torque NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 901 of 5121

PRECAUTIONS

BR-5

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003890162

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003811170

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

Only use “DOT 3 or DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

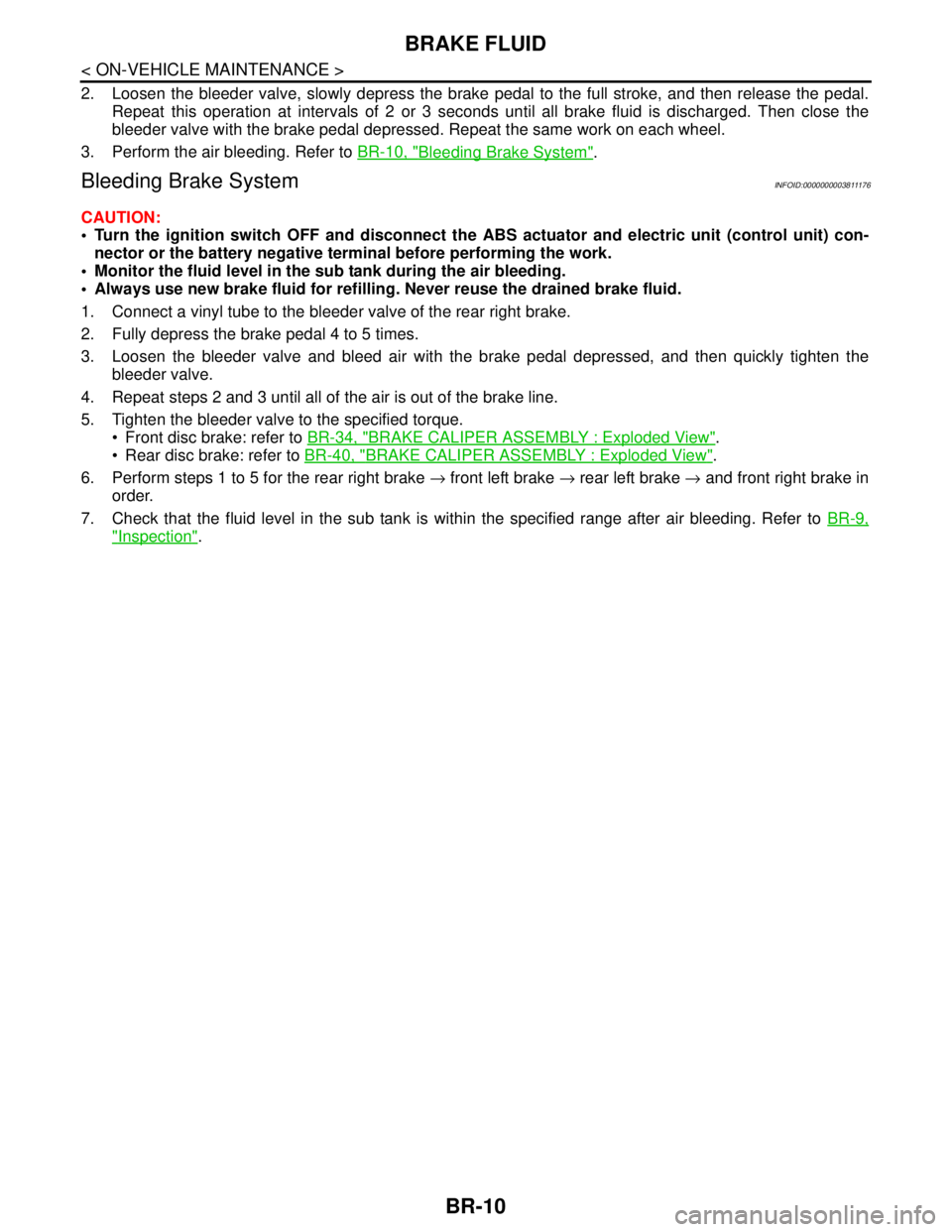

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with

torque wrench (A).

Always confirm the specified tightening torque when install-

ing the brake pipes.

Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

Check that no brake fluid leakage is present after replacing

the parts.

Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

- Front brake pad: refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0061ZZ

Page 906 of 5121

BR-10

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

2. Loosen the bleeder valve, slowly depress the brake pedal to the full stroke, and then release the pedal.

Repeat this operation at intervals of 2 or 3 seconds until all brake fluid is discharged. Then close the

bleeder valve with the brake pedal depressed. Repeat the same work on each wheel.

3. Perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000003811176

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before performing the work.

Monitor the fluid level in the sub tank during the air bleeding.

Always use new brake fluid for refilling. Never reuse the drained brake fluid.

1. Connect a vinyl tube to the bleeder valve of the rear right brake.

2. Fully depress the brake pedal 4 to 5 times.

3. Loosen the bleeder valve and bleed air with the brake pedal depressed, and then quickly tighten the

bleeder valve.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleeder valve to the specified torque.

Front disc brake: refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

Rear disc brake: refer to BR-40, "

BRAKE CALIPER ASSEMBLY : Exploded View".

6. Perform steps 1 to 5 for the rear right brake → front left brake → rear left brake → and front right brake in

order.

7. Check that the fluid level in the sub tank is within the specified range after air bleeding. Refer to BR-9,

"Inspection".

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ

Page 920 of 5121

BR-24

< ON-VEHICLE REPAIR >

BRAKE PIPING

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

Page 922 of 5121

BR-26

< ON-VEHICLE REPAIR >

BRAKE MASTER CYLINDER

The piston may drop off when pulled out strongly. Never hold the piston. Hold the cylinder body

when handling the master cylinder assembly.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Note the following, and install the reverse order of removal.

Never depress the brake pedal after the master cylinder assembly is removed.

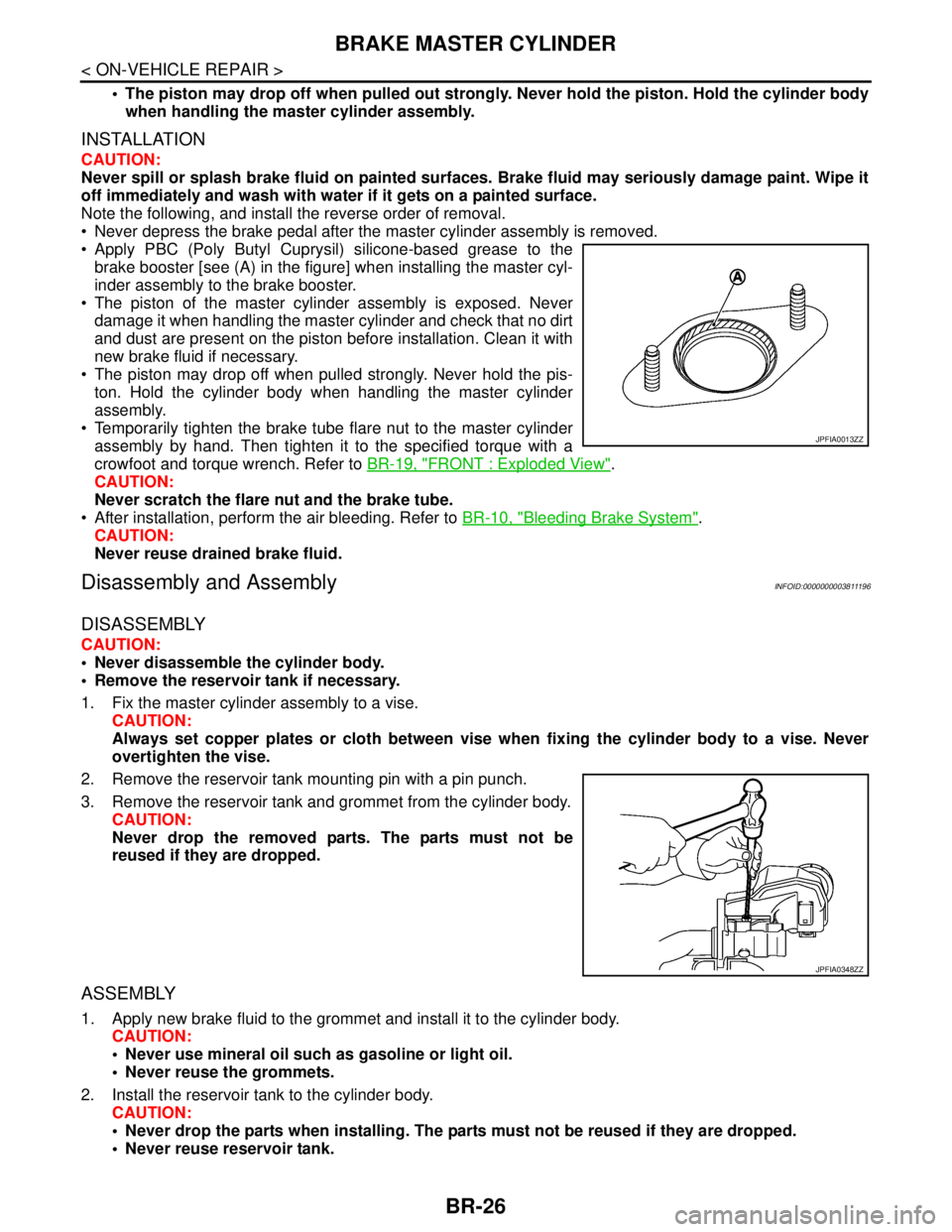

Apply PBC (Poly Butyl Cuprysil) silicone-based grease to the

brake booster [see (A) in the figure] when installing the master cyl-

inder assembly to the brake booster.

The piston of the master cylinder assembly is exposed. Never

damage it when handling the master cylinder and check that no dirt

and dust are present on the piston before installation. Clean it with

new brake fluid if necessary.

The piston may drop off when pulled strongly. Never hold the pis-

ton. Hold the cylinder body when handling the master cylinder

assembly.

Temporarily tighten the brake tube flare nut to the master cylinder

assembly by hand. Then tighten it to the specified torque with a

crowfoot and torque wrench. Refer to BR-19, "

FRONT : Exploded View".

CAUTION:

Never scratch the flare nut and the brake tube.

After installation, perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Disassembly and AssemblyINFOID:0000000003811196

DISASSEMBLY

CAUTION:

Never disassemble the cylinder body.

Remove the reservoir tank if necessary.

1. Fix the master cylinder assembly to a vise.

CAUTION:

Always set copper plates or cloth between vise when fixing the cylinder body to a vise. Never

overtighten the vise.

2. Remove the reservoir tank mounting pin with a pin punch.

3. Remove the reservoir tank and grommet from the cylinder body.

CAUTION:

Never drop the removed parts. The parts must not be

reused if they are dropped.

ASSEMBLY

1. Apply new brake fluid to the grommet and install it to the cylinder body.

CAUTION:

Never use mineral oil such as gasoline or light oil.

Never reuse the grommets.

2. Install the reservoir tank to the cylinder body.

CAUTION:

Never drop the parts when installing. The parts must not be reused if they are dropped.

Never reuse reservoir tank.

JPFIA0013ZZ

JPFIA0348ZZ

Page 925 of 5121

BRAKE BOOSTER

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Replace the clevis pin if it is damaged. Refer to BR-18, "Inspection and Adjustment".

After installation, perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Inspection and AdjustmentINFOID:0000000003811200

INSPECTION AFTER REMOVAL

Output Rod Length Inspection

1. With a handy vacuum pump, apply vacuum pressure of −66.7

kPa (−500 mmHg, −19.70 inHg, –0.667 bar) to the brake

booster.

2. Check the output rod length (A).

Input Rod Length Inspection

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (B).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower pane decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

Air Tight

Standard

A: Refer to BR-45, "

Brake Booster".

JPFIA0021ZZ

Standard

B: Refer to BR-45, "

Brake Booster".

JPFIA0020ZZ

BRA0037D

Page 929 of 5121

FRONT DISC BRAKE

BR-33

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

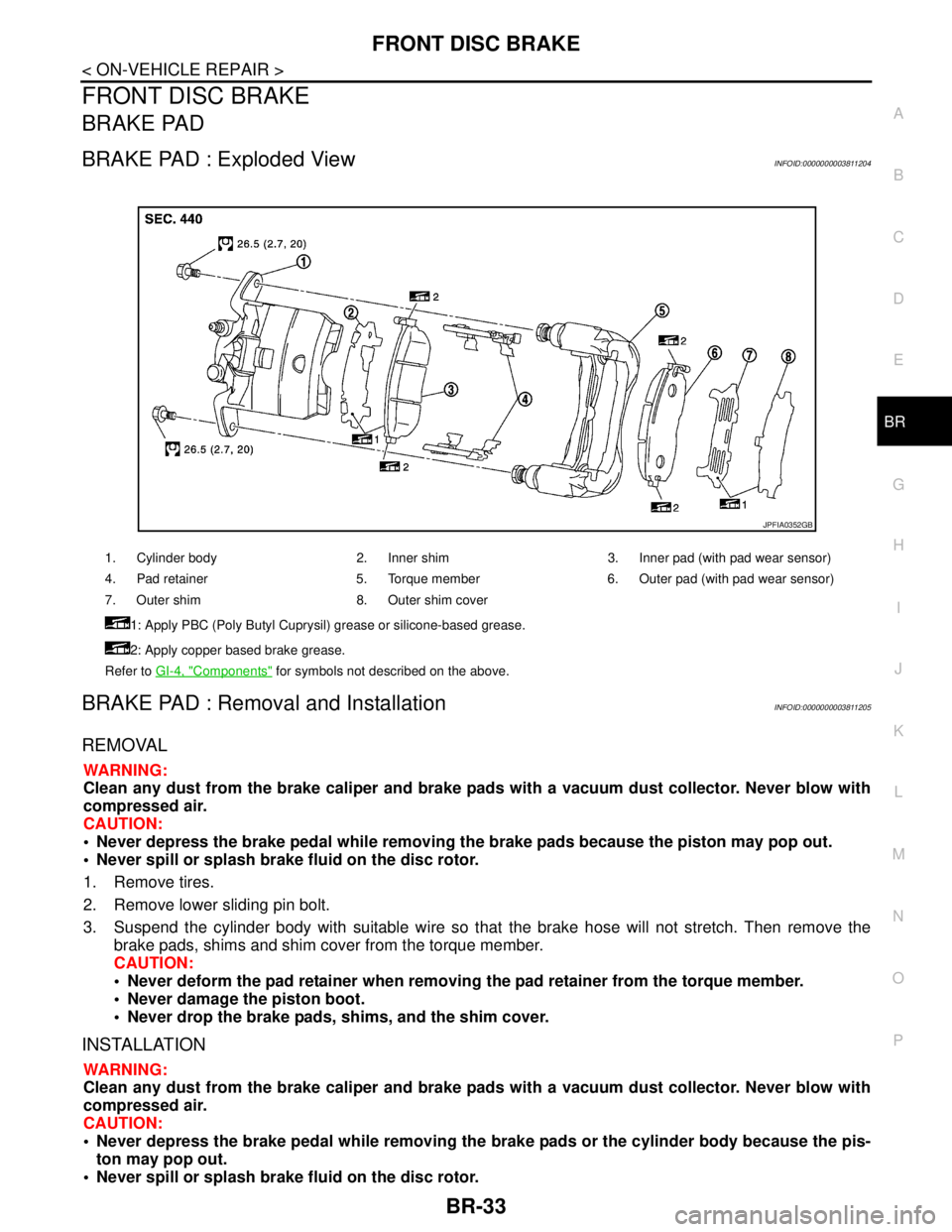

BRAKE PAD : Exploded ViewINFOID:0000000003811204

BRAKE PAD : Removal and InstallationINFOID:0000000003811205

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads because the piston may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Remove tires.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Then remove the

brake pads, shims and shim cover from the torque member.

CAUTION:

Never deform the pad retainer when removing the pad retainer from the torque member.

Never damage the piston boot.

Never drop the brake pads, shims, and the shim cover.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Cylinder body 2. Inner shim 3. Inner pad (with pad wear sensor)

4. Pad retainer 5. Torque member 6. Outer pad (with pad wear sensor)

7. Outer shim 8. Outer shim cover

1: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

2: Apply copper based brake grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0352GB

Page 930 of 5121

BR-34

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

1. Install the pad retainer to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers so that it will not be lifted up from the torque member.

Never deform the pad retainers.

2. Apply copper based brake grease to the mating faces between the brake pads and pad retainers.

3. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, shims and shim cover, and install them to the brake pad.

CAUTION:

Always replace the shims together with the shim cover when replacing the brake pad.

4. Install the cylinder body and brake pads to the torque member.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the lower sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-34, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811206

INSPECTION AFTER REMOVAL

Replace the shims and the shim cover if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

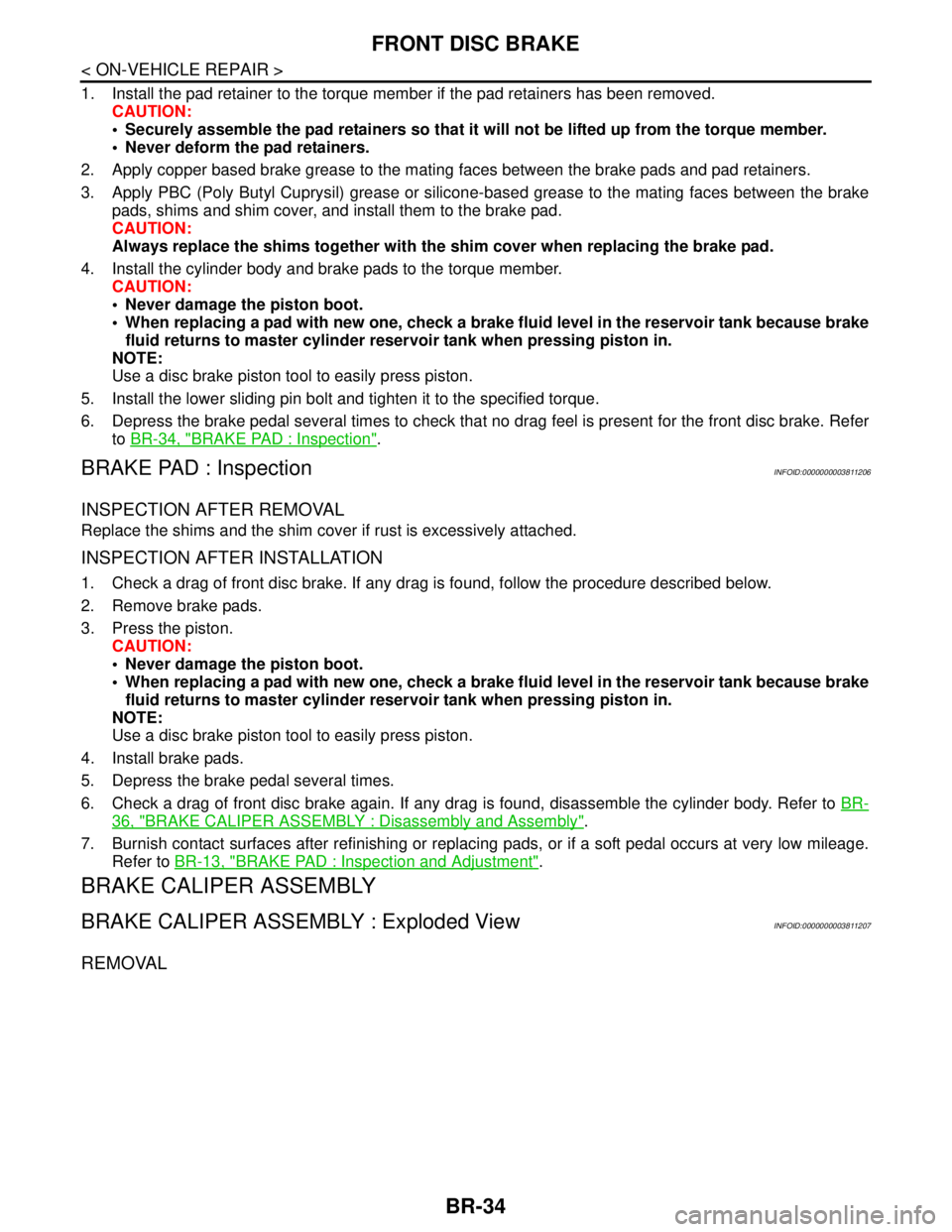

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811207

REMOVAL

Page 931 of 5121

FRONT DISC BRAKE

BR-35

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

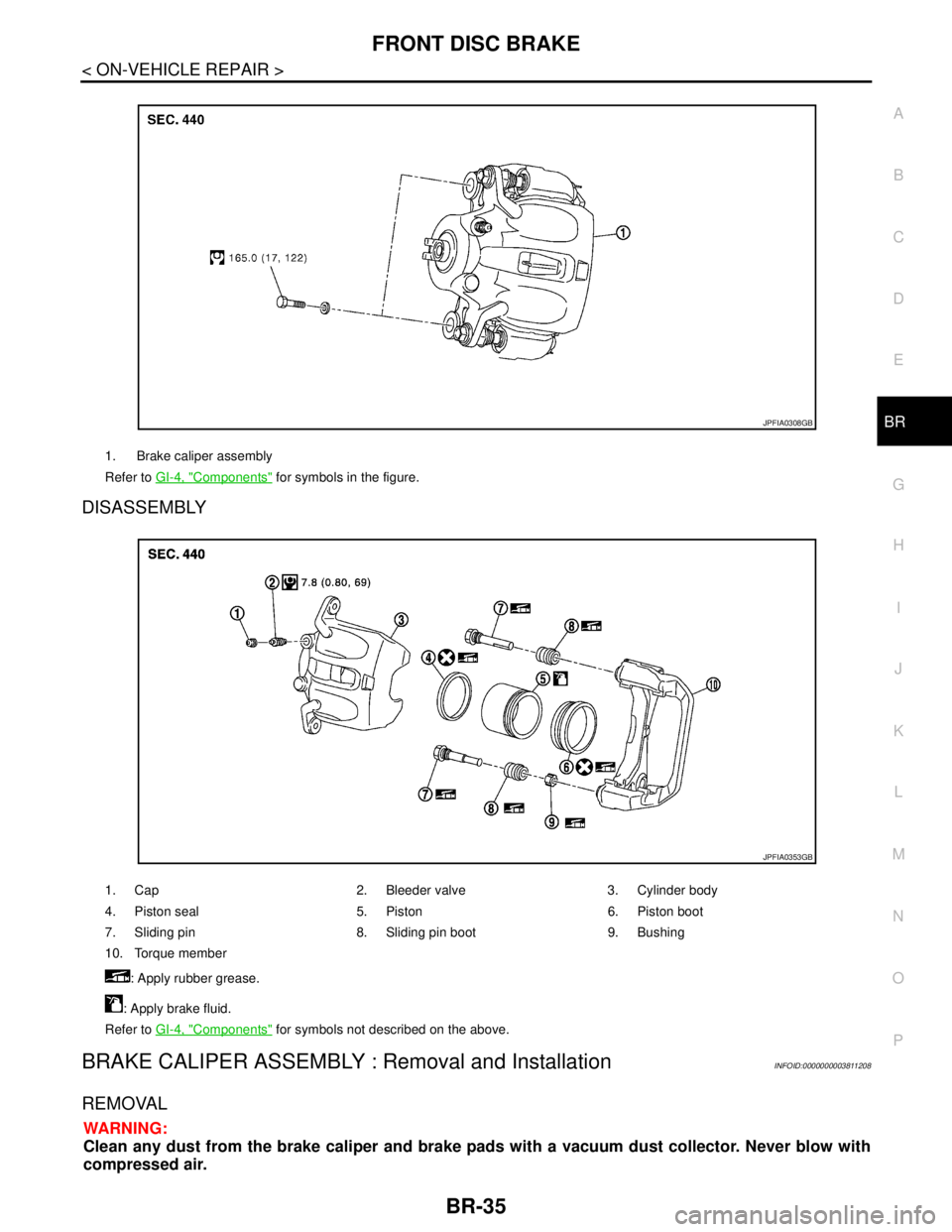

DISASSEMBLY

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000003811208

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

1. Brake caliper assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0308GB

1. Cap 2. Bleeder valve 3. Cylinder body

4. Piston seal 5. Piston 6. Piston boot

7. Sliding pin 8. Sliding pin boot 9. Bushing

10. Torque member

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0353GB