NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2541 of 4801

ABBREVIATIONSGI-13

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PABBREVIATIONS

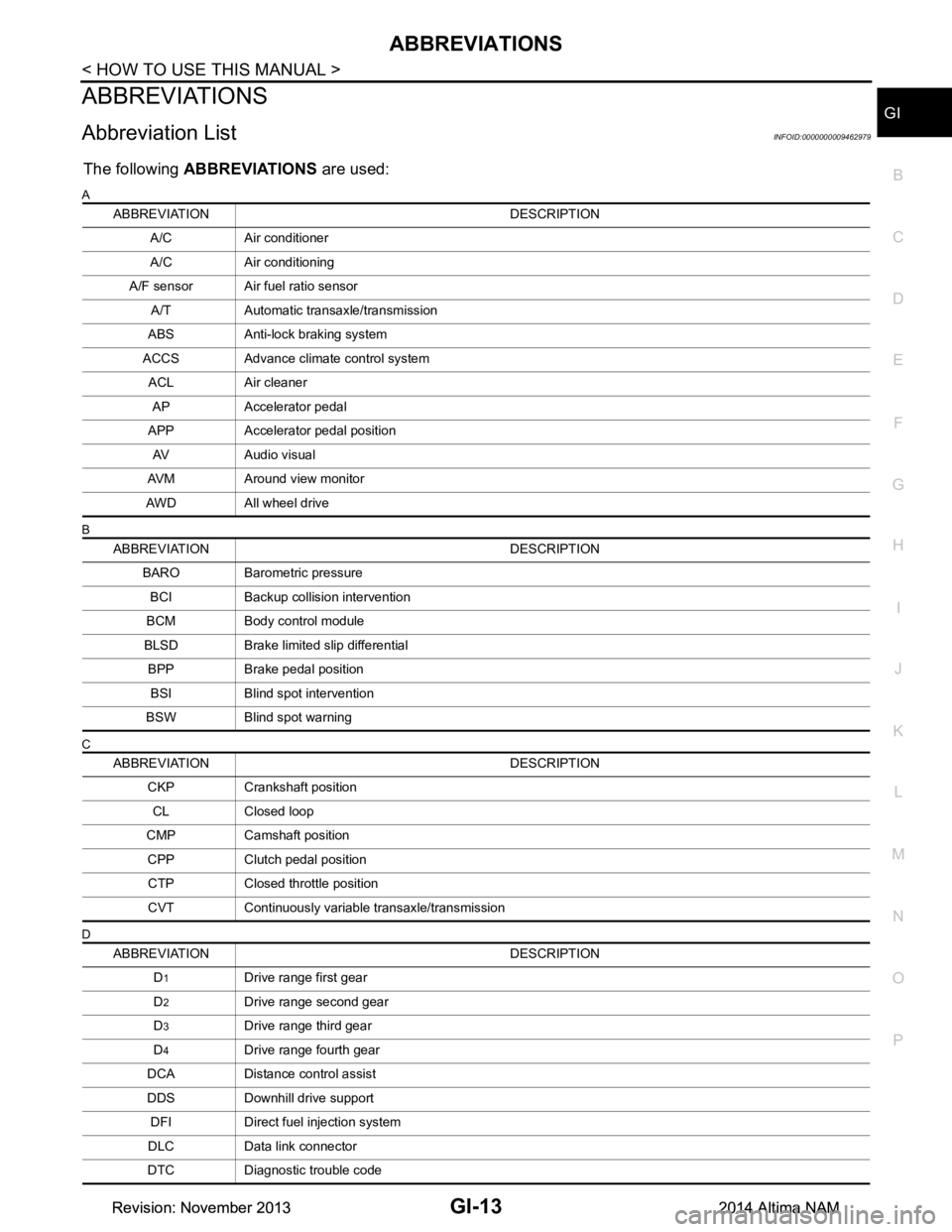

Abbreviation ListINFOID:0000000009462979

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position AV Audio visual

AVM Around view monitor

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCI Backup collision intervention

BCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist

DDS Downhill drive support DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2542 of 4801

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

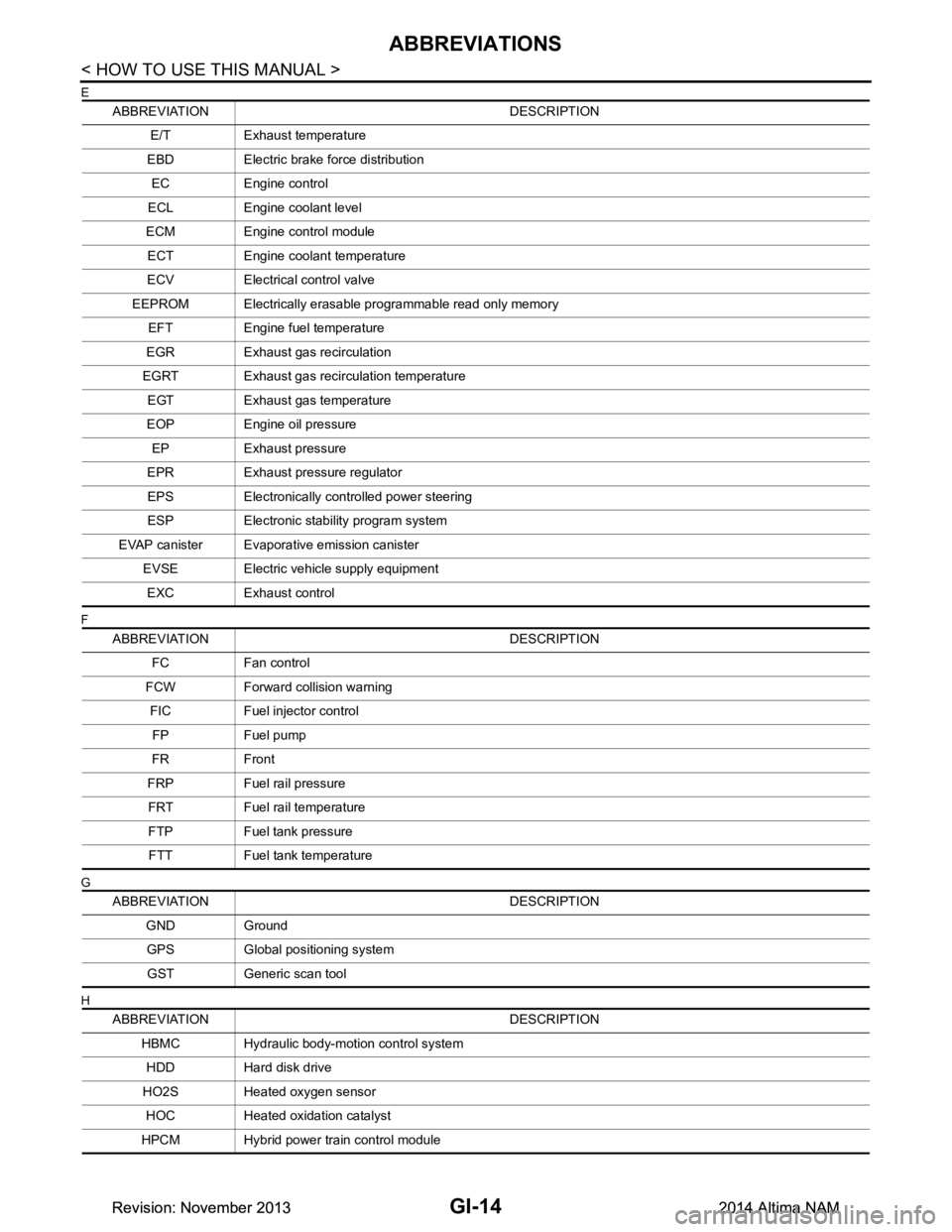

E

F

G

H

ABBREVIATION DESCRIPTION E/T Exhaust temperature

EBD Electric brake force distribution EC Engine control

ECL Engine coolant level

ECM Engine control module ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable pr ogrammable read only memory

EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure EP Exhaust pressure

EPR Exhaust pressure regulator EPS Electronically cont rolled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipmentEXC Exhaust control

ABBREVIATION DESCRIPTION FC Fan control

FCW Forward collision warning FIC Fuel injector controlFP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperatureFTP Fuel tank pressure FTT Fuel tank temperature

ABBREVIATION DESCRIPTION GND GroundGPS Global positioning systemGST Generic scan tool

ABBREVIATION DESCRIPTION HBMC Hydraulic body-motion control systemHDD Hard disk drive

HO2S Heated oxygen sensor HOC Heated oxidation catalyst

HPCM Hybrid power train control module

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2543 of 4801

ABBREVIATIONSGI-15

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

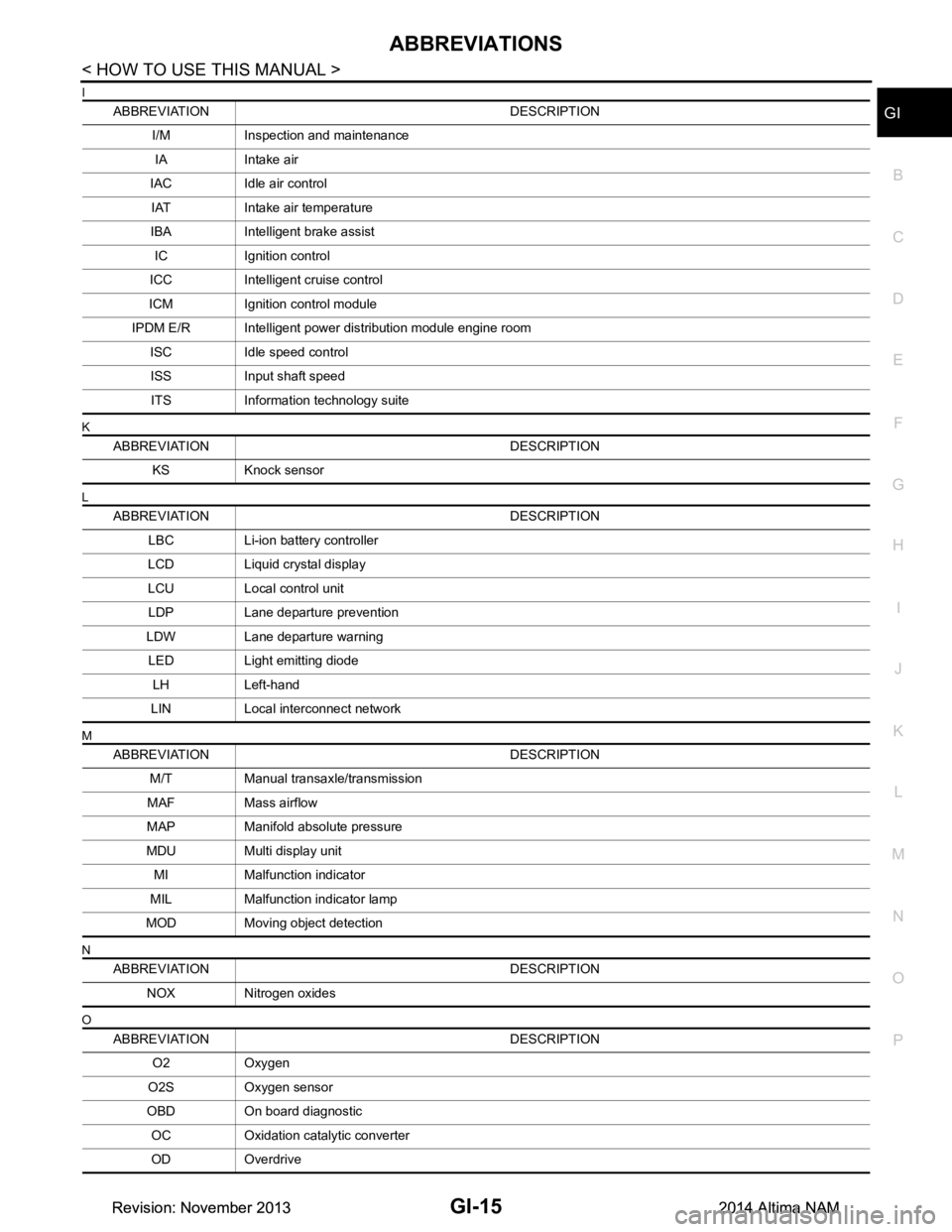

I

K

L

M

N

O

ABBREVIATION DESCRIPTION I/M Inspection and maintenanceIA Intake air

IAC Idle air control IAT Intake air temperature

IBA Intelligent brake assist IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed controlISS Input shaft speed ITS Information technology suite

ABBREVIATION DESCRIPTION KS Knock sensor

ABBREVIATION DESCRIPTION LBC Li-ion battery controller

LCD Liquid crystal display

LCU Local control unit LDP Lane departure prevention

LDW Lane departure warning LED Light emitting diode LH Left-hand

LIN Local interconnect network

ABBREVIATION DESCRIPTION M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure

MDU Multi display unit MI Malfunction indicator

MIL Malfunction indicator lamp

MOD Moving object detection

ABBREVIATION DESCRIPTION NOX Nitrogen oxides

ABBREVIATION DESCRIPTION O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic OC Oxidation catalytic converter

OD Overdrive

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2544 of 4801

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

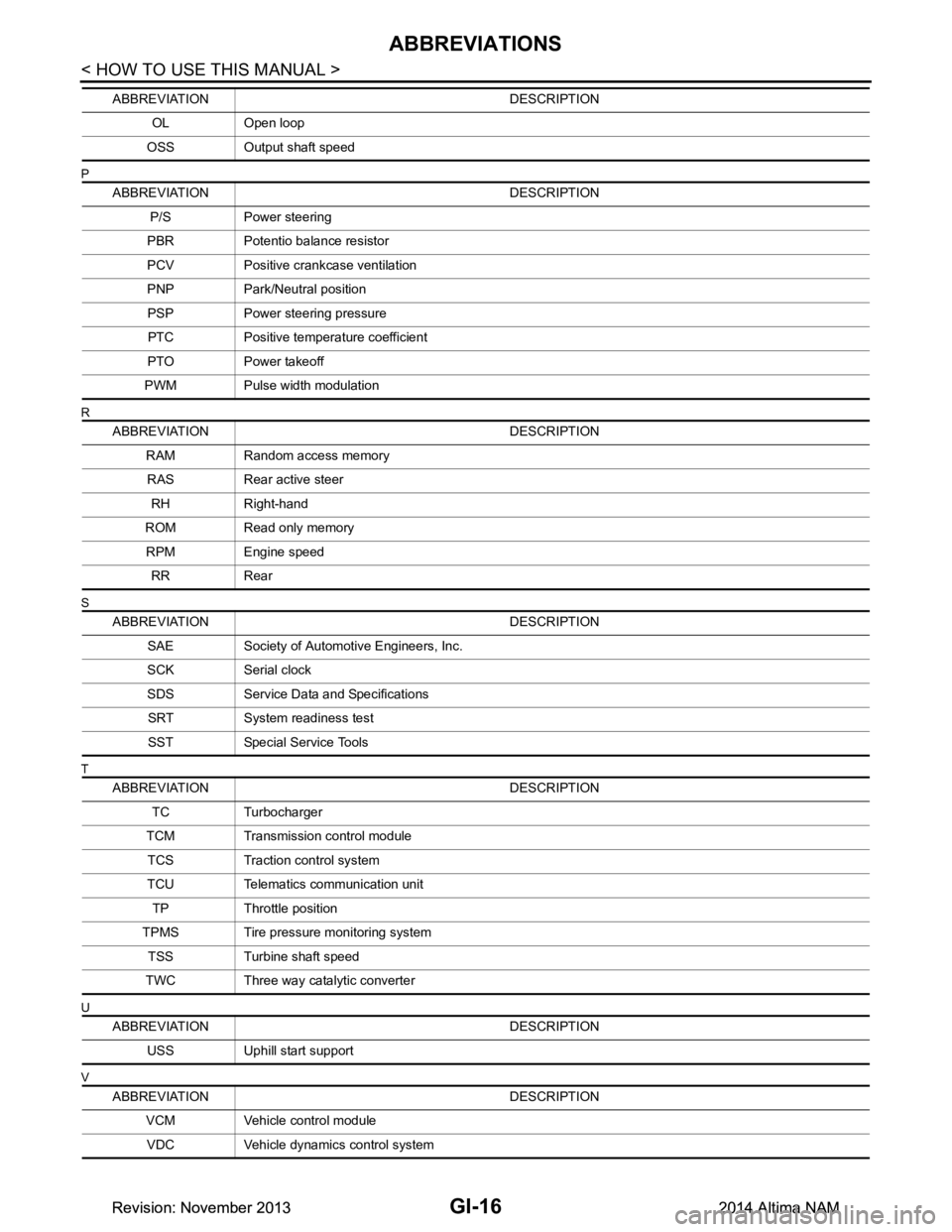

P

R

S

T

U

V

OL Open loop

OSS Output shaft speed

ABBREVIATION DESCRIPTION P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position PSP Power steering pressurePTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION RAM Random access memoryRAS Rear active steer RH Right-hand

ROM Read only memory RPM Engine speed RR Rear

ABBREVIATION DESCRIPTION SAE Society of Automotive Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications SRT System readiness testSST Special Service Tools

ABBREVIATION DESCRIPTION TC Turbocharger

TCM Transmission control module TCS Traction control system

TCU Telematics communication unit TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

ABBREVIATION DESCRIPTION USS Uphill start support

ABBREVIATION DESCRIPTION VCM Vehicle control moduleVDC Vehicle dynamics control system

ABBREVIATION DESCRIPTION

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2545 of 4801

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

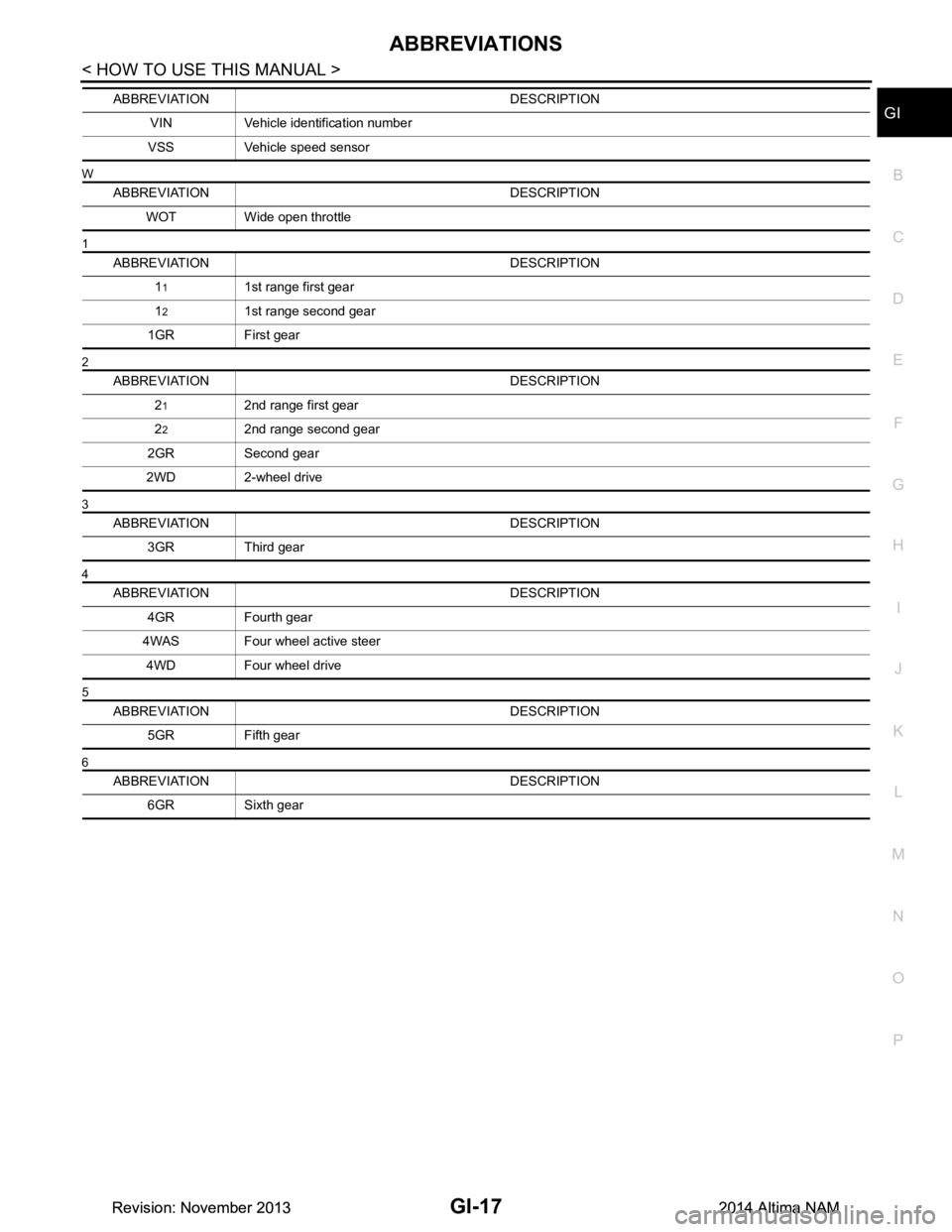

W

1

2

3

4

5

6

VIN Vehicle identification number

VSS Vehicle speed sensor

ABBREVIATION DESCRIPTION WOT Wide open throttle

ABBREVIATION DESCRIPTION 1

11st range first gear

1

21st range second gear

1GR First gear

ABBREVIATION DESCRIPTION 2

12nd range first gear

2

22nd range second gear

2GR Second gear

2WD 2-wheel drive

ABBREVIATION DESCRIPTION 3GR Third gear

ABBREVIATION DESCRIPTION 4GR Fourth gear

4WAS Four wheel active steer 4WD Four wheel drive

ABBREVIATION DESCRIPTION 5GR Fifth gear

ABBREVIATION DESCRIPTION 6GR Sixth gear

ABBREVIATION DESCRIPTION

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2546 of 4801

GI-18

< HOW TO USE THIS MANUAL >

TIGHTENING TORQUE OF STANDARD BOLTS

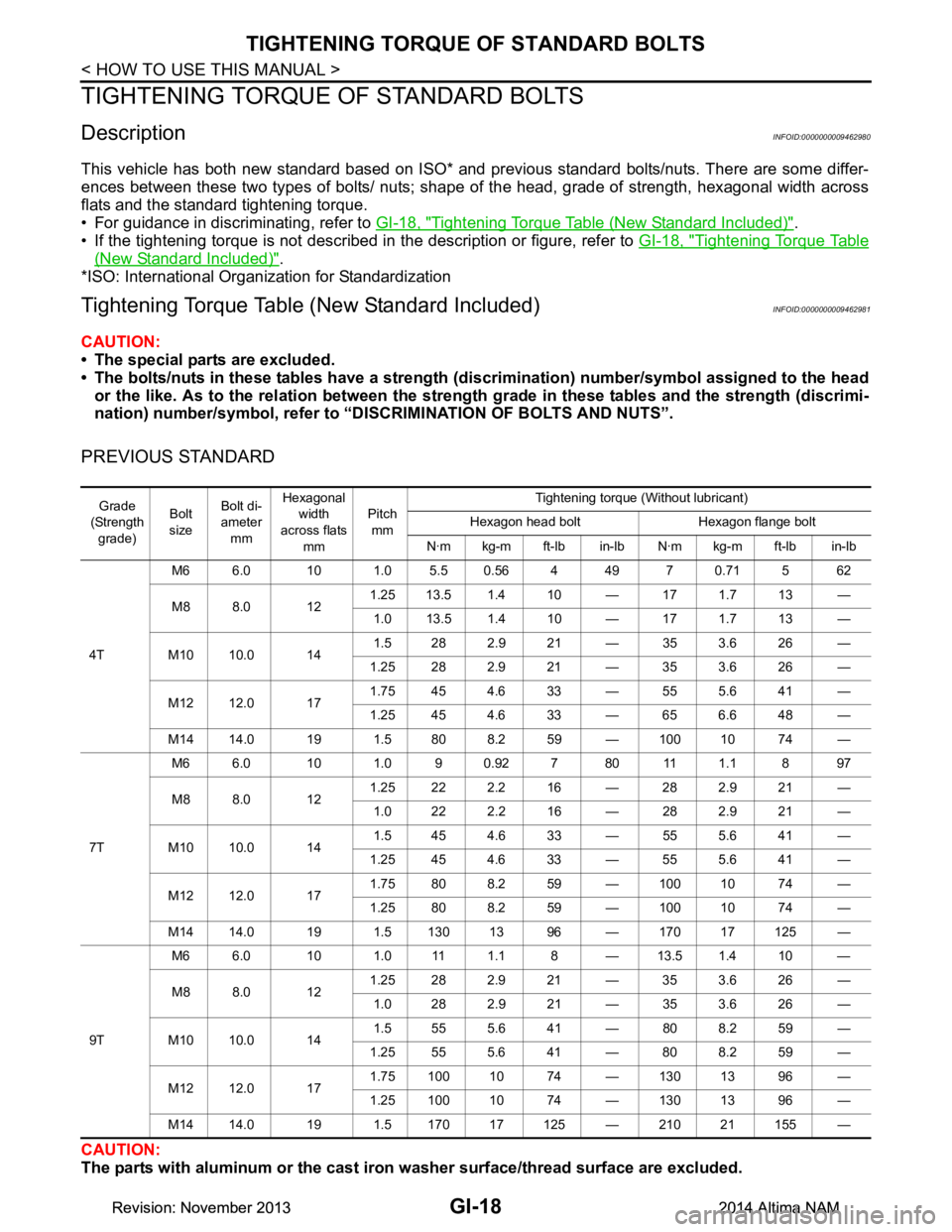

TIGHTENING TORQUE OF STANDARD BOLTS

DescriptionINFOID:0000000009462980

This vehicle has both new standard based on ISO* and previous standard bolts/nuts. There are some differ-

ences between these two types of bolts/ nuts; shape of the head, grade of strength, hexagonal width across

flats and the standard tightening torque.

• For guidance in discriminating, refer to GI-18, "Tightening Torque Table (New Standard Included)"

.

• If the tightening torque is not described in the description or figure, refer to GI-18, "Tightening Torque Table

(New Standard Included)".

*ISO: International Organization for Standardization

Tightening Torque Tabl e (New Standard Included)INFOID:0000000009462981

CAUTION:

• The special parts are excluded.

• The bolts/nuts in these tables have a strength (d iscrimination) number/symbol assigned to the head

or the like. As to the relation between the stre ngth grade in these tables and the strength (discrimi-

nation) number/symbol, refer to “DISCRIMINATION OF BOLTS AND NUTS”.

PREVIOUS STANDARD

CAUTION:

The parts with aluminum or the cast iron washer surface/thread surface are excluded.

Grade

(Strength

grade) Bolt

size Bolt di-

ameter

mm Hexagonal

width

across flats mm Pitch

mm Tightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

4T M6 6.0 10 1.0 5.5 0.56 4 49 7 0.71 5 62

M8 8.0 12 1.25 13.5 1.4 10 — 17 1.7 13 —

1.0 13.5 1.4 10 — 17 1.7 13 —

M10 10.0 14 1.5 28 2.9 21 — 35 3.6 26 —

1.25 28 2.9 21 — 35 3.6 26 —

M12 12.0 17 1.75 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 65 6.6 48 —

M14 14.0 19 1.5 80 8.2 59 — 100 10 74 —

7T M6 6.0 10 1.0 9 0.92 7 80 11 1.1 8 97

M8 8.0 12 1.25 22 2.2 16 — 28 2.9 21 —

1.0 22 2.2 16 — 28 2.9 21 —

M10 10.0 14 1.5 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 55 5.6 41 —

M12 12.0 17 1.75 80 8.2 59 — 100 10 74 —

1.25 80 8.2 59 — 100 10 74 —

M14 14.0 19 1.5 130 13 96 — 170 17 125 —

9T M6 6.0 10 1.0 11 1.1 8 — 13.5 1.4 10 —

M8 8.0 12 1.25 28 2.9 21 — 35 3.6 26 —

1.0 28 2.9 21 — 35 3.6 26 —

M10 10.0 14 1.5 55 5.6 41 — 80 8.2 59 —

1.25 55 5.6 41 — 80 8.2 59 —

M12 12.0 17 1.75 100 10 74 — 130 13 96 —

1.25 100 10 74 — 130 13 96 —

M14 14.0 19 1.5 170 17 125 — 210 21 155 —

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2547 of 4801

TIGHTENING TORQUE OF STANDARD BOLTSGI-19

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

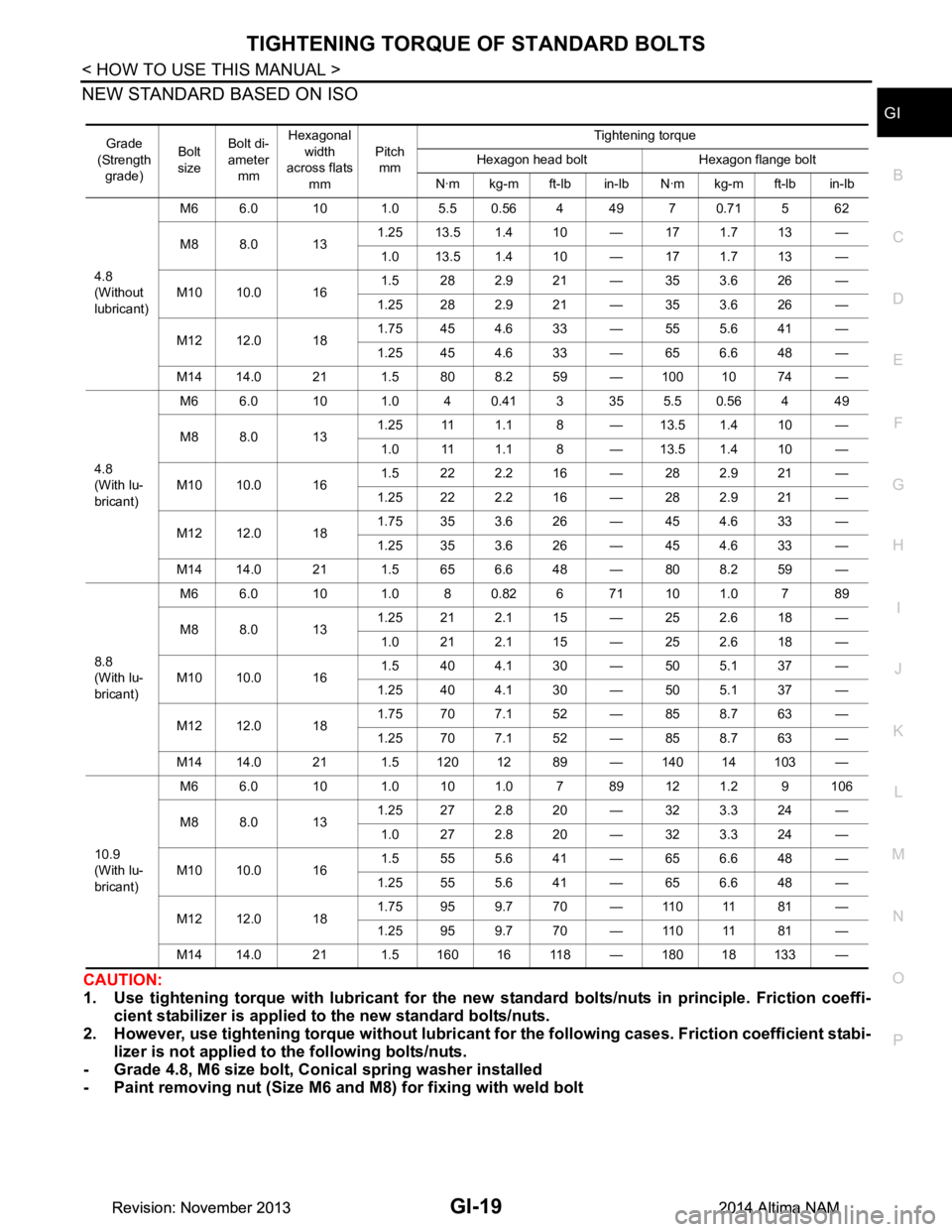

NEW STANDARD BASED ON ISO

CAUTION:

1. Use tightening torque with lubricant for the new standard bolts/nuts in principle. Friction coeffi- cient stabilizer is applied to the new standard bolts/nuts.

2. However, use tightening torque wi thout lubricant for the following cases. Friction coefficient stabi-

lizer is not applied to the following bolts/nuts.

- Grade 4.8, M6 size bolt, Co nical spring washer installed

- Paint removing nut (Size M6 and M8) for fixing with weld bolt

Grade

(Strength grade) Bolt

size Bolt di-

ameter mm Hexagonal

width

across flats

mm Pitch

mm Tightening torque

Hexagon head bolt Hexagon flange bolt

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

4.8

(Without

lubricant) M6 6.0 10 1.0 5.5 0.56 4 49 7 0.71 5 62

M8 8.0 13 1.25 13.5 1.4 10 — 17 1.7 13 —

1.0 13.5 1.4 10 — 17 1.7 13 —

M10 10.0 16 1.5 282.921 — 353.626 —

1.25 28 2.9 21 — 35 3.6 26 —

M12 12.0 18 1.75 45 4.6 33 — 55 5.6 41 —

1.25 45 4.6 33 — 65 6.6 48 —

M14 14.0 21 1.5 80 8.2 59 — 100 10 74 —

4.8

(With lu-

bricant) M6 6.0 10 1.0 40.413 355.50.564 49

M8 8.0 13 1.25 11 1.1 8 — 13.5 1.4 10 —

1.0 11 1.1 8 — 13.5 1.4 10 —

M10 10.0 16 1.5 222.216 — 282.921 —

1.25 22 2.2 16 — 28 2.9 21 —

M12 12.0 18 1.75 35 3.6 26 — 45 4.6 33 —

1.25 35 3.6 26 — 45 4.6 33 —

M14 14.0 21 1.5 65 6.6 48 — 80 8.2 59 —

8.8

(With lu-

bricant) M6 6.0 10 1.0 8 0.82 6 71 10 1.0 7 89

M8 8.0 13 1.25 21 2.1 15 — 25 2.6 18 —

1.0 212.115 — 252.618 —

M10 10.0 16 1.5 404.130 — 505.137 —

1.25 40 4.1 30 — 50 5.1 37 —

M12 12.0 18 1.75 70 7.1 52 — 85 8.7 63 —

1.25 70 7.1 52 — 85 8.7 63 —

M14 14.0 21 1.5 120 12 89 — 140 14 103 —

10.9

(With lu-

bricant) M6 6.0 10 1.0 10 1.0 7 89 12 1.2 9 106

M8 8.0 13 1.25 27 2.8 20 — 32 3.3 24 —

1.0 272.820 — 323.324 —

M10 10.0 16 1.5 555.641 — 656.648 —

1.25 55 5.6 41 — 65 6.6 48 —

M12 12.0 18 1.75 95 9.7 70 — 110 11 81 —

1.25 95 9.7 70 — 110 11 81 —

M14 14.0 21 1.5 160 16 118 — 180 18 133 —

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2548 of 4801

GI-20

< HOW TO USE THIS MANUAL >

TIGHTENING TORQUE OF STANDARD BOLTS

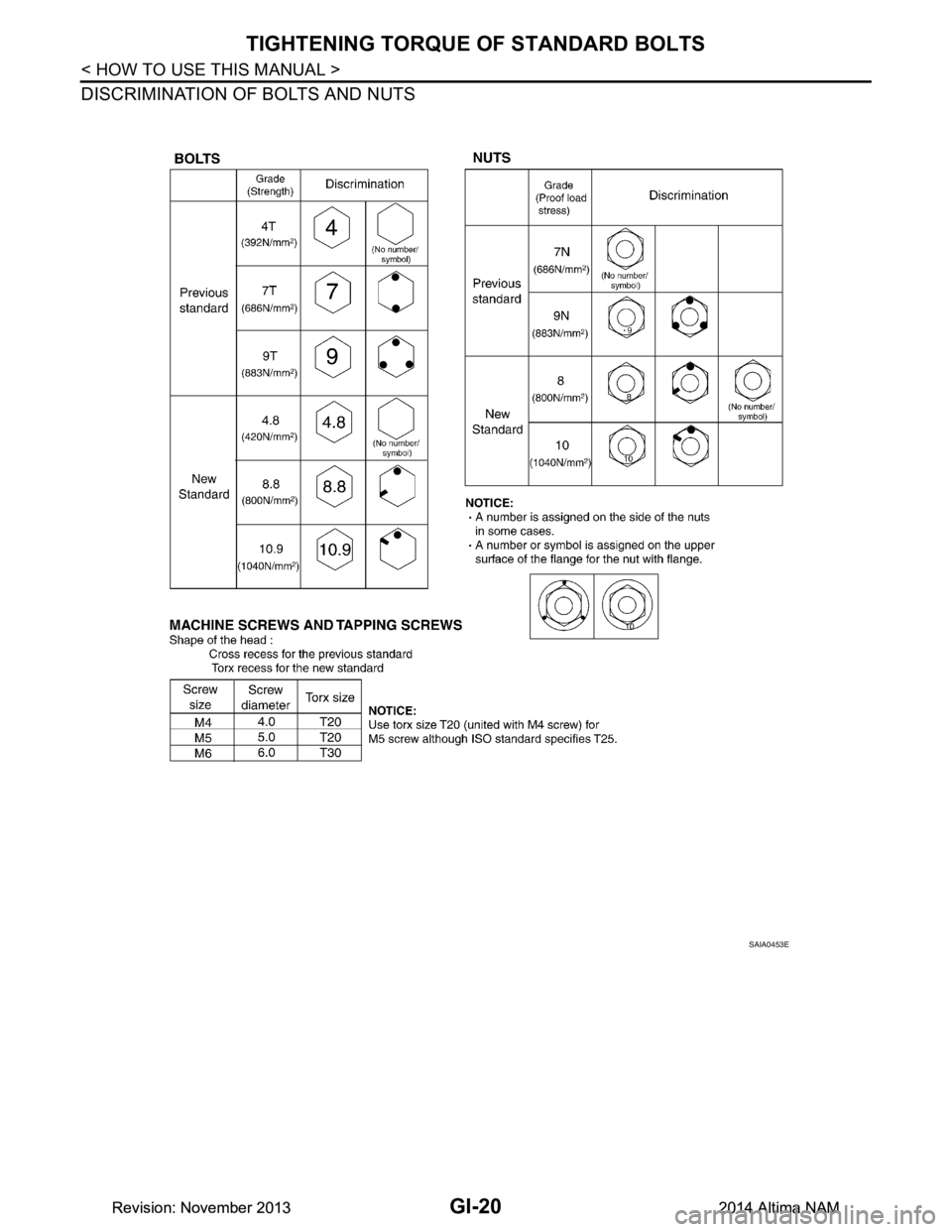

DISCRIMINATION OF BOLTS AND NUTS

SAIA0453E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2549 of 4801

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

GI-21

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PRECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

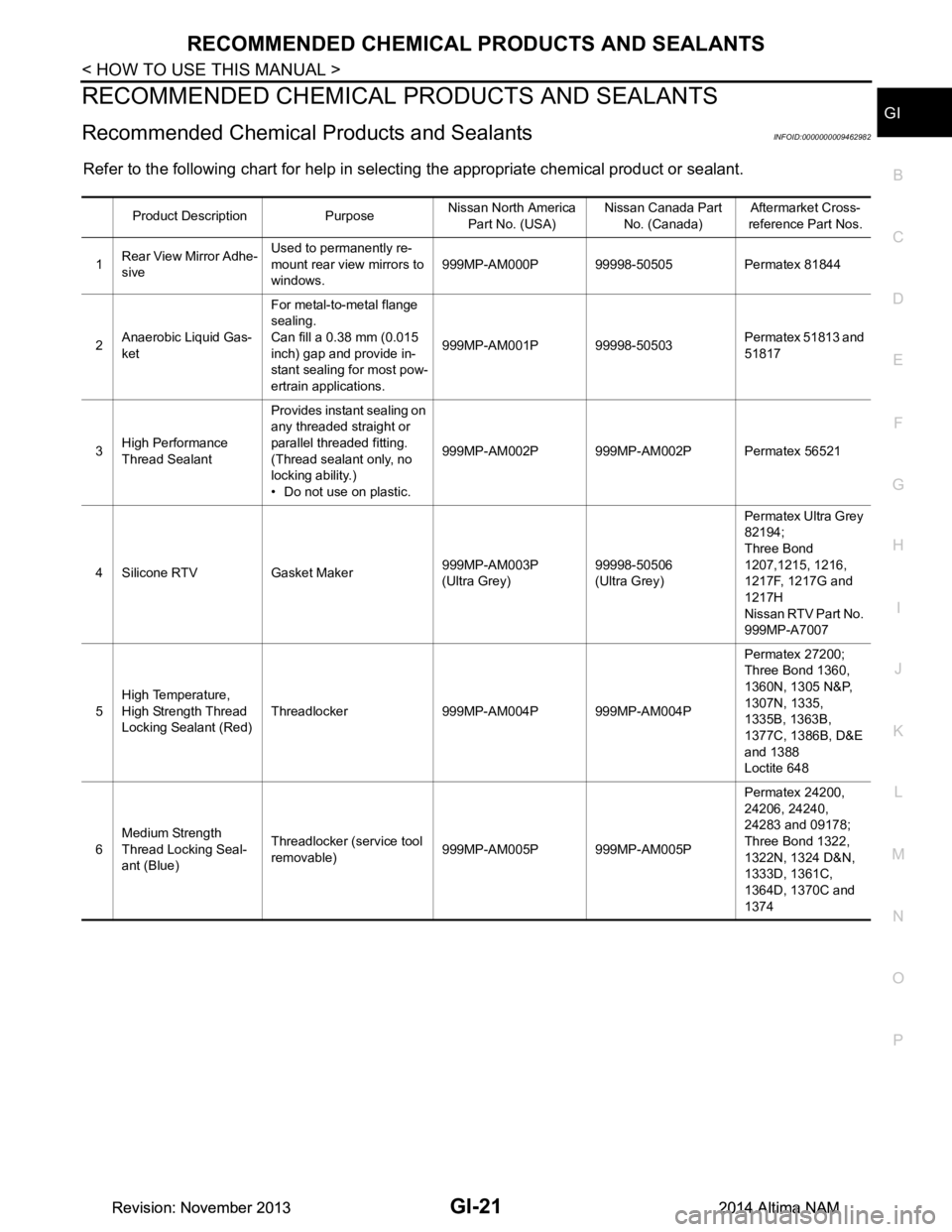

Recommended Chemical Products and SealantsINFOID:0000000009462982

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description Purpose Nissan North America

Part No. (USA) Nissan Canada Part

No. (Canada) Aftermarket Cross-

reference Part Nos.

1 Rear View Mirror Adhe-

sive Used to permanently re-

mount rear view mirrors to

windows. 999MP-AM000P 99998-50505 Permatex 81844

2 Anaerobic Liquid Gas-

ket For metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide in-

stant sealing for most pow-

ertrain applications. 999MP-AM001P 99998-50503

Permatex 51813 and

51817

3 High Performance

Thread Sealant Provides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

• Do not use on plastic. 999MP-AM002P 999MP-AM002P Permatex 56521

4 Silicone RTV Gasket Maker 999MP-AM003P

(Ultra Grey) 99998-50506

(Ultra Grey) Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

5 High Temperature,

High Strength Thread

Locking Sealant (Red) Threadlocker 999MP-AM004P 999MP-AM004P Permatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

6 Medium Strength

Thread Locking Seal-

ant (Blue) Threadlocker (service tool

removable) 999MP-AM005P 999MP-AM005P Permatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2550 of 4801

GI-22

< VEHICLE INFORMATION >

IDENTIFICATION INFORMATION

VEHICLE INFORMATION

IDENTIFICATION INFORMATION

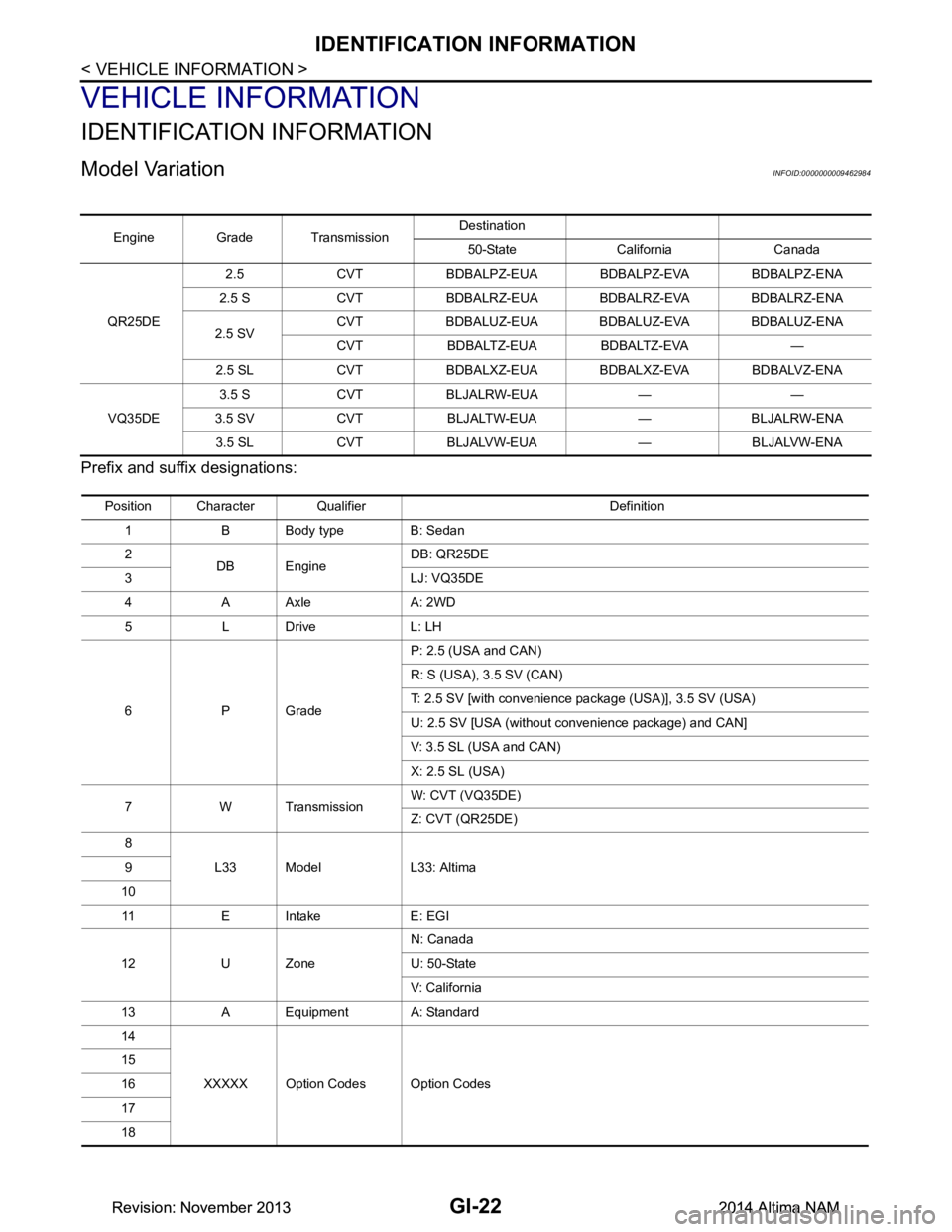

Model VariationINFOID:0000000009462984

Prefix and suffix designations:

Engine Grade TransmissionDestination

50-State California Canada

QR25DE 2.5 CVT BDBALPZ-EUA BDBALPZ-EVA BDBALPZ-ENA

2.5 S CVT BDBALRZ-EUA BDBALRZ-EVA BDBALRZ-ENA

2.5 SV CVT BDBALUZ-EUA BDBALUZ-EVA BDBALUZ-ENA

CVT BDBALTZ-EUA BDBALTZ-EVA —

2.5 SL CVT BDBALXZ-EUA BDBALXZ-EVA BDBALVZ-ENA

VQ35DE 3.5 S CVT BLJALRW-EUA — —

3.5 SV CVT BLJALTW-EUA — BLJALRW-ENA 3.5 SL CVT BLJALVW-EUA — BLJALVW-ENA

Position Character Qualifier Definition 1 B Body type B: Sedan

2 DB Engine DB: QR25DE

3LJ: VQ35DE

4AAxle A: 2WD

5LDrive L: LH

6PGrade P: 2.5 (USA and CAN)

R: S (USA), 3.5 SV (CAN)

T: 2.5 SV [with convenience package (USA)], 3.5 SV (USA)

U: 2.5 SV [USA (without convenience package) and CAN]

V: 3.5 SL (USA and CAN)

X: 2.5 SL (USA)

7 W Transmission W: CVT (VQ35DE)

Z: CVT (QR25DE)

8 L33 Model L33: Altima

9

10 11 E I n t a k e E : E G I

12 U Zone N: Canada

U: 50-State

V: California

13 A Equipment A: Standard

14

XXXXX Option Codes Option Codes

15

16

17

18

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM