ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2406 of 5121

REAR BUMPER

EXT-17

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

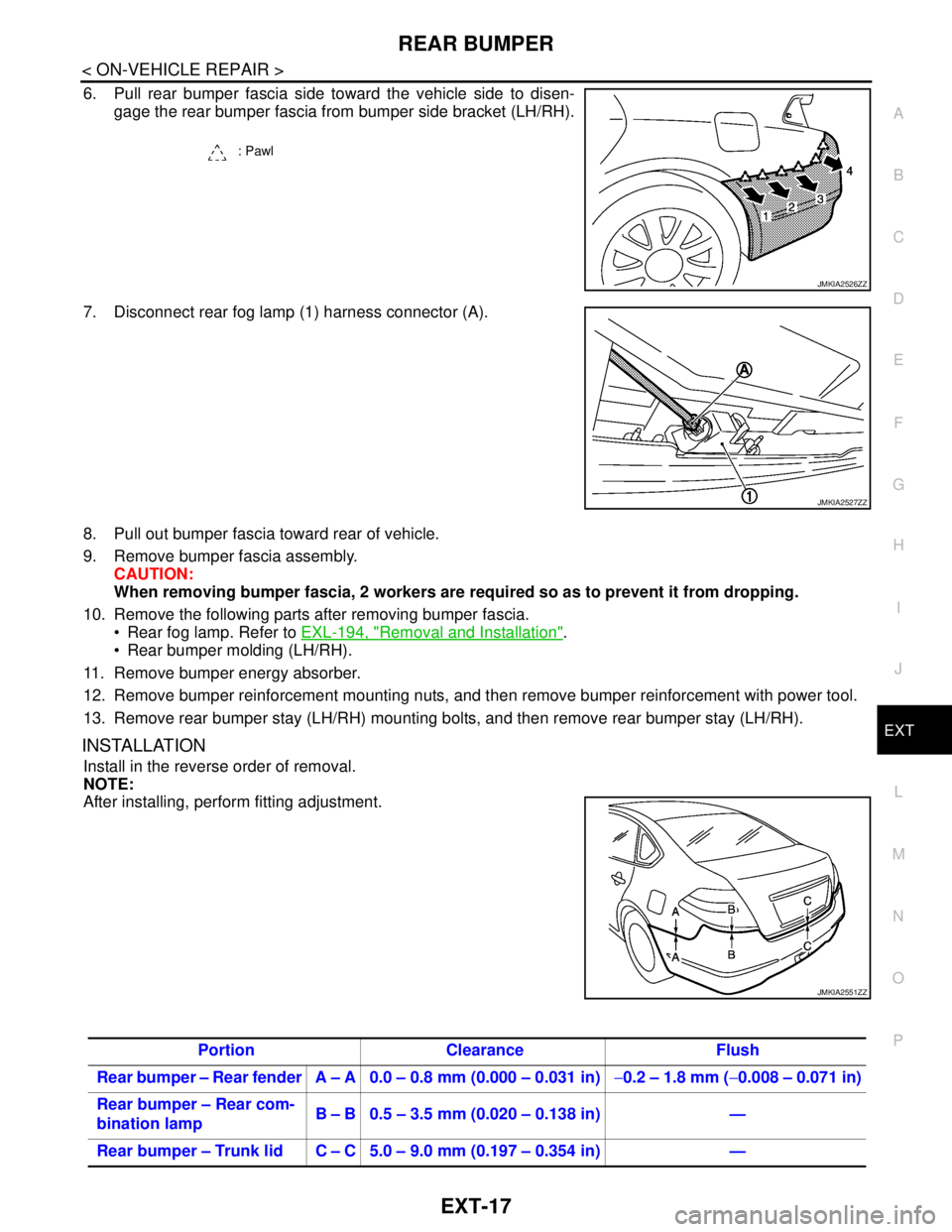

6. Pull rear bumper fascia side toward the vehicle side to disen-

gage the rear bumper fascia from bumper side bracket (LH/RH).

7. Disconnect rear fog lamp (1) harness connector (A).

8. Pull out bumper fascia toward rear of vehicle.

9. Remove bumper fascia assembly.

CAUTION:

When removing bumper fascia, 2 workers are required so as to prevent it from dropping.

10. Remove the following parts after removing bumper fascia.

Rear fog lamp. Refer to EXL-194, "

Removal and Installation".

Rear bumper molding (LH/RH).

11. Remove bumper energy absorber.

12. Remove bumper reinforcement mounting nuts, and then remove bumper reinforcement with power tool.

13. Remove rear bumper stay (LH/RH) mounting bolts, and then remove rear bumper stay (LH/RH).

INSTALLATION

Install in the reverse order of removal.

NOTE:

