general NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 50 of 1767

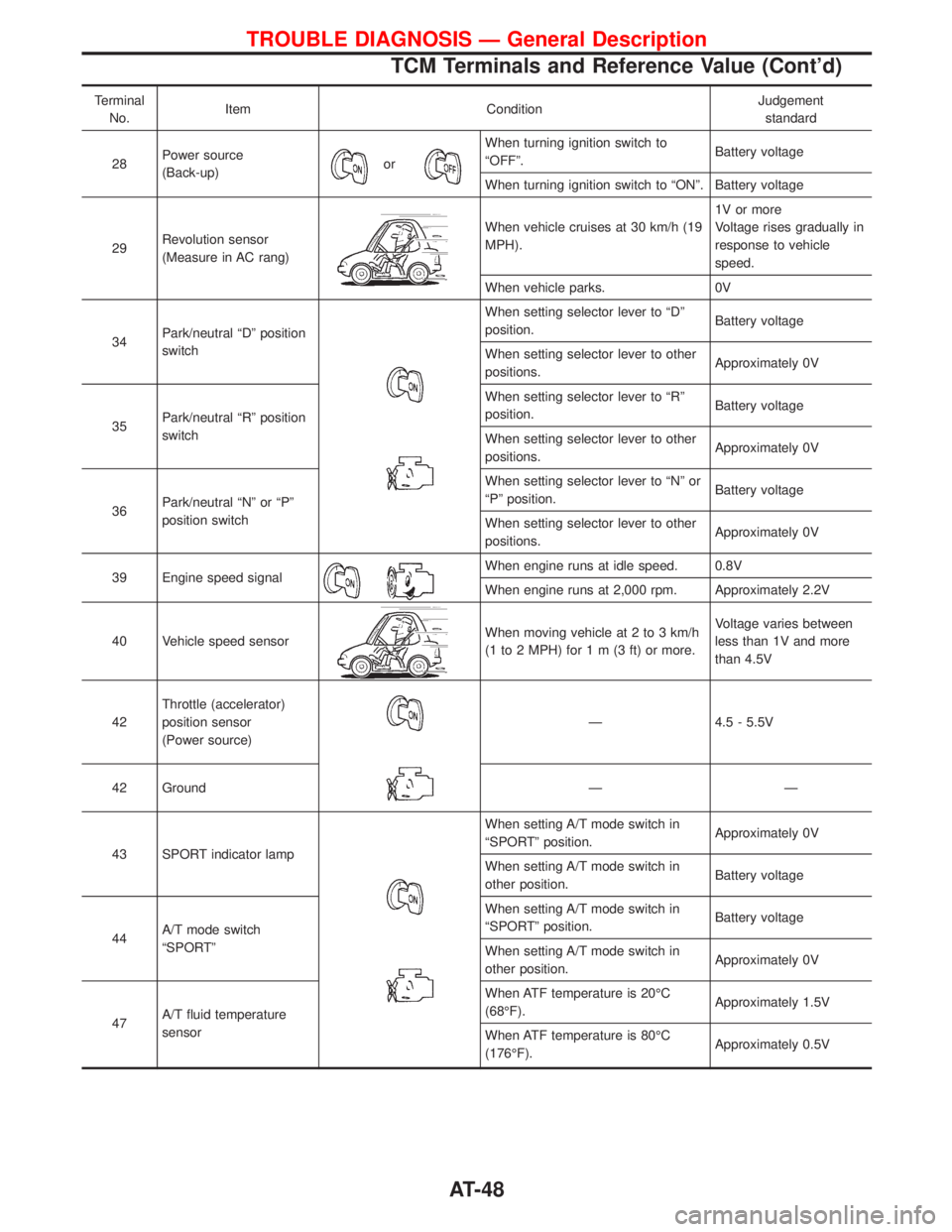

Terminal

No.Item ConditionJudgement

standard

28Power source

(Back-up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to ªONº. Battery voltage

29Revolution sensor

(Measure in AC rang)

When vehicle cruises at 30 km/h (19

MPH).1V or more

Voltage rises gradually in

response to vehicle

speed.

When vehicle parks. 0V

34Park/neutral ªDº position

switch

When setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

35Park/neutral ªRº position

switchWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

36Park/neutral ªNº or ªPº

position switchWhen setting selector lever to ªNº or

ªPº position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

39 Engine speed signal

When engine runs at idle speed. 0.8V

When engine runs at 2,000 rpm. Approximately 2.2V

40 Vehicle speed sensor

When moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for1m(3ft)ormore.Voltage varies between

less than 1V and more

than 4.5V

42Throttle (accelerator)

position sensor

(Power source)

Ð 4.5 - 5.5V

42 Ground Ð Ð

43 SPORT indicator lamp

When setting A/T mode switch in

ªSPORTº position.Approximately 0V

When setting A/T mode switch in

other position.Battery voltage

44A/T mode switch

ªSPORTºWhen setting A/T mode switch in

ªSPORTº position.Battery voltage

When setting A/T mode switch in

other position.Approximately 0V

47A/T fluid temperature

sensorWhen ATF temperature is 20ÉC

(68ÉF).Approximately 1.5V

When ATF temperature is 80ÉC

(176ÉF).Approximately 0.5V

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-48

Page 198 of 1767

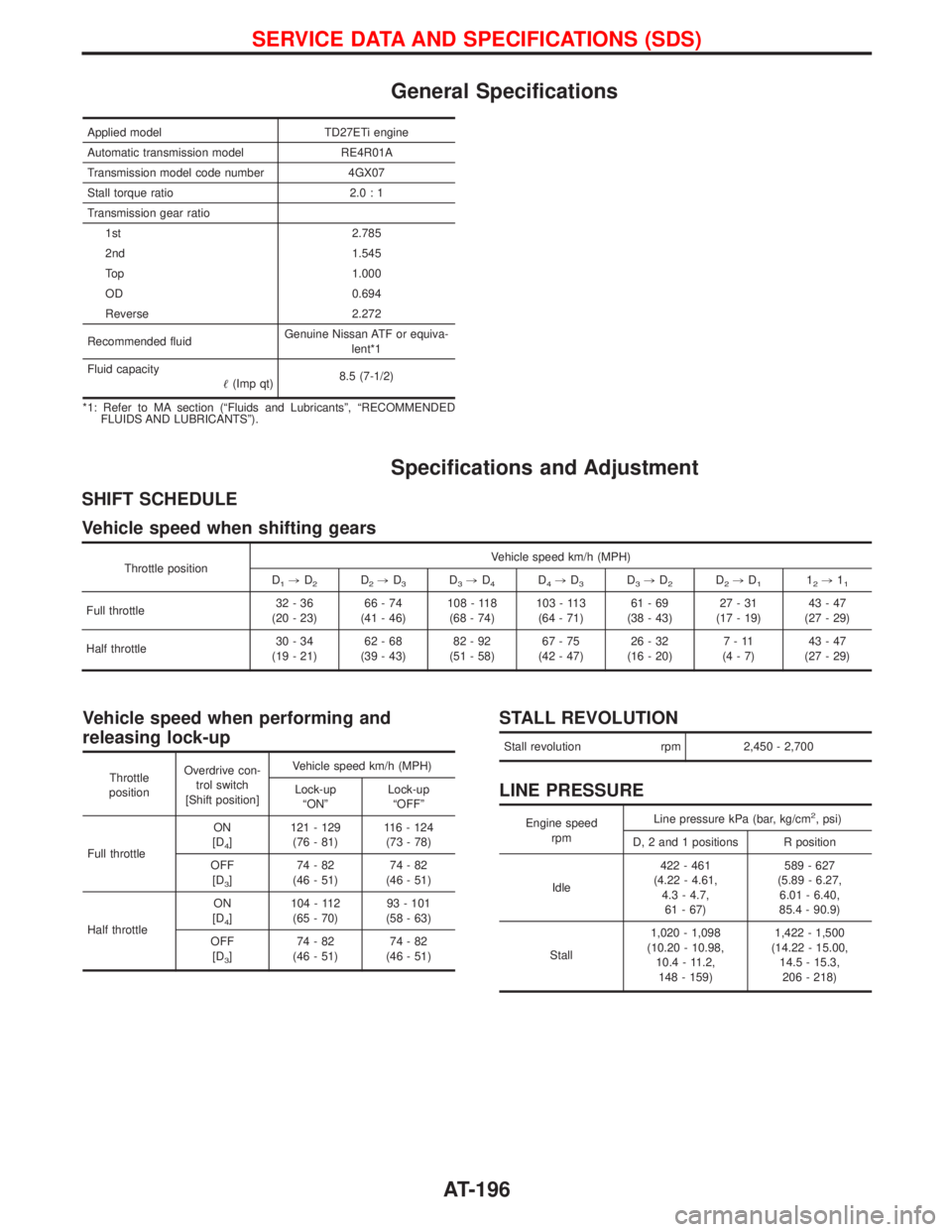

General Specifications

Applied model TD27ETi engine

Automatic transmission model RE4R01A

Transmission model code number 4GX07

Stall torque ratio 2.0 : 1

Transmission gear ratio

1st 2.785

2nd 1.545

Top 1.000

OD 0.694

Reverse 2.272

Recommended fluidGenuine Nissan ATF or equiva-

lent*1

Fluid capacity

(Imp qt)8.5 (7-1/2)

*1: Refer to MA section (ªFluids and Lubricantsº, ªRECOMMENDED

FLUIDS AND LUBRICANTSº).

Specifications and Adjustment

SHIFT SCHEDULE

Vehicle speed when shifting gears

Throttle positionVehicle speed km/h (MPH)

D1,D2D2,D3D3,D4D4,D3D3,D2D2,D112,11

Full throttle32-36

(20 - 23)66-74

(41 - 46)108 - 118

(68 - 74)103 - 113

(64 - 71)61-69

(38 - 43)27-31

(17 - 19)43-47

(27 - 29)

Half throttle30-34

(19 - 21)62-68

(39 - 43)82-92

(51 - 58)67-75

(42 - 47)26-32

(16 - 20)7-11

(4-7)43-47

(27 - 29)

Vehicle speed when performing and

releasing lock-up

Throttle

positionOverdrive con-

trol switch

[Shift position]Vehicle speed km/h (MPH)

Lock-up

ªONºLock-up

ªOFFº

Full throttleON

[D

4]121 - 129

(76 - 81)116 - 124

(73 - 78)

OFF

[D

3]74-82

(46 - 51)74-82

(46 - 51)

Half throttleON

[D

4]104 - 112

(65 - 70)93 - 101

(58 - 63)

OFF

[D

3]74-82

(46 - 51)74-82

(46 - 51)

STALL REVOLUTION

Stall revolution rpm 2,450 - 2,700

LINE PRESSURE

Engine speed

rpmLine pressure kPa (bar, kg/cm2, psi)

D, 2 and 1 positions R position

Idle422 - 461

(4.22 - 4.61,

4.3 - 4.7,

61 - 67)589 - 627

(5.89 - 6.27,

6.01 - 6.40,

85.4 - 90.9)

Stall1,020 - 1,098

(10.20 - 10.98,

10.4 - 11.2,

148 - 159)1,422 - 1,500

(14.22 - 15.00,

14.5 - 15.3,

206 - 218)

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-196

Page 204 of 1767

Diagnostic Procedure 2 (Warning lamp stays on

when ignition switch is turned ON)............................69

Diagnostic Procedure 3 (ABS actuator solenoid

valve and solenoid valve relay) .................................71

Diagnostic Procedure 4 (Wheel sensor or rotor) ......73

Diagnostic Procedure 5 (Motor Relay or motor) .......75

Diagnostic Procedure 7 (Low voltage) ......................77

Diagnostic Procedure 8 (G sensor) ...........................78

Diagnostic Procedure 9 (Control unit) .......................79

Diagnostic Procedure 10 (Pedal vibration and

noise) .........................................................................80Diagnostic Procedure 11 (Long stopping

distance) ....................................................................80

Diagnostic Procedure 12 (Unexpected pedal

action) ........................................................................81

Diagnostic Procedure 13 ...........................................82

Diagnostic Procedure 14 ...........................................82

Electrical Components Inspection .............................83

SERVICE DATA AND SPECIFICATIONS (SDS)..........84

General Specifications ...............................................84

Inspection and Adjustment ........................................85

CONTENTS(Cont'd)

BR-2

Page 286 of 1767

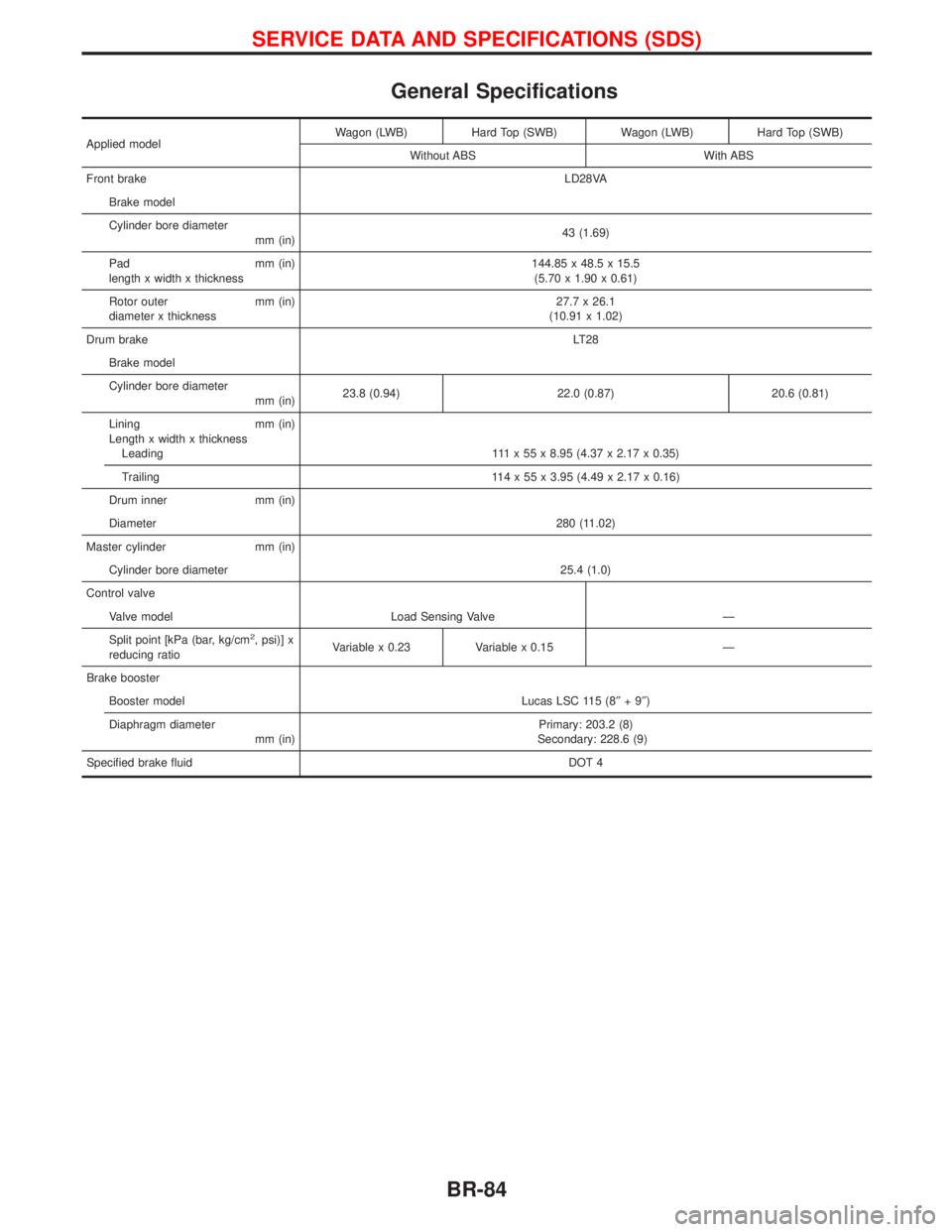

General Specifications

Applied modelWagon (LWB) Hard Top (SWB) Wagon (LWB) Hard Top (SWB)

Without ABS With ABS

Front brakeLD28VA

Brake model

Cylinder bore diameter

mm (in)43 (1.69)

Pad mm (in)

length x width x thickness144.85 x 48.5 x 15.5

(5.70 x 1.90 x 0.61)

Rotor outer mm (in)

diameter x thickness27.7 x 26.1

(10.91 x 1.02)

Drum brakeLT28

Brake model

Cylinder bore diameter

mm (in)23.8 (0.94) 22.0 (0.87) 20.6 (0.81)

Lining mm (in)

Length x width x thickness

Leading 111 x 55 x 8.95 (4.37 x 2.17 x 0.35)

Trailing 114 x 55 x 3.95 (4.49 x 2.17 x 0.16)

Drum inner mm (in)

Diameter280 (11.02)

Master cylinder mm (in)

Cylinder bore diameter 25.4 (1.0)

Control valve

Valve model Load Sensing Valve Ð

Split point [kPa (bar, kg/cm

2, psi)] x

reducing ratioVariable x 0.23 Variable x 0.15 Ð

Brake booster

Booster model Lucas LSC 115 (8²+9²)

Diaphragm diameter

mm (in)Primary: 203.2 (8)

Secondary: 228.6 (9)

Specified brake fluidDOT 4

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-84

Page 349 of 1767

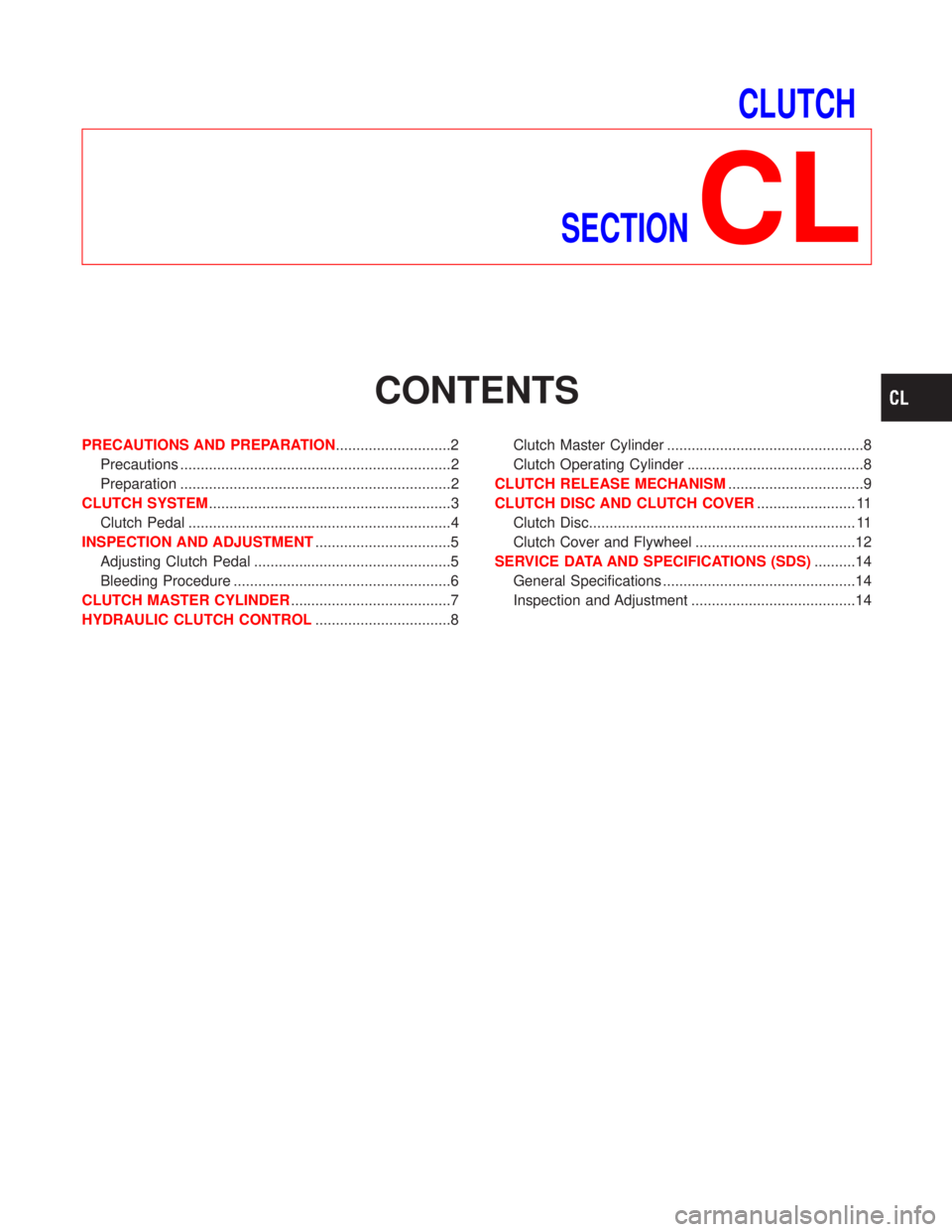

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS AND PREPARATION............................2

Precautions ..................................................................2

Preparation ..................................................................2

CLUTCH SYSTEM...........................................................3

Clutch Pedal ................................................................4

INSPECTION AND ADJUSTMENT.................................5

Adjusting Clutch Pedal ................................................5

Bleeding Procedure .....................................................6

CLUTCH MASTER CYLINDER.......................................7

HYDRAULIC CLUTCH CONTROL.................................8Clutch Master Cylinder ................................................8

Clutch Operating Cylinder ...........................................8

CLUTCH RELEASE MECHANISM.................................9

CLUTCH DISC AND CLUTCH COVER........................ 11

Clutch Disc................................................................. 11

Clutch Cover and Flywheel .......................................12

SERVICE DATA AND SPECIFICATIONS (SDS)..........14

General Specifications ...............................................14

Inspection and Adjustment ........................................14

Page 362 of 1767

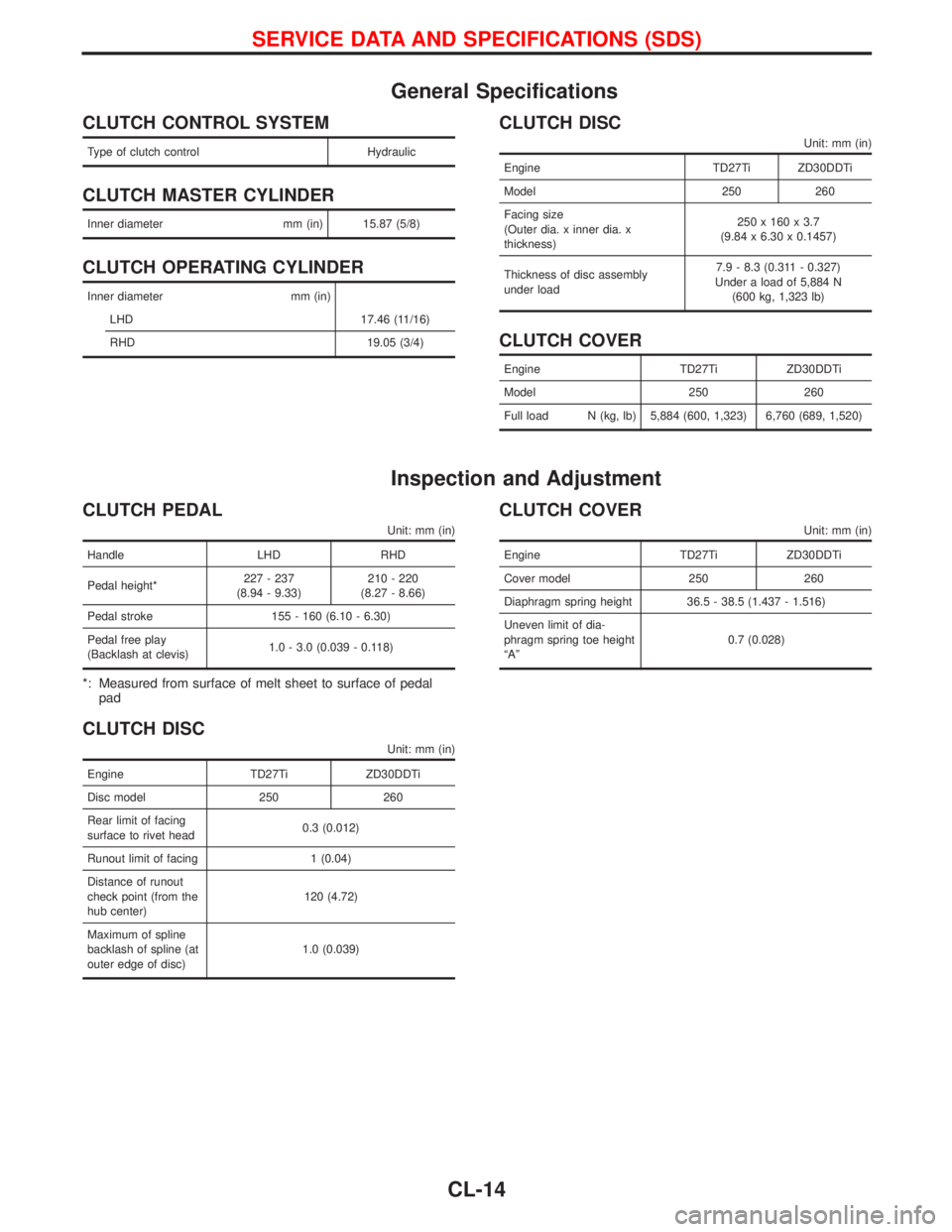

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH MASTER CYLINDER

Inner diameter mm (in) 15.87 (5/8)

CLUTCH OPERATING CYLINDER

Inner diameter mm (in)

LHD 17.46 (11/16)

RHD 19.05 (3/4)

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Model 250 260

Facing size

(Outer dia. x inner dia. x

thickness)250 x 160 x 3.7

(9.84 x 6.30 x 0.1457)

Thickness of disc assembly

under load7.9 - 8.3 (0.311 - 0.327)

Under a load of 5,884 N

(600 kg, 1,323 lb)

CLUTCH COVER

Engine TD27Ti ZD30DDTi

Model 250 260

Full load N (kg, lb) 5,884 (600, 1,323) 6,760 (689, 1,520)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in)

Handle LHD RHD

Pedal height*227 - 237

(8.94 - 9.33)210 - 220

(8.27 - 8.66)

Pedal stroke 155 - 160 (6.10 - 6.30)

Pedal free play

(Backlash at clevis)1.0 - 3.0 (0.039 - 0.118)

*: Measured from surface of melt sheet to surface of pedal

pad

CLUTCH DISC

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Disc model 250 260

Rear limit of facing

surface to rivet head0.3 (0.012)

Runout limit of facing 1 (0.04)

Distance of runout

check point (from the

hub center)120 (4.72)

Maximum of spline

backlash of spline (at

outer edge of disc)1.0 (0.039)

CLUTCH COVER

Unit: mm (in)

Engine TD27Ti ZD30DDTi

Cover model 250 260

Diaphragm spring height 36.5 - 38.5 (1.437 - 1.516)

Uneven limit of dia-

phragm spring toe height

ªAº0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-14

Page 363 of 1767

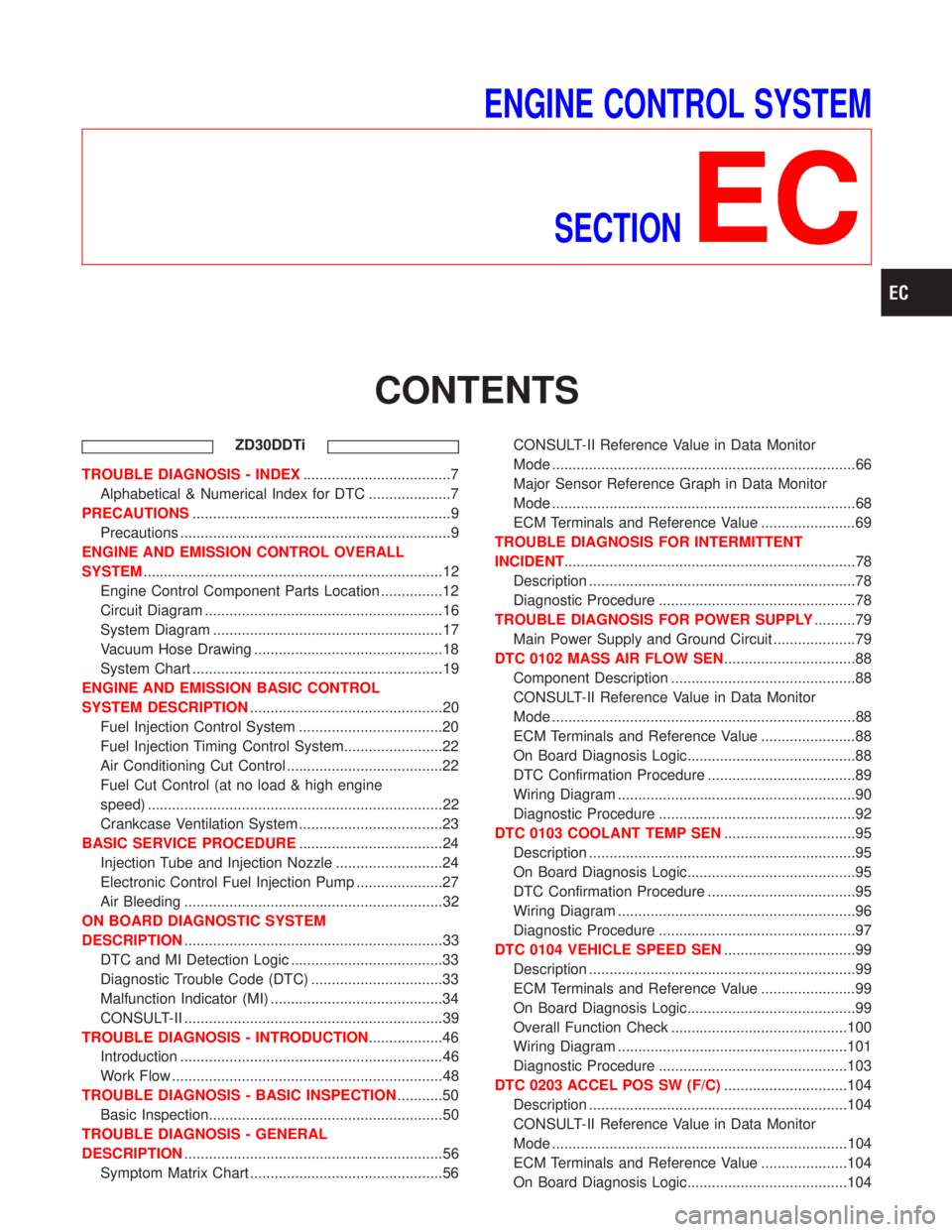

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

ZD30DDTi

TROUBLE DIAGNOSIS - INDEX....................................7

Alphabetical & Numerical Index for DTC ....................7

PRECAUTIONS...............................................................9

Precautions ..................................................................9

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................12

Engine Control Component Parts Location ...............12

Circuit Diagram ..........................................................16

System Diagram ........................................................17

Vacuum Hose Drawing ..............................................18

System Chart .............................................................19

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................20

Fuel Injection Control System ...................................20

Fuel Injection Timing Control System........................22

Air Conditioning Cut Control ......................................22

Fuel Cut Control (at no load & high engine

speed) ........................................................................22

Crankcase Ventilation System ...................................23

BASIC SERVICE PROCEDURE...................................24

Injection Tube and Injection Nozzle ..........................24

Electronic Control Fuel Injection Pump .....................27

Air Bleeding ...............................................................32

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

DTC and MI Detection Logic .....................................33

Diagnostic Trouble Code (DTC) ................................33

Malfunction Indicator (MI) ..........................................34

CONSULT-II ...............................................................39

TROUBLE DIAGNOSIS - INTRODUCTION..................46

Introduction ................................................................46

Work Flow ..................................................................48

TROUBLE DIAGNOSIS - BASIC INSPECTION...........50

Basic Inspection.........................................................50

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................56

Symptom Matrix Chart ...............................................56CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................66

Major Sensor Reference Graph in Data Monitor

Mode ..........................................................................68

ECM Terminals and Reference Value .......................69

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.......................................................................78

Description .................................................................78

Diagnostic Procedure ................................................78

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........79

Main Power Supply and Ground Circuit ....................79

DTC 0102 MASS AIR FLOW SEN................................88

Component Description .............................................88

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................88

ECM Terminals and Reference Value .......................88

On Board Diagnosis Logic.........................................88

DTC Confirmation Procedure ....................................89

Wiring Diagram ..........................................................90

Diagnostic Procedure ................................................92

DTC 0103 COOLANT TEMP SEN................................95

Description .................................................................95

On Board Diagnosis Logic.........................................95

DTC Confirmation Procedure ....................................95

Wiring Diagram ..........................................................96

Diagnostic Procedure ................................................97

DTC 0104 VEHICLE SPEED SEN................................99

Description .................................................................99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.........................................99

Overall Function Check ...........................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................103

DTC 0203 ACCEL POS SW (F/C)..............................104

Description ...............................................................104

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................104

ECM Terminals and Reference Value .....................104

On Board Diagnosis Logic.......................................104

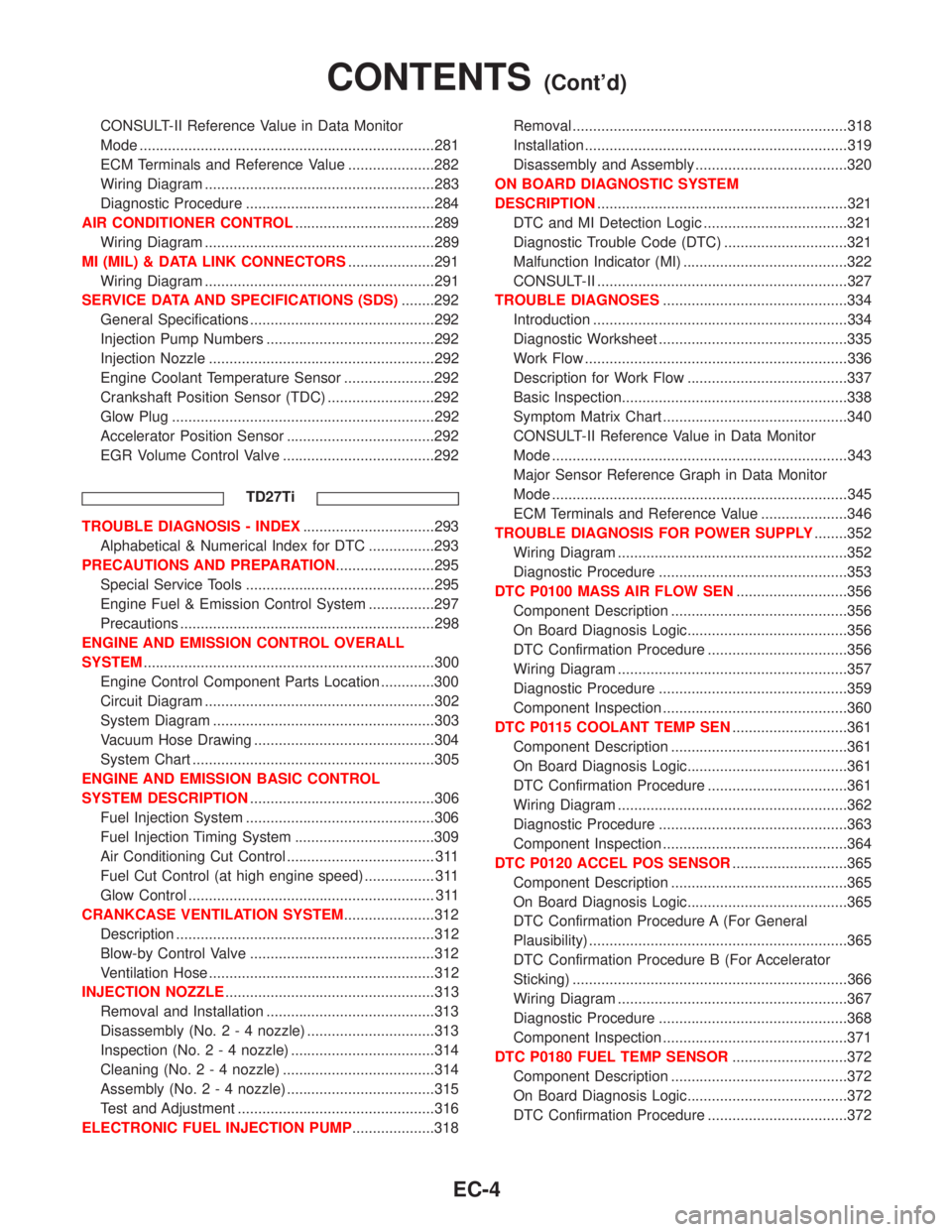

Page 366 of 1767

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................281

ECM Terminals and Reference Value .....................282

Wiring Diagram ........................................................283

Diagnostic Procedure ..............................................284

AIR CONDITIONER CONTROL..................................289

Wiring Diagram ........................................................289

MI (MIL) & DATA LINK CONNECTORS.....................291

Wiring Diagram ........................................................291

SERVICE DATA AND SPECIFICATIONS (SDS)........292

General Specifications .............................................292

Injection Pump Numbers .........................................292

Injection Nozzle .......................................................292

Engine Coolant Temperature Sensor ......................292

Crankshaft Position Sensor (TDC) ..........................292

Glow Plug ................................................................292

Accelerator Position Sensor ....................................292

EGR Volume Control Valve .....................................292

TD27Ti

TROUBLE DIAGNOSIS - INDEX................................293

Alphabetical & Numerical Index for DTC ................293

PRECAUTIONS AND PREPARATION........................295

Special Service Tools ..............................................295

Engine Fuel & Emission Control System ................297

Precautions ..............................................................298

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................300

Engine Control Component Parts Location .............300

Circuit Diagram ........................................................302

System Diagram ......................................................303

Vacuum Hose Drawing ............................................304

System Chart ...........................................................305

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................306

Fuel Injection System ..............................................306

Fuel Injection Timing System ..................................309

Air Conditioning Cut Control .................................... 311

Fuel Cut Control (at high engine speed) ................. 311

Glow Control ............................................................ 311

CRANKCASE VENTILATION SYSTEM......................312

Description ...............................................................312

Blow-by Control Valve .............................................312

Ventilation Hose .......................................................312

INJECTION NOZZLE...................................................313

Removal and Installation .........................................313

Disassembly (No.2-4nozzle) ...............................313

Inspection (No.2-4nozzle) ...................................314

Cleaning (No.2-4nozzle) .....................................314

Assembly (No.2-4nozzle) ....................................315

Test and Adjustment ................................................316

ELECTRONIC FUEL INJECTION PUMP....................318Removal ...................................................................318

Installation ................................................................319

Disassembly and Assembly .....................................320

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................321

DTC and MI Detection Logic ...................................321

Diagnostic Trouble Code (DTC) ..............................321

Malfunction Indicator (MI) ........................................322

CONSULT-II .............................................................327

TROUBLE DIAGNOSES.............................................334

Introduction ..............................................................334

Diagnostic Worksheet ..............................................335

Work Flow ................................................................336

Description for Work Flow .......................................337

Basic Inspection.......................................................338

Symptom Matrix Chart .............................................340

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................343

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................345

ECM Terminals and Reference Value .....................346

TROUBLE DIAGNOSIS FOR POWER SUPPLY........352

Wiring Diagram ........................................................352

Diagnostic Procedure ..............................................353

DTC P0100 MASS AIR FLOW SEN...........................356

Component Description ...........................................356

On Board Diagnosis Logic.......................................356

DTC Confirmation Procedure ..................................356

Wiring Diagram ........................................................357

Diagnostic Procedure ..............................................359

Component Inspection .............................................360

DTC P0115 COOLANT TEMP SEN............................361

Component Description ...........................................361

On Board Diagnosis Logic.......................................361

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................363

Component Inspection .............................................364

DTC P0120 ACCEL POS SENSOR............................365

Component Description ...........................................365

On Board Diagnosis Logic.......................................365

DTC Confirmation Procedure A (For General

Plausibility) ...............................................................365

DTC Confirmation Procedure B (For Accelerator

Sticking) ...................................................................366

Wiring Diagram ........................................................367

Diagnostic Procedure ..............................................368

Component Inspection .............................................371

DTC P0180 FUEL TEMP SENSOR............................372

Component Description ...........................................372

On Board Diagnosis Logic.......................................372

DTC Confirmation Procedure ..................................372

CONTENTS(Cont'd)

EC-4

Page 368 of 1767

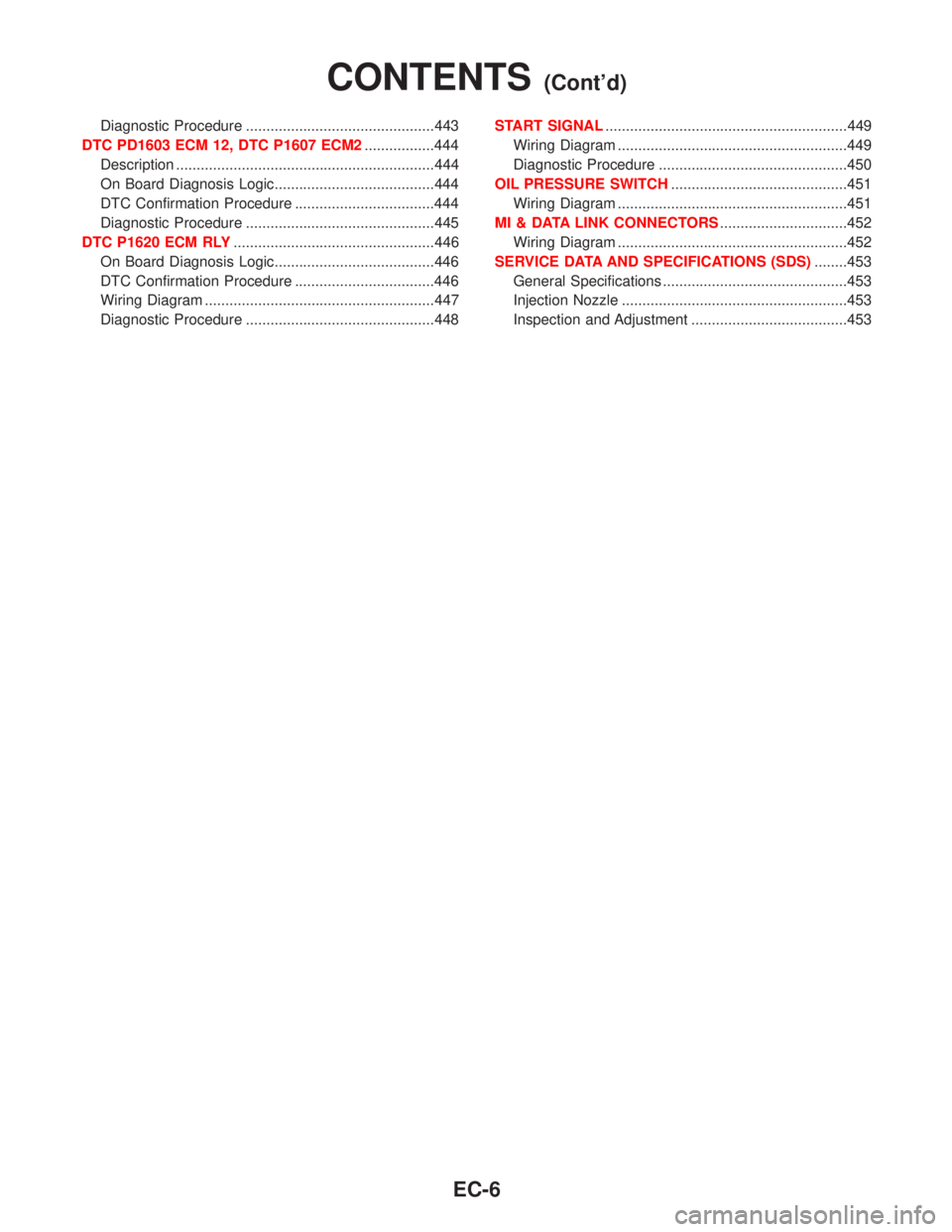

Diagnostic Procedure ..............................................443

DTC PD1603 ECM 12, DTC P1607 ECM2.................444

Description ...............................................................444

On Board Diagnosis Logic.......................................444

DTC Confirmation Procedure ..................................444

Diagnostic Procedure ..............................................445

DTC P1620 ECM RLY.................................................446

On Board Diagnosis Logic.......................................446

DTC Confirmation Procedure ..................................446

Wiring Diagram ........................................................447

Diagnostic Procedure ..............................................448START SIGNAL...........................................................449

Wiring Diagram ........................................................449

Diagnostic Procedure ..............................................450

OIL PRESSURE SWITCH...........................................451

Wiring Diagram ........................................................451

MI & DATA LINK CONNECTORS...............................452

Wiring Diagram ........................................................452

SERVICE DATA AND SPECIFICATIONS (SDS)........453

General Specifications .............................................453

Injection Nozzle .......................................................453

Inspection and Adjustment ......................................453

CONTENTS(Cont'd)

EC-6

Page 408 of 1767

Introduction

The engine has an ECM to control major systems such as fuel

injection control, fuel injection timing control, glow control system,

etc. The ECM accepts input signals from sensors and instantly

drives electronic control fuel injection pump. It is essential that both

input and output signals are proper and stable. At the same time,

it is important that there are no problems such as vacuum leaks,

or other problems with the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº, EC-48.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

DIAGNOSTIC WORKSHEET

There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

SEF858S

SEF233G

SEF234G

SEF907L

TROUBLE DIAGNOSIS Ð INTRODUCTIONZD30DDTi

EC-46