cooling NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1786 of 5121

![NISSAN TEANA 2008 Workshop Manual COOLING FAN

EC-325

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2.DETECT MALFUNCTIONING PART

Check the following.

40A fusible link (letter K)

10A fuse (No.42)

IPDM E/R NISSAN TEANA 2008 Workshop Manual COOLING FAN

EC-325

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2.DETECT MALFUNCTIONING PART

Check the following.

40A fusible link (letter K)

10A fuse (No.42)

IPDM E/R](/img/5/57391/w960_57391-1785.png)

COOLING FAN

EC-325

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2.DETECT MALFUNCTIONING PART

Check the following.

40A fusible link (letter K)

10A fuse (No.42)

IPDM E/R harness connector E10

Harness for open or short between cooling fan relay-2 and battery

Harness for open or short between cooling fan relay-3 and battery

Harness for open or short between cooling fan relay-2 and IPDM E/R

Harness for open or short between cooling fan relay-3 and IPDM E/R

>> Repair open circuit, short to ground or short to power in harness or connectors.

3.CHECK COOLING FAN RELAY OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connectors.

3. Check the continuity between cooling fan relay-2, -3 harness connectors and IPDM E/R harness connec-

tor.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK COOLING FAN MOTOR POWER SUPPLY CIRCUIT

1. Disconnect cooling fan motor-1 harness connector.

2. Check the voltage between cooling fan motor-1 harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

Harness connector E70, E305

40A fusible link (letter M)

Harness for open or short between cooling fan motor-1 and battery

>> Repair open circuit, short to ground or short to power in harness or connectors.

6.CHECK COOLING FAN MOTOR CIRCUIT-I

1. Disconnect cooling fan motor-2 harness connector.

2. Check the continuity between cooling fan relay-2, -3 harness connectors and cooling fan motor-1, -2 har-

ness connectors.

Cooling fan relay IPDM E/R

Continuity

Connector Terminal Connector Terminal

E57

(cooling fan relay-2)1E1142

Existed

E59

(cooling fan relay-3)1E1034

Cooling fan motor-1

Ground Voltage

Connector Terminal

E3011

Ground Battery voltage

2

Page 1787 of 5121

![NISSAN TEANA 2008 Workshop Manual EC-326

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUN NISSAN TEANA 2008 Workshop Manual EC-326

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUN](/img/5/57391/w960_57391-1786.png)

EC-326

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

Harness connector E70, E305

Harness for open or short between cooling fan motor-1 and cooling fan relay-2

Harness for open or short between cooling fan motor-1 and cooling fan relay-3

Harness for open or short between cooling fan motor-2 and cooling fan relay-2

Harness for open or short between cooling fan motor-2 and cooling fan relay-3

>> Repair open circuit, short to ground or short to power in harness or connectors.

8.CHECK COOLING FAN MOTOR CIRCUIT-II

1. Check the continuity between IPDM E/R harness connector and cooling fan motor-1, -2 harness connec-

tor.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 9.

9.DETECT MALFUNCTIONING PART

Check the following.

Harness connector E70, E305

Harness for open or short between cooling fan motor-1 and IPDM E/R

Harness for open or short between cooling fan motor-2 and IPDM E/R

>> Repair open circuit, short to ground or short to power in harness or connectors.

10.CHECK COOLING FAN MOTOR CIRCUIT-III

1. Check the continuity between cooling fan relay-2, -3 harness connectors and ground.

Cooling fan relay Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E57

(cooling fan relay-2)3E302

(Cooling fan motor-2)2

Existed 7E301

(Cooling fan motor-1)3

E59

(cooling fan relay-3)3E302

(Cooling fan motor-2)1

7E301

(Cooling fan motor-1)4

IPDM E/R Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E1035E301

(Cooling fan motor-1)4

Existed

38E302

(Cooling fan motor-2)1

Page 1788 of 5121

![NISSAN TEANA 2008 Workshop Manual COOLING FAN

EC-327

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 1 NISSAN TEANA 2008 Workshop Manual COOLING FAN

EC-327

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 1](/img/5/57391/w960_57391-1787.png)

COOLING FAN

EC-327

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

11 .CHECK COOLING FAN MOTOR CIRCUIT-IV

1. Check the continuity between cooling fan motor-2 harness connector and ground.

2. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 12.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

12.CHECK COOLING FAN RELAYS-2 AND -3

Refer to EC-328, "

Component Inspection (Cooling Fan Relay)".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Replace malfunctioning cooling fan relay.

13.CHECK COOLING FAN MOTORS-1 AND -2

Refer to EC-327, "

Component Inspection (Cooling Fan Motor)".

Is the inspection result normal?

YES >> GO TO 14.

NO >> Replace malfunctioning cooling fan motor.

14.CHECK INTERMITTENT INCIDENT

Perform GI-35, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace IPDM E/R.

NO >> Repair or replace harness connectors.

Component Inspection (Cooling Fan Motor)INFOID:0000000003856830

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch OFF.

2. Disconnect cooling fan motor harness connector.

3. Supply cooling fan motor terminals with battery voltage and check operation.

Cooling fan motor

Ground Continuity

Connector Terminal

E57

(cooling fan relay-2)6

Ground Existed

E59

(cooling fan relay-3)6

Cooling fan motor-2

Ground Continuity

Connector Terminal

E3023

Ground Existed

4

Page 1789 of 5121

![NISSAN TEANA 2008 Workshop Manual EC-328

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace co NISSAN TEANA 2008 Workshop Manual EC-328

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace co](/img/5/57391/w960_57391-1788.png)

EC-328

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

COOLING FAN

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace cooling fan motor.

Component Inspection (Cooling Fan Relay)INFOID:0000000003856831

1.CHECK COOLING FAN RELAY

1. Disconnect cooling fan relays -2, -3 harness connectors.

2. Check continuity between cooling fan relay -2, -3 terminals

under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace cooling fan relay.

ConditionTe r m i n a l s

(+) (−)

Cooling fan motorA1 3 and 4

2 3 and 4

1 and 2 3

1 and 2 4

B 1, 2 3, 4

Terminals Conditions Continuity

3 and 5

6 and 712 V direct current supply between terminals 1 and 2 Existed

No current supply Not existed

SEF745U

Page 1809 of 5121

![NISSAN TEANA 2008 Workshop Manual EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser NISSAN TEANA 2008 Workshop Manual EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser](/img/5/57391/w960_57391-1808.png)

EC-348

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

REFRIGERANT PRESSURE SENSOR

REFRIGERANT PRESSURE SENSOR

DescriptionINFOID:0000000003856862

The refrigerant pressure sensor is installed at the condenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

Component Function CheckINFOID:0000000003856863

1.CHECK REFRIGERANT PRESSURE SENSOR FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-348, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003856864

1.CHECK GROUND CONNECTION

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine.

3. Turn ignition switch OFF.

4. Check ground connection E38. Refer to Ground Inspection in GI-37, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect refrigerant pressure sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between refrigerant pressure sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

PBIB2657E

ECM

Voltage (V)

Connector+–

Te r m i n a l Te r m i n a l

F839

(Refrigerant pressure sensor signal)40

(Sensor ground)1.0 - 4.0

Refrigerant pressure sensor

Ground Voltage (V)

Connector Terminal

E300 1 Ground Approx. 5

Page 1820 of 5121

![NISSAN TEANA 2008 Workshop Manual ECM

EC-359

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INT/V TIM (B1) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

NISSAN TEANA 2008 Workshop Manual ECM

EC-359

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INT/V TIM (B1) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle−5° - 5°CA](/img/5/57391/w960_57391-1819.png)

ECM

EC-359

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INT/V TIM (B1) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 30°CA