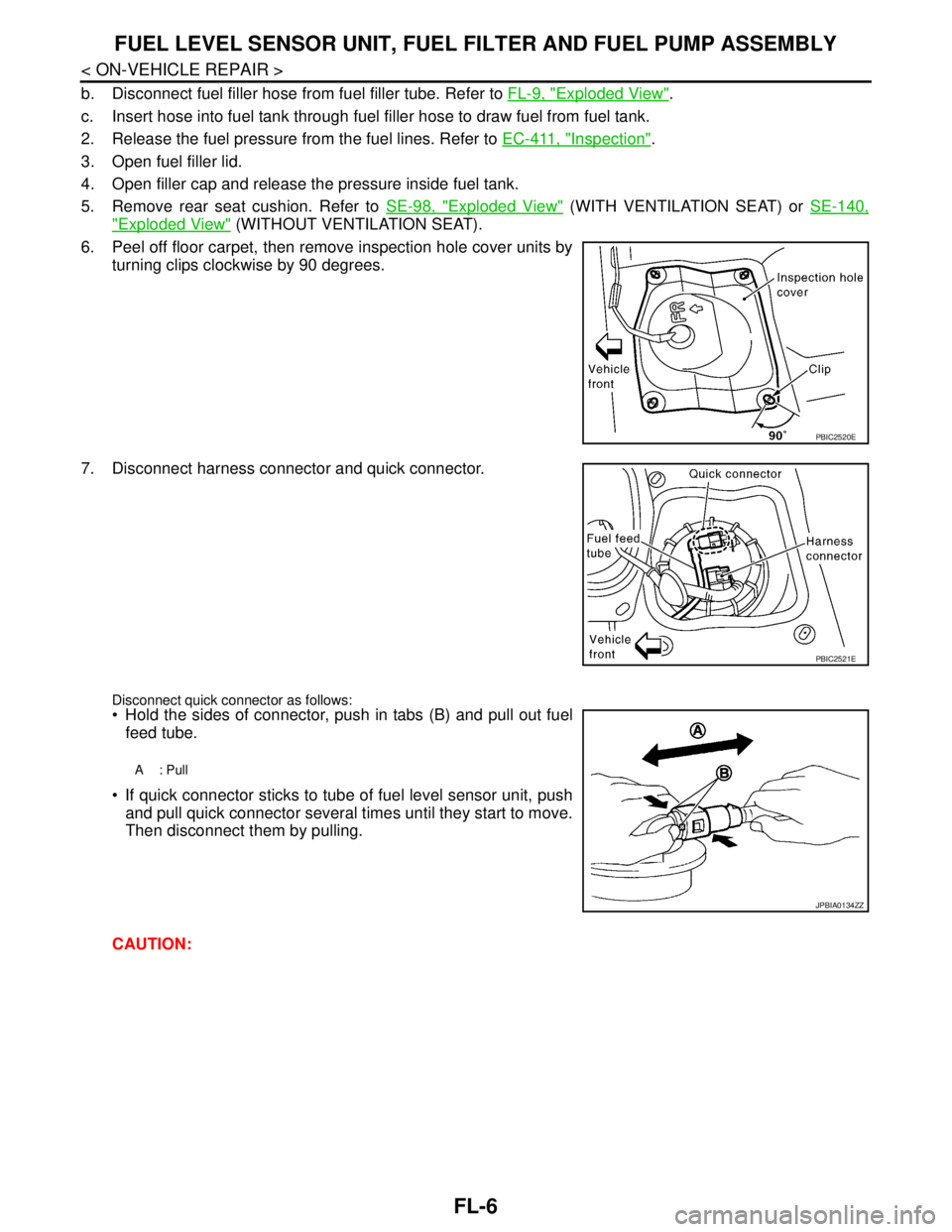

After installing, perform fitting adjustment.

: Pawl

JMKIA2526ZZ

JMKIA2527ZZ

JMKIA2551ZZ

Portion Clearance Flush

Rear bumper – Rear fender A – A 0.0 – 0.8 mm (0.000 – 0.031 in)−0.2 – 1.8 mm (−0.008 – 0.071 in)

Rear bumper – Rear com-

bination lampB – B 0.5 – 3.5 mm (0.020 – 0.138 in) —

Rear bumper – Trunk lid C – C 5.0 – 9.0 mm (0.197 – 0.354 in) —

Page 2469 of 5121

FL-6

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

b. Disconnect fuel filler hose from fuel filler tube. Refer to FL-9, "Exploded View".

c. Insert hose into fuel tank through fuel filler hose to draw fuel from fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-411, "

Inspection".

3. Open fuel filler lid.

4. Open filler cap and release the pressure inside fuel tank.

5. Remove rear seat cushion. Refer to SE-98, "

Exploded View" (WITH VENTILATION SEAT) or SE-140,

"Exploded View" (WITHOUT VENTILATION SEAT).

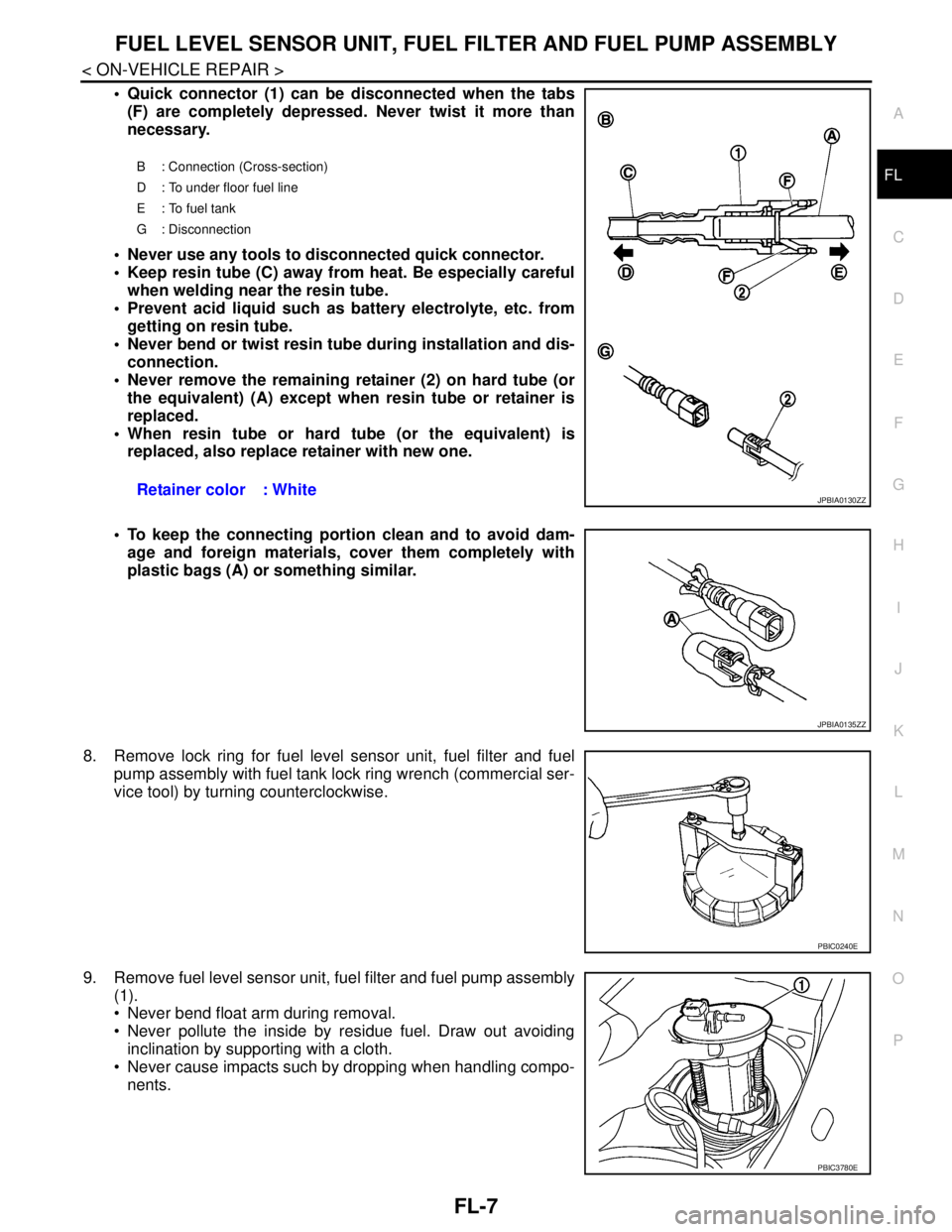

6. Peel off floor carpet, then remove inspection hole cover units by

turning clips clockwise by 90 degrees.

7. Disconnect harness connector and quick connector.

Disconnect quick connector as follows:

Hold the sides of connector, push in tabs (B) and pull out fuel

feed tube.

If quick connector sticks to tube of fuel level sensor unit, push

and pull quick connector several times until they start to move.

Then disconnect them by pulling.

CAUTION:

PBIC2520E

PBIC2521E

A: Pull

JPBIA0134ZZ

Page 2470 of 5121

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

Quick connector (1) can be disconnected when the tabs

(F) are completely depressed. Never twist it more than

necessary.

Never use any tools to disconnected quick connector.

Keep resin tube (C) away from heat. Be especially careful

when welding near the resin tube.

Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

Never bend or twist resin tube during installation and dis-

connection.

Never remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

To keep the connecting portion clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

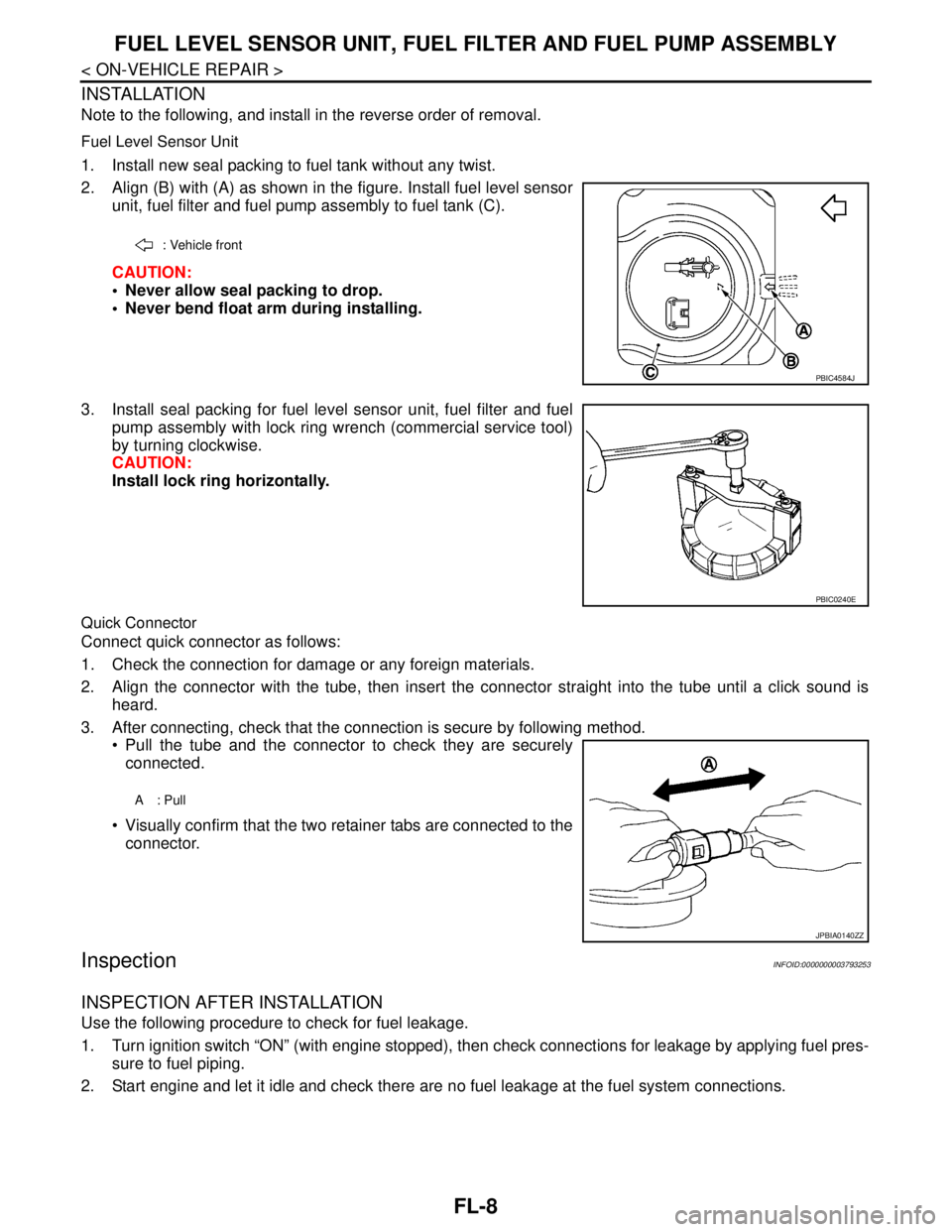

8. Remove lock ring for fuel level sensor unit, fuel filter and fuel

pump assembly with fuel tank lock ring wrench (commercial ser-

vice tool) by turning counterclockwise.

9. Remove fuel level sensor unit, fuel filter and fuel pump assembly

(1).

Never bend float arm during removal.

Never pollute the inside by residue fuel. Draw out avoiding

inclination by supporting with a cloth.

Never cause impacts such by dropping when handling compo-

nents.

B : Connection (Cross-section)

D : To under floor fuel line

E : To fuel tank

G : Disconnection

Retainer color : WhiteJPBIA0130ZZ

JPBIA0135ZZ

PBIC0240E

PBIC3780E

Page 2471 of 5121

FL-8

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

INSTALLATION

Note to the following, and install in the reverse order of removal.

Fuel Level Sensor Unit

1. Install new seal packing to fuel tank without any twist.

2. Align (B) with (A) as shown in the figure. Install fuel level sensor

unit, fuel filter and fuel pump assembly to fuel tank (C).

CAUTION:

Never allow seal packing to drop.

Never bend float arm during installing.

3. Install seal packing for fuel level sensor unit, fuel filter and fuel

pump assembly with lock ring wrench (commercial service tool)

by turning clockwise.

CAUTION:

Install lock ring horizontally.

Quick Connector

Connect quick connector as follows:

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3. After connecting, check that the connection is secure by following method.

Pull the tube and the connector to check they are securely

connected.

Visually confirm that the two retainer tabs are connected to the

connector.

InspectionINFOID:0000000003793253

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leakage by applying fuel pres-

sure to fuel piping.

2. Start engine and let it idle and check there are no fuel leakage at the fuel system connections.

: Vehicle front

PBIC4584J

PBIC0240E

A: Pull

JPBIA0140ZZ

Page 2476 of 5121

FSU-2

< SYMPTOM DIAGNOSIS >

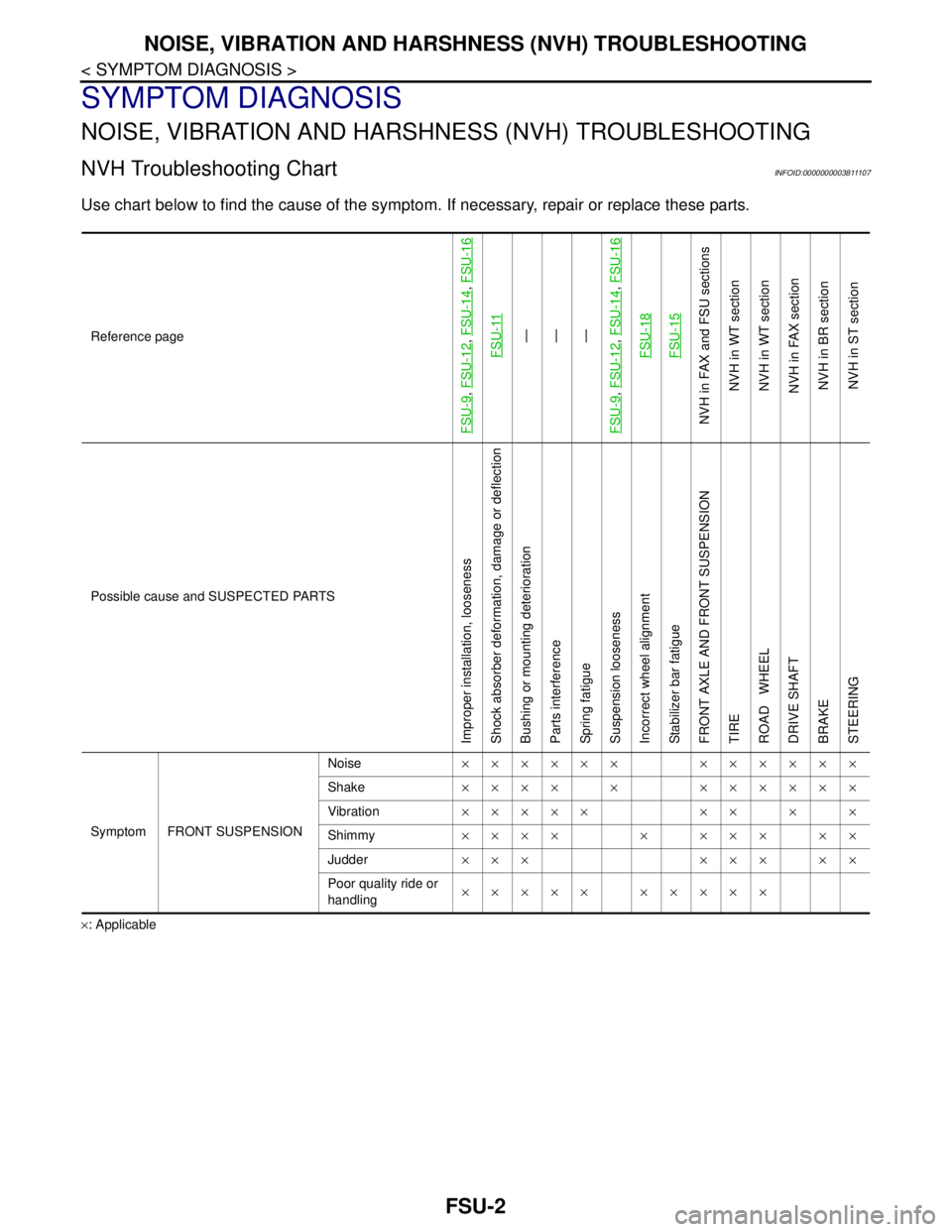

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003811107

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

FSU-9

, FSU-12

, FSU-14

, FSU-16

FSU-11

—

—

—

FSU-9

, FSU-12

, FSU-14

, FSU-16

FSU-18FSU-15

NVH in FAX and FSU sections

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in BR section

NVH in ST section

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

FRONT AXLE AND FRONT SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

Symptom FRONT SUSPENSIONNoise×××××× ××××××

Shake×××× × ××××××

Vibration××××× ×× × ×

Shimmy×××× × ××× ××

Judder ××× ××× ××

Poor quality ride or

handling××××× ×××××

Page 2511 of 5121

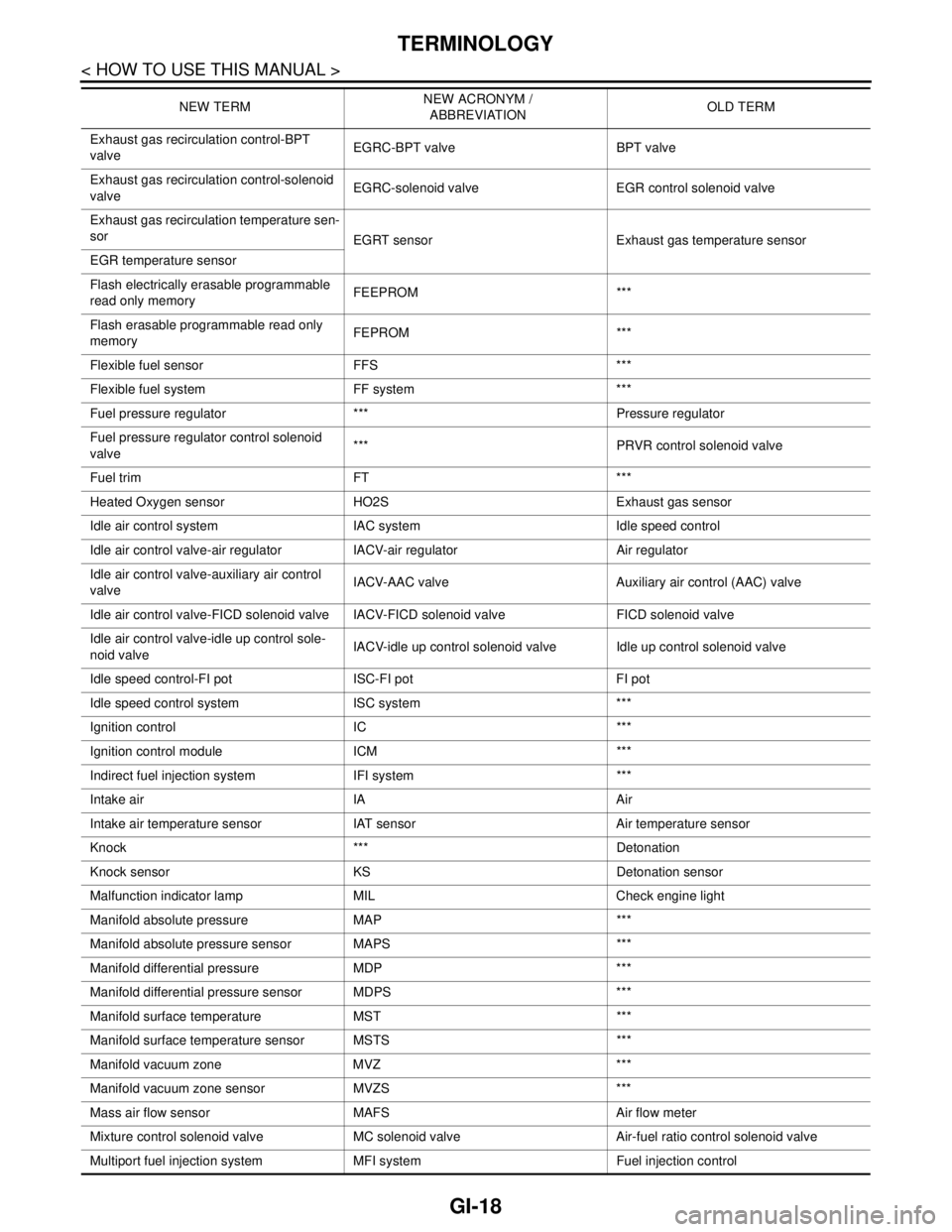

GI-18

< HOW TO USE THIS MANUAL >

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2536 of 5121

CONSULT-III/GST CHECKING SYSTEM

GI-43

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

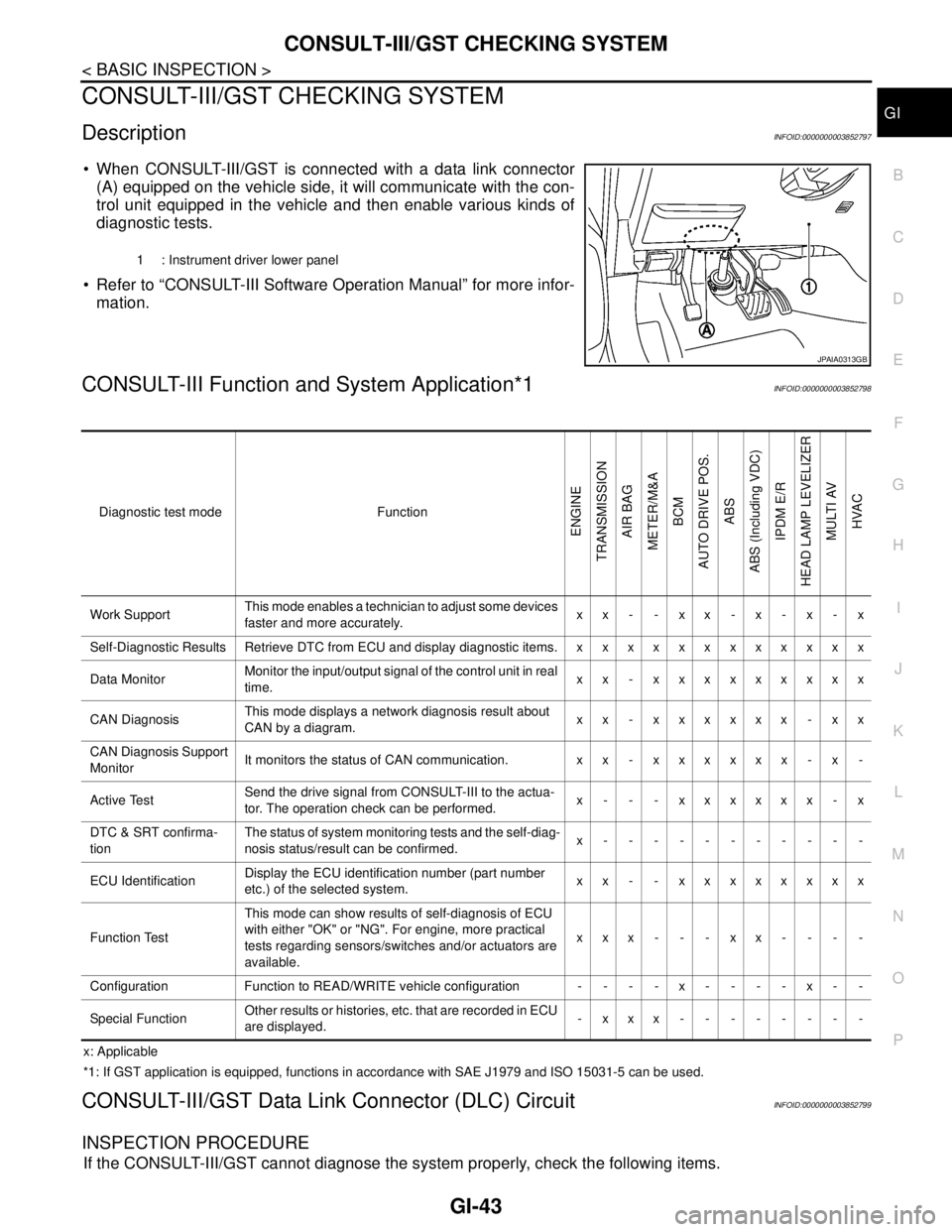

PCONSULT-III/GST CHECKING SYSTEM

DescriptionINFOID:0000000003852797

When CONSULT-III/GST is connected with a data link connector

(A) equipped on the vehicle side, it will communicate with the con-

trol unit equipped in the vehicle and then enable various kinds of

diagnostic tests.

Refer to “CONSULT-III Software Operation Manual” for more infor-

mation.

CONSULT-III Function and System Application*1INFOID:0000000003852798

x: Applicable

*1: If GST application is equipped, functions in accordance with SAE J1979 and ISO 15031-5 can be used.

CONSULT-III/GST Data Link Connector (DLC) CircuitINFOID:0000000003852799

INSPECTION PROCEDURE

If the CONSULT-III/GST cannot diagnose the system properly, check the following items.

1 : Instrument driver lower panel

JPAIA0313GB

Diagnostic test mode Function

ENGINE

TRANSMISSION

AIR BAG

METER/M&A

BCM

AUTO DRIVE POS.

ABS

ABS (Including VDC)

IPDM E/R

HEAD LAMP LEVELIZER

MULTI AV

HVAC

Work SupportThis mode enables a technician to adjust some devices

faster and more accurately.xx- -xx-x-x-x

Self-Diagnostic Results Retrieve DTC from ECU and display diagnostic items. x x x x x x x x x x x x

Data MonitorMonitor the input/output signal of the control unit in real

time.xx - xxxxxxxxx

CAN DiagnosisThis mode displays a network diagnosis result about

CAN by a diagram.xx - xxxxxx - xx

CAN Diagnosis Support

MonitorIt monitors the status of CAN communication. x x - x x x x x x - x -

Active TestSend the drive signal from CONSULT-III to the actua-

tor. The operation check can be performed.x - - - xxxxxx - x

DTC & SRT confirma-

tionThe status of system monitoring tests and the self-diag-

nosis status/result can be confirmed.x-----------

ECU IdentificationDisplay the ECU identification number (part number

etc.) of the selected system.xx - - xxxxxxxx

Function TestThis mode can show results of self-diagnosis of ECU

with either "OK" or "NG". For engine, more practical

tests regarding sensors/switches and/or actuators are

available.xxx---xx----

Configuration Function to READ/WRITE vehicle configuration - - - - x - - - - x - -

Special FunctionOther results or histories, etc. that are recorded in ECU

are displayed.-xxx--------

Page 2582 of 5121

PRECAUTIONS

HA-13

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

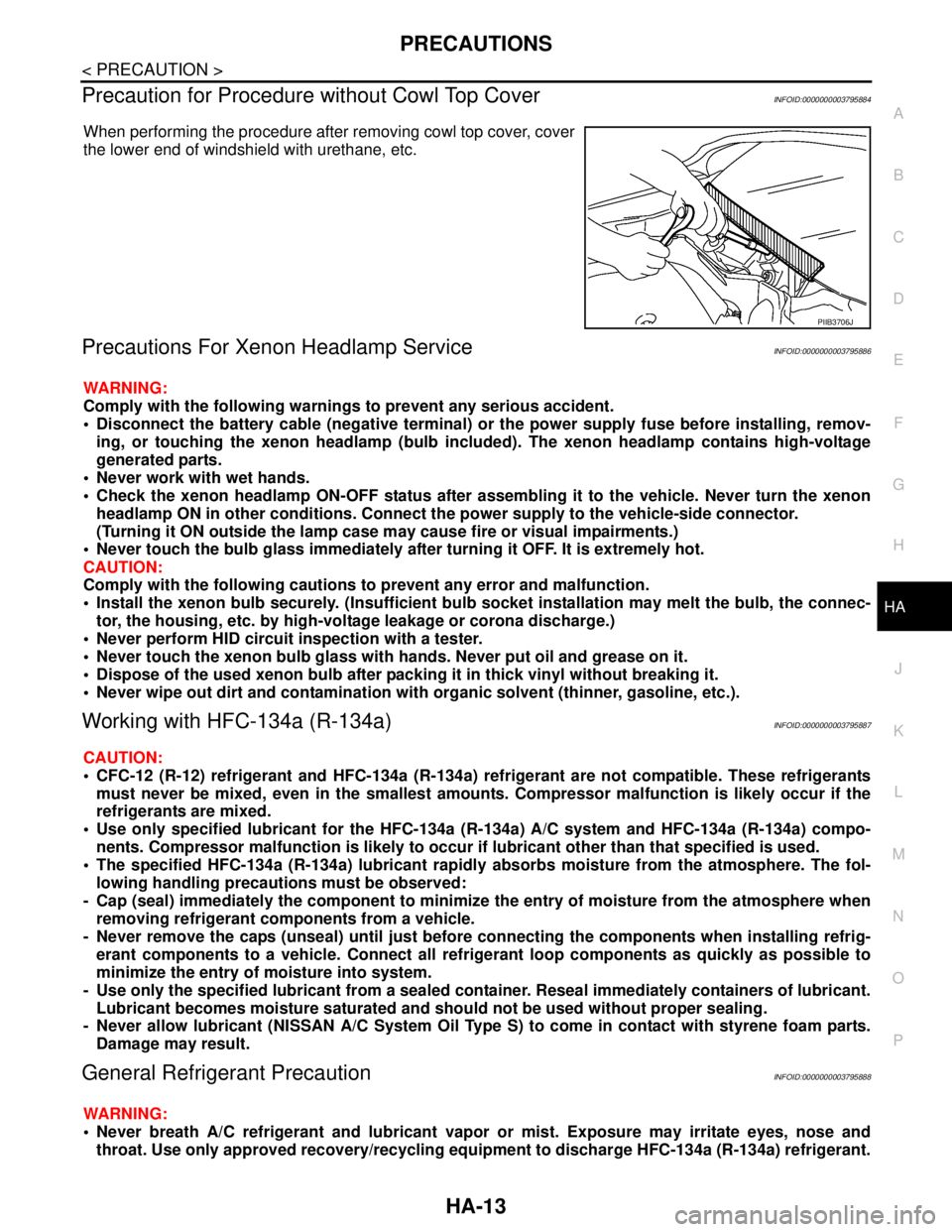

Precaution for Procedure without Cowl Top CoverINFOID:0000000003795884

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Xenon Headlamp ServiceINFOID:0000000003795886

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Working with HFC-134a (R-134a)INFOID:0000000003795887

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. Compressor malfunction is likely occur if the

refrigerants are mixed.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

- Cap (seal) immediately the component to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refrigerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed container. Reseal immediately containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

- Never allow lubricant (NISSAN A/C System Oil Type S) to come in contact with styrene foam parts.

Damage may result.

General Refrigerant PrecautionINFOID:0000000003795888

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant.

