Ccu NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3076 of 5121

![NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is](/img/5/57391/w960_57391-3075.png)

LAN

TROUBLE DIAGNOSIS

LAN-9

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N Example: Data link connector branch line open circuit

NOTE:

When data link connector branch line is open, transmission and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

EPS control unit Normal operation.

Combination meter Shift position indicator and OD OFF indicator turn OFF.

Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.Unit name Symptom

SKIB8739E

Unit name Symptom

ECM

Normal operation. BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuitMost of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

Page 3078 of 5121

![NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root NISSAN TEANA 2008 Service Manual LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root](/img/5/57391/w960_57391-3077.png)

LAN

TROUBLE DIAGNOSIS

LAN-11

< FUNCTION DIAGNOSIS >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L B A

O

P N

CAN Diagnosis with CONSULT-IIIINFOID:0000000003767672

CAN diagnosis on CONSULT-III extracts the root cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

Self-DiagnosisINFOID:0000000003767673

CAN Diagnostic Support MonitorINFOID:0000000003767674

MONITOR ITEM (CONSULT-III)

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni-

tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning

the ignition switch OFF.)

EPS control unit The steering effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

DTCSelf-diagnosis item

(CONSULT-III indication)DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit. When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMMWhen a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less.

U1010 CONTROL UNIT [CAN]

When an error is detected during the initial diag-

nosis for CAN controller of each control unit.Replace the control unit

indicating “U1010” or

“P0607”. P0607 ECM

Page 3114 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-47

< COMPONENT DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble dia NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-47

< COMPONENT DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble dia](/img/5/57391/w960_57391-3113.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-47

< COMPONENT DIAGNOSIS >[CAN]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3126 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-59

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-59

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow](/img/5/57391/w960_57391-3125.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-59

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 2)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3140 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-73

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-73

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow](/img/5/57391/w960_57391-3139.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-73

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3156 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-89

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-89

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow](/img/5/57391/w960_57391-3155.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-89

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3172 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follo NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follo](/img/5/57391/w960_57391-3171.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3199 of 5121

RECOMMENDED FLUIDS AND LUBRICANTS

MA-11

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

RECOMMENDED FLUIDS AND LUBRICANTS

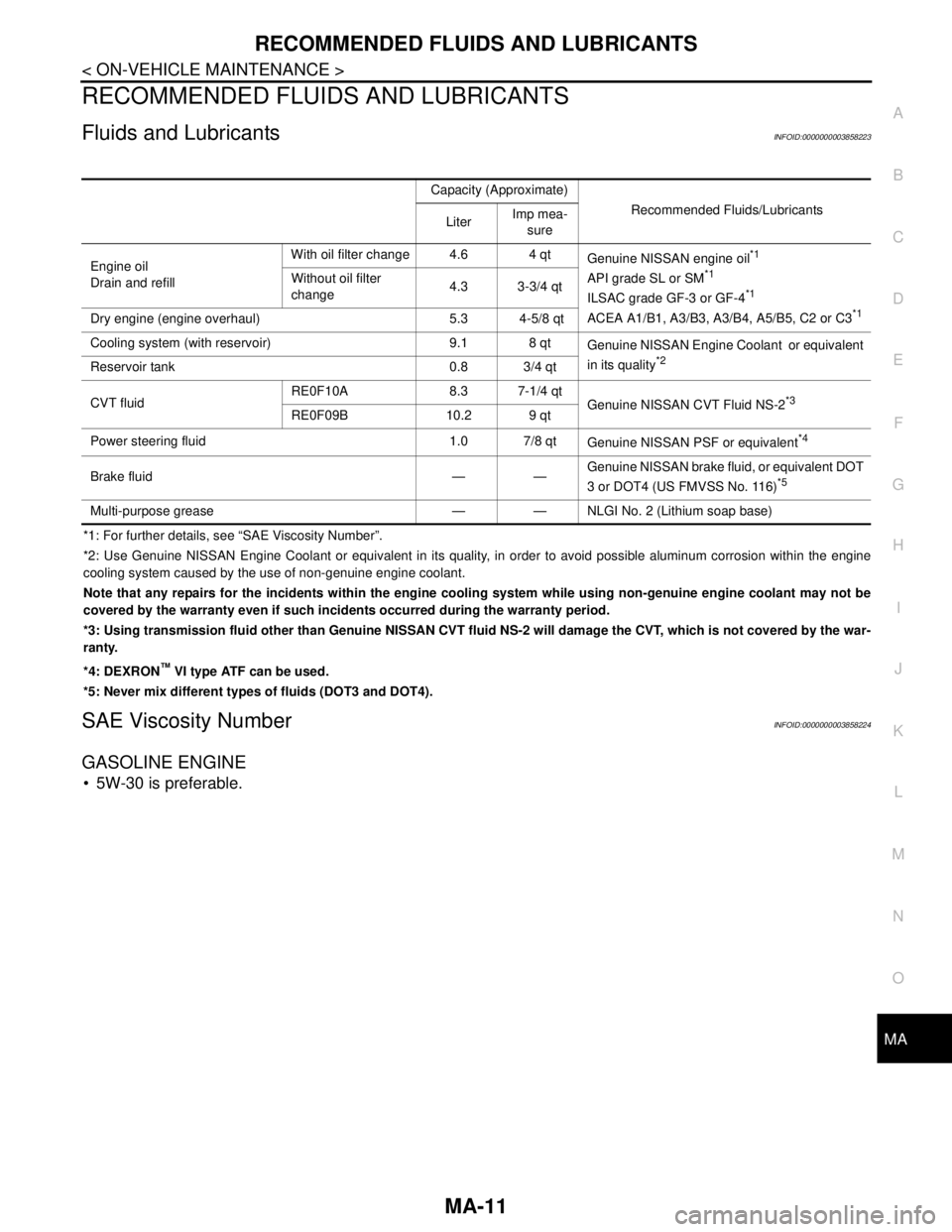

Fluids and LubricantsINFOID:0000000003858223

*1: For further details, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*3: Using transmission fluid other than Genuine NISSAN CVT fluid NS-2 will damage the CVT, which is not covered by the war-

ranty.

*4: DEXRON

™ VI type ATF can be used.

*5: Never mix different types of fluids (DOT3 and DOT4).

SAE Viscosity NumberINFOID:0000000003858224

GASOLINE ENGINE

5W-30 is preferable.

Capacity (Approximate)

Recommended Fluids/Lubricants

LiterImp mea-

sure

Engine oil

Drain and refillWith oil filter change 4.6 4 qt

Genuine NISSAN engine oil

*1

API grade SL or SM*1

ILSAC grade GF-3 or GF-4*1

ACEA A1/B1, A3/B3, A3/B4, A5/B5, C2 or C3*1

Without oil filter

change4.3 3-3/4 qt

Dry engine (engine overhaul) 5.3 4-5/8 qt

Cooling system (with reservoir) 9.1 8 qt

Genuine NISSAN Engine Coolant or equivalent

in its quality

*2Reservoir tank 0.8 3/4 qt

CVT fluidRE0F10A 8.3 7-1/4 qt

Genuine NISSAN CVT Fluid NS-2

*3

RE0F09B 10.2 9 qt

Power steering fluid 1.0 7/8 qt

Genuine NISSAN PSF or equivalent

*4

Brake fluid — —Genuine NISSAN brake fluid, or equivalent DOT

3 or DOT4 (US FMVSS No. 116)*5

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 3202 of 5121

MA-14

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

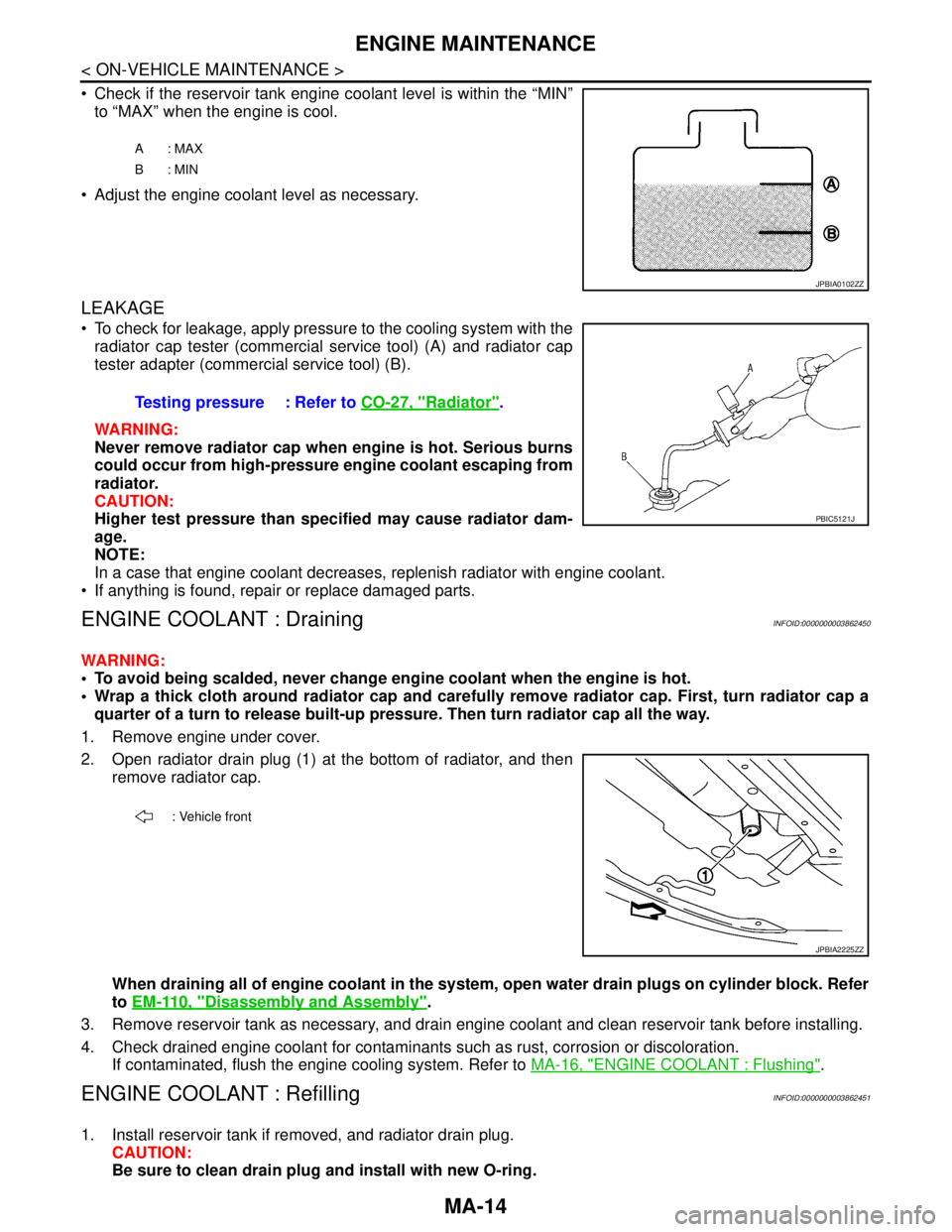

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” when the engine is cool.

Adjust the engine coolant level as necessary.

LEAKAGE

To check for leakage, apply pressure to the cooling system with the

radiator cap tester (commercial service tool) (A) and radiator cap

tester adapter (commercial service tool) (B).

WARNING:

Never remove radiator cap when engine is hot. Serious burns

could occur from high-pressure engine coolant escaping from

radiator.

CAUTION:

Higher test pressure than specified may cause radiator dam-

age.

NOTE:

In a case that engine coolant decreases, replenish radiator with engine coolant.

If anything is found, repair or replace damaged parts.

ENGINE COOLANT : DrainingINFOID:0000000003862450

WARNING:

To avoid being scalded, never change engine coolant when the engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

1. Remove engine under cover.

2. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to EM-110, "

Disassembly and Assembly".

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to MA-16, "

ENGINE COOLANT : Flushing".

ENGINE COOLANT : RefillingINFOID:0000000003862451

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

A: MAX

B: MIN

JPBIA0102ZZ

Testing pressure : Refer to CO-27, "Radiator".

PBIC5121J

: Vehicle front

JPBIA2225ZZ

Page 3228 of 5121

MA-40

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

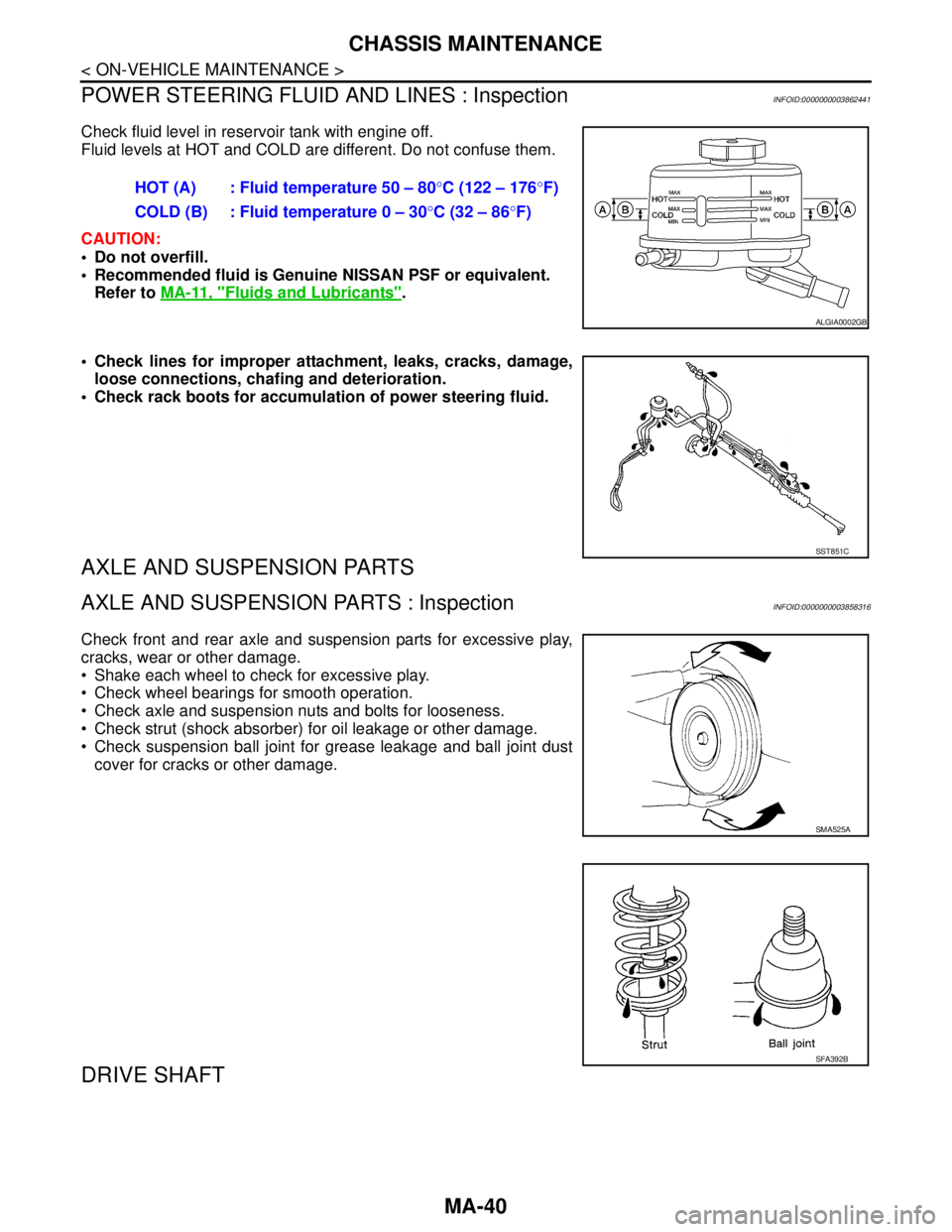

POWER STEERING FLUID AND LINES : Inspection

INFOID:0000000003862441

Check fluid level in reservoir tank with engine off.

Fluid levels at HOT and COLD are different. Do not confuse them.

CAUTION:

Do not overfill.

Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

Check lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

Check rack boots for accumulation of power steering fluid.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : InspectionINFOID:0000000003858316

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage.

DRIVE SHAFT

HOT (A) : Fluid temperature 50 – 80°C (122 – 176°F)

COLD (B) : Fluid temperature 0 – 30°C (32 – 86°F)

ALGIA0002GB

SST851C

SMA525A

SFA392B