Ccu NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2583 of 5121

HA-14

< PRECAUTION >

PRECAUTIONS

Ventilate work area before resuming service if accidental system discharge occurs. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

Never release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant each time an air conditioning system is discharged.

Wear always eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Never store or heat refrigerant containers above 52°C (126°F).

Never heat a refrigerant container with an open flame; Place the bottom of the container in a warm

pail of water if container warming is required.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: poisonous gas is produced if refrigerant burns.

Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo-

cation.

Never pressure test or leakage test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

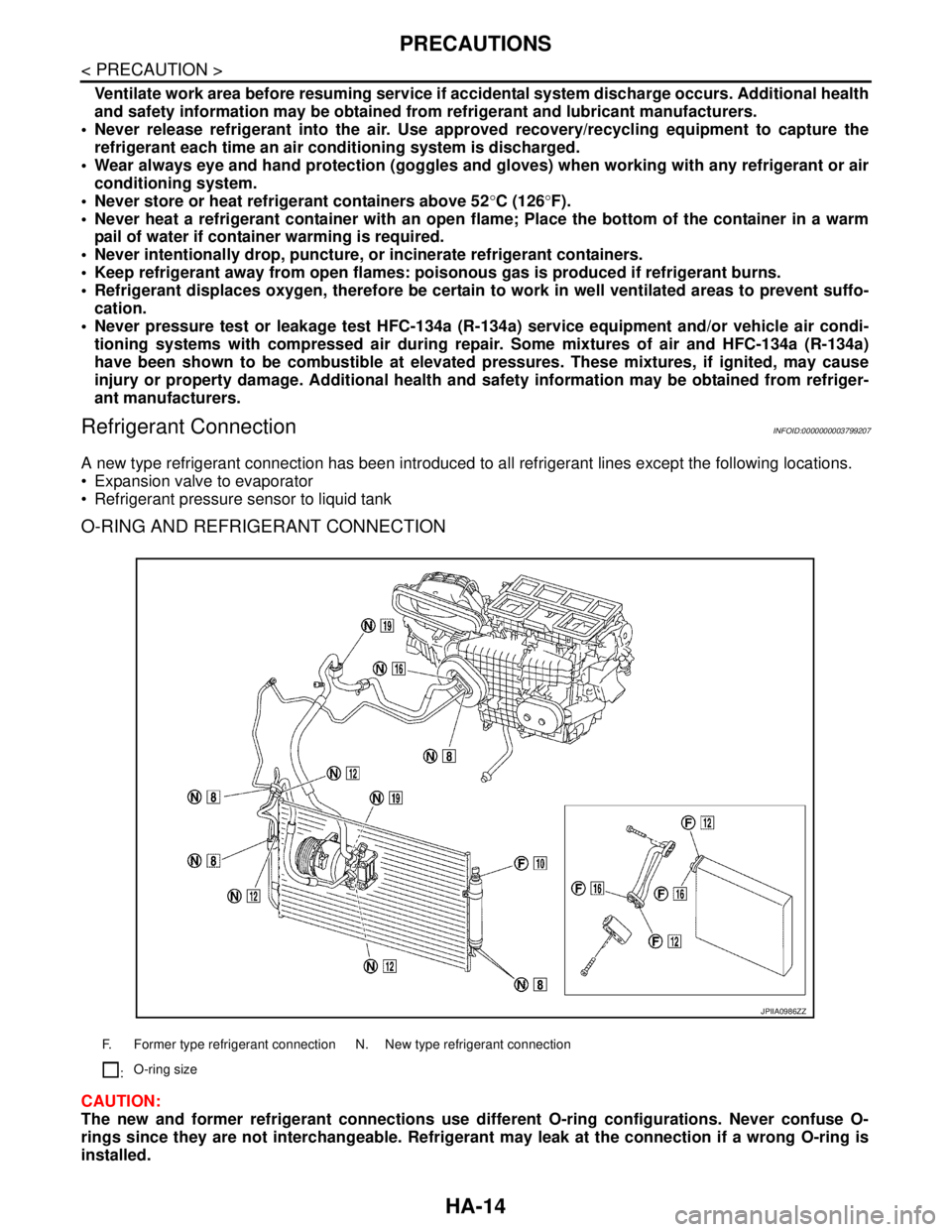

Refrigerant ConnectionINFOID:0000000003799207

A new type refrigerant connection has been introduced to all refrigerant lines except the following locations.

Expansion valve to evaporator

Refrigerant pressure sensor to liquid tank

O-RING AND REFRIGERANT CONNECTION

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Never confuse O-

rings since they are not interchangeable. Refrigerant may leak at the connection if a wrong O-ring is

installed.

F. Former type refrigerant connection N. New type refrigerant connection

:O-ring size

JPIIA0986ZZ

Page 2586 of 5121

PRECAUTIONS

HA-17

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

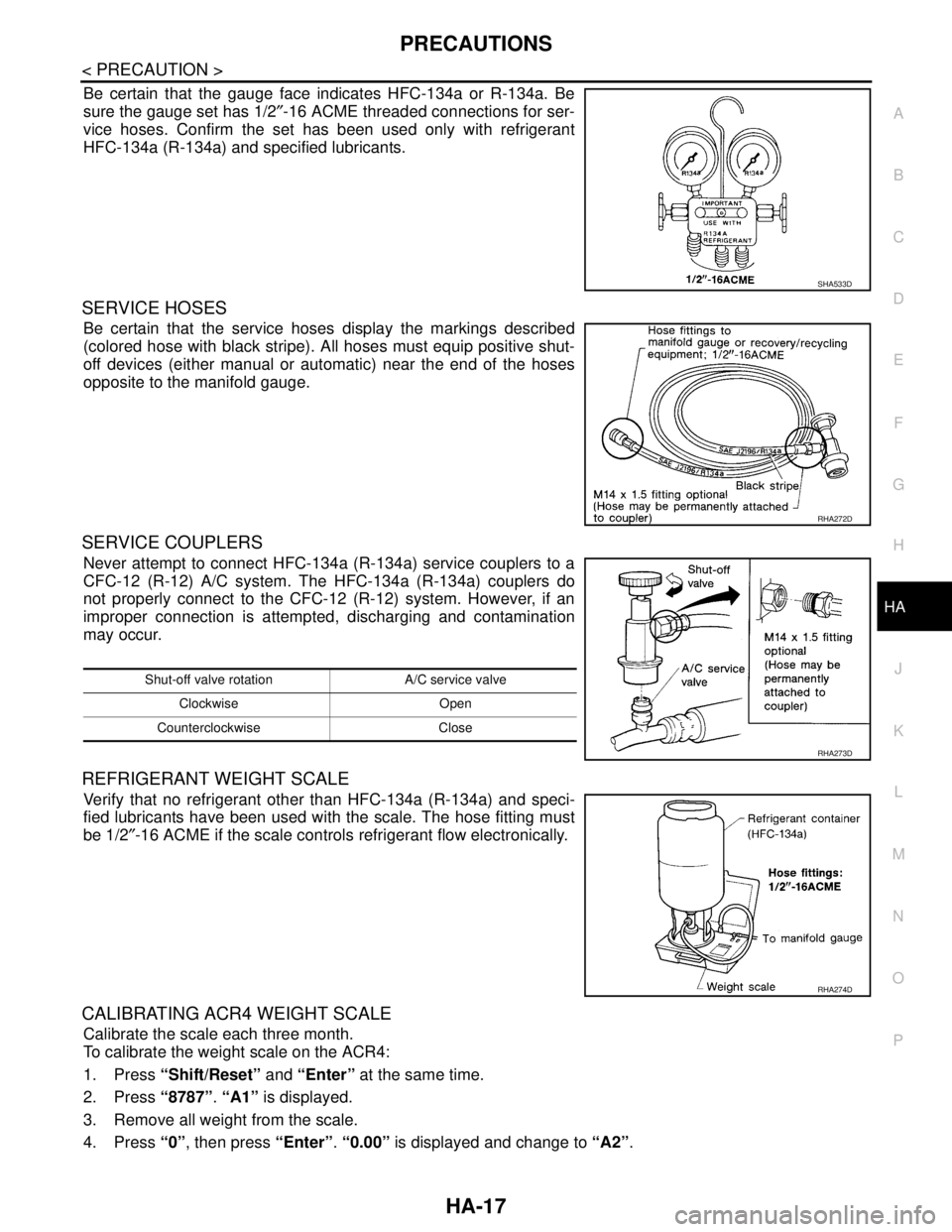

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must equip positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite to the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers do

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. The hose fitting must

be 1/2″-16 ACME if the scale controls refrigerant flow electronically.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale each three month.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset” and “Enter” at the same time.

2. Press “8787”. “A1” is displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”. “0.00” is displayed and change to “A2”.

SHA533D

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 2587 of 5121

HA-18

< PRECAUTION >

PRECAUTIONS

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digits. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press “Shift/Reset” and “Enter” at the same time.

9. Press “6”— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” is displayed.

11. Press “Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Page 2589 of 5121

HA-20

< PRECAUTION >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003795892

CAUTION:

The A/C system contains a fluorescent leak detection dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to illuminate the dye when inspecting for leakages.

Wear always fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacement for an electrical leak detector (SST). The fluo-

rescent dye leak detector should be used in conjunction with an electrical leak detector (SST) to pin-

point refrigerant leakages.

Read and follow all manufacture’s operating instructions and precautions prior to performing the

work for the purpose of safety and customer’s satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after confirming the leakage with an electrical leak detector

(SST).

Remove always any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cleaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains for three or more years unless a compressor malfunc-

tion occurs.

IDENTIFICATION

NOTE:

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have the identification label on the front side of hood.

Page 2590 of 5121

PREPARATION

HA-21

< PREPARATION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003795893

HFC-134a (R-134a) Service Tool and Equipment Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

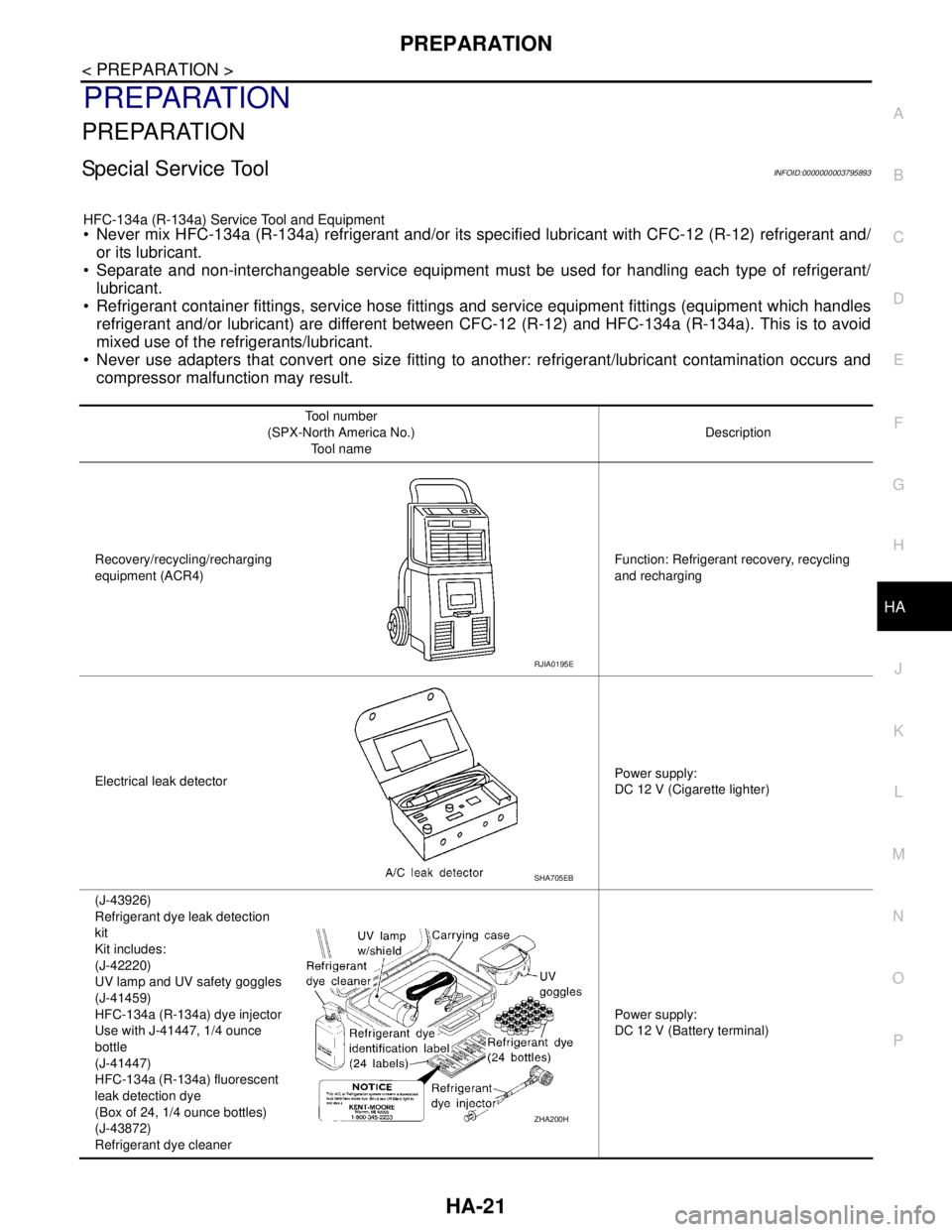

Tool number

(SPX-North America No.)