INT/V TIM (B2) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 30°CA

INT/V SOL (B1) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle 0% - 2%

2,000 rpm Approx. 0% - 50%

INT/V SOL (B2) Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle 0% - 2%

2,000 rpm Approx. 0% - 50%

VIAS S/V-1 Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadWhen revving engine up to 5,000 rpm

quicklyOFF →ON → OFF

VIAS S/V-2 Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadWhen revving engine up to 5,000 rpm

quicklyOFF →ON → OFF

AIR COND RLY Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

ENGINE MOUNT Engine: After warming upBelow 950 rpm IDLE

Above 950 rpm TRVL

FUEL PUMP RLY For 1 second after turning ignition switch: ON

Engine running or crankingON

Except above OFF

THRTL RELAY Ignition switch: ON ON

COOLING FAN Engine: After warming up, idle the

engine

Air conditioner switch: OFFEngine coolant temperature: 97°C

(206°F) or lessOFF

Engine coolant temperature: Between

98°C (208°F) and 99°C (210

°F)LOW

Engine coolant temperature: Between

100°C (212°F) and 104°C (219°F)MID

Engine coolant temperature: 105°C

(221°F) or moreHI

HO2S2 HTR (B1) Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no loadON

Engine speed: Above 3,600 rpm OFF

HO2S2 HTR (B2) Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no loadON

Engine speed: Above 3,600 rpm OFF

I/P PULLY SPD Vehicle speed: More than 20km/h (12 MPH)Almost the same speed as

the tachometer indication

VEHICLE SPEED Turn drive wheels and compare CONSULT-III value with the speedometer in-

dication.Almost the same speed as

the speedometer indication Monitor Item Condition Values/Status

Page 1848 of 5121

![NISSAN TEANA 2008 Workshop Manual ECM

EC-387

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not NISSAN TEANA 2008 Workshop Manual ECM

EC-387

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not](/img/5/57391/w960_57391-1847.png)

ECM

EC-387

< ECU DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not

rise more than 2,500 rpm

due to the fuel cutMalfunction indicator

circuitWhen there is an open circuit on MI circuit, the ECM cannot warn the

driver by illuminating MI when there is malfunction on engine control

system.

Therefore, when electrical controlled throttle and part of ECM related

diagnoses are continuously detected as NG for 5 trips, ECM warns the

driver that engine control system malfunctions and MI circuit is open by

means of operating the fail-safe function.

The fail-safe function also operates when above diagnoses except MI

circuit are detected and demands the driver to repair the malfunction.EC-346

DTC No. Detected items Engine operating condition in fail-safe mode

P0011

P0021Intake valve timing control The signal is not energized to the intake valve timing control solenoid valve and the valve

control does not function.

P0102

P0103Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the following condition.

CONSULT-III displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON

or START40°C (104°F)

Approx. 4 minutes or more after

engine starting80°C (176°F)

Except as shown above40 - 80°C (104 - 176°F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0500 Vehicle speed sensor The cooling fan operates (Highest) while engine is running.

P0605 ECM (When ECM calculation function is a malfunctioning:)

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

ECM deactivates ASCD operation.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P1805 Brake switch ECM controls the electric throttle control actuator by regulating the throttle opening to a

small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P2100

P2103Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control

functionECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

Page 1864 of 5121

![NISSAN TEANA 2008 Workshop Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-403

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Va l v e

mecha-

nismTiming chain

55555 NISSAN TEANA 2008 Workshop Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-403

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Va l v e

mecha-

nismTiming chain

55555](/img/5/57391/w960_57391-1863.png)

