NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3221 of 4801

CHASSIS AND BODY MAINTENANCEMA-37

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

34. Select “Data Monitor” in “TRANSMISSION” using CONSULT.

35. Select “CONFORM CVTF DETERIORTN”.

36. Select “Erase”.

37. Stop the engine.

CVT FLUID : AdjustmentINFOID:0000000009464573

CAUTION:

• During adjustment of the CVT fluid level, check CO NSULT so that the oil temperature may be main-

tained from 35 to 45 °C (95 to 113 °F).

• During adjustment of the CVT fluid level, check that the engine speed is maintaining 500 rpm.

• Use caution when looking into the drain hole as there is a risk of dripping fluid entering the eye.

1. Check that the selector lever is in the “P ” position, then completely engage the parking brake.

2. Start the engine.

3. Adjust the CVT fluid temperature to be approximately 40 °C (104 °F).

NOTE:

The CVT fluid is largely affected by temperature. Therefore be sure to use CONSULT and check the

“FLUID TEMP” under “TRA NSMISSION” in “Data Monitor” while adjusting.

4. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “DS”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

5. Lift up the vehicle.

6. Check that there is no CVT fluid leakage.

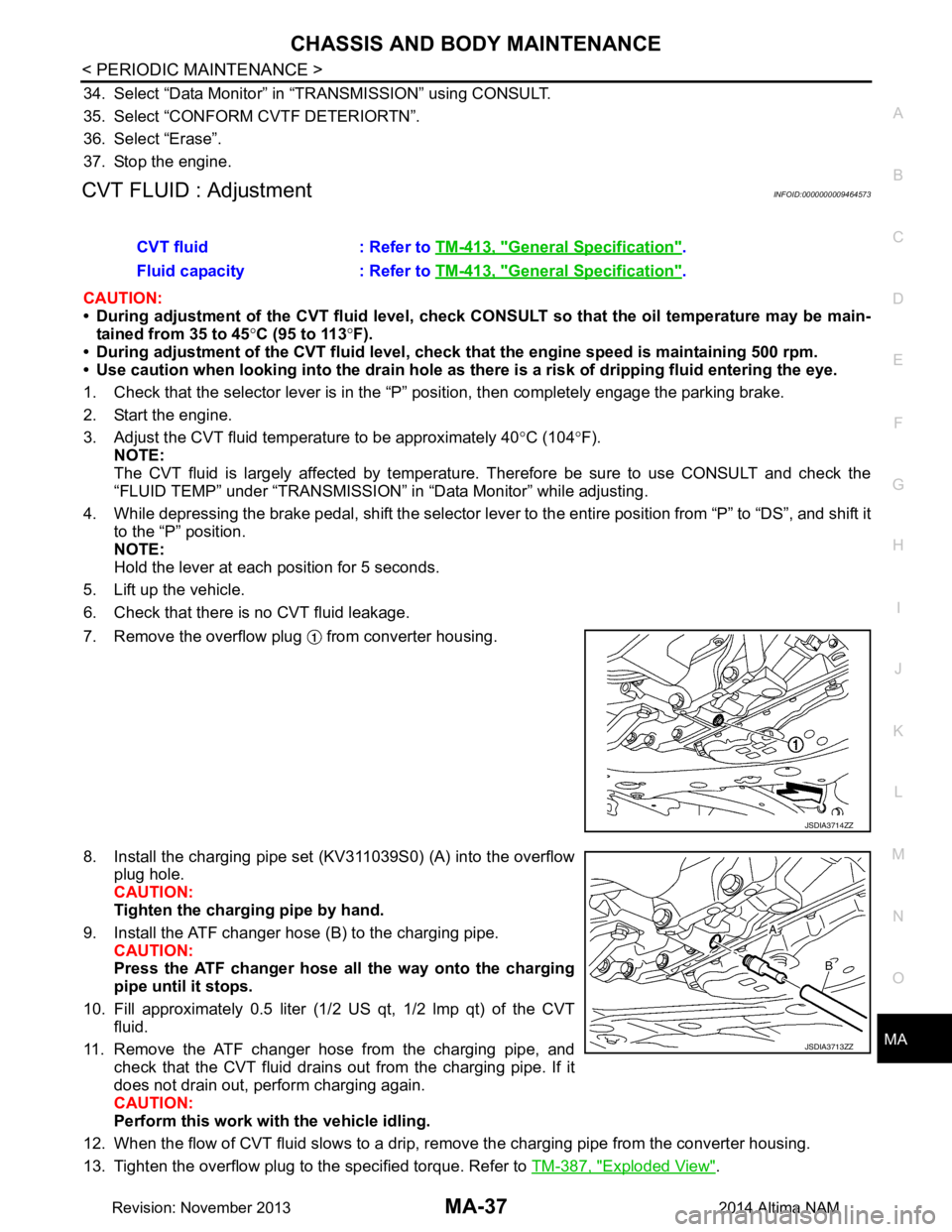

7. Remove the overflow plug from converter housing.

8. Install the charging pipe set (KV311039S0) (A) into the overflow plug hole.

CAUTION:

Tighten the charging pipe by hand.

9. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

10. Fill approximately 0.5 liter (1/2 US qt, 1/2 lmp qt) of the CVT

fluid.

11. Remove the ATF changer hose from the charging pipe, and check that the CVT fluid drains out from the charging pipe. If it

does not drain out, perform charging again.