Tool nameDescription

Recovery/recycling/recharging

equipment (ACR4)Function: Refrigerant recovery, recycling

and recharging

Electrical leak detectorPower supply:

DC 12 V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection

kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12 V (Battery terminal)

RJIA0195E

SHA705EB

ZHA200H

Page 2592 of 5121

PREPARATION

HA-23

< PREPARATION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

PSealant or/and LubricantINFOID:0000000003795894

HFC-134a (R-134a) Service Tool and Equipment Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

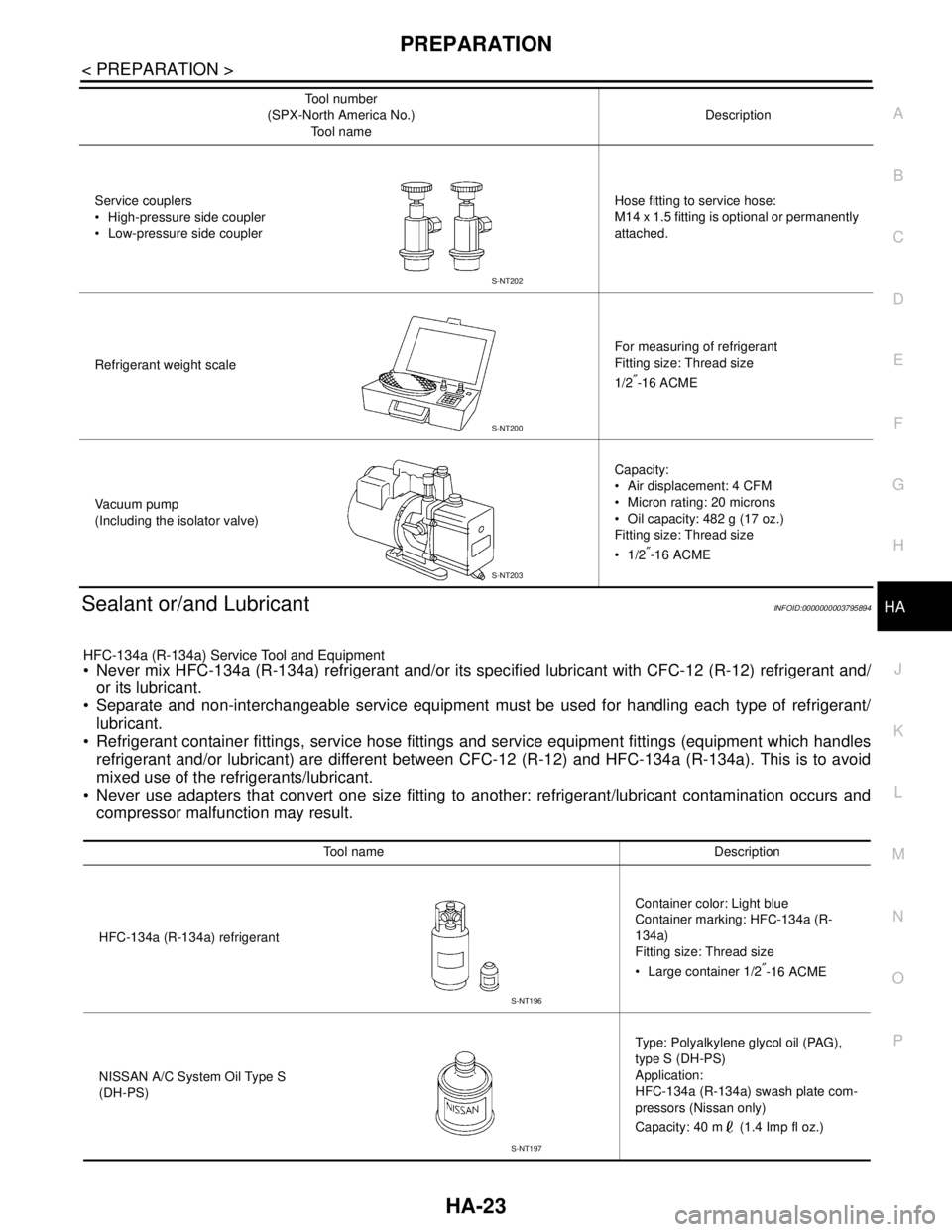

Service couplers

High-pressure side coupler

Low-pressure side couplerHose fitting to service hose:

M14 x 1.5 fitting is optional or permanently

attached.

Refrigerant weight scaleFor measuring of refrigerant

Fitting size: Thread size

1/2

″-16 ACME

Va c u u m p u m p

(Including the isolator valve)Capacity:

Air displacement: 4 CFM

Micron rating: 20 microns

Oil capacity: 482 g (17 oz.)

Fitting size: Thread size

1/2

″-16 ACME Tool number

(SPX-North America No.)

Tool nameDescription

S-NT202

S-NT200

S-NT203

Tool name Description

HFC-134a (R-134a) refrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

Large container 1/2

″-16 ACME

NISSAN A/C System Oil Type S

(DH-PS)Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application:

HFC-134a (R-134a) swash plate com-

pressors (Nissan only)

Capacity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Page 2594 of 5121

REFRIGERANT

HA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling recharging equipment to discharge HFC-134a (R-134a) refriger-

ant. Ventilate work area before resuming service if accidental system discharge occurs. Additional

health and safety information may be obtained from refrigerant and lubricant manufacturers.

1.CHECK A/C SYSTEM

1. Check that A/C system operates normally. Refer to the following.

-HAC-8, "

Description & Inspection" (WITHOUT 7 INCH DISPLAY)

-HAC-108, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7

INCH DISPLAY (WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

-HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7 INCH

DISPLAY (WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

2. Check if there is a large amount of leakage of refrigerant or oil.

CAUTION:

Never perform the lubricant return operation if a large amount of leakage of lubricant is detected.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check for refrigerant leakage. Refer to HA-32, "

Inspection".

2.LUBRICANT RETURN OPERATION

1. Start the engine and run it as follows.

- Engine speed: Idle - 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Air inlet: Recirculation (REC)

- Set temperature: FULL HOT

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Operate recovery/recycling recharging equipment.

CAUTION:

Follow the instructions of the manufacturer for the handling or maintenance of the equipment.

Never fill the equipment with undesignated refrigerant.

2. Check the gauge pressure of recovery/recycling recharging equipment.

Is there pressure?

YES >> GO TO 4.

NO >> GO TO 5.

4.DISCHARGE REFRIGERANT INSIDE PIPES

Discharge the refrigerant from the high-pressure hose and low-pressure hose of recovery/recycling recharging

equipment.

>> GO TO 5.

5.CONNECT RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Remove the service valve caps from the vehicle.

2. Connect recovery/recycling recharging equipment to the service valves.

>> GO TO 6.

6.DISCHARGE REFRIGERANT FROM THE VEHICLE

Operate recovery/recycling recharging equipment to discharge the refrigerant from the vehicle.

Page 2597 of 5121

HA-28

< ON-VEHICLE MAINTENANCE >

LUBRICANT

LUBRICANT

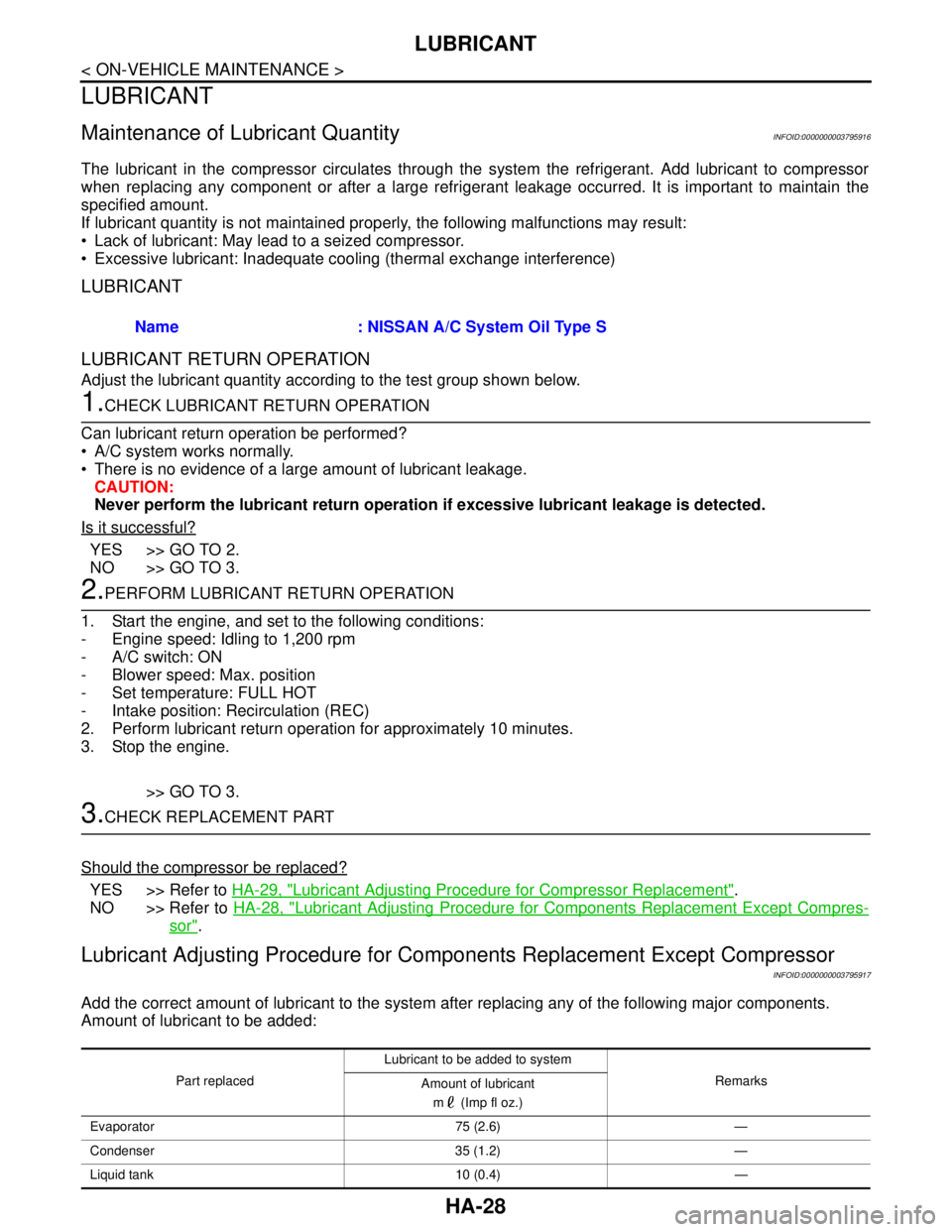

Maintenance of Lubricant QuantityINFOID:0000000003795916

The lubricant in the compressor circulates through the system the refrigerant. Add lubricant to compressor

when replacing any component or after a large refrigerant leakage occurred. It is important to maintain the

specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

Lack of lubricant: May lead to a seized compressor.

Excessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

A/C system works normally.

There is no evidence of a large amount of lubricant leakage.

CAUTION:

Never perform the lubricant return operation if excessive lubricant leakage is detected.

Is it successful?

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION

1. Start the engine, and set to the following conditions:

- Engine speed: Idling to 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Set temperature: FULL HOT

- Intake position: Recirculation (REC)

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK REPLACEMENT PART

Should the compressor be replaced?

YES >> Refer to HA-29, "Lubricant Adjusting Procedure for Compressor Replacement".

NO >> Refer to HA-28, "

Lubricant Adjusting Procedure for Components Replacement Except Compres-

sor".

Lubricant Adjusting Procedure for Components Replacement Except Compressor

INFOID:0000000003795917

Add the correct amount of lubricant to the system after replacing any of the following major components.

Amount of lubricant to be added:Name : NISSAN A/C System Oil Type S

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m (Imp fl oz.)

Evaporator 75 (2.6) —

Condenser 35 (1.2) —

Liquid tank 10 (0.4) —

Page 2602 of 5121

ELECTRICAL LEAK DETECTOR

HA-33

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

ELECTRICAL LEAK DETECTOR

InspectionINFOID:0000000003795982

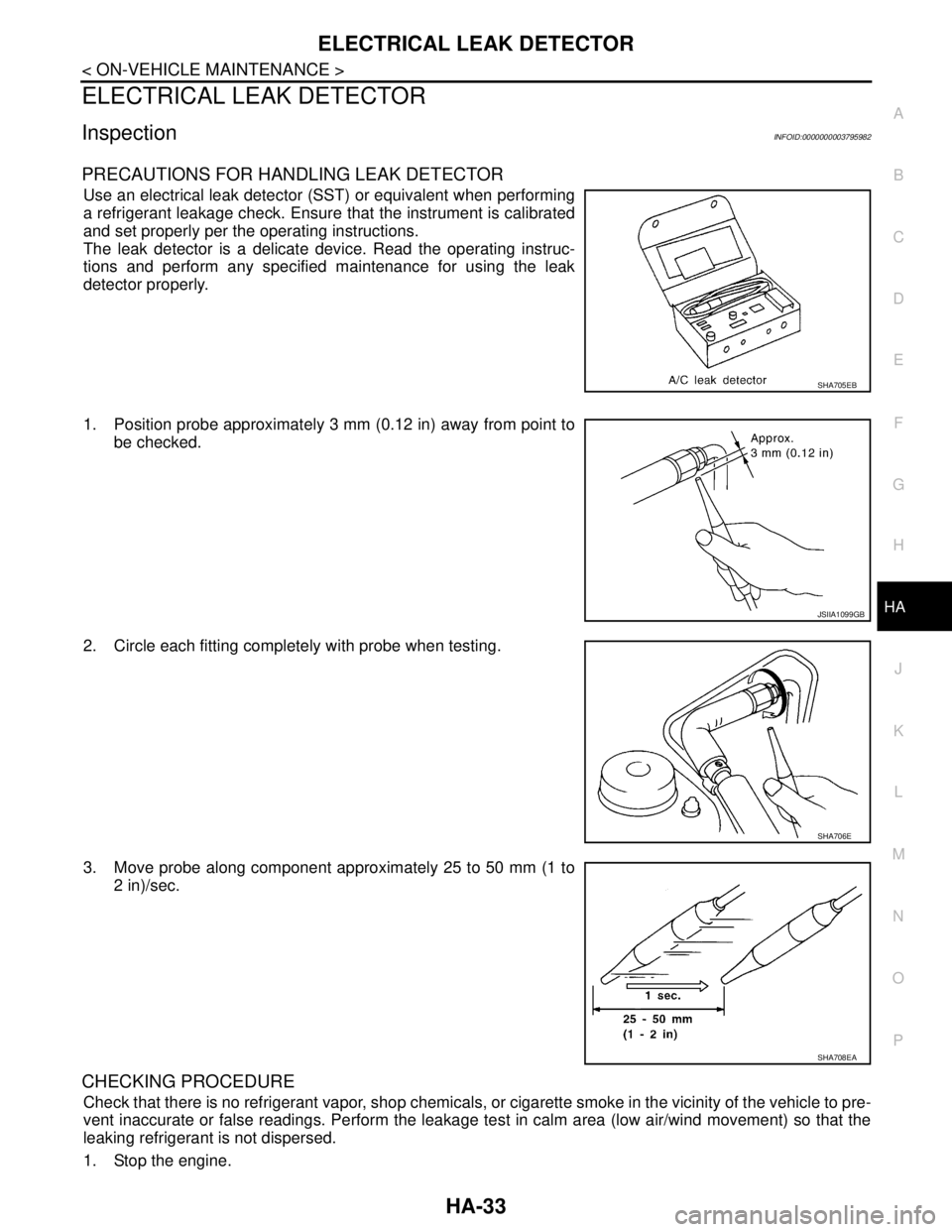

PRECAUTIONS FOR HANDLING LEAK DETECTOR

Use an electrical leak detector (SST) or equivalent when performing

a refrigerant leakage check. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. Read the operating instruc-

tions and perform any specified maintenance for using the leak

detector properly.

1. Position probe approximately 3 mm (0.12 in) away from point to

be checked.

2. Circle each fitting completely with probe when testing.

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

Check that there is no refrigerant vapor, shop chemicals, or cigarette smoke in the vicinity of the vehicle to pre-

vent inaccurate or false readings. Perform the leakage test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Stop the engine.

SHA705EB

JSIIA1099GB

SHA706E

SHA708EA

Page 2603 of 5121

HA-34

< ON-VEHICLE MAINTENANCE >

ELECTRICAL LEAK DETECTOR

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) above 16°C

(61°F). Recover/evacuate and recharge the system with the specified amount of refrigerant if less than

specification.

NOTE:

Leakages may not be detected since the system may not reach 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) at

temperatures below 16°C (61°F).

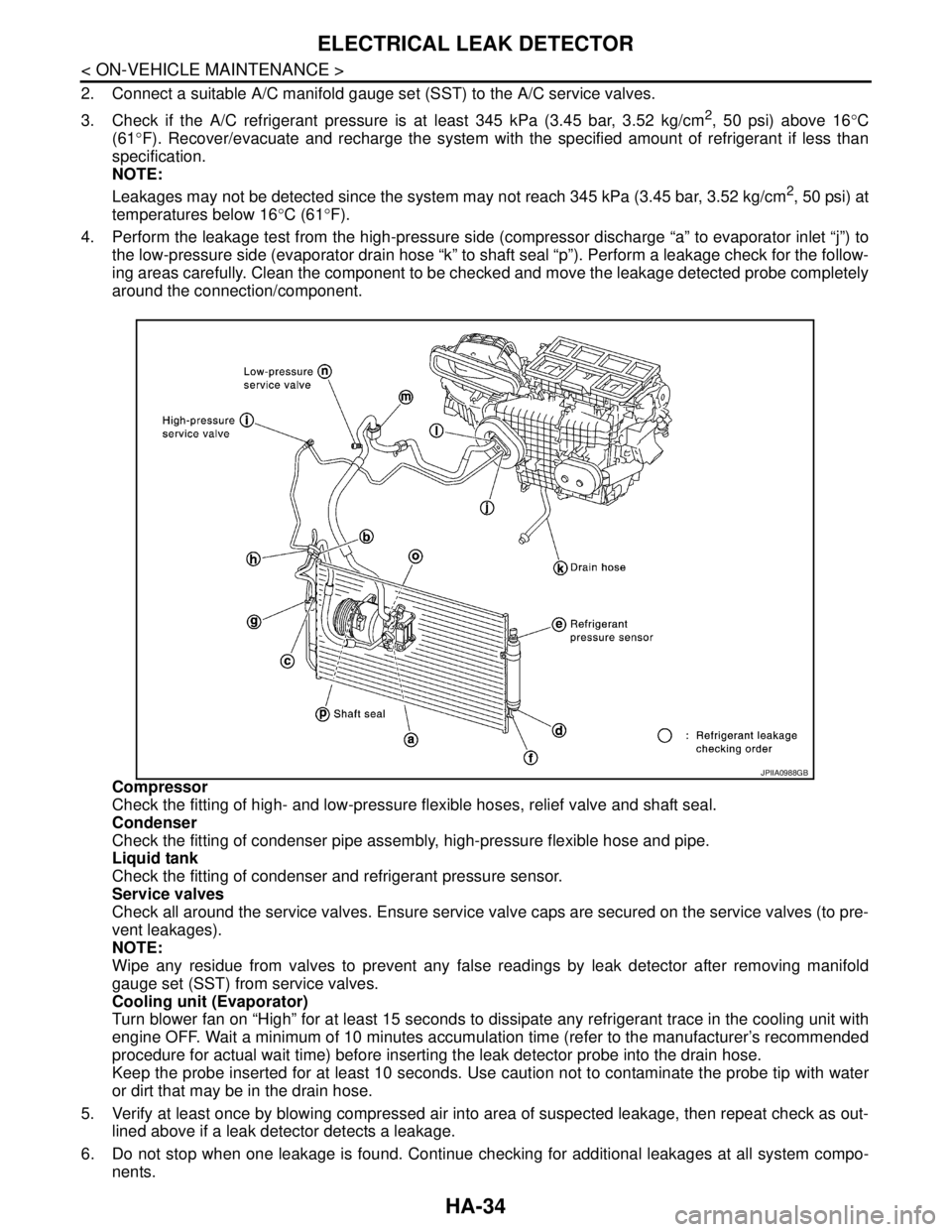

4. Perform the leakage test from the high-pressure side (compressor discharge “a” to evaporator inlet “j”) to

the low-pressure side (evaporator drain hose “k” to shaft seal “p”). Perform a leakage check for the follow-

ing areas carefully. Clean the component to be checked and move the leakage detected probe completely

around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Condenser

Check the fitting of condenser pipe assembly, high-pressure flexible hose and pipe.

Liquid tank

Check the fitting of condenser and refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leakages).

NOTE:

Wipe any residue from valves to prevent any false readings by leak detector after removing manifold

gauge set (SST) from service valves.

Cooling unit (Evaporator)

Turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the cooling unit with

engine OFF. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. Verify at least once by blowing compressed air into area of suspected leakage, then repeat check as out-

lined above if a leak detector detects a leakage.

6. Do not stop when one leakage is found. Continue checking for additional leakages at all system compo-

nents.

JPIIA0988GB