NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1261 of 1767

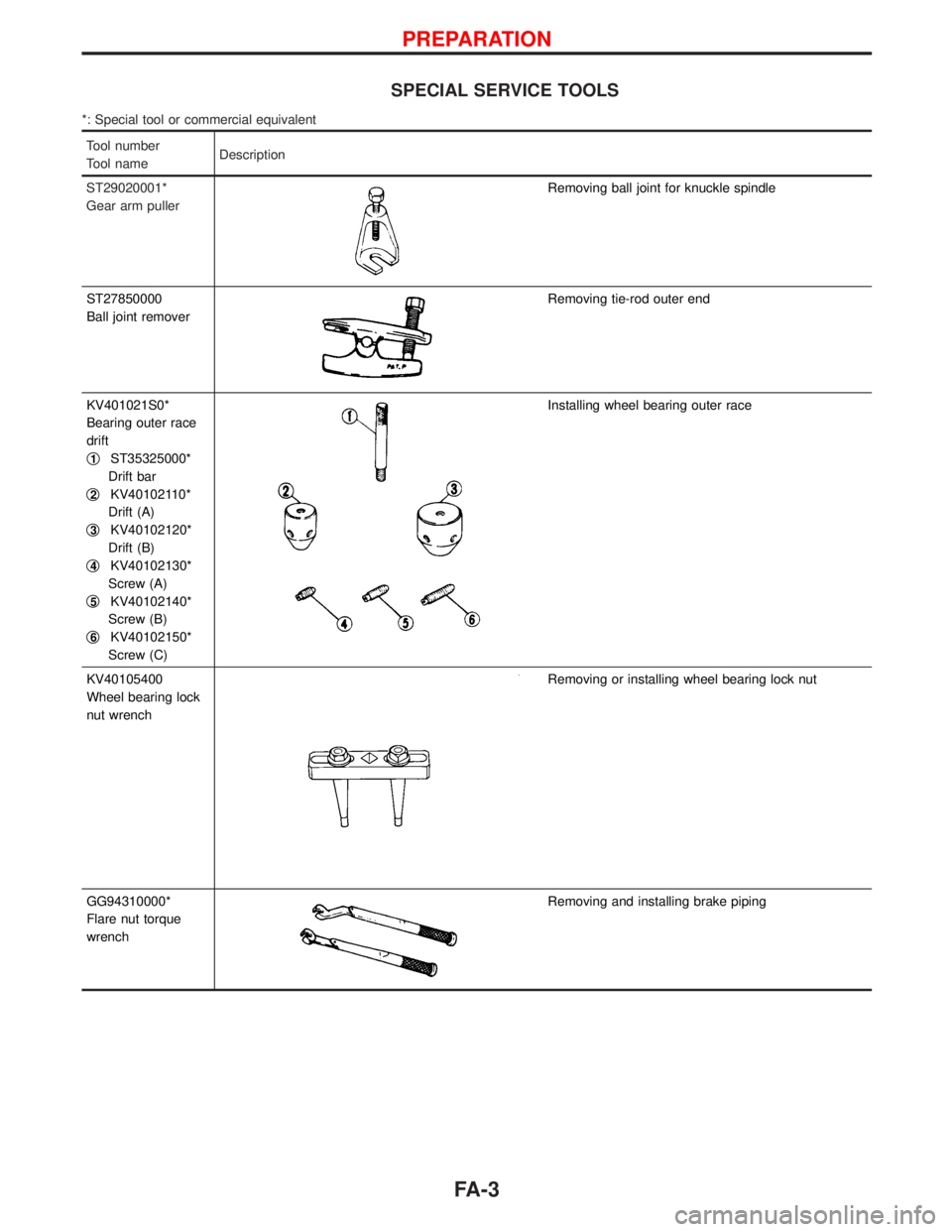

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST29020001*

Gear arm puller

Removing ball joint for knuckle spindle

ST27850000

Ball joint remover

Removing tie-rod outer end

KV401021S0*

Bearing outer race

drift

q

1ST35325000*

Drift bar

q

2KV40102110*

Drift (A)

q

3KV40102120*

Drift (B)

q

4KV40102130*

Screw (A)

q

5KV40102140*

Screw (B)

q

6KV40102150*

Screw (C)

Installing wheel bearing outer race

KV40105400

Wheel bearing lock

nut wrench

Removing or installing wheel bearing lock nut

GG94310000*

Flare nut torque

wrench

Removing and installing brake piping

PREPARATION

FA-3

Page 1262 of 1767

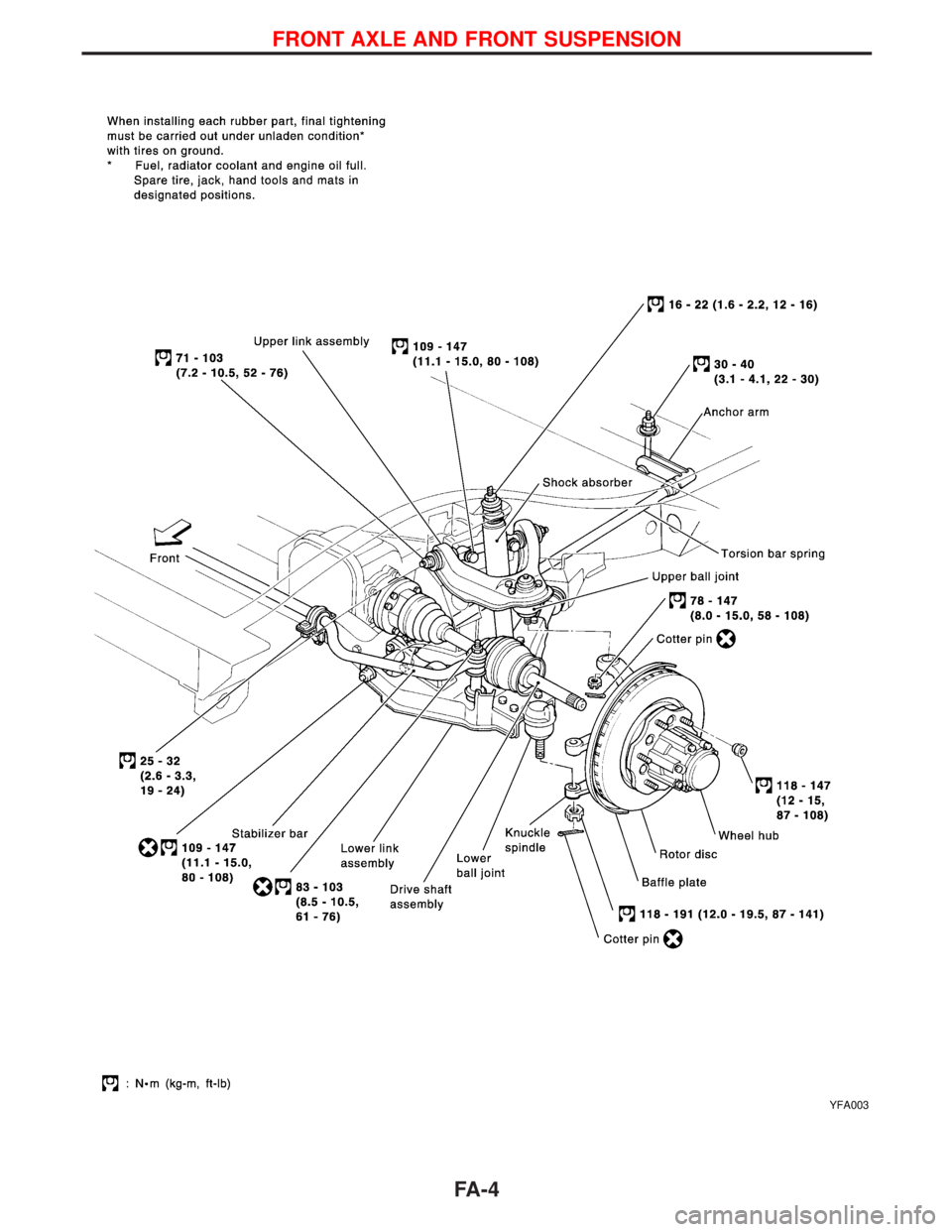

YFA003

FRONT AXLE AND FRONT SUSPENSION

FA-4

Page 1263 of 1767

Front Axle and Front Suspension Parts

ICheck front axle and front suspension parts for looseness,

cracks, wear or other damage.

(1) Shake each front wheel.

(2) Make sure that cotter pin is inserted.

(3) Retighten all nuts and bolts to the specified torque.

: Refer to ªFRONT SUSPENSIONº, FA-29.

(4) Check front axle and front suspension parts for wear, cracks or

other damage.

ICheck shock absorber for oil leakage or other damage.

ICheck suspension ball joints for grease leakage and dust cov-

ers for cracks or other damage.

