NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3211 of 5121

CHASSIS MAINTENANCE

MA-23

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

CHASSIS MAINTENANCE

HEADLAMP AIMING ADJUSTMENT (XENON TYPE)

HEADLAMP AIMING ADJUSTMENT (XENON TYPE) : DescriptionINFOID:0000000003862420

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

Before performing aiming adjustment, check the following. Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the trunk

room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

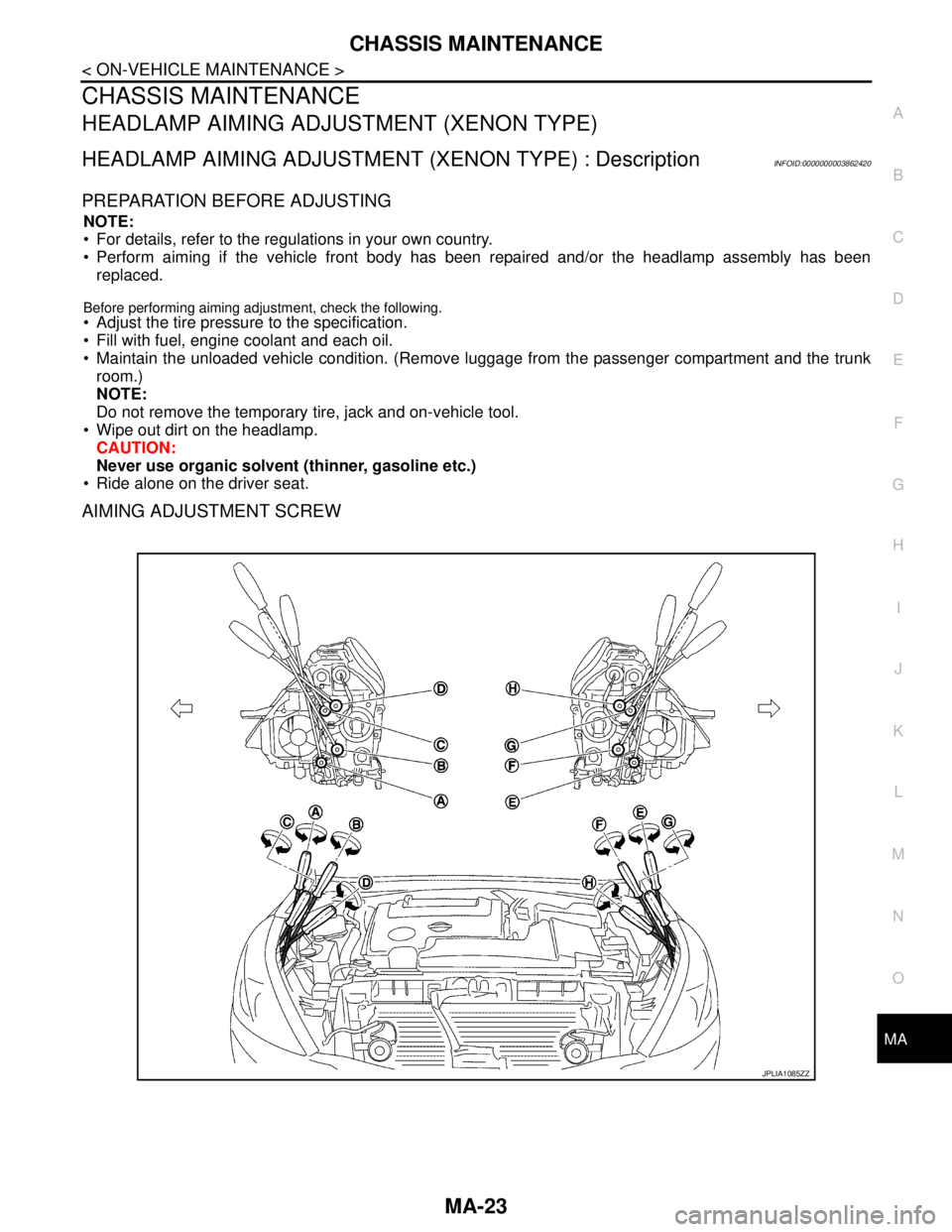

AIMING ADJUSTMENT SCREW

JPLIA1085ZZ

Page 3212 of 5121

MA-24

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

HEADLAMP AIMING ADJUSTMENT (XENON TYPE) : Aiming Adjustment Procedure

(Low Beam)

INFOID:0000000003862421

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and

the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (LO).

NOTE:

Block light from the headlamp that is not being adjusted with a thick fabric or another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so

that it is within the aiming adjustment area.

A. Headlamp (LO) RH

(UP/DOWN) adjustment screwB. Headlamp (HI) RH

(UP/DOWN) adjustment screwC. Headlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screw

D. Headlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screwE. Headlamp (LO) LH

(UP/DOWN) adjustment screwF. Headlamp (HI) LH

(UP/DOWN) adjustment screw

G. H e a d l a m p ( L O ) L H

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screwH. Headlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screw

: Vehicle center

Adjustment screw Screw driver rotation Facing direction

AHeadlamp (LO) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

BHeadlamp (HI) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

CHeadlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

DHeadlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE

EHeadlamp (LO) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

FHeadlamp (HI) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

GHeadlamp (LO) LH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

HHeadlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE

Page 3213 of 5121

CHASSIS MAINTENANCE

MA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

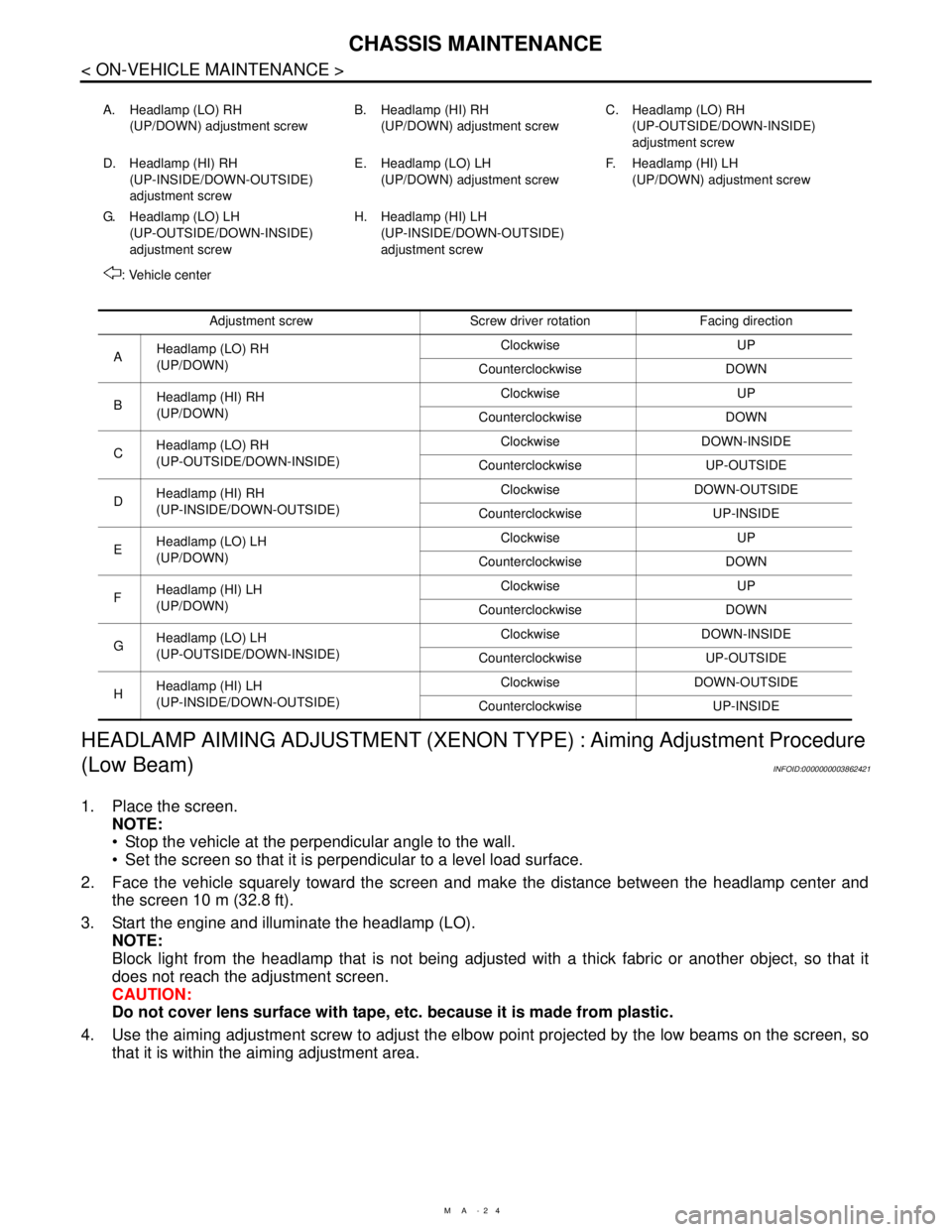

Low beam distribution on the screen

Unit: mm (in)

HEADLAMP AIMING ADJUSTMENT (XENON TYPE) : Aiming Adjustment Procedure

(High Beam)

INFOID:0000000003862422

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

JSLIA0030ZZ

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp H. Horizontal center line of headlamp L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10m (32.8 ft)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 100 (3.94)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 150 (5.91)

JPLIA1062ZZ

Page 3214 of 5121

MA-26

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and

the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (HI).

NOTE:

Block light from the headlamp that is not being adjusted with a thick fabric or another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so

that it is within the aiming adjustment area.

