U1000 NISSAN TEANA 2014 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2960 of 4801

![NISSAN TEANA 2014 Workshop Manual

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000009461395

Condition of Error DetectionINFOID: NISSAN TEANA 2014 Workshop Manual

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000009461395

Condition of Error DetectionINFOID:](/img/5/57390/w960_57390-2959.png)

LAN

TROUBLE DIAGNOSISLAN-11

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

TROUBLE DIAGNOSIS

Component DescriptionINFOID:0000000009461395

Condition of Error DetectionINFOID:0000000009461396

DTC (e.g. U1000 and U1001) of CAN communication is

indicated on SELF-DIAG RESULTS on CONSULT if a

CAN communication signal is not transmitted or received between units for 2 seconds or more.

CAN COMMUNICATION SYSTEM ERROR

• CAN communication line open (CAN-H, CAN-L, or both)

• CAN communication line short (ground, betw een CAN communication lines, other harnesses)

• Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN DTC OF CAN COMMUNICATION IS I NDICATED EVEN THOUGH CAN COMMUNICATION

SYSTEM IS NORMAL

• Removal/installation of parts: Error may be detec ted when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

• Fuse blown out (removed): CAN communication of the unit may cease.

• Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition switch ON (Depending on the control unit which carries out CAN communication).

• Error may be detected if the power supply circuit of the control unit, which carries out CAN communication,

malfunctions (Depending on the control unit which carries out CAN communication).

• Error may be detected if reprogramming is not completed normally.

NOTE:

CAN communication system is normal if DTC of CAN communication is indicated on SELF-DIAG RESULTS of

CONSULT under the above conditions. Erase the memory of the self-diagnosis of each control unit.

JSMIA0527GB

Component Description

Main line CAN communication line between splices

Branch line CAN communication line between splice and a control unit

Splice A point connecting a branch line with a main line

Termination circuit Circuit connected across the CAN communication system. (Resistor)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2964 of 4801

![NISSAN TEANA 2014 Workshop Manual

LAN

TROUBLE DIAGNOSISLAN-15

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• C NISSAN TEANA 2014 Workshop Manual

LAN

TROUBLE DIAGNOSISLAN-15

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• C](/img/5/57390/w960_57390-2963.png)

LAN

TROUBLE DIAGNOSISLAN-15

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D E

F

G H

I

J

K L

B

A

O P

N

• Response to the system call

• Control unit diagnosis information

• Self-diagnosis

• CAN diagnostic support monitor

Self-DiagnosisINFOID:0000000009461399

If communication signals cannot be transmitted or rece ived among control units communicating via CAN com-

munication line, CAN communication-related DTC is displayed on the CONSULT “Self Diagnostic Result”

screen.

NOTE:

The following table shows examples of CAN communicati on-related DTC. For other DTC, refer to the applica-

ble sections.

CAN Diagnostic Support MonitorINFOID:0000000009461400

MONITOR ITEM (CONSULT)

Example: CAN DIAG SUPPORT MNTR indication

Without PAST

DTC Self-diagnosis item

(CONSULT indication) DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUIT ECM

When ECM is not transmitting or receiving CAN

communication signal of OBD (emission-relat-

ed diagnosis) for 2 seconds or more.

Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit.

Except

for ECM When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUIT When ECM is not transmitting or receiving CAN communi-

cation signal other than OBD (emission-related diagnosis)

for 2 seconds or more.

U1002 SYSTEM COMM When a control unit is not transmitting or receiving CAN

communication signal for 2 seconds or less.

U1010 CONTROL UNIT(CAN) When an error is detected during the initial diagnosis for

CAN controller of each control unit. Replace the control unit

indicating “U1010”.

