NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: Condition, VEHICLE INFORMATION, radio controls, steering wheel adjustment, differential, lighting system, gearbox

Page 1221 of 1767

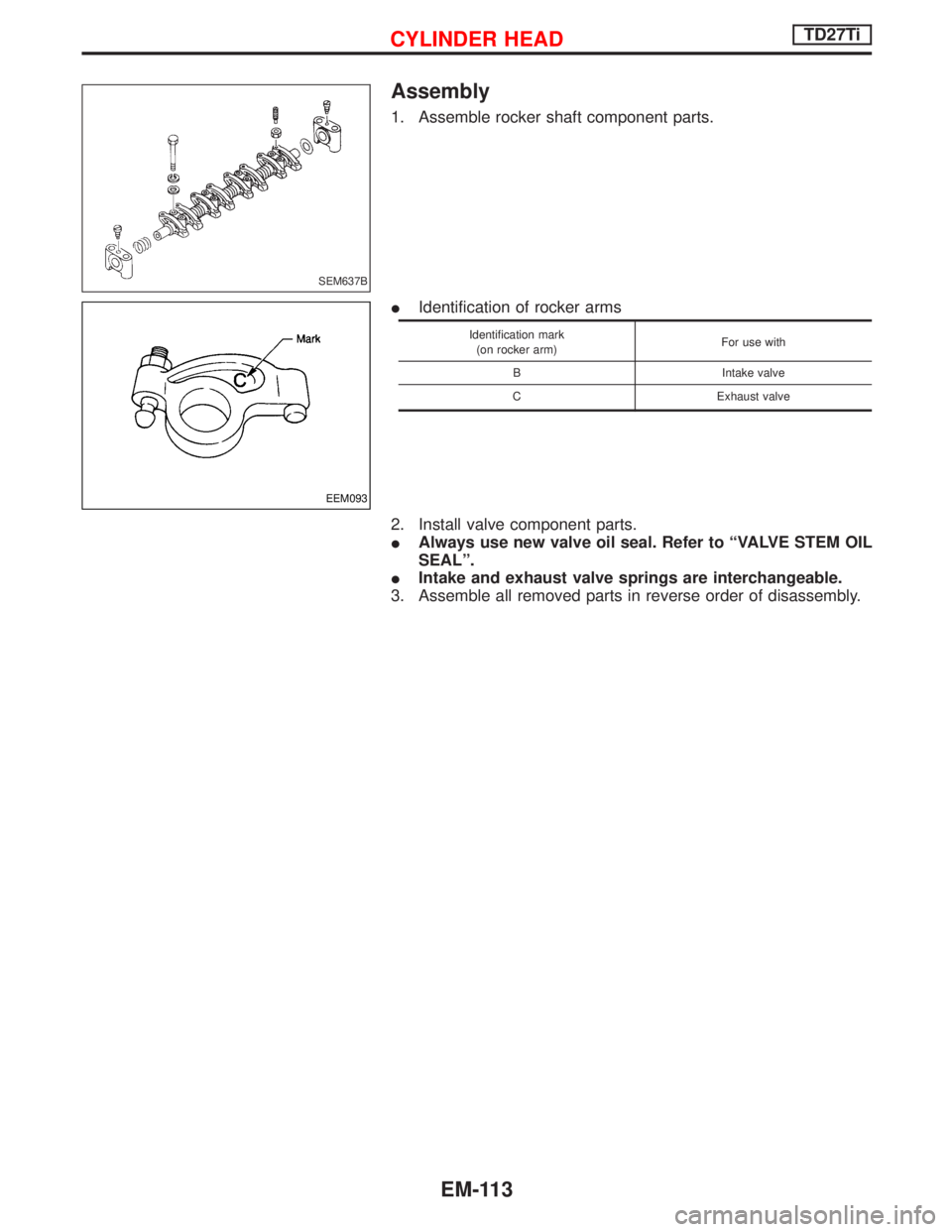

Assembly

1. Assemble rocker shaft component parts.

IIdentification of rocker arms

Identification mark

(on rocker arm)For use with

B Intake valve

C Exhaust valve

2. Install valve component parts.

IAlways use new valve oil seal. Refer to ªVALVE STEM OIL

SEALº.

IIntake and exhaust valve springs are interchangeable.