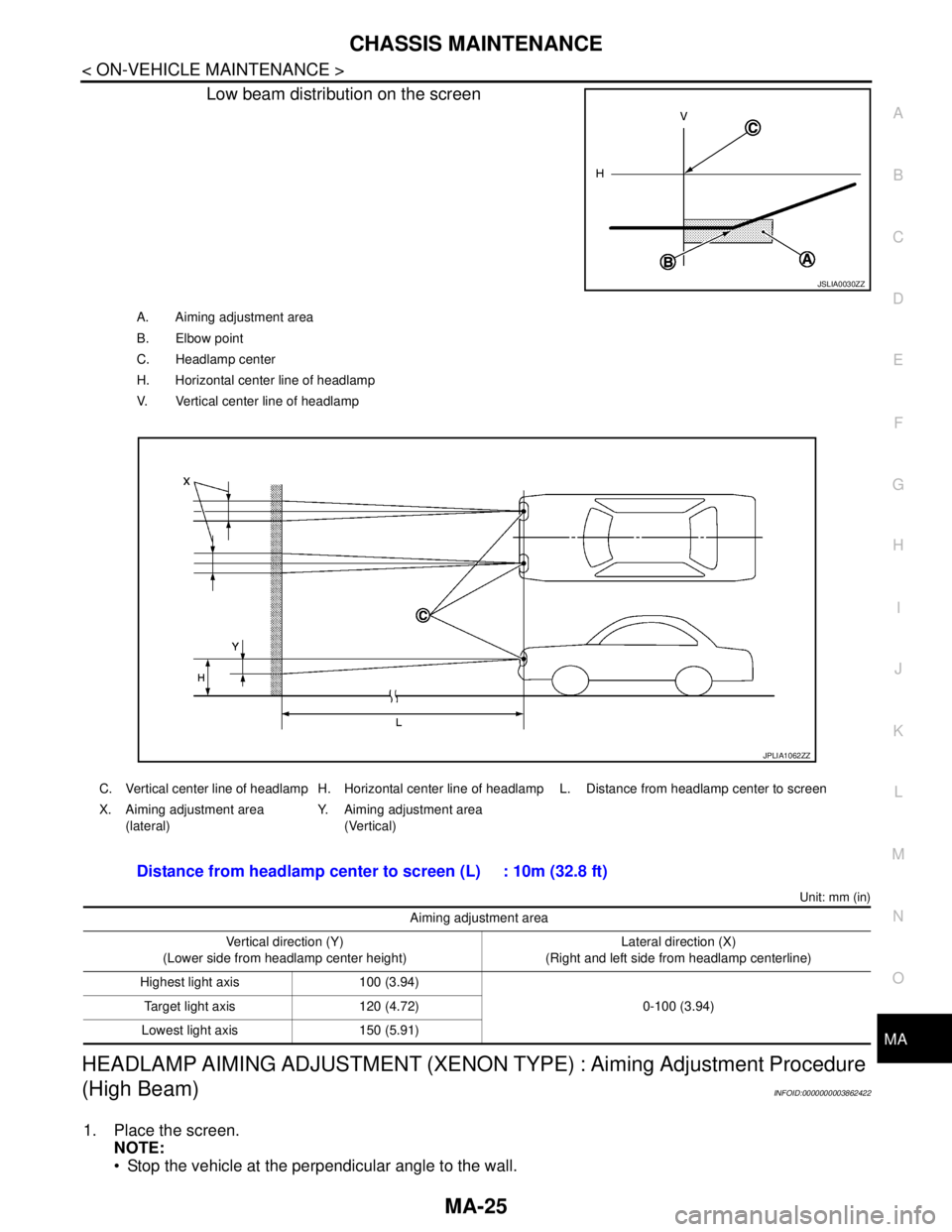

High beam distribution on the screen

JSLIA0030ZZ

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp H. Horizontal center line of headlamp L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10m (32.8 ft)

JPLIA1062ZZ

Page 3215 of 5121

CHASSIS MAINTENANCE

MA-27

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

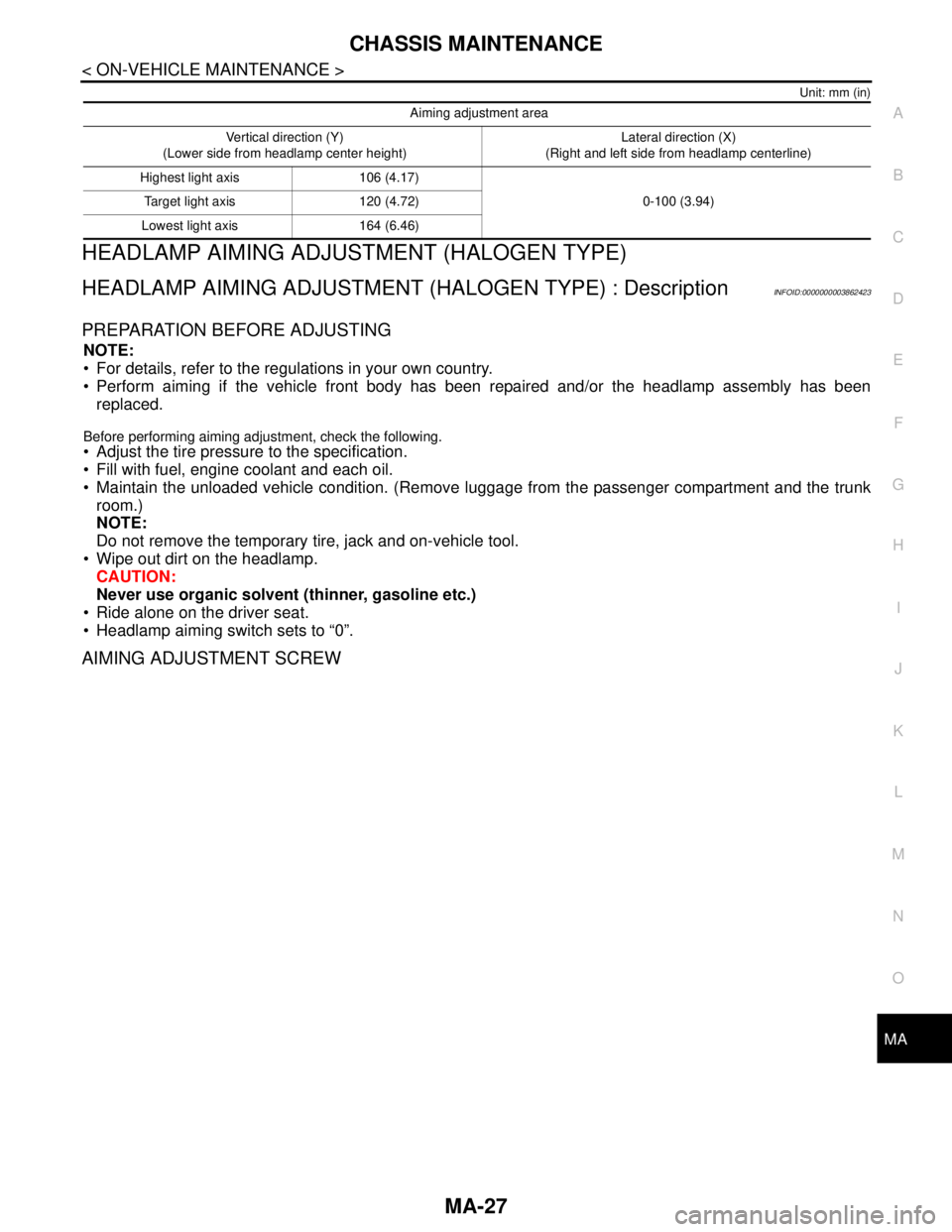

Unit: mm (in)

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE)

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE) : DescriptionINFOID:0000000003862423

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the trunk

room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

Headlamp aiming switch sets to “0”.

AIMING ADJUSTMENT SCREW

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 106 (4.17)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 164 (6.46)

Page 3216 of 5121

MA-28

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

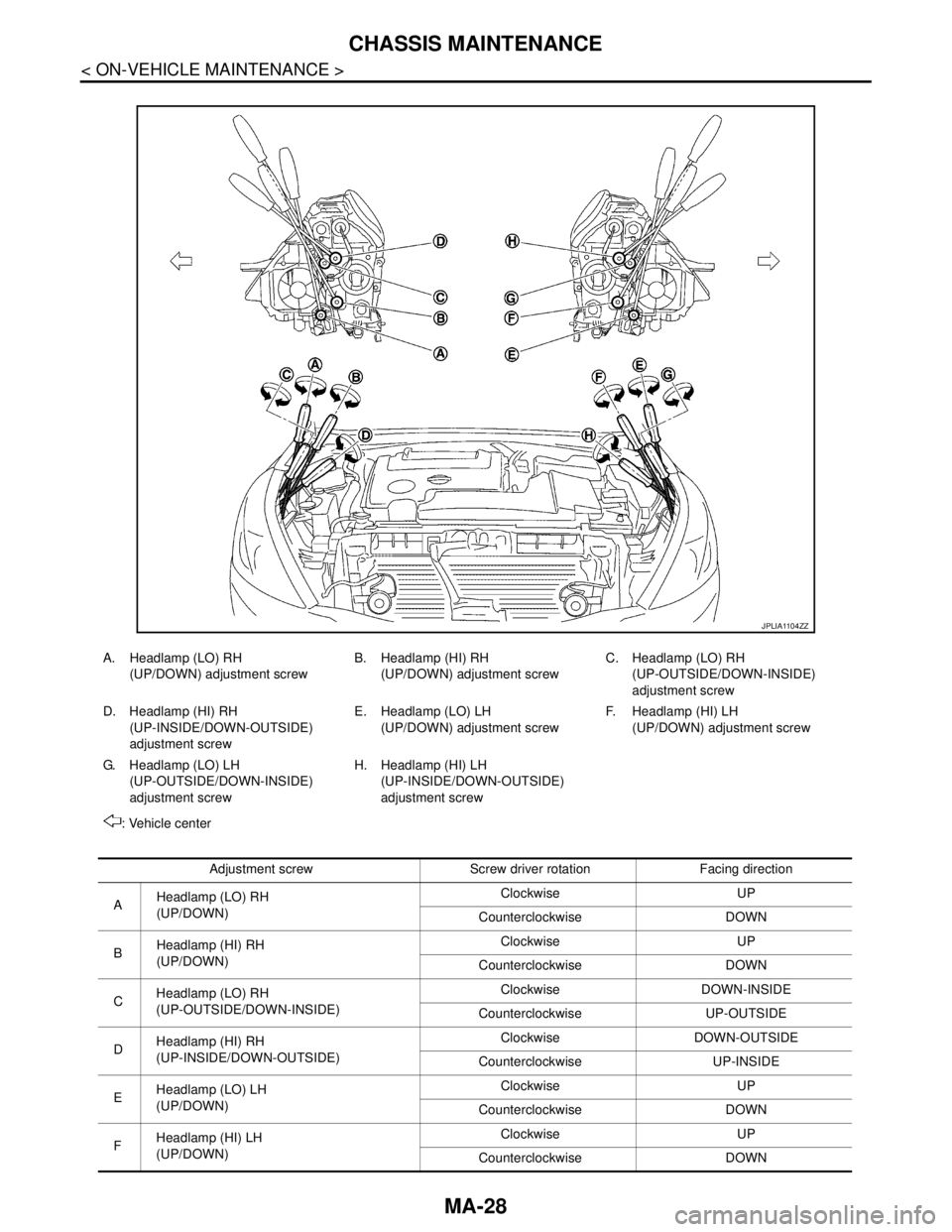

JPLIA1104ZZ

A. Headlamp (LO) RH

(UP/DOWN) adjustment screwB. Headlamp (HI) RH

(UP/DOWN) adjustment screwC. Headlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screw

D. Headlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screwE. Headlamp (LO) LH

(UP/DOWN) adjustment screwF. Headlamp (HI) LH

(UP/DOWN) adjustment screw

G. H e a d l a m p ( L O ) L H

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screwH. Headlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screw

: Vehicle center

Adjustment screw Screw driver rotation Facing direction

AHeadlamp (LO) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

BHeadlamp (HI) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

CHeadlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

DHeadlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE

EHeadlamp (LO) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

FHeadlamp (HI) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

Page 3217 of 5121

CHASSIS MAINTENANCE

MA-29

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

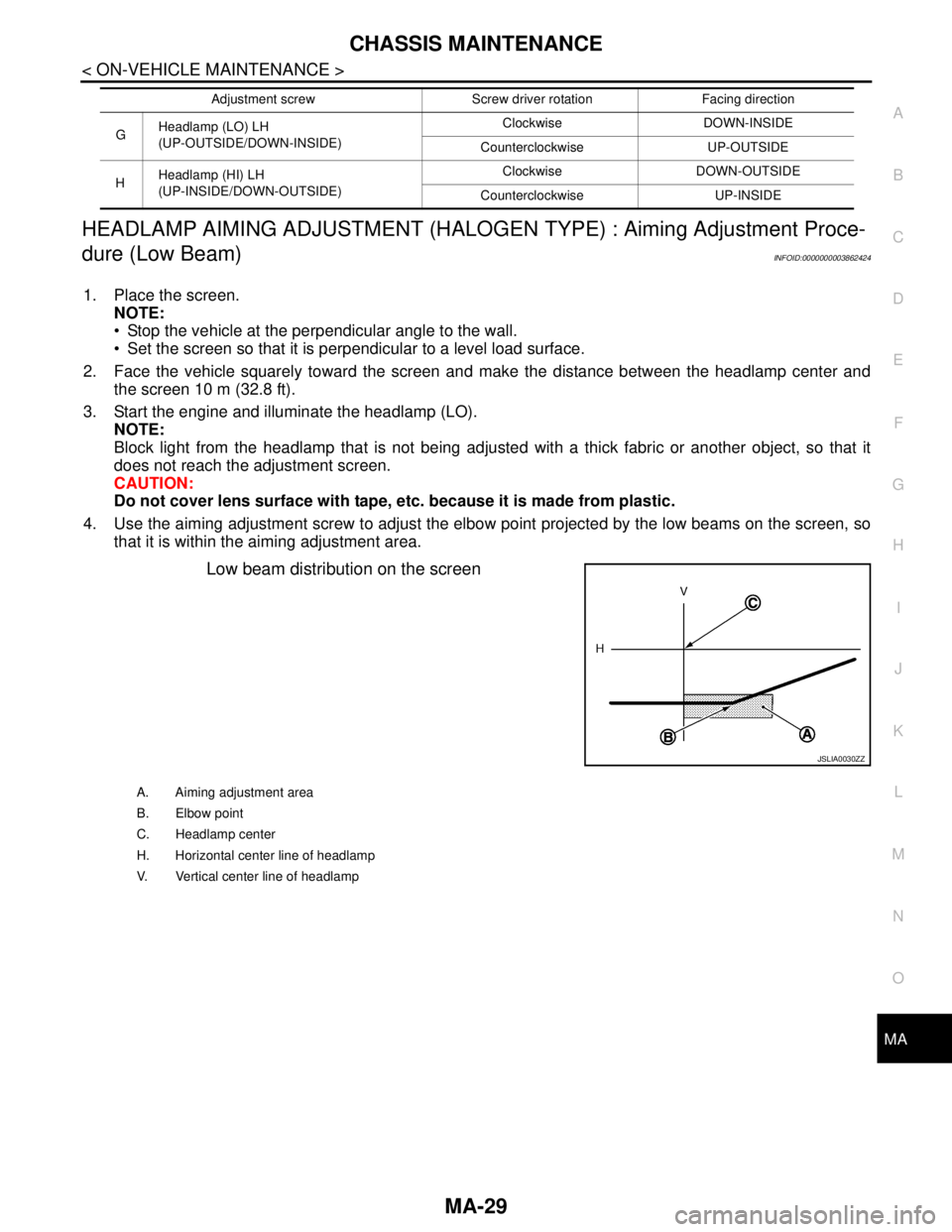

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE) : Aiming Adjustment Proce-

dure (Low Beam)

INFOID:0000000003862424

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and

the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (LO).

NOTE:

Block light from the headlamp that is not being adjusted with a thick fabric or another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so

that it is within the aiming adjustment area.

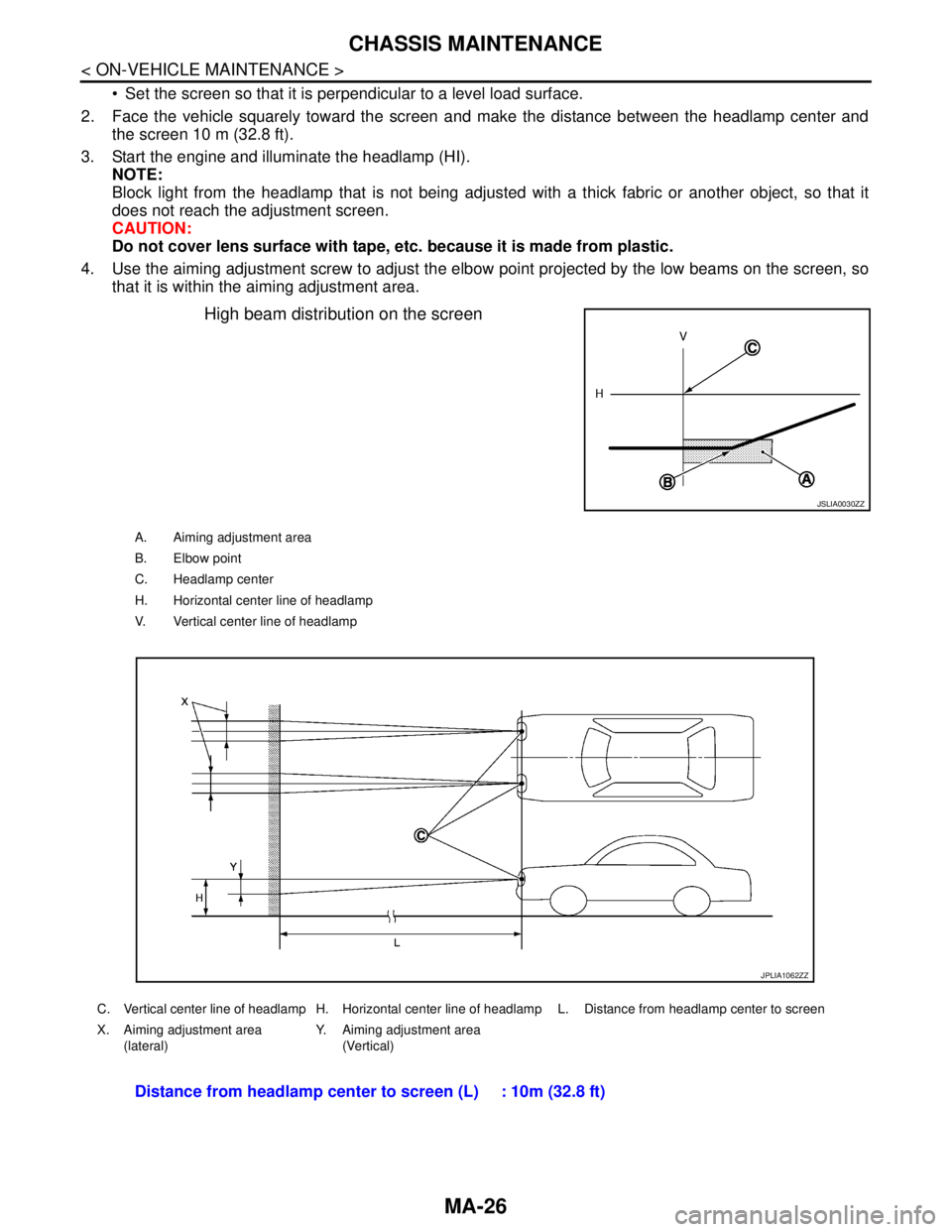

Low beam distribution on the screen

GHeadlamp (LO) LH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

HHeadlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE Adjustment screw Screw driver rotation Facing direction

JSLIA0030ZZ

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

Page 3218 of 5121

MA-30

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

Unit: mm (in)

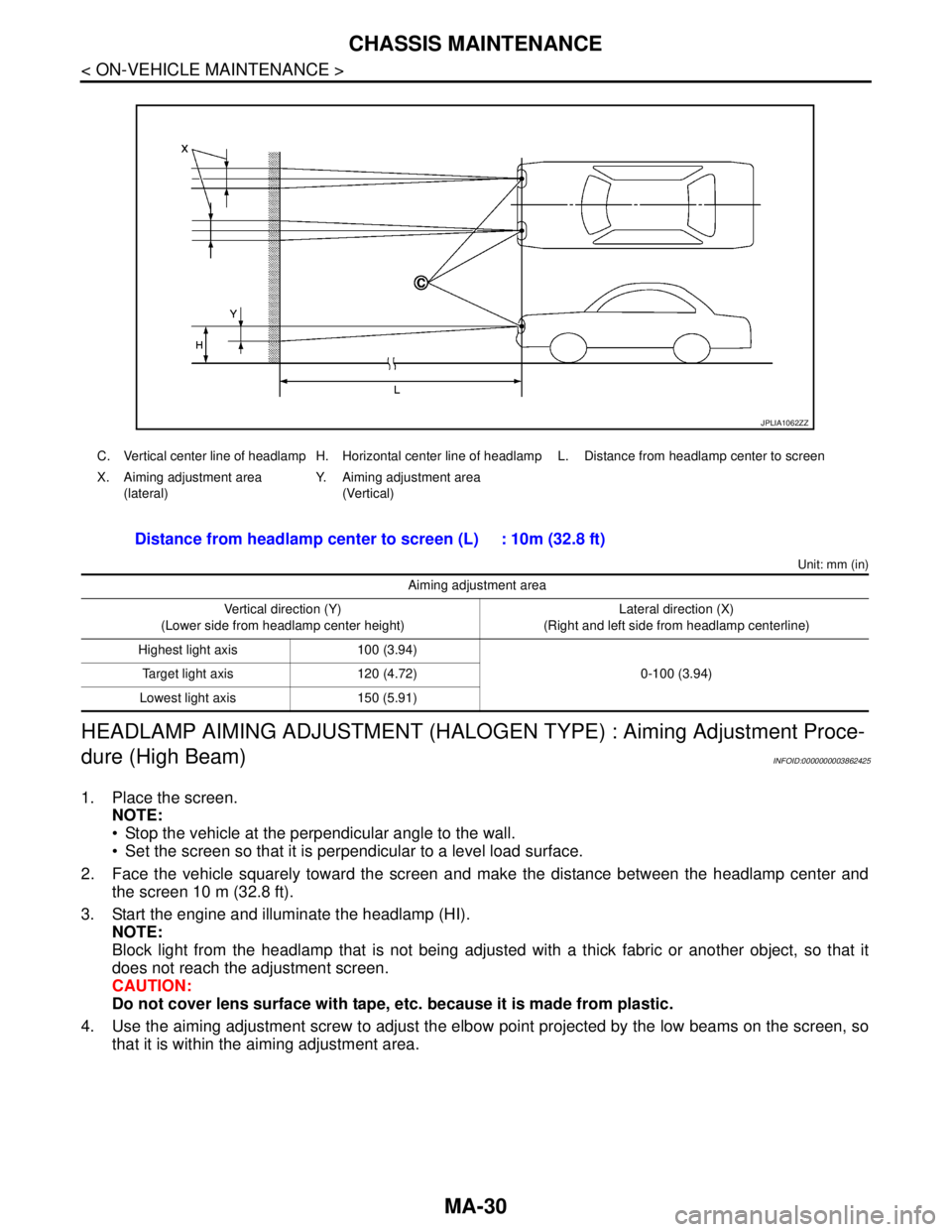

HEADLAMP AIMING ADJUSTMENT (HALOGEN TYPE) : Aiming Adjustment Proce-

dure (High Beam)

INFOID:0000000003862425

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and

the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (HI).

NOTE:

Block light from the headlamp that is not being adjusted with a thick fabric or another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so

that it is within the aiming adjustment area.

C. Vertical center line of headlamp H. Horizontal center line of headlamp L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10m (32.8 ft)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 100 (3.94)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 150 (5.91)

JPLIA1062ZZ

Page 3219 of 5121

CHASSIS MAINTENANCE

MA-31

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

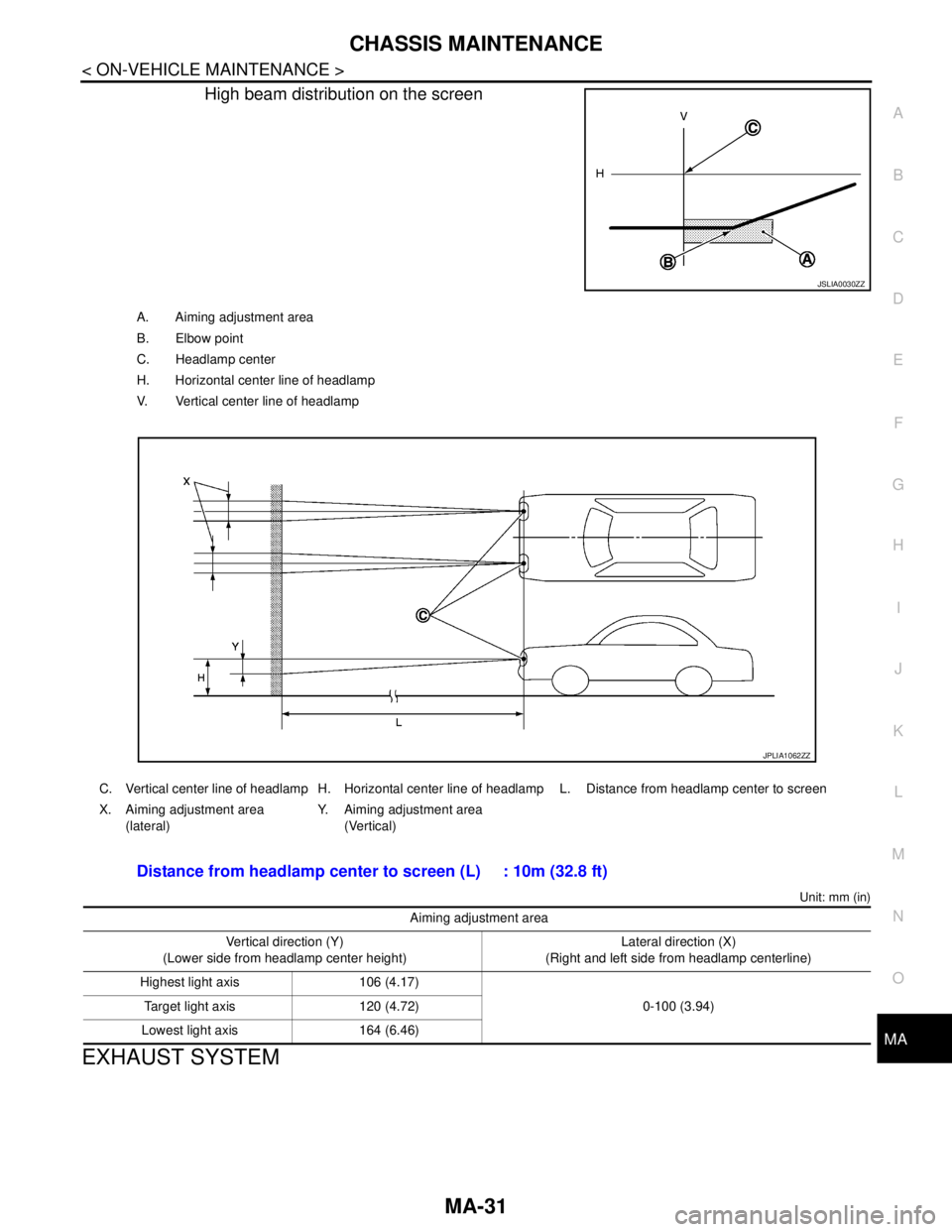

High beam distribution on the screen

Unit: mm (in)

EXHAUST SYSTEM

JSLIA0030ZZ

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp H. Horizontal center line of headlamp L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10m (32.8 ft)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 106 (4.17)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 164 (6.46)

JPLIA1062ZZ

Page 3220 of 5121

MA-32

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

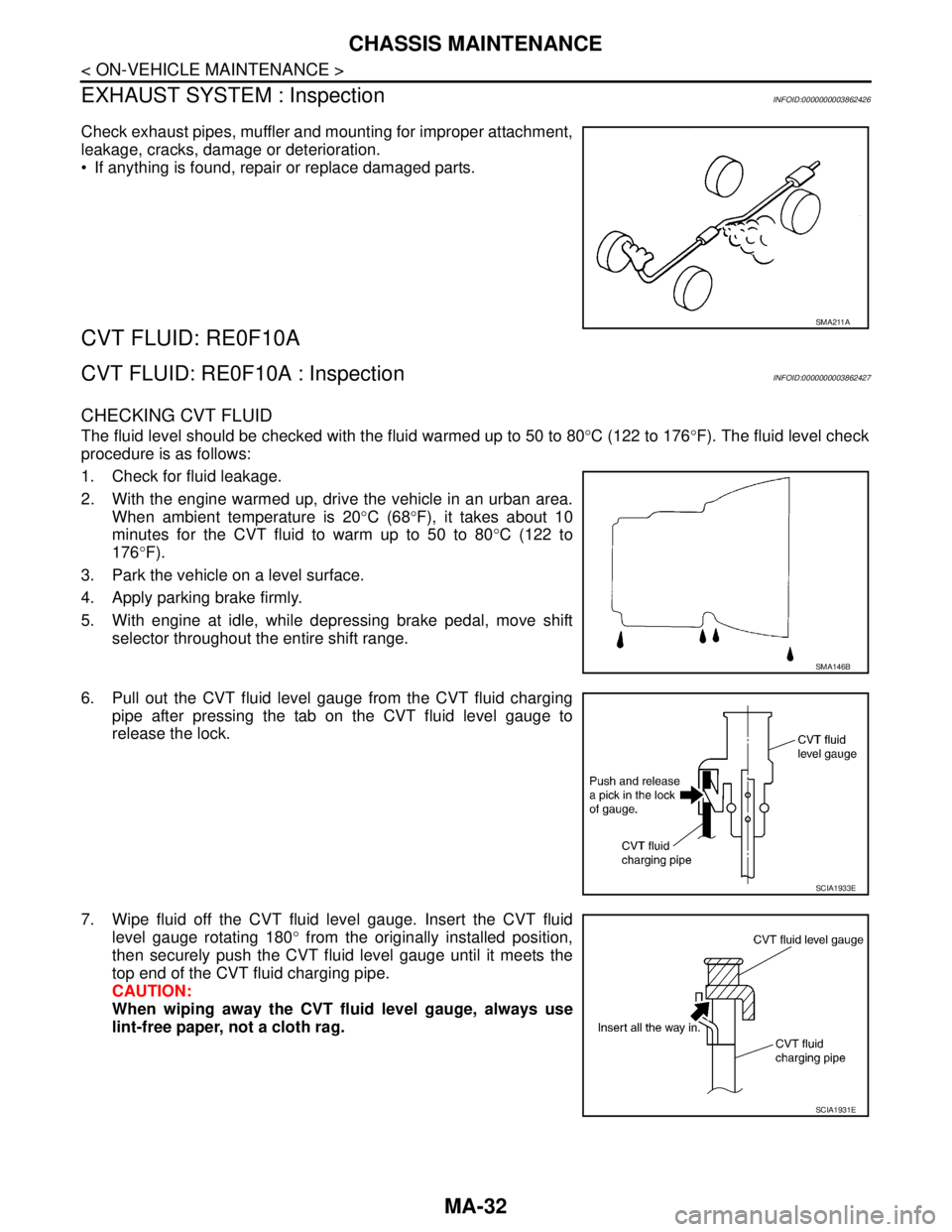

EXHAUST SYSTEM : Inspection

INFOID:0000000003862426

Check exhaust pipes, muffler and mounting for improper attachment,

leakage, cracks, damage or deterioration.

If anything is found, repair or replace damaged parts.

CVT FLUID: RE0F10A

CVT FLUID: RE0F10A : InspectionINFOID:0000000003862427

CHECKING CVT FLUID

The fluid level should be checked with the fluid warmed up to 50 to 80°C (122 to 176°F). The fluid level check

procedure is as follows:

1. Check for fluid leakage.

2. With the engine warmed up, drive the vehicle in an urban area.

When ambient temperature is 20°C (68°F), it takes about 10

minutes for the CVT fluid to warm up to 50 to 80°C (122 to

176°F).

3. Park the vehicle on a level surface.

4. Apply parking brake firmly.

5. With engine at idle, while depressing brake pedal, move shift

selector throughout the entire shift range.

6. Pull out the CVT fluid level gauge from the CVT fluid charging

pipe after pressing the tab on the CVT fluid level gauge to

release the lock.

7. Wipe fluid off the CVT fluid level gauge. Insert the CVT fluid

level gauge rotating 180° from the originally installed position,

then securely push the CVT fluid level gauge until it meets the

top end of the CVT fluid charging pipe.

CAUTION:

When wiping away the CVT fluid level gauge, always use

lint-free paper, not a cloth rag.

SMA211A

SMA146B

SCIA1933E

SCIA1931E