Ccu NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3985 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-121

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000 NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-121

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000](/img/5/57391/w960_57391-3984.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-121

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000003940140

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any of

the customer's comments; refer to SE-125, "

Diagnostic Worksheet". This information is necessary to duplicate

the conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick – (Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz – (Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that a technician

may judge as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Page 3986 of 5121

![NISSAN TEANA 2008 Service Manual SE-122

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional informati NISSAN TEANA 2008 Service Manual SE-122

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional informati](/img/5/57391/w960_57391-3985.png)

SE-122

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that is are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that is are suspected to be the cause of the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration by hand by touching the component(s) that is are suspected to be the cause of the

noise.

Placing a piece of paper between components that is are suspected to be the cause of the noise.

Looking for loose components and contact marks.

Refer to SE-123, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. These insulators are available through the authorized Nissan Parts Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

URETHANE PADS

Insulates connectors, harness, etc.

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

INSULATOR (Light foam block)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

The following materials, not available through NISSAN Parts Department, can also be used to repair

squeaks and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is be visible or does not fit.

Note: Will only last a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

Page 3987 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-123

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Op NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-123

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Op](/img/5/57391/w960_57391-3986.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-123

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003940141

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 3988 of 5121

![NISSAN TEANA 2008 Service Manual SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of thes NISSAN TEANA 2008 Service Manual SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of thes](/img/5/57391/w960_57391-3987.png)

SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 4015 of 5121

![NISSAN TEANA 2008 Service Manual SEC-6

< BASIC INSPECTION >[INTELLIGENT KEY SYSTEM]

DIAGNOSIS AND REPAIR WORKFLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the e NISSAN TEANA 2008 Service Manual SEC-6

< BASIC INSPECTION >[INTELLIGENT KEY SYSTEM]

DIAGNOSIS AND REPAIR WORKFLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the e](/img/5/57391/w960_57391-4014.png)

SEC-6

< BASIC INSPECTION >[INTELLIGENT KEY SYSTEM]

DIAGNOSIS AND REPAIR WORKFLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred).

>> GO TO 2.

2.CHECK DTC

1. Check DTC for BCM and IPDM E/R.

2. Perform the following procedure if DTC is detected.

- Record DTC and freeze frame data (Print them out with CONSULT-III.)

- Erase DTC.

- Study the relationship between the cause detected by DTC and the symptom described by the customer.

3. Check related service bulletins for information.

Are any symptoms described and any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

3.CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONITOR” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

4.CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONITOR ” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure for the detected DTC, and then check that DTC is detected again.

At this time, always connect CONSULT-III to the vehicle, and check diagnostic results in real time.

If two or more DTCs are detected, refer to SEC-175, "

DTCInspectionPriorityChart", and determine trouble

diagnosis order.

NOTE:

Perform Component Function Check if DTC Confirmation Procedure is not included in Service Manual. This

simplified check procedure is an effective alternative though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC Confirmation

Procedure.

Is DTC detected?

YES >> GO TO 7.

NO >> Refer to GI-35, "

Intermittent Incident".

6.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM TABLE

Detect malfunctioning system according to SEC-192, "

Symptom Table" based on the confirmed symptom in

step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 7.

7.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure described is based on open circuit inspection. A short circuit inspection is also

required for the circuit check in the Diagnostic Procedure.

Page 4215 of 5121

SR-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SR

A

B

SR

N

O P

CONTENTS

SRS AIRBAG

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Service ......................................................................2

Occupant Classification System ..............................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

ON-VEHICLE REPAIR ..................................6

DRIVER AIR BAG MODULE .......................... .....6

Exploded View .................................................... ......6

Removal and Installation ...........................................6

SPIRAL CABLE ..................................................9

Exploded View .................................................... ......9

Removal and Installation ...........................................9

FRONT PASSENGER AIR BAG MODULE .......12

Exploded View .................................................... ....12

Removal and Installation ..................................... ....12

SIDE CURTAIN AIR BAG MODULE ................14

Exploded View .........................................................14

Removal and Installation .........................................14

FRONT SIDE AIR BAG MODULE ....................16

Exploded View .........................................................16

Removal and Installation .........................................16

CRASH ZONE SENSOR ...................................18

Exploded View ..................................................... ....18

Removal and Installation .........................................18

SIDE AIR BAG (SATELLITE) SENSOR ...........20

Exploded View .........................................................20

Removal and Installation .........................................20

DIAGNOSIS SENSOR UNIT .............................22

Exploded View .........................................................22

Removal and Installation .........................................22

FRONT SEAT BELT PRE-TENSIONER ...........24

Removal and Installation .........................................24

DISPOSAL OF AIR BAG MODULE AND

SEAT BELT PRE-TENSIONER ........................

25

Caution for Air Bag Module and Seat Belt Pre-ten-

sioner .......................................................................

25

Page 4217 of 5121

PRECAUTIONS

SR-3

< PRECAUTION >

C

D

E

F

G

I

J

K

L

MA

B

SR

N

O

P

Diagnosis sensor unit must always be installed with their arrow marks “⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned in the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side

facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper functioning after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Occupant Classification SystemINFOID:0000000003751422

Replace occupant classification system control unit and passenger front seat cushion as an assembly.

With VENTILATION SEAT: Refer to SE-89, "

Exploded View".

Without VENTILATION SEAT: Refer to SE-130, "

Exploded View".

Page 4253 of 5121

SRC-10

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (AIRBAG)

DIAGNOSIS SYSTEM (AIRBAG)

Diagnosis DescriptionINFOID:0000000003813934

CAUTION:

• Never use electrical test equipment on any circuit related to the SRS unless instructed in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Never repair, splice or modify the SRS wiring harness. If the harness is damaged, replace it with a

new one.

Keep ground portion clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using air bag warning lamp and/or CONSULT-III.

The user mode is exclusively prepared for the customer (driver). This mode warns the driver of a system

malfunction through the operation of the air bag warning lamp.

The diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the air bag warning lamp and CONSULT-III are as follows.

HOW TO PERFORM TROUBLE DIAGNOSIS FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information from Customer.

WHAT..... Vehicle model.

WHEN..... Date, Frequency.

WHERE..... Road conditions.

HOW..... Operating conditions, Symptoms.

Preliminary Check.

Check that the following parts are in good order.

Battery (Refer to PG-3, "

How to Handle Battery").

Fuse (Refer to PG-82, "

Fuse").

System component-to-harness connections.

Air Bag Warning Lamp DiagnosisINFOID:0000000003843289

SELF-DIAGNOSIS FUNCTION

The reading of these results is accomplished by “User mode” and “Diagnosis mode”.

After a malfunction is repaired, turn ignition switch ON. Diagnosis mode returns to the User mode. At that

time, the self-diagnosis result is cleared.

User mode Diagnosis mode Display type

Air bag warning lamp X X ON-OFF operation

CONSULT-III – X Monitoring

Page 4295 of 5121

SRC-52

< COMPONENT DIAGNOSIS >

B1081 PRE-TEN FRONT RH

B1081 PRE-TEN FRONT RH

DescriptionINFOID:0000000003813987

For front RH seat belt pre-tensioner, crash is judged by main “G” sensor output signal and safing algorithm in

front direction.

OPERATION

In the case of a frontal collision that exceeds specified impact level, the air bag diagnosis sensor unit detects

the deceleration caused by collision. It restrains the passenger with seat belt easing the stress on passengers

chest with load limiter.

STRUCTURE

The restraint system for front seat occupant consists of the pre-tensioner mechanism and load limiter mecha-

nism.

INSTALLATION

Front RH seat belt pre-tensioner is installed on the underside of center pillar with fixed nuts.

DTC LogicINFOID:0000000003813988

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “AIR BAG” Self Diagnostic Result.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-10, "

Air Bag Warning Lamp Diagnosis".

NOTE:

SRS does not enter Diagnosis mode if no malfunction is detected in User mode.

Is malfunctioning part detected?

YES >> Refer to SRC-52, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003813989

WARNING:

Before servicing, turn ignition switch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B1081 PRE-TEN FRONT RH

[OPEN]Front RH seat belt pre-tensioner circuit

is open Disconnection of wiring harness and

open

Malfunction in front RH seat belt pre-

tensioner

Malfunction in air bag diagnosis sen-

sor unit

Page 4297 of 5121

SRC-54

< COMPONENT DIAGNOSIS >

B1082 PRE-TEN FRONT RH

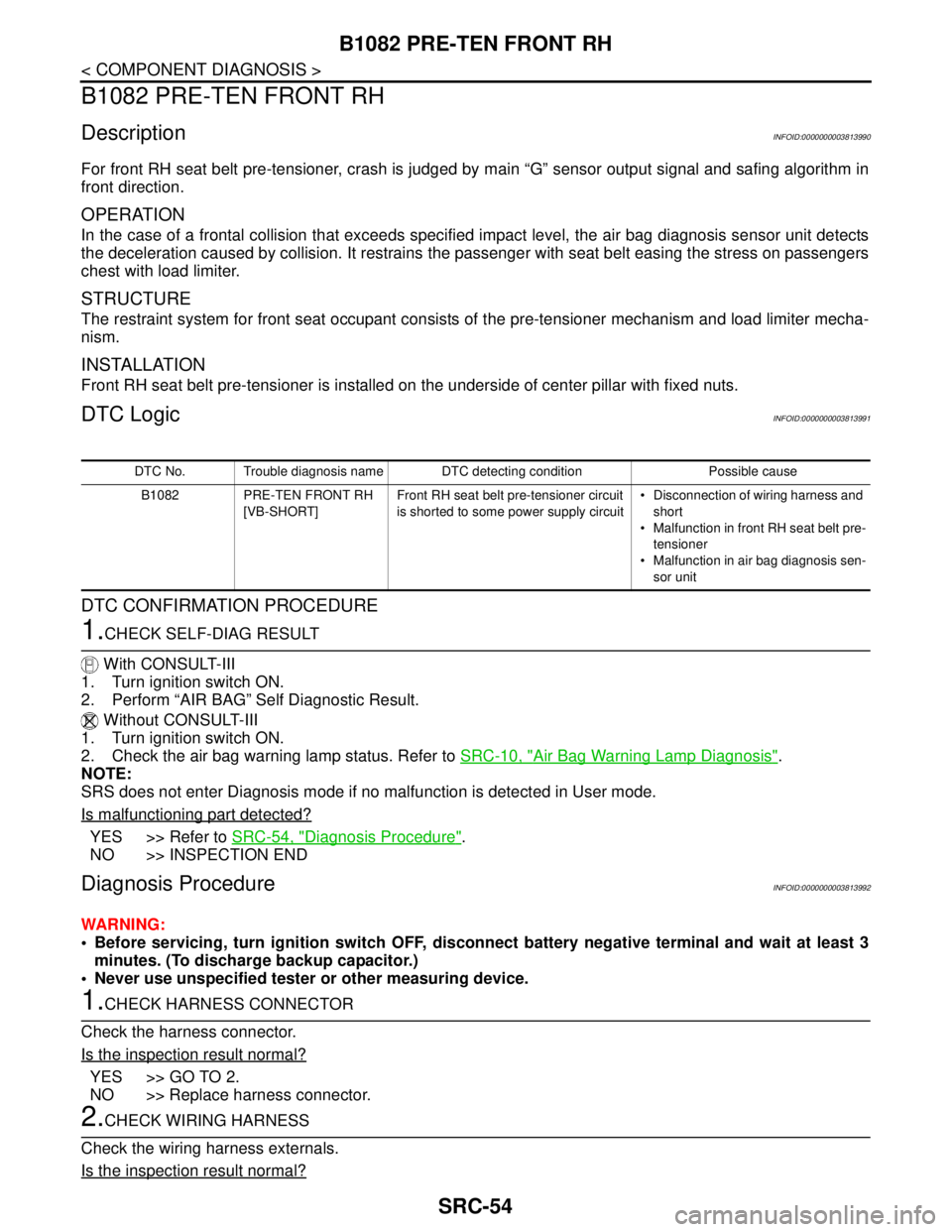

B1082 PRE-TEN FRONT RH

DescriptionINFOID:0000000003813990

For front RH seat belt pre-tensioner, crash is judged by main “G” sensor output signal and safing algorithm in

front direction.

OPERATION

In the case of a frontal collision that exceeds specified impact level, the air bag diagnosis sensor unit detects

the deceleration caused by collision. It restrains the passenger with seat belt easing the stress on passengers

chest with load limiter.

STRUCTURE

The restraint system for front seat occupant consists of the pre-tensioner mechanism and load limiter mecha-

nism.

INSTALLATION

Front RH seat belt pre-tensioner is installed on the underside of center pillar with fixed nuts.

DTC LogicINFOID:0000000003813991

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “AIR BAG” Self Diagnostic Result.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-10, "

Air Bag Warning Lamp Diagnosis".

NOTE:

SRS does not enter Diagnosis mode if no malfunction is detected in User mode.

Is malfunctioning part detected?

YES >> Refer to SRC-54, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003813992

WARNING:

Before servicing, turn ignition switch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B1082 PRE-TEN FRONT RH

[VB-SHORT]Front RH seat belt pre-tensioner circuit

is shorted to some power supply circuit Disconnection of wiring harness and

short

Malfunction in front RH seat belt pre-

tensioner

Malfunction in air bag diagnosis sen-

sor unit