3. Assemble all removed parts in reverse order of disassembly.

SEM637B

EEM093

CYLINDER HEADTD27Ti

EM-113

Page 1222 of 1767

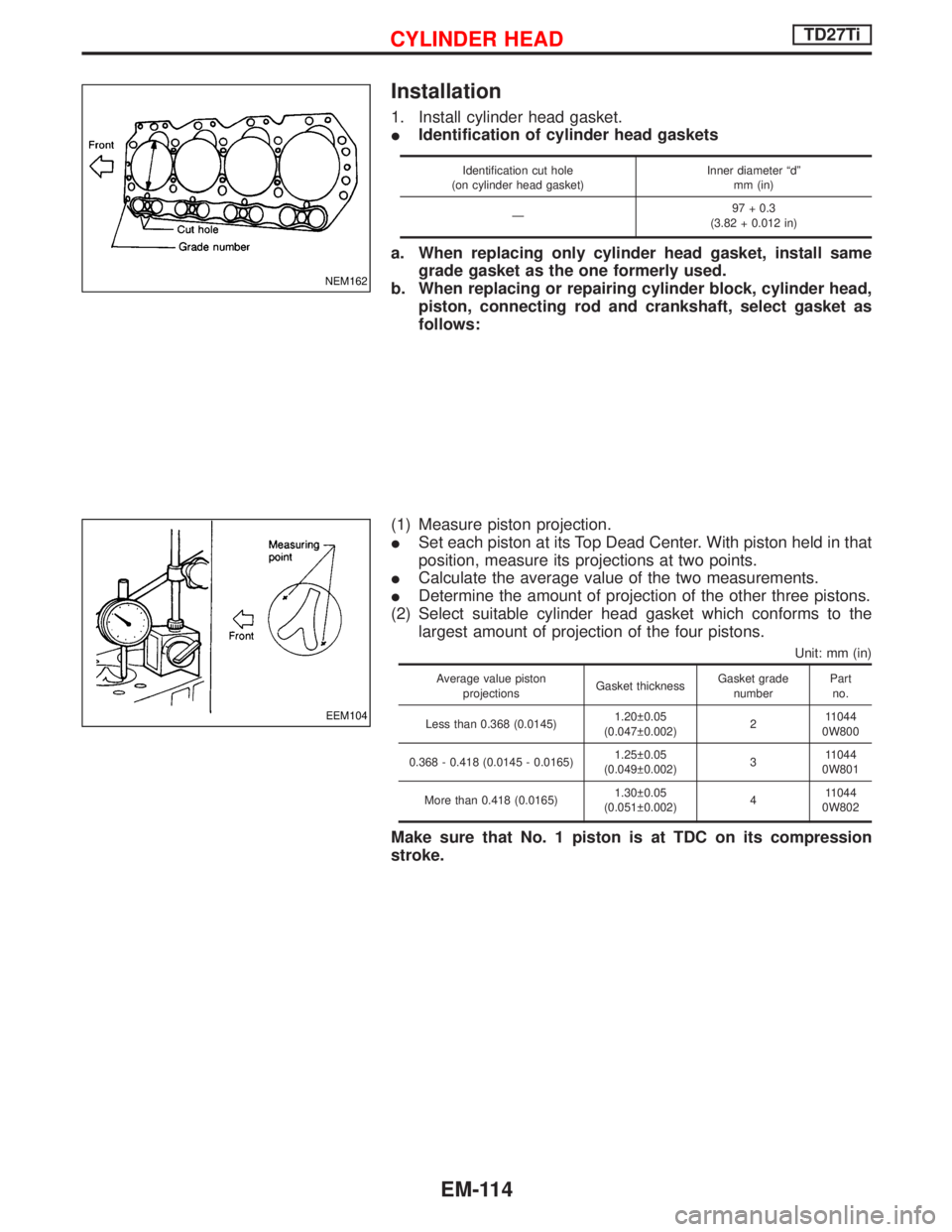

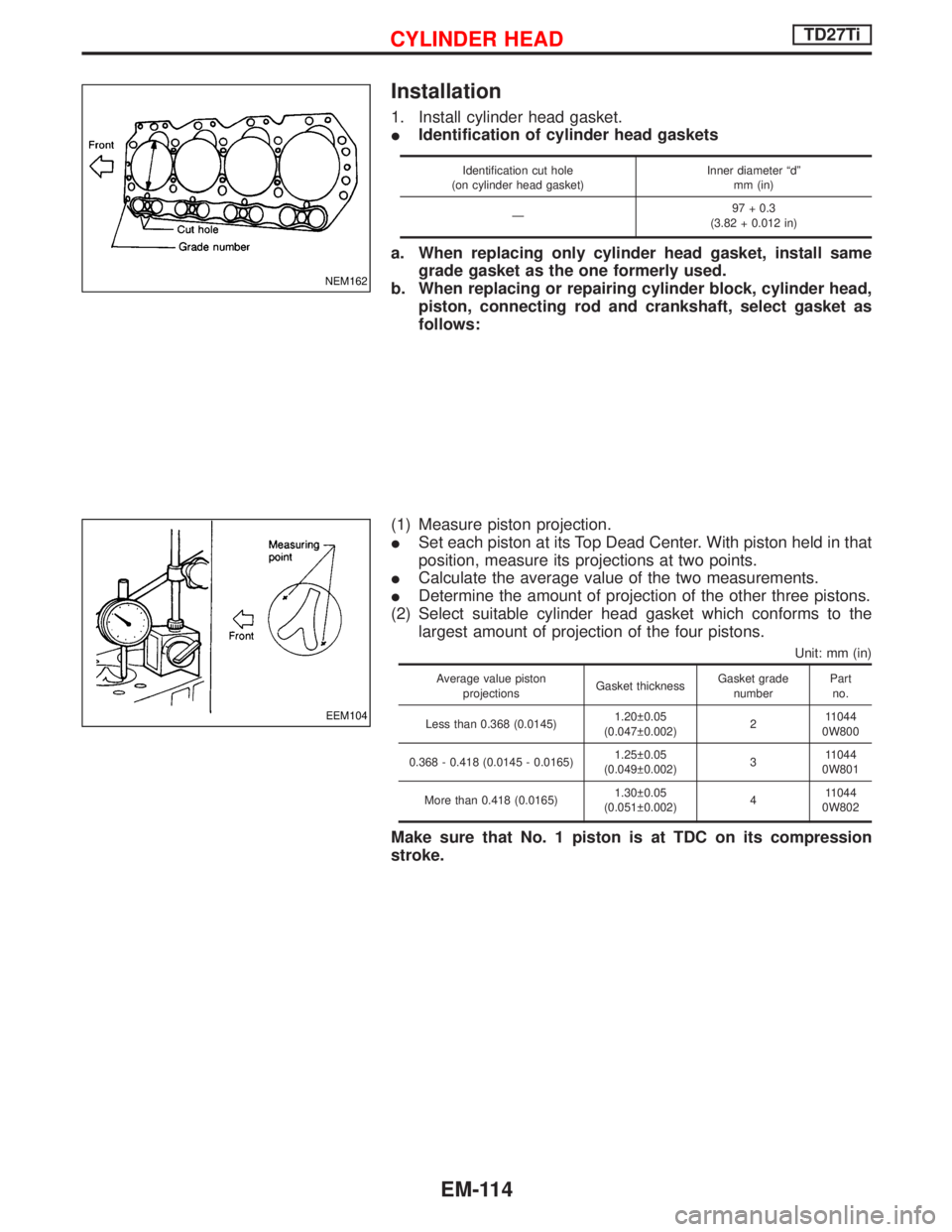

Installation

1. Install cylinder head gasket.

IIdentification of cylinder head gaskets

Identification cut hole

(on cylinder head gasket)Inner diameter ªdº

mm (in)

Ð97 + 0.3

(3.82 + 0.012 in)

a. When replacing only cylinder head gasket, install same

grade gasket as the one formerly used.

b. When replacing or repairing cylinder block, cylinder head,

piston, connecting rod and crankshaft, select gasket as

follows:

(1) Measure piston projection.

ISet each piston at its Top Dead Center. With piston held in that

position, measure its projections at two points.

ICalculate the average value of the two measurements.

IDetermine the amount of projection of the other three pistons.

(2) Select suitable cylinder head gasket which conforms to the

largest amount of projection of the four pistons.

Unit: mm (in)

Average value piston

projectionsGasket thicknessGasket grade

numberPart

no.

Less than 0.368 (0.0145)1.20 0.05

(0.047 0.002)211044

0W800

0.368 - 0.418 (0.0145 - 0.0165)1.25 0.05

(0.049 0.002)311044

0W801

More than 0.418 (0.0165)1.30 0.05

(0.051 0.002)411044

0W802

Make sure that No. 1 piston is at TDC on its compression

stroke.