JSMIA0964GB

Item PRESENT Description

Initial diagnosis OK Normal at present

NG Control unit e rror (Except for some control units)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3257 of 4801

MWI-2

Wiring Diagram .......................................................30

METER ...............................................................32

Wiring Diagram .................................................... ...32

BASIC INSPECTION ...................................51

DIAGNOSIS AND REPAIR WORKFLOW ...... ...51

Work flow ............................................................. ...51

DTC/CIRCUIT DIAGNOSIS ...................... ...53

U1000 CAN COMM CIRCUIT ......................... ...53

DTC Logic ............................................................ ...53

Diagnosis Procedure .............................................53

U1010 CONTROL UNIT (CAN) .........................54

Description ........................................................... ...54

DTC Logic ...............................................................54

Diagnosis Procedure ..............................................54

B2205 VEHICLE SPEED ...................................55

Description ........................................................... ...55

DTC Logic ...............................................................55

Diagnosis Procedure .............................................55

B2267 ENGINE SPEED .....................................56

Description ........................................................... ...56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................56

B2268 WATER TEMP ........................................57

Description ........................................................... ...57

DTC Logic ...............................................................57

Diagnosis Procedure ..............................................57

POWER SUPPLY AND GROUND CIRCUIT .....58

COMBINATION METER ........................................ ...58

COMBINATION METER : Diagnosis Procedure ....58

BCM (BODY CONTROL MODULE) ...................... ...58

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ...

58

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ...

59

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .................................................................. ...

59

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......61

Description ........................................................... ...61

Component Function Check ...................................61

Diagnosis Procedure .............................................61

Component Inspection ............................................62

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ................................................................ ...

63

Description ........................................................... ...63

Component Function Check ...................................63

Diagnosis Procedure ..............................................63

Component Inspection ......................................... ...63

WASHER FLUID LEVEL SWITCH CIRCUIT ....64

Description ........................................................... ...64

Diagnosis Procedure ...............................................64

Component Inspection ............................................64

AMBIENT SENSOR SIGNAL CIRCUIT ............66

Description ........................................................... ...66

Component Function Check ...................................66

Diagnosis Procedure ...............................................66

Component Inspection ............................................67

METER CONTROL SWITCH SIGNAL CIR-

CUIT ................................................................ ...

68

Diagnosis Procedure ............................................ ...68

Component Inspection ............................................69

STEERING SWITCH ..........................................70

Description ........................................................... ...70

Diagnosis Procedure ...............................................70

Component Inspection ............................................70

SYMPTOM DIAGNOSIS ............................72

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE ....................................................... ...

72

Description ........................................................... ...72

Diagnosis Procedure ...............................................72

THE METER CONTROL SWITCH IS INOPER-

ATIVE .............................................................. ...

73

Description ........................................................... ...73

Diagnosis Procedure ...............................................73

THE OIL PRESSURE WARNING CONTIN-

UES DISPLAYING, OR DOES NOT DISPLAY ...

74

Description ........................................................... ...74

Diagnosis Procedure ...............................................74

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ......................................................... ...

75

Description ........................................................... ...75

Diagnosis Procedure ...............................................75

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY ............................................................... ...

76

Description ........................................................... ...76

Diagnosis Procedure ...............................................76

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ...... ...

77

Description ........................................................... ...77

Diagnosis Procedure ...............................................77

THE TRUNK OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ...... ...

78

Description ........................................................... ...78

Diagnosis Procedure ...............................................78

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3282 of 4801

MWI

COMBINATION METERMWI-27

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

M B

A

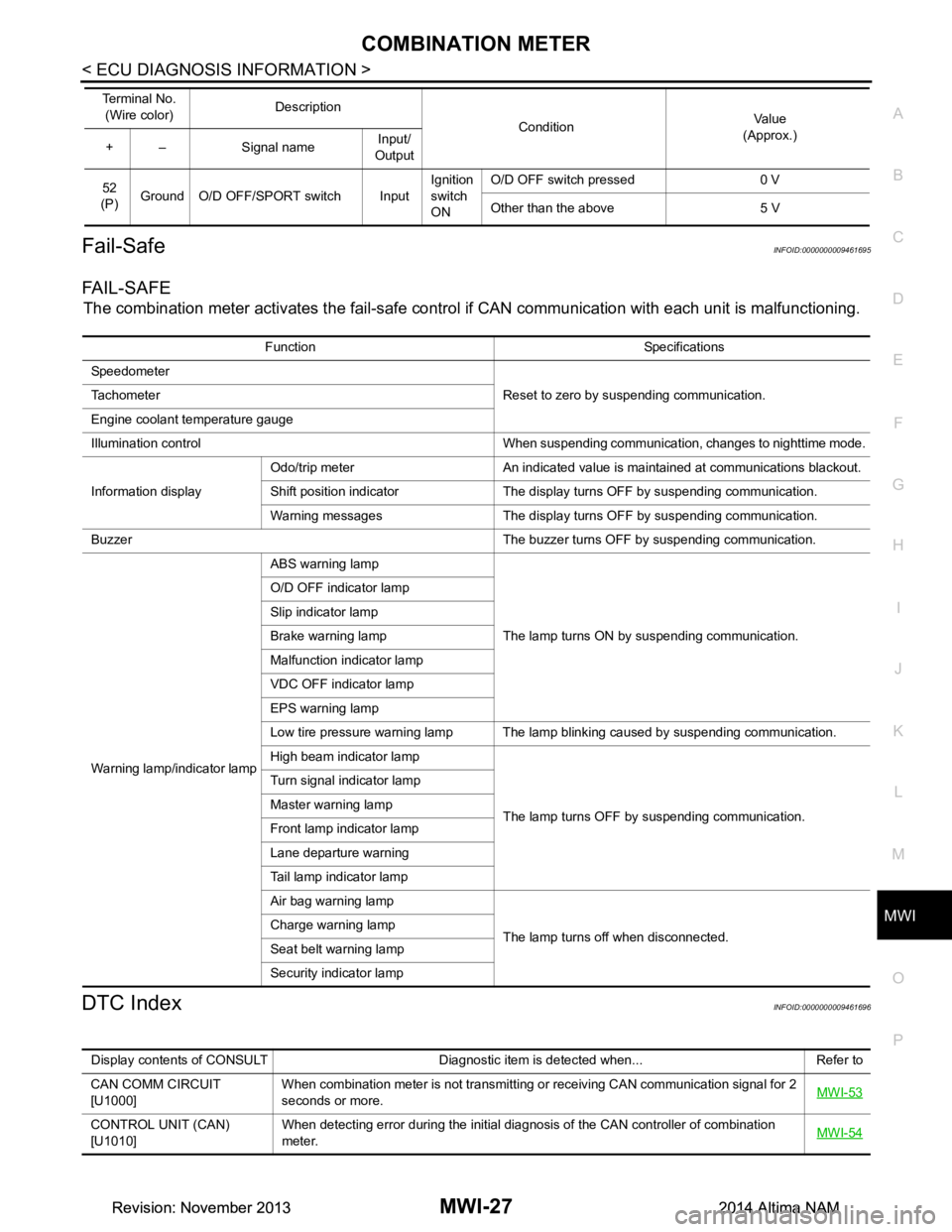

O PFail-SafeINFOID:0000000009461695

FA I L - S A F E

The combination meter activates the fail-safe contro l if CAN communication with each unit is malfunctioning.

DTC IndexINFOID:0000000009461696

52

(P) Ground O/D OFF/SPORT switch Input Ignition

switch

ON O/D OFF switch pressed 0 V

Other than the above 5 V

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

Function Specifications

Speedometer Reset to zero by suspending communication.

Tachometer

Engine coolant temperature gauge

Illumination control When suspending communication, changes to nighttime mode.

Information display Odo/trip meter An indicated value is maintained at communications blackout.

Shift position indicator The display turns OFF by suspending communication.

Warning messages The display turns OFF by suspending communication.

Buzzer The buzzer turns OFF by suspending communication.

Warning lamp/indicator lamp ABS warning lamp

The lamp turns ON by suspending communication.

O/D OFF indicator lamp

Slip indicator lamp

Brake warning lamp

Malfunction indicator lamp

VDC OFF indicator lamp

EPS warning lamp

Low tire pressure warning lamp The lamp blinking caused by suspending communication.

High beam indicator lamp

The lamp turns OFF by suspending communication.

Turn signal indicator lamp

Master warning lamp

Front lamp indicator lamp

Lane departure warning

Tail lamp indicator lamp

Air bag warning lamp

The lamp turns off when disconnected.

Charge warning lamp

Seat belt warning lamp

Security indicator lamp

Display contents of CONSULT Diagnostic item is detected when... Refer to

CAN COMM CIRCUIT

[U1000] When combination meter is not transmitting or receiving CAN communication signal for 2

seconds or more. MWI-53

CONTROL UNIT (CAN)

[U1010] When detecting error during the initial diagnosis of the CAN controller of combination

meter. MWI-54

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3308 of 4801

MWI

U1000 CAN COMM CIRCUITMWI-53

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

A

O P

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DTC LogicINFOID:0000000009461701

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000009461702

1.CHECK CAN COMMUNICATION

Select SELF-DIAG RESULTS m ode for METER/M&A with CONSULT.

>> GO TO LAN system. Refer to LAN-18, "Trouble Diagnosis Flow Chart"

.

DTC CONSULT Detection condition Possible malfunction location

U1000 CAN COMM CIRC

[U1000] When combination meter is not receiving CAN communication

signals for 2 seconds or more. Combination meter

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3350 of 4801

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

D E

F

G H

I

J

K L

B

SECTION PCS

A

O P

N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

PRECAUTION ................ ...............................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

SYSTEM ..............................................................5

RELAY CONTROL SYSTEM ................................ ......5

RELAY CONTROL SYSTEM : System Diagram ......5

RELAY CONTROL SYSTEM : System Descrip-

tion ...................................................................... ......

6

POWER CONSUMPTION CONTROL SYSTEM ... ......6

POWER CONSUMPTION CONTROL SYSTEM :

System Diagram .................................................. ......

7

POWER CONSUMPTION CONTROL SYSTEM :

System Description ............................................. ......

7

DIAGNOSIS SYSTEM (IPDM E/R) ......................8

Diagnosis Description ......................................... ......8

CONSULT Function (IPDM E/R) ...............................9

ECU DIAGNOSIS INFORMATION ..............12

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ............. ....

12

Reference Value ................................................. ....12

Fail Safe .................................................................19

DTC Index ..............................................................20

WIRING DIAGRAM ......................................21

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

21

Wiring Diagram .................................................... ....21

DTC/CIRCUIT DIAGNOSIS .........................27

U1000 CAN COMM CIRCUIT ...........................27

Description ........................................................... ....27

DTC Logic ................................................................27

Diagnosis Procedure ...............................................27

U1010 CONTROL UNIT (CAN) .........................28

DTC Logic ................................................................28

Diagnosis Procedure ...............................................28

B2098 IGNITION RELAY ON STUCK ..............29

DTC Logic ................................................................29

Diagnosis Procedure ...............................................29

B2099 IGNITION RELAY OFF STUCK ............30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

POWER SUPPLY AND GROUND CIRCUIT ....31

Diagnosis Procedure ...............................................31

REMOVAL AND INSTALLATION ...............32

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

32

Removal and Installation ..................................... ....32

POWER DISTRIBUTION SYSTEM

PRECAUTION ...... ........................................

