stop start NISSAN TEANA 2008 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1967 of 5121

EM-92

< DISASSEMBLY AND ASSEMBLY >

CAMSHAFT

b. Disconnect ignition coil and injector harness connectors. Refer to EM-49, "Exploded View" and EM-44,

"Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-79, "

Exploded View".

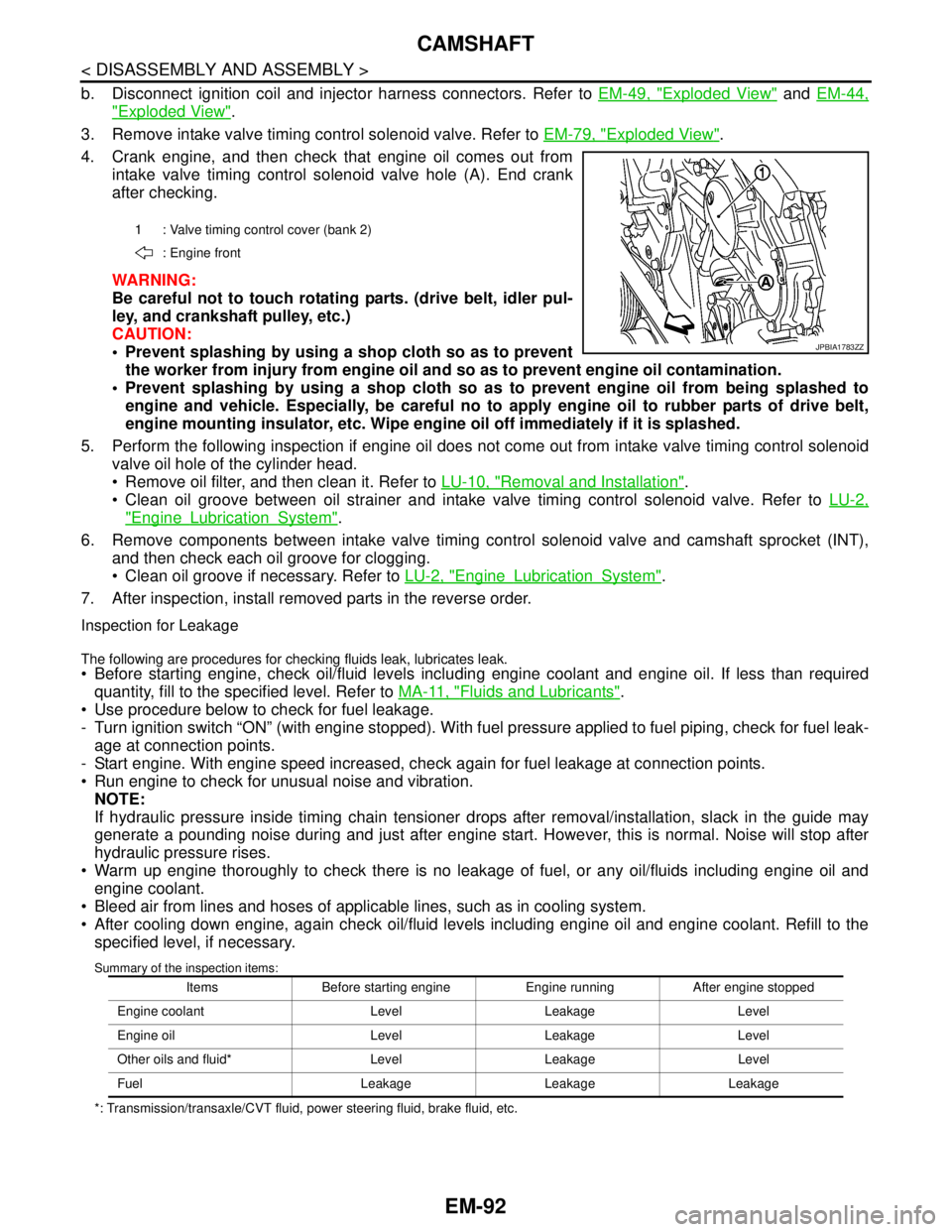

4. Crank engine, and then check that engine oil comes out from

intake valve timing control solenoid valve hole (A). End crank

after checking.

WARNING:

Be careful not to touch rotating parts. (drive belt, idler pul-

ley, and crankshaft pulley, etc.)

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful no to apply engine oil to rubber parts of drive belt,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

5. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid

valve oil hole of the cylinder head.

Remove oil filter, and then clean it. Refer to LU-10, "

Removal and Installation".

Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-2,

"EngineLubricationSystem".

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

Clean oil groove if necessary. Refer to LU-2, "

EngineLubricationSystem".

7. After inspection, install removed parts in the reverse order.

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak. Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.1 : Valve timing control cover (bank 2)

: Engine front

JPBIA1783ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 1981 of 5121

EM-106

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

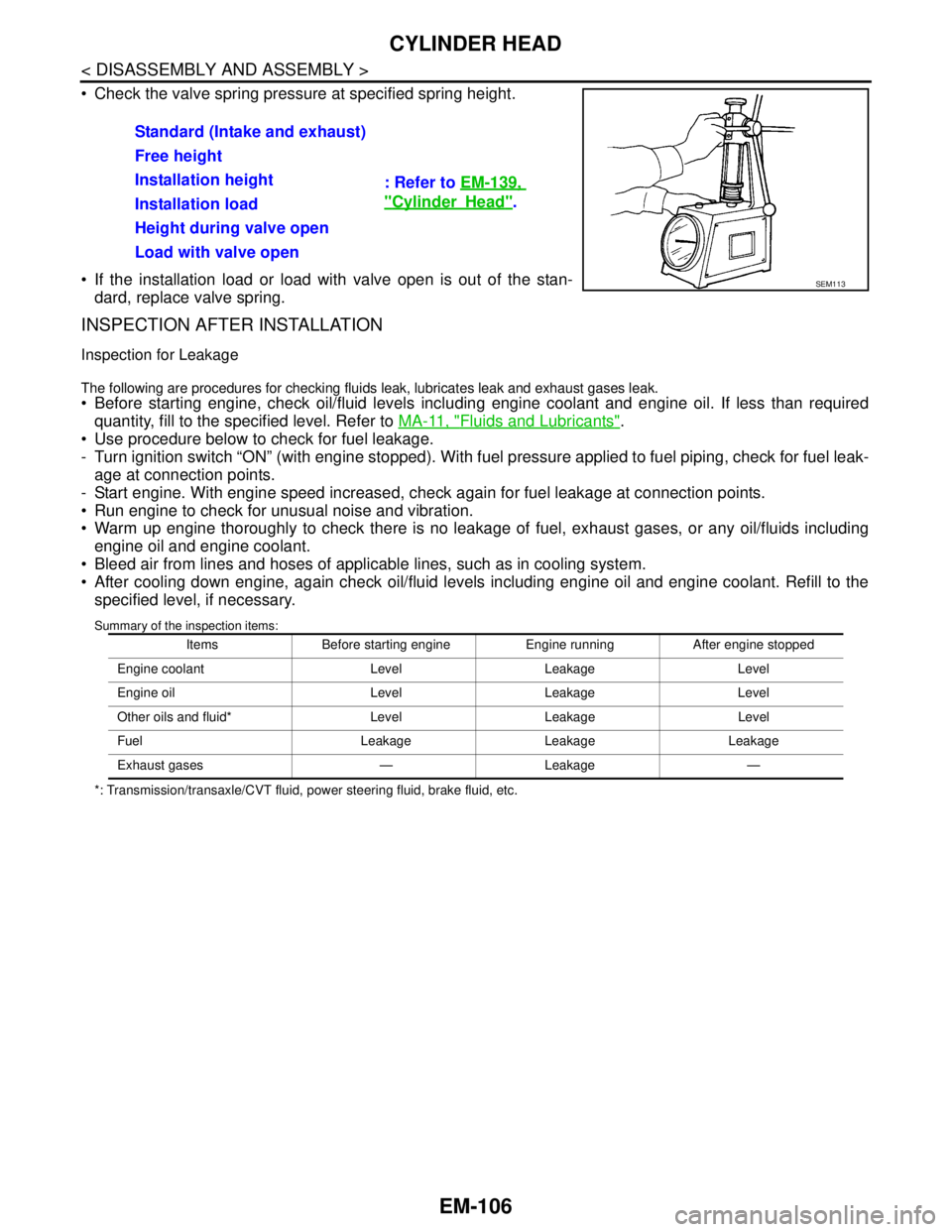

Check the valve spring pressure at specified spring height.

If the installation load or load with valve open is out of the stan-

dard, replace valve spring.

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to check there is no leakage of fuel, exhaust gases, or any oil/fluids including

engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Standard (Intake and exhaust)

: Refer to EM-139,

"CylinderHead". Free height

Installation height

Installation load

Height during valve open

Load with valve open

SEM113

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2169 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-140

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

DTC Index

INFOID:0000000003959694

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A mal NISSAN TEANA 2008 Manual PDF EXL-140

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

DTC Index

INFOID:0000000003959694

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A mal](/img/5/57391/w960_57391-2168.png)

EXL-140

< ECU DIAGNOSIS >[XENON TYPE]

BCM (BODY CONTROL MODULE)

DTC Index

INFOID:0000000003959694

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A malfunction was detected in the past.

IGN counter is displayed on Freeze Frame Data. For details of Freeze Frame Data and IGN Counter, refer to

BCS-16, "

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)".

4 B2013: ID DISCORD BCM-S/L

B2014: CHAIN OF S/L-BCM

B2553: IGNITION RELAY

B2555: STOP LAMP

B2556: PUSH-BTN IGN SW

B2557: VEHICLE SPEED

B2560: STARTER CONT RELAY

B2601: SHIFT POSITION

B2602: SHIFT POSITION

B2603: SHIFT POSI STATUS

B2604: PNP SW

B2605: PNP SW

B2606: S/L RELAY

B2607: S/L RELAY

B2608: STARTER RELAY

B2609: S/L STATUS

B260A: IGNITION RELAY

B260B: STEERING LOCK UNIT

B260C: STEERING LOCK UNIT

B260D: STEERING LOCK UNIT

B260F: ENG STATE SIG LOST

B2612: S/L STATUS

B2614: ACC RELAY CIRC

B2615: BLOWER RELAY CIRC

B2616: IGN RELAY CIRC

B2617: STARTER RELAY CIRC

B2618: BCM

B2619: BCM

B261A: PUSH-BTN IGN SW

B261E: VEHICLE TYPE

B26E1: ENG STATE NO RES

B26E9: S/L STATUS

B26EA: KEY REGISTRATION

U0415: VEHICLE SPEED SIG

5 B2621: INSIDE ANTENNA

B2622: INSIDE ANTENNA

B2623: INSIDE ANTENNA Priority DTC

CONSULT display Fail-safe Freeze Frame DataIntelligent Key warn-

ing lamp ONReference page

No DTC is detected.

further testing

may be required.————

U1000: CAN COMM CIRCUIT — — —BCS-33

U1010: CONTROL UNIT (CAN) — — —BCS-34

U0415: VEHICLE SPEED SIG — — —BCS-35

B2013: ID DISCORD BCM-S/L××—SEC-46

B2014: CHAIN OF S/L-BCM××—SEC-47

B2190: NATS ANTENNA AMP×——SEC-39

B2191: DIFFERENCE OF KEY×——SEC-42

Page 2170 of 5121

![NISSAN TEANA 2008 Manual PDF BCM (BODY CONTROL MODULE)

EXL-141

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

B2192: ID DISCORD BCM-ECM×——SEC-43

B2193: CHAIN OF BCM-ECM×——SEC-45

B2553: IGNITION RELAY — NISSAN TEANA 2008 Manual PDF BCM (BODY CONTROL MODULE)

EXL-141

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

B2192: ID DISCORD BCM-ECM×——SEC-43

B2193: CHAIN OF BCM-ECM×——SEC-45

B2553: IGNITION RELAY —](/img/5/57391/w960_57391-2169.png)

BCM (BODY CONTROL MODULE)

EXL-141

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

B2192: ID DISCORD BCM-ECM×——SEC-43

B2193: CHAIN OF BCM-ECM×——SEC-45

B2553: IGNITION RELAY —×—PCS-49

B2555: STOP LAMP —×—SEC-50

B2556: PUSH-BTN IGN SW —××SEC-52

B2557: VEHICLE SPEED×××SEC-54

B2560: STARTER CONT RELAY×××SEC-55

B2562: LOW VOLTAGE —×—BCS-36

B2601: SHIFT POSITION×××SEC-56

B2602: SHIFT POSITION×××SEC-59

B2603: SHIFT POSI STATUS×××SEC-61

B2604: PNP SW×××SEC-64

B2605: PNP SW×××SEC-67

B2606: S/L RELAY×××SEC-69

B2607: S/L RELAY×××SEC-70

B2608: STARTER RELAY×××SEC-72

B2609: S/L STATUS×××SEC-74

B260A: IGNITION RELAY×××PCS-51

B260B: STEERING LOCK UNIT —××SEC-78

B260C: STEERING LOCK UNIT —××SEC-79

B260D: STEERING LOCK UNIT —××SEC-80

B260F: ENG STATE SIG LOST×××SEC-81

B2612: S/L STATUS×××SEC-85

B2614: ACC RELAY CIRC —××PCS-53

B2615: BLOWER RELAY CIRC —××PCS-55

B2616: IGN RELAY CIRC —××PCS-57

B2617: STARTER RELAY CIRC×××SEC-89

B2618: BCM×××PCS-59

B2619: BCM×××SEC-91

B261A: PUSH-BTN IGN SW —××SEC-92

B261E: VEHICLE TYPE××× (Turn ON for 15

seconds)SEC-95

B2621: INSIDE ANTENNA —×—DLK-50

B2622: INSIDE ANTENNA —×—DLK-52

B2623: INSIDE ANTENNA —×—DLK-54

B26E1: ENG STATE NO RES×××SEC-82

B26E9: S/L STATUS××× (Turn ON for 15

seconds)SEC-83

B26EA: KEY REGISTRATION —×× (Turn ON for 15

seconds)SEC-84

CONSULT display Fail-safe Freeze Frame DataIntelligent Key warn-

ing lamp ONReference page

Page 2175 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-146

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

28

(SB)GroundPush-button ignition

switchInputPress the push-button ignition switch 0 V

Release the p NISSAN TEANA 2008 Manual PDF EXL-146

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

28

(SB)GroundPush-button ignition

switchInputPress the push-button ignition switch 0 V

Release the p](/img/5/57391/w960_57391-2174.png)

EXL-146

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

28

(SB)GroundPush-button ignition

switchInputPress the push-button ignition switch 0 V

Release the push-button ignition switch Battery voltage

30

(BR)Ground Starter relay control InputIgnition

switch ONSelector lever in any posi-

tion other than P or N0 V

Selector lever P or N Battery voltage

32

(V)GroundSteering lock unit condi-

tion-1InputSteering lock is activated 0 V

Steering lock is deactivated Battery voltage

33

(G)GroundSteering lock unit condi-

tion-2InputSteering lock is activated Battery voltage

Steering lock is deactivated 0 V

34

(O)Ground Cooling fan relay-3 control InputCooling fan stopped Battery voltage

Cooling fan at HI operation 0 V

35

(P)GroundCooling fan relay-1 power

supplyInputCooling fan stopped Battery voltage

Cooling fan at LO operation 6.0 V

36

(G)Ground Battery power supply Input Ignition switch OFF Battery voltage

38

(GR)GroundCooling fan relay-1 power

supplyOutputCooling fan not operating 0 V

Cooling fan at LO operation 6.0 V

39

(P)—CAN-LInput/

Output——

40

(L)—CAN-HInput/

Output——

41

(B)Ground Ground — Ignition switch ON 0 V

42

(SB)Ground Cooling fan relay-2 control InputCooling fan stopped Battery voltage

Cooling fan MID operating

Cooling fan HI operating0 V

43

(Y)GroundControl device

(Detention switch)InputIgnition

switch ONPress the selector button

(selector lever P)Battery voltage

Selector lever in any po-

sition other than P

Release the selector

button (selector lever P)0 V

44

(G)Ground Horn relay control InputThe horn is deactivated Battery voltage

The horn is activated 0 V

45

(O)Ground Horn switch InputThe horn is deactivated Battery voltage

The horn is activated 0 V

46

(BR)Ground Starter relay control InputIgnition

switch ONSelector lever in any posi-

tion other than P or N0 V

Selector lever P or N Battery voltage

48

(Y/R)Ground A/C relay power supply OutputEngine

runningA/C switch OFF 0 V

A/C switch ON

(A/C compressor is oper-

ating)Battery voltage Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +−

Page 2177 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-148

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

75

(P/L)Ground Oil pressure switch InputIgnition

switch ONEngine stopped 0 V

Engine running Battery NISSAN TEANA 2008 Manual PDF EXL-148

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

75

(P/L)Ground Oil pressure switch InputIgnition

switch ONEngine stopped 0 V

Engine running Battery](/img/5/57391/w960_57391-2176.png)

EXL-148

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

75

(P/L)Ground Oil pressure switch InputIgnition

switch ONEngine stopped 0 V

Engine running Battery voltage

76

(SB)GroundPower generation com-

mand signalOutputIgnition switch ON

6.3 V

40% is set on “ACTIVE TEST”, “AL-

TERNATOR DUTY” of “ENGINE”

3.8 V

80% is set on “ACTIVE TEST”, “AL-

TERNATOR DUTY” of “ENGINE”

1.4 V

77

(GR)Ground Fuel pump relay control Output Approximately 1 second after turning

the ignition switch ON

Engine running0 - 1.5 V

Approximately 1 second or more after

turning the ignition switch ONBattery voltage

80

(B/W)Ground Starter motor Output At engine cranking Battery voltage

83

(Y)Ground Headlamp LO (RH) OutputIgnition

switch ONLighting switch OFF 0 V

Lighting switch 2ND Battery voltage

84

(SB)Ground Headlamp LO (LH) OutputIgnition

switch ONLighting switch OFF 0 V

Lighting switch 2ND Battery voltage

86

(L)Ground Front fog lamp (RH) OutputLighting

switch

2ND Front fog lamp switch

ON

Daytime running light

activated (Only for Can-

ada)Battery voltage

Front fog lamp switch OFF 0 V

87

(R)Ground Front fog lamp (LH) OutputLighting

switch

2ND Front fog lamp switch

ON

Daytime running light

activated (Only for Can-

ada)Battery voltage

Front fog lamp switch OFF 0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +−

JPMIA0001GB

JPMIA0002GB

JPMIA0003GB

Page 2183 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-154

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/ NISSAN TEANA 2008 Manual PDF EXL-154

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/](/img/5/57391/w960_57391-2182.png)

EXL-154

< ECU DIAGNOSIS >[XENON TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

Control part Fail-safe operation

Cooling fan Turns ON the cooling fan relay-2 and the cooling fan relay-3 when ignition switch is

turned ON (Cooling fan operates at HI)

Turns OFF the cooling fan relay-1, the cooling fan relay-2 and the cooling fan relay-3

when the ignition switch is turned OFF (Cooling fan does not operate)

A/C compressor A/C relay OFF

Alternator Outputs the power generation command signal (PWM signal) 0%

Control part Fail-safe operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Illuminations

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Front fog lamps Front fog lamp relay OFF

Horn Horn OFF

Ignition relay The status just before activation of fail-safe is maintained.

Starter motor Starter control relay OFF

Steering lock unit Steering lock relay OFF

Headlamp washer relay Headlamp washer relay OFF

Voltage judgment

IPDM E/R judgment Operation

Ignition relay contact sideIgnition relay excitation coil

side

ON ON Ignition relay ON normal —

OFF OFF Ignition relay OFF normal —

ON OFF Ignition relay ON stuck Detects DTC “B2098: IGN RELAY ON”

Turns ON the tail lamp relay for 10 min-

utes

OFF ON Ignition relay OFF stuck Detects DTC “B2099: IGN RELAY OFF”

Page 2184 of 5121

![NISSAN TEANA 2008 Manual PDF IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-155

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Data NISSAN TEANA 2008 Manual PDF IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-155

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Data](/img/5/57391/w960_57391-2183.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-155

< ECU DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

DTC IndexINFOID:0000000003894276

NOTE:

The details of time display are as follows.

- CRNT: A malfunction is detected now

- PAST: A malfunction was detected in the past.

IGN counter is displayed on FFD (Freeze Frame data).

- The number is 0 when is detected now

- The number increases like 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF →

ON.

- The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

×: Applicable

Ignition switch Front wiper switch Front wiper auto stop signal

ONOFFThe front wiper auto stop signal (stop posi-

tion) cannot be input for 10 seconds.

ONThe front wiper auto stop signal does not

change for 10 seconds.

CONSULT display Fail-safe Refer to

No DTC is detected.

further testing

may be required.——

U1000: CAN COMM CIRCUIT×PCS-16

B2098: IGN RELAY ON×PCS-17

B2099: IGN RELAY OFF —PCS-18

B2108: STRG LCK RELAY ON —SEC-96

B2109: STRG LCK RELAY OFF —SEC-97

B210A: STRG LCK STATE SW —SEC-98

B210B: START CONT RLY ON —SEC-102

B210C: START CONT RLY OFF —SEC-103

B210D: STARTER RELAY ON —SEC-104

B210E: STARTER RELAY OFF —SEC-105

B210F: INTRLCK/PNP SW ON —SEC-107

B2110: INTRLCK/PNP SW OFF —SEC-109

Page 2203 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-174

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure (Low Beam)

INFOID:0000000003774533

1. Place the screen.

NOTE:

Stop the vehicle at the perpendic NISSAN TEANA 2008 Manual PDF EXL-174

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure (Low Beam)

INFOID:0000000003774533

1. Place the screen.

NOTE:

Stop the vehicle at the perpendic](/img/5/57391/w960_57391-2202.png)

EXL-174

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure (Low Beam)

INFOID:0000000003774533

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

Set the screen so that it is perpendicular to a level load surface.

2. Face the vehicle squarely toward the screen and make the distance between the headlamp center and

the screen 10 m (32.8 ft).

3. Start the engine and illuminate the headlamp (LO).

NOTE:

Block light from the headlamp that is not being adjusted with a thick fabric or another object, so that it

does not reach the adjustment screen.

CAUTION:

Do not cover lens surface with tape, etc. because it is made from plastic.

4. Use the aiming adjustment screw to adjust the elbow point projected by the low beams on the screen, so

that it is within the aiming adjustment area.

A. Headlamp (LO) RH

(UP/DOWN) adjustment screwB. Headlamp (HI) RH

(UP/DOWN) adjustment screwC. Headlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screw

D. Headlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screwE. Headlamp (LO) LH

(UP/DOWN) adjustment screwF. Headlamp (HI) LH

(UP/DOWN) adjustment screw

G. H e a d l a m p ( L O ) L H

(UP-OUTSIDE/DOWN-INSIDE)

adjustment screwH. Headlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)

adjustment screw

: Vehicle center

Adjustment screw Screw driver rotation Facing direction

AHeadlamp (LO) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

BHeadlamp (HI) RH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

CHeadlamp (LO) RH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

DHeadlamp (HI) RH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE

EHeadlamp (LO) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

FHeadlamp (HI) LH

(UP/DOWN)Clockwise UP

Counterclockwise DOWN

GHeadlamp (LO) LH

(UP-OUTSIDE/DOWN-INSIDE)Clockwise DOWN-INSIDE

Counterclockwise UP-OUTSIDE

HHeadlamp (HI) LH

(UP-INSIDE/DOWN-OUTSIDE)Clockwise DOWN-OUTSIDE

Counterclockwise UP-INSIDE

Page 2207 of 5121

![NISSAN TEANA 2008 Manual PDF EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re NISSAN TEANA 2008 Manual PDF EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re](/img/5/57391/w960_57391-2206.png)

EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the lug-

gage room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the

figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000003773618

1. Place the screen.

NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Illuminate the front fog lamp.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

4. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

A: UP

B: DOWN

JPLIA1086ZZ

JPLIA0008ZZ