CAUTION:

Perform this work with the vehicle idling.

12. When the flow of CVT fluid slows to a drip, re move the charging pipe from the converter housing.

13. Tighten the overflow plug to the specified torque. Refer to TM-387, "Exploded View"

.

CVT fluid : Refer to

TM-413, "General Specification"

.

Fluid capacity : Refer to TM-413, "General Specification"

.

JSDIA3714ZZ

JSDIA3713ZZ

Revision: November 20132014 Altima NAM

Page 3222 of 4801

MA-38

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

CAUTION:

Do not reuse O-ring.

14. Lift down the vehicle.

15. Stop the engine.

WHEELS

WHEELS : InspectionINFOID:0000000009464574

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other dam age. If deformed, remove wheel and check wheel

runout.

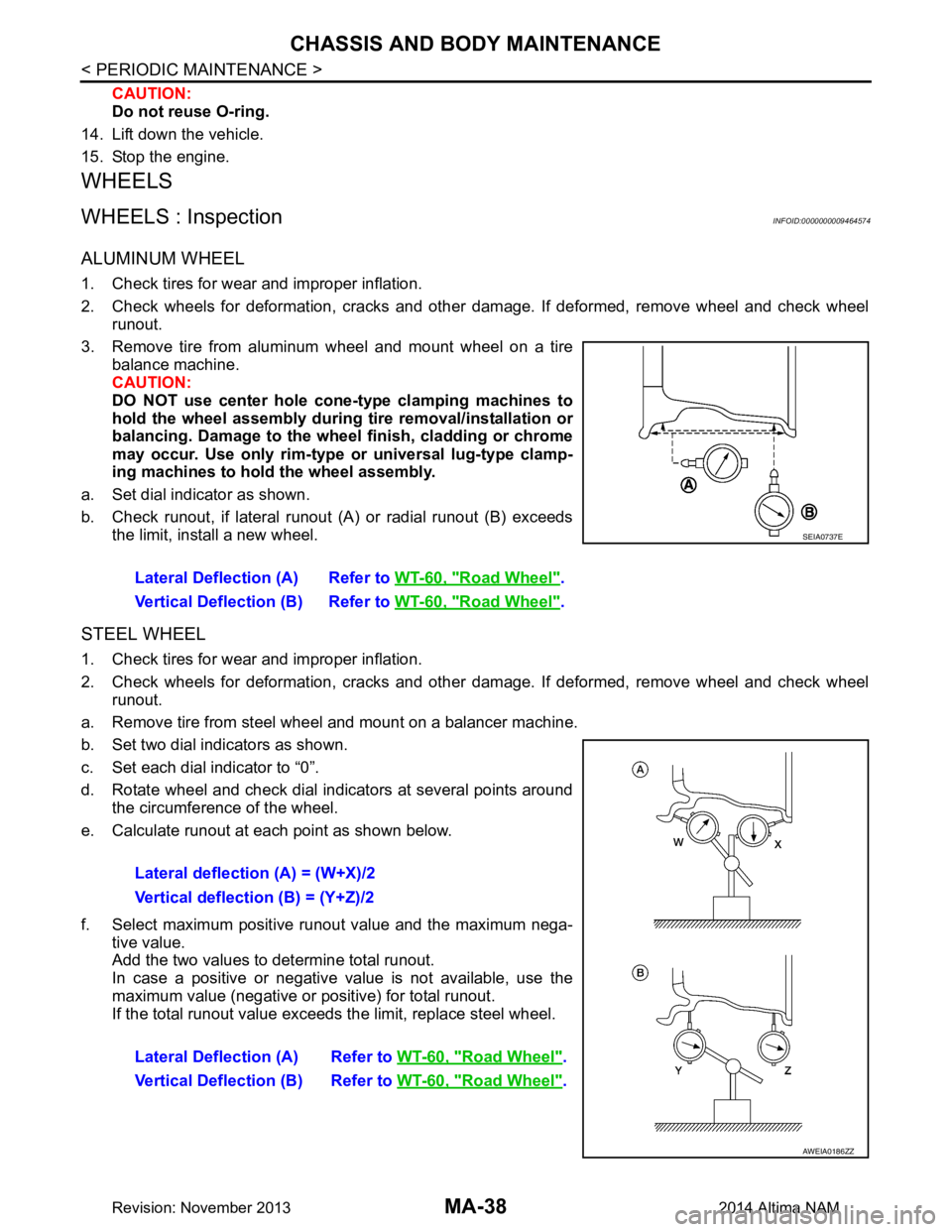

3. Remove tire from aluminum wheel and mount wheel on a tire balance machine.

CAUTION:

DO NOT use center hole cone -type clamping machines to

hold the wheel assembly during tire removal/installation or

balancing. Damage to the wheel finish, cladding or chrome

may occur. Use only rim-type or universal lug-type clamp-

ing machines to hold the wheel assembly.

a. Set dial indicator as shown.

b. Check runout, if lateral runout (A) or radial runout (B) exceeds the limit, install a new wheel.

STEEL WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other dam age. If deformed, remove wheel and check wheel

runout.

a. Remove tire from steel wheel and mount on a balancer machine.

b. Set two dial indicators as shown.

c. Set each dial indicator to “0”.

d. Rotate wheel and check dial indicators at several points around the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega- tive value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel. Lateral Deflection (A) Refer to

WT-60, "Road Wheel"

.

Vertical Deflection (B) Refer to WT-60, "Road Wheel"

.

SEIA0737E

Lateral deflection (A) = (W+X)/2

Vertical deflection (B) = (Y+Z)/2

Lateral Deflection (A) Refer to WT-60, "Road Wheel"

.

Vertical Deflection (B) Refer to WT-60, "Road Wheel"

.

AWEIA0186ZZ

Revision: November 20132014 Altima NAM

Page 3223 of 4801

CHASSIS AND BODY MAINTENANCEMA-39

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

WHEELS : AdjustmentINFOID:0000000009464575

BALANCING WHEELS (ADH

ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel. Using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

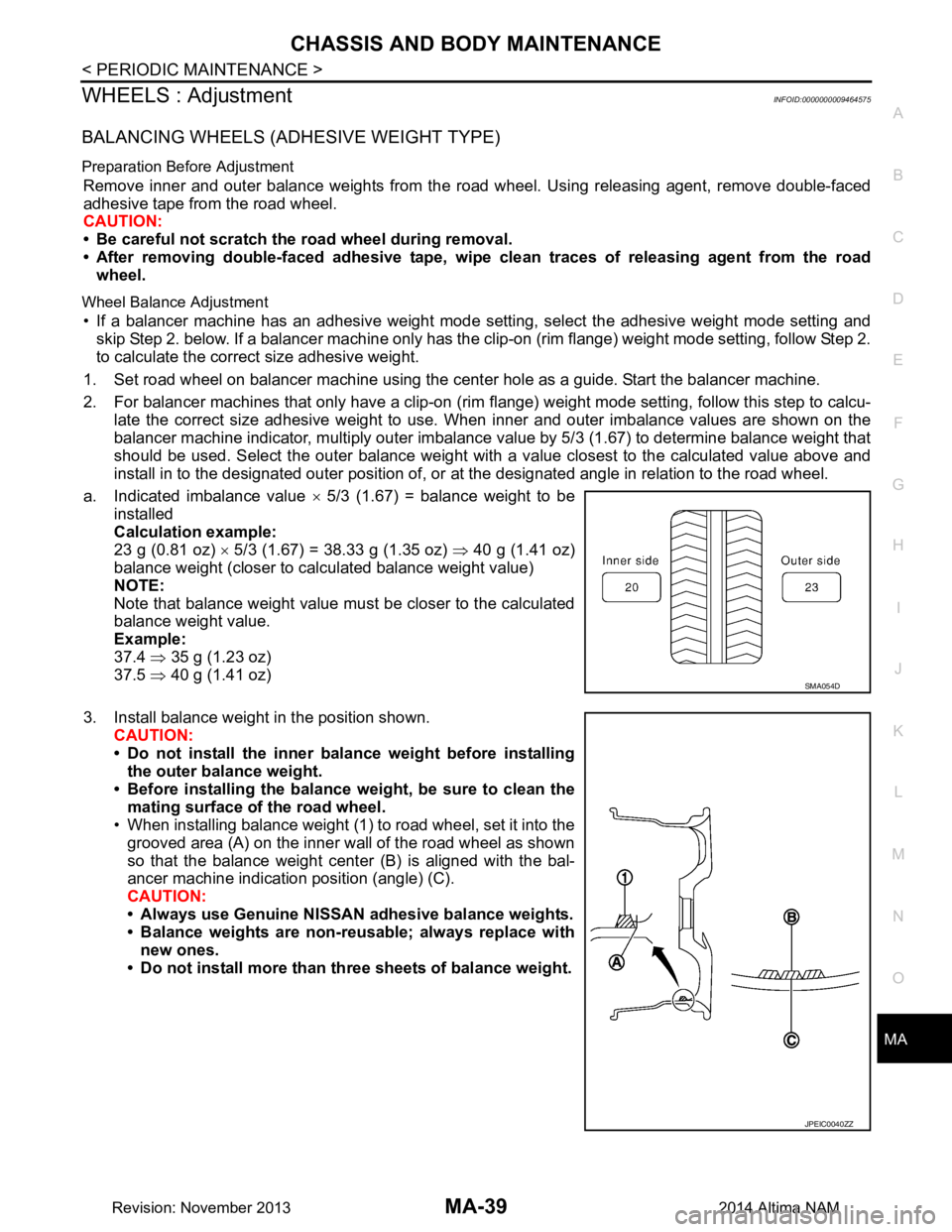

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

2. For balancer machines that only have a clip-on (rim fl ange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. W hen inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the

grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight cent er (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use Genuine NISSAN adhesive balance weights.

• Balance weights are non-re usable; always replace with

new ones.

• Do not install more than th ree sheets of balance weight.

SMA054D

JPEIC0040ZZ

Revision: November 20132014 Altima NAM

Page 3224 of 4801

MA-40

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

4. If calculated balance weight value exceeds 50 g (1.76 oz), installtwo balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "FOR USA AND CANADA : Introduction of Periodic

Maintenance".

• When installing the wheel, tighten wheel nuts to the specified torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

• Perform the ID registration, after tire rotation. Refer to WT-25, "Work Procedure"

.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : InspectionINFOID:0000000009464576

BRAKE FLUID LEVEL

• Make sure that the brake fluid level in the reservoir tank is between

the MAX and MIN lines.

• Visually check around the reservoir tank for brake fluid leakage.

• If the brake fluid level is excessively low, check the brake system for leakage.

• If brake warning lamp remains illuminated after parking brake

pedal is released, check the brake system for brake fluid leakage.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to

WT-55, "Adjustment"

.

PEIA0033E

Wheel nut tightening

torque : 113 N·m (12 kg-m, 83 ft-lb)

SMA829C

ALFIA0273ZZ

Revision: November 20132014 Altima NAM

Page 3225 of 4801

CHASSIS AND BODY MAINTENANCEMA-41

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

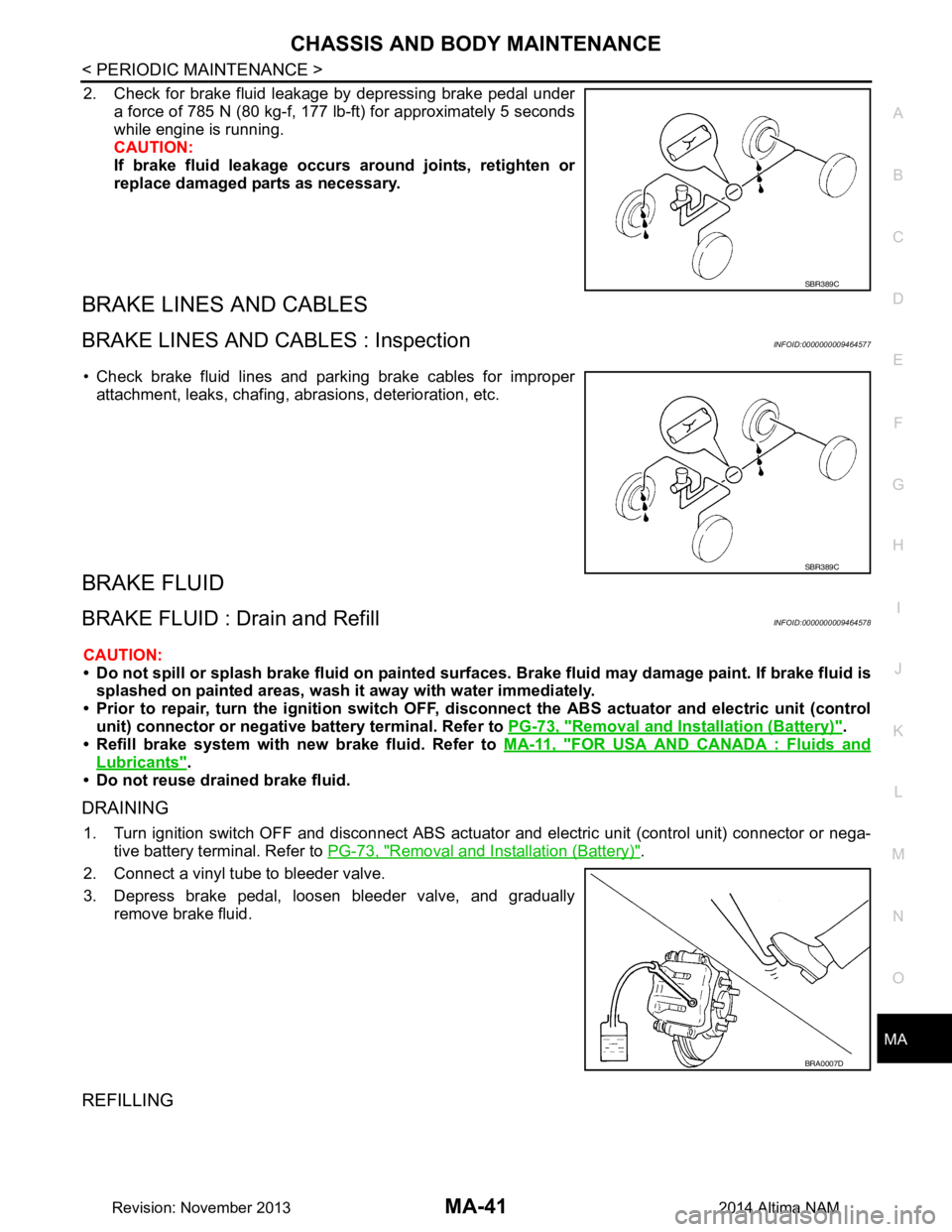

2. Check for brake fluid leakage by depressing brake pedal under

a force of 785 N (80 kg-f, 177 lb-ft) for approximately 5 seconds

while engine is running.

CAUTION:

If brake fluid leakage occurs around joints, retighten or

replace damaged parts as necessary.

BRAKE LINES AND CABLES

BRAKE LINES AND CABLES : InspectionINFOID:0000000009464577

• Check brake fluid lines and parking brake cables for improper attachment, leaks, chafing, abrasions, deterioration, etc.

BRAKE FLUID

BRAKE FLUID : Drain and RefillINFOID:0000000009464578

CAUTION:

• Do not spill or splash brake fluid on painted surf aces. Brake fluid may damage paint. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Prior to repair, turn the ignition switch OFF, disconnect the ABS actuator and electric unit (control

unit) connector or negative battery terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

• Refill brake system with new brake fluid. Refer to MA-11, "FOR USA AND CANADA : Fluids and

Lubricants".

• Do not reuse drained brake fluid.

DRAINING

1. Turn ignition switch OFF and disconnect ABS actuat or and electric unit (control unit) connector or nega-

tive battery terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

2. Connect a vinyl tube to bleeder valve.

3. Depress brake pedal, loosen bleeder valve, and gradually remove brake fluid.

REFILLING

SBR389C

SBR389C

BRA0007D

Revision: November 20132014 Altima NAM

Page 3226 of 4801

MA-42

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

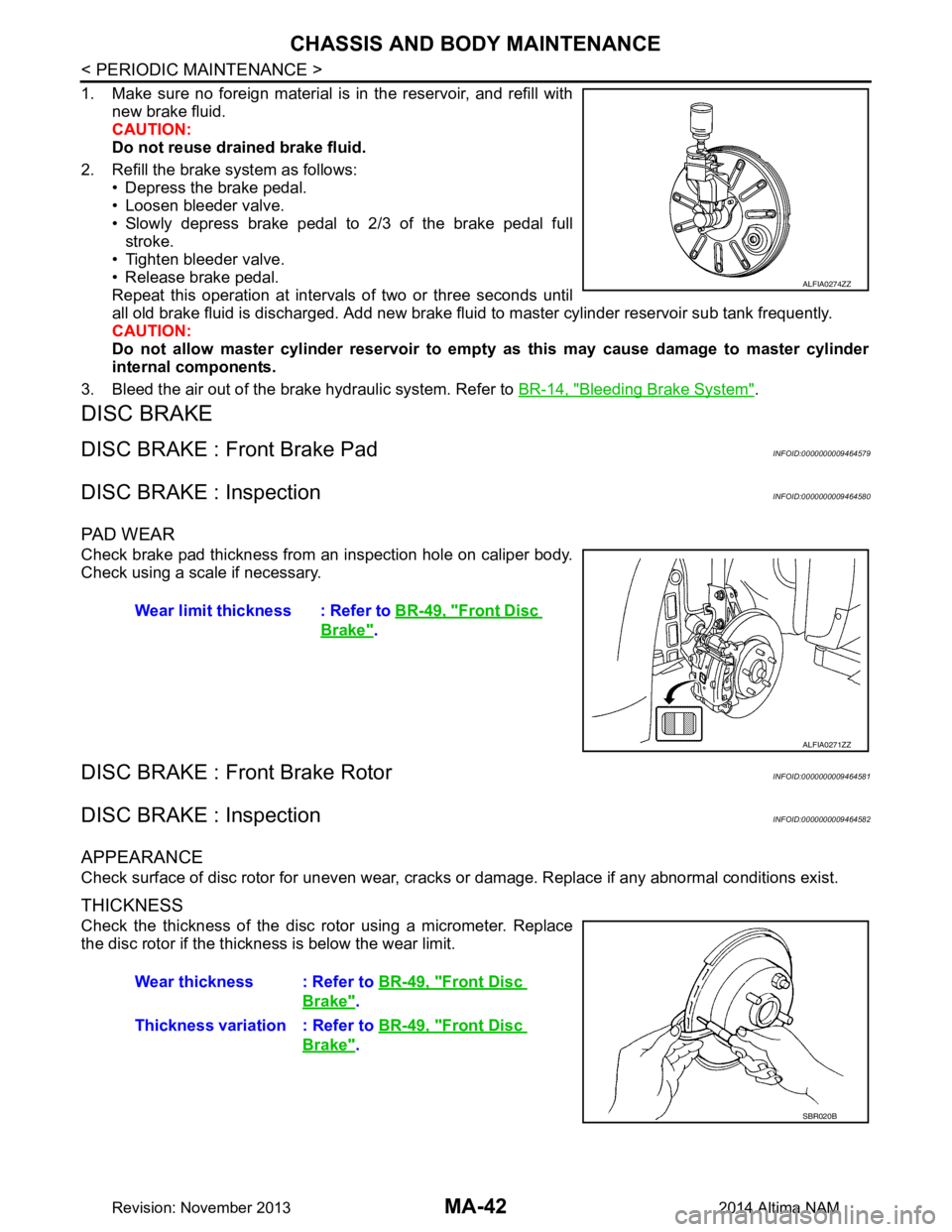

1. Make sure no foreign material is in the reservoir, and refill withnew brake fluid.

CAUTION:

Do not reuse drained brake fluid.

2. Refill the brake system as follows: • Depress the brake pedal.

• Loosen bleeder valve.

• Slowly depress brake pedal to 2/3 of the brake pedal full stroke.

• Tighten bleeder valve.

• Release brake pedal.

Repeat this operation at intervals of two or three seconds until

all old brake fluid is discharged. Add new brake flui d to master cylinder reservoir sub tank frequently.

CAUTION:

Do not allow master cylinder reservoir to empt y as this may cause damage to master cylinder

internal components.

3. Bleed the air out of the brake hydraulic system. Refer to BR-14, "Bleeding Brake System"

.

DISC BRAKE

DISC BRAKE : Front Brake PadINFOID:0000000009464579

DISC BRAKE : InspectionINFOID:0000000009464580

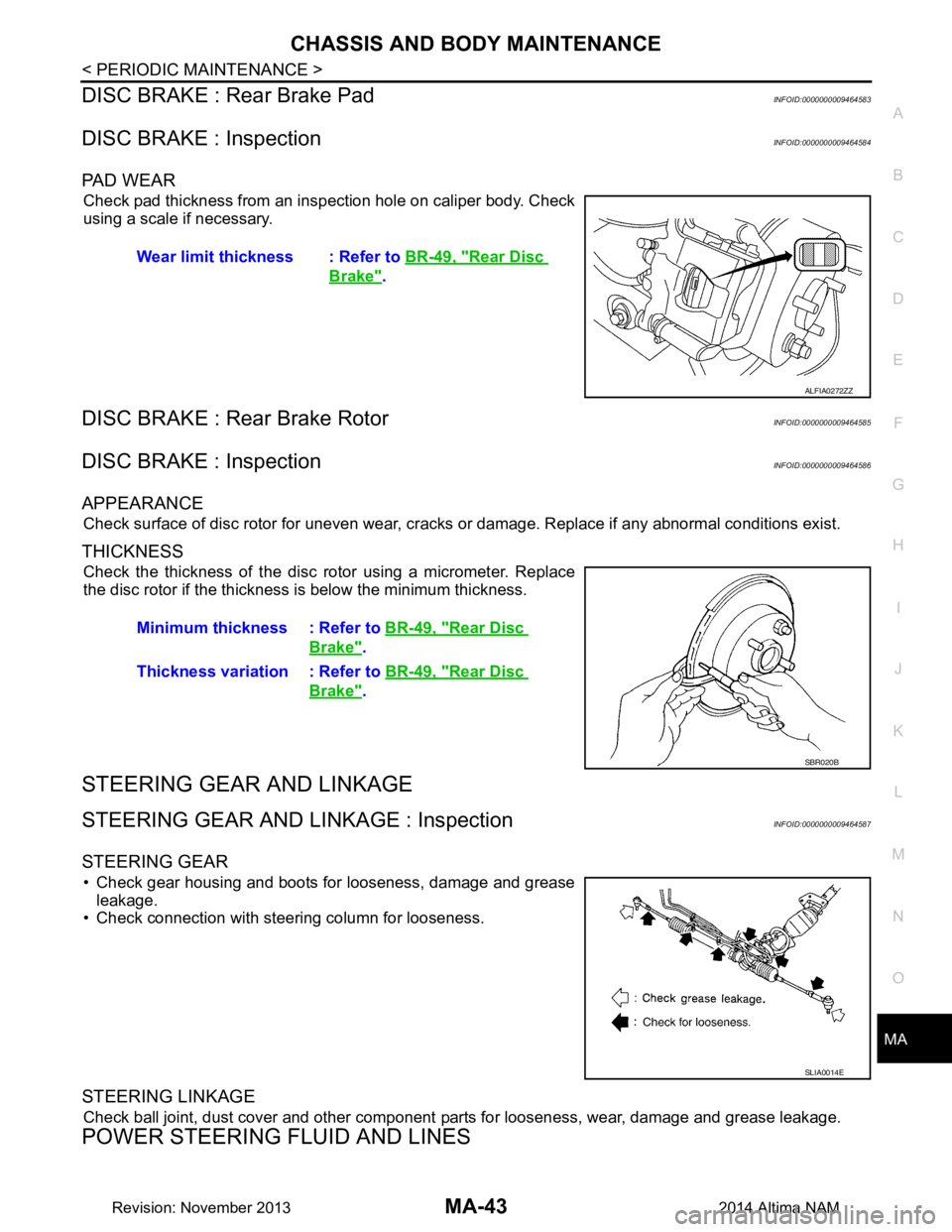

PA D W E A R

Check brake pad thickness from an inspection hole on caliper body.

Check using a scale if necessary.

DISC BRAKE : Front Brake RotorINFOID:0000000009464581

DISC BRAKE : InspectionINFOID:0000000009464582

APPEARANCE

Check surface of disc rotor for uneven wear, cracks or damage. Replace if any abnormal conditions exist.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ALFIA0274ZZ

Wear limit thickness : Refer to BR-49, "Front Disc

Brake".

ALFIA0271ZZ

Wear thickness : Refer to BR-49, "Front Disc

Brake".

Thickness variation : Refer to BR-49, "Front Disc

Brake".

SBR020B

Revision: November 20132014 Altima NAM

Page 3227 of 4801

CHASSIS AND BODY MAINTENANCEMA-43

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

DISC BRAKE : Rear Brake PadINFOID:0000000009464583

DISC BRAKE : InspectionINFOID:0000000009464584

PA D W E A R

Check pad thickness from an inspection hole on caliper body. Check

using a scale if necessary.

DISC BRAKE : Rear Brake RotorINFOID:0000000009464585

DISC BRAKE : InspectionINFOID:0000000009464586

APPEARANCE

Check surface of disc rotor for uneven wear, cracks or damage. Replace if any abnormal conditions exist.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the minimum thickness.

STEERING GEAR AND LINKAGE

STEERING GEAR AND LINKAGE : InspectionINFOID:0000000009464587

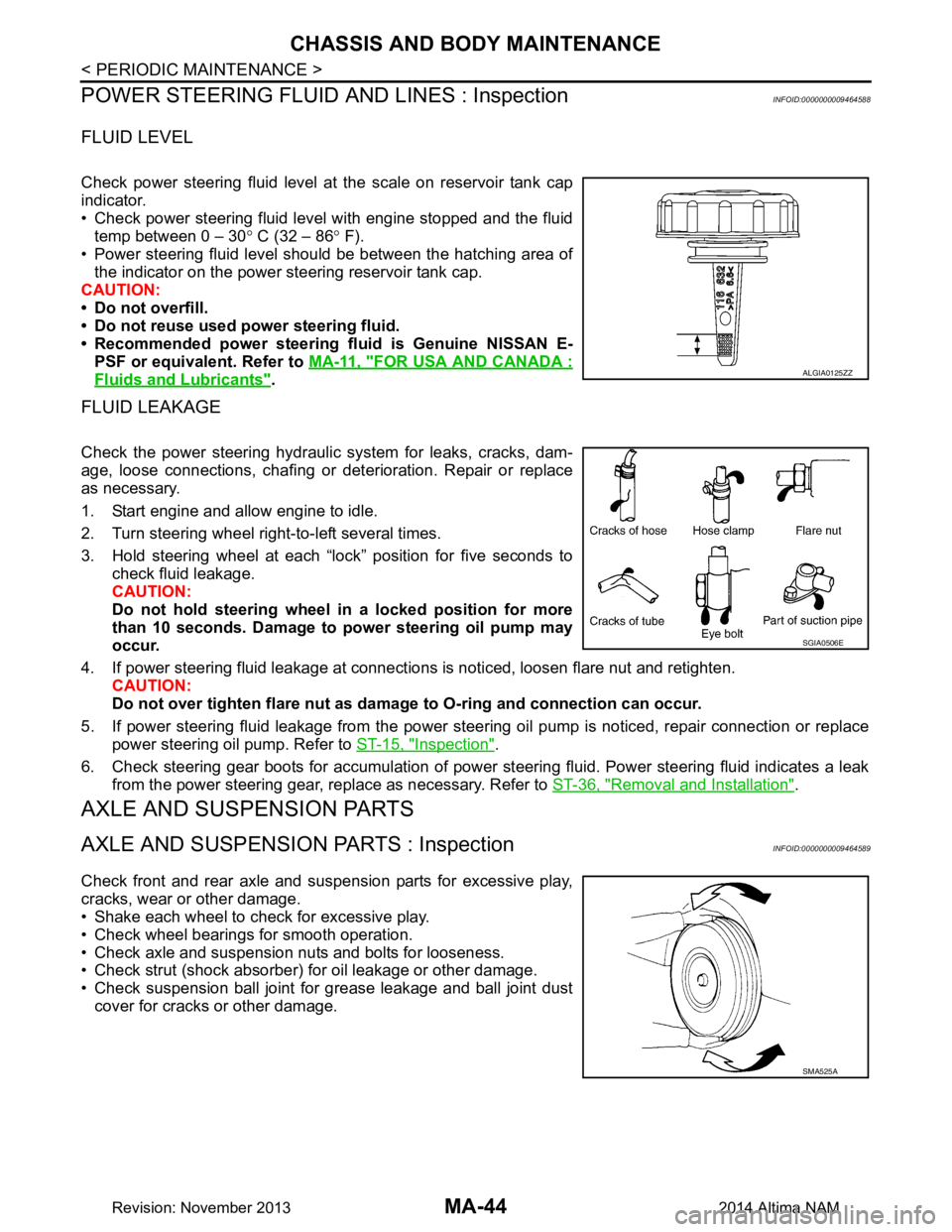

STEERING GEAR

• Check gear housing and boots for looseness, damage and grease leakage.

• Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

POWER STEERING FLUID AND LINES

Wear limit thickness : Refer to BR-49, "Rear Disc

Brake".

ALFIA0272ZZ

Minimum thickness : Refer to BR-49, "Rear Disc

Brake".

Thickness variation : Refer to BR-49, "Rear Disc

Brake".

SBR020B

SLIA0014E

Revision: November 20132014 Altima NAM

Page 3228 of 4801

MA-44

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

POWER STEERING FLUID AND LINES : Inspection

INFOID:0000000009464588

FLUID LEVEL

Check power steering fluid level at the scale on reservoir tank cap

indicator.

• Check power steering fluid level with engine stopped and the fluid temp between 0 – 30 ° C (32 – 86 ° F).

• Power steering fluid level should be between the hatching area of the indicator on the power steering reservoir tank cap.

CAUTION:

• Do not overfill.

• Do not reuse used power steering fluid.

• Recommended power steering fluid is Genuine NISSAN E-

PSF or equivalent. Refer to MA-11, "FOR USA AND CANADA :

Fluids and Lubricants".

FLUID LEAKAGE

Check the power steering hydraulic system for leaks, cracks, dam-

age, loose connections, chafing or det erioration. Repair or replace

as necessary.

1. Start engine and allow engine to idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. Damage to power steering oil pump may

occur.

4. If power steering fluid leakage at connections is noticed, loosen flare nut and retighten.

CAUTION:

Do not over tighten flare nut as damage to O-ring and connection can occur.

5. If power steering fluid leakage from the power steer ing oil pump is noticed, repair connection or replace

power steering oil pump. Refer to ST-15, "Inspection"

.

6. Check steering gear boots for accumulation of power steering fluid. Power steering fluid indicates a leak from the power steering gear, replace as necessary. Refer to ST-36, "Removal and Installation"

.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : InspectionINFOID:0000000009464589

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Check wheel bearings for smooth operation.

• Check axle and suspension nuts and bolts for looseness.

• Check strut (shock absorber) for oil leakage or other damage.

• Check suspension ball joint for grease leakage and ball joint dust cover for cracks or other damage.

ALGIA0125ZZ

SGIA0506E

SMA525A

Revision: November 20132014 Altima NAM

Page 3229 of 4801

CHASSIS AND BODY MAINTENANCEMA-45

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

K L

M B

MA

N

O A

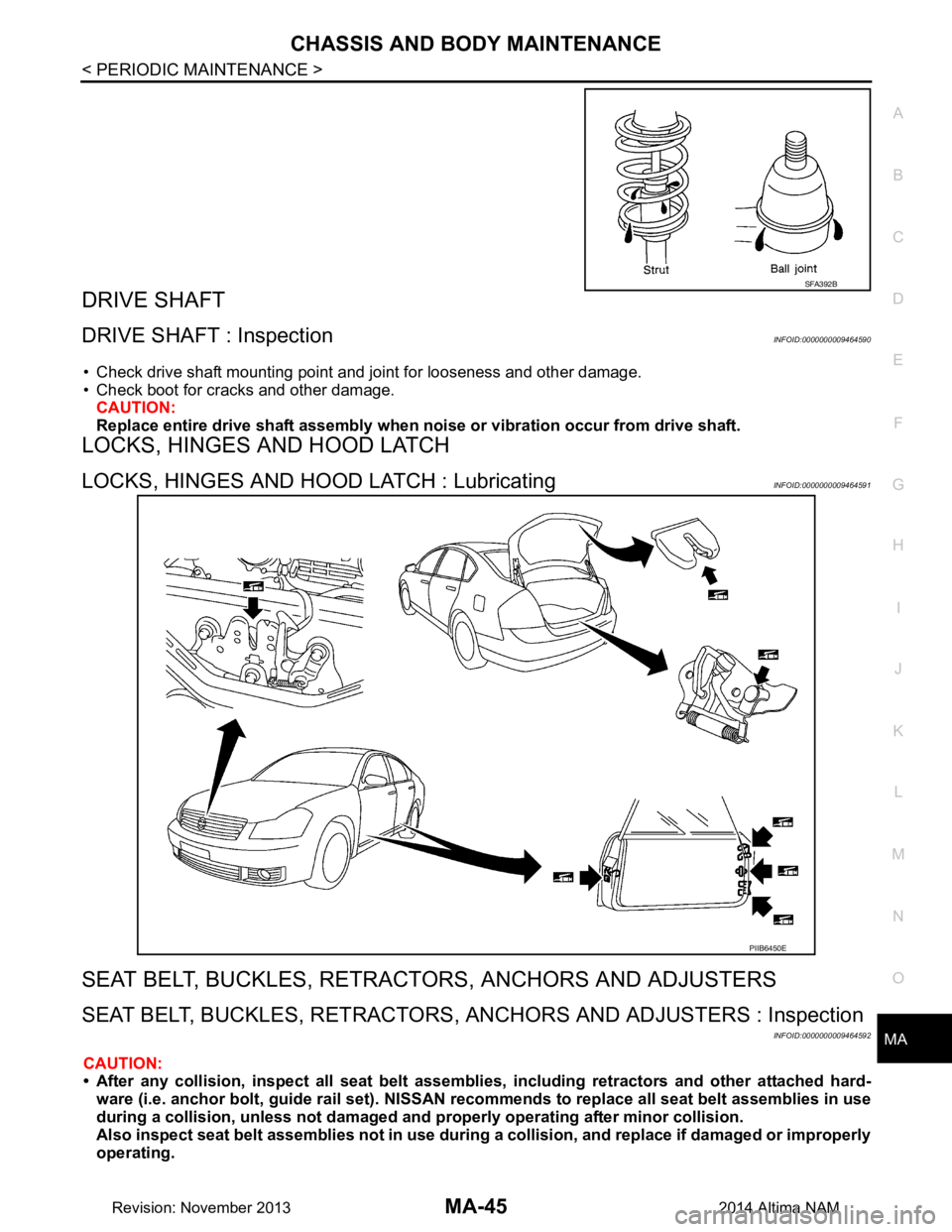

DRIVE SHAFT

DRIVE SHAFT : InspectionINFOID:0000000009464590

• Check drive shaft mounting point and joint for looseness and other damage.

• Check boot for cracks and other damage.

CAUTION:

Replace entire drive shaft assembly when noi se or vibration occur from drive shaft.

LOCKS, HINGES AND HOOD LATCH

LOCKS, HINGES AND HOOD LATCH : LubricatingINFOID:0000000009464591

SEAT BELT, BUCKLES, RETRAC TORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

INFOID:0000000009464592

CAUTION:

• After any collision, inspect all seat belt assembli es, including retractors and other attached hard-

ware (i.e. anchor bolt, guide ra il set). NISSAN recommends to repl ace all seat belt assemblies in use

during a collision, unless not damaged an d properly operating after minor collision.

Also inspect seat belt assemblies no t in use during a collision, and replace if damaged or improperly

operating.

SFA392B

PIIB6450E

Revision: November 20132014 Altima NAM

Page 3230 of 4801

MA-46

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

Seat belt pre-tensioner should be replaced even if the seat belts are not in use during a frontal colli-

sion where the driver and passenger air bags are deployed.

• If any component of seat belt assembl y is questionable, do not repair.

Replace as seat belt assembly.

• If webbing is cut, frayed, or damaged, replace seat belt assembly.

• Do not oil tongue and buckle.

• Use only a Genuine NISSAN seat belt assembly.

For details, refer to SB-5, "Inspection"

in the SB section.

• Check anchors for loose mounting.

• Check belts for damage.

• Check retractor for smooth operation.

• Check function of buckles and tongues when buckled and released.

Revision: November 20132014 Altima NAM