal and Installation" (VQ35DE).

11. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-38, "

Exploded

View".

12. Remove crankshaft position sensor (POS). Refer to EM-38, "

Exploded View".

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part at sensor tip.

Never place sensors in a location where they are exposed to magnetism.

Removal

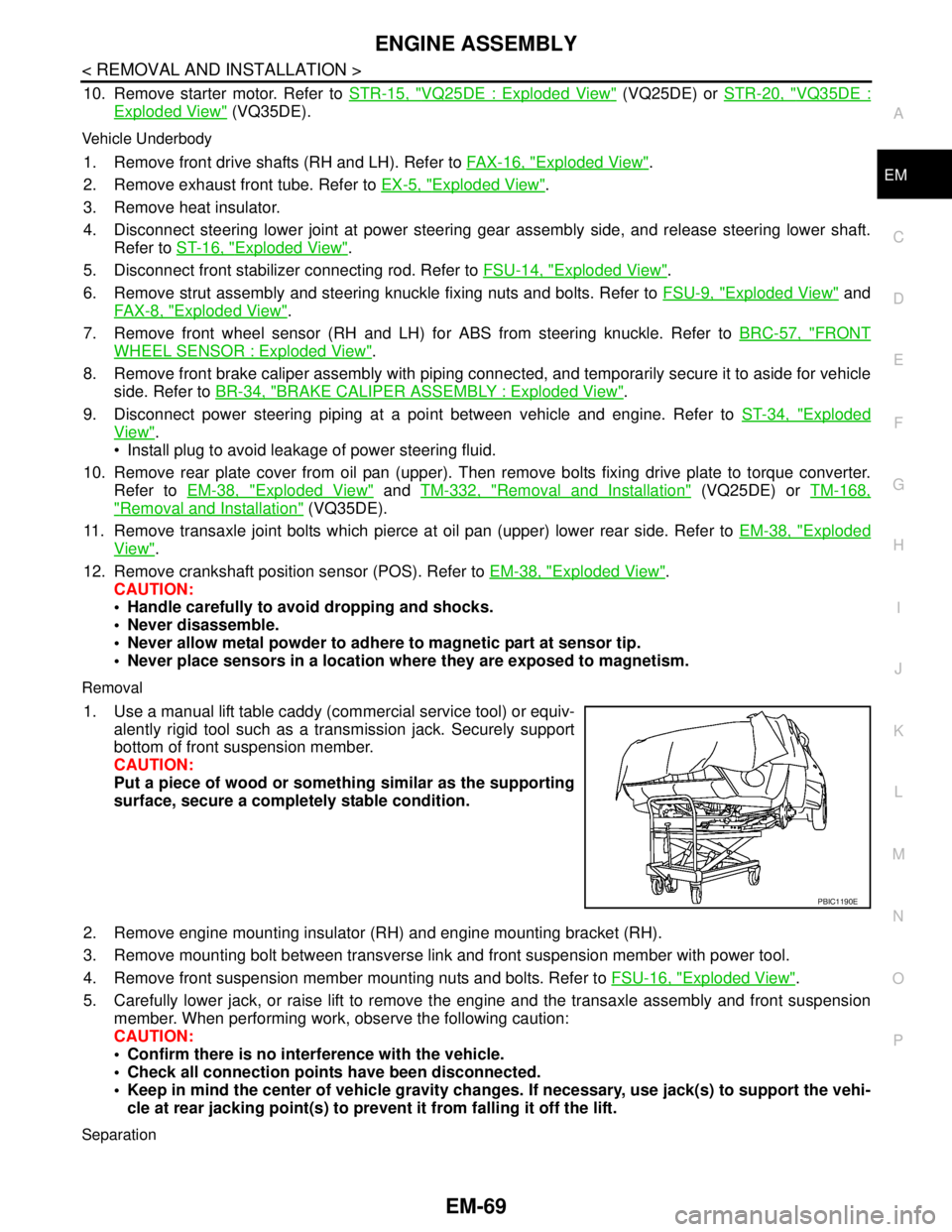

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of front suspension member.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine mounting insulator (RH) and engine mounting bracket (RH).

