oil type NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 179 of 5121

![NISSAN TEANA 2008 Service Manual AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information, NISSAN TEANA 2008 Service Manual AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information,](/img/5/57391/w960_57391-178.png)

AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information, refer to Owner's Manual.

The majority of the audio concerns are the result of outside causes (bad CD, electromagnetic interference,

etc.).

NOISE

The following noise results from variations in field strength, such as fading noise and multi-path noise, or

external noise from trains and other sources. It is not a malfunction.

Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the

antenna at a different time from the waves that reflect off mountains or buildings.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and then determine the cause.

NOTE:

The source of the noise can be easily found by listening to the noise while removing the fuses of electrical

components, one by one.

Types of Noise and Possible Causes

Occurrence condition Possible cause

Occurs only when engine is ON.A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed. Ignition components

The occurrence of the noise is linked with the operation of the fuel pump. Fuel pump condenser

Noise only occurs when various

electrical components are oper-

ating.A cracking or snapping sound occurs with the op-

eration of various switches. Relay malfunction, audio unit malfunction

The noise occurs when various motors are operat-

ing. Motor case ground

Motor

The noise occurs constantly, not just under certain conditions. Rear defogger coil malfunction

Open circuit in printed heater

Poor ground of antenna feeder line

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. Ground wire of body parts

Ground due to improper part installation

Wiring connections or a short circuit

Page 996 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000 NISSAN TEANA 2008 Service Manual PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000000](/img/5/57391/w960_57391-995.png)

PRECAUTIONS

BRC-55

< PRECAUTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003893848

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000003928740

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003766860

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

Only use “DOT 3” or “DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Never use mineral oils such as gasoline or light oil. They may damage rubber parts and cause improper

operation.

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a flare

nut torque wrench (A).

Always conform the specified tightening torque when installing the

brake pipes.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) connector or the battery negative terminal

before performing the work.

PIIB3706J

JPFIA0061ZZ

Page 997 of 5121

![NISSAN TEANA 2008 Service Manual BRC-56

< PRECAUTION >[ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003766861

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor NISSAN TEANA 2008 Service Manual BRC-56

< PRECAUTION >[ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003766861

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor](/img/5/57391/w960_57391-996.png)

BRC-56

< PRECAUTION >[ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003766861

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for estimate causes before starting diagnos-

tic servicing. Besides electrical system inspection, check brake booster operation, brake fluid level, and oil

leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

Precautions for Harness RepairINFOID:0000000003859437

COMMUNICATION LINE

Solder the repaired area and wrap tape around the soldered area.

NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

Bypass connection is never allowed at the repaired area.

NOTE:

Bypass connection may cause communication error as spliced

wires that are separate from the main line or twisted lines lose

noise immunity.

Replace the applicable harness as an assembly if error is detected

on the shield lines of communication line.

SKIB8766E

SKIB8767E

Page 1090 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

BRC-149

< PRECAUTION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO NISSAN TEANA 2008 Service Manual PRECAUTIONS

BRC-149

< PRECAUTION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/5/57391/w960_57391-1089.png)

PRECAUTIONS

BRC-149

< PRECAUTION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003893849

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000003928809

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003767031

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

Only use “DOT 3” or “DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Never use mineral oils such as gasoline or light oil. They may damage rubber parts and cause improper

operation.

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a flare

nut torque wrench (A).

Always conform the specified tightening torque when installing the

brake pipes.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) connector or the battery negative terminal

before performing the work.

PIIB3706J

JPFIA0061ZZ

Page 1091 of 5121

![NISSAN TEANA 2008 Service Manual BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate NISSAN TEANA 2008 Service Manual BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate](/img/5/57391/w960_57391-1090.png)

BRC-150

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

Precaution for Brake Control

INFOID:0000000003767032

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for estimate causes before starting diagnos-

tic servicing. Besides electrical system inspection, check brake booster operation, brake fluid level, and oil

leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

VDC system may not operate normally or a VDC OFF indicator lamp or SLIP indicator lamp may light.

- When replacing the following parts with parts other than genuine parts or making modifications: Suspension

related parts (shock absorber, spring, bushing, etc.), tires, wheels (other than specified sizes), brake-related

parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-related parts

(roll bar, tower bar, etc.).

- When driving with worn or deteriorated suspension, tires and brake-related parts.

Precautions for Harness RepairINFOID:0000000003843440

COMMUNICATION LINE

Solder the repaired area and wrap tape around the soldered area.

NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

Bypass connection is never allowed at the repaired area.

NOTE:

Bypass connection may cause communication error as spliced

wires that are separate from the main line or twisted lines lose

noise immunity.

Replace the applicable harness as an assembly if error is detected

on the shield lines of communication line.

SKIB8766E

SKIB8767E

Page 1120 of 5121

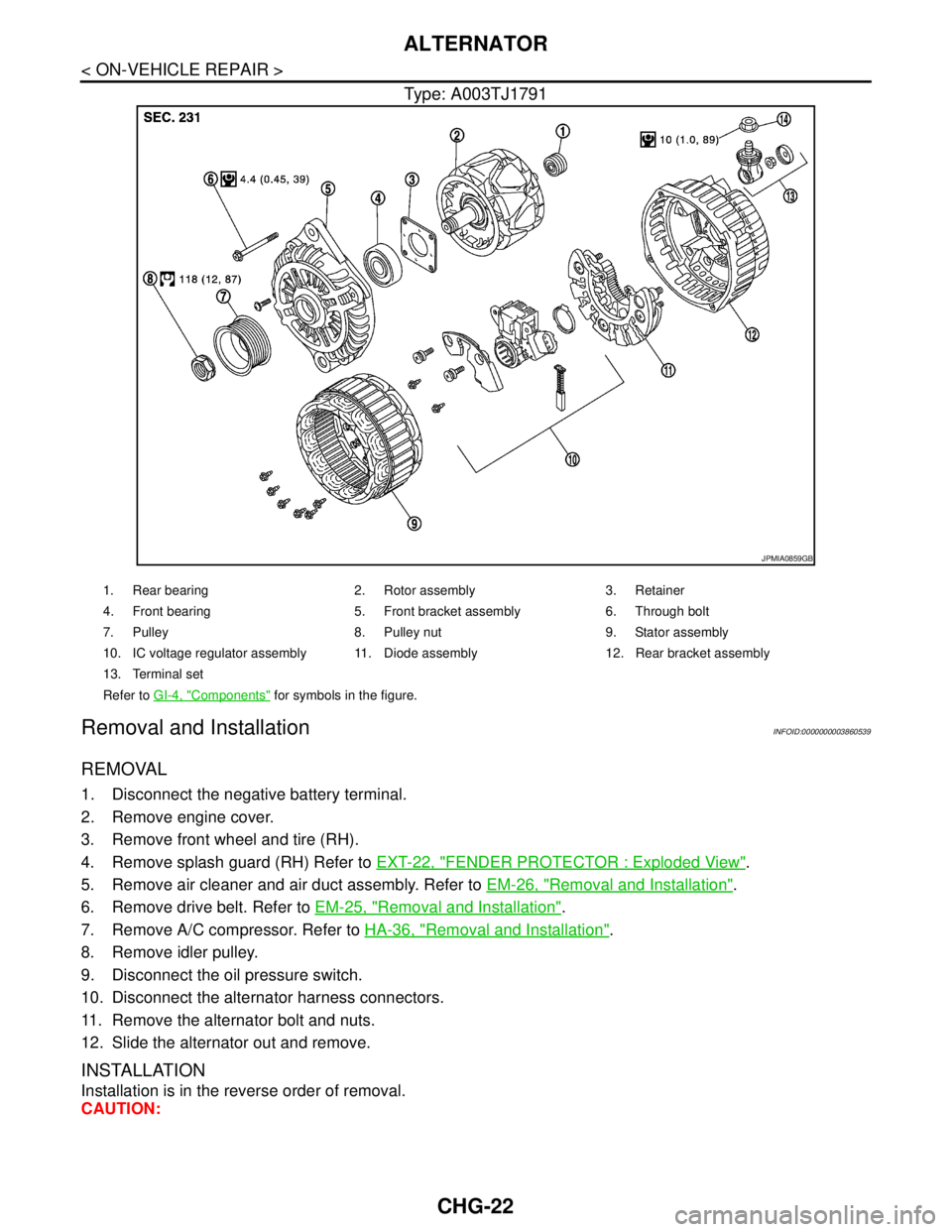

CHG-22

< ON-VEHICLE REPAIR >

ALTERNATOR

Type: A003TJ1791

Removal and InstallationINFOID:0000000003860539

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove engine cover.

3. Remove front wheel and tire (RH).

4. Remove splash guard (RH) Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

5. Remove air cleaner and air duct assembly. Refer to EM-26, "

Removal and Installation".

6. Remove drive belt. Refer to EM-25, "

Removal and Installation".

7. Remove A/C compressor. Refer to HA-36, "

Removal and Installation".

8. Remove idler pulley.

9. Disconnect the oil pressure switch.

10. Disconnect the alternator harness connectors.

11. Remove the alternator bolt and nuts.

12. Slide the alternator out and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

JPMIA0859GB

1. Rear bearing 2. Rotor assembly 3. Retainer

4. Front bearing 5. Front bracket assembly 6. Through bolt

7. Pulley 8. Pulley nut 9. Stator assembly

10. IC voltage regulator assembly 11. Diode assembly 12. Rear bracket assembly

13. Terminal set

Refer to GI-4, "

Components" for symbols in the figure.

Page 1673 of 5121

![NISSAN TEANA 2008 Service Manual EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal NISSAN TEANA 2008 Service Manual EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal](/img/5/57391/w960_57391-1672.png)

EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-136, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-136, "

Spark

Plug".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-22, "

Inspection".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-411, "

Inspection".

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-411, "

Inspection".

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace “fuel filter and fuel pump assembly”.

NO >> Repair or replace malfunctioning part.

12.CHECK IGNITION TIMING

Check idle speed and ignition timing.

For procedure, refer to EC-11, "

BASIC INSPECTION : Special Repair Requirement".

For specification, refer to EC-414, "

Idle Speed" and EC-414, "Ignition Timing".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Follow the EC-11, "

BASIC INSPECTION : Special Repair Requirement".

13.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

SEF156I

Spark should be generated.

At idle: Approximately 350 kPa (3.50 bar, 3.57 kg/cm

2, 51 psi)

Page 1691 of 5121

![NISSAN TEANA 2008 Service Manual EC-230

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) wit NISSAN TEANA 2008 Service Manual EC-230

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) wit](/img/5/57391/w960_57391-1690.png)

EC-230

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-136, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 9.

9.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-136, "

Spark

Plug".

10.CHECK FUEL INJECTOR

1. Turn ignition switch OFF.

2. Remove fuel injector assembly.

Refer to EM-44, "

Removal and Installation".

Keep fuel hose and all fuel injectors connected to fuel tube.

3. Disconnect all ignition coil harness connectors.

4. Reconnect all fuel injector harness connectors disconnected.

5. Turn ignition switch ON.

Check the fuel does not drip from fuel injector.

Does fuel drip from fuel injector?

YES >> Replace the fuel injector(s) from which fuel is dripping.

NO >> GO TO 11.

11 .CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

Is the inspection result norma?

YES >> Replace three way catalyst assembly.

NO >> Repair or replace harness or connector.

SEF156I

Spark should be generated.

Page 1866 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF](/img/5/57391/w960_57391-1865.png)

PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003960684

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precautions For Xenon Headlamp ServiceINFOID:0000000003856878

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Precaution for Procedure without Cowl Top CoverINFOID:0000000003856879

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnostic (OBD) System of Engine and CVTINFOID:0000000003856880

The ECM has an on board diagnostic system. It will illuminate the malfunction indicator MI to warn the driver of

a malfunction causing emission deterioration.

PIIB3706J

Page 1868 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-407

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When connecting or disconnecting pin connectors into or

from ECM, never damage pin terminals (bends or break).

Check NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-407

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When connecting or disconnecting pin connectors into or

from ECM, never damage pin terminals (bends or break).

Check](/img/5/57391/w960_57391-1867.png)

PRECAUTIONS

EC-407

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

When connecting or disconnecting pin connectors into or

from ECM, never damage pin terminals (bends or break).

Check that there are not any bends or breaks on ECM pin ter-

minal, when connecting pin connectors.

Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and condenser, thus resulting in dam-

age to ICs.

Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving external noise, degraded operation

of ICs, etc.

Keep engine control system parts and harness dry.

Before replacing ECM, perform ECM Terminals and Reference

Value inspection and check ECM functions properly. Refer to

EC-357, "

Reference Value".

Handle mass air flow sensor carefully to avoid damage.

Never clean mass air flow sensor with any type of detergent.

Never disassemble electric throttle control actuator.

Even a slight leak in the air intake system can cause serious

incidents.

Never shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

After performing each TROUBLE DIAGNOSIS, perform DTC

Confirmation Procedure or Component Function Check.

The DTC should not be displayed in the DTC Confirmation

Procedure if the repair is completed. The Component Func-

tion Check should be a good result if the repair is completed.

PBIB0090E

MEF040D

SAT652J