Pro pressure NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 214 of 4801

![NISSAN TEANA 2014 User Guide

BRC-68

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC LogicINFOID:0000000009463772

DTC DETECTION LOGIC

DTC CONFIRMATION P NISSAN TEANA 2014 User Guide

BRC-68

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC LogicINFOID:0000000009463772

DTC DETECTION LOGIC

DTC CONFIRMATION P](/img/5/57390/w960_57390-213.png)

BRC-68

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC LogicINFOID:0000000009463772

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Start engine and drive vehicle at approximately 21 km/h (13 MPH) or more for approximately 5 minutes.

2. Perform self diagnostic result.

Is DTC C1105, C1106, C1107 or C1108 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-68, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463773

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

CAUTION:

Do not check between wheel sensor terminals.

1.CONFIRM DTC

With CONSULT

1. Perform self-diagnostic result of ABS and record all active DTCs.

2. Clear all DTCs.

3. Perform DTC confirmation procedure. Refer to BRC-68, "DTC Logic"

.

Does DTC C1105, C1106, C1107 or C1108 reset?

YES >> GO TO 2.

NO >> Refer to GI-43, "Intermittent Incident"

.

2.CHECK TIRE PRESSURE AND TIRE WEAR

Check tires for excessive wear and proper inflation. Refer to WT-53, "Inspection"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace as necessary.

3.CHECK WHEEL SENSOR

DTC Display Item Malfunction detected condition Possible causes

C1105 RR RH SENSOR-2 • When distance between rear wheel sensor RH and

rear wheel sensor RH rotor is large.

• When installation of rear wheel sensor RH or rear wheel sensor RH rotor is not normal.

• Wheel sensor

• ABS actuator and electric unit

(control unit)

• Sensor rotor

C1106 RR LH SENSOR-2

• When distance between rear wheel sensor LH and

rear wheel sensor LH rotor is large.

• When installation of rear wheel sensor LH or rear wheel sensor LH rotor is not normal.

C1107 FR RH SENSOR-2 • When distance between front wheel sensor RH

and front wheel sensor RH rotor is large.

• When installation of front wheel sensor RH or front wheel sensor RH rotor is not normal.

C1108 FR LH SENSOR-2 • When distance between front wheel sensor LH and

front wheel sensor LH rotor is large.

• When installation of front wheel sensor LH or front wheel sensor LH rotor is not normal.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 218 of 4801

![NISSAN TEANA 2014 User Guide

BRC-72

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1110, C1153, C1170 ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)

DTC LogicINFOID:0000 NISSAN TEANA 2014 User Guide

BRC-72

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1110, C1153, C1170 ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)

DTC LogicINFOID:0000](/img/5/57390/w960_57390-217.png)

BRC-72

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1110, C1153, C1170 ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)

DTC LogicINFOID:0000000009463776

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> Proceed to diagnosis procedure. Refer to BRC-72, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463777

1.REPLACE ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

CAUTION:

Replace ABS actuator and electric unit (control uni t) when self diagnostic result shows items other

than those applicable.

>> Replace ABS actuator and electr ic unit (control unit). Refer to BRC-128, "Removal and Installa-

tion".

DTC Display item Malfunction detected condition Possible cause

C1110 CONTROLLER FAILURE When there is an internal malfunction in the ABS actuator

and electric unit (control unit). • ABS actuator and electric unit

(control unit)

C1153 EMERGENCY BRAKE When ABS actuator and electric unit (control unit) is mal-

functioning. (Pressure increase is too much or too little)

C1170 VARIANT CODING In a case wh ere VARIANT CODING is different.

Self-diagnosis results

CONTROLLER FAILURE EMERGENCY BRAKE VARIANT CODING

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 219 of 4801

![NISSAN TEANA 2014 User Guide

C1111 PUMP MOTORBRC-73

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1111 PUMP MOTOR

DTC LogicINFOID:0000000009463778

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. NISSAN TEANA 2014 User Guide

C1111 PUMP MOTORBRC-73

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1111 PUMP MOTOR

DTC LogicINFOID:0000000009463778

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.](/img/5/57390/w960_57390-218.png)

C1111 PUMP MOTORBRC-73

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1111 PUMP MOTOR

DTC LogicINFOID:0000000009463778

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Turn ignition switch OFF.

2. Depress brake pedal 20 times or more.

3. Start the engine and wait for 3 minutes or more.

4. Perform self diagnostic result.

I s D T C C 1111 d e t e c t e d ?

YES >> Proceed to diagnosis procedure. Refer to BRC-73, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463779

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

1.CONNECTOR INSPECTION

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) connectors.

3. Check connectors and terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.CHECK ABS MOTOR AND MOTOR RELAY BATTERY POWER SUPPLY

Check voltage between ABS actuator and electric uni t (control unit) connector E54 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace malfunctioning components.

3.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

Check continuity between ABS actuator and electric unit (contro l unit) connector E54 terminals 13, 38 and

ground.

DTC Display Item Malfunction detected condition Possible causes

C 1111 P U M P M O T O R • When a malfunction is detected in motor or motor

relay.

• When a low pressure malfunction is detected in ac- cumulator.

• When a malfunction is detected in accumulator

pressure sensor. • Harness or connector

• ABS actuator and electric unit

(control unit)

• Fusible link

• Battery power supply system

• Motor/accumulator assembly

ABS actuator and electric unit (control unit) —Voltage

Connector Terminal

E54 1 Ground Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 222 of 4801

![NISSAN TEANA 2014 User Guide

BRC-76

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 ABS SENSOR

[ABNORMAL SIGNAL]

C1115 ABS SENSOR [ABNORMAL SIGNAL]

DTC LogicINFOID:0000000009463782

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1 NISSAN TEANA 2014 User Guide

BRC-76

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 ABS SENSOR

[ABNORMAL SIGNAL]

C1115 ABS SENSOR [ABNORMAL SIGNAL]

DTC LogicINFOID:0000000009463782

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1](/img/5/57390/w960_57390-221.png)

BRC-76

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 ABS SENSOR

[ABNORMAL SIGNAL]

C1115 ABS SENSOR [ABNORMAL SIGNAL]

DTC LogicINFOID:0000000009463782

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Start engine and drive vehicle at approximately 30 km /h (19 MPH) or more for approximately 1 minute.

2. Perform self diagnostic result.

Is DTC C1115 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-76, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463783

Regarding Wiring Diagram information, refer to BRC-47, "Wiring Diagram".

CAUTION:

Do not check between wheel sensor terminals.

1.CONNECTOR INSPECTION

1. Disconnect ABS actuator and electric unit (contro l unit) connector E54 and wheel sensor connector of

wheel with DTC.

2. Check terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J- 45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch. NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3.

NO >> Replace the wheel sensor. Refer to BRC-124, "Removal and Installation - Front Wheel Sensor"

or

BRC-125, "Removal and Installation - Rear Wheel Sensor"

.

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

DTC Display Item Malfunction detected condition Possible causes

C 111 5 ABS SENSOR

[ABNORMAL SIGNAL] When difference in wheel speed between any wheel

and others is detected while the vehicle is driven, be-

cause of installation of tires other than specified. • Harness or connector

• Wheel sensor

• Sensor rotor

• ABS actuator and electric unit (control unit)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 233 of 4801

![NISSAN TEANA 2014 User Guide

C1142 PRESS SENSORBRC-87

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1142 PRESS SENSOR

DTC LogicINFOID:0000000009463794

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDUR NISSAN TEANA 2014 User Guide

C1142 PRESS SENSORBRC-87

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1142 PRESS SENSOR

DTC LogicINFOID:0000000009463794

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDUR](/img/5/57390/w960_57390-232.png)

C1142 PRESS SENSORBRC-87

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

C1142 PRESS SENSOR

DTC LogicINFOID:0000000009463794

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Turn ignition switch ON.

2. Perform self diagnostic result.

Is DTC C1142 detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-87, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009463795

1.CHECK STOP LAMP SWITCH SYSTEM

Check stop lamp switch system. Refer to BRC-78, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning components.

2.CHECK BRAKE FLUID LEAKAGE

Check brake fluid leakage. Refer to BR-8, "Inspection"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace malfunctioning components.

3.CHECK BRAKE PEDAL

Check brake pedal. Refer to BR-13, "Inspection and Adjustment"

.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace malfunctioning components.

4.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

1. Turn ignition switch ON.

2. Perform self diagnostic result.

3. Erase DTCs.

4. Start engine and drive vehicle for a short period of time.

5. Turn ignition switch ON.

6. Perform self diagnostic result.

Is DTC C1142 detected?

YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-128, "Removal and Installa-

tion".

NO >> Inspection End.

DTC Display Item Malfunction detected condition Possible causes

C1142 PRESS SEN CIRCUIT When a malfunction is detected in master cylinder

pressure sensor. • Stop lamp switch system

• ABS actuator and electric unit

(control unit)

• Brake system

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 378 of 4801

CHG

GENERATORCHG-33

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

B

A

O P

N

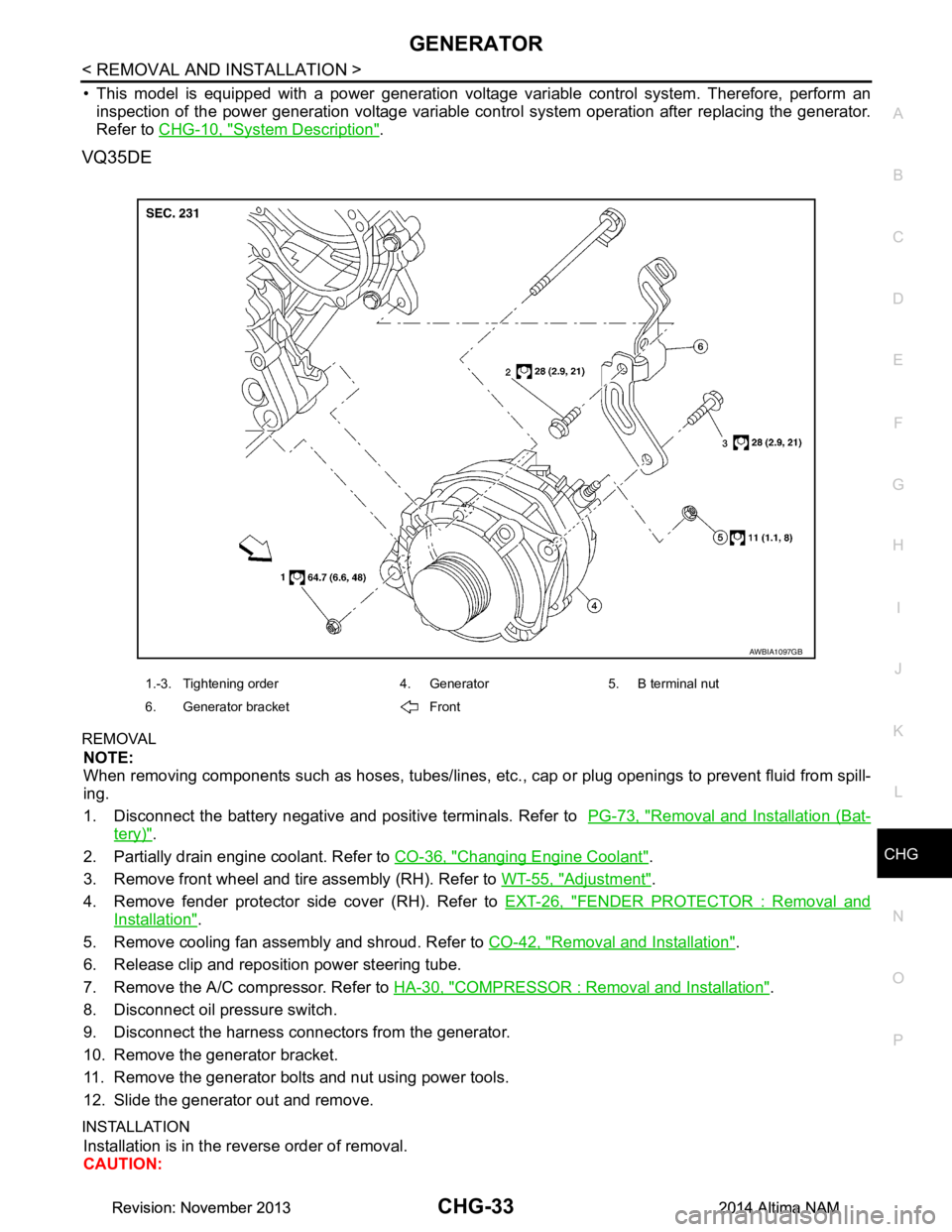

• This model is equipped with a power generation voltage

variable control system. Therefore, perform an

inspection of the power generation voltage variable c ontrol system operation after replacing the generator.

Refer to CHG-10, "System Description"

.

VQ35DE

REMOVAL

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Disconnect the battery negative and positive terminals. Refer to PG-73, "Removal and Installation (Bat-

tery)".

2. Partially drain engine coolant. Refer to CO-36, "Changing Engine Coolant"

.

3. Remove front wheel and tire assembly (RH). Refer to WT-55, "Adjustment"

.

4. Remove fender protector side cover (RH). Refer to EXT-26, "FENDER PROTECTOR : Removal and

Installation".

5. Remove cooling fan assembly and shroud. Refer to CO-42, "Removal and Installation"

.

6. Release clip and reposition power steering tube.

7. Remove the A/C compressor. Refer to HA-30, "COMPRESSOR : Removal and Installation"

.

8. Disconnect oil pressure switch.

9. Disconnect the harness connectors from the generator.

10. Remove the generator bracket.

11. Remove the generator bolts and nut using power tools.

12. Slide the generator out and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

AWBIA1097GB

1.-3. Tightening order 4. Generator 5. B terminal nut

6. Generator bracket Front

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 391 of 4801

![NISSAN TEANA 2014 User Guide

ENGINE COOLANTCO-11

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460390

WARNING:

Do not remove the radiato NISSAN TEANA 2014 User Guide

ENGINE COOLANTCO-11

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460390

WARNING:

Do not remove the radiato](/img/5/57390/w960_57390-390.png)

ENGINE COOLANTCO-11

< PERIODIC MAINTENANCE > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460390

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

CHECKING RESERVOIR LEVEL

• Check if the reservoir tank coolant level is within MIN to MAX when

the engine is cool.

• Adjust coolant level if it is too much or too little.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system using

suitable tool (A) and Tool (B).

WARNING:

Do not remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

CHECKING RADIATOR CAP

1. Inspect the radiator cap. • Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or

the metal retainer.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : Refer to CO-26, "Radiator"

.

AWBIA0740ZZ

Revision: November 20132014 Altima NAM

Page 394 of 4801

![NISSAN TEANA 2014 User Guide

CO-14

< PERIODIC MAINTENANCE >[QR25DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill t NISSAN TEANA 2014 User Guide

CO-14

< PERIODIC MAINTENANCE >[QR25DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill t](/img/5/57390/w960_57390-393.png)

CO-14

< PERIODIC MAINTENANCE >[QR25DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use recommended coolant or equivalent.

Refer to MA-11, "FOR USA AND CANADA : Fluids and Lubri-

cants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog th e cooling system and cause

damage to the engine, transm ission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose insert ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and t op up the system as necessary.

13. Install the engine under cover. Refer to EXT-17, "Removal and Installation"

.

FLUSHING COOLING SYSTEM

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

CO-26, "Capacity"

.

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: November 20132014 Altima NAM

Page 397 of 4801

![NISSAN TEANA 2014 User Guide

RADIATORCO-17

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000009460393

REMOVAL

1. Remove radiator cap and drain coolant from radiator. Re NISSAN TEANA 2014 User Guide

RADIATORCO-17

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000009460393

REMOVAL

1. Remove radiator cap and drain coolant from radiator. Re](/img/5/57390/w960_57390-396.png)

RADIATORCO-17

< REMOVAL AND INSTALLATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

Removal and InstallationINFOID:0000000009460393

REMOVAL

1. Remove radiator cap and drain coolant from radiator. Refer to

CO-12, "Changing Engine Coolant".

CAUTION:

• Perform this step when the engine is cold.

• Do not spill coolant on the drive belt.

2. Remove front air duct. Refer to EM-84, "Removal and Installation"

.

3. Disconnect coolant reservoir hose from the radiator.

4. Remove fender protector side cover (LH/RH). Refer to EXT-26, "FENDER PROTECTOR : Exploded

View".

5. Disconnect radiator hose (upper) and radiat or hose (lower) from the radiator.

CAUTION:

Do not allow the coolant to contact the drive belt.

NOTE:

The radiator hose clamps on the radiator hose (upper ) and on the radiator hose (lower), are not serviced

separately. Radiator hose clamps are part of the radiator hose assembly and serviced as one unit with the

radiator hose.

6. Disconnect the CVT oil cooler hoses.

7. Remove the front bumper fascia. Refer to EXT-17, "Removal and Installation"

.

8. Remove A/C condenser. Refer to HA-30, "COMPRESSOR : Removal and Installation"

.

CAUTION:

Be careful not to damage condenser core.

9. Remove the radiator mounts (upper).

10. Remove radiator. CAUTION:

Do not damage or scratch the radiator core when removing.

INSTALLATION

Installation is in the reverse order of removal.

• After installation, refill coolant and check for leaks. Refer to CO-12, "Changing Engine Coolant"

and CO-11,

"System Inspection".

CAUTION:

Do not spill coolant in engi ne compartment. Use a shop cloth to absorb coolant.

InspectionINFOID:0000000009460394

INSPECTION AFTER INSTALLATION

• Check that the reservoir tank cap is tightened.

• Check for leakage of engine coolant using Tool (B) and suitable tool (A). Refer to CO-11, "System Inspection"

.

WARNING:

Do not remove the radiator cap wh en the engine is hot. Seri-

ous burns could occur from high pressure coolant escaping

from the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

• Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

Tool number : EG17650301 (J-33984-A)

Testing pressure : Refer to CO-26, "Radiator"

.

AWBIA0740ZZ

Revision: November 20132014 Altima NAM

Page 415 of 4801

![NISSAN TEANA 2014 User Guide

ENGINE COOLANTCO-35

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460413

WARNING:

Do not remove the radiato NISSAN TEANA 2014 User Guide

ENGINE COOLANTCO-35

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460413

WARNING:

Do not remove the radiato](/img/5/57390/w960_57390-414.png)

ENGINE COOLANTCO-35

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

PERIODIC MAINTENANCE

ENGINE COOLANT

System InspectionINFOID:0000000009460413

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

CHECKING RESERVOIR LEVEL

• Check if the reservoir tank coolant level is within MIN to MAX

range when the engine is cool.

• Adjust coolant level if it is too much or too little.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool (A) and Tool (B).

WARNING:

Do not remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

CHECKING RADIATOR CAP

1. Inspect the radiator cap. • Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or

the metal retainer.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : Refer to CO-53, "Radiator"

.

AWBIA0740ZZ

Revision: November 20132014 Altima NAM