Pro pressure NISSAN TEANA 2014 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1008 of 4801

EC-8

POSITIVE CRANKCASE VENTILATION ........539

Inspection ............................................................ ..539

REMOVAL AND INSTALLATION ..............540

ECM ................................................................ .540

Removal and Installation ..................................... ..540

SERVICE DATA AND SPECIFICATIONS

(SDS) .............. ............................................

541

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

541

Idle Speed ........................................................... ..541

Ignition Timing .......................................................541

Calculated Load Value ..........................................541

Mass Air Flow Sensor ............................................541

VQ35DE

PRECAUTION .............. ..............................

542

PRECAUTIONS .............................................. .542

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

542

On Board Diagnostic (OBD) System of Engine

and CVT .............................................................. ..

542

General Precautions ..............................................543

PREPARATION ..........................................546

PREPARATION .............................................. .546

Special Service Tools .......................................... ..546

Commercial Service Tools .....................................546

SYSTEM DESCRIPTION ...........................548

COMPONENT PARTS .................................... .548

ENGINE CONTROL SYSTEM .................................548

ENGINE CONTROL SYSTEM : Component Parts

Location ............................................................... ..

548

Accelerator Pedal Position Sensor ........................552

Air Fuel Ratio (A/F) Sensor 1 ................................552

ASCD Steering Switch ...........................................553

Battery Current Sensor (With Battery Tempera-

ture Sensor) ......................................................... ..

553

Camshaft Position Sensor (PHASE) .....................554

Cooling Fan ......................................................... ..554

Crankshaft Position Sensor (POS) ........................554

ECM .......................................................................555

Electric Throttle Control Actuator ......................... ..555

Electronic Controlled Engine Mount .................... ..556

Engine Coolant Temperature Sensor ....................556

Engine Oil Pressure Sensor ................................ ..557

Engine Oil Temperature Sensor ............................557

EVAP Canister ..................................... ..................557

EVAP Canister Purge Volu me Control Solenoid

Valve .................................................................... ..

557

EVAP Canister Vent Control Valve ........................558

EVAP Control System Pressu re Sensor ................558

Fuel Injector ......................................................... .558

Fuel Level Sensor Unit and Fuel Pump (With Fuel

Tank Temperature Sensor) .................................. .

558

Heated Oxygen Sensor 2 ......................................559

Ignition Coil (With Power Transistor) ....................560

Intake Valve Timing Control Solenoid Valve .........560

Knock Sensor ....................................................... .560

Malfunction Indicator lamp (MIL) ...........................560

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) ......................................................... .

560

Oil Pressure Warning Lamp ..................................561

Power Valve Actuator 1 and 2 ..............................561

Refrigerant Pressure Sensor ................................562

Stop Lamp Switch & Brak e Pedal Position Switch .562

VIAS Control Solenoid Valve 1 and 2 .................. .562

STRUCTURE AND OPERATION .....................563

Positive Crankcase Ventilation (PCV) ...................563

On Board Refueling Vapor Recovery (ORVR) ..... .564

SYSTEM ...........................................................565

ENGINE CONTROL SYSTEM ................................ .565

ENGINE CONTROL SYSTEM : System Descrip-

tion ....................................................................... .

565

ENGINE CONTROL SYSTEM : Fail-safe .............566

MULTIPORT FUEL INJECTION SYSTEM ............. .568

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description .................................................... .

568

ELECTRIC IGNITION SYSTEM ............................. .571

ELECTRIC IGNITION SYSTEM : System De-

scription ................................................................ .

571

AIR CONDITIONING CUT CONTROL ................... .572

AIR CONDITIONING CUT CONTROL : System

Description ........................................................... .

573

AUTOMATIC SPEED CONTROL DEVICE (ASCD) .574

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Description ..................................... .

574

COOLING FAN CONTROL .................................... .575

COOLING FAN CONTROL : System Description .575

ELECTRONIC CONTROLLED ENGINE MOUNT .. .577

ELECTRONIC CONTROLLED ENGINE MOUNT

: System Description ............................................ .

577

EVAPORATIVE EMISSION SYSTEM .....................579

EVAPORATIVE EMISSION SYSTEM : System

Description ........................................................... .

580

THROTTLE CONTROL ...........................................581

THROTTLE CONTROL : Syst em Description ......581

INTAKE VALVE TIMING CONTROL ..................... .582

INTAKE VALVE TIMING CONTROL : System De-

scription ................................................................ .

583

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE ........................................... .

583

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1009 of 4801

EC-9

C

D E

F

G H

I

J

K L

M

EC A

N

O P

ENGINE PROTECTION CO

NTROL AT LOW EN-

GINE OIL PRESSURE : System Description ...... ..

583

FUEL FILLER CAP WARNING SYSTEM ............. ..584

FUEL FILLER CAP WARNING SYSTEM : System

Description .......................................................... ..

585

VARIABLE INDUCTION AIR SYSTEM ...................586

VARIABLE INDUCTION AIR SYSTEM : System

Description .......................................................... ..

586

INTEGRATED CONTROL OF ENGINE, CVT, AND

ABS ........................................................................ ..

587

INTEGRATED CONTROL OF ENGINE, CVT,

AND ABS : System Descri ption ............................

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTROL SYSTEM .................. ..

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTRO L SYSTEM : System

Description .......................................................... ..

588

CAN COMMUNICATION ....................................... ..588

CAN COMMUNICATION : System Description ....588

OPERATION ................................................... ..589

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ..589

AUTOMATIC SPEED CONT ROL DEVICE (AS-

CD) : Switch Name and Function ........................ ..

589

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....590

Diagnosis Description ......................................... ..590

GST (Generic Scan Tool) ......................................590

DIAGNOSIS SYSTEM (ECM) ...........................591

DIAGNOSIS DESCRIPTION ................................. ..591

DIAGNOSIS DESCRIPTION : 1st Trip Detection

Logic and Two Trip Detection Logic .................... ..

591

DIAGNOSIS DESCRIPTION : DTC and Freeze

Frame Data ......................................................... ..

591

DIAGNOSIS DESCRIPTION : Counter System ....592

DIAGNOSIS DESCRIPTION : Driving Pattern ......595

DIAGNOSIS DESCRIPTION : System Readiness

Test (SRT) Code ................................................. ..

596

DIAGNOSIS DESCRIPTION : Permanent Diag-

nostic Trouble Code (Permanent DTC) ............... ..

597

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ..

598

On Board Diagnosis Function ...............................598

CONSULT Function ..............................................601

ECU DIAGNOSIS INFORMATION ............613

ECM ................................................................ ..613

Reference Value ................................................. ..613

Fail-safe ................................................................627

DTC Inspection Priority Chart .............................629

DTC Index ............................................................630

Test Value and Test Limit .....................................634

WIRING DIAGRAM ....................................642

ENGINE CONTRO L SYSTEM ........................642

Wiring Diagram .................................................... ..642

BASIC INSPECTION .................................670

DIAGNOSIS AND REPAIR WORKFLOW ......670

Work Flow ............................................................ ..670

Diagnostic Work Sheet ..........................................673

BASIC INSPECTION .......................................675

Work Procedure .....................................................675

ADDITIONAL SERVICE WHEN REPLACING

ECM .................................................................

679

Description ........................................................... ..679

Work Procedure .....................................................679

ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING ............................................

681

Description ........................................................... ..681

Work Procedure .....................................................681

THROTTLE VALVE CLOSED POSITION

LEARNING ....... ...............................................

682

Description ........................................................... ..682

Work Procedure .....................................................682

IDLE AIR VOLUME LEARNING .....................683

Description .............................................................683

Work Procedure .....................................................683

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ............................................................

685

Description ........................................................... ..685

Work Procedure .....................................................685

VIN REGISTRATION .......................................686

Description .............................................................686

Work Procedure .....................................................686

FUEL PRESSURE ...........................................687

Work Procedure .....................................................687

HOW TO SET SRT CODE ..............................689

Description .............................................................689

SRT Set Driving Pattern ........................................690

Work Procedure .....................................................692

HOW TO ERASE PERMANENT DTC ............695

Description .............................................................695

Work Procedure (Group A) ....................................696

Work Procedure (Group B) ....................................698

DTC/CIRCUIT DIAGNOSIS .......................701

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

701

Description ........................................................... ..701

Component Function Check ..................................701

Diagnosis Procedure .............................................702

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1012 of 4801

EC-12

Diagnosis Procedure .............................................865

P0462, P0463 FUEL LEVEL SENSOR ...........866

DTC Logic ............................................................ ..866

Diagnosis Procedure .............................................866

P0500 VSS .......................................................867

Description ........................................................... ..867

DTC Logic ..............................................................867

Diagnosis Procedure .............................................867

P0506 ISC SYSTEM ........................................869

Description ........................................................... ..869

DTC Logic ..............................................................869

Diagnosis Procedure .............................................869

P0507 ISC SYSTEM ........................................871

Description ........................................................... ..871

DTC Logic ..............................................................871

Diagnosis Procedure .............................................871

P050A, P050E COLD START CONTROL .......873

Description ........................................................... ..873

DTC Logic ..............................................................873

Diagnosis Procedure .............................................874

P0520 EOP SENSOR ......................................875

DTC Logic ............................................................ ..875

Diagnosis Procedure .............................................875

Component Inspection ...........................................877

P0524 ENGINE OIL PRESSURE ....................878

DTC Logic ............................................................ ..878

Diagnosis Procedure .............................................879

Component Inspection ...........................................880

P0603 ECM POWER SUPPLY ........................881

DTC Logic ............................................................ ..881

Diagnosis Procedure .............................................881

P0605 ECM ......................................................883

DTC Logic ............................................................ ..883

Diagnosis Procedure .............................................883

P0607 ECM ......................................................884

DTC Logic ............................................................ ..884

Diagnosis Procedure .............................................884

P0643 SENSOR POWER SUPPLY .................885

Description ........................................................... ..885

DTC Logic ..............................................................885

Diagnosis Procedure .............................................885

P0850 PNP SWITCH .......................................887

Description ........................................................... ..887

DTC Logic ..............................................................887

Component Function Check ..................................888

Diagnosis Procedure .............................................888

P1148, P1168 CLOSED LOOP CONTROL .....890

DTC Logic ............................................................ ..890

P1212 TCS COMMUNICATION LINE ..............891

Description ........................................................... .891

DTC Logic .............................................................891

Diagnosis Procedure .............................................891

P1217 ENGINE OVER TEMPERATURE .........892

DTC Logic ............................................................ .892

Component Function Check .................................892

Diagnosis Procedure .............................................893

P1225 TP SENSOR ..........................................895

DTC Logic ............................................................ .895

Diagnosis Procedure .............................................895

P1226 TP SENSOR ..........................................896

DTC Logic ............................................................ .896

Diagnosis Procedure .............................................896

P1550 BATTERY CURRENT SENSOR ...........897

DTC Logic ............................................................ .897

Diagnosis Procedure .............................................897

Component Inspection ..........................................898

P1551, P1552 BATTERY CURRENT SEN-

SOR ................................................................ ..

899

DTC Logic ............................................................ .899

Diagnosis Procedure .............................................899

Component Inspection ..........................................900

P1553 BATTERY CURRENT SENSOR ...........901

DTC Logic ............................................................ .901

Diagnosis Procedure .............................................901

Component Inspection ..........................................902

P1554 BATTERY CURRENT SENSOR ...........903

DTC Logic ............................................................ .903

Component Function Check .................................903

Diagnosis Procedure .............................................903

Component Inspection ..........................................904

P1556, P1557 BATTERY TEMPERATURE

SENSOR ......................................................... ..

906

DTC Logic ............................................................ .906

Diagnosis Procedure .............................................906

Component Inspection (Battery Temperature

Sensor) ................................................................ .

907

P1564 ASCD STEERING SWITCH ..................908

DTC Logic ............................................................ .908

Diagnosis Procedure .............................................908

Component Inspection ..........................................910

P1572 ASCD BRAKE SWITCH ........................911

Description ........................................................... .911

DTC Logic .............................................................911

Component Function Check .................................912

Diagnosis Procedure .............................................913

Component Inspection (Brake Pedal Position

Switch) ................................................................. .

916

Component Inspection (Stop Lamp Switch) ..........916

Component Inspection (Stop Lamp Relay) ...........917

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1014 of 4801

EC-14

Component Inspection ...........................................976

REFRIGERANT PRESSURE SENSOR ..........979

Component Function Check ................................ ..979

Diagnosis Procedure .............................................979

SENSOR POWER SUPPLY2 CIRCUIT ...........981

Description ........................................................... ..981

Diagnosis Procedure .............................................981

VARIABLE INDUCTION AIR SYSTEM ...........983

Component Function Check ................................ ..983

Diagnosis Procedure .............................................984

SYMPTOM DIAGNOSIS ............................987

ENGINE CONTROL SYSTEM SYMPTOMS .. .987

Symptom Table ................................................... ..987

NORMAL OPERATING CONDITION ..............991

Description ........................................................... ..991

PERIODIC MAINTENANCE ..................... ..992

IDLE SPEED ................................................... .992

Work Procedure ................................................... ..992

IGNITION TIMING .............................................993

Work Procedure ................................................... .993

EVAP LEAK CHECK ........................................994

Work Procedure ................................................... .994

POSITIVE CRANKCASE VENTILATION .........996

Work Procedure ................................................... .996

REMOVAL AND INSTALLATION .............997

ECM ................................................................ ..997

Removal and Installation .......................................997

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

998

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

998

Idle Speed ............................................................ .998

Ignition Timing .......................................................998

Calculated Load Value ..........................................998

Mass Air Flow Sensor ...........................................998

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1022 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-22

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ENGINE COMPARTMENT

Intake manifold runner control valve actuator

EC-31, "Intake Manifold Runner Control Valve"

Electric throttle control actuator NISSAN TEANA 2014 Workshop Manual

EC-22

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ENGINE COMPARTMENT

Intake manifold runner control valve actuator

EC-31, "Intake Manifold Runner Control Valve"

Electric throttle control actuator](/img/5/57390/w960_57390-1021.png)

EC-22

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ENGINE COMPARTMENT

Intake manifold runner control valve actuator

EC-31, "Intake Manifold Runner Control Valve"

Electric throttle control actuator

(with built in throttle position sensor and throttle control motor) EC-25, "Electric Thrott

le Control Actuator"

EVAP service port When perform the EVAP leak check, positive pressure is

delivered to the EVAP system through the EVAP service

port.

Refer to EC-537, "Inspection"

.

No. Component Function

JPBIA5840ZZ

Engine rear side Intake side

: Vehicle front

No. Component Function

Exhaust valve timing control position sensor EC-30, "Exhaust Valve Timing Control Position Sensor"

Camshaft position sensor (PHASE)EC-29, "Camshaft Position Sensor (PHASE)"

PCV valveThe positive crankcase ventilation (PCV) valve is provided

to conduct crankcase blow-by gas to the intake manifold.

Fuel injector EC-26, "Fuel Injector"

Crankshaft position sensor (POS)EC-29, "Crankshaft Position Sensor (POS)"

Knock sensorEC-33, "Knock Sensor"

Engine oil temperature sensorEC-33, "Engine Oil Temperature Sensor"

Engine oil pressure sensorEC-33, "Engine Oil Pressure Sensor"

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1030 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control sol NISSAN TEANA 2014 Workshop Manual

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control sol](/img/5/57390/w960_57390-1029.png)

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

Intake Valve Timing Intermediate Lock Control Solenoid ValveINFOID:0000000009462067

Intake valve timing intermediate lock control solenoid valve is acti-

vated by ON/OFF signals from the ECM.

The intake valve timing intermediate lock control solenoid valve

opens/closes the path of oil pressure acting on the lock key in the

camshaft sprocket (INT).

• When the solenoid valve becomes ON, oil pressure to the lock key

is trained to perform intermediate lock.

• When the solenoid valve becomes OFF, oil pressure is acted on the lock key to release the intermediate lock.

Exhaust Valve Timing Control Position SensorINFOID:0000000009462068

Exhaust valve timing control position sensor detects the protrusion of

the signal plate installed to the exhaust camshaft front end.

This sensor signal is used for sensing a position of the exhaust cam-

shaft.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

JMBIA0714GB

PBIB1842E

PBIB1842E

JPBIA5847ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1036 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-36

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Battery temperature sensor is int

egrated in battery current sensor.

The sensor measures temperature around the battery.

The electrical resistanc NISSAN TEANA 2014 Workshop Manual

EC-36

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Battery temperature sensor is int

egrated in battery current sensor.

The sensor measures temperature around the battery.

The electrical resistanc](/img/5/57390/w960_57390-1035.png)

EC-36

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

Battery temperature sensor is int

egrated in battery current sensor.

The sensor measures temperature around the battery.

The electrical resistance of the t hermistor decreases as temperature

increases.

*: These data are reference values and are measured between battery temperature

sensor signal terminal and sensor ground.

Malfunction Indicator lamp (MIL)INFOID:0000000009462083

The Malfunction Indicator lamp (MIL) is located on the combination

meter.

The MIL will illuminate when the ignition switch is turned ON without

the engine running. This is a bulb check.

When the engine is started, the MI L should turn OFF. If the MIL

remains illuminated, the on board diagnostic system has detected an

engine system malfunction.

For details, refer to EC-74, "DIAGNOSIS DESCRIPTION : Malfunc-

tion Indicator Lamp (MIL)".

Oil Pressure Warning LampINFOID:0000000009462084

Oil pressure warning lamp is located on the combination meter.

It indicates the low pressure of the engine oil and the malfunction of

the engine oil pressure system.

Combination meter turns the oil pressure warning lamp ON/OFF

according to the oil pressure warning lamp signal received from

ECM via CAN communication.

For details, refer to EC-55, "ENGINE PROTECTION CONTROL AT

LOW ENGINE OIL PRESSURE : System Description".

Refrigerant Pressure SensorINFOID:0000000009462085

The refrigerant pressure sensor is installed at the c ondenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

Stop Lamp Switch & Brake Pedal Position SwitchINFOID:0000000009462086

Stop lamp switch and brake pedal position switch are installed to brake pedal bracket.

ECM detects the state of the brake pedal by those two types of input (ON/OFF signal).

Temperature [°C ( °F)]

Vo l ta g e* (V) Resistance (k

Ω)

25 (77) 3.333 1.9 - 2.1

90 (194) 0.969 0.222 - 0.258

SEF012P

JSBIA1315ZZ

PBIA8559J

PBIB2657E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1039 of 4801

![NISSAN TEANA 2014 Workshop Manual

STRUCTURE AND OPERATIONEC-39

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

On Board Refueling Vapor Recovery (ORVR)INFOID:0000000009462090

From the beginning of refueling, the air NISSAN TEANA 2014 Workshop Manual

STRUCTURE AND OPERATIONEC-39

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

On Board Refueling Vapor Recovery (ORVR)INFOID:0000000009462090

From the beginning of refueling, the air](/img/5/57390/w960_57390-1038.png)

STRUCTURE AND OPERATIONEC-39

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

On Board Refueling Vapor Recovery (ORVR)INFOID:0000000009462090

From the beginning of refueling, the air and vapor insi

de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The v apor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspectio ns below, be sure to observe the following:

• Put a “CAUTION: FLAMMABL E” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof containe r and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-536, "Inspection"

.

- Disconnect battery ground cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine a nd check for fuel leaks at connection.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

JMBIA1930GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1041 of 4801

![NISSAN TEANA 2014 Workshop Manual

SYSTEMEC-41

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

ECM controls the engine by various functions.

ENGINE CONTROL SYSTEM : Fail SafeINFOID:0000000009462092

NON DTC RELATED ITE NISSAN TEANA 2014 Workshop Manual

SYSTEMEC-41

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

ECM controls the engine by various functions.

ENGINE CONTROL SYSTEM : Fail SafeINFOID:0000000009462092

NON DTC RELATED ITE](/img/5/57390/w960_57390-1040.png)

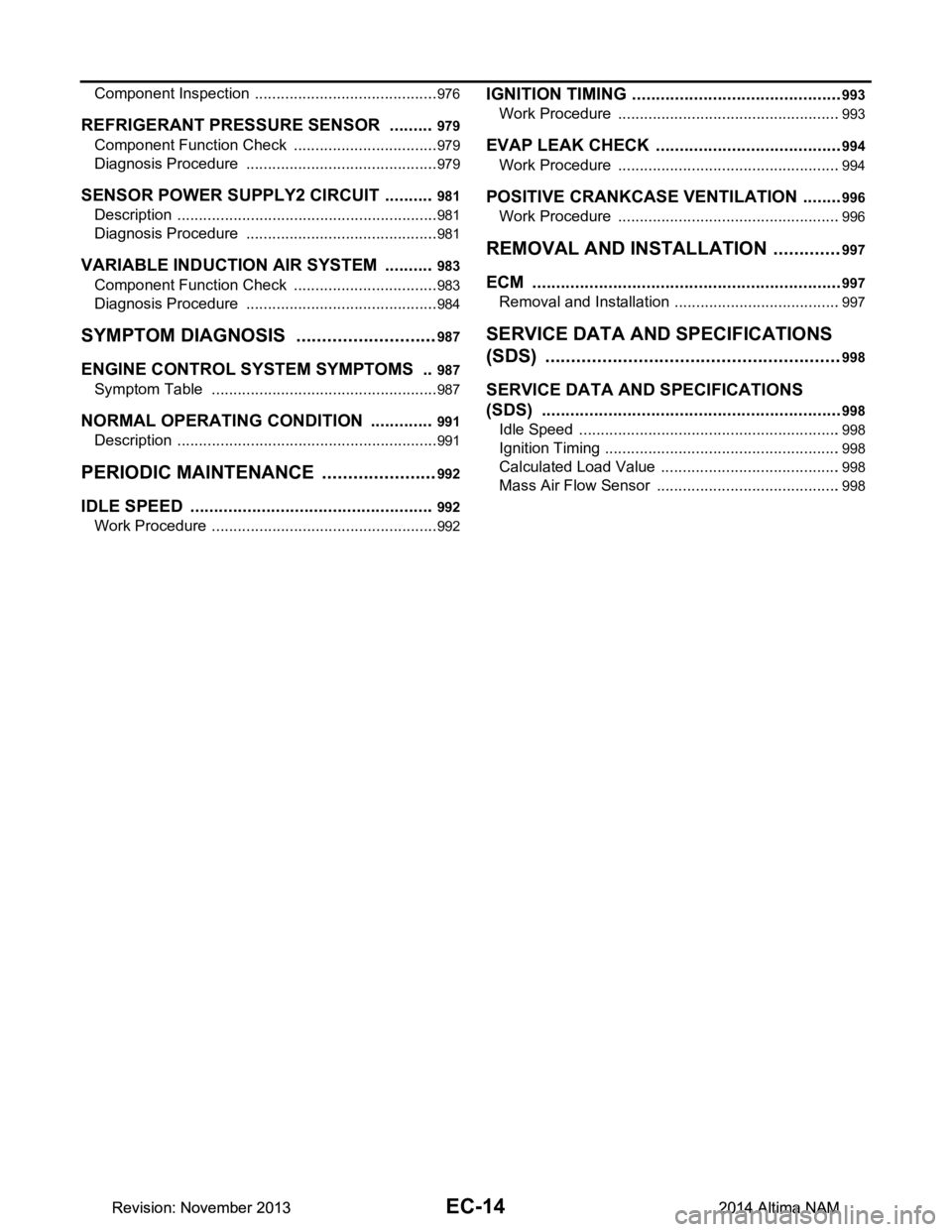

SYSTEMEC-41

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

ECM controls the engine by various functions.

ENGINE CONTROL SYSTEM : Fail SafeINFOID:0000000009462092

NON DTC RELATED ITEM

DTC RELATED ITEM

Description

When a DTC is detected, ECM executes a mode (in the

Fail-safe mode) applicable to the DTC. The fail-safe

mode has the preset traveling control mode (accelera tor angle variation and engine output limit) and device fix

mode.

Function Reference

Multiport fuel injection system EC-43, "MULTIPORT FUEL INJECTION SYSTEM : System De-

scription (with automatic air conditioner)"

Electric ignition system

EC-48, "ELECTRIC IGNITION SYSTEM : System Description"

Intake valve timing control EC-49, "INTAKE VALVE TIMING CONTROL : System Description"

Exhaust valve timing control EC-52, "EXHAUST VALVE TIMING

CONTROL : System Descrip-tion"

Intake manifold runner control EC-53, "INTAKE MANIFOLD RUNNER CONTROL : System De-scription"

Intake manifold tuning system

EC-54, "INTAKE MANIFOLD TUNI

NG SYSTEM : System Descrip-tion"

