NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1341 of 1767

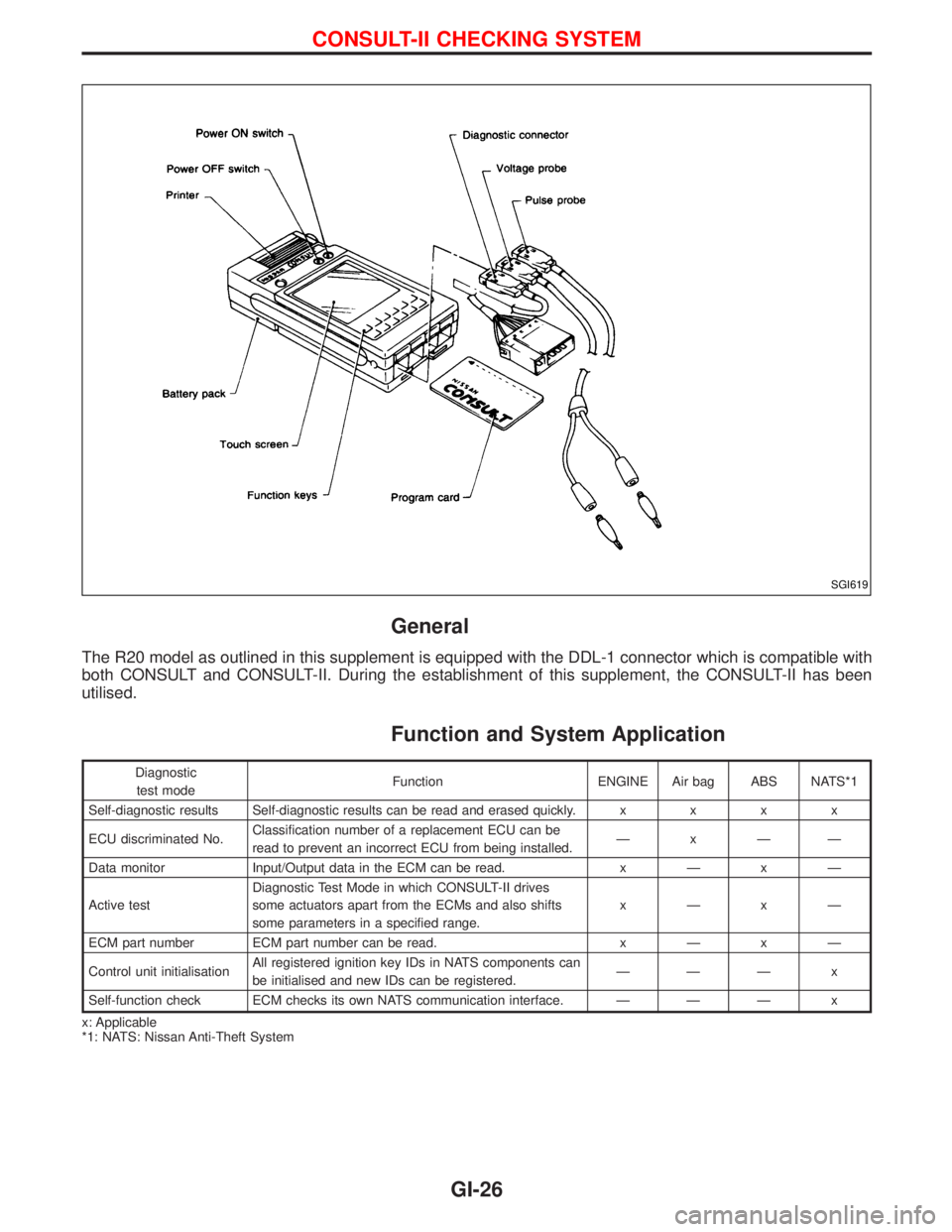

General

The R20 model as outlined in this supplement is equipped with the DDL-1 connector which is compatible with

both CONSULT and CONSULT-II. During the establishment of this supplement, the CONSULT-II has been

utilised.

Function and System Application

Diagnostic

test modeFunction ENGINE Air bag ABS NATS*1

Self-diagnostic results Self-diagnostic results can be read and erased quickly.xxxx

ECU discriminated No.Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being installed.ÐxÐÐ

Data monitor Input/Output data in the ECM can be read.xÐxÐ

Active testDiagnostic Test Mode in which CONSULT-II drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range.xÐxÐ

ECM part number ECM part number can be read.xÐxÐ

Control unit initialisationAll registered ignition key IDs in NATS components can

be initialised and new IDs can be registered.ÐÐÐ x

Self-function check ECM checks its own NATS communication interface. Ð Ð Ð x

x: Applicable

*1: NATS: Nissan Anti-Theft System

SGI619

CONSULT-II CHECKING SYSTEM

GI-26

Page 1342 of 1767

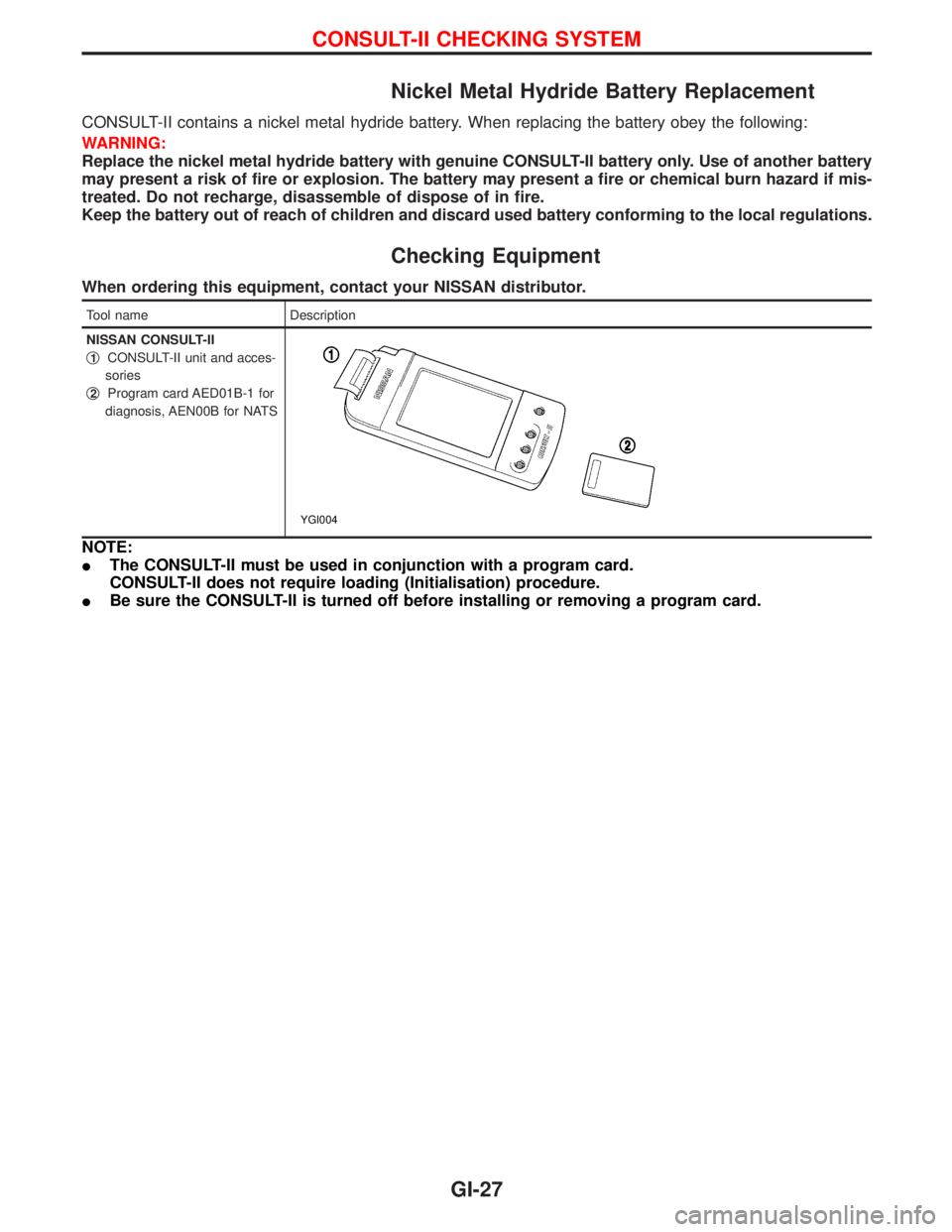

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another battery

may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering this equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

q

1CONSULT-II unit and acces-

sories

q

2Program card AED01B-1 for

diagnosis, AEN00B for NATS

YGI004

NOTE:

IThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

IBe sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II CHECKING SYSTEM

GI-27

Page 1343 of 1767

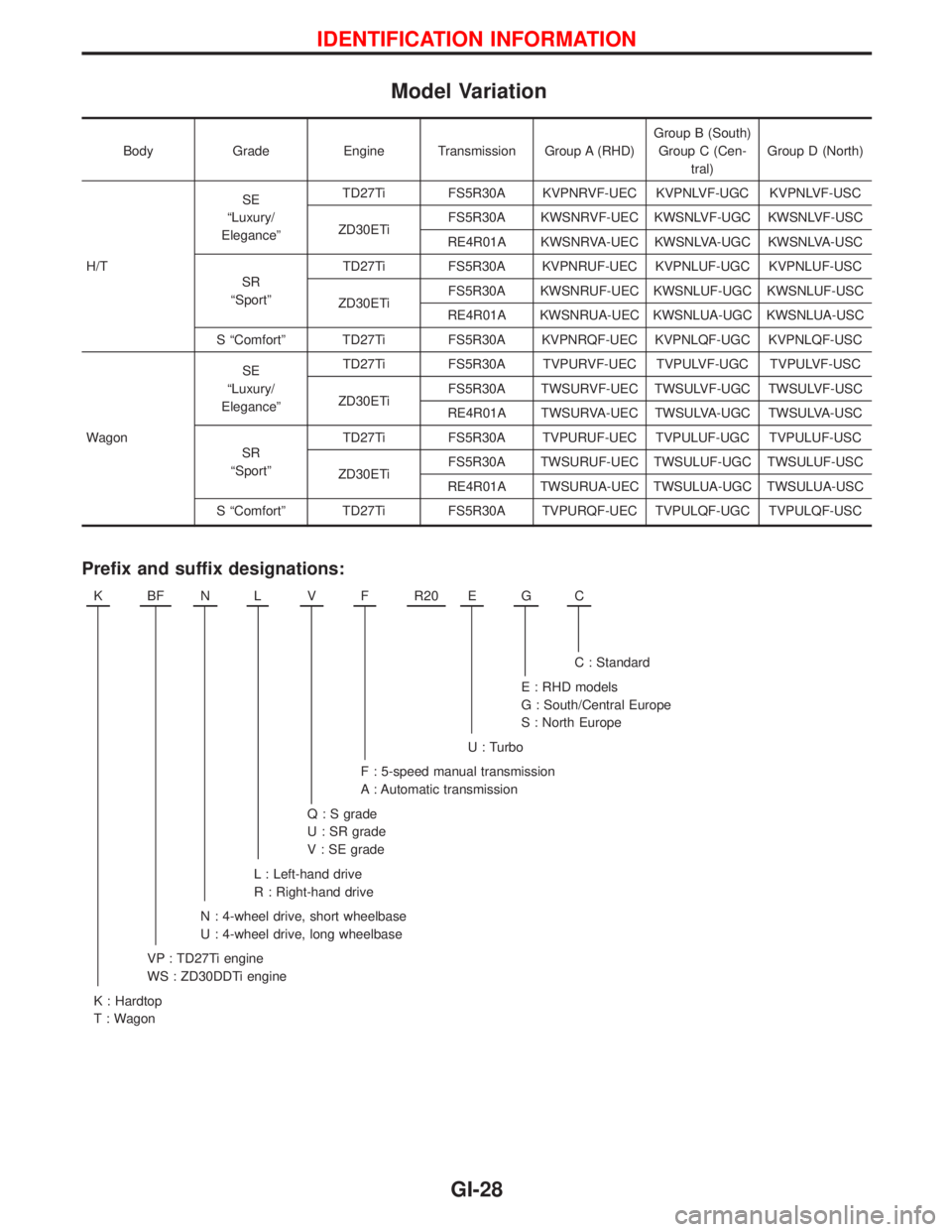

Model Variation

Body Grade Engine Transmission Group A (RHD)Group B (South)

Group C (Cen-

tral)Group D (North)

H/TSE

ªLuxury/

EleganceºTD27Ti FS5R30A KVPNRVF-UEC KVPNLVF-UGC KVPNLVF-USC

ZD30ETiFS5R30A KWSNRVF-UEC KWSNLVF-UGC KWSNLVF-USC

RE4R01A KWSNRVA-UEC KWSNLVA-UGC KWSNLVA-USC

SR

ªSportºTD27Ti FS5R30A KVPNRUF-UEC KVPNLUF-UGC KVPNLUF-USC

ZD30ETiFS5R30A KWSNRUF-UEC KWSNLUF-UGC KWSNLUF-USC

RE4R01A KWSNRUA-UEC KWSNLUA-UGC KWSNLUA-USC

S ªComfortº TD27Ti FS5R30A KVPNRQF-UEC KVPNLQF-UGC KVPNLQF-USC

WagonSE

ªLuxury/

EleganceºTD27Ti FS5R30A TVPURVF-UEC TVPULVF-UGC TVPULVF-USC

ZD30ETiFS5R30A TWSURVF-UEC TWSULVF-UGC TWSULVF-USC

RE4R01A TWSURVA-UEC TWSULVA-UGC TWSULVA-USC

SR

ªSportºTD27Ti FS5R30A TVPURUF-UEC TVPULUF-UGC TVPULUF-USC

ZD30ETiFS5R30A TWSURUF-UEC TWSULUF-UGC TWSULUF-USC

RE4R01A TWSURUA-UEC TWSULUA-UGC TWSULUA-USC

S ªComfortº TD27Ti FS5R30A TVPURQF-UEC TVPULQF-UGC TVPULQF-USC

Prefix and suffix designations:

KBFNLVFR20EGC

C : Standard

E : RHD models

G : South/Central Europe

S : North Europe

U : Turbo

F : 5-speed manual transmission

A : Automatic transmission

Q : S grade

U : SR grade

V : SE grade

L : Left-hand drive

R : Right-hand drive

N : 4-wheel drive, short wheelbase

U : 4-wheel drive, long wheelbase

VP : TD27Ti engine

WS : ZD30DDTi engine

K : Hardtop

T : Wagon

IDENTIFICATION INFORMATION

GI-28

Page 1344 of 1767

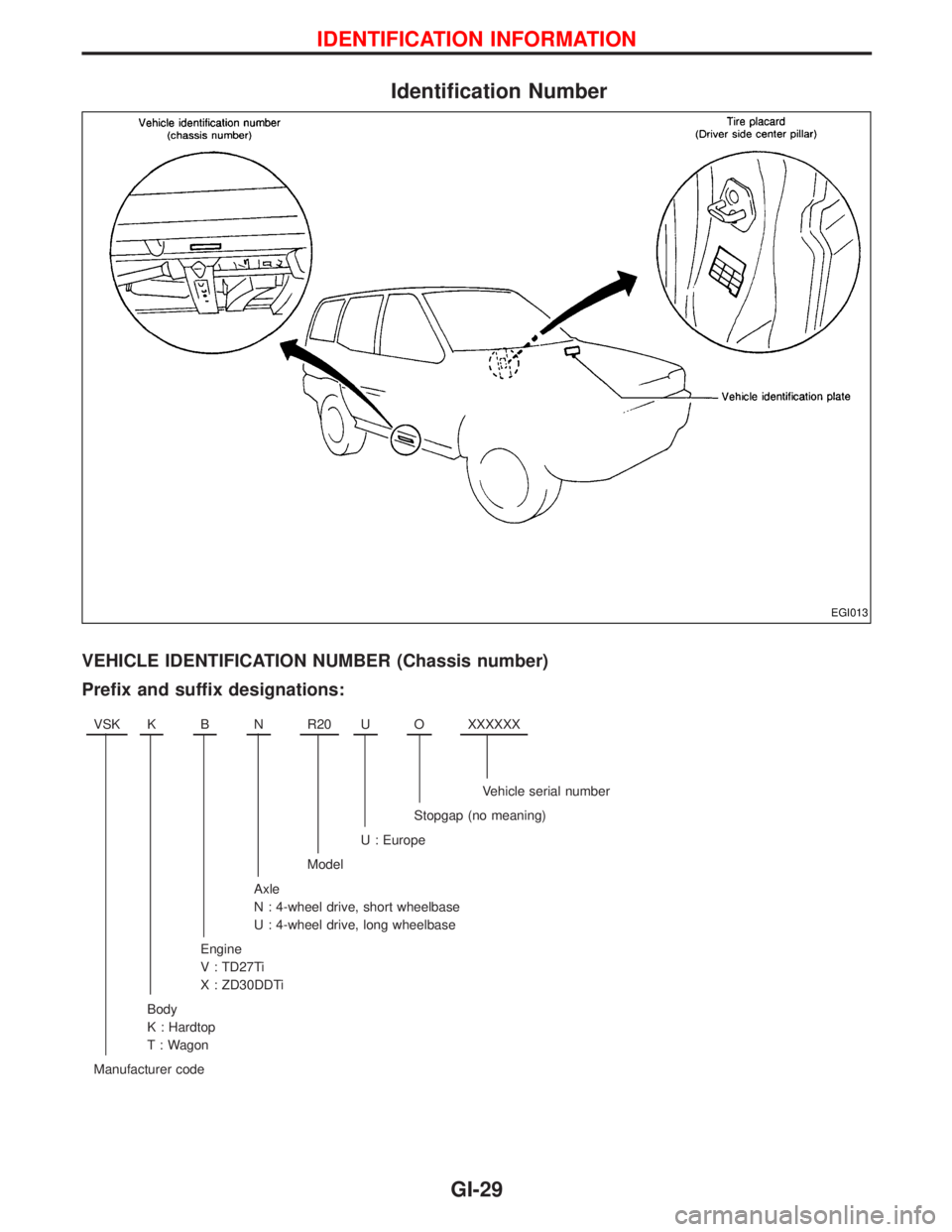

Identification Number

VEHICLE IDENTIFICATION NUMBER (Chassis number)

Prefix and suffix designations:

VSKKBNR20UOXXXXXX

Vehicle serial number

Stopgap (no meaning)

U : Europe

Model

Axle

N : 4-wheel drive, short wheelbase

U : 4-wheel drive, long wheelbase

Engine

V : TD27Ti

X : ZD30DDTi

Body

K : Hardtop

T : Wagon

Manufacturer code

EGI013

IDENTIFICATION INFORMATION

GI-29

Page 1345 of 1767

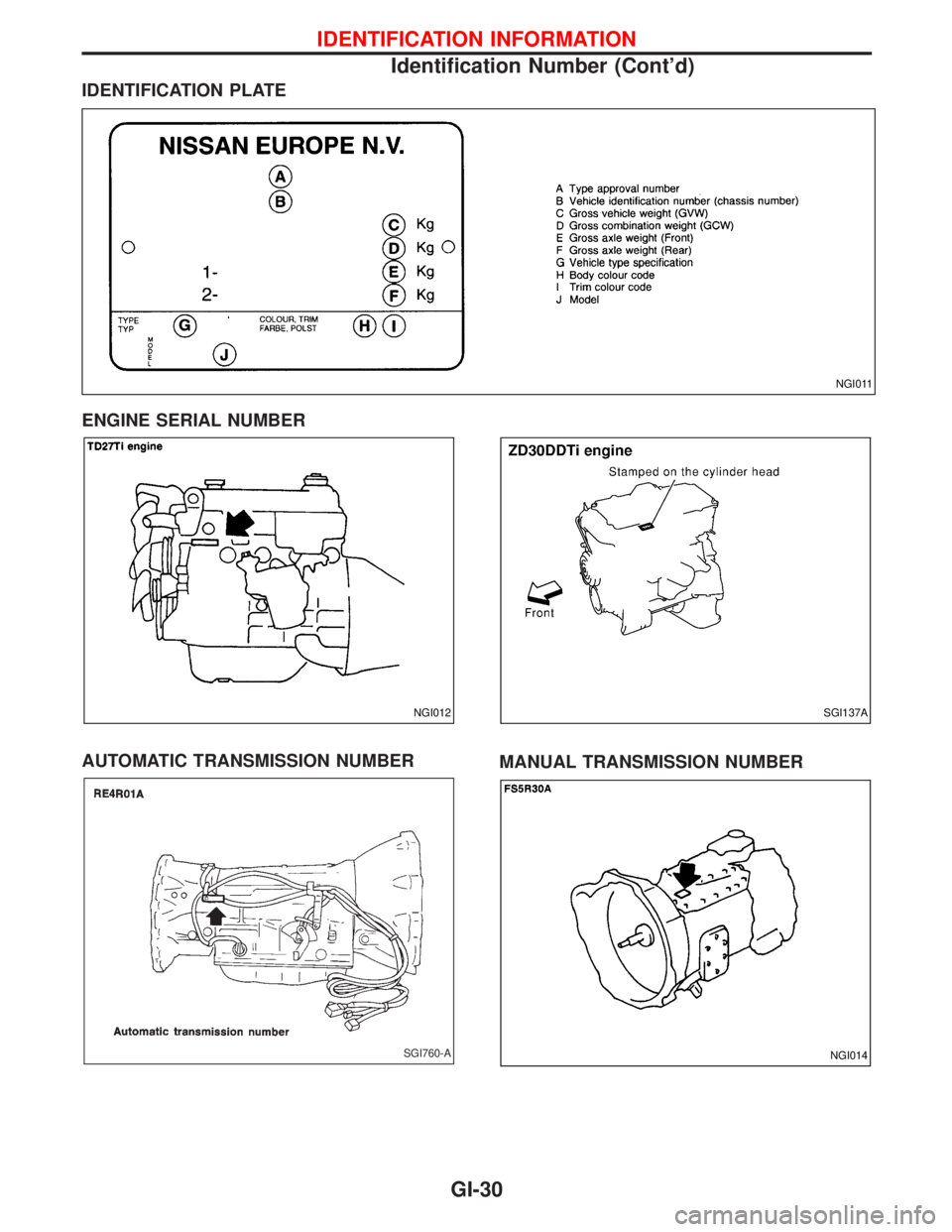

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

MANUAL TRANSMISSION NUMBER

NGI011

NGI012SGI137A

SGI760-ANGI014

IDENTIFICATION INFORMATION

Identification Number (Cont'd)

GI-30

Page 1346 of 1767

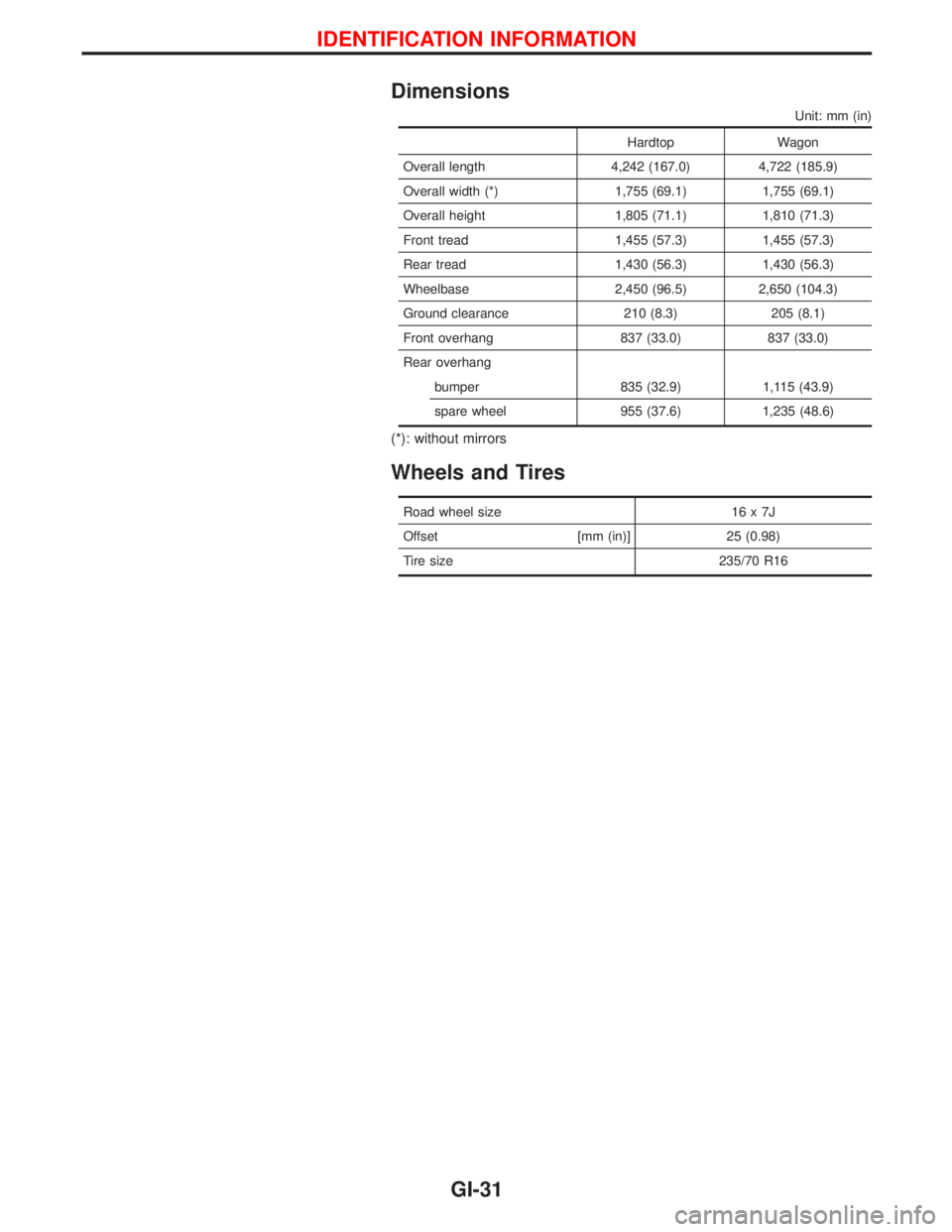

Dimensions

Unit: mm (in)

Hardtop Wagon

Overall length 4,242 (167.0) 4,722 (185.9)

Overall width (*) 1,755 (69.1) 1,755 (69.1)

Overall height 1,805 (71.1) 1,810 (71.3)

Front tread 1,455 (57.3) 1,455 (57.3)

Rear tread 1,430 (56.3) 1,430 (56.3)

Wheelbase 2,450 (96.5) 2,650 (104.3)

Ground clearance 210 (8.3) 205 (8.1)

Front overhang 837 (33.0) 837 (33.0)

Rear overhang

bumper 835 (32.9) 1,115 (43.9)

spare wheel 955 (37.6) 1,235 (48.6)

(*): without mirrors

Wheels and Tires

Road wheel size 16 x 7J

Offset [mm (in)] 25 (0.98)

Tire size 235/70 R16

IDENTIFICATION INFORMATION

GI-31

Page 1347 of 1767

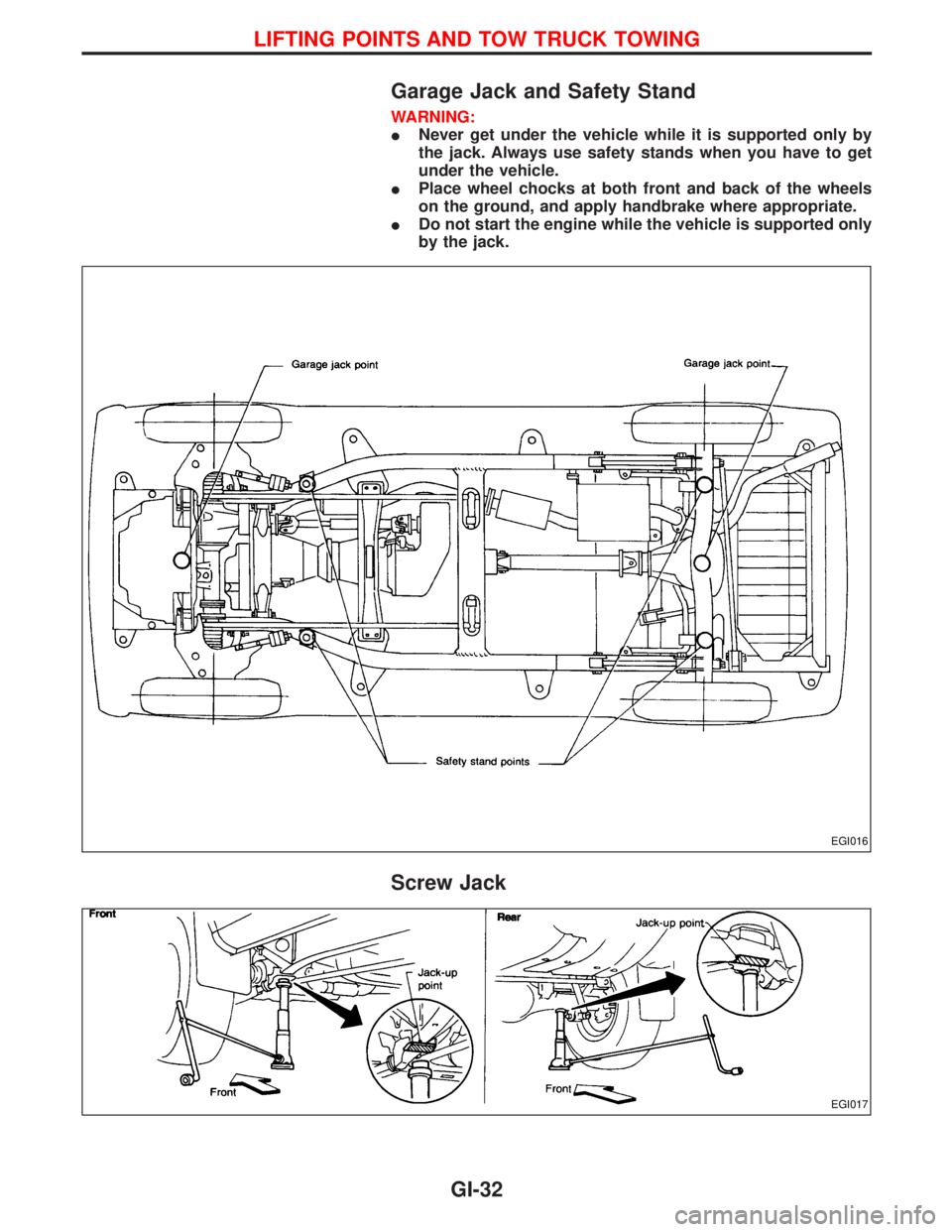

Garage Jack and Safety Stand

WARNING:

INever get under the vehicle while it is supported only by

the jack. Always use safety stands when you have to get

under the vehicle.

IPlace wheel chocks at both front and back of the wheels

on the ground, and apply handbrake where appropriate.

IDo not start the engine while the vehicle is supported only

by the jack.

Screw Jack

EGI016

EGI017

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

Page 1348 of 1767

4-pole Lift

WARNING:

Do not use a 2-pole lift.

Due to weight balance of the vehicle and shape of underbody,

lift arms can not be attached in a safe way. Therefore it is rec-

ommended to use a 4-pole lift only.

Tow Truck Towing

CAUTION:

IAll applicable local laws regarding the towing operation

must be obeyed.

IIt is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

IAttach safety chains for all towing.

IWhen towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

IWhen towing with the front wheels on the ground:

Move both the gearshift and transfer levers to neutral (ªNº

position).

Turn the ignition key to the ªOFFº position and secure the

steering wheel in a straightahead position with a rope or

similar device. Never place the ignition key in the ªLOCKº

position. This will result in damage to the steering lock

mechanism.

IWhen towing with the rear wheels on the ground, release

the parking brake and move both the gearshift and trans-

fer levers to neutral (ªNº position).

INever tow vehicle from the rear (i.e., backward) with four

wheels on the ground as this may cause serious and

expensive damage to the transmission.

LIFTING POINTS AND TOW TRUCK TOWING

GI-33

Page 1349 of 1767

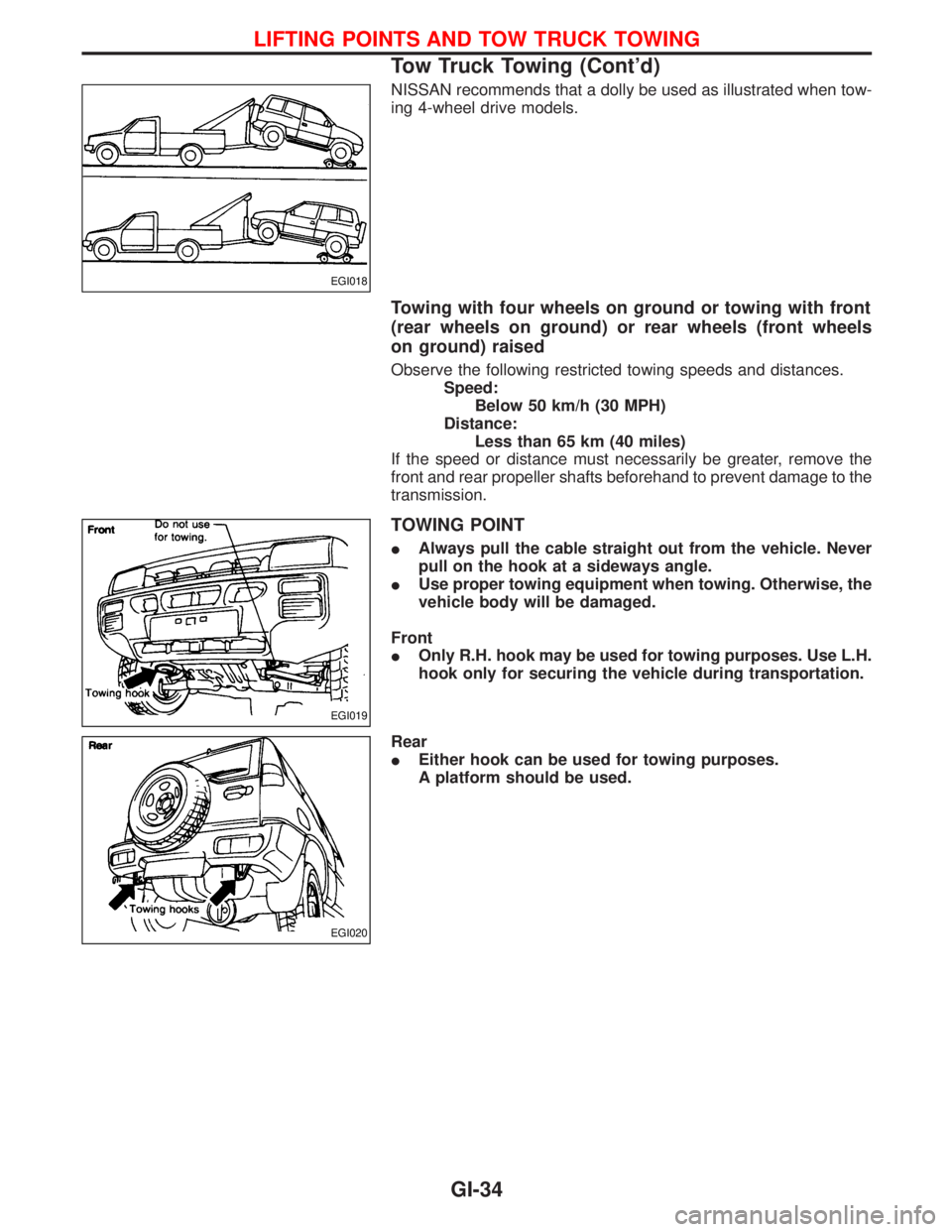

NISSAN recommends that a dolly be used as illustrated when tow-

ing 4-wheel drive models.

Towing with four wheels on ground or towing with front

(rear wheels on ground) or rear wheels (front wheels

on ground) raised

Observe the following restricted towing speeds and distances.

Speed:

Below 50 km/h (30 MPH)

Distance:

Less than 65 km (40 miles)

If the speed or distance must necessarily be greater, remove the

front and rear propeller shafts beforehand to prevent damage to the

transmission.

TOWING POINT

IAlways pull the cable straight out from the vehicle. Never

pull on the hook at a sideways angle.

IUse proper towing equipment when towing. Otherwise, the

vehicle body will be damaged.

Front

IOnly R.H. hook may be used for towing purposes. Use L.H.

hook only for securing the vehicle during transportation.

Rear

IEither hook can be used for towing purposes.

A platform should be used.

EGI018

EGI019

EGI020

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-34

Page 1350 of 1767

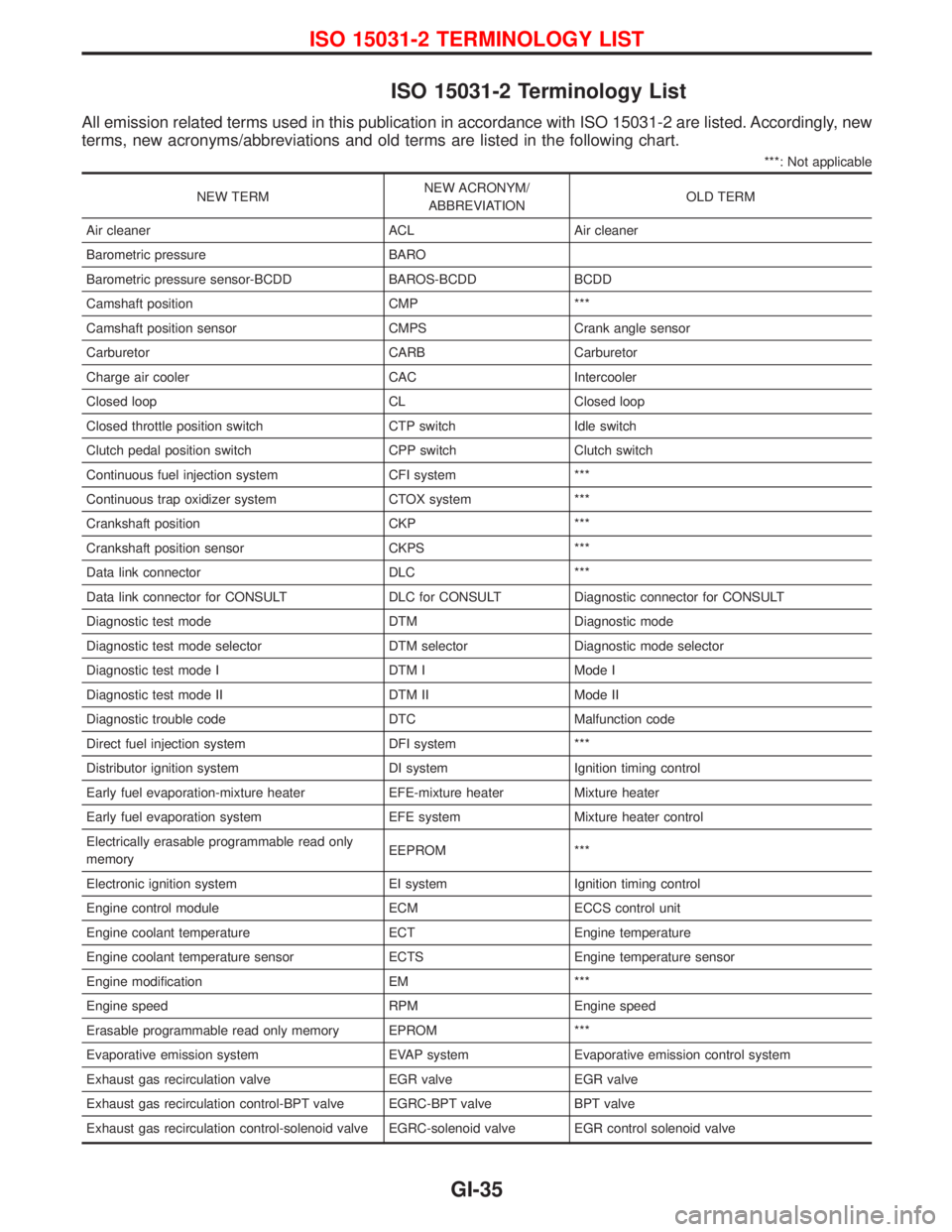

ISO 15031-2 Terminology List

All emission related terms used in this publication in accordance with ISO 15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT DLC for CONSULT Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read only

memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

ISO 15031-2 TERMINOLOGY LIST

GI-35