33

PRECAUTIONS .................................................33

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

33

Precaution for Work .................................................33

PREPARATION ...........................................34

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3351 of 4801

PCS-2

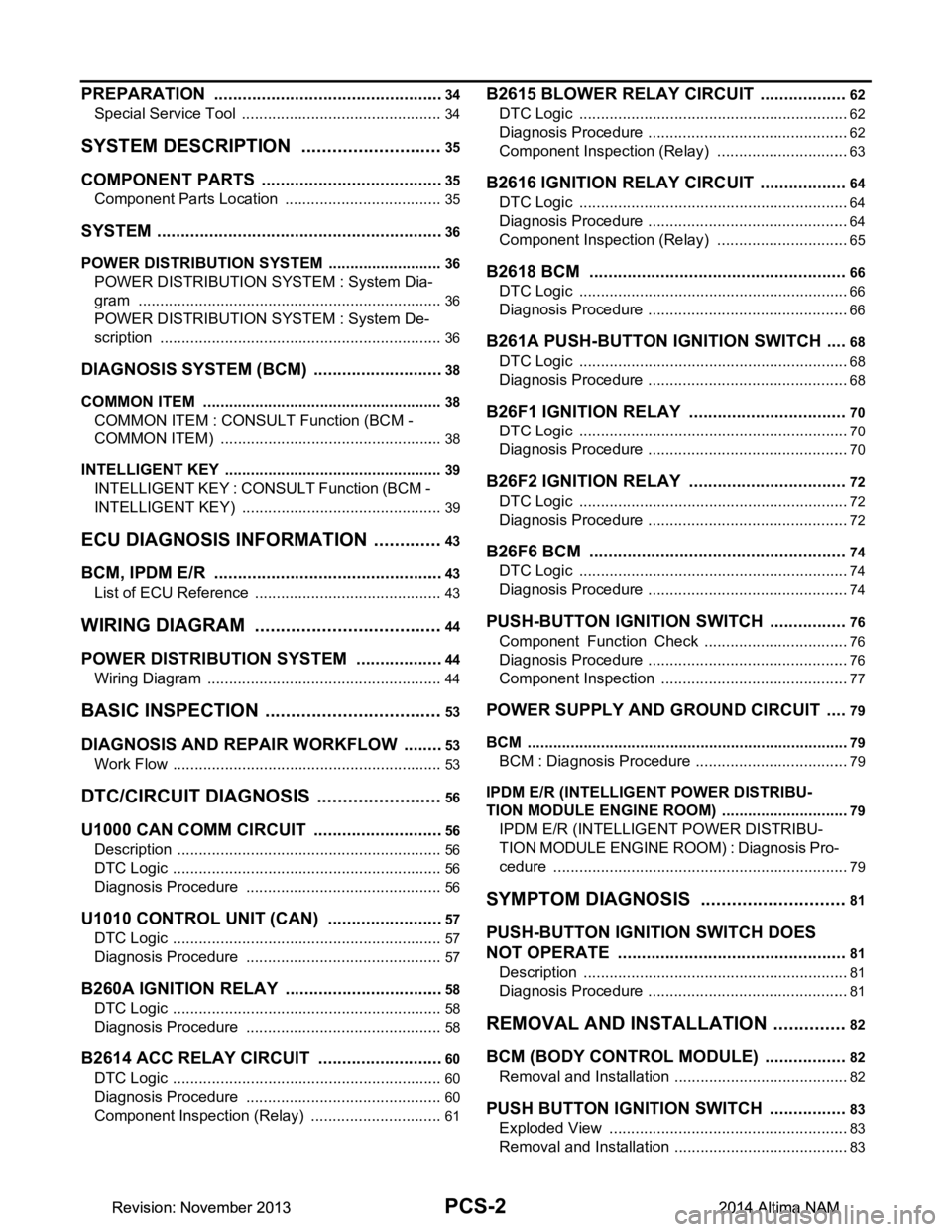

PREPARATION .............................................. ...34

Special Service Tool ............................................ ...34

SYSTEM DESCRIPTION ............................35

COMPONENT PARTS .................................... ...35

Component Parts Location .................................. ...35

SYSTEM .......................................................... ...36

POWER DISTRIBUTION SYST EM ........................ ...36

POWER DISTRIBUTION SYSTEM : System Dia-

gram .................................................................... ...

36

POWER DISTRIBUTION SYSTEM : System De-

scription ............................................................... ...

36

DIAGNOSIS SYSTEM (BCM) ............................38

COMMON ITEM ..................................................... ...38

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) ................................................. ...