PIIB3706J

Page 2616 of 5121

CONDENSER

HA-47

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

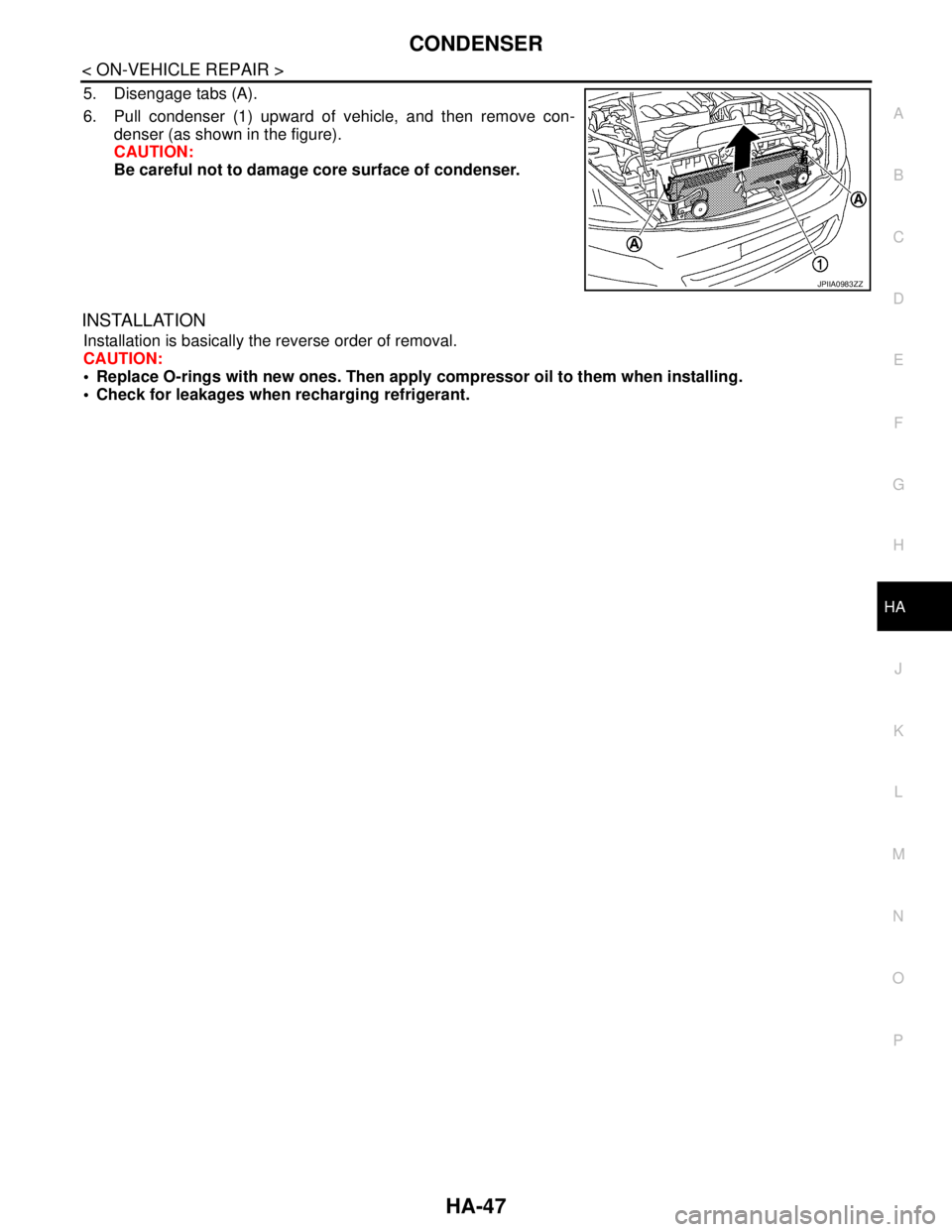

5. Disengage tabs (A).

6. Pull condenser (1) upward of vehicle, and then remove con-

denser (as shown in the figure).

CAUTION:

Be careful not to damage core surface of condenser.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0983ZZ

Page 2722 of 5121

![NISSAN TEANA 2008 Service Manual HAC-94

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003846390

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:00000000038 NISSAN TEANA 2008 Service Manual HAC-94

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003846390

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:00000000038](/img/5/57391/w960_57391-2721.png)

HAC-94

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003846390

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:0000000003846391

1.CHECK OPERATION

1. Operate the A/C system and check the operation. Refer to HAC-8, "

Description & Inspection".

2. Check the parts where noise is occurring.

Can the parts where noise is occurring be checked?

YES-1 >> Noise from blower motor: GO TO 2.

YES-2 >> Noise from compressor: GO TO 3.

YES-3 >> Noise from expansion valve: GO TO 4.

YES-4 >> Noise from A/C piping (pipe, flexible hose): GO TO 6.

YES-5 >> Noise from drive belt: GO TO 7.

NO >> END.

2.CHECK BLOWER MOTOR

1. Remove blower motor.

2. Remove foreign materials that are in the blower unit.

3. Check the noise from blower motor again.

Is the inspection result normal?

YES >> END.

NO >> Replace blower motor.

3.CHECK COMPRESSOR

Perform trouble diagnosis for the compressor and check the compressor. Refer to HA-11, "

Symptom Table".

Is the inspection result normal?

YES >> END.

NO >> Refill the refrigerant or replace the compressor according to the inspection results.

4.CHECK WITH GAUGE PRESSURE

Perform the diagnosis with the gauge pressure. Refer to HA-8, "

Trouble Diagnosis For Unusual Pressure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts according to the inspection results.

5.CHECK EXPANSION VALVE

1. Correct the refrigerant with recovery/recycling recharging equipment.

2. Recharge with the proper amount of the collected refrigerant after recycling or new refrigerant.

3. Check for the noise from expansion valve again.

Are the malfunction solved?

YES >> END.

NO >> Replace expansion valve.

6.CHECK A/C PIPING (PIPE, FLEXIBLE HOSE)

1. Check the A/C piping (pipes, flexible hoses) (for deformation and damage, etc.).

2. Check the installation condition of clips and brackets, etc, of the A/C piping (pipes, flexible hoses).

Is the inspection result normal?

YES >> Fix the line with rubber or come vibration absorbing material.

NO >> Repair or replace parts according to the inspection results.

7.CHECK DRIVE BELT