Engine protection control EC-55, "ENGINE PROTECTION CONTROL AT LOW ENGINE OIL PRESSURE : System Description"

Fuel filler cap warning systemEC-56, "FUEL FILLER CAP WARNING SYSTEM : System De-scription"

Air conditioning cut control

EC-56, "AIR CONDITIONING CUT CONTROL : System Descrip-tion (with automatic air conditioner)"

Cooling fan controlEC-59, "COOLING FAN CONTROL :

System Description (with au-tomatic air conditioner)"

Evaporative emission system EC-62, "EVAPORATIVE EMISSION

SYSTEM : System Descrip-tion"

Automatic speed control device (ASCD) EC-63, "AUTOMATIC SPEED CONTROL DEVICE (ASCD) : Sys-tem Description"

CAN communication

EC-64, "CAN COMMUNICATION : System Description"

Detected

items Engine operating condition

in fail-safe mode Remarks Reference page

Malfunction

indicator

lamp circuit Engine speed will not rise

more than 2,500 rpm due

to the fuel cut When there is an open circuit on MIL circuit, the ECM cannot warn the

driver by lighting up MIL when there is malfunction on engine control

system.

Therefore, when electrical controlled throttle and part of ECM related

diagnoses are continuously detected as NG for 5 trips, ECM warns the

driver that engine control system malfunctions and MIL circuit is open

by means of operating fail safe function.

The fail safe function also operates when above diagnoses except MIL

circuit are detected and demands the driver to repair the malfunction. EC-517, "Compo-

nent Function

Check"

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1042 of 4801

![NISSAN TEANA 2014 Workshop Manual

EC-42

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

Fail Safe Pattern

Fail Safe List

× :Applicable —: Not applicable

Fail safe mode Vehicle behavior

Traveling con-

trol mode Accelerator an-

gle variatio NISSAN TEANA 2014 Workshop Manual

EC-42

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

Fail Safe Pattern

Fail Safe List

× :Applicable —: Not applicable

Fail safe mode Vehicle behavior

Traveling con-

trol mode Accelerator an-

gle variatio](/img/5/57390/w960_57390-1041.png)

EC-42

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

Fail Safe Pattern

Fail Safe List

× :Applicable —: Not applicable

Fail safe mode Vehicle behavior

Traveling con-

trol mode Accelerator an-

gle variation

control ECM controls the accelerator pedal depression speed to make it slower than actual speed. This

causes a drop in accelerating performance and encourages the driver to repair malfunction.

NOTE:

ECM does not control the accelerator pedal releasing speed.

Engine output

control ECM reduces the engine output, according to the rise in engine speed. This reduces the vehicle

speed to encourage the driver to repair malfunction.

Device fix mode • This mode fixes the IVT control solenoid valve and the EVT control solenoid valve in the refer-

ence position.

• The intake manifold runner control valve motor is turned OFF (intake manifold runner control valve opens).

Pattern Fail safe mode

A Traveling control mode Accelerator angle variation control

B Engine output control

C Device fix mode

DTC No. Detected items Vehicle behavior

Pattern Others

ABC

P0011 Intake valve timing control ——×ECM activates the IVT intermediate lock control solenoid

valve to bring the cam sprocket into an intermediate lock con-

dition.

P0014

P0078 Exhaust valve timing control

——× —

P0101

P0102

P0103 Mass air flow sensor circuit

××× —

P0122

P0123

P0222

P0223

P2135 Throttle position sensor

———The ECM controls the electric throttle control actuator in reg-

ulating the throttle opening in order for the idle position to be

within +10 degrees.

The ECM regulates the opening speed of the throttle valve to

be slower than the normal condition.

So, the acceleration will be poor.

P0171

P0172 Fuel injection system

×—— —

P0197

P0198 Engine oil temperature sensor

———Exhaust valve timing control does not function.

P0300

P0301

P0302

P0303

P0304 Misfire

×—— —

P0500 Vehicle speed sensor ×—— —

P050A Cold start control ×—— —

P0524 Engine oil pressure

———• ECM illuminates oil pressure warning lamp on the combina-

tion meter.

• Engine speed will not rise more than 4,000rpm due to the

fuel cut.

• Fail-safe is canceled when ignition switch OFF → ON.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM