ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2726 of 5121

![NISSAN TEANA 2008 Service Manual HAC-98

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003846397

When performing the procedure after removing cowl top cover, cover

the NISSAN TEANA 2008 Service Manual HAC-98

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003846397

When performing the procedure after removing cowl top cover, cover

the](/img/5/57391/w960_57391-2725.png)

HAC-98

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003846397

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Xenon Headlamp ServiceINFOID:0000000003846398

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Working with HFC-134a (R-134a)INFOID:0000000003846399

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. Compressor mal-

function is likely to occur if the refrigerants are mixed, refer to “CONTAMINATED REFRIGERANT”

below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refriger-

ant Recovery/Recycling Recharging equipment and Refrigerant Identifier.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

- Immediately cap (seal) the component to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refrigerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed container. Immediately reseal containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

- Never allow lubricant (NISSAN A/C System Oil Type S) to come in to contact with styrene foam parts.

Damage may result.

CONTAMINATED REFRIGERANT

Take the appropriate steps shown below if a refrigerant other than pure HFC-134a (R-134a) is identified

in a vehicle:

Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

PIIB3706J

Page 2862 of 5121

![NISSAN TEANA 2008 Service Manual HAC-234

< SYMPTOM DIAGNOSIS >[WITH 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003884805

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:0000000003884 NISSAN TEANA 2008 Service Manual HAC-234

< SYMPTOM DIAGNOSIS >[WITH 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003884805

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:0000000003884](/img/5/57391/w960_57391-2861.png)

HAC-234

< SYMPTOM DIAGNOSIS >[WITH 7 INCH DISPLAY]

NOISE

NOISE

DescriptionINFOID:0000000003884805

Symptom

Noise

Noise is heard when the A/C system operates.

Inspection procedureINFOID:0000000003884806

1.CHECK OPERATION

1. Operate the A/C system and check the operation. Refer to HAC-108, "

WITHOUT INTELLIGENT AIR

CONDITIONER SYSTEM : Description & Inspection" (WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM) or HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection"

(WITH INTELLIGENT AIR CONDITIONER SYSTEM).

2. Check the parts where noise is occurring.

Can the parts where noise is occurring be checked?

YES-1 >> Noise from blower motor: GO TO 2.

YES-2 >> Noise from compressor: GO TO 3.

YES-3 >> Noise from expansion valve: GO TO 4.

YES-4 >> Noise from A/C piping (pipe, flexible hose): GO TO 6.

YES-5 >> Noise from drive belt: GO TO 7.

NO >> END.

2.CHECK BLOWER MOTOR

1. Remove blower motor.

2. Remove foreign materials that are in the blower unit.

3. Check the noise from blower motor again.

Is the inspection result normal?

YES >> END.

NO >> Replace blower motor.

3.CHECK COMPRESSOR

Perform trouble diagnosis for the compressor and check the compressor. Refer to HA-11, "

Symptom Table".

Is the inspection result normal?

YES >> END.

NO >> Refill the refrigerant or replace the compressor according to the inspection results.

4.CHECK WITH GAUGE PRESSURE

Perform the diagnosis with the gauge pressure. Refer to HA-8, "

Trouble Diagnosis For Unusual Pressure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts according to the inspection results.

5.CHECK EXPANSION VALVE

1. Correct the refrigerant with recovery/recycling recharging equipment.

2. Recharge with the proper amount of the collected refrigerant after recycling or new refrigerant.

3. Check for the noise from expansion valve again.

Are the malfunction solved?

YES >> END.

NO >> Replace expansion valve.

6.CHECK A/C PIPING (PIPE, FLEXIBLE HOSE)

1. Check the A/C piping (pipes, flexible hoses) (for deformation and damage, etc.).

2. Check the installation condition of clips and brackets, etc, of the A/C piping (pipes, flexible hoses).

Is the inspection result normal?

YES >> Fix the line with rubber or come vibration absorbing material.

Page 2866 of 5121

![NISSAN TEANA 2008 Service Manual HAC-238

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003884814

When performing the procedure after removing cowl top cover, cover

the l NISSAN TEANA 2008 Service Manual HAC-238

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003884814

When performing the procedure after removing cowl top cover, cover

the l](/img/5/57391/w960_57391-2865.png)

HAC-238

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003884814

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Xenon Headlamp ServiceINFOID:0000000003884815

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Working with HFC-134a (R-134a)INFOID:0000000003884816

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. Compressor mal-

function is likely to occur if the refrigerants are mixed, refer to “CONTAMINATED REFRIGERANT”

below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refriger-

ant Recovery/Recycling Recharging equipment and Refrigerant Identifier.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

- Immediately cap (seal) the component to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refrigerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed container. Immediately reseal containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

- Never allow lubricant (NISSAN A/C System Oil Type S) to come in to contact with styrene foam parts.

Damage may result.

CONTAMINATED REFRIGERANT

Take the appropriate steps shown below if a refrigerant other than pure HFC-134a (R-134a) is identified

in a vehicle:

Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

PIIB3706J

Page 2962 of 5121

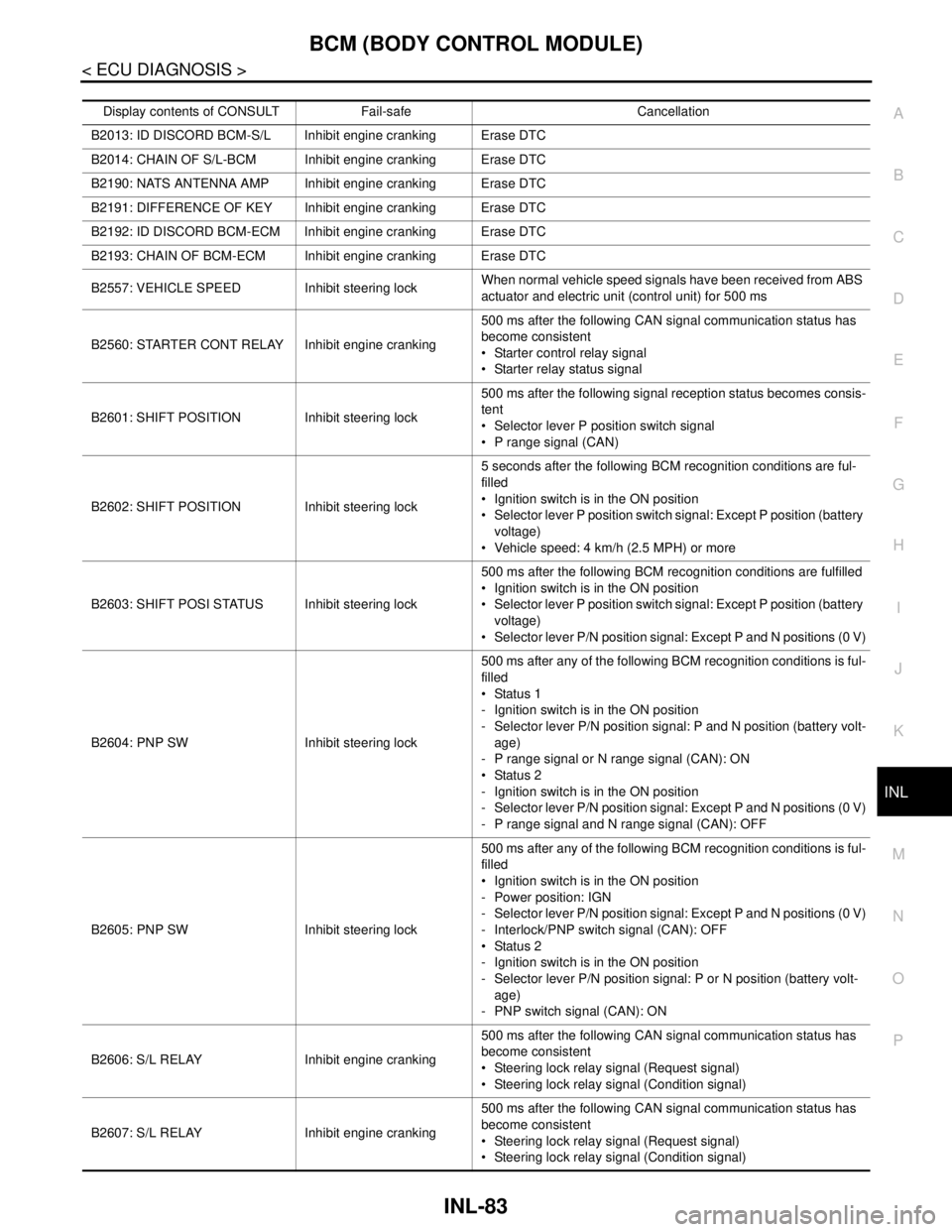

BCM (BODY CONTROL MODULE)

INL-83

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

INL

N

O

P

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITIONInhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITIONInhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 3068 of 5121

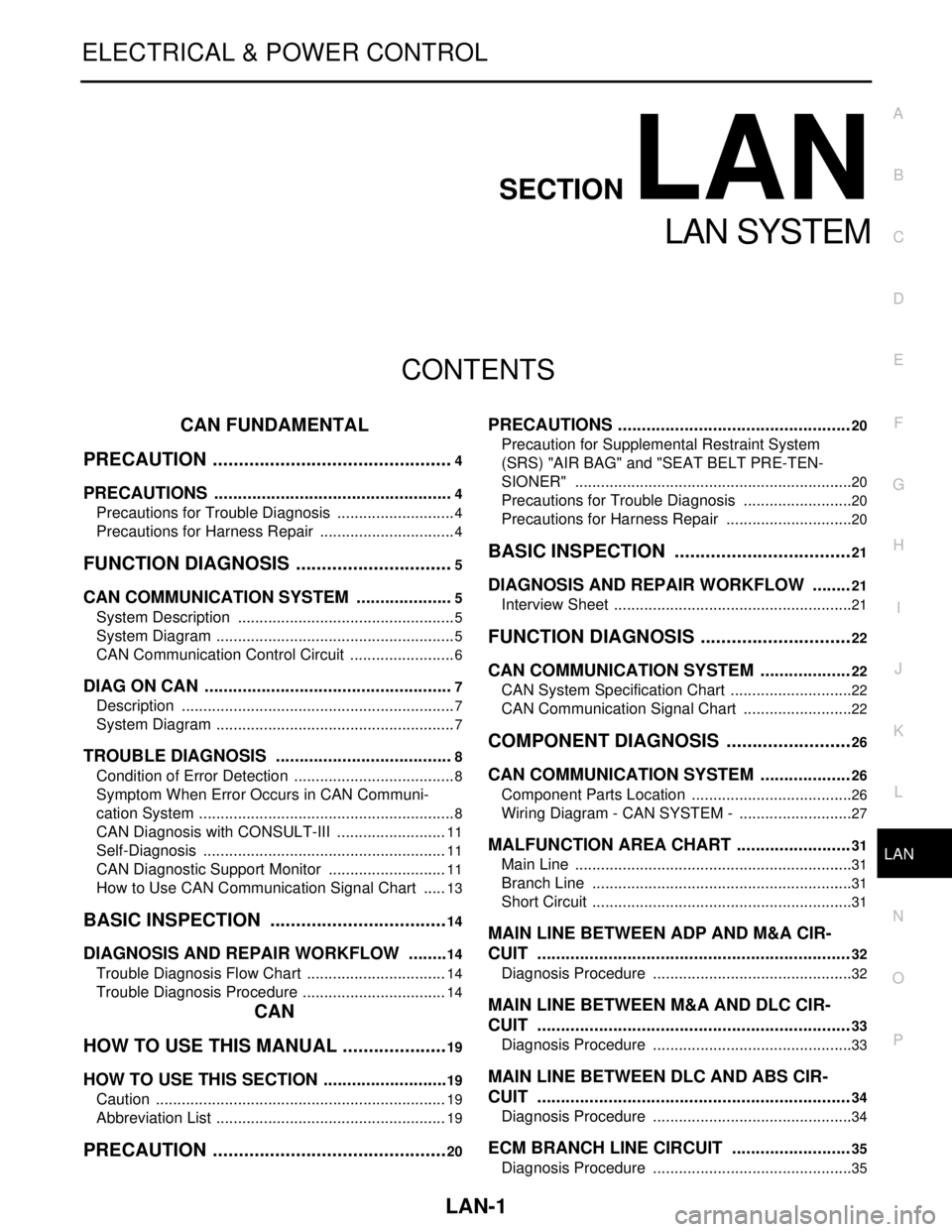

LAN

LAN-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION LAN

A

O P

N

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precautions for Trouble Diagnosis ...................... ......4

Precautions for Harness Repair ................................4

FUNCTION DIAGNOSIS ...............................5

CAN COMMUNICATION SYSTEM ................ .....5

System Description ............................................. ......5

System Diagram ........................................................5

CAN Communication Control Circuit .........................6

DIAG ON CAN .....................................................7

Description .......................................................... ......7

System Diagram ........................................................7

TROUBLE DIAGNOSIS ......................................8

Condition of Error Detection ................................ ......8

Symptom When Error Occurs in CAN Communi-

cation System ...................................................... ......

8

CAN Diagnosis with CONSULT-III ..........................11

Self-Diagnosis .........................................................11

CAN Diagnostic Support Monitor ............................11

How to Use CAN Communication Signal Chart ......13

BASIC INSPECTION ...................................14

DIAGNOSIS AND REPAIR WORKFLOW ..... ....14

Trouble Diagnosis Flow Chart ............................. ....14

Trouble Diagnosis Procedure ..................................14

CAN

HOW TO USE THIS MANU AL .....................

19

HOW TO USE THIS SECTION ....................... ....19

Caution ................................................................ ....19

Abbreviation List ......................................................19

PRECAUTION ..............................................20

PRECAUTIONS .................................................20

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

20

Precautions for Trouble Diagnosis ..........................20

Precautions for Harness Repair ..............................20

BASIC INSPECTION ...................................21

DIAGNOSIS AND REPAIR WORKFLOW ........21

Interview Sheet .................................................... ....21

FUNCTION DIAGNOSIS ..............................22

CAN COMMUNICATION SYSTEM ...................22

CAN System Specification Chart ......................... ....22

CAN Communication Signal Chart ..........................22

COMPONENT DIAGNOSIS .........................26

CAN COMMUNICATION SYSTEM ...................26

Component Parts Location .................................. ....26

Wiring Diagram - CAN SYSTEM - ...........................27

MALFUNCTION AREA CHART ........................31

Main Line ............................................................. ....31

Branch Line .............................................................31

Short Circuit .............................................................31

MAIN LINE BETWEEN ADP AND M&A CIR-

CUIT ..................................................................

32

Diagnosis Procedure ...............................................32

MAIN LINE BETWEEN M&A AND DLC CIR-

CUIT ..................................................................

33

Diagnosis Procedure ...............................................33

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ..................................................................

34

Diagnosis Procedure ...............................................34

ECM BRANCH LINE CIRCUIT .........................35

Diagnosis Procedure ...............................................35

Page 3069 of 5121

LAN-2

ADP BRANCH LINE CIRCUIT ..........................36

Diagnosis Procedure ..............................................36

AV BRANCH LINE CIRCUIT .............................37

Diagnosis Procedure ..............................................37

HVAC BRANCH LINE CIRCUIT ........................38

Diagnosis Procedure ..............................................38

M&A BRANCH LINE CIRCUIT ..........................39

Diagnosis Procedure ..............................................39

STRG BRANCH LINE CIRCUIT ........................40

Diagnosis Procedure ..............................................40

BCM BRANCH LINE CIRCUIT ..........................41

Diagnosis Procedure ..............................................41

DLC BRANCH LINE CIRCUIT ...........................42

Diagnosis Procedure ..............................................42

ABS BRANCH LINE CIRCUIT ..........................43

Diagnosis Procedure ..............................................43

TCM BRANCH LINE CIRCUIT ..........................44

Diagnosis Procedure ..............................................44

IPDM-E BRANCH LINE CIRCUIT .....................45

Diagnosis Procedure ..............................................45

CAN COMMUNICATION CIRCUIT ....................46

Diagnosis Procedure ..............................................46

CAN SYSTEM (TYPE 2)

COMPONENT DIAGNOSIS ........................

48

MAIN LINE BETWEEN M&A AND DLC CIR-

CUIT ...................................................................

48

Diagnosis Procedure ..............................................48

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ...................................................................

49

Diagnosis Procedure ..............................................49

ECM BRANCH LINE CIRCUIT ..........................50

Diagnosis Procedure ..............................................50

HVAC BRANCH LINE CIRCUIT ........................51

Diagnosis Procedure ..............................................51

M&A BRANCH LINE CIRCUIT ..........................52

Diagnosis Procedure ..............................................52

BCM BRANCH LINE CIRCUIT ..........................53

Diagnosis Procedure ..............................................53

DLC BRANCH LINE CIRCUIT ...........................54

Diagnosis Procedure ..............................................54

ABS BRANCH LINE CIRCUIT ..........................55

Diagnosis Procedure ..............................................55

TCM BRANCH LINE CIRCUIT ..........................56

Diagnosis Procedure ...............................................56

IPDM-E BRANCH LINE CIRCUIT .....................57

Diagnosis Procedure ...............................................57

CAN COMMUNICATION CIRCUIT ...................58

Diagnosis Procedure ...............................................58

CAN SYSTEM (TYPE 4)

COMPONENT DIAGNOSIS .......................

60

MAIN LINE BETWEEN M&A AND DLC CIR-

CUIT ...................................................................

60

Diagnosis Procedure ...............................................60

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ...................................................................

61

Diagnosis Procedure ...............................................61

ECM BRANCH LINE CIRCUIT ..........................62

Diagnosis Procedure ...............................................62

AV BRANCH LINE CIRCUIT .............................63

Diagnosis Procedure ...............................................63

HVAC BRANCH LINE CIRCUIT ........................64

Diagnosis Procedure ...............................................64

M&A BRANCH LINE CIRCUIT ..........................65

Diagnosis Procedure ...............................................65

STRG BRANCH LINE CIRCUIT ........................66

Diagnosis Procedure ...............................................66

BCM BRANCH LINE CIRCUIT ..........................67

Diagnosis Procedure ...............................................67

DLC BRANCH LINE CIRCUIT ..........................68

Diagnosis Procedure ...............................................68

ABS BRANCH LINE CIRCUIT ..........................69

Diagnosis Procedure ...............................................69

TCM BRANCH LINE CIRCUIT ..........................70

Diagnosis Procedure ...............................................70

IPDM-E BRANCH LINE CIRCUIT .....................71

Diagnosis Procedure ...............................................71

CAN COMMUNICATION CIRCUIT ...................72

Diagnosis Procedure ...............................................72

CAN SYSTEM (TYPE 6)

COMPONENT DIAGNOSIS .......................

74

MAIN LINE BETWEEN ADP AND M&A CIR-

CUIT ...................................................................

74

Diagnosis Procedure ...............................................74

MAIN LINE BETWEEN M&A AND DLC CIR-

CUIT ...................................................................

75

Diagnosis Procedure ...............................................75

Page 3070 of 5121

LAN

LAN-3

C

D

E

F

G

H

I

J

K

L B A

O

P N

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ....................................................................

76

Diagnosis Procedure ...............................................76

ECM BRANCH LINE CIRCUIT ...........................77

Diagnosis Procedure ...............................................77

ADP BRANCH LINE CIRCUIT ...........................78

Diagnosis Procedure ...............................................78

AV BRANCH LINE CIRCUIT ..............................79

Diagnosis Procedure ...............................................79

HVAC BRANCH LINE CIRCUIT ........................80

Diagnosis Procedure ...............................................80

M&A BRANCH LINE CIRCUIT ..........................81

Diagnosis Procedure ...............................................81

STRG BRANCH LINE CIRCUIT .........................82

Diagnosis Procedure ...............................................82

BCM BRANCH LINE CIRCUIT ..........................83

Diagnosis Procedure ...............................................83

DLC BRANCH LINE CIRCUIT ...........................84

Diagnosis Procedure ...............................................84

ABS BRANCH LINE CIRCUIT ...........................85

Diagnosis Procedure ...............................................85

TCM BRANCH LINE CIRCUIT ...........................86

Diagnosis Procedure ...............................................86

IPDM-E BRANCH LINE CIRCUIT ......................87

Diagnosis Procedure ...............................................87

CAN COMMUNICATION CIRCUIT ....................88

Diagnosis Procedure ...............................................88

CAN SYSTEM (TYPE 9)

COMPONENT DIAGNOSIS .........................

90

MAIN LINE BETWEEN ADP AND M&A CIR-

CUIT ....................................................................

90

Diagnosis Procedure ...............................................90

MAIN LINE BETWEEN M&A AND DLC CIR-

CUIT ..................................................................

91

Diagnosis Procedure ...............................................91

MAIN LINE BETWEEN DLC AND ABS CIR-

CUIT ..................................................................

92

Diagnosis Procedure ...............................................92

ECM BRANCH LINE CIRCUIT .........................93

Diagnosis Procedure ...............................................93

ADP BRANCH LINE CIRCUIT ..........................94

Diagnosis Procedure ...............................................94

AV BRANCH LINE CIRCUIT ............................95

Diagnosis Procedure ...............................................95

HVAC BRANCH LINE CIRCUIT .......................96

Diagnosis Procedure ...............................................96

M&A BRANCH LINE CIRCUIT .........................97

Diagnosis Procedure ...............................................97

STRG BRANCH LINE CIRCUIT .......................98

Diagnosis Procedure ...............................................98

BCM BRANCH LINE CIRCUIT .........................99

Diagnosis Procedure ...............................................99

DLC BRANCH LINE CIRCUIT ........................100

Diagnosis Procedure .............................................100

ABS BRANCH LINE CIRCUIT ........................101

Diagnosis Procedure .............................................101

TCM BRANCH LINE CIRCUIT ........................102

Diagnosis Procedure .............................................102

IPDM-E BRANCH LINE CIRCUIT ...................103

Diagnosis Procedure .............................................103

CAN COMMUNICATION CIRCUIT .................104

Diagnosis Procedure .............................................104

Page 3076 of 5121

![NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is](/img/5/57391/w960_57391-3075.png)