3. Remove mounting bolt between transverse link and front suspension member with power tool.

4. Remove front suspension member mounting nuts and bolts. Refer to FSU-16, "

Exploded View".

5. Carefully lower jack, or raise lift to remove the engine and the transaxle assembly and front suspension

member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Check all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support the vehi-

cle at rear jacking point(s) to prevent it from falling it off the lift.

Separation

PBIC1190E

Page 1976 of 5121

![NISSAN TEANA 2008 Service Manual CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide dr NISSAN TEANA 2008 Service Manual CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide dr](/img/5/57391/w960_57391-1975.png)

CYLINDER HEAD

EM-101

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

b. Drive out valve guide with a press [under a 20 kN (2 ton, 2.0 lmp

ton) pressure] or a hammer and the valve guide drift (commer-

cial service tool).

WARNING:

Cylinder head contains heat. When working, wear protec-

tive equipment to avoid getting burned.

9. Remove spark plug tube, as necessary.

Using a pliers, pull spark plug tube out of cylinder head.

CAUTION:

Take care not to damage cylinder head.

Once removed, spark plug tube will be deformed and cannot be reused. Never remove it unless

absolutely necessary.

ASSEMBLY

1. If valve guide is removed in step 8 (DISASSEMBLY), install it.

Replace with oversized [0.2 mm (0.008 in)] valve guide.

a. Using the valve guide reamer (commercial service tool) (A),

ream cylinder head valve guide hole.

b. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil (A).

c. Using the valve guide drift (commercial service tool), press valve

guide from camshaft side to the dimensions as in the figure.

WARNING:

Cylinder head contains heat. When working, wear protec-

tive equipment to avoid getting burned.

SEM931C

Valve guide hole diameter (for service parts):

Intake and exhaust

: Refer to EM-139, "

CylinderHead".

JPBIA0185ZZ

JPBIA0184ZZ

Projection (A)

Intake and exhaust

: Refer to EM-139, "

CylinderHead".

JPBIA0186ZZ

Page 2167 of 5121

![NISSAN TEANA 2008 Service Manual EXL-138

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM I NISSAN TEANA 2008 Service Manual EXL-138

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM I](/img/5/57391/w960_57391-2166.png)

EXL-138

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 2339 of 5121

![NISSAN TEANA 2008 Service Manual EXL-310

< ECU DIAGNOSIS >[HALOGEN TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM NISSAN TEANA 2008 Service Manual EXL-310

< ECU DIAGNOSIS >[HALOGEN TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM](/img/5/57391/w960_57391-2338.png)

EXL-310

< ECU DIAGNOSIS >[HALOGEN TYPE]

