torque NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 932 of 5121

BR-36

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers, and then disconnect brake hose from caliper assembly. Refer to

BR-19, "

FRONT : Exploded View".

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-19, "

FRONT : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check a drag of front disc brake. If any drag is found, refer to BR-38, "

BRAKE CALIPER ASSEMBLY :

Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811209

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts, and remove the cylinder body from the torque member.

CAUTION:

Never drop brake pads, shims, shim cover and pad retainers from torque member.

2. Remove brake pads, shims and shim cover. Refer to BR-33, "

BRAKE PAD : Exploded View".

3. Remove sliding pins and sliding pin boots from torque member.

4. Remove bushing from sliding pin.

Page 934 of 5121

BR-38

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

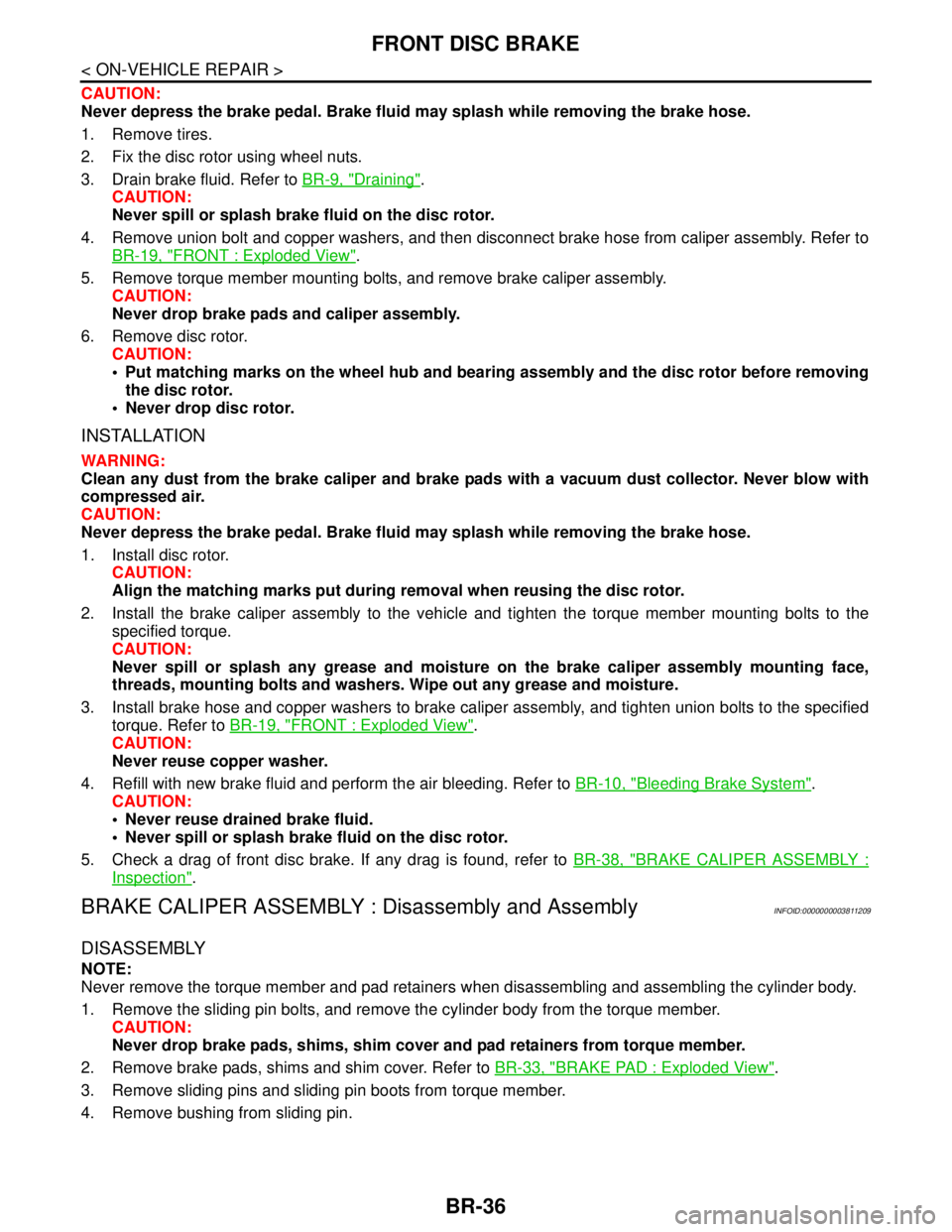

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston-side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin.

6. Apply rubber grease to sliding pins and sliding pin boots, install

sliding pins and sliding pin boots to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811210

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace if necessary.

Piston

Check the surface of the piston for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check the sliding pins, sliding boot and bushing for rust, wear, cracks or damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0034ZZ

Page 935 of 5121

REAR DISC BRAKE

BR-39

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Exploded ViewINFOID:0000000003811211

BRAKE PAD : Removal and InstallationINFOID:0000000003811212

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Remove tires.

2. Remove the upper sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Remove the brake

pads and shims from the torque member.

CAUTION:

Never deform the pad retainers if removing the pad retainers.

Never damage the piston boot.

Never drop the brake pad and shims.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

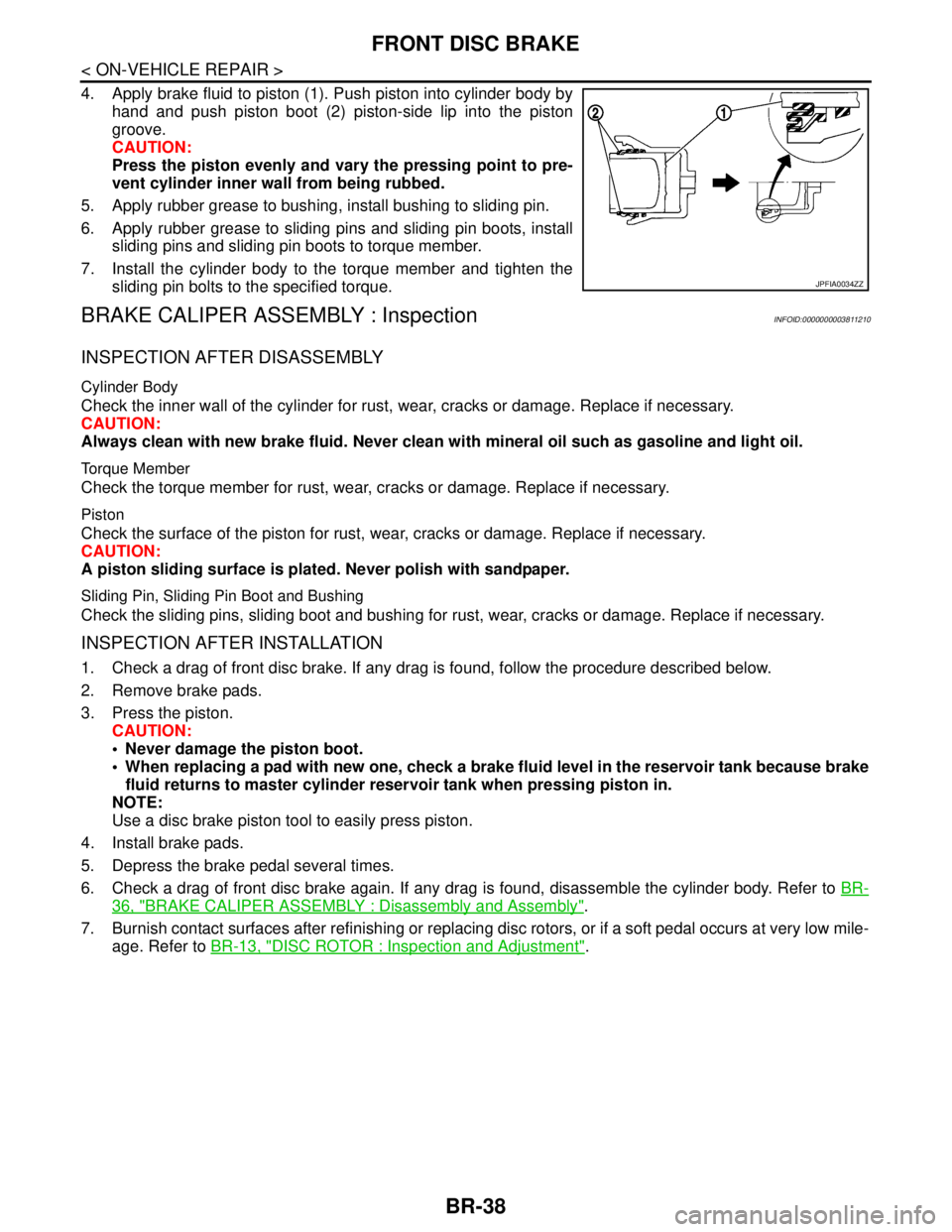

1. Sliding pin bolt 2. Cylinder body 3. Inner shim

4. Inner pad (only RH side with pad

wear sensor)5. Pad retainer 6. Torque member

7. Outer pad 8. Outer shim

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0354GB

Page 936 of 5121

BR-40

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Install the pad retainers to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers not to be lifted up from the torque member.

Never deform the pad retainers.

2. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, the shims and pawls part of cylinder body, and install them to the brake pad.

CAUTION:

Always replace the shims together when replacing the brake pad.

3. Install cylinder body and brake pads to torque member.

CAUTION:

Never damage the piston boot.

When replacing pads with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install the upper sliding pin bolt and tighten it to the specified torque.

5. Depress the brake pedal several times to check that no drag feel is present for the rear disc brake. Refer

to BR-40, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811213

INSPECTION AFTER REMOVAL

Replace the shims if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811214

REMOVAL

Page 937 of 5121

REAR DISC BRAKE

BR-41

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

DISASSEMBLY

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000003811215

REMOVAL

WARNING:

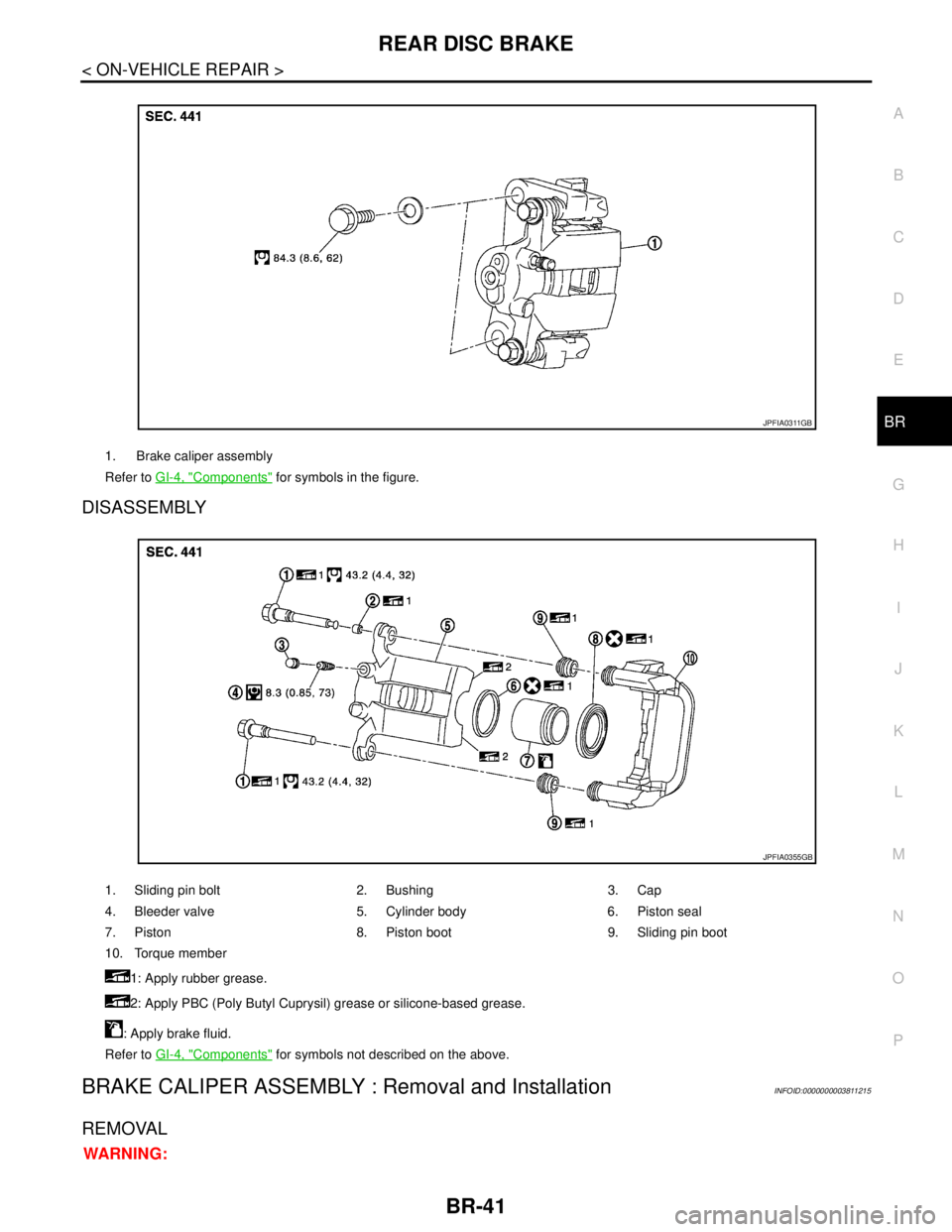

1. Brake caliper assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0311GB

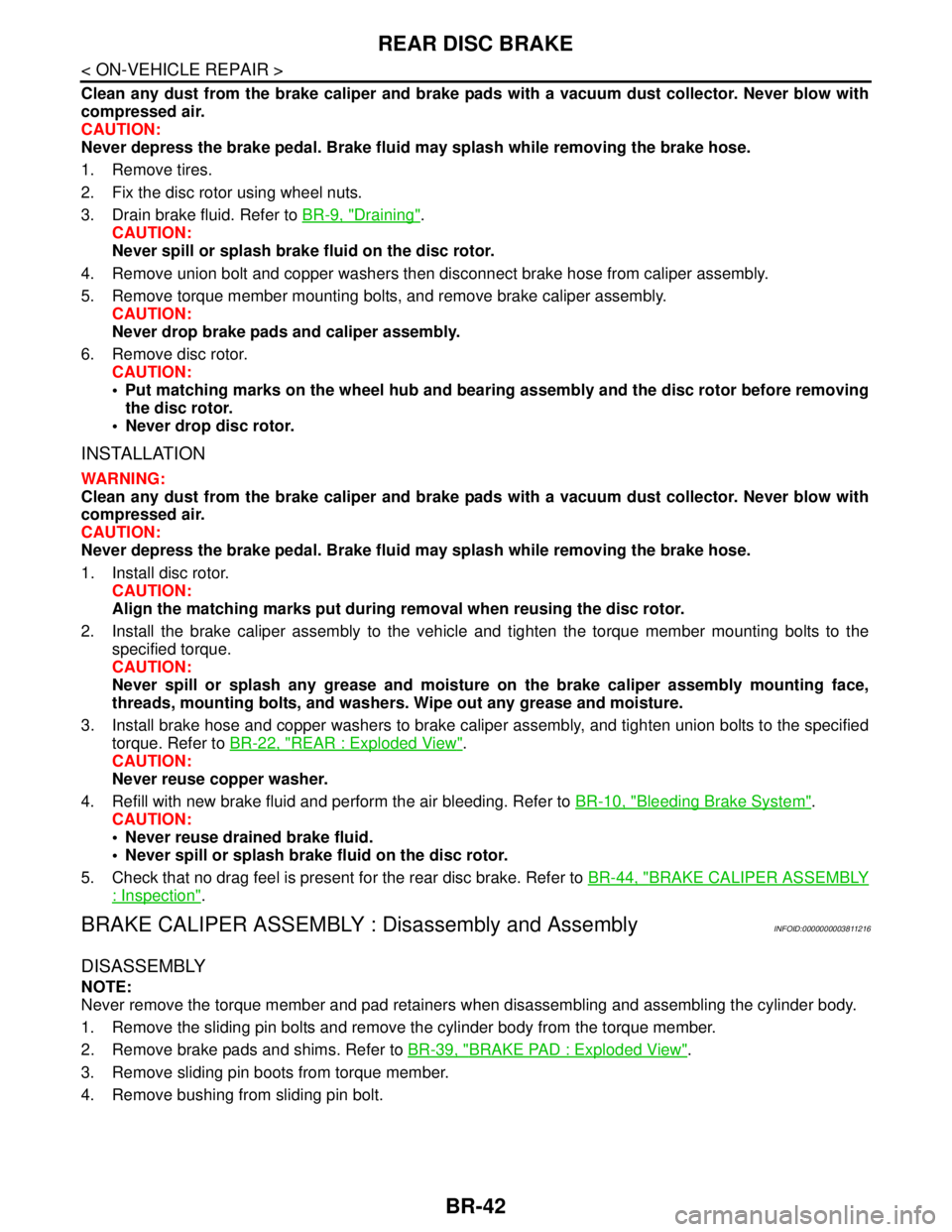

1. Sliding pin bolt 2. Bushing 3. Cap

4. Bleeder valve 5. Cylinder body 6. Piston seal

7. Piston 8. Piston boot 9. Sliding pin boot

10. Torque member

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0355GB

Page 938 of 5121

BR-42

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers then disconnect brake hose from caliper assembly.

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts, and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-22, "

REAR : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check that no drag feel is present for the rear disc brake. Refer to BR-44, "

BRAKE CALIPER ASSEMBLY

: Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811216

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts and remove the cylinder body from the torque member.

2. Remove brake pads and shims. Refer to BR-39, "

BRAKE PAD : Exploded View".

3. Remove sliding pin boots from torque member.

4. Remove bushing from sliding pin bolt.

Page 940 of 5121

BR-44

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

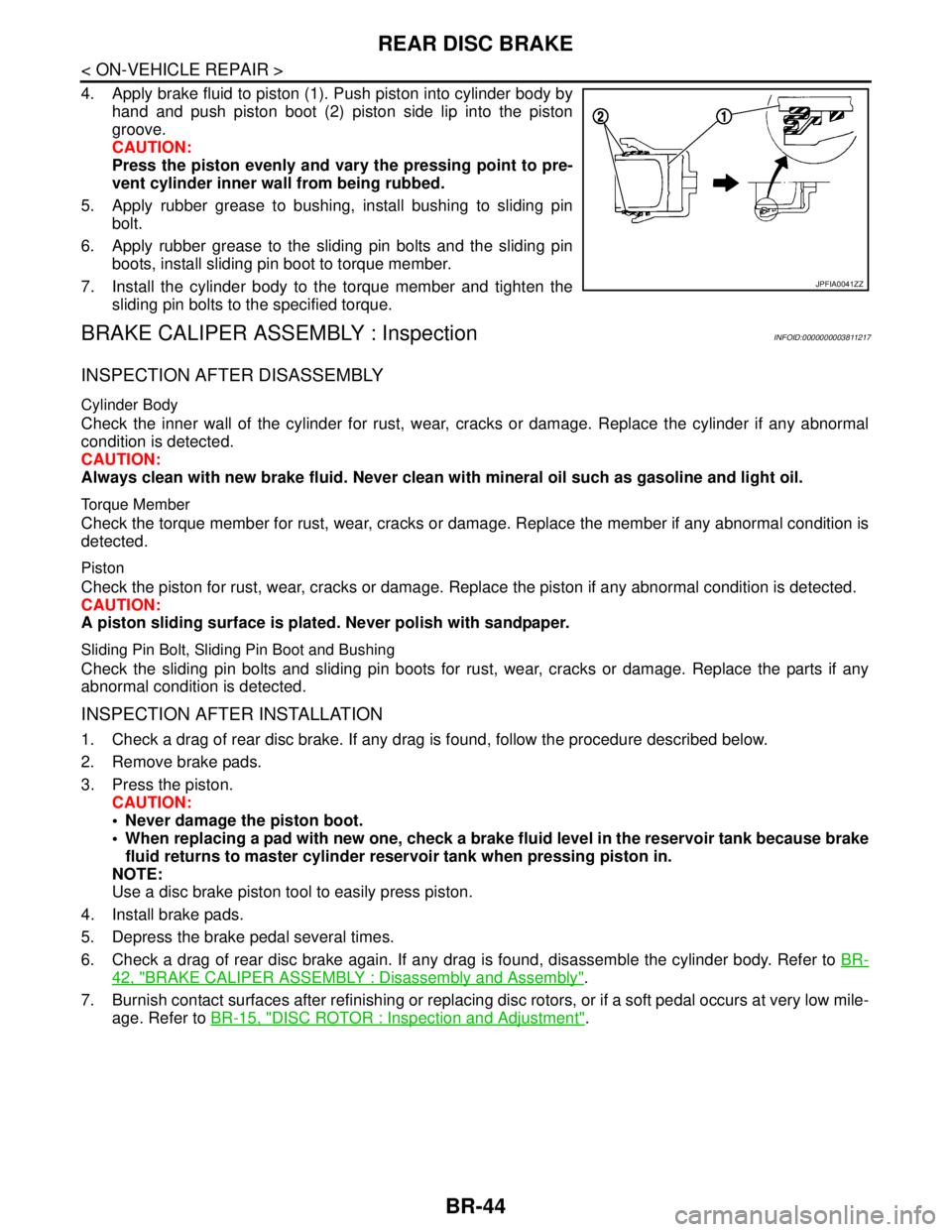

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin

bolt.

6. Apply rubber grease to the sliding pin bolts and the sliding pin

boots, install sliding pin boot to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811217

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace the cylinder if any abnormal

condition is detected.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the member if any abnormal condition is

detected.

Piston

Check the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin Bolt, Sliding Pin Boot and Bushing

Check the sliding pin bolts and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any

abnormal condition is detected.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0041ZZ

Page 996 of 5121

![NISSAN TEANA 2008 User Guide PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000 NISSAN TEANA 2008 User Guide PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000](/img/5/57391/w960_57391-995.png)

PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003893848

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000003928740

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003766860

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

Only use “DOT 3” or “DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Never use mineral oils such as gasoline or light oil. They may damage rubber parts and cause improper

operation.

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a flare

nut torque wrench (A).

Always conform the specified tightening torque when installing the

brake pipes.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) connector or the battery negative terminal

before performing the work.

PIIB3706J

JPFIA0061ZZ

Page 998 of 5121

![NISSAN TEANA 2008 User Guide WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The ab NISSAN TEANA 2008 User Guide WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The ab](/img/5/57391/w960_57391-997.png)

WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The above figure shows left side. Right side is the mirror image.

FRONT WHEEL SENSOR : Removal and InstallationINFOID:0000000003766866

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting

hole of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove

any foreign material and clean the mount.

1. Front LH wheel sensor 2. Front LH wheel sensor connector

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0221GB

Page 999 of 5121

![NISSAN TEANA 2008 User Guide BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness wi NISSAN TEANA 2008 User Guide BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness wi](/img/5/57391/w960_57391-998.png)

BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness will not be twisted. Install grommet groove onto

bracket with orange line on the harness facing bracket opening (mounting hole). There should be no

twists in the harness when installed.

REAR WHEEL SENSOR

REAR WHEEL SENSOR : Exploded ViewINFOID:0000000003766867

NOTE:

The above figure shows left side. Right side is the mirror image.

REAR WHEEL SENSOR : Removal and InstallationINFOID:0000000003766868

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-58, "

REAR WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole

of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any

foreign material and clean the mount.

1. Rear LH wheel sensor connector 2. Rear LH wheel sensor

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0222GB