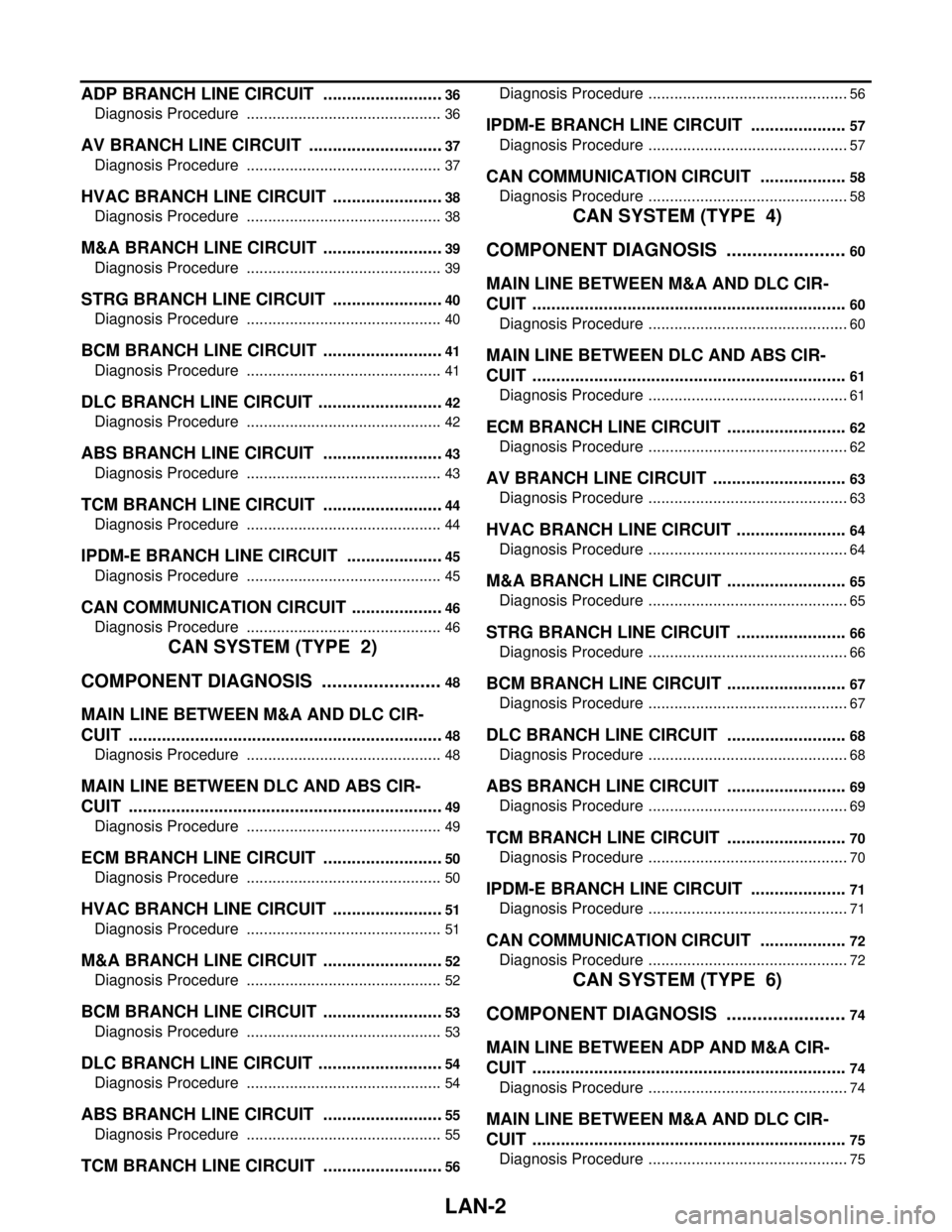

LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

EPS control unit Normal operation.

Combination meter Shift position indicator and OD OFF indicator turn OFF.

Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.Unit name Symptom

SKIB8739E

Unit name Symptom

ECM

Normal operation. BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuitMost of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

Page 3077 of 5121

![NISSAN TEANA 2008 Service Manual LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Har NISSAN TEANA 2008 Service Manual LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Har](/img/5/57391/w960_57391-3076.png)

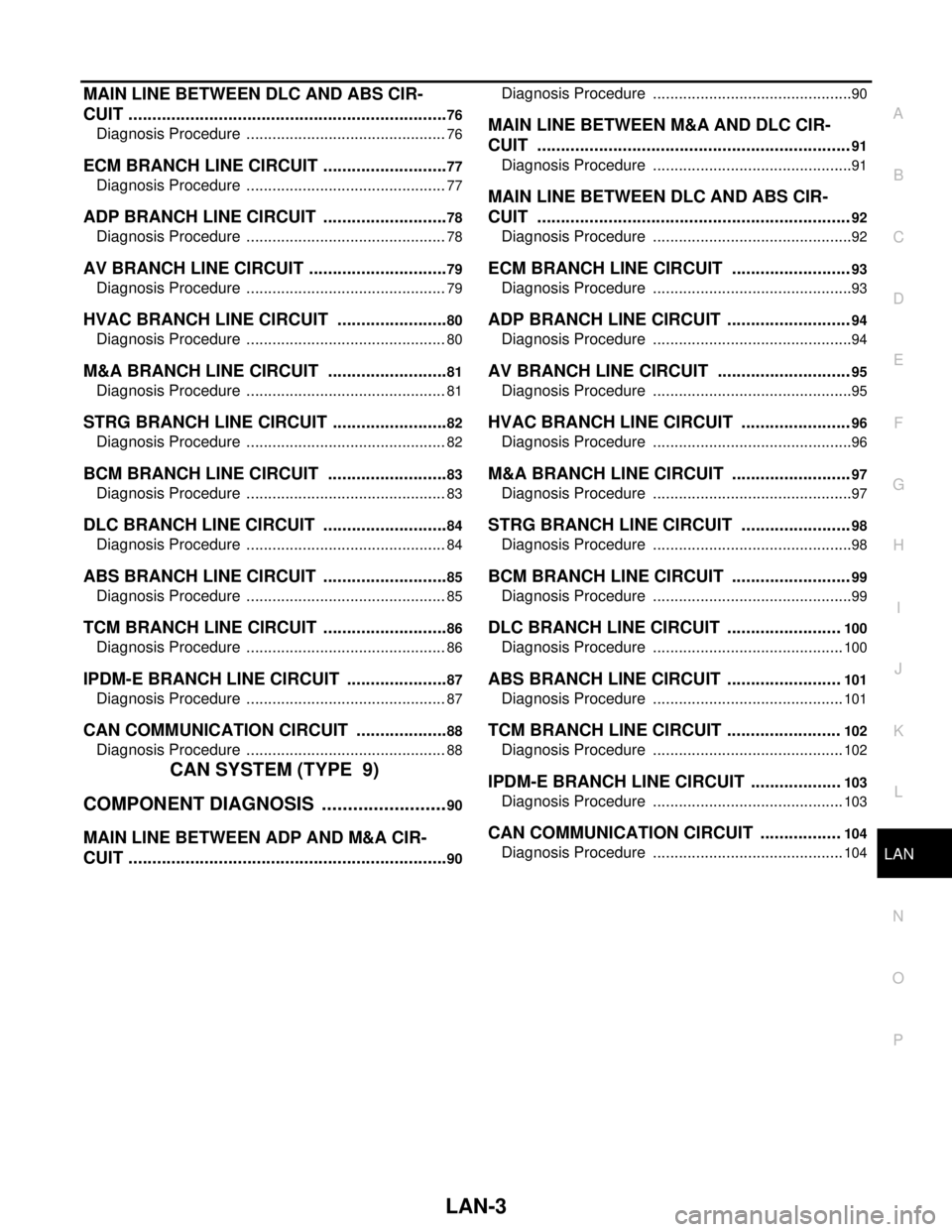

LAN-10

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Harness Short Circuit

SKIB8740E

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter The shift position indicator and OD OFF indicator turn OFF.

The speedometer is inoperative.

The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

SKIB8741E

Page 3078 of 5121

![NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root](/img/5/57391/w960_57391-3077.png)

LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

Self-DiagnosisINFOID:0000000003767673

CAN Diagnostic Support MonitorINFOID:0000000003767674

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni-

tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning

the ignition switch OFF.)

EPS control unit The steering effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTCSelf-diagnosis item

(CONSULT-III indication)DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit. When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMMWhen a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less.

U1010 CONTROL UNIT [CAN]

When an error is detected during the initial diag-

nosis for CAN controller of each control unit.Replace the control unit

indicating “U1010” or

“P0607”. P0607 ECM