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 2400 of 5121

FRONT BUMPER

EXT-11

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

ON-VEHICLE REPAIR

FRONT BUMPER

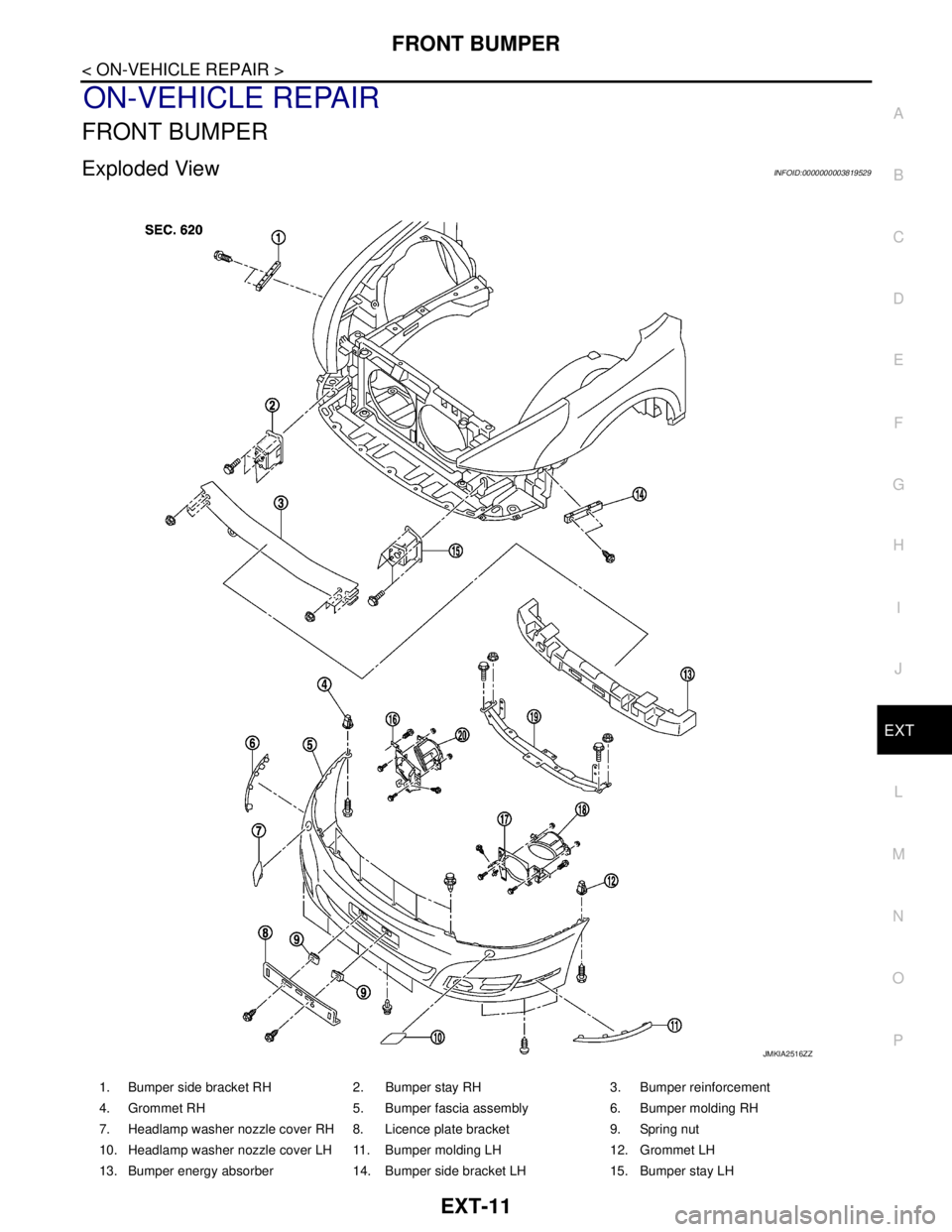

Exploded ViewINFOID:0000000003819529

1. Bumper side bracket RH 2. Bumper stay RH 3. Bumper reinforcement

4. Grommet RH 5. Bumper fascia assembly 6. Bumper molding RH

7. Headlamp washer nozzle cover RH 8. Licence plate bracket 9. Spring nut

10. Headlamp washer nozzle cover LH 11. Bumper molding LH 12. Grommet LH

13. Bumper energy absorber 14. Bumper side bracket LH 15. Bumper stay LH

JMKIA2516ZZ

Page 2402 of 5121

FRONT BUMPER

EXT-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

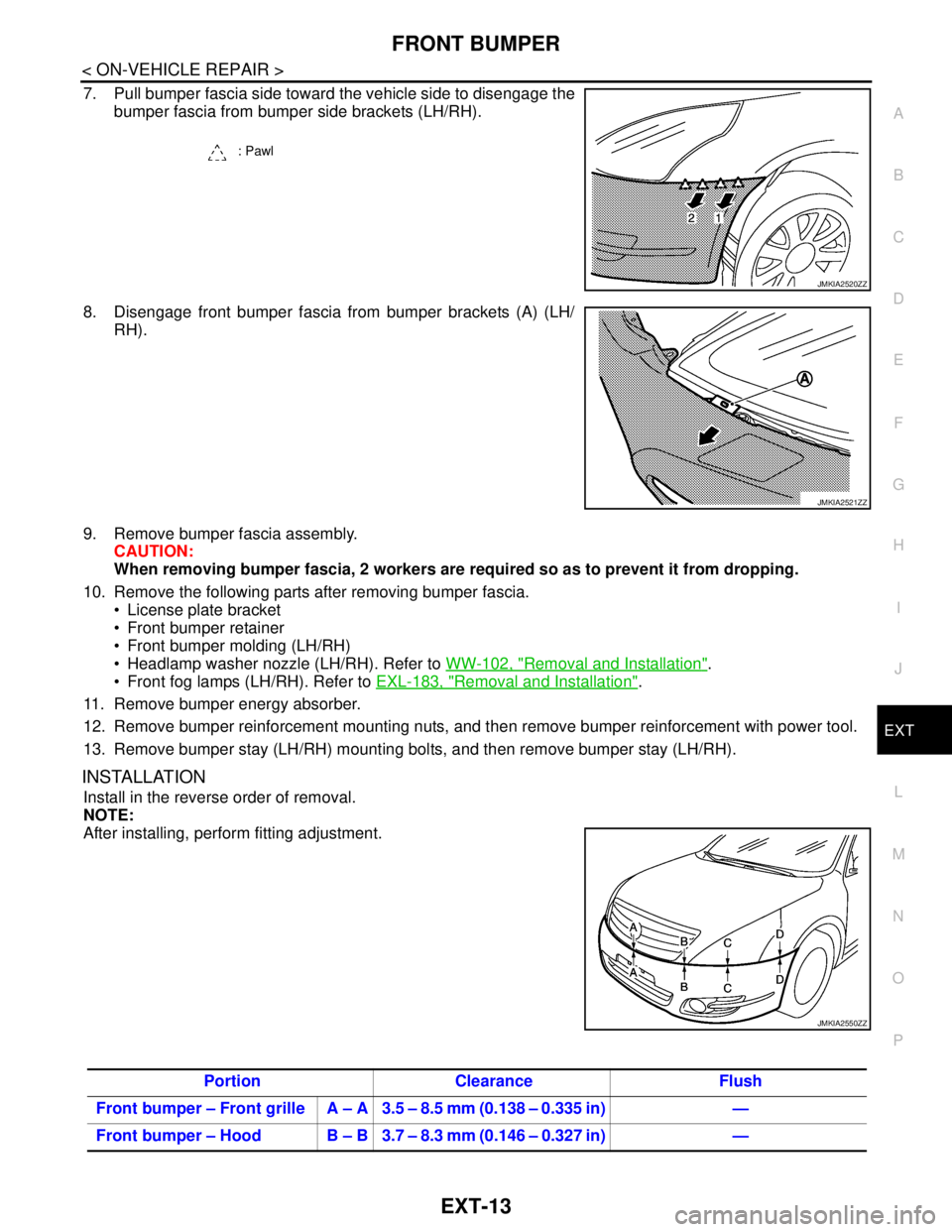

7. Pull bumper fascia side toward the vehicle side to disengage the

bumper fascia from bumper side brackets (LH/RH).

8. Disengage front bumper fascia from bumper brackets (A) (LH/

RH).

9. Remove bumper fascia assembly.

CAUTION:

When removing bumper fascia, 2 workers are required so as to prevent it from dropping.

10. Remove the following parts after removing bumper fascia.

License plate bracket

Front bumper retainer

Front bumper molding (LH/RH)

Headlamp washer nozzle (LH/RH). Refer to WW-102, "

Removal and Installation".

Front fog lamps (LH/RH). Refer to EXL-183, "

Removal and Installation".

11. Remove bumper energy absorber.

12. Remove bumper reinforcement mounting nuts, and then remove bumper reinforcement with power tool.

13. Remove bumper stay (LH/RH) mounting bolts, and then remove bumper stay (LH/RH).

INSTALLATION

Install in the reverse order of removal.

NOTE:

After installing, perform fitting adjustment.

: Pawl

JMKIA2520ZZ

JMKIA2521ZZ

JMKIA2550ZZ

Portion Clearance Flush

Front bumper â Front grille A â A 3.5 â 8.5 mm (0.138 â 0.335 in) â

Front bumper â Hood B â B 3.7 â 8.3 mm (0.146 â 0.327 in) â

Page 2404 of 5121

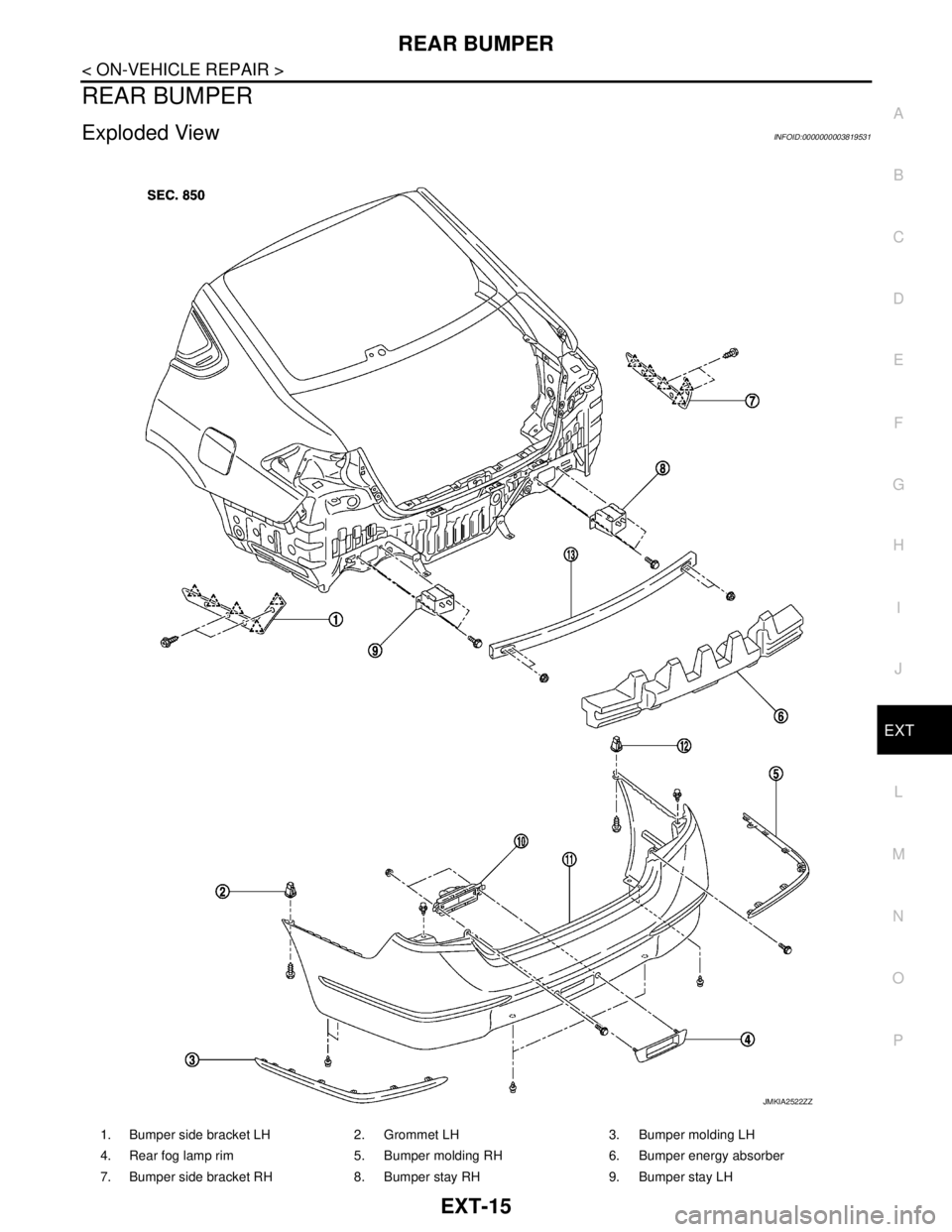

REAR BUMPER

EXT-15

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

REAR BUMPER

Exploded ViewINFOID:0000000003819531

1. Bumper side bracket LH 2. Grommet LH 3. Bumper molding LH

4. Rear fog lamp rim 5. Bumper molding RH 6. Bumper energy absorber

7. Bumper side bracket RH 8. Bumper stay RH 9. Bumper stay LH

JMKIA2522ZZ