NEM162

EEM104

CYLINDER HEADTD27Ti

EM-114

Page 1223 of 1767

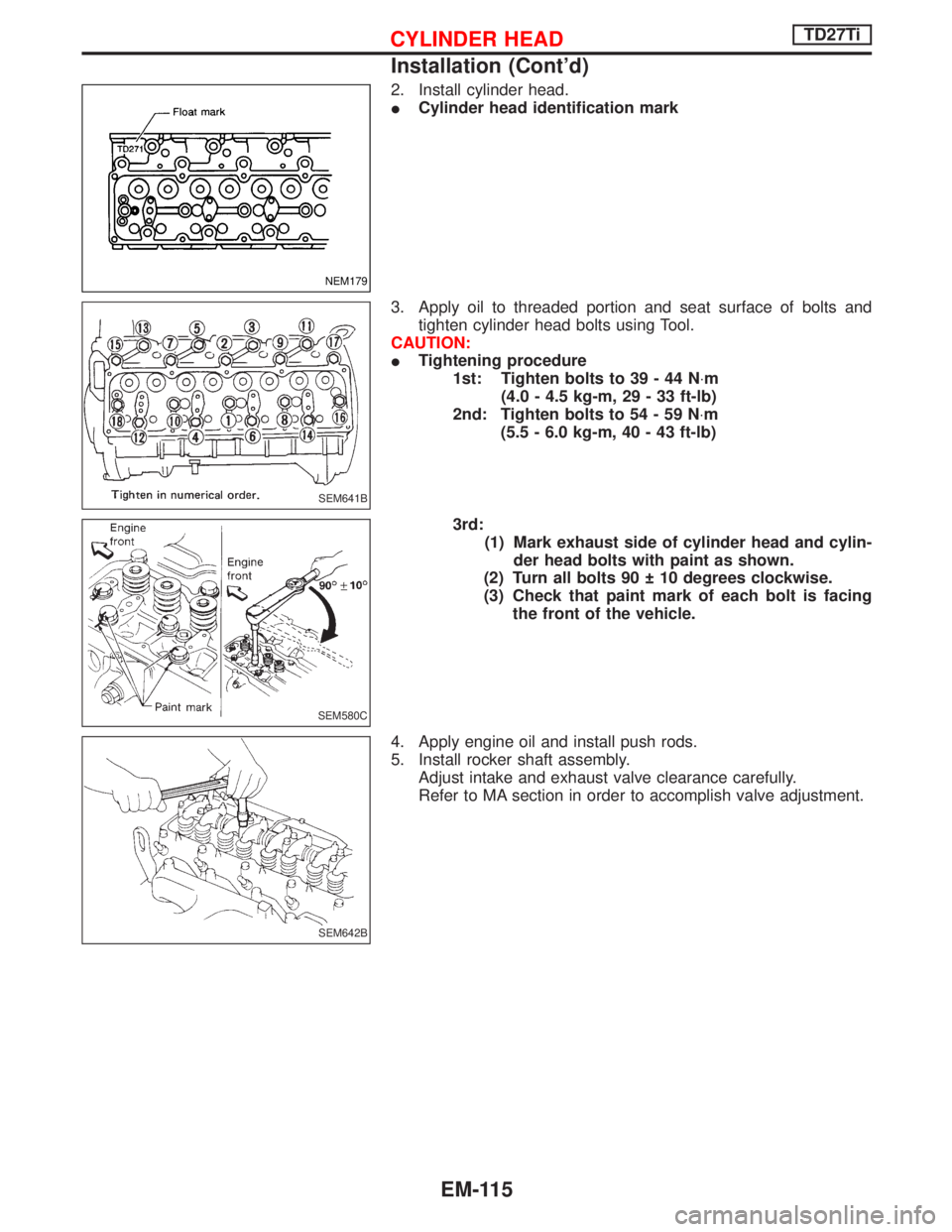

2. Install cylinder head.

ICylinder head identification mark

3. Apply oil to threaded portion and seat surface of bolts and

tighten cylinder head bolts using Tool.

CAUTION:

ITightening procedure

1st: Tighten bolts to 39 - 44 N×m

(4.0 - 4.5 kg-m, 29 - 33 ft-lb)

2nd: Tighten bolts to 54 - 59 N×m

(5.5 - 6.0 kg-m, 40 - 43 ft-lb)

3rd:

(1) Mark exhaust side of cylinder head and cylin-

der head bolts with paint as shown.

(2) Turn all bolts 90 10 degrees clockwise.

(3) Check that paint mark of each bolt is facing

the front of the vehicle.

4. Apply engine oil and install push rods.

5. Install rocker shaft assembly.

Adjust intake and exhaust valve clearance carefully.

Refer to MA section in order to accomplish valve adjustment.

NEM179

SEM641B

SEM580C

SEM642B

CYLINDER HEADTD27Ti

Installation (Cont'd)

