NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: battery replacement, airbag, low oil pressure, clock, Start, change wheel, fuel cap release

Page 1301 of 1767

YFE020

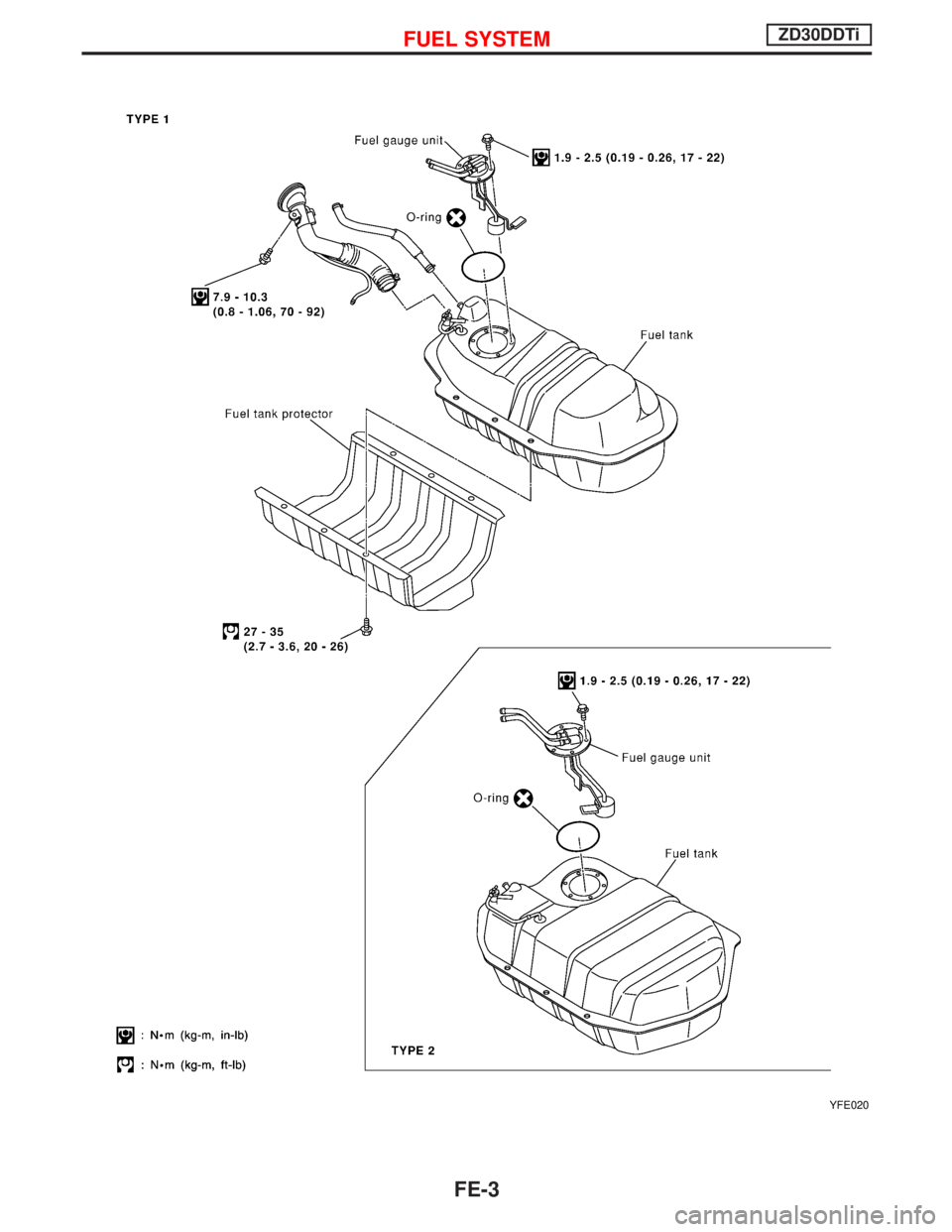

FUEL SYSTEMZD30DDTi

FE-3

Page 1302 of 1767

YFE021

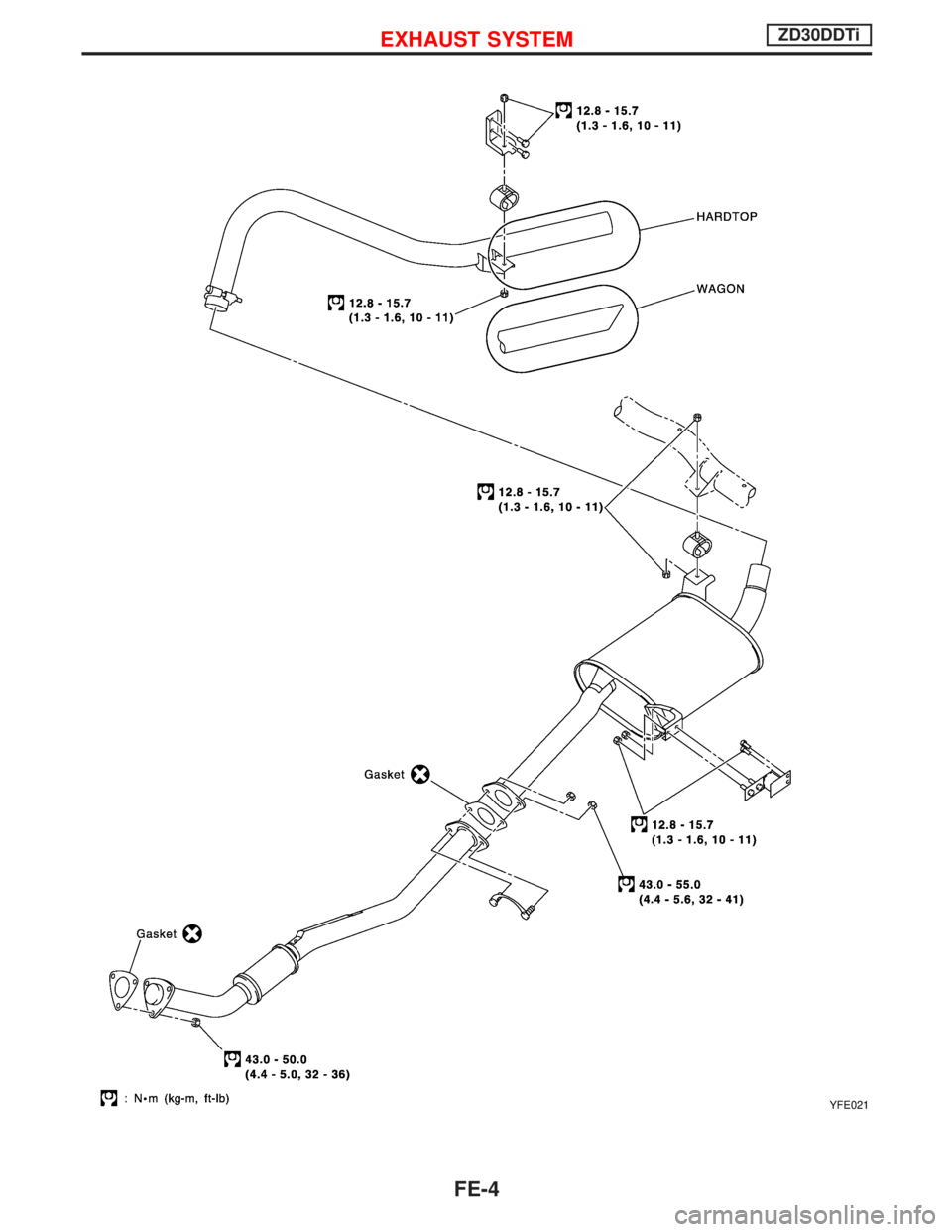

EXHAUST SYSTEMZD30DDTi

FE-4

Page 1303 of 1767

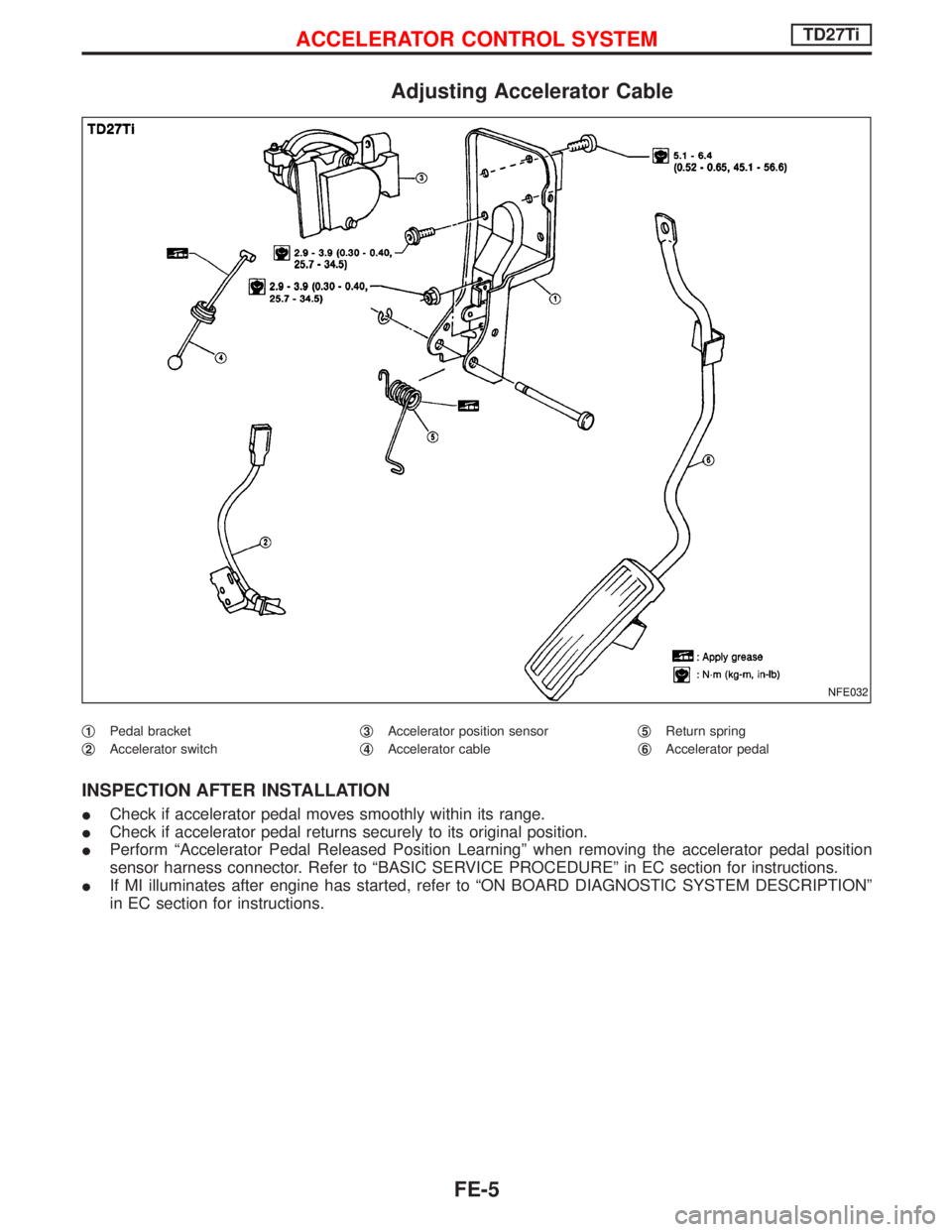

Adjusting Accelerator Cable

q1Pedal bracket

q

2Accelerator switchq

3Accelerator position sensor

q

4Accelerator cableq

5Return spring

q

6Accelerator pedal

INSPECTION AFTER INSTALLATION

ICheck if accelerator pedal moves smoothly within its range.

ICheck if accelerator pedal returns securely to its original position.

IPerform ªAccelerator Pedal Released Position Learningº when removing the accelerator pedal position

sensor harness connector. Refer to ªBASIC SERVICE PROCEDUREº in EC section for instructions.

IIf MI illuminates after engine has started, refer to ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº

in EC section for instructions.

NFE032

ACCELERATOR CONTROL SYSTEMTD27Ti

FE-5

Page 1304 of 1767

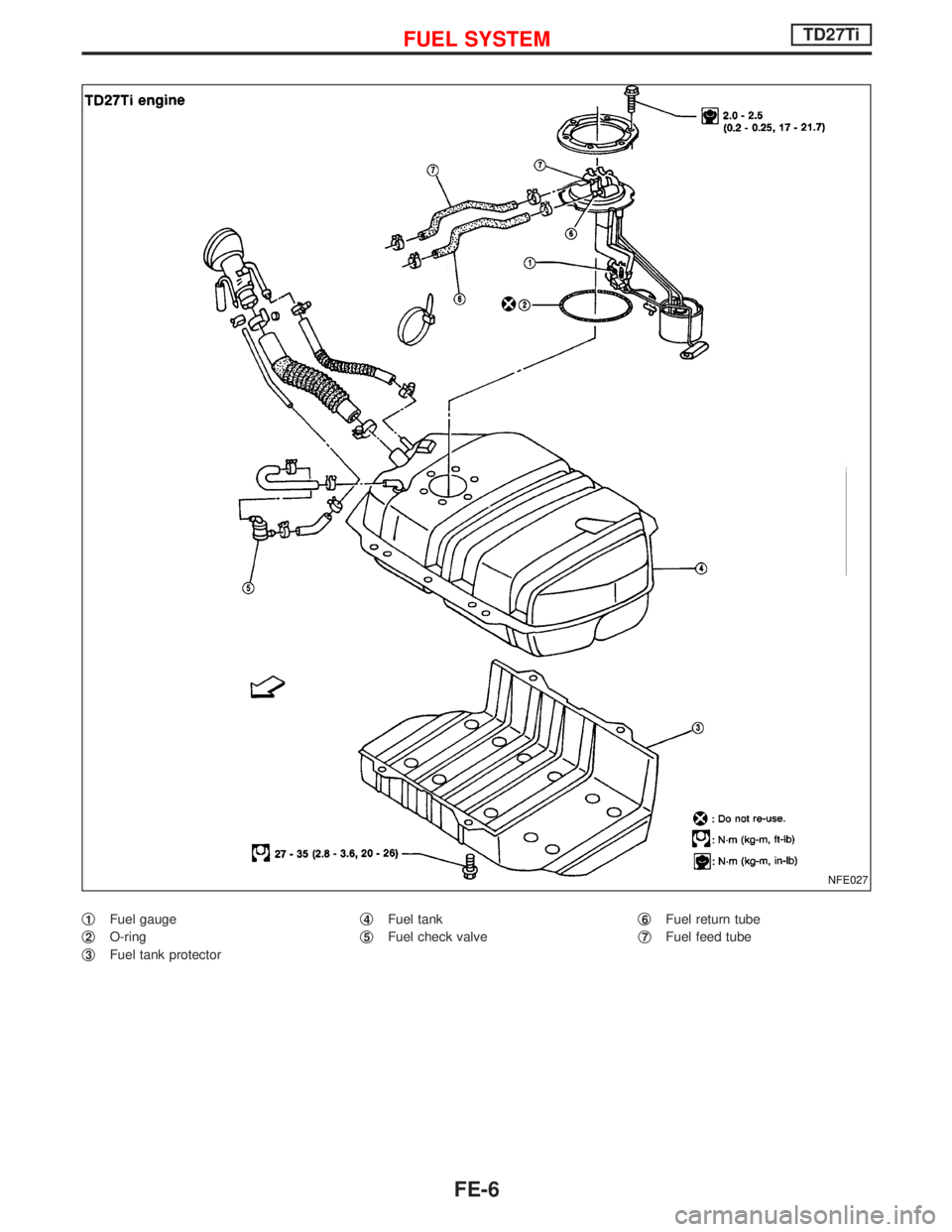

q1Fuel gauge

q

2O-ring

q

3Fuel tank protectorq

4Fuel tank

q

5Fuel check valveq

6Fuel return tube

q

7Fuel feed tube

NFE027

FUEL SYSTEMTD27Ti

FE-6

Page 1305 of 1767

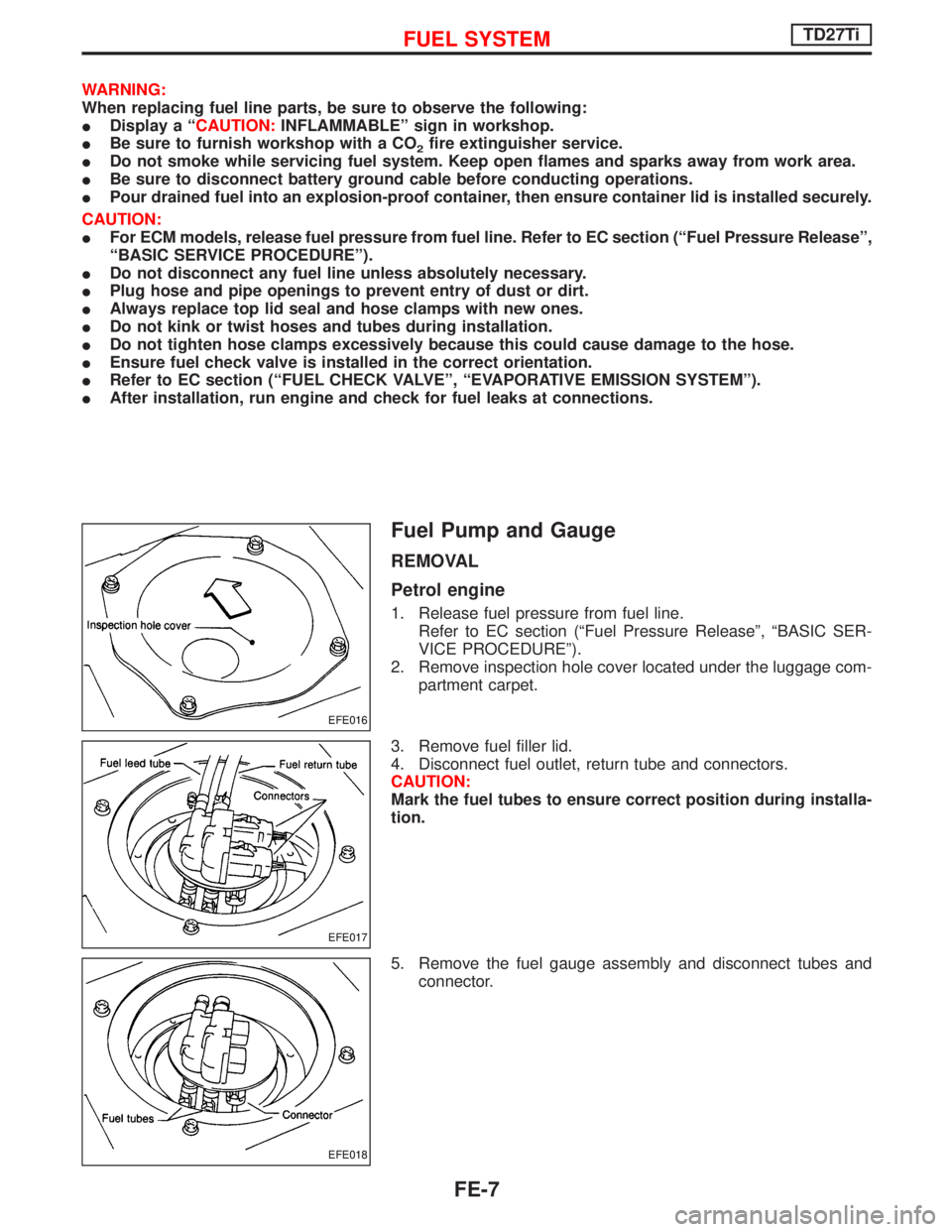

WARNING:

When replacing fuel line parts, be sure to observe the following:

IDisplay a ªCAUTION:INFLAMMABLEº sign in workshop.

IBe sure to furnish workshop with a CO

2fire extinguisher service.

IDo not smoke while servicing fuel system. Keep open flames and sparks away from work area.

IBe sure to disconnect battery ground cable before conducting operations.

IPour drained fuel into an explosion-proof container, then ensure container lid is installed securely.

CAUTION:

IFor ECM models, release fuel pressure from fuel line. Refer to EC section (ªFuel Pressure Releaseº,

ªBASIC SERVICE PROCEDUREº).

IDo not disconnect any fuel line unless absolutely necessary.

IPlug hose and pipe openings to prevent entry of dust or dirt.

IAlways replace top lid seal and hose clamps with new ones.

IDo not kink or twist hoses and tubes during installation.

IDo not tighten hose clamps excessively because this could cause damage to the hose.

IEnsure fuel check valve is installed in the correct orientation.

IRefer to EC section (ªFUEL CHECK VALVEº, ªEVAPORATIVE EMISSION SYSTEMº).

IAfter installation, run engine and check for fuel leaks at connections.

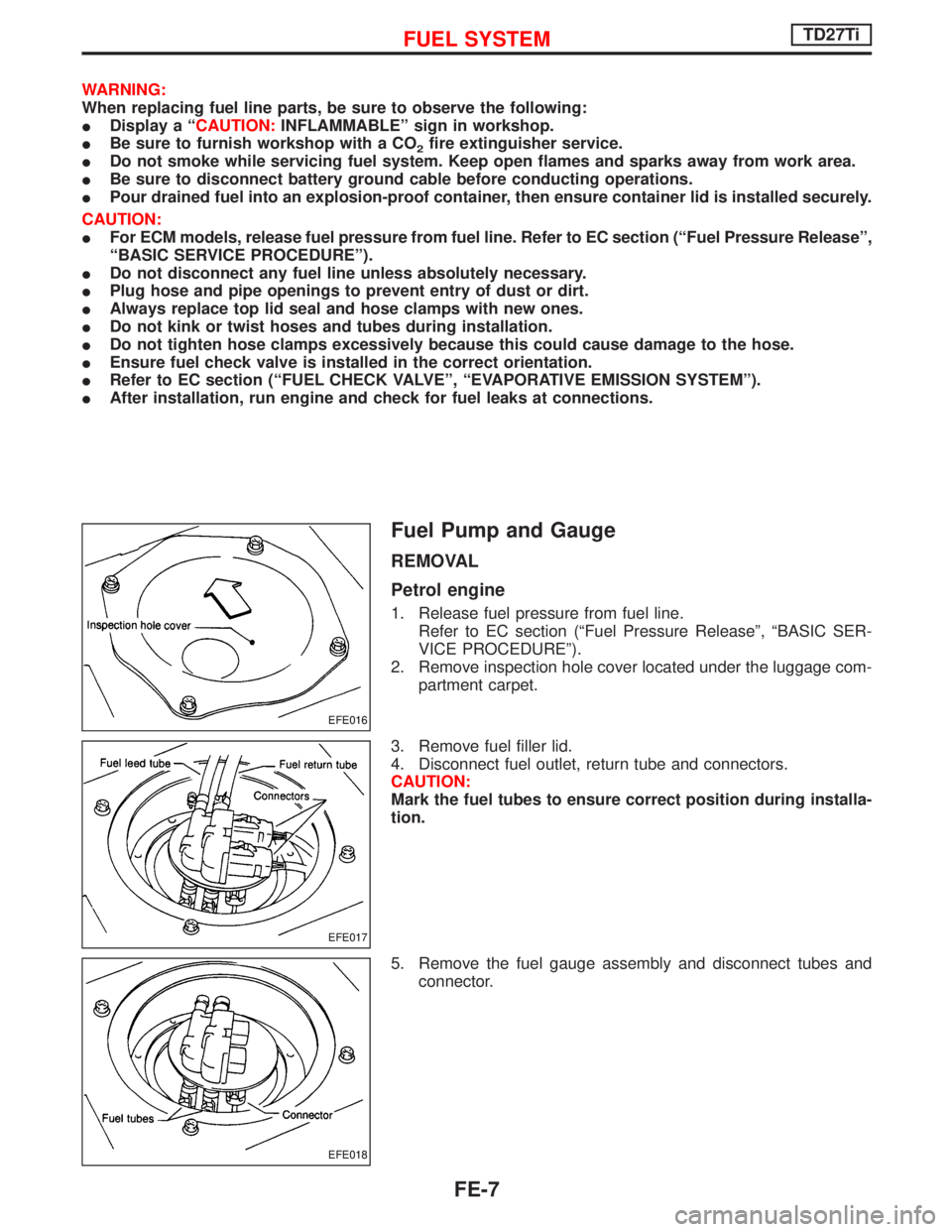

Fuel Pump and Gauge

REMOVAL

Petrol engine

1. Release fuel pressure from fuel line.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

2. Remove inspection hole cover located under the luggage com-

partment carpet.

3. Remove fuel filler lid.

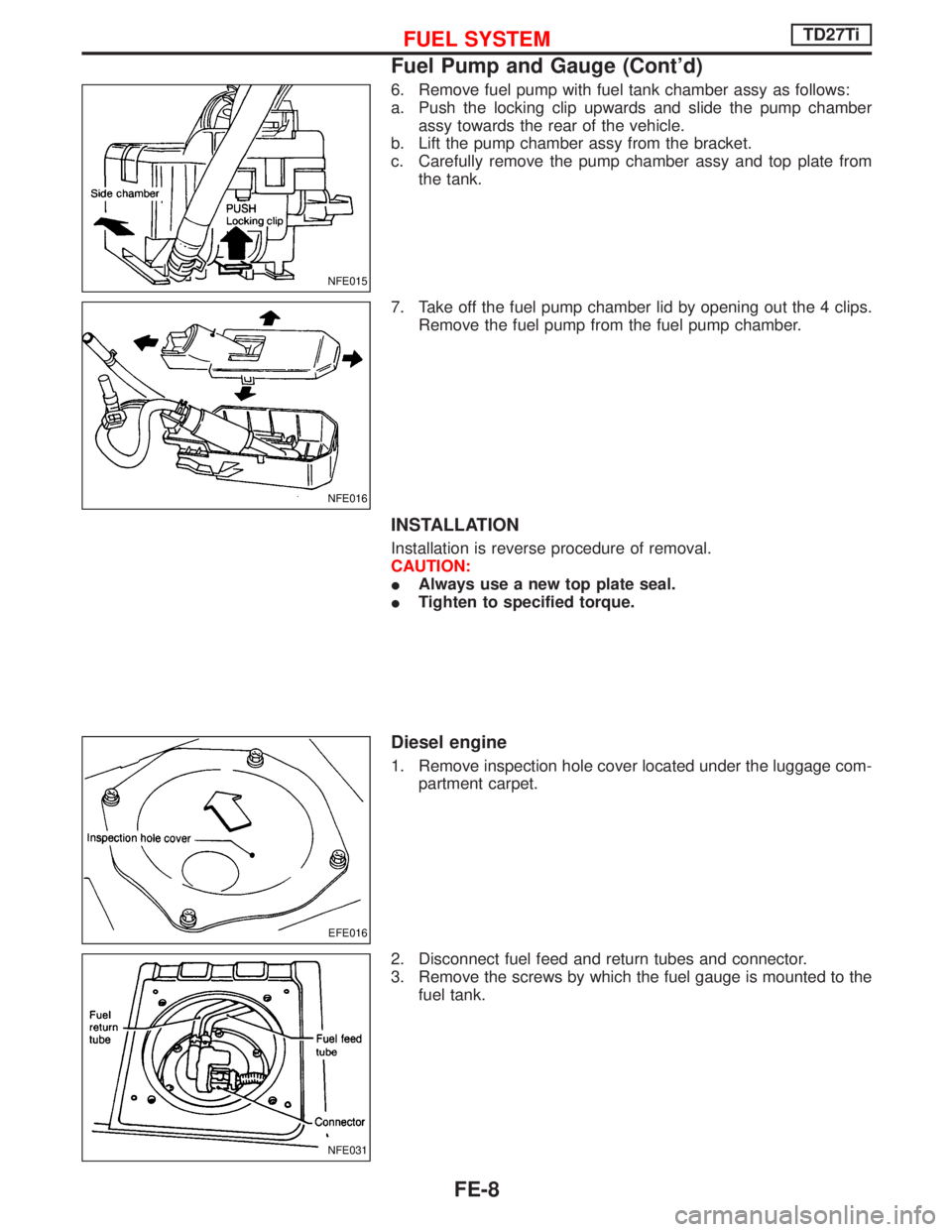

4. Disconnect fuel outlet, return tube and connectors.

CAUTION:

Mark the fuel tubes to ensure correct position during installa-

tion.

5. Remove the fuel gauge assembly and disconnect tubes and

connector.

EFE016

EFE017

EFE018

FUEL SYSTEMTD27Ti

FE-7

Page 1306 of 1767

6. Remove fuel pump with fuel tank chamber assy as follows:

a. Push the locking clip upwards and slide the pump chamber

assy towards the rear of the vehicle.

b. Lift the pump chamber assy from the bracket.

c. Carefully remove the pump chamber assy and top plate from

the tank.

7. Take off the fuel pump chamber lid by opening out the 4 clips.

Remove the fuel pump from the fuel pump chamber.

INSTALLATION

Installation is reverse procedure of removal.

CAUTION:

IAlways use a new top plate seal.

ITighten to specified torque.

Diesel engine

1. Remove inspection hole cover located under the luggage com-

partment carpet.

2. Disconnect fuel feed and return tubes and connector.

3. Remove the screws by which the fuel gauge is mounted to the

fuel tank.

NFE015

NFE016

EFE016

NFE031

FUEL SYSTEMTD27Ti

Fuel Pump and Gauge (Cont'd)

FE-8

Page 1307 of 1767

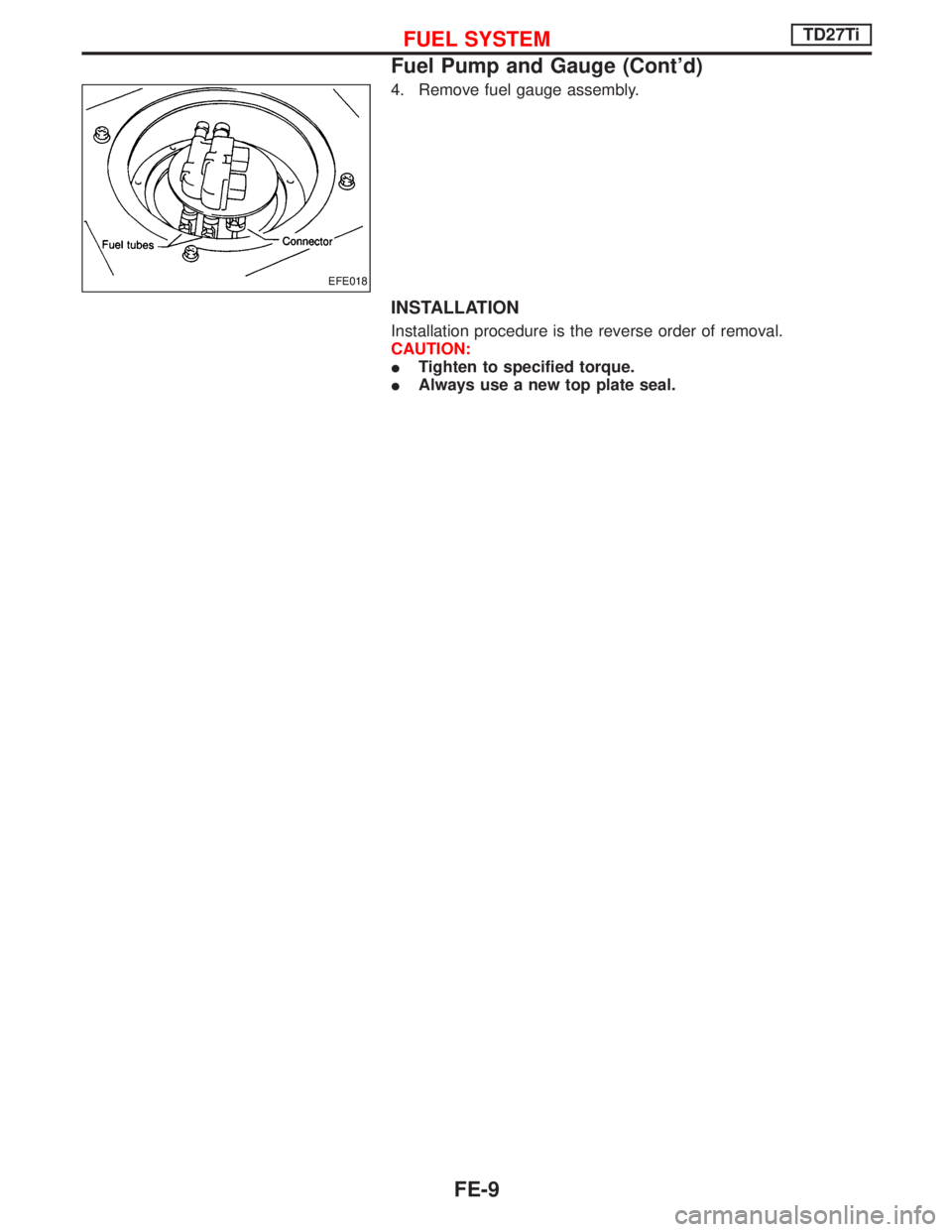

4. Remove fuel gauge assembly.

INSTALLATION

Installation procedure is the reverse order of removal.

CAUTION:

ITighten to specified torque.

IAlways use a new top plate seal.

EFE018

FUEL SYSTEMTD27Ti

Fuel Pump and Gauge (Cont'd)

FE-9

Page 1308 of 1767

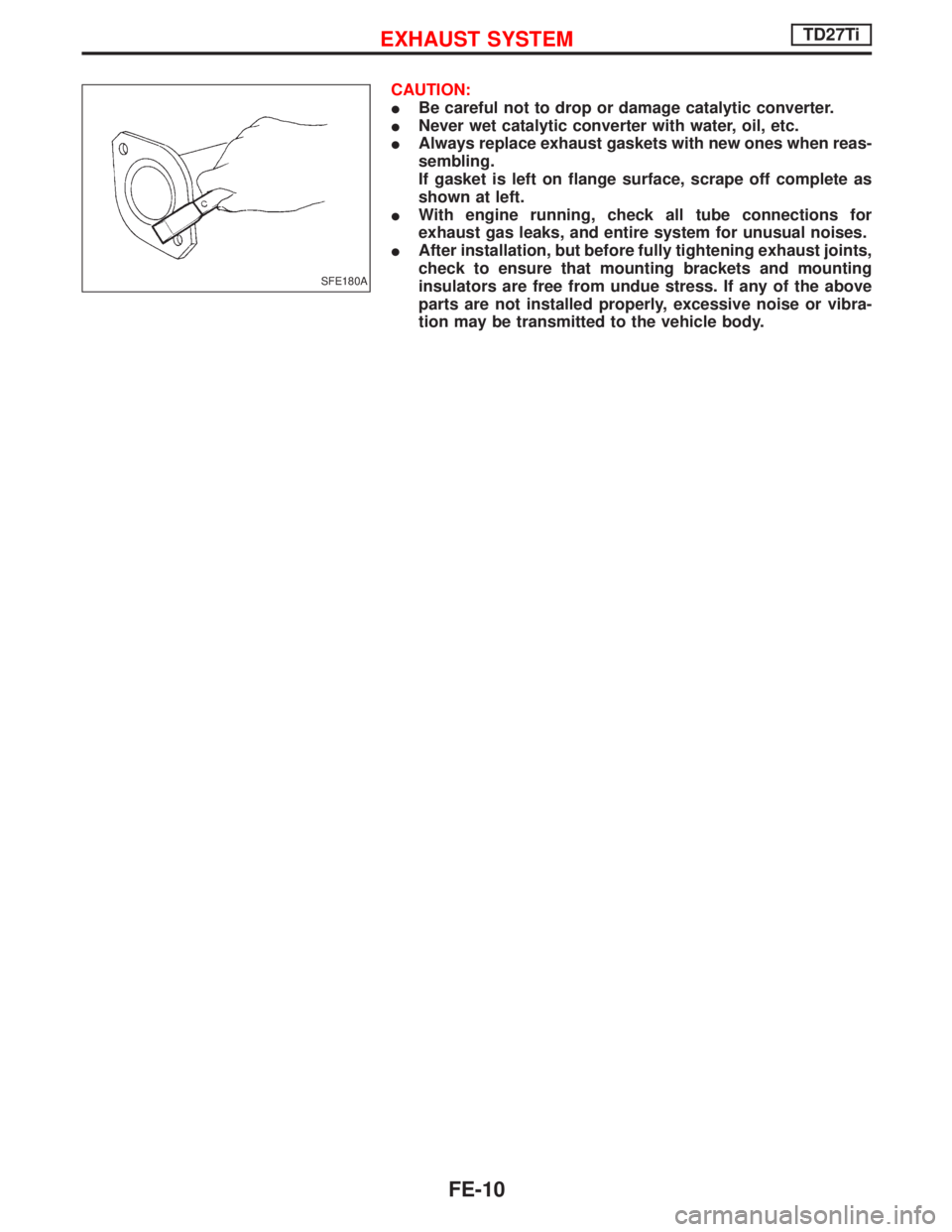

CAUTION:

IBe careful not to drop or damage catalytic converter.

INever wet catalytic converter with water, oil, etc.

IAlways replace exhaust gaskets with new ones when reas-

sembling.

If gasket is left on flange surface, scrape off complete as

shown at left.

IWith engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

IAfter installation, but before fully tightening exhaust joints,

check to ensure that mounting brackets and mounting

insulators are free from undue stress. If any of the above

parts are not installed properly, excessive noise or vibra-

tion may be transmitted to the vehicle body.

SFE180A

EXHAUST SYSTEMTD27Ti

FE-10

Page 1309 of 1767

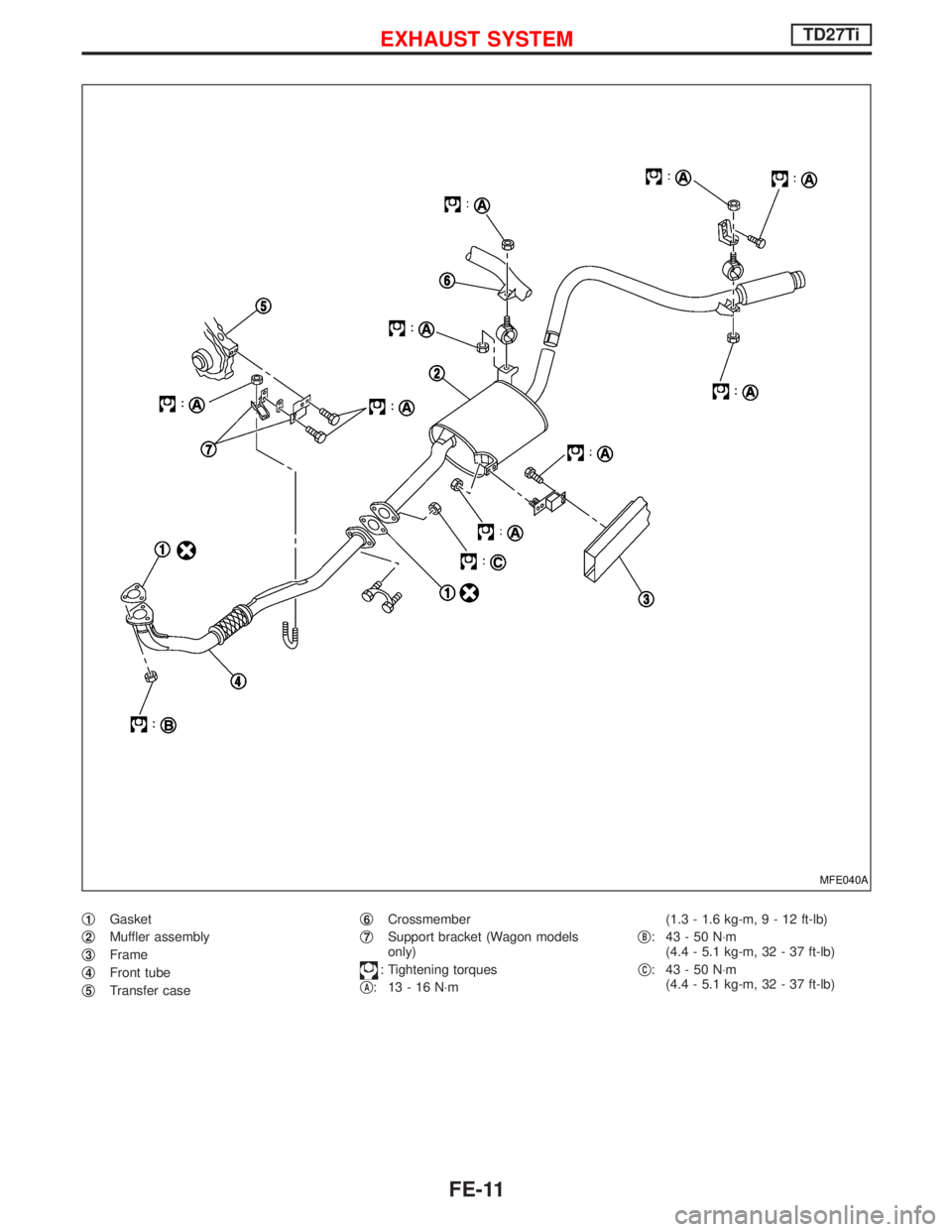

q1Gasket

q

2Muffler assembly

q

3Frame

q

4Front tube

q

5Transfer caseq

6Crossmember

q

7Support bracket (Wagon models

only)

: Tightening torques

q

A: 13-16N×m(1.3 - 1.6 kg-m,9-12ft-lb)

q

B: 43-50N×m

(4.4 - 5.1 kg-m, 32 - 37 ft-lb)

q

C: 43-50N×m

(4.4 - 5.1 kg-m, 32 - 37 ft-lb)

MFE040A

EXHAUST SYSTEMTD27Ti

FE-11

Page 1310 of 1767

Trending: engine oil, immobilizer, spare wheel, fuse box, cooling, headrest, service indicator