transmission fluid NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1585 of 5121

![NISSAN TEANA 2008 Service Manual EC-124

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003856505

The specification NISSAN TEANA 2008 Service Manual EC-124

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003856505

The specification](/img/5/57391/w960_57391-1584.png)

EC-124

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003856505

The specification (SP) value indicates the tolerance of the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode of CONSULT-III during normal operation of the Engine Control System. When the value in “SPEC”

in “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may have one or more

malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not illuminate

the MI.

The SP value will be displayed for the following three items:

B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc-

tion)

A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Component Function CheckINFOID:0000000003856506

1.START

Check that all of the following conditions are satisfied.

Vehicle driven distance: More than 5,000 km (3,107 miles)

Barometric pressure: 98.3 - 104.3 kPa (0.983 - 1.043 bar, 1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

Atmospheric temperature: 20 - 30°C (68 - 86°F)

Engine coolant temperature: 75 - 95°C (167 - 203°F)

Transmission: Warmed-up

- After the engine is warmed up to normal operating temperature, drive vehicle until “FLUID TEMP SE” (CVT

fluid temperature sensor signal) indicates more than 60°C (140°F).

Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

Engine speed: Idle

>> GO TO 2.

2.PERFORM “SPEC” OF “DATA MONITOR” MODE

With CONSULT-III

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform “EC-11, "

BASIC INSPECTION : Special Repair Requirement".

2. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2” and “MAS A/F SE-B1” in “SPEC” of “DATA

MONITOR” mode with CONSULT-III.

3. Check that monitor items are within the SP value.

Is the measurement value within the SP value?

YES >> INSPECTION END

NO >> Go to EC-125, "

Diagnosis Procedure".

Page 1941 of 5121

EM-66

< ON-VEHICLE REPAIR >

TIMING CHAIN

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate an unusualness. Noise

will stop after hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 1943 of 5121

EM-68

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

Place chocks at front and back of rear wheels.

For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS

CATALOG.

CAUTION:

Always be careful to work safely, avoid forceful or uninstructed operations.

Never start working until exhaust system and engine coolant are cool enough.

If items or work required are not covered by the engine section, refer to the applicable sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with transmission jack or similar tool before

starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-30, "

Garage Jack and

Safety Stand and 2-Pole Lift".

REMOVAL

Outline

At first, remove the engine and the transaxle assembly with front suspension member downward. Then sepa-

rate the engine and the transaxle.

Preparation

1. Release fuel pressure. Refer to EC-411, "Inspection".

2. Drain engine coolant. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

3. Remove the following parts:

Engine cover: Refer to EM-24, "

Exploded View".

Front road wheel and tires

Splash guards (RH and LH): Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

Air duct (inlet), air cleaner cases (upper and lower) with mass air flow sensor and air duct assembly:

Refer to EM-26, "

Exploded View".

Battery and battery tray: Refer to PG-109, "

Removal and Installation".

Drive belt: Refer to EM-12, "

Removal and Installation".

Reservoir tank of radiator. Refer to CO-13, "

Exploded View".

Front wiper arm: Refer to WW-105, "

Exploded View".

4. Disconnect engine room harness at the TCM, ECM and other sides.

CAUTION:

To keep clean harness connector and avoid damage and foreign materials, cover them completely

with plastic bags or something similar.

5. Remove battery bracket with ECM and TCM.

6. Remove extension cowl top. Refer to EXT-20, "

Exploded View".

Engine Room

1. Disconnect heater hoses. Refer to CO-25, "Exploded View".

Install plug to avoid leakage of engine coolant.

2. Remove EVAP hose. Refer to EM-28, "

Exploded View".

3. Disconnect fuel feed hose quick connector at fuel tube side. Refer to EM-44, "

Exploded View".

Install plug to avoid leakage of fuel.

4. Disconnect transaxle shift control cable at transaxle side. Refer to TM-319, "

Exploded View" (VQ25DE) or

TM-157, "

Exploded View" (VQ35DE).

5. Disconnect brake booster vacuum hose at engine side. Refer to EM-28, "

Exploded View".

6. Disconnect ground cable.

7. Disconnect A/C compressor piping at A/C compressor side. Refer to HA-36, "

Exploded View".

8. Disconnect suction hoses of power steering oil pump at reservoir tank side. Refer to ST-34, "

Exploded

View".

Install plug to avoid leakage of power steering fluid.

9. Disconnect CVT fluid cooler hoses from radiator. Refer to CO-13, "

Exploded View".

Page 1944 of 5121

ENGINE ASSEMBLY

EM-69

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove starter motor. Refer to STR-15, "VQ25DE : Exploded View" (VQ25DE) or STR-20, "VQ35DE :

Exploded View" (VQ35DE).

Vehicle Underbody

1. Remove front drive shafts (RH and LH). Refer to FAX-16, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove heat insulator.

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to ST-16, "

Exploded View".

5. Disconnect front stabilizer connecting rod. Refer to FSU-14, "

Exploded View".

6. Remove strut assembly and steering knuckle fixing nuts and bolts. Refer to FSU-9, "

Exploded View" and

FA X - 8 , "

Exploded View".

7. Remove front wheel sensor (RH and LH) for ABS from steering knuckle. Refer to BRC-57, "

FRONT

WHEEL SENSOR : Exploded View".

8. Remove front brake caliper assembly with piping connected, and temporarily secure it to aside for vehicle

side. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

9. Disconnect power steering piping at a point between vehicle and engine. Refer to ST-34, "

Exploded

View".

Install plug to avoid leakage of power steering fluid.

10. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-38, "

Exploded View" and TM-332, "Removal and Installation" (VQ25DE) or TM-168,

"Removal and Installation" (VQ35DE).

11. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-38, "

Exploded

View".

12. Remove crankshaft position sensor (POS). Refer to EM-38, "

Exploded View".

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part at sensor tip.

Never place sensors in a location where they are exposed to magnetism.

Removal

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of front suspension member.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine mounting insulator (RH) and engine mounting bracket (RH).

3. Remove mounting bolt between transverse link and front suspension member with power tool.

4. Remove front suspension member mounting nuts and bolts. Refer to FSU-16, "

Exploded View".

5. Carefully lower jack, or raise lift to remove the engine and the transaxle assembly and front suspension

member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Check all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support the vehi-

cle at rear jacking point(s) to prevent it from falling it off the lift.

Separation

PBIC1190E

Page 1950 of 5121

ENGINE ASSEMBLY

EM-75

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

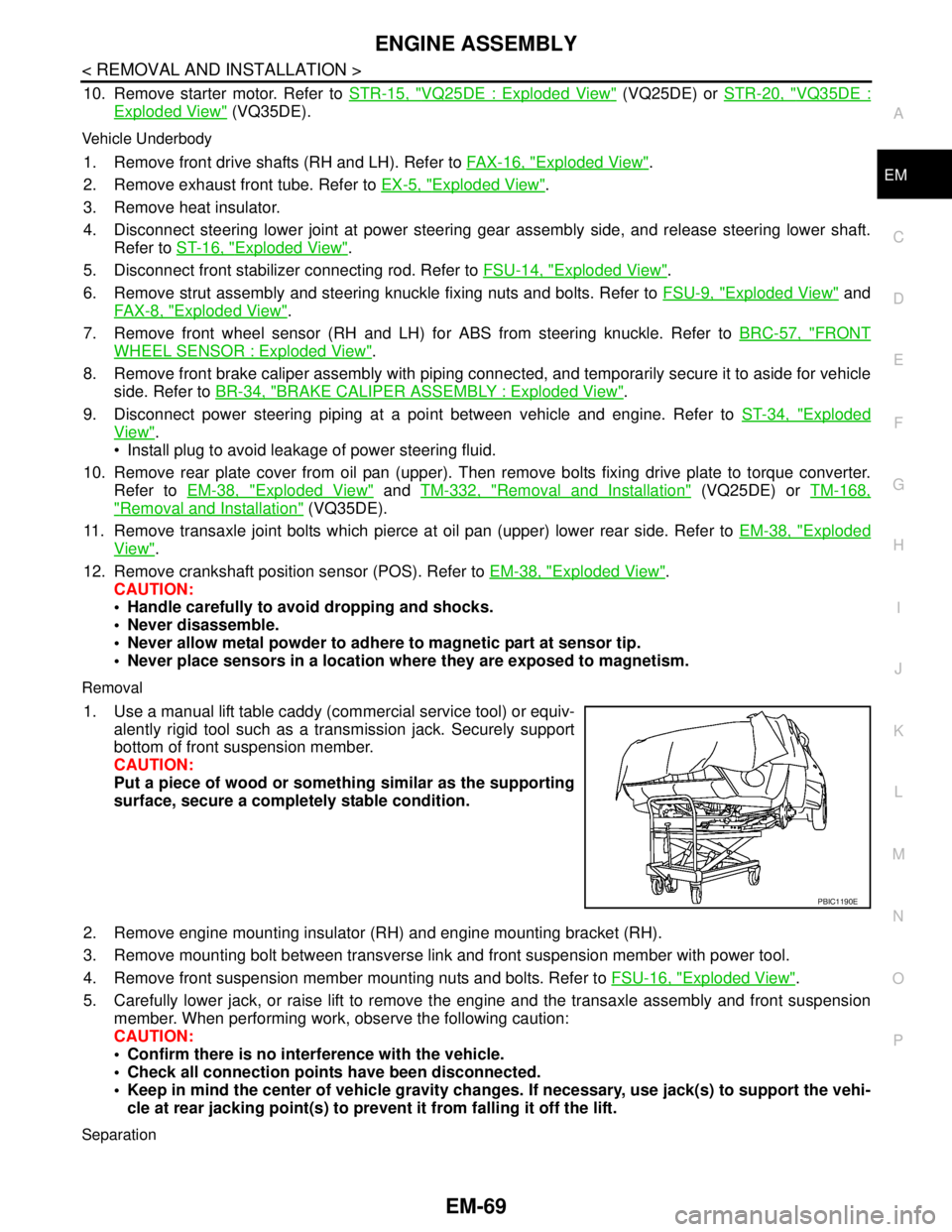

a. Tighten the bolt No. 2 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure.

(specified torque)

InspectionINFOID:0000000003802274

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to check there is no leakage of fuel, exhaust gases, or any oil/fluids including

engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.: Vehicle front

JPBIA1743ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1967 of 5121

EM-92

< DISASSEMBLY AND ASSEMBLY >

CAMSHAFT

b. Disconnect ignition coil and injector harness connectors. Refer to EM-49, "Exploded View" and EM-44,

"Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-79, "

Exploded View".

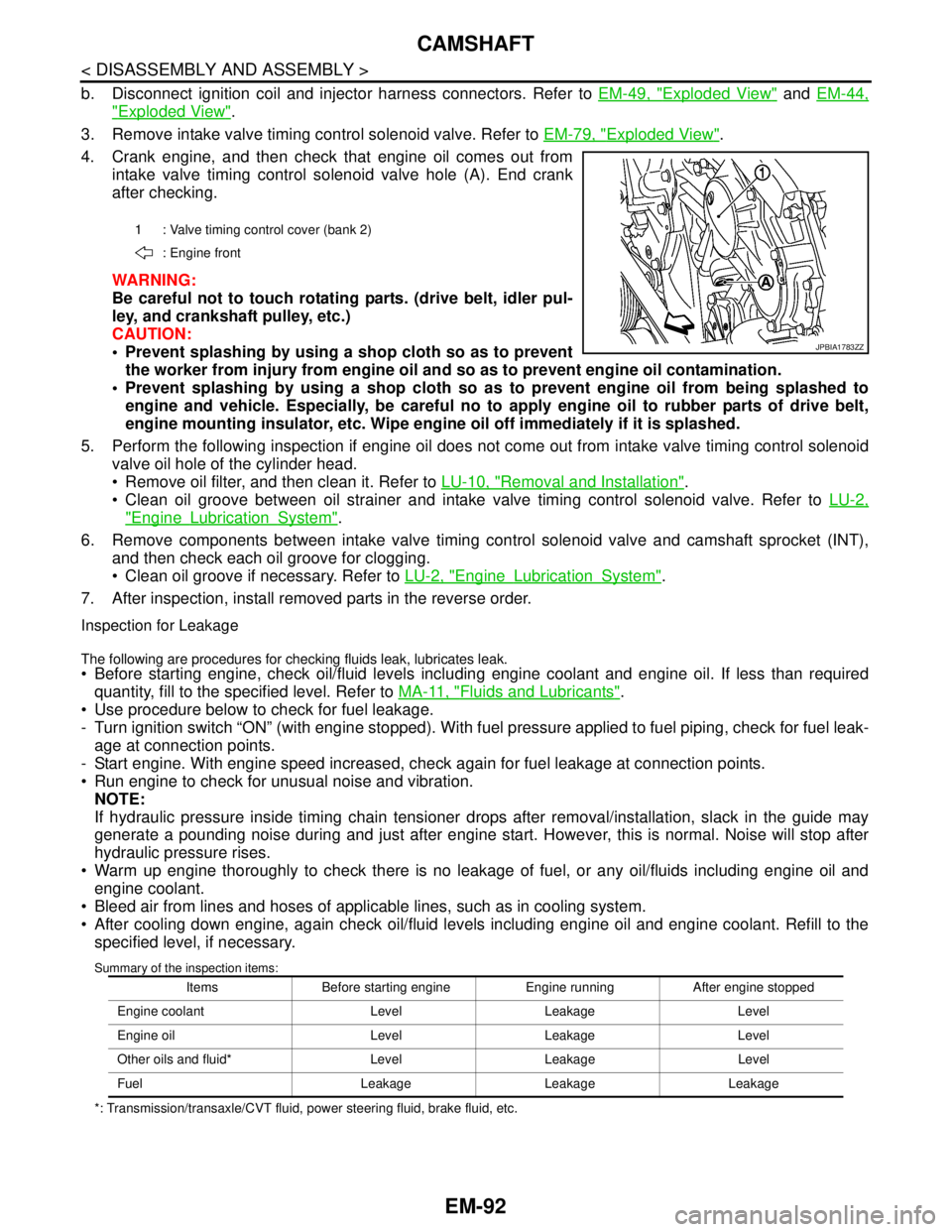

4. Crank engine, and then check that engine oil comes out from

intake valve timing control solenoid valve hole (A). End crank

after checking.

WARNING:

Be careful not to touch rotating parts. (drive belt, idler pul-

ley, and crankshaft pulley, etc.)

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful no to apply engine oil to rubber parts of drive belt,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

5. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid

valve oil hole of the cylinder head.

Remove oil filter, and then clean it. Refer to LU-10, "

Removal and Installation".

Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-2,

"EngineLubricationSystem".

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

Clean oil groove if necessary. Refer to LU-2, "

EngineLubricationSystem".

7. After inspection, install removed parts in the reverse order.

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak. Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to check there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.1 : Valve timing control cover (bank 2)

: Engine front

JPBIA1783ZZ

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Page 1981 of 5121

EM-106

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

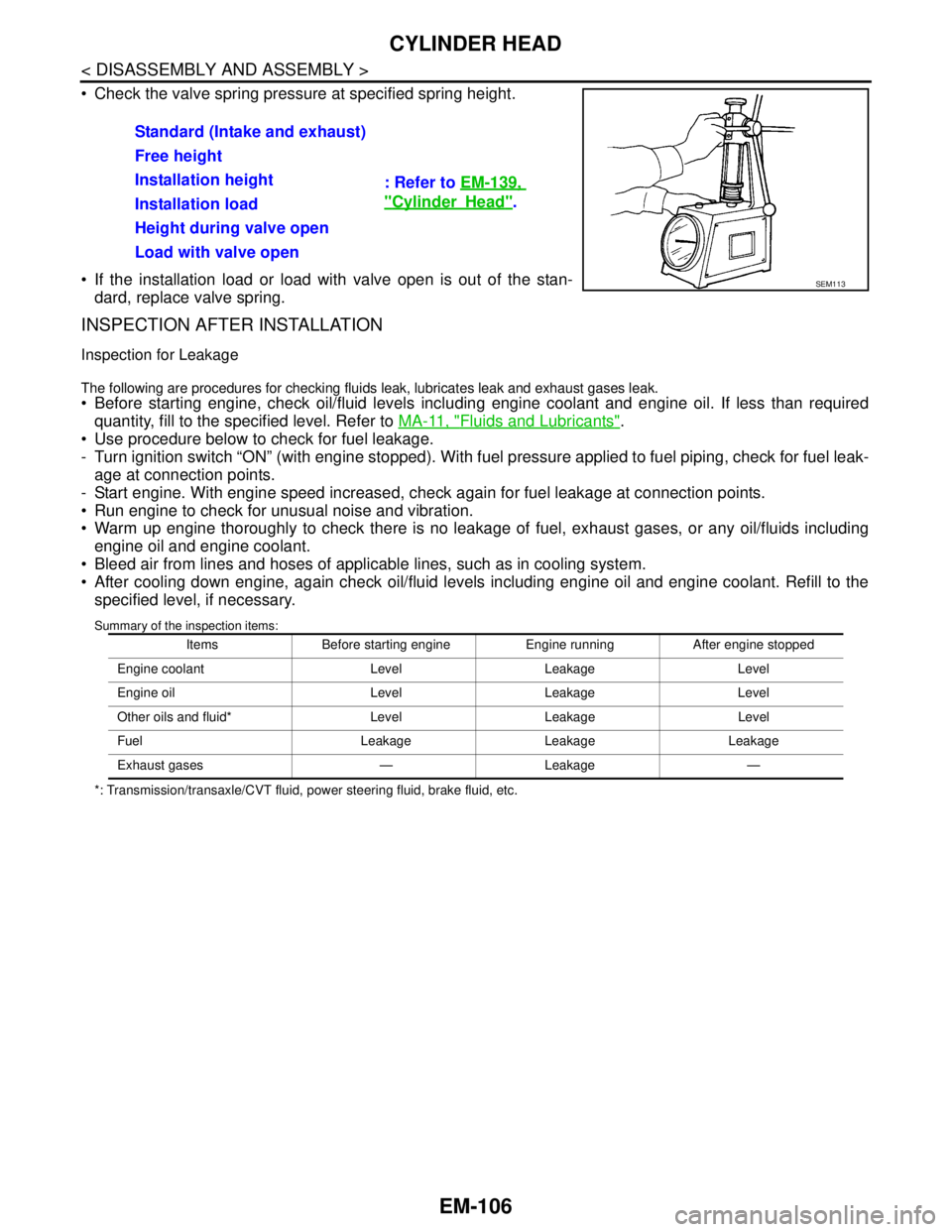

Check the valve spring pressure at specified spring height.

If the installation load or load with valve open is out of the stan-

dard, replace valve spring.

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to check there is no leakage of fuel, exhaust gases, or any oil/fluids including

engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Standard (Intake and exhaust)

: Refer to EM-139,

"CylinderHead". Free height

Installation height

Installation load

Height during valve open

Load with valve open

SEM113

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2506 of 5121

ABBREVIATIONS

GI-13

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PABBREVIATIONS

Abbreviation ListINFOID:0000000003852769

The following ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 2519 of 5121

GI-26

< PRECAUTION >

PRECAUTIONS

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of drained oil or the solvent used for cleaning parts in an

appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234

Page 3195 of 5121

PERIODIC MAINTENANCE

MA-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

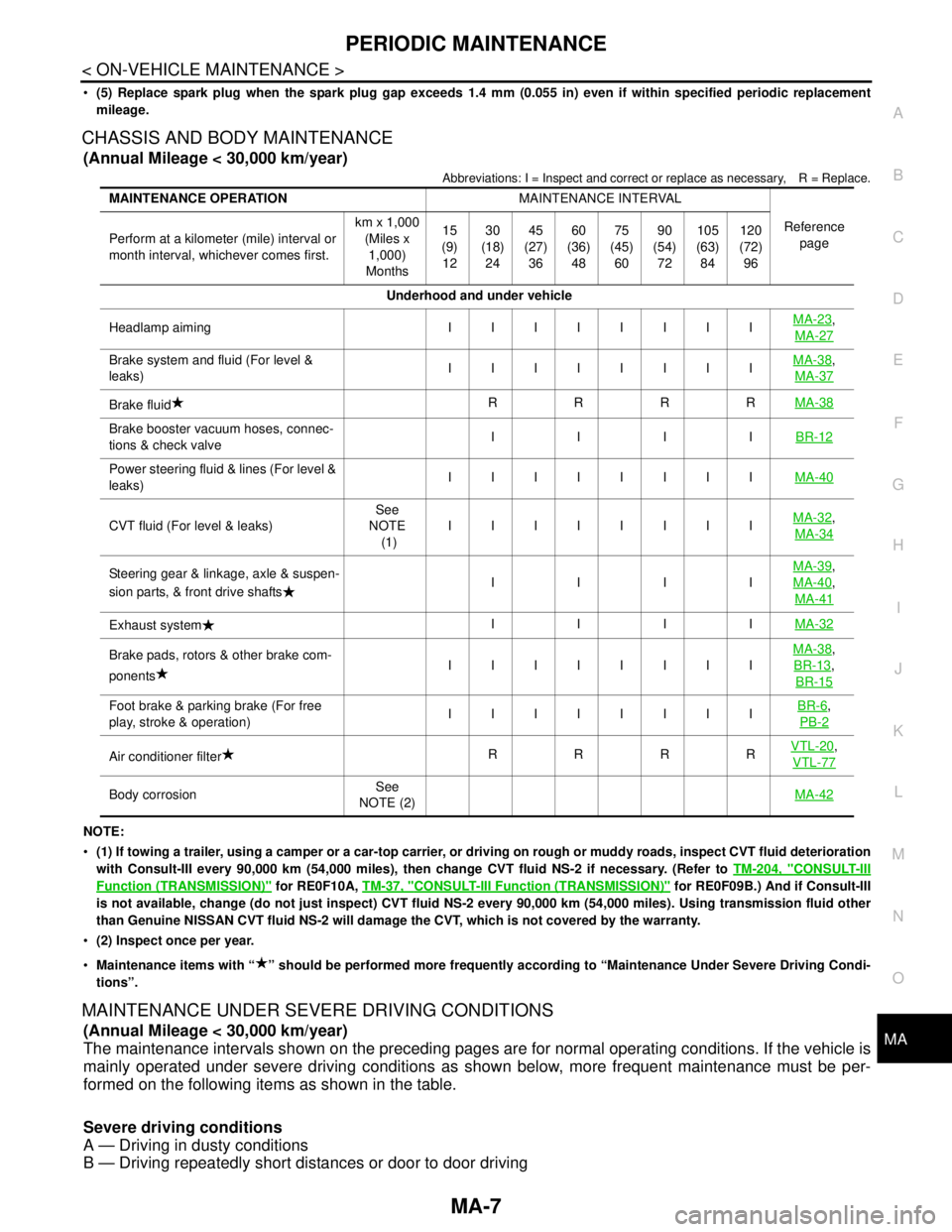

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

CHASSIS AND BODY MAINTENANCE

(Annual Mileage < 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration

with Consult-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. (Refer to TM-204, "

CONSULT-III

Function (TRANSMISSION)" for RE0F10A, TM-37, "CONSULT-III Function (TRANSMISSION)" for RE0F09B.) And if Consult-III

is not available, change (do not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other

than Genuine NISSAN CVT fluid NS-2 will damage the CVT, which is not covered by the warranty.

(2) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at a kilometer (mile) interval or

month interval, whichever comes first.km x 1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIIIIIMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIIIIIMA-38,

MA-37

Brake fluidRRRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIIIIIMA-40

CVT fluid (For level & leaks)See

NOTE

(1)IIIIIIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shaftsIIIIMA-39,

MA-40

,

MA-41

Exhaust systemIIIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIIIIIBR-6,

PB-2

Air conditioner filterRRRRVTL-20,

VTL-77

Body corrosionSee

NOTE (2)MA-42