EM-115

Page 1224 of 1767

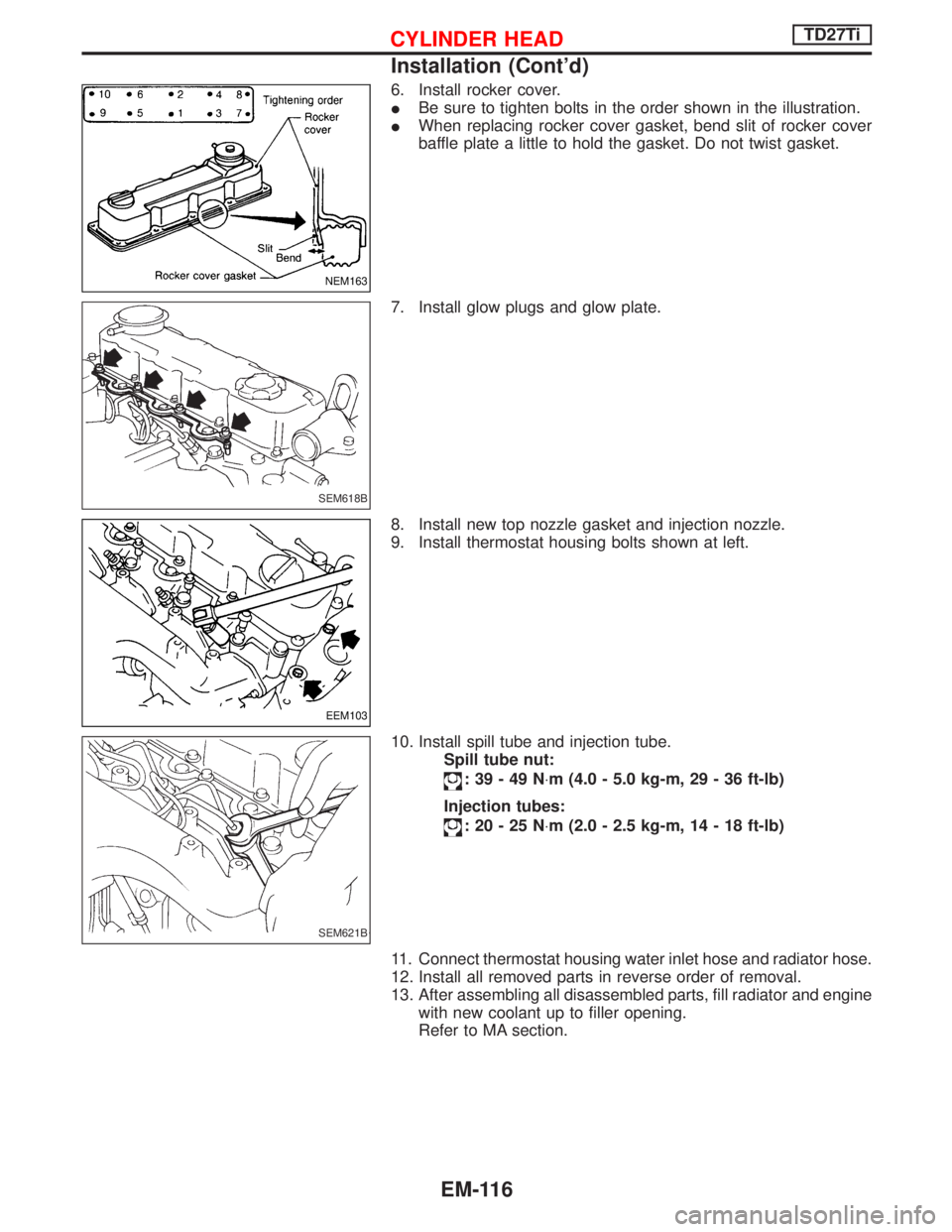

6. Install rocker cover.

IBe sure to tighten bolts in the order shown in the illustration.

IWhen replacing rocker cover gasket, bend slit of rocker cover

baffle plate a little to hold the gasket. Do not twist gasket.

7. Install glow plugs and glow plate.

8. Install new top nozzle gasket and injection nozzle.

9. Install thermostat housing bolts shown at left.

10. Install spill tube and injection tube.

Spill tube nut:

:39-49N×m (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

Injection tubes:

:20-25N×m (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

11. Connect thermostat housing water inlet hose and radiator hose.

12. Install all removed parts in reverse order of removal.

13. After assembling all disassembled parts, fill radiator and engine

with new coolant up to filler opening.

Refer to MA section.

NEM163

SEM618B

EEM103

SEM621B

CYLINDER HEADTD27Ti

Installation (Cont'd)

EM-116

Page 1225 of 1767

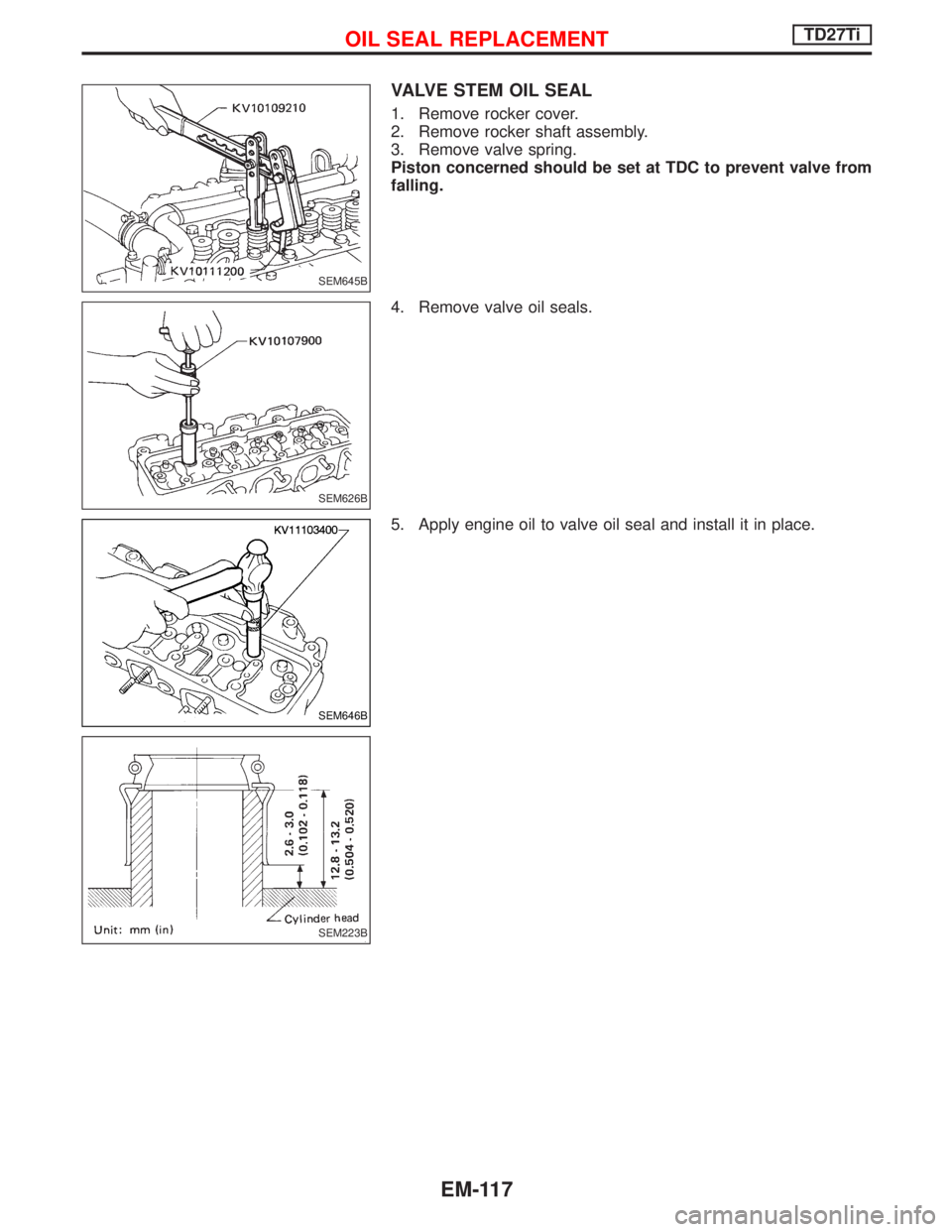

VALVE STEM OIL SEAL

1. Remove rocker cover.

2. Remove rocker shaft assembly.

3. Remove valve spring.

Piston concerned should be set at TDC to prevent valve from

falling.

4. Remove valve oil seals.

5. Apply engine oil to valve oil seal and install it in place.

SEM645B

SEM626B

SEM646B

SEM223B

OIL SEAL REPLACEMENTTD27Ti

EM-117

Page 1226 of 1767

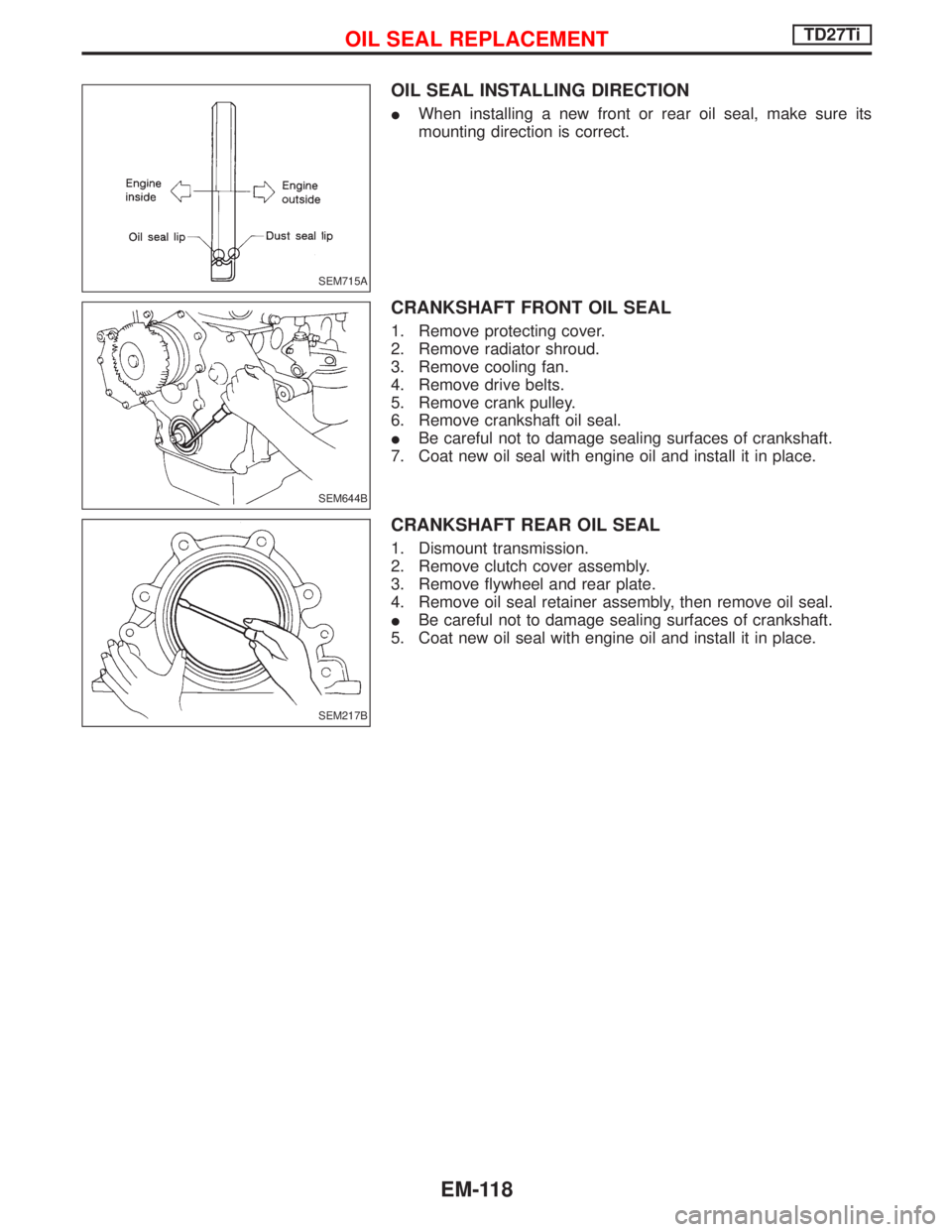

OIL SEAL INSTALLING DIRECTION

IWhen installing a new front or rear oil seal, make sure its

mounting direction is correct.

CRANKSHAFT FRONT OIL SEAL

1. Remove protecting cover.

2. Remove radiator shroud.

3. Remove cooling fan.

4. Remove drive belts.

5. Remove crank pulley.

6. Remove crankshaft oil seal.

IBe careful not to damage sealing surfaces of crankshaft.

7. Coat new oil seal with engine oil and install it in place.

CRANKSHAFT REAR OIL SEAL

1. Dismount transmission.

2. Remove clutch cover assembly.

3. Remove flywheel and rear plate.

4. Remove oil seal retainer assembly, then remove oil seal.

IBe careful not to damage sealing surfaces of crankshaft.

5. Coat new oil seal with engine oil and install it in place.

SEM715A

SEM644B

SEM217B

OIL SEAL REPLACEMENTTD27Ti

EM-118

Page 1227 of 1767

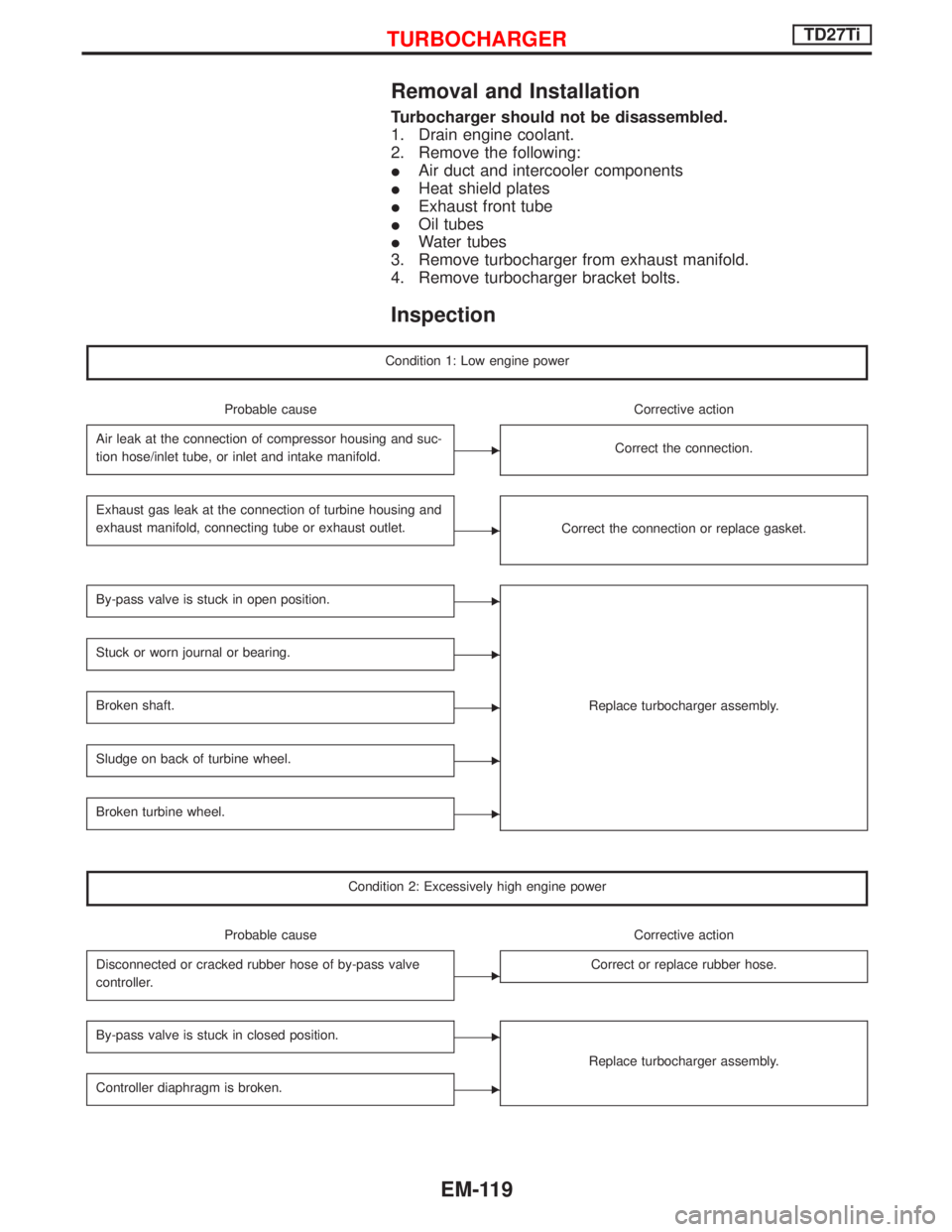

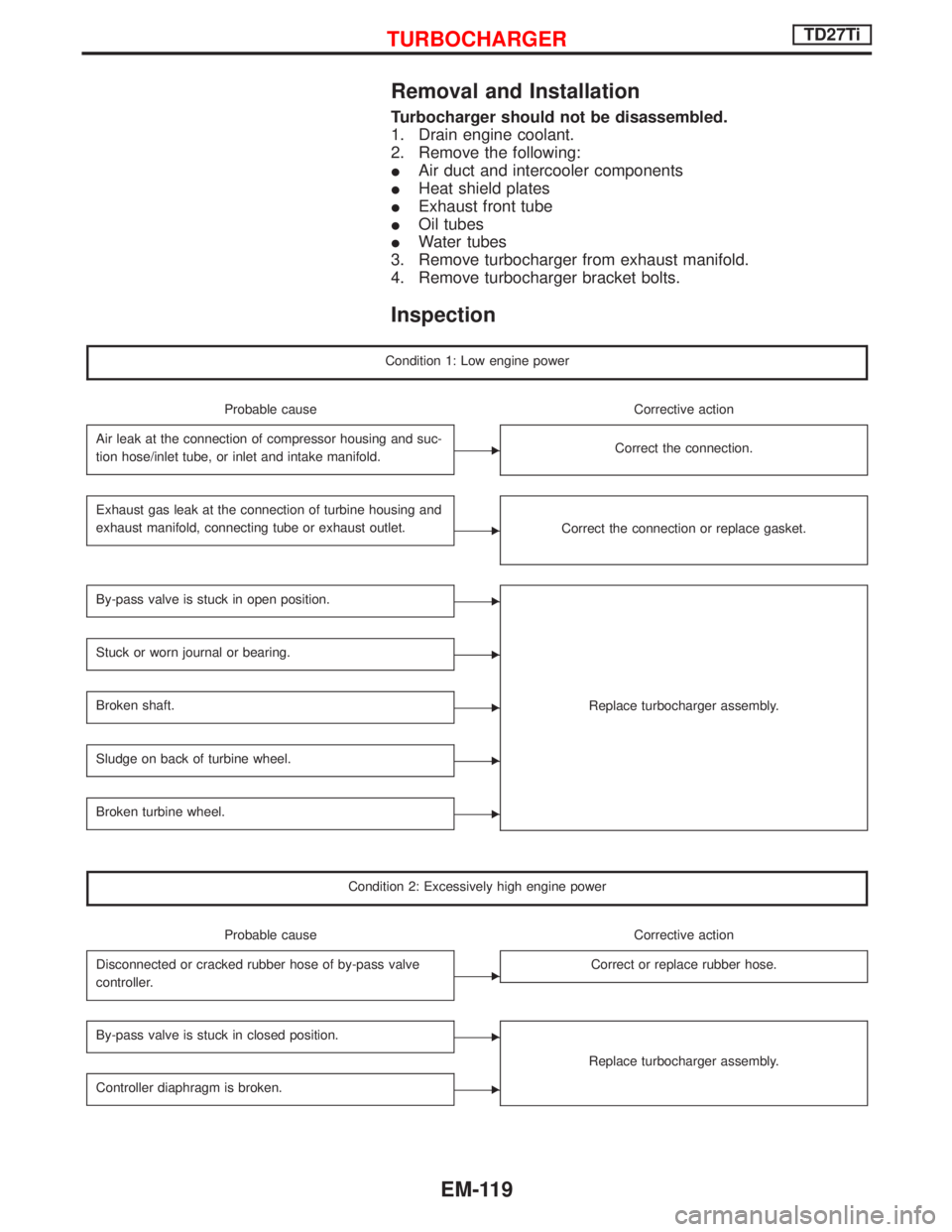

Removal and Installation

Turbocharger should not be disassembled.

1. Drain engine coolant.

2. Remove the following:

IAir duct and intercooler components

IHeat shield plates

IExhaust front tube

IOil tubes

IWater tubes

3. Remove turbocharger from exhaust manifold.

4. Remove turbocharger bracket bolts.

Inspection

Condition 1: Low engine power

Probable cause Corrective action

Air leak at the connection of compressor housing and suc-

tion hose/inlet tube, or inlet and intake manifold.

ECorrect the connection.

Exhaust gas leak at the connection of turbine housing and

exhaust manifold, connecting tube or exhaust outlet.

ECorrect the connection or replace gasket.

By-pass valve is stuck in open position.E

Replace turbocharger assembly.

Stuck or worn journal or bearing.E

Broken shaft.E

Sludge on back of turbine wheel.E

Broken turbine wheel.E

Condition 2: Excessively high engine power

Probable cause Corrective action

Disconnected or cracked rubber hose of by-pass valve

controller.

ECorrect or replace rubber hose.

By-pass valve is stuck in closed position.E

Replace turbocharger assembly.

Controller diaphragm is broken.E

TURBOCHARGERTD27Ti

EM-119

Page 1228 of 1767

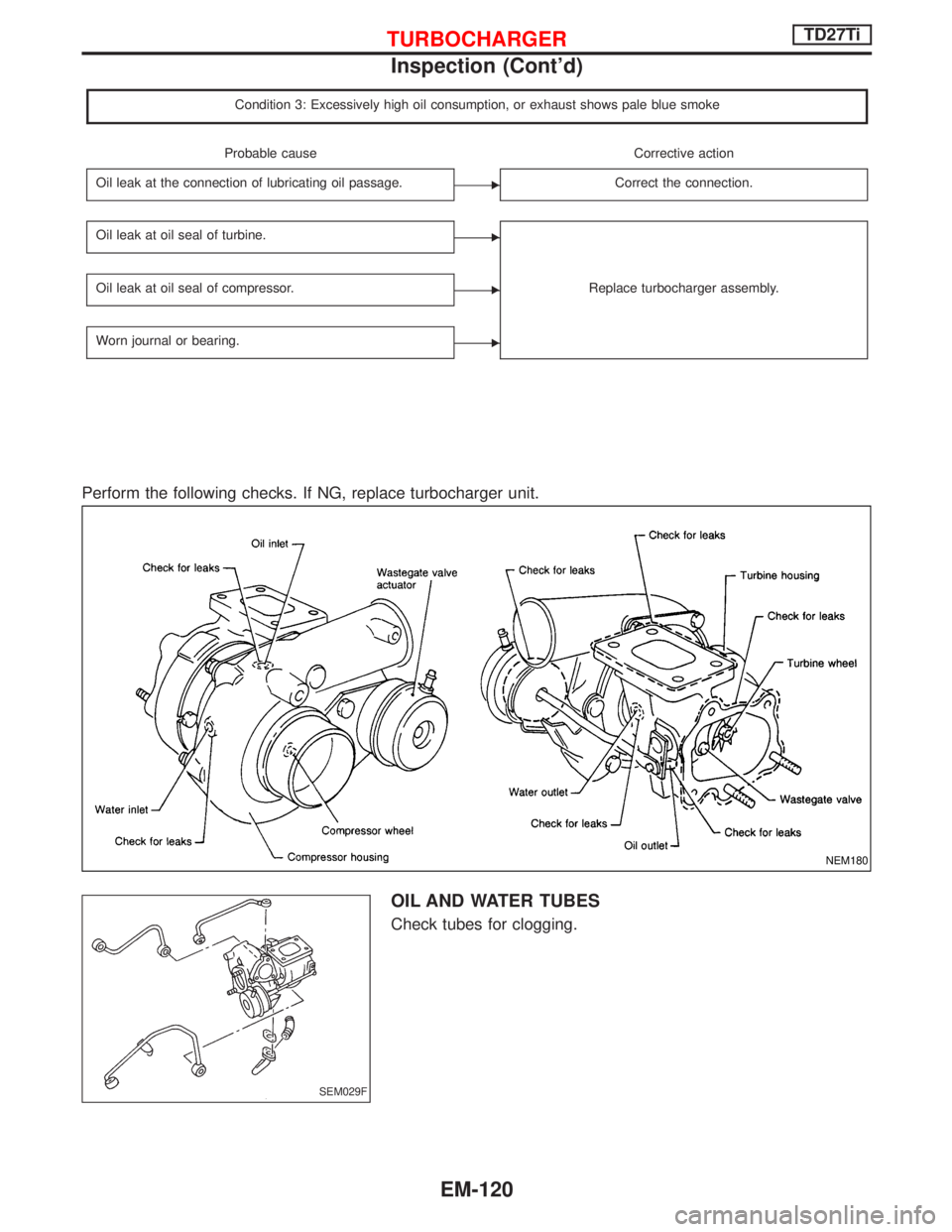

Condition 3: Excessively high oil consumption, or exhaust shows pale blue smoke

Probable cause Corrective action

Oil leak at the connection of lubricating oil passage.

ECorrect the connection.

Oil leak at oil seal of turbine.E

Replace turbocharger assembly.Oil leak at oil seal of compressor.E

Worn journal or bearing.E

Perform the following checks. If NG, replace turbocharger unit.

OIL AND WATER TUBES

Check tubes for clogging.

NEM180

SEM029F

TURBOCHARGERTD27Ti

Inspection (Cont'd)

EM-120

Page 1229 of 1767

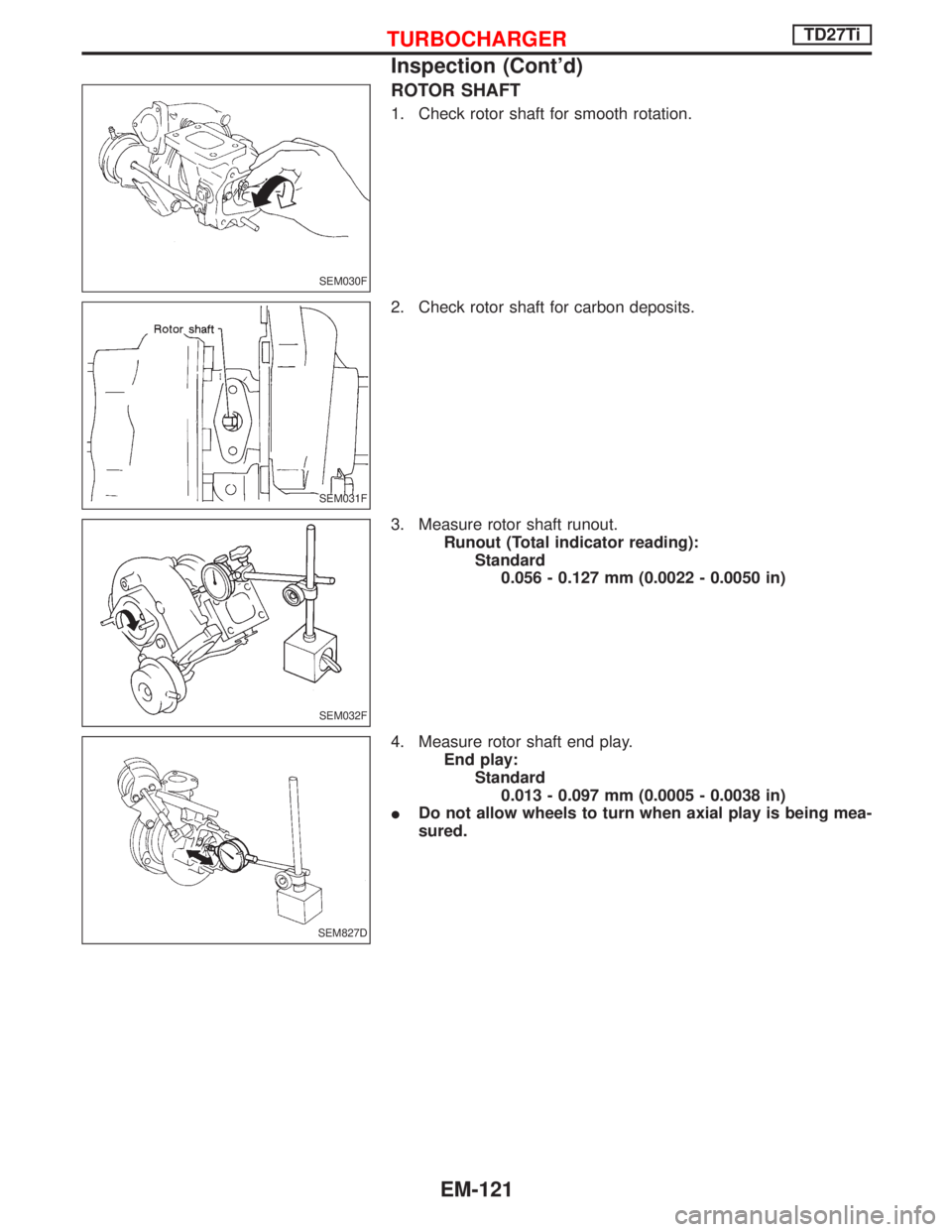

ROTOR SHAFT

1. Check rotor shaft for smooth rotation.

2. Check rotor shaft for carbon deposits.

3. Measure rotor shaft runout.

Runout (Total indicator reading):

Standard

0.056 - 0.127 mm (0.0022 - 0.0050 in)

4. Measure rotor shaft end play.

End play:

Standard

0.013 - 0.097 mm (0.0005 - 0.0038 in)

IDo not allow wheels to turn when axial play is being mea-

sured.

SEM030F

SEM031F

SEM032F

SEM827D

TURBOCHARGERTD27Ti

Inspection (Cont'd)

EM-121

Page 1230 of 1767

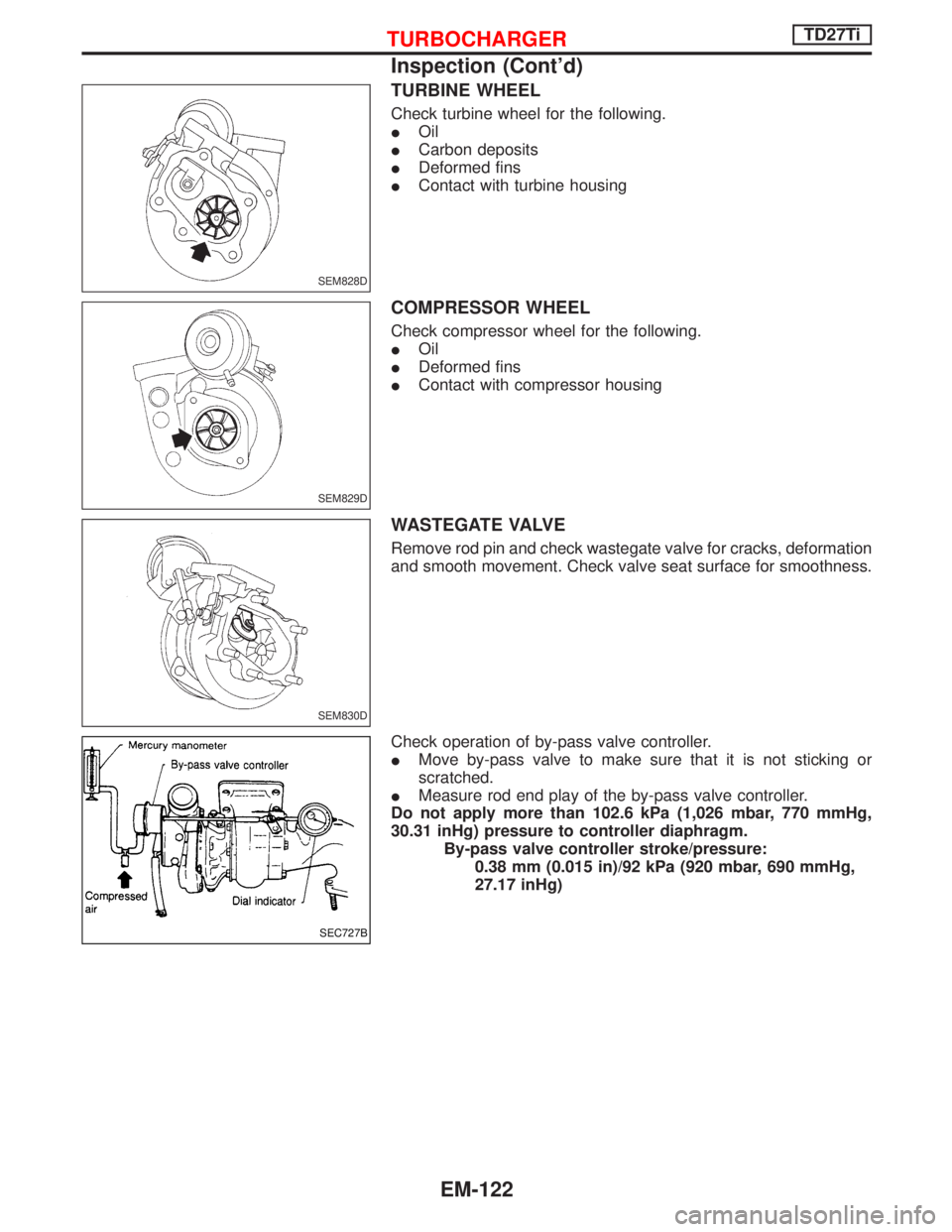

TURBINE WHEEL

Check turbine wheel for the following.

IOil

ICarbon deposits

IDeformed fins

IContact with turbine housing

COMPRESSOR WHEEL

Check compressor wheel for the following.

IOil

IDeformed fins

IContact with compressor housing

WASTEGATE VALVE

Remove rod pin and check wastegate valve for cracks, deformation

and smooth movement. Check valve seat surface for smoothness.

Check operation of by-pass valve controller.

IMove by-pass valve to make sure that it is not sticking or

scratched.

IMeasure rod end play of the by-pass valve controller.

Do not apply more than 102.6 kPa (1,026 mbar, 770 mmHg,

30.31 inHg) pressure to controller diaphragm.

By-pass valve controller stroke/pressure:

0.38 mm (0.015 in)/92 kPa (920 mbar, 690 mmHg,

27.17 inHg)

SEM828D

SEM829D

SEM830D

SEC727B

TURBOCHARGERTD27Ti

Inspection (Cont'd)

EM-122

Trending: brake rotor, height, tire size, drain bolt, warning light, immobilizer, open hood