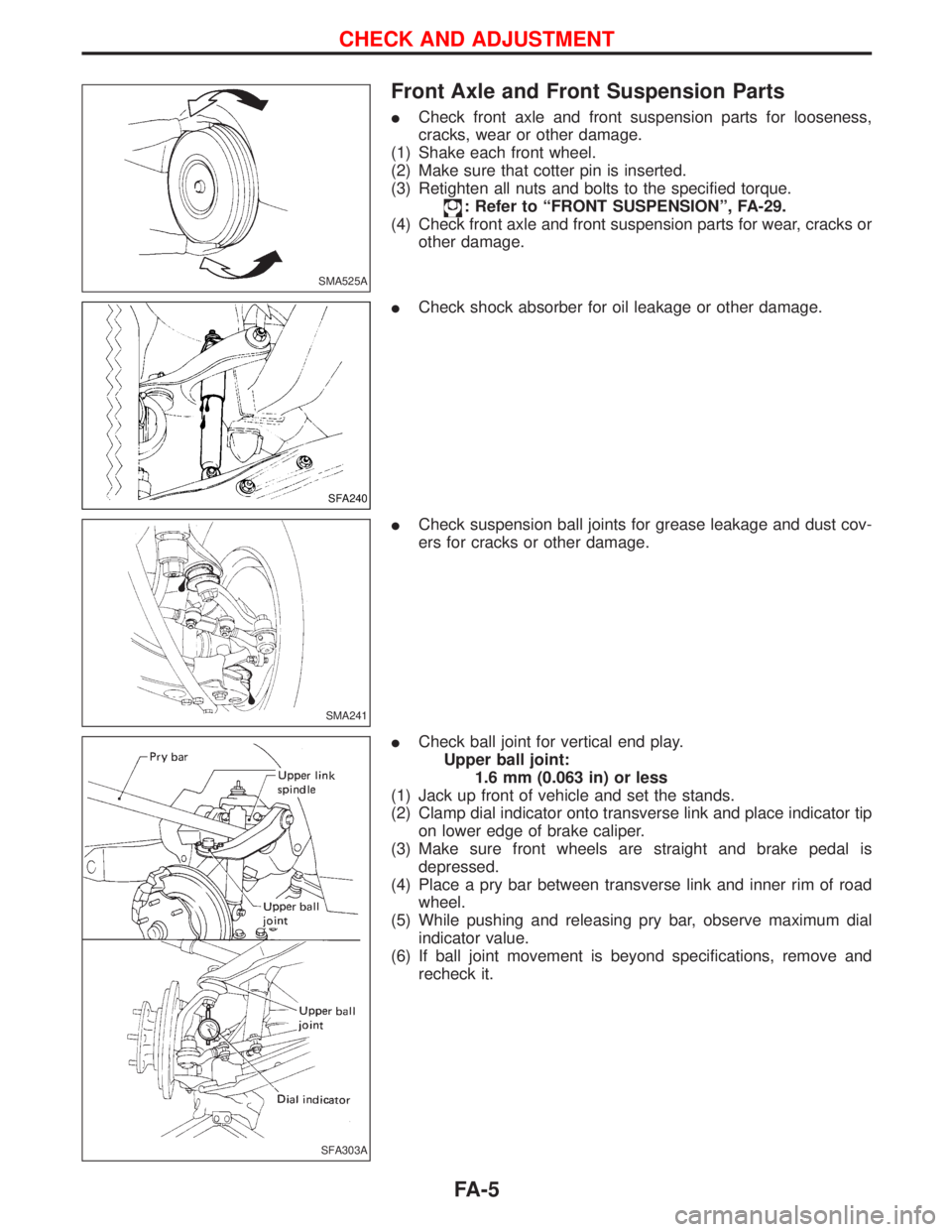

ICheck ball joint for vertical end play.

Upper ball joint:

1.6 mm (0.063 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

(3) Make sure front wheels are straight and brake pedal is

depressed.

(4) Place a pry bar between transverse link and inner rim of road

wheel.

(5) While pushing and releasing pry bar, observe maximum dial

indicator value.

(6) If ball joint movement is beyond specifications, remove and

recheck it.

SMA525A

SFA240

SMA241

SFA303A

CHECK AND ADJUSTMENT

FA-5

Page 1264 of 1767

Lower ball joint:

0.5 mm (0.020 in) or less

(1) Jack up front of vehicle and set the stands.

(2) Remove road wheel.

(3) Clamp dial indicator onto upper link and place indicator tip on

knuckle near ball joint.

(4) Jack up lower link [Approx. 20 mm (0.79 in)].

(5) Place a pry bar between upper link and upper link spindle.

(6) While pushing and releasing pry bar observe maximum dial

indicator value.

(7) If ball joint movement is beyond specifications, remove and

recheck it.

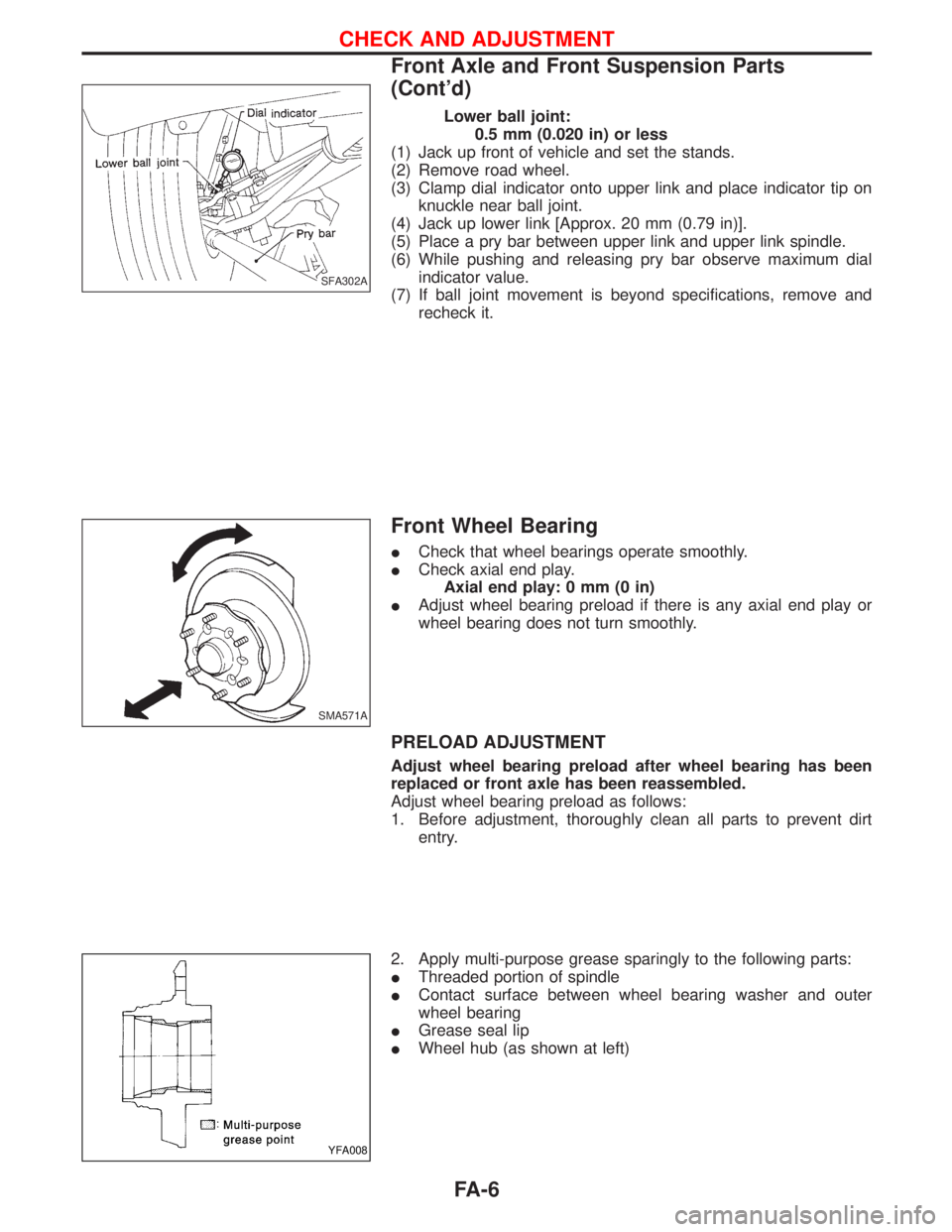

Front Wheel Bearing

ICheck that wheel bearings operate smoothly.

ICheck axial end play.

Axial end play: 0 mm (0 in)

IAdjust wheel bearing preload if there is any axial end play or

wheel bearing does not turn smoothly.

PRELOAD ADJUSTMENT

Adjust wheel bearing preload after wheel bearing has been

replaced or front axle has been reassembled.

Adjust wheel bearing preload as follows:

1. Before adjustment, thoroughly clean all parts to prevent dirt

entry.

2. Apply multi-purpose grease sparingly to the following parts:

IThreaded portion of spindle

IContact surface between wheel bearing washer and outer

wheel bearing

IGrease seal lip

IWheel hub (as shown at left)

SFA302A

SMA571A

YFA008

CHECK AND ADJUSTMENT

Front Axle and Front Suspension Parts

(Cont'd)

FA-6

Page 1265 of 1767

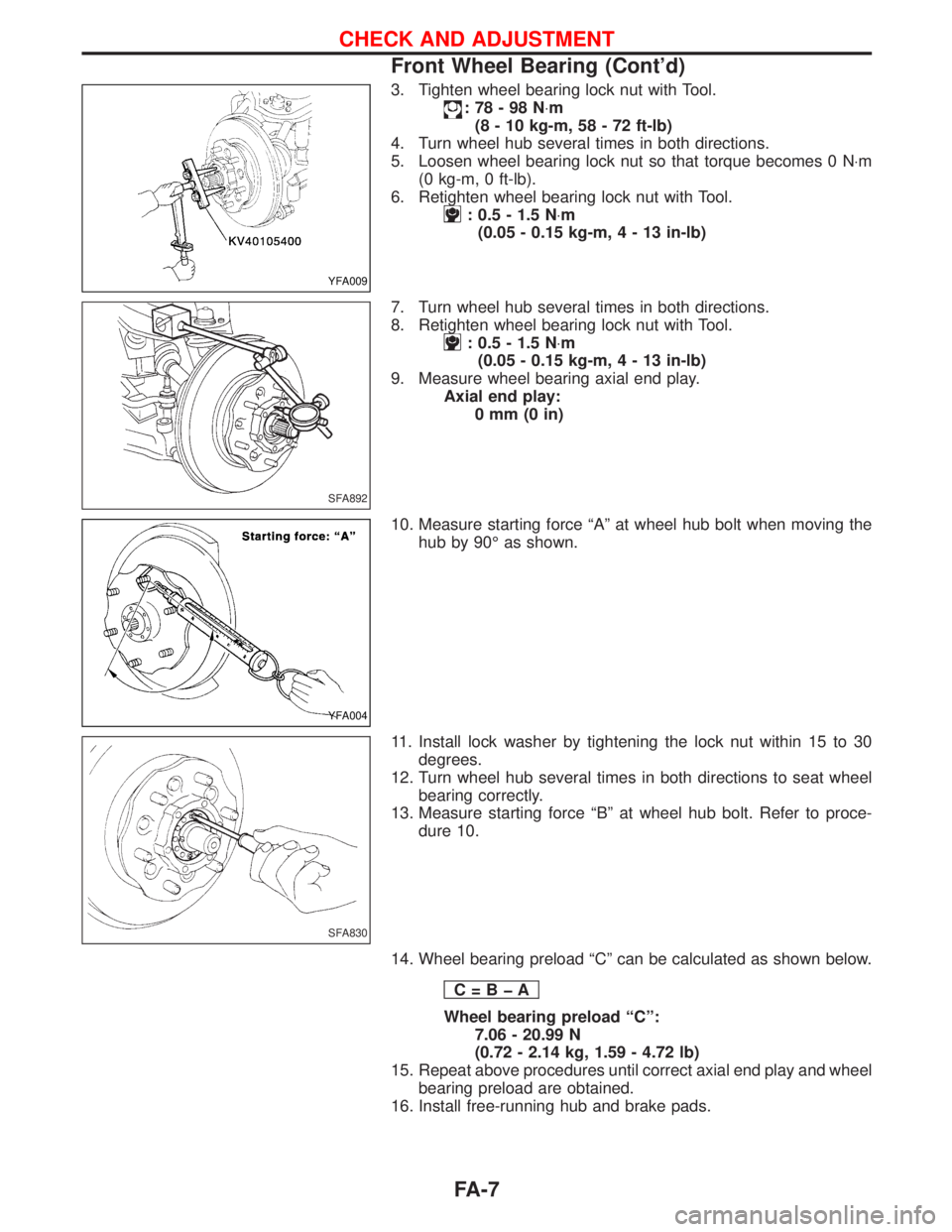

3. Tighten wheel bearing lock nut with Tool.

:78-98N×m

(8 - 10 kg-m, 58 - 72 ft-lb)

4. Turn wheel hub several times in both directions.

5. Loosen wheel bearing lock nut so that torque becomes 0 N×m

(0 kg-m, 0 ft-lb).

6. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

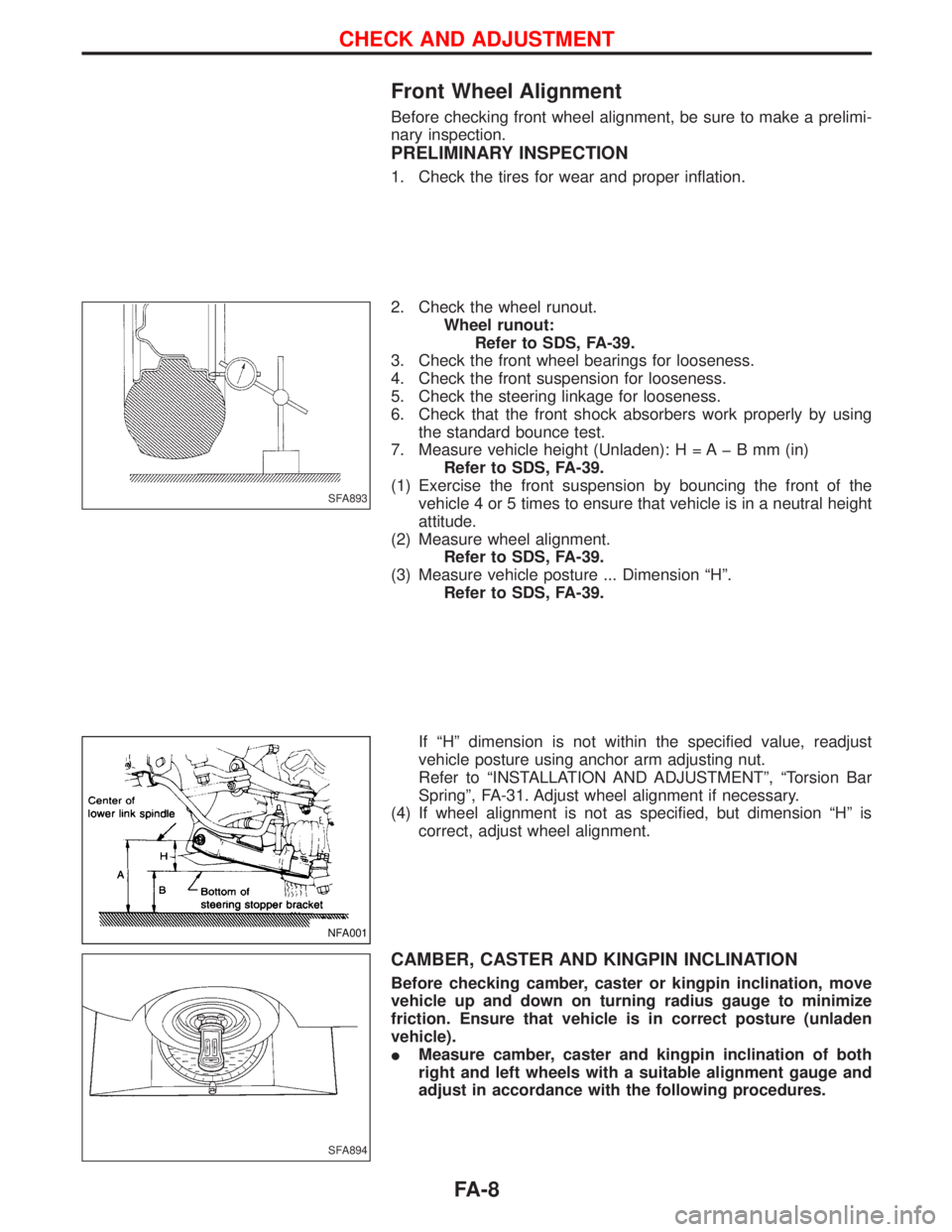

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N×m

(0.05 - 0.15 kg-m,4-13in-lb)

9. Measure wheel bearing axial end play.

Axial end play:

0mm(0in)

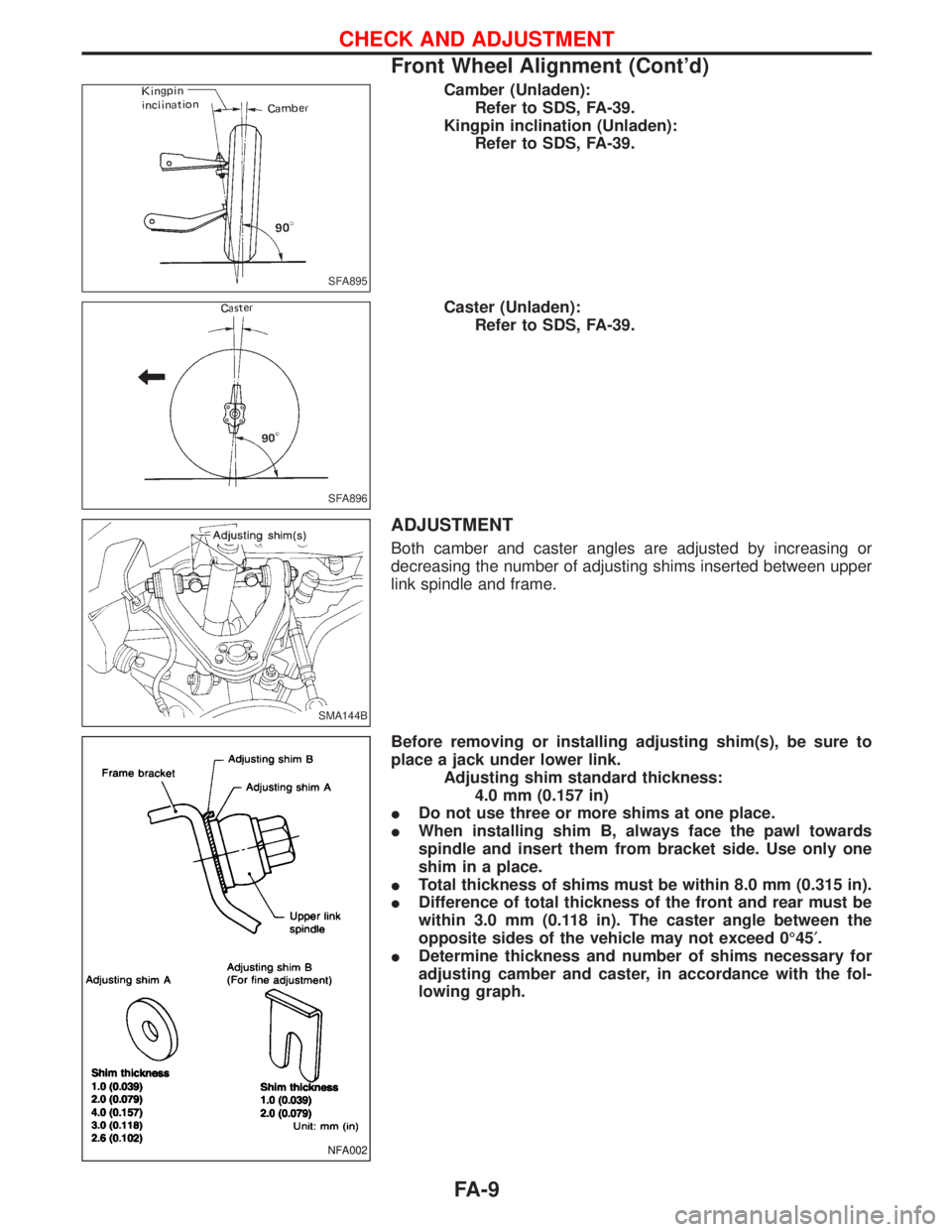

10. Measure starting force ªAº at wheel hub bolt when moving the

hub by 90É as shown.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N

(0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat above procedures until correct axial end play and wheel

bearing preload are obtained.

16. Install free-running hub and brake pads.

YFA009

SFA892

YFA004

SFA830

CHECK AND ADJUSTMENT

Front Wheel Bearing (Cont'd)

FA-7

Page 1266 of 1767

Front Wheel Alignment

Before checking front wheel alignment, be sure to make a prelimi-

nary inspection.

PRELIMINARY INSPECTION

1. Check the tires for wear and proper inflation.

2. Check the wheel runout.

Wheel runout:

Refer to SDS, FA-39.

3. Check the front wheel bearings for looseness.

4. Check the front suspension for looseness.

5. Check the steering linkage for looseness.

6. Check that the front shock absorbers work properly by using

the standard bounce test.

7. Measure vehicle height (Unladen): H = A þ B mm (in)

Refer to SDS, FA-39.

(1) Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that vehicle is in a neutral height

attitude.

(2) Measure wheel alignment.

Refer to SDS, FA-39.

(3) Measure vehicle posture ... Dimension ªHº.

Refer to SDS, FA-39.

If ªHº dimension is not within the specified value, readjust

vehicle posture using anchor arm adjusting nut.

Refer to ªINSTALLATION AND ADJUSTMENTº, ªTorsion Bar

Springº, FA-31. Adjust wheel alignment if necessary.

(4) If wheel alignment is not as specified, but dimension ªHº is

correct, adjust wheel alignment.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that vehicle is in correct posture (unladen

vehicle).

IMeasure camber, caster and kingpin inclination of both

right and left wheels with a suitable alignment gauge and

adjust in accordance with the following procedures.

SFA893

NFA001

SFA894

CHECK AND ADJUSTMENT

FA-8

Page 1267 of 1767

Camber (Unladen):

Refer to SDS, FA-39.

Kingpin inclination (Unladen):

Refer to SDS, FA-39.

Caster (Unladen):

Refer to SDS, FA-39.

ADJUSTMENT

Both camber and caster angles are adjusted by increasing or

decreasing the number of adjusting shims inserted between upper

link spindle and frame.

Before removing or installing adjusting shim(s), be sure to

place a jack under lower link.

Adjusting shim standard thickness:

4.0 mm (0.157 in)

IDo not use three or more shims at one place.

IWhen installing shim B, always face the pawl towards

spindle and insert them from bracket side. Use only one

shim in a place.

ITotal thickness of shims must be within 8.0 mm (0.315 in).

IDifference of total thickness of the front and rear must be

within 3.0 mm (0.118 in). The caster angle between the

opposite sides of the vehicle may not exceed 0É45¢.

IDetermine thickness and number of shims necessary for

adjusting camber and caster, in accordance with the fol-

lowing graph.

SFA895

SFA896

SMA144B

NFA002

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-9

Page 1268 of 1767

![NISSAN TERRANO 2002 Service Repair Manual [Example]

(Measures taken at one side):

(1)

Angle

Specified value Measured Change

Camber angle 0É30¢0É5¢+0É25¢

Caster angle 1É54¢2É10¢þ0É16¢

The above values relate to the graph below:

Sh NISSAN TERRANO 2002 Service Repair Manual [Example]

(Measures taken at one side):

(1)

Angle

Specified value Measured Change

Camber angle 0É30¢0É5¢+0É25¢

Caster angle 1É54¢2É10¢þ0É16¢

The above values relate to the graph below:

Sh](/img/5/57393/w960_57393-1267.png)

[Example]

(Measures taken at one side):

(1)

Angle

Specified value Measured Change

Camber angle 0É30¢0É5¢+0É25¢

Caster angle 1É54¢2É10¢þ0É16¢

The above values relate to the graph below:

Shim thickness selection graph

(2) Obtain intersection point of lines in accordance with the graph.

Front: 1.4 mm

Rear: 2.0 mm

(3) Choose shims which are nearest to the values found in the

graph:

Front: 1.6 mm

Rear: 2.0 mm

(4) If shim thicknesses as calculated appear not to be available,

combinations of different shims should be used to meet the

desired total thickness of the shims.

EFA015

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-10

Page 1269 of 1767

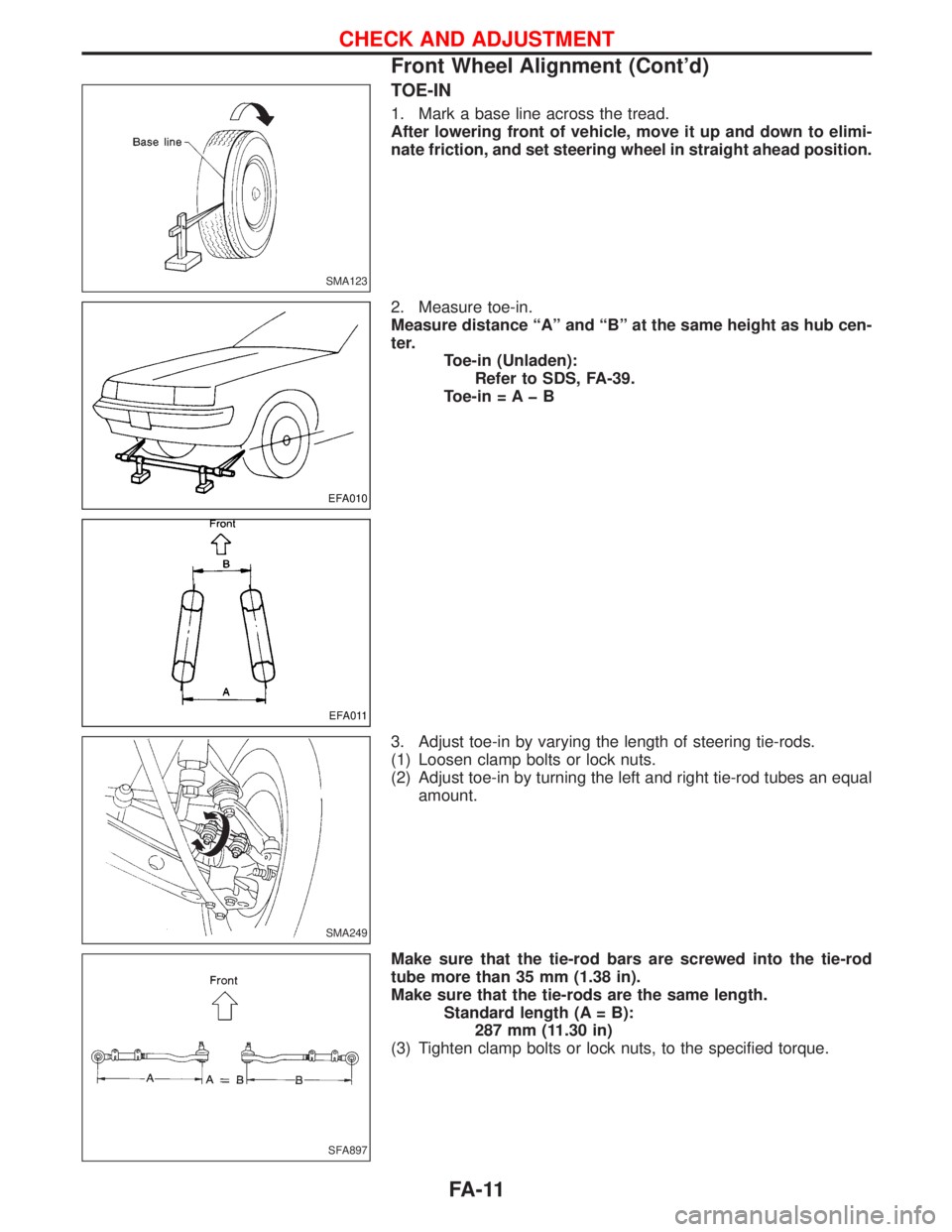

TOE-IN

1. Mark a base line across the tread.

After lowering front of vehicle, move it up and down to elimi-

nate friction, and set steering wheel in straight ahead position.

2. Measure toe-in.

Measure distance ªAº and ªBº at the same height as hub cen-

ter.

Toe-in (Unladen):

Refer to SDS, FA-39.

Toe-in = A þ B

3. Adjust toe-in by varying the length of steering tie-rods.

(1) Loosen clamp bolts or lock nuts.

(2) Adjust toe-in by turning the left and right tie-rod tubes an equal

amount.

Make sure that the tie-rod bars are screwed into the tie-rod

tube more than 35 mm (1.38 in).

Make sure that the tie-rods are the same length.

Standard length (A = B):

287 mm (11.30 in)

(3) Tighten clamp bolts or lock nuts, to the specified torque.

SMA123

EFA010

EFA011

SMA249

SFA897

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-11

Page 1270 of 1767

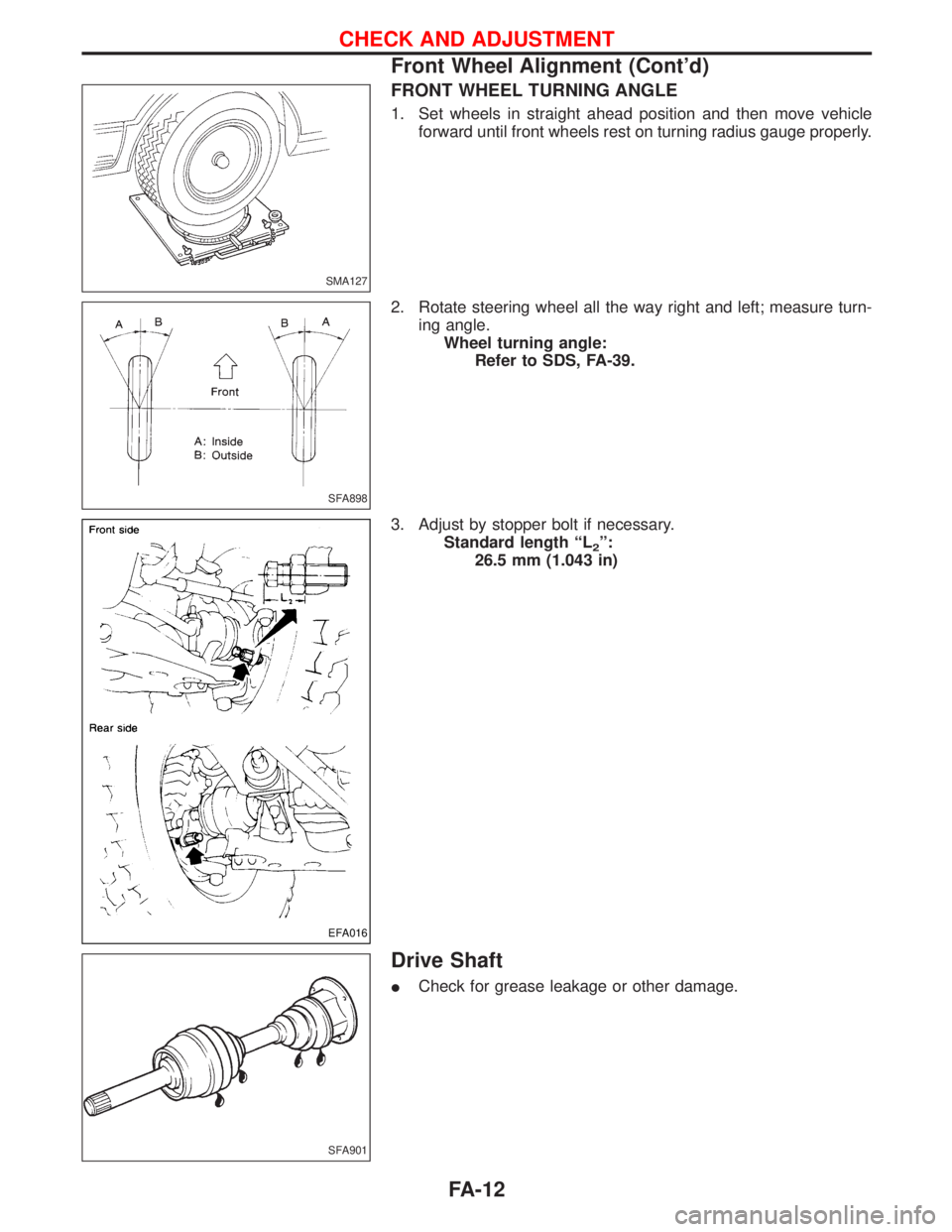

FRONT WHEEL TURNING ANGLE

1. Set wheels in straight ahead position and then move vehicle

forward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Wheel turning angle:

Refer to SDS, FA-39.

3. Adjust by stopper bolt if necessary.

Standard length ªL

2º:

26.5 mm (1.043 in)

Drive Shaft

ICheck for grease leakage or other damage.

SMA127

SFA898

EFA016

SFA901

CHECK AND ADJUSTMENT

Front Wheel Alignment (Cont'd)

FA-12