ENGINE CONTROL SYSTEM SYMPTOMS

EC-403

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Va l v e

mecha-

nismTiming chain

55555 55 5EM-65

CamshaftEM-84

Intake valve timing controlEM-65

Intake valve

3EM-97

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5EM-34

, EX-

4Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

55555 55 5LU-7

, LU-

10, LU-11,

LU-13

Oil level (Low)/Filthy oilLU-7

Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-12,

CO-12

Thermostat 5CO-23

Water pumpCO-18

Water galleryCO-2

Cooling fan

5CO-16

Coolant level (Low)/Contaminat-

ed coolantCO-8

NVIS (NISSAN Vehicle Immobilizer System —

NATS)11SEC-14

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 1909 of 5121

EM-34

< ON-VEHICLE REPAIR >

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

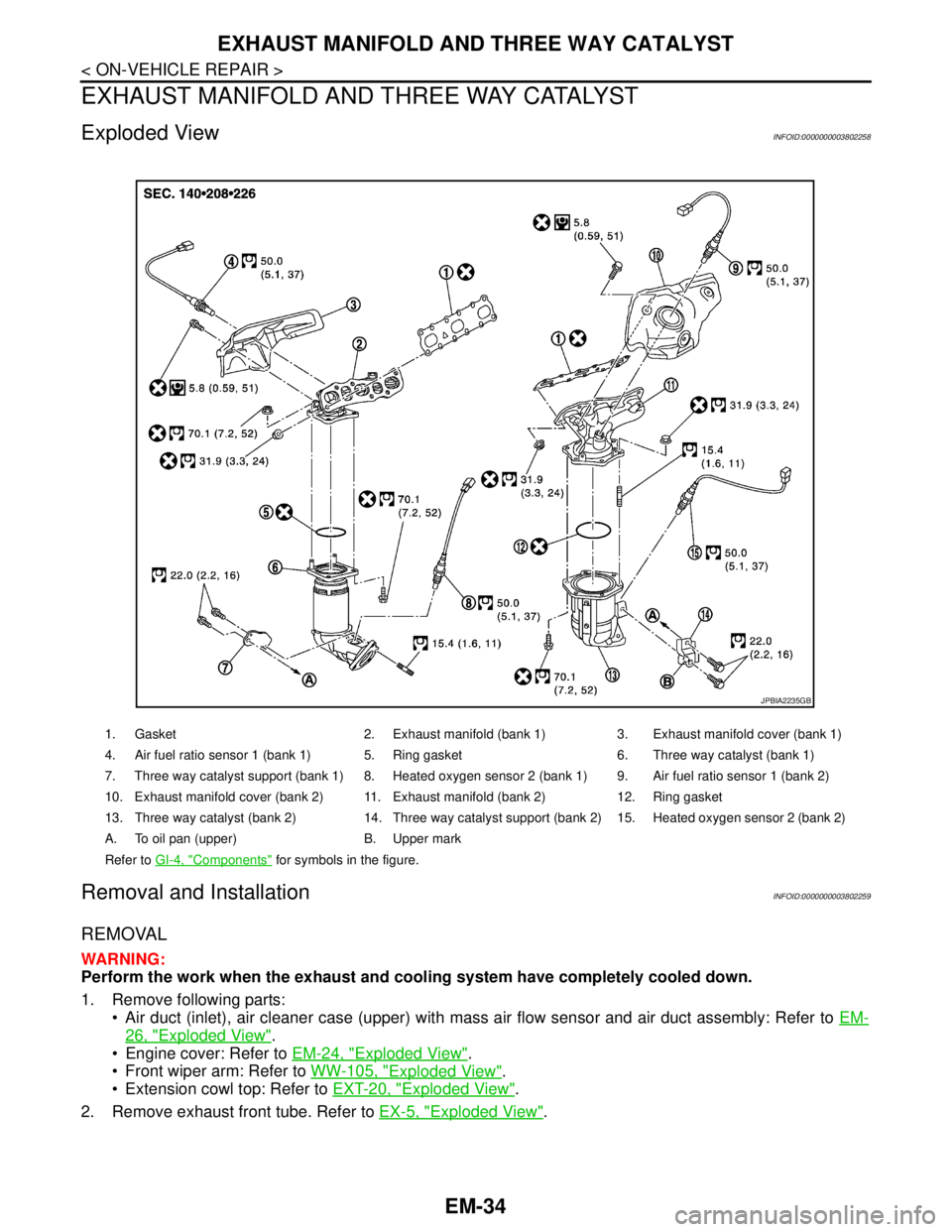

Exploded ViewINFOID:0000000003802258

Removal and InstallationINFOID:0000000003802259

REMOVAL

WARNING:

Perform the work when the exhaust and cooling system have completely cooled down.

1. Remove following parts:

Air duct (inlet), air cleaner case (upper) with mass air flow sensor and air duct assembly: Refer to EM-

26, "Exploded View".

Engine cover: Refer to EM-24, "

Exploded View".

Front wiper arm: Refer to WW-105, "

Exploded View".

Extension cowl top: Refer to EXT-20, "

Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

1. Gasket 2. Exhaust manifold (bank 1) 3. Exhaust manifold cover (bank 1)

4. Air fuel ratio sensor 1 (bank 1) 5. Ring gasket 6. Three way catalyst (bank 1)

7. Three way catalyst support (bank 1) 8. Heated oxygen sensor 2 (bank 1) 9. Air fuel ratio sensor 1 (bank 2)

10. Exhaust manifold cover (bank 2) 11. Exhaust manifold (bank 2) 12. Ring gasket

13. Three way catalyst (bank 2) 14. Three way catalyst support (bank 2) 15. Heated oxygen sensor 2 (bank 2)

A. To oil pan (upper) B. Upper mark

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2235GB

Page 1941 of 5121

EM-66

< ON-VEHICLE REPAIR >

TIMING CHAIN

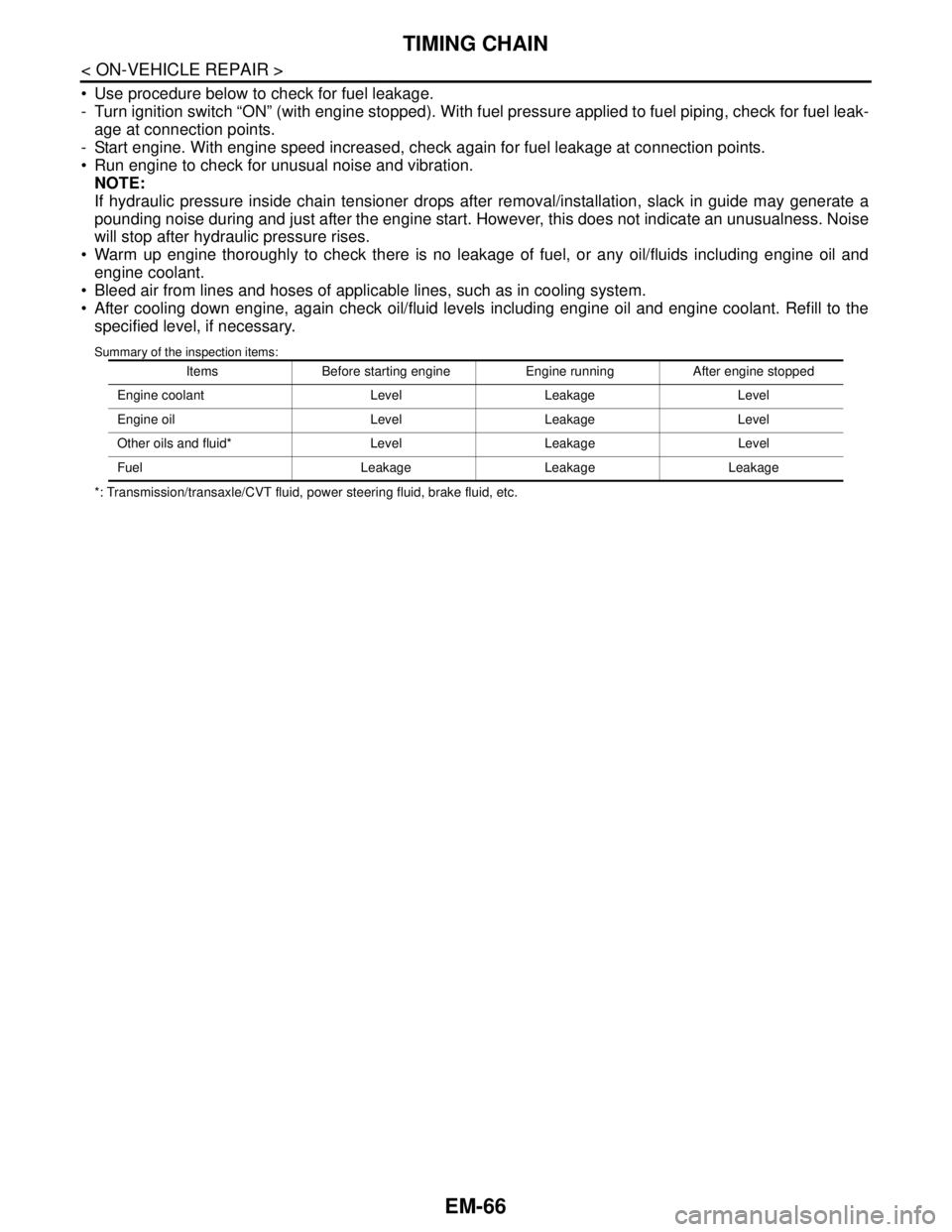

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage