sensor NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 544 of 1767

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 0704 P4×SPILL/V CIRC, DTC 0706 P6×SPILL VALVEZD30DDTi

EC-182

Page 551 of 1767

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 0705 P5×PUMP C/MODULEZD30DDTi

EC-189

Page 554 of 1767

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 0707 P7×F/INJ TIMG FBZD30DDTi

EC-192

Page 562 of 1767

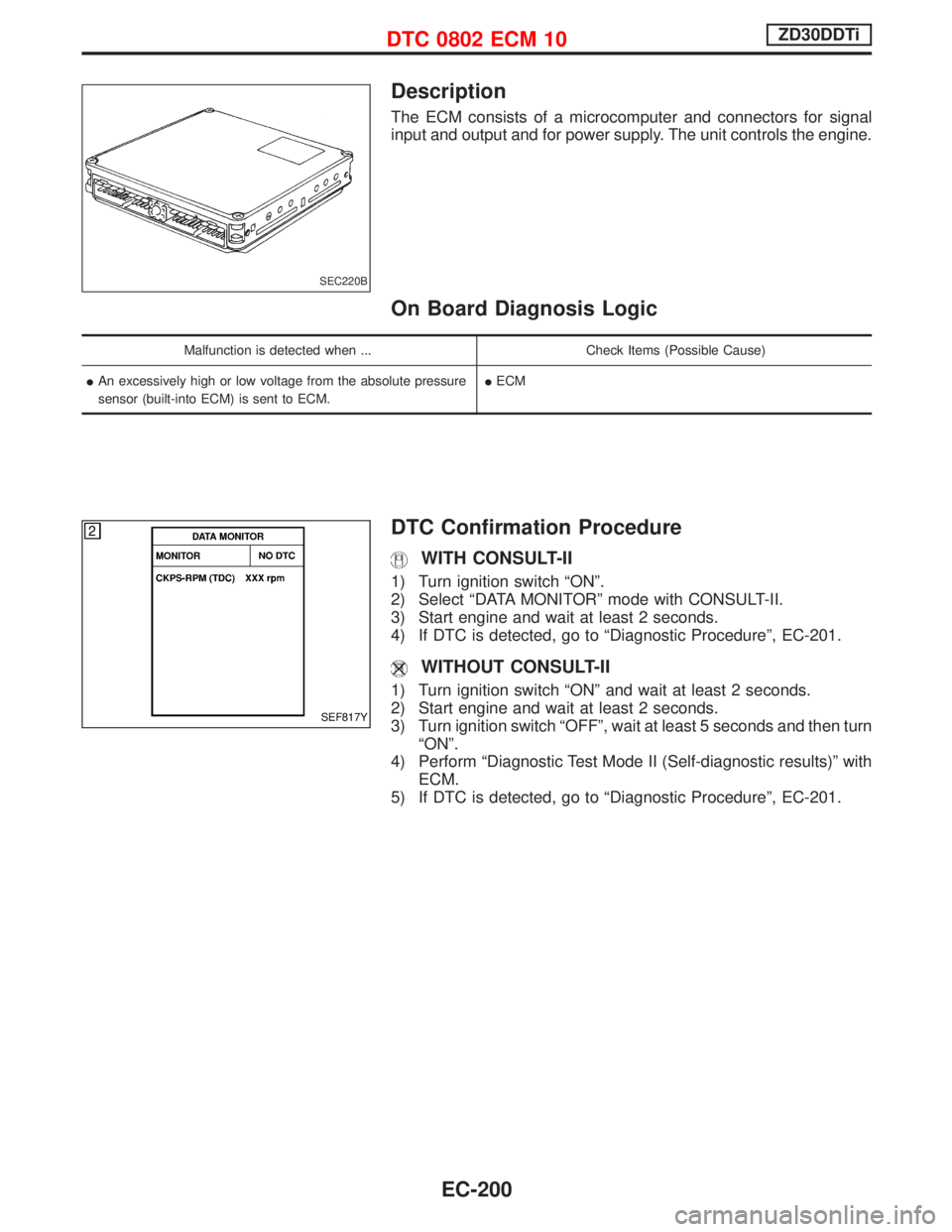

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

IAn excessively high or low voltage from the absolute pressure

sensor (built-into ECM) is sent to ECM.IECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-201.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-201.

SEC220B

SEF817Y

DTC 0802 ECM 10ZD30DDTi

EC-200

Page 577 of 1767

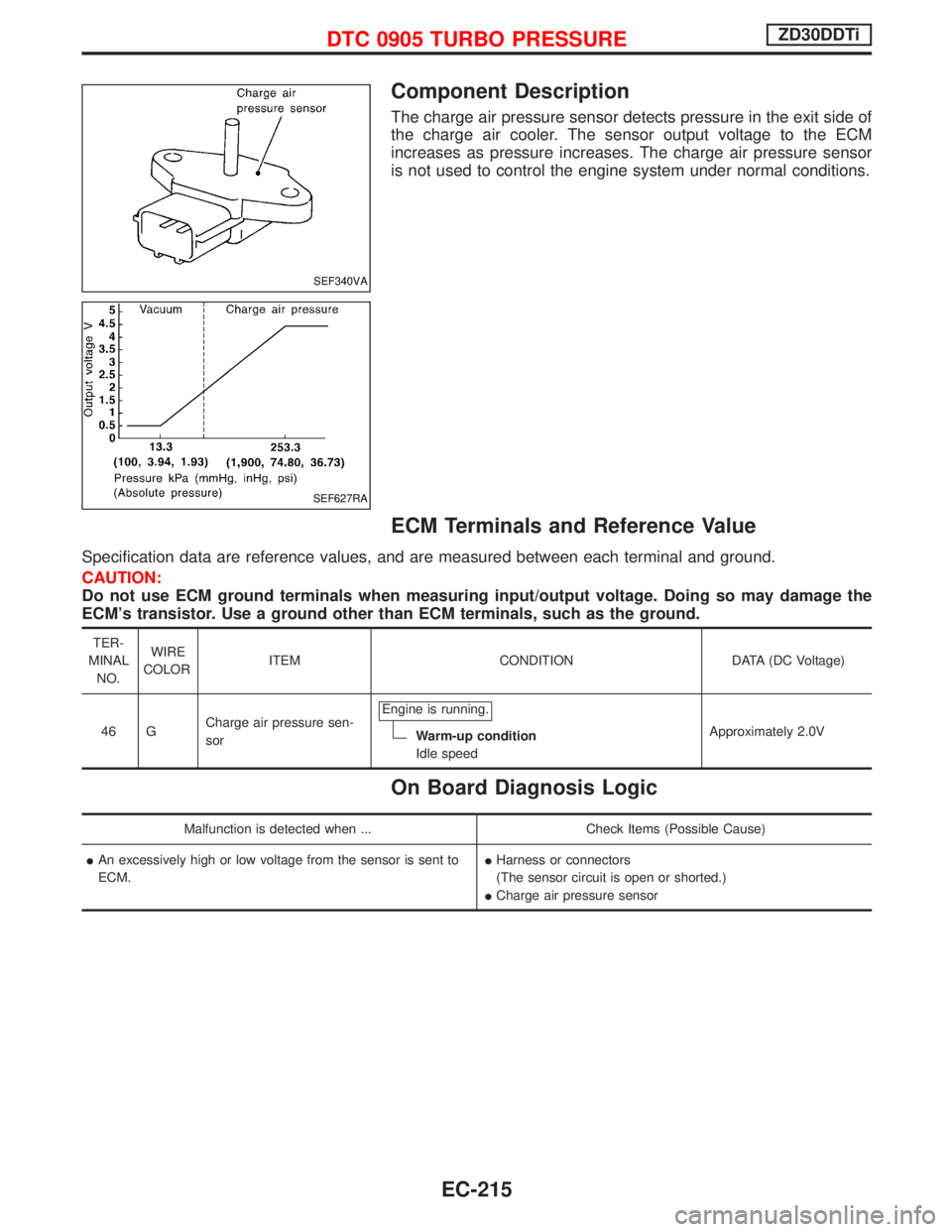

Component Description

The charge air pressure sensor detects pressure in the exit side of

the charge air cooler. The sensor output voltage to the ECM

increases as pressure increases. The charge air pressure sensor

is not used to control the engine system under normal conditions.

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

46 GCharge air pressure sen-

sorEngine is running.

Warm-up condition

Idle speedApproximately 2.0V

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

IAn excessively high or low voltage from the sensor is sent to

ECM.IHarness or connectors

(The sensor circuit is open or shorted.)

ICharge air pressure sensor

SEF340VA

SEF627RA

DTC 0905 TURBO PRESSUREZD30DDTi

EC-215

Page 581 of 1767

Diagnostic Procedure

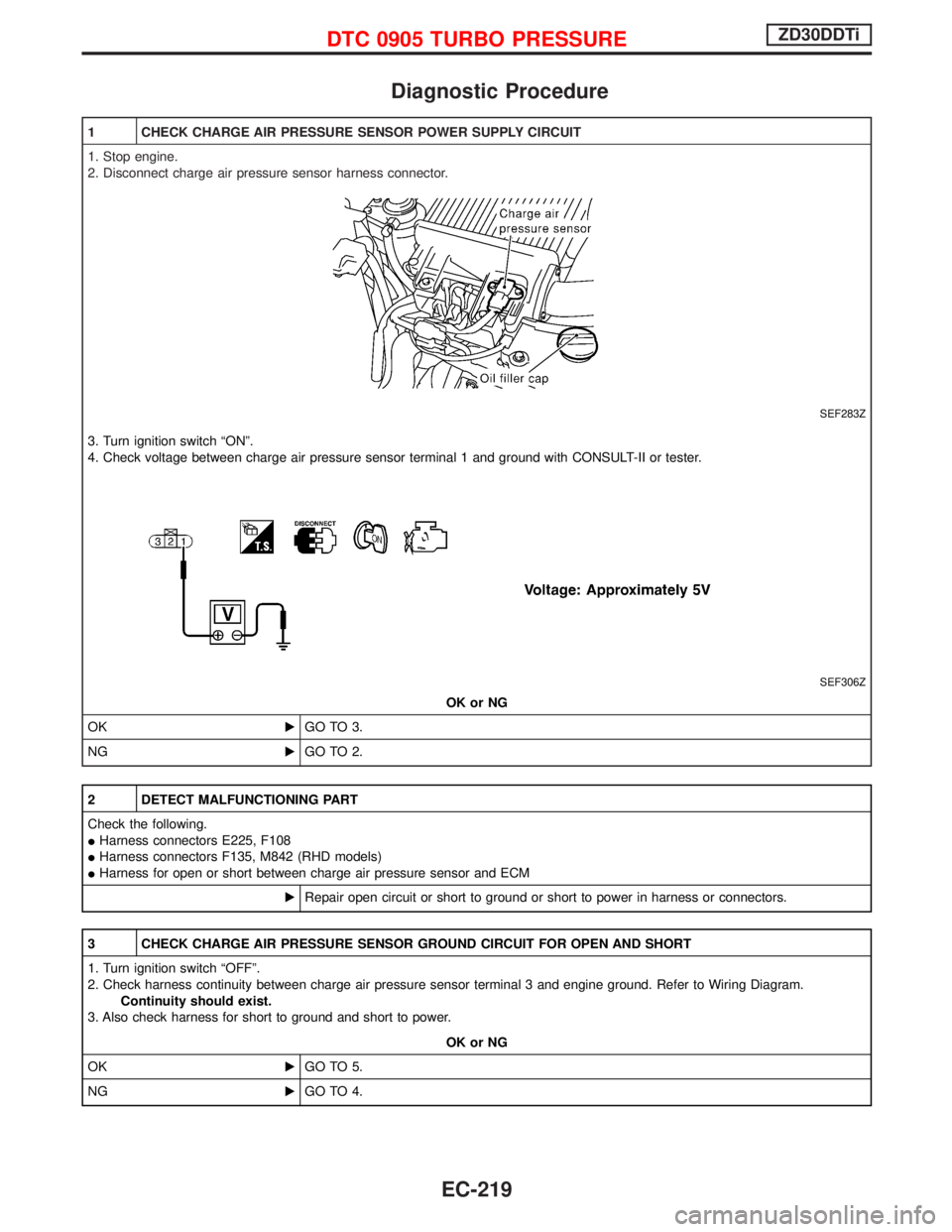

1 CHECK CHARGE AIR PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Stop engine.

2. Disconnect charge air pressure sensor harness connector.

SEF283Z

3. Turn ignition switch ªONº.

4. Check voltage between charge air pressure sensor terminal 1 and ground with CONSULT-II or tester.

SEF306Z

OK or NG

OKEGO TO 3.

NGEGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between charge air pressure sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK CHARGE AIR PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between charge air pressure sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 5.

NGEGO TO 4.

DTC 0905 TURBO PRESSUREZD30DDTi

EC-219

Page 582 of 1767

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M852 (RHD models)

IHarness for open or short between ECM and charge air pressure sensor

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK CHARGE AIR PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and charge air pressure sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 7.

NGEGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between charge air pressure sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

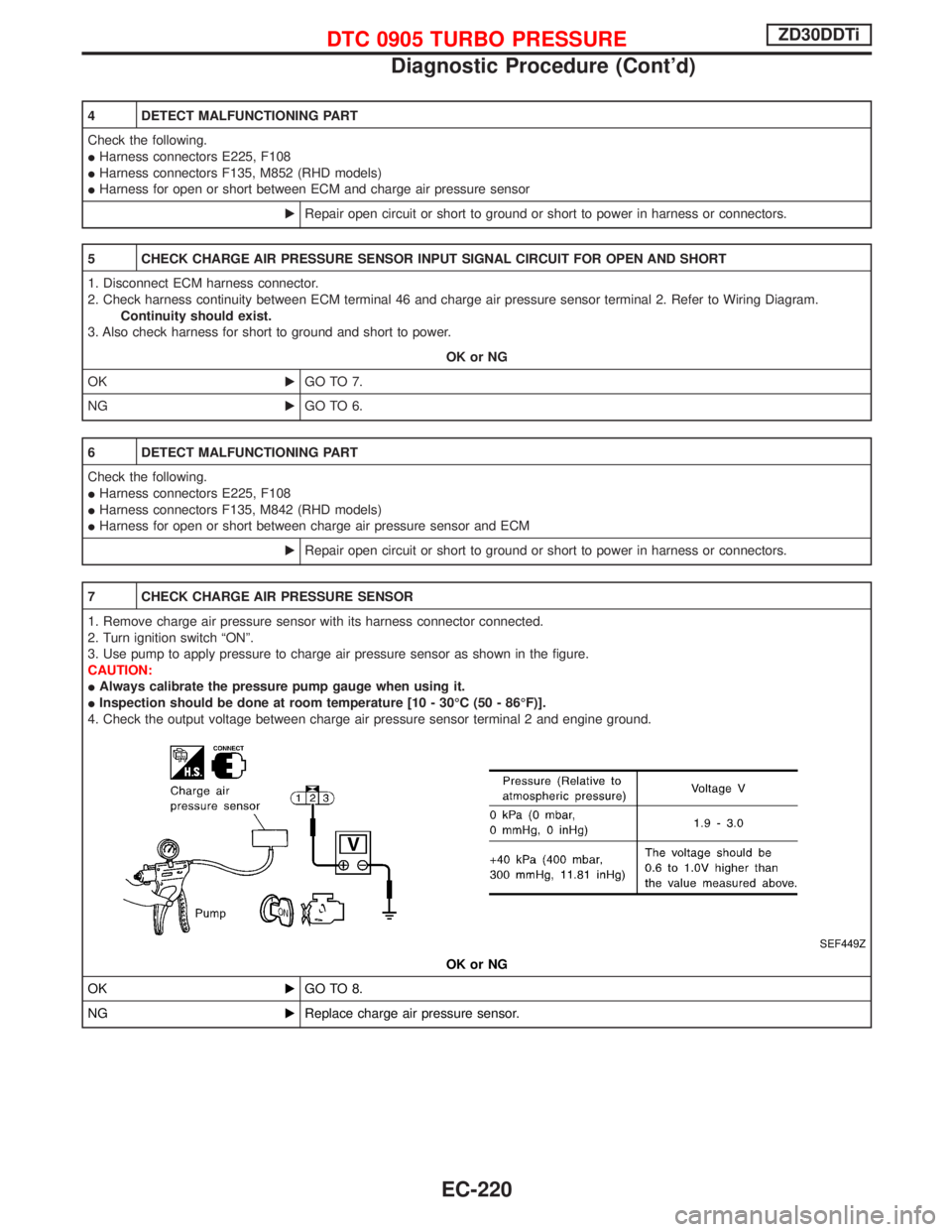

7 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

IAlways calibrate the pressure pump gauge when using it.

IInspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OKEGO TO 8.

NGEReplace charge air pressure sensor.

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-220

Page 583 of 1767

8 CHECK SHIELD CIRCUIT

1. Disconnect charge air pressure sensor sub-harness connectors E225, F108 and ECM harness connector.

2. Check continuity between boost sensor sub-harness connector terminal 15 and ground.

Continuity should exist.

3. Check continuity between ECM terminal 43 and ground.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OKEGO TO 10.

NGEGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

IHarness connectors F135, M842 (RHD models)

IHarness for open or short between charge air pressure sensor and ground

IHarness for open or short between ECM and ground

E

10 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-221

Page 584 of 1767

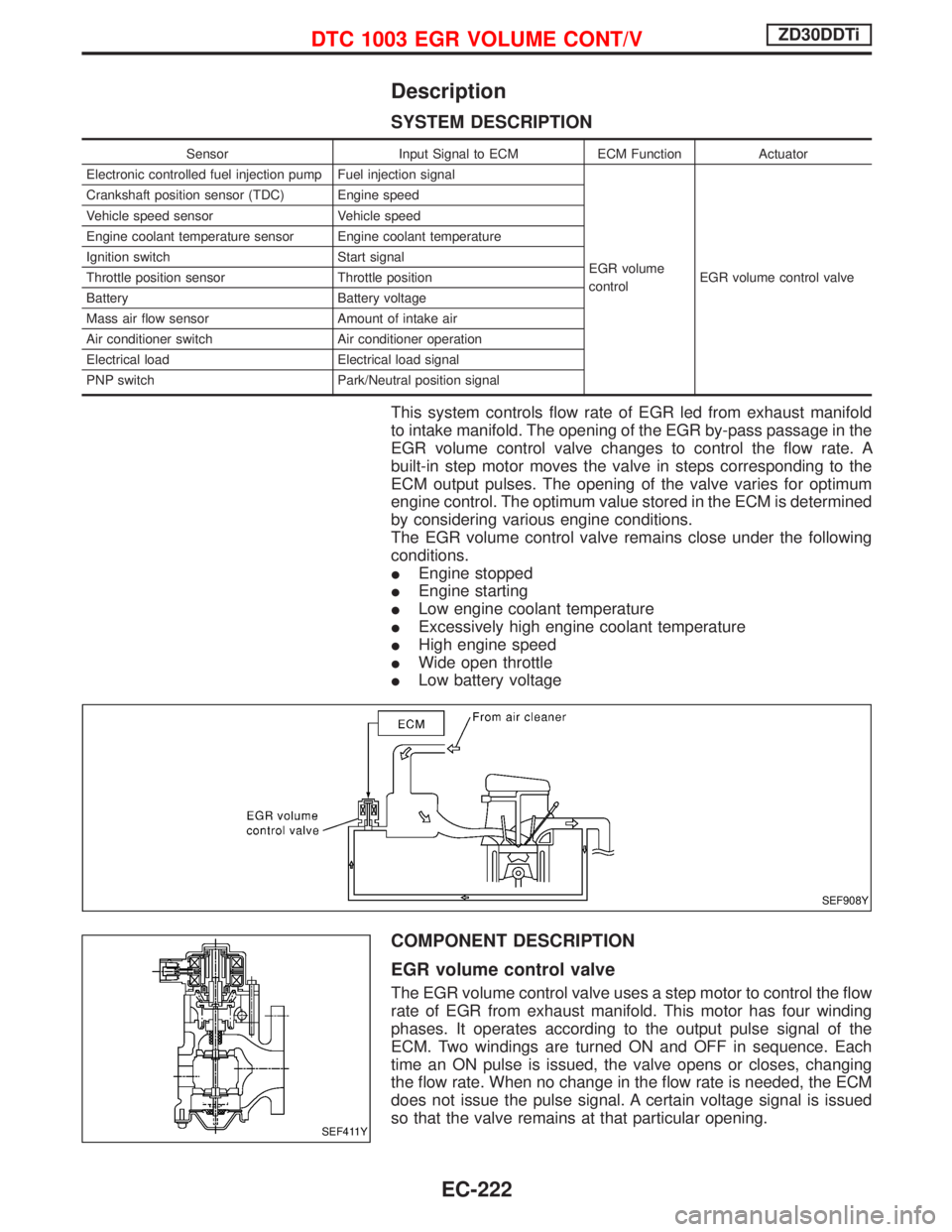

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECM ECM Function Actuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume

controlEGR volume control valve Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Battery Battery voltage

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions.

The EGR volume control valve remains close under the following

conditions.

IEngine stopped

IEngine starting

ILow engine coolant temperature

IExcessively high engine coolant temperature

IHigh engine speed

IWide open throttle

ILow battery voltage

COMPONENT DESCRIPTION

EGR volume control valve

The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

SEF908Y

SEF411Y

DTC 1003 EGR VOLUME CONT/VZD30DDTi

EC-222

Page 594 of 1767

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives the

signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

SEF437Y

DTC 1004 FUEL CUT SYSTEM1ZD30DDTi

EC-232