seats NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2079 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-81

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

After confirming that the dimensions of valve guides and valves are

within specifications, perform this proc NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-81

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

After confirming that the dimensions of valve guides and valves are

within specifications, perform this proc](/img/5/57390/w960_57390-2078.png)

CYLINDER HEADEM-81

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

After confirming that the dimensions of valve guides and valves are

within specifications, perform this procedure:

• Apply prussian blue (or white lead) onto contacting surface of valve

seat to check the condition of t he valve contact on the seat sur-

face.

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve fitti ng and check again. If the contacting

surface still has NG conditions even after the re-check, replace the

valve seat.

VALVE SEAT REPLACEMENT

NOTE:

When valve seat is removed, replace with an oversized [0.5 mm (0.020 in)] valve seat.

1. Bore out old seat until it collapses. Boring shoul d not continue beyond the bottom face of the seat recess

in the cylinder head. Set the machine depth stop to ensure this.

2. Ream cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.This will enable the valve seat to fit correctly.

3. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

4. Use valve seats cooled well with dry ice. Force fit valve seat into cylinder head. CAUTION:

Avoid directly touching the cold valve seats.

5. Finish the seat to the specified dimensions using suitable tool. Refer to EM-111, "Standard and Limit"

.

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cu t in a single drive. Improper

pressure on the cutter or cutting many different times may

result in a defective valve seat.

6. Using compound, grind to adjust valve fitting.

7. Check again for normal contact.

SBIA0322E

Intake : 37.000 - 37.016 mm (1.4567 - 1.4573 in)

Exhaust : 32.000 - 32.016 mm (1.2598 - 1.2605 in)

SEM795A

SEM008A

SEM934C

Revision: November 20132014 Altima NAM

Page 2093 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER BLOCKEM-95

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

The gap of the upper rail on the oil ring shall face

the direction opposite to that of the lower rail. NISSAN TEANA 2014 User Guide

CYLINDER BLOCKEM-95

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

The gap of the upper rail on the oil ring shall face

the direction opposite to that of the lower rail.](/img/5/57390/w960_57390-2092.png)

CYLINDER BLOCKEM-95

< UNIT DISASSEMBLY AND ASSEMBLY > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

The gap of the upper rail on the oil ring shall face

the direction opposite to that of the lower rail.

• Install the top ring and the second ring with the stamped surface (E) facing upward.

12. Install the connecting rod bearings to the connecting rod and the connecting rod cap. Assemble the components in their original

positions.

• When installing the connecting rod bearings, apply engine oil

to the bearing friction surface (inside). Do not apply oil to the

back surface, but thoroughly clean the back.

• When installing, align the connecting rod bearing stopper pro- trusion (A) with the notch (B) of the connecting rod to install.

• Check the oil holes on the connecting rod and those on the corresponding bearing are aligned.

13. Install the piston and connecting rod assembly using Tool. Assemble the components in their original positions.

• Rotate the crankshaft so the pin corresponding to the connect- ing rod to be installed is at the bottom dead center position.

• Apply engine oil sufficiently to the cylinder bore, piston, and crankshaft pin.

• Match the cylinder position number with the cylinder No. on

the connecting rod for installation.

• Install the piston with the front mark on the piston crown facing the front of the engine using Tool.

CAUTION:

Be careful not to damage the crankshaft pin, resu lting from an interference of the connecting rod

big end.

14. Install the connecting rod caps. Assemble the components in their original positions.

• Match the stamped cylinder number marks (F) on the connect- ing rod with those on the cap to install.

15. Tighten the connecting rod bolts using Tool (A) as follows:

Apply engine oil to the threads and seats of the connecting rod

bolts.

CAUTION:

Check tightening angle. Do not judge angle by visual

inspection. Stamped mark : 2K (second ring)

AWBIA1376ZZ

Tool number : EM03470000 (J-8037)

(A) : Oil splash

(B) : Small end diameter grade

(C) : Reference code

(D) : Bearing stopper groove

(E) : Reference code

(G) : Big end diameter grade

WBIA0485E

AWBIA1279GB

Step 1 : 29.4 N·m (3.0 kg-m, 22 ft-lb)

Step 2 : 0 N·m

Step 3 : 19.6 N·m (2.0 kg-m, 14 lb-ft)

Step 4 : Rotate bolts 90 ° + 0.5 °

JPBIA0688ZZ

Revision: November 20132014 Altima NAM

Page 2186 of 4801

![NISSAN TEANA 2014 User Guide

EM-188

< REMOVAL AND INSTALLATION >[VQ35DE]

TIMING CHAIN

8. Install the internal chain guide and slack guide.

CAUTION:

• Do not overtighten the slack guid e bolts. It is normal for a gap

to exist NISSAN TEANA 2014 User Guide

EM-188

< REMOVAL AND INSTALLATION >[VQ35DE]

TIMING CHAIN

8. Install the internal chain guide and slack guide.

CAUTION:

• Do not overtighten the slack guid e bolts. It is normal for a gap

to exist](/img/5/57390/w960_57390-2185.png)

EM-188

< REMOVAL AND INSTALLATION >[VQ35DE]

TIMING CHAIN

8. Install the internal chain guide and slack guide.

CAUTION:

• Do not overtighten the slack guid e bolts. It is normal for a gap

to exist under the bolt seats wh en the bolts are tightened to

specification.

9. Install the timing chain tensioner for the slack guide. • When installing the chain tensioner, push in the sleeve andkeep it pressed in with the stopper pin.

• Remove any dirt and foreign materials completely from the back and the mounting surfaces of the chain tensioner.

• After installation, pull out the stopper pin while pressing the

slack guide.

10. Reconfirm that the matching marks on the sprockets and the timing chain have not slipped out of alignment.

11. Install the front timing chain case. Refer to EM-174, "Removal and Installation"

.

SEM740G

SEM741G

SEM733G

Revision: November 20132014 Altima NAM

Page 2213 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir](/img/5/57390/w960_57390-2212.png)

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confirming that the dimensions of valve guides and valves are

within specifications, perform this procedure.

• Apply prussian blue onto contacting surface of valve seat to check the condition of the valve contact on the surface.

• Check if the contact area band is continuous all around the circum- ference.

• If not, grind to adjust valve fitti ng and check again. If the contacting

surface still has NG conditions even after the re-check, replace

valve seat.

VALVE SEAT REPLACEMENT

1. Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Be sure to ream in circles co ncentric to the valve guide cen-

ter.

This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable t ool to the specified dimensions. Refer to EM-249, "Cylinder Head"

.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition. Intake and exhaust

finished size : 6.000 - 6.018 mm

(0.2362 - 0.2369 in)

SEM932C

SBIA0322E

Oversize : 0.5 mm (0.020 in)

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.100 - 32.116 mm (1.2638 - 1.2644 in)

SEM795A

SEM008A

Revision: November 20132014 Altima NAM

Page 2231 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position t NISSAN TEANA 2014 User Guide

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position t](/img/5/57390/w960_57390-2230.png)

CYLINDER BLOCKEM-233

< UNIT DISASSEMBLY AND ASSEMBLY > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

13. Install the piston and connecting rod assembly into the corre-

sponding cylinder.

• Position the crankshaft pin corresponding to the connecting

rod to be installed onto the bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston, and crankshaft pin.

• Match the cylinder position wit h the cylinder No. (B) on the

connecting rod to install.

• Install the piston with the piston front mark (A) on the crown

facing the front of the engine ( ), using a suitable tool.

- Oil hole (C)

CAUTION:

Be careful not to damage the crankshaft pin and cyl inder wall, resulting from an interference of the

connecting rod big end.

14. Install the connecting rod cap. • Match the stamped cylinder number marks on the connectingrod with those on the cylinder cap for installation.

• Install the piston connecting rod assembly and cap so that the front mark on the cap and piston are facing the front of the

engine.

• Lubricate the threads and seat surfaces with new engine

oil.

15. Check the connecting rod cap bolts before reusing, then install

in their original position in the connecting rod. The bolts should

screw in smoothly by hand.

• Measure the outer diameter of the connecting rod cap bolts as

shown.

16. Tighten the connecting rod cap bolts in two stages using Tool: CAUTION:

Always use either an angle wr ench or protractor. Avoid

tightening based on visual check alone.

• Apply engine oil to the threads and seats of the connecting rod cap bolts.

• After tightening the connecting rod cap bolts, make sure that the crankshaft rotates smoothly.

• Check the connecting rod side clearance. If beyond t he limit, replace the connecting rod and/or crank-

shaft.

AWBIA0029ZZ

SEM457G

Outer diameter (d) of th e connecting rod cap bolt

Standard : 7.90 - 8.00 mm (0.3110 - 0.3150 in)

Limit : 7.75 mm (0.3051 in)

SEM538G

Stage 1 : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Stage 2 : 90 ° - 95 ° degrees clockwise

Tool number : KV10112100 (BT-8653-A)

Connecting rod side clearance:

Standard : 0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit : 0.40 mm (0.0157 in)

SEM953E

Revision: November 20132014 Altima NAM

Page 2271 of 4801

PRECAUTIONSEXL-5

< PRECAUTION >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

Precaution for WorkINFOID:0000000009463539

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2418 of 4801

EXT-4

< PRECAUTION >

PRECAUTIONS

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirtyarea.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAM

Page 2427 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-13

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: November 20132014 Altima NAM

Page 2523 of 4801

FSU-22

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT COIL SPRING AND STRUT

UNIT DISASSEMBLY AND ASSEMBLY

FRONT COIL SPRING AND STRUT

Disassembly and AssemblyINFOID:0000000009460638

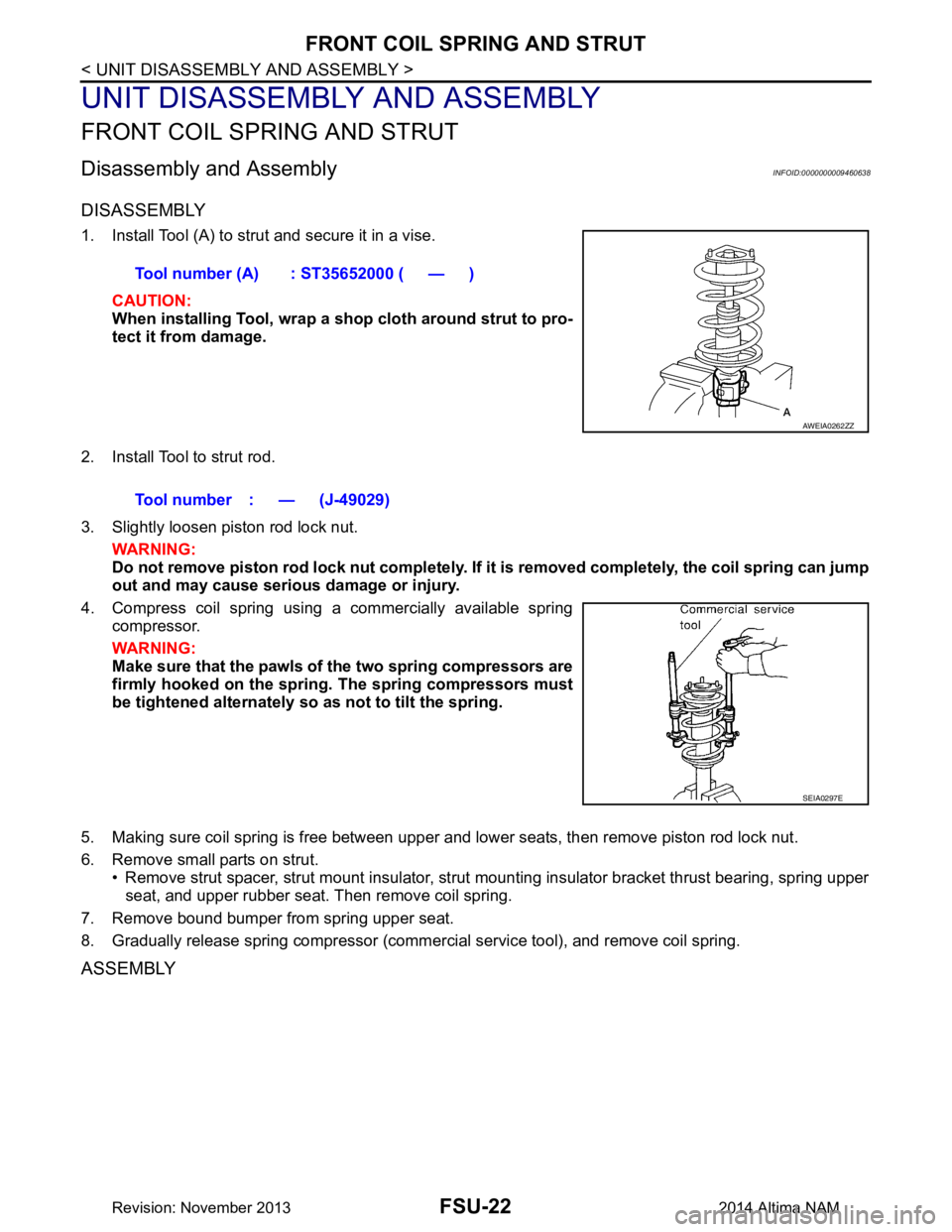

DISASSEMBLY

1. Install Tool (A) to strut and secure it in a vise.CAUTION:

When installing Tool, wrap a sh op cloth around strut to pro-

tect it from damage.

2. Install Tool to strut rod.

3. Slightly loosen piston rod lock nut. WARNING:

Do not remove piston rod lock nut completely. If it is removed completely, the coil spring can jump

out and may cause serious damage or injury.

4. Compress coil spring using a commercially available spring compressor.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must

be tightened alternately so as not to tilt the spring.

5. Making sure coil spring is free between upper and lower seats, then remove piston rod lock nut.

6. Remove small parts on strut. • Remove strut spacer, strut mount insulator, strut mounting insulator bracket thrust bearing, spring upper

seat, and upper rubber seat. Then remove coil spring.

7. Remove bound bumper from spring upper seat.

8. Gradually release spring compressor (commercial service tool), and remove coil spring.

ASSEMBLY

Tool number (A) : ST35652000 ( — )

AWEIA0262ZZ

Tool number : — (J-49029)

SEIA0297E

Revision: November 20132014 Altima NAM

Page 2524 of 4801

FRONT COIL SPRING AND STRUTFSU-23

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

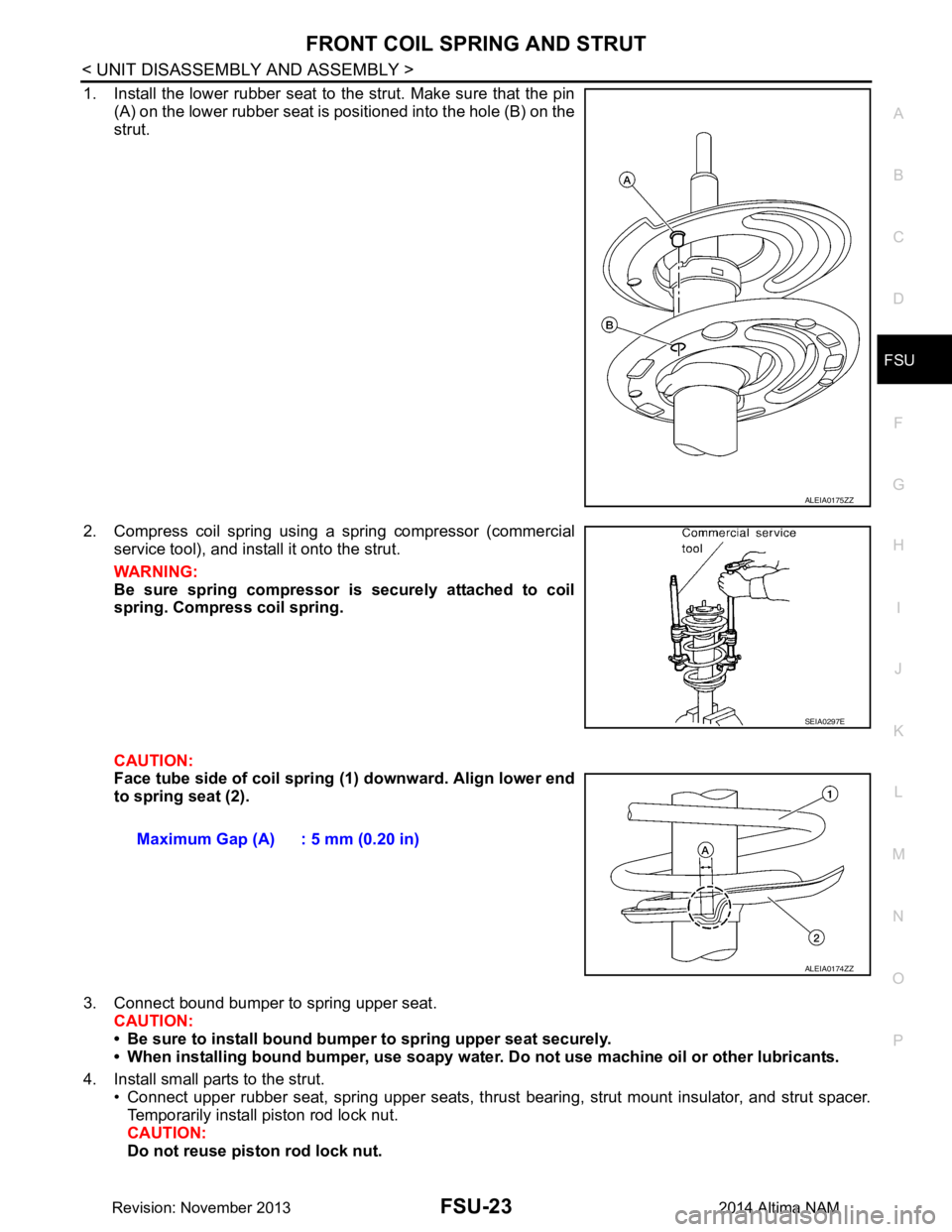

1. Install the lower rubber seat to the strut. Make sure that the pin (A) on the lower rubber seat is positioned into the hole (B) on the

strut.

2. Compress coil spring using a spring compressor (commercial service tool), and install it onto the strut.

WARNING:

Be sure spring compressor is securely attached to coil

spring. Compress coil spring.

CAUTION:

Face tube side of coil spring (1) downward. Align lower end

to spring seat (2).

3. Connect bound bumper to spring upper seat. CAUTION:

• Be sure to install bound bump er to spring upper seat securely.

• When installing bound bumper, use soapy water. Do not use machine oil or other lubricants.

4. Install small parts to the strut. • Connect upper rubber seat, spring upper seats, thrust bearing, strut mount insulator, and strut spacer.

Temporarily install piston rod lock nut.

CAUTION:

Do not reuse piston rod lock nut.

ALEIA0175ZZ

SEIA0297E

Maximum Gap (A) : 5 mm (0.20 in)

ALEIA0174ZZ

Revision: November 20132014 Altima NAM