Trans NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3693 of 5121

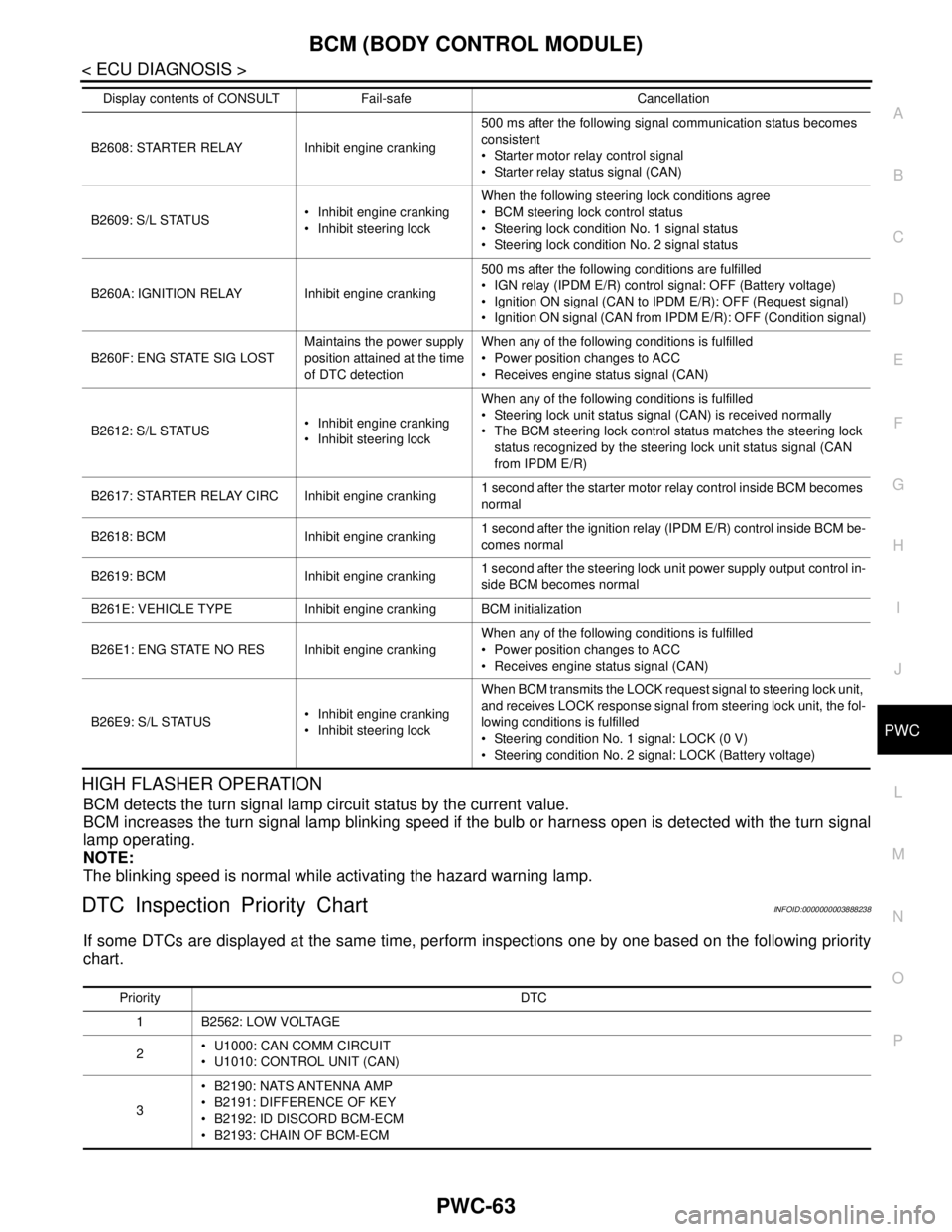

BCM (BODY CONTROL MODULE)

PWC-63

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003888238

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 3726 of 5121

RAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION RAX

A

B

RAX

N

O P

CONTENTS

REAR AXLE

SYMPTOM DIAGNOSIS ..... ..........................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

2

NVH Troubleshooting Chart ................................ ......2

ON-VEHICLE MAINTENANCE .....................3

REAR WHEEL HUB AND HOUSING ............ .....3

Inspection ............................................................ ......3

ON-VEHICLE REPAIR ..................................4

REAR WHEEL HUB AND HOUSING ................4

Exploded View ..................................................... .....4

Removal and Installation ..........................................4

Inspection .................................................................5

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..............................................

6

SERVICE DATA AND SPECIFICATIONS

(SDS) ..................................................................

6

Wheel Bearing ..................................................... .....6

Page 3739 of 5121

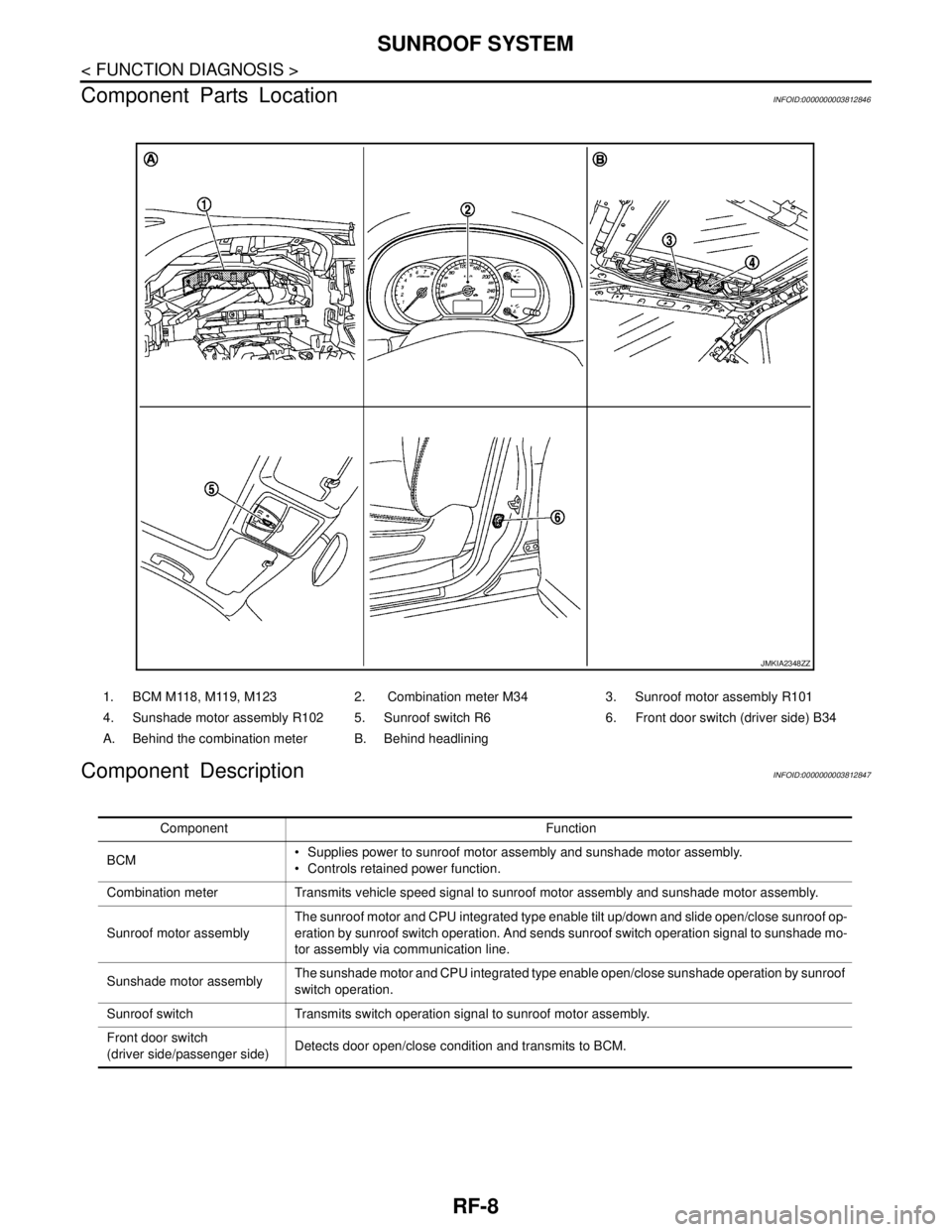

RF-8

< FUNCTION DIAGNOSIS >

SUNROOF SYSTEM

Component Parts Location

INFOID:0000000003812846

Component DescriptionINFOID:0000000003812847

1. BCM M118, M119, M123 2. Combination meter M34 3. Sunroof motor assembly R101

4. Sunshade motor assembly R102 5. Sunroof switch R6 6. Front door switch (driver side) B34

A. Behind the combination meter B. Behind headlining

JMKIA2348ZZ

Component Function

BCM Supplies power to sunroof motor assembly and sunshade motor assembly.

Controls retained power function.

Combination meter Transmits vehicle speed signal to sunroof motor assembly and sunshade motor assembly.

Sunroof motor assemblyThe sunroof motor and CPU integrated type enable tilt up/down and slide open/close sunroof op-

eration by sunroof switch operation. And sends sunroof switch operation signal to sunshade mo-

tor assembly via communication line.

Sunshade motor assemblyThe sunshade motor and CPU integrated type enable open/close sunshade operation by sunroof

switch operation.

Sunroof switch Transmits switch operation signal to sunroof motor assembly.

Front door switch

(driver side/passenger side)Detects door open/close condition and transmits to BCM.

Page 3746 of 5121

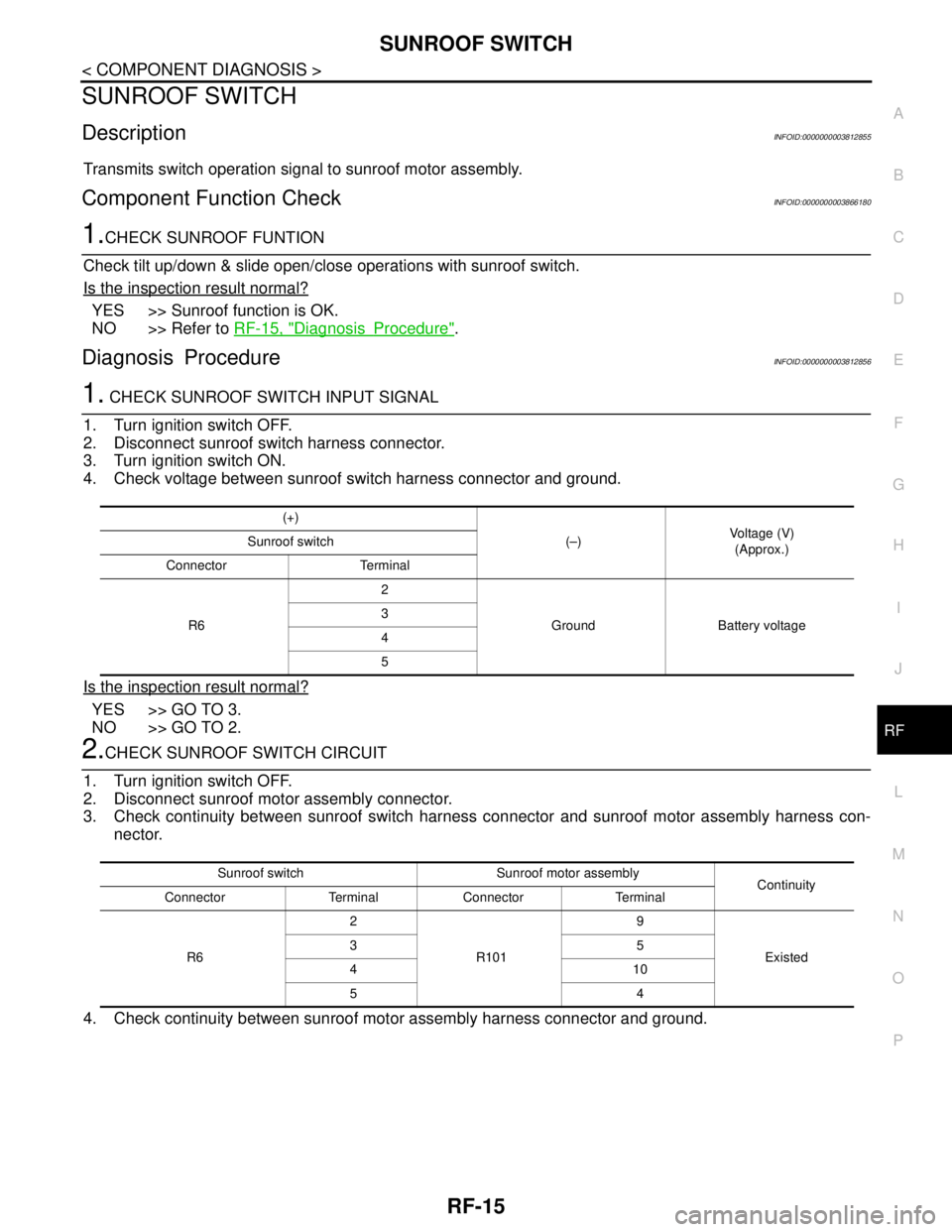

SUNROOF SWITCH

RF-15

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

SUNROOF SWITCH

DescriptionINFOID:0000000003812855

Transmits switch operation signal to sunroof motor assembly.

Component Function CheckINFOID:0000000003866180

1.CHECK SUNROOF FUNTION

Check tilt up/down & slide open/close operations with sunroof switch.

Is the inspection result normal?

YES >> Sunroof function is OK.

NO >> Refer to RF-15, "

DiagnosisProcedure".

Diagnosis ProcedureINFOID:0000000003812856

1. CHECK SUNROOF SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect sunroof switch harness connector.

3. Turn ignition switch ON.

4. Check voltage between sunroof switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK SUNROOF SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly connector.

3. Check continuity between sunroof switch harness connector and sunroof motor assembly harness con-

nector.

4. Check continuity between sunroof motor assembly harness connector and ground.

(+)

(–)Voltage (V)

(Approx.) Sunroof switch

Connector Terminal

R62

Ground Battery voltage 3

4

5

Sunroof switch Sunroof motor assembly

Continuity

Connector Terminal Connector Terminal

R62

R1019

Existed 35

410

54

Page 3782 of 5121

BCM (BODY CONTROL MODULE)

RF-51

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

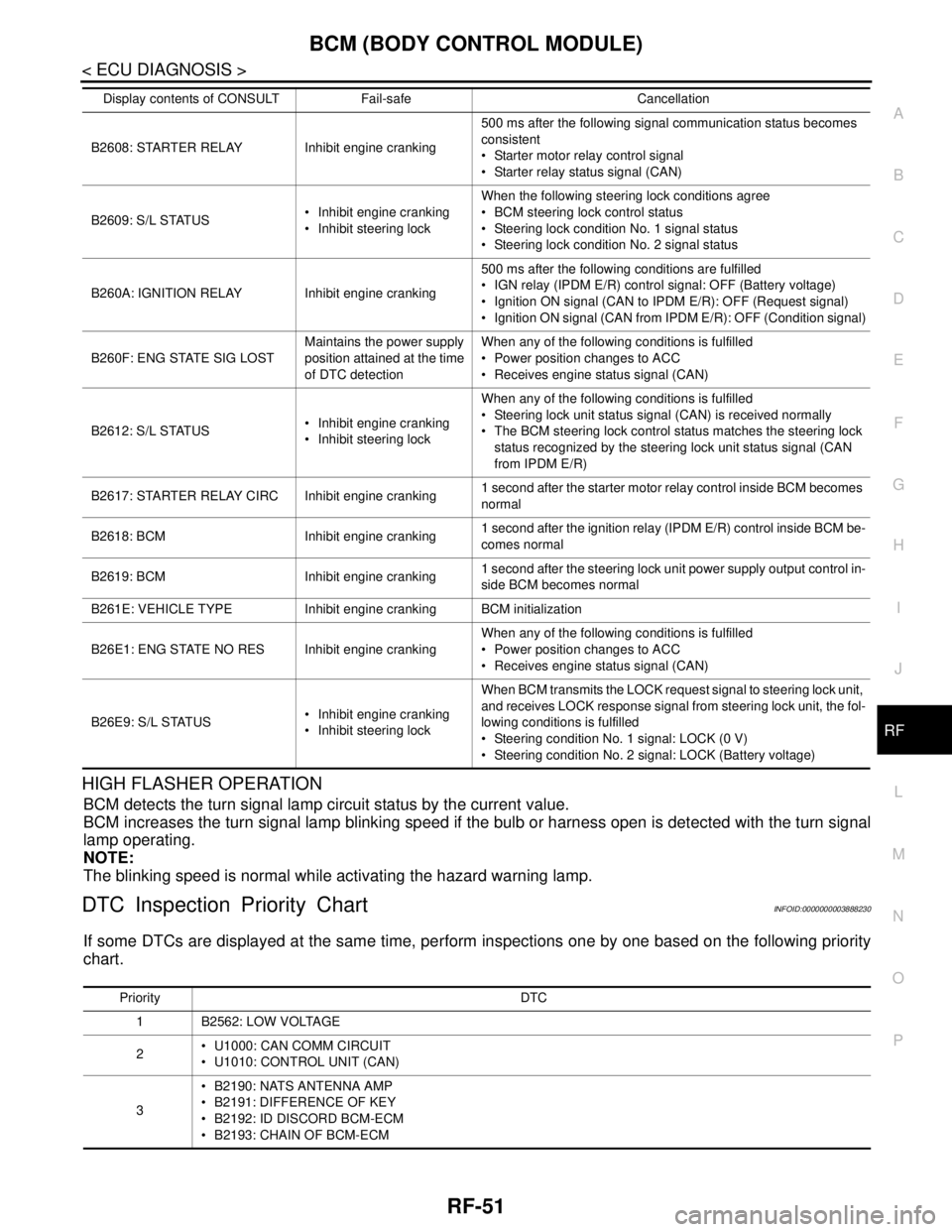

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003888230

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 3805 of 5121

RF-74

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

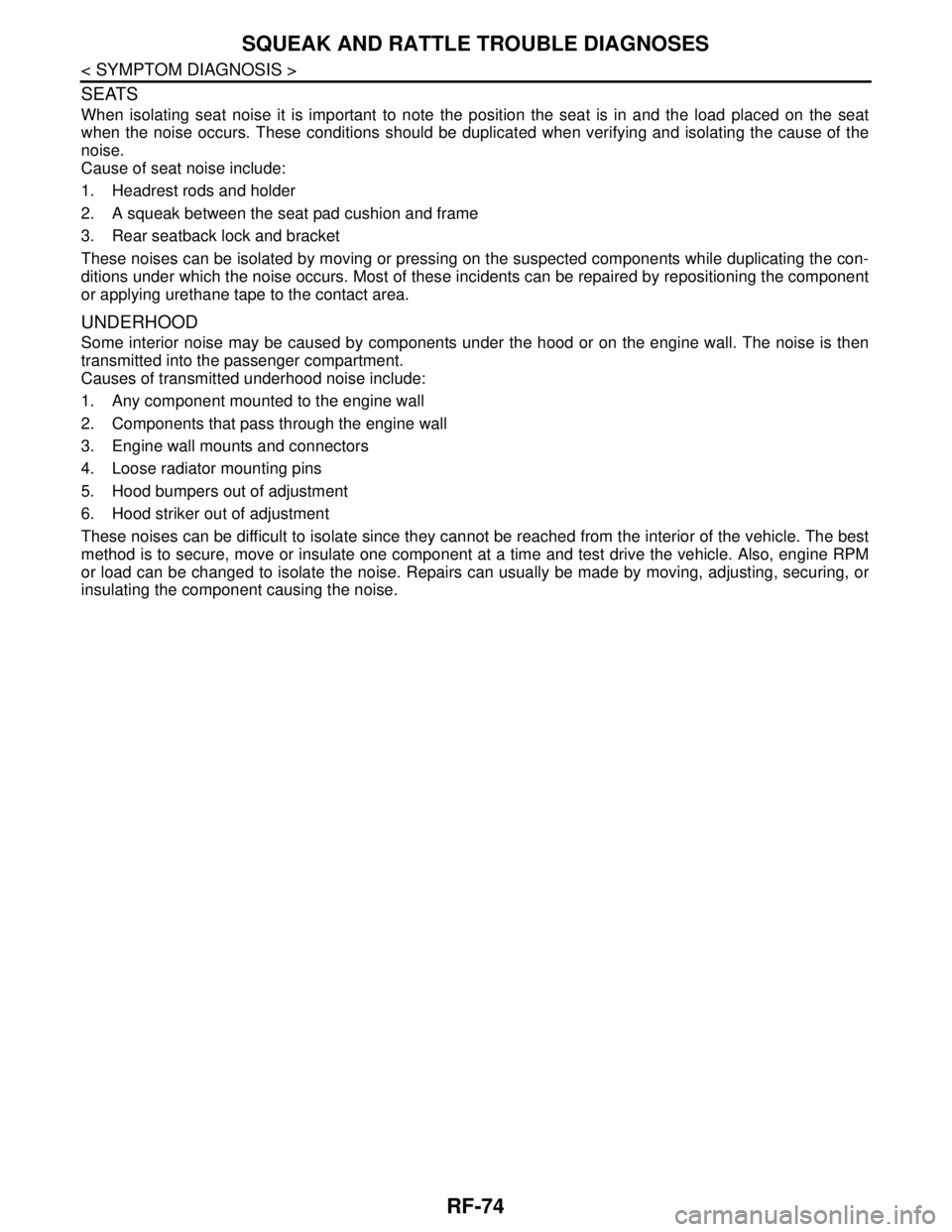

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3947 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is](/img/5/57391/w960_57391-3946.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3988 of 5121

![NISSAN TEANA 2008 Service Manual SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of thes NISSAN TEANA 2008 Service Manual SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of thes](/img/5/57391/w960_57391-3987.png)

SE-124

< SYMPTOM DIAGNOSIS >[WITHOUT VENTILATION SEAT]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 4018 of 5121

![NISSAN TEANA 2008 Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Syste NISSAN TEANA 2008 Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Syste](/img/5/57391/w960_57391-4017.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

System DiagramINFOID:0000000003814902

System DescriptionINFOID:0000000003814903

The engine start function of Intelligent Key system is a system that makes it possible to start and stop the

engine without removing the key. It verifies the electronic ID using two-way communication when pressing

the push-button ignition switch while carrying the Intelligent Key, which operates based on the results of

electronic ID verification for Intelligent Key using two-way communication between the Intelligent Key and

the vehicle.

NOTE:

The driver should carry the Intelligent Key at all times.

Intelligent Key has 2 IDs [for Intelligent Key and for NVIS (NATS)]. It can perform the door lock/unlock oper-

ation and the push-button ignition switch operation when the registered Intelligent Key is carried.

When the Intelligent Key battery is discharged, it can be used as emergency back-up by inserting the Intelli-

gent Key to the key slot. At that time, perform the NVIS (NATS) ID verification. If it is used when the Intelli-

gent Key is carried, perform the Intelligent Key ID verification.

If the ID is successfully verified, and when push-button ignition switch is pressed, steering lock will be

released and starting the engine will be possible.

If the door lock/unlock operation is performed when the Intelligent Key battery is discharged, all doors lock/

unlock can be performed by operating the driver door key cylinder using the mechanical key set in the Intel-

ligent Key.

Up to 4 Intelligent Keys can be registered (Including the standard Intelligent Key) on request from the owner.

NOTE:

Refer to SEC-9, "

System Description" for any functions other than engine start function of Intelligent Key

system.

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

In the Intelligent Key system, the transponder [the chip for NVIS (NATS) ID verification] is integrated

into the Intelligent Key. (For the conventional models, it is integrated into the mechanical key.) There-

fore, the mechanical key cannot perform the ID verification, and thus it cannot start the engine.

Instead, the NVIS (NATS) ID verification can be performed by inserting the Intelligent Key into the key

slot, and then it can start the engine.

OPERATION WHEN INTELLIGENT KEY IS CARRIED

1. When the push-button ignition switch is pressed, the BCM signals the inside key antenna and transmits

the request signal to the Intelligent Key.

2. The Intelligent Key receives the request signal and transmits the Intelligent Key ID signal to the BCM via

the remote keyless entry receiver.

3. The BCM receives the Intelligent Key ID signal and verifies it with the registered ID.

JMKIA1870GB

Page 4019 of 5121

![NISSAN TEANA 2008 Service Manual SEC-10

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

4. BCM transmits the steering lock unlock signal to steering lock unit and IPDM E/R if the verificati NISSAN TEANA 2008 Service Manual SEC-10

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

4. BCM transmits the steering lock unlock signal to steering lock unit and IPDM E/R if the verificati](/img/5/57391/w960_57391-4018.png)

SEC-10

< FUNCTION DIAGNOSIS >[INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

4. BCM transmits the steering lock unlock signal to steering lock unit and IPDM E/R if the verification results

are OK.

5. IPDM E/R turns the steering lock relay ON and supplies power to the steering lock unit.

6. Release of the steering lock.

7. BCM transmits the power supply stop signal to IPDM E/R when it confirms that the steering lock is in the

unlock condition.

8. IPDM E/R turns the steering lock relay OFF and stops power supply to the steering lock unit.

9. BCM turns ACC relay ON and transmits the ignition power supply ON signal to IPDM E/R.

10. IPDM E/R turns the ignition relay ON and starts the ignition power supply.

11. BCM confirms that the shift position is P or N.

12. BCM transmits the starter request signal via CAN communication to IPDM E/R and turns the starter relay

in IPDM E/R ON if BCM judges that the engine start condition is satisfied.

13. IPDM E/R turns the starter control relay ON when receiving the starter request signal.

14. Battery power is supplied through the starter relay and the starter control relay to operate the starter motor

and to start the cranking.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning lamp in the combina-

tion meter illuminates. At that time, the engine cannot be started.

15. When BCM receives feedback signal from ECM acknowledging the engine has been initiated, the BCM

transmits a stop signal to IPDM E/R and stops the cranking by turning OFF the starter motor relay. (If the

engine initiating has failed, the cranking will stop automatically within 5 seconds.)

CAUTION:

When the Intelligent Key is carried outside of the vehicle (inside key antenna detection area) with

the power supply in the ACC or ON position, even if the engine start condition* is satisfied, the

engine cannot be started.

*: For the engine start condition, refer to “PUSH-BUTTON IGNITION SWITCH OPERATION PROCEDURE”.

OPERATION RANGE

Engine can be started when Intelligent Key is inside the vehicle. However, sometimes engine might not start

when Intelligent Key is on instrument panel or in glove box.

OPERATION WHEN KEY SLOT IS USED

When the Intelligent Key battery is discharged, it performs the NVIS (NATS) ID verification between the inte-

grated transponder and BCM by inserting the Intelligent Key into the key slot, and then the engine can be

started.

For details relating to starting the engine using key slot, refer to SEC-14, "

System Description".

BATTERY SAVER SYSTEM

When all the following conditions are met for 60 minutes, the battery saver system will cut off the power supply

to prevent battery discharge.

The ignition switch is in the ACC position

All doors are closed

Selector lever is in the P position

Reset Condition of Battery Saver System

If any of the following conditions are met the battery saver system is released and the steering will change

automatically to the lock position from the OFF position.

Opening any door

Operating with request switch on door lock

Operating with Intelligent Key on door lock

Pressing the push-button ignition switch and ignition switch will change the ignition switch to ACC position

from OFF position.

STEERING LOCK OPERATION

Steering is locked by steering lock unit when ignition switch is in the OFF position, selector lever is in the P

position and any of the following conditions are met.

Opening door

Closing door

Door is locked with request switch

Door is locked with Intelligent Key