38

INTELLIGENT KEY ................................................ ...39

INTELLIGENT KEY : CONSULT Function (BCM -

INTELLIGENT KEY) ........ .......................................

39

ECU DIAGNOSIS INFORMATION ........... ...43

BCM, IPDM E/R .............................................. ...43

List of ECU Reference ......................................... ...43

WIRING DIAGRAM .....................................44

POWER DISTRIBUTION SYSTEM ................ ...44

Wiring Diagram .................................................... ...44

BASIC INSPECTION ...................................53

DIAGNOSIS AND REPAIR WORKFLOW ...... ...53

Work Flow ............................................................ ...53

DTC/CIRCUIT DIAGNOSIS ...................... ...56

U1000 CAN COMM CIRCUIT ......................... ...56

Description ........................................................... ...56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................56

U1010 CONTROL UNIT (CAN) .........................57

DTC Logic ............................................................ ...57

Diagnosis Procedure ..............................................57

B260A IGNITION RELAY ..................................58

DTC Logic ............................................................ ...58

Diagnosis Procedure ..............................................58

B2614 ACC RELAY CIRCUIT ...........................60

DTC Logic ............................................................ ...60

Diagnosis Procedure ..............................................60

Component Inspection (Relay) ...............................61

B2615 BLOWER RELAY CIRCUIT ...................62

DTC Logic ............................................................ ...62

Diagnosis Procedure ...............................................62

Component Inspection (Relay) ...............................63

B2616 IGNITION RELAY CIRCUIT ...................64

DTC Logic ............................................................ ...64

Diagnosis Procedure ...............................................64

Component Inspection (Relay) ...............................65

B2618 BCM .......................................................66

DTC Logic ............................................................ ...66

Diagnosis Procedure ...............................................66

B261A PUSH-BUTTON IGNITION SWITCH .....68

DTC Logic ............................................................ ...68

Diagnosis Procedure ...............................................68

B26F1 IGNITION RELAY ..................................70

DTC Logic ............................................................ ...70

Diagnosis Procedure ...............................................70

B26F2 IGNITION RELAY ..................................72

DTC Logic ............................................................ ...72

Diagnosis Procedure ...............................................72

B26F6 BCM .......................................................74

DTC Logic ............................................................ ...74

Diagnosis Procedure ...............................................74

PUSH-BUTTON IGNITION SWITCH .................76

Component Function Check ............................... ...76

Diagnosis Procedure ...............................................76

Component Inspection ............................................77

POWER SUPPLY AND GROUND CIRCUIT .....79

BCM ........................................................................ ...79

BCM : Diagnosis Procedure ....................................79

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) ........................... ...

79

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .................................................................. ...

79

SYMPTOM DIAGNOSIS ............................81

PUSH-BUTTON IGNITION SWITCH DOES

NOT OPERATE .............................................. ...

81

Description ........................................................... ...81

Diagnosis Procedure ...............................................81

REMOVAL AND INSTALLATION ..............82

BCM (BODY CONTROL MODULE) ............... ...82

Removal and Installation .........................................82

PUSH BUTTON IGNITION SWITCH .............. ...83

Exploded View ..................................................... ...83

Removal and Installation .........................................83

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3369 of 4801

![NISSAN TEANA 2014 Workshop Manual

PCS-20

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the con NISSAN TEANA 2014 Workshop Manual

PCS-20

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the con](/img/5/57390/w960_57390-3368.png)

PCS-20

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

• If the ignition relay cannot turn OFF due to contact seiz ure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop posit ion by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/ R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

DTC IndexINFOID:0000000009461605

NOTE:

The details of TIME display are as follows.

• CRNT: The malfunctions that are detected now

• 1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It

increases like 0 → 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is

fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is

detected again in the process.

DTC Ignition switch Ignition relay Tail lamp relay

—ONON—

—OFFOFF—

B2098: IGN RELAY ON OFF ON ON (10 minutes)

B2099: IGN RELAY OFF ON OFF —

Ignition switch Front wiper switch Auto stop signal

ON OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

CONSULT display Fail-safe TIMENOTERefer to

No DTC is detected. Further testing may be required. — — — —

U1000: CAN COMM CIRCUIT ×CRNT 1 – 39 PCS-27

U1010: CONTROL UNIT (CAN) ×CRNT 1 – 39 PCS-28

B2098: IGN RELAY ON ×CRNT 1 – 39 PCS-29

B2099: IGN RELAY OFF — CRNT 1 – 39 PCS-30

B210B: INHIBIT relay ON stuck failure — CRNT 1 – 39 SEC-73

B210C: INHIBIT relay OFF stuck failure — CRNT 1 – 39 SEC-74

B210D: STARTER relay ON stuck failure — CRNT 1 – 39 SEC-76

B210E: STARTER relay OFF stuck failure — CRNT 1 – 39SEC-78

B210F: Interlock/NP switch ON stuck failure — CRNT 1 – 39 SEC-80

B2110: Interlock/NP switch OFF stuck failure — CRNT 1 – 39 SEC-82

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3376 of 4801

![NISSAN TEANA 2014 Workshop Manual

PCS

U1000 CAN COMM CIRCUITPCS-27

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461607

Refer to

LAN-9, NISSAN TEANA 2014 Workshop Manual

PCS

U1000 CAN COMM CIRCUITPCS-27

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461607

Refer to

LAN-9,](/img/5/57390/w960_57390-3375.png)

PCS

U1000 CAN COMM CIRCUITPCS-27

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D E

F

G H

I

J

K L

B

A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461607

Refer to

LAN-9, "CAN COMMUNICATION S YSTEM : System Description".

DTC LogicINFOID:0000000009461608

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000009461609

1. PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON and wait for 2 second or more.

2. Check “SELF-DIAG RESULTS” of IPDM E/R.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-18, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-43, "Intermittent Incident"

.

CONSULT Display DTC Detectio n Condition Possible Cause

CAN COMM CIRCUIT

[U1000] When IPDM E/R cannot communicate with CAN com-

munication signal continuously for 2 seconds or more In CAN communication system, any item (or items) of

the following listed below is malfunctioning.

•Transmission

• Receiving (ECM)

• Receiving (BCM)

• Receiving (Combination meter)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3405 of 4801

![NISSAN TEANA 2014 Workshop Manual

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

U1000 CAN COMM CIRCUIT

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461631

Refer to

LAN-9, "CAN COMMUNICATION NISSAN TEANA 2014 Workshop Manual

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

U1000 CAN COMM CIRCUIT

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461631

Refer to

LAN-9, "CAN COMMUNICATION](/img/5/57390/w960_57390-3404.png)

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

U1000 CAN COMM CIRCUIT

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009461631

Refer to

LAN-9, "CAN COMMUNICATION SYSTEM : System Description".

DTC LogicINFOID:0000000009461632

DTC DETECTION LOGIC

NOTE:

U1000 can be set if a module harness was disconnected and reconnected, perhaps during a repair. Confirm

that there are actual CAN diagnostic symptoms and a pr esent DTC by performing the Self Diagnostic Result

procedure.

Diagnosis ProcedureINFOID:0000000009461633

1. PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON and wait for 2 second or more.

2. Check “SELF- DIAG RESULTS”.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Perform CAN Diagnosis as described in DIAG NOSIS section of CONSULT Operation Manual.

NO >> Refer to GI-43, "Intermittent Incident"

.

CONSULT Display DTC Detectio n Condition Possible cause

CAN COMM CIRCUIT

[U1000] When any listed module cannot communicate with CAN

communication signal continuously for 2 seconds or

more with ignition switch ON In CAN communication system, any item (or items)

of the following listed below is malfunctioning.

•Transmission

• Receiving (ECM)

• Receiving (VDC/TCS/ABS)

• Receiving (METER/M&A)

• Receiving (TCM)

• Receiving (IPDM E/R)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM