ignition NISSAN TERRANO 2002 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 47 of 1767

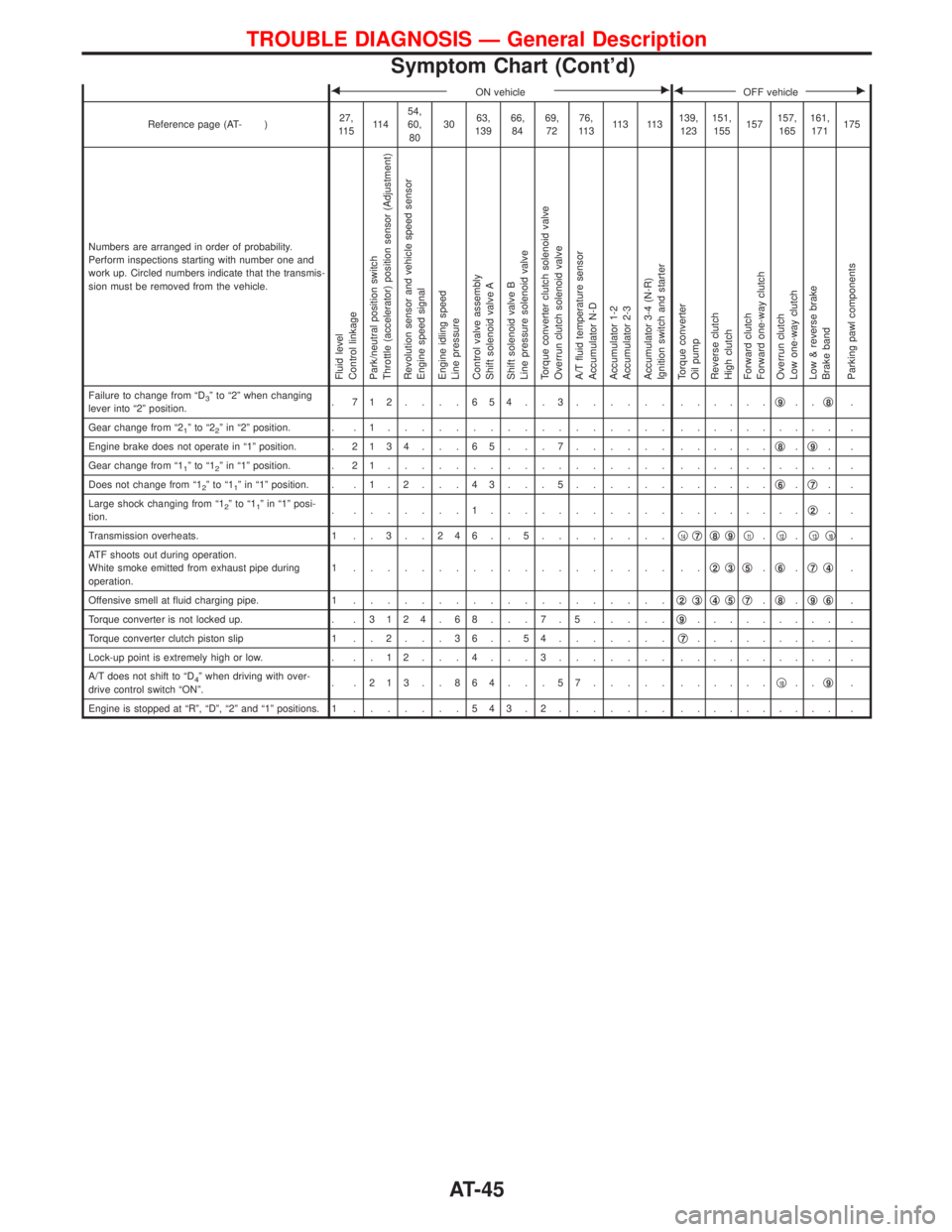

FON vehicleEFOFF vehicleE

Reference page (AT- )27,

11 511 454,

60,

803063,

13966,

8469,

7276,

11 311 3 11 3139,

123151,

155157157,

165161,

171175

Numbers are arranged in order of probability.

Perform inspections starting with number one and

work up. Circled numbers indicate that the transmis-

sion must be removed from the vehicle.

Fluid level

Control linkage

Park/neutral position switch

Throttle (accelerator) position sensor (Adjustment)

Revolution sensor and vehicle speed sensor

Engine speed signal

Engine idling speed

Line pressure

Control valve assembly

Shift solenoid valve A

Shift solenoid valve B

Line pressure solenoid valve

Torque converter clutch solenoid valve

Overrun clutch solenoid valve

A/T fluid temperature sensor

Accumulator N-D

Accumulator 1-2

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition switch and starter

Torque converter

Oil pump

Reverse clutch

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

Low one-way clutch

Low & reverse brake

Brake band

Parking pawl components

Failure to change from ªD3º to ª2º when changing

lever into ª2º position.. 712....654..3...... ......q9..q8.

Gear change from ª2

1ºtoª22º in ª2º position. . . 1................. .......... .

Engine brake does not operate in ª1º position. .2134 . . . 65 . . . 7...... ......q

8.q9..

Gear change from ª1

1ºtoª12º in ª1º position. . 2 1................. .......... .

Does not change from ª1

2ºtoª11º in ª1º position. . . 1 . 2 . . . 4 3 . . . 5...... ......q6.q7..

Large shock changing from ª1

2ºtoª11º in ª1º posi-

tion.. .......1........... ........q2..

Transmission overheats. 1 . . 3 . . 2 4 6 . . 5........q

14q7q8q9q11.q12.q13q10.

ATF shoots out during operation.

White smoke emitted from exhaust pipe during

operation.1 ................... ..q

2q3q5.q6.q7q4.

Offensive smell at fluid charging pipe. 1...................q

2q3q4q5q7.q8.q9q6.

Torque converter is not locked up. . .3124 . 68 . . . 7 . 5.....q

9......... .

Torque converter clutch piston slip 1 . . 2 . . . 3 6 . . 5 4.......q

7......... .

Lock-up point is extremely high or low. . . . 1 2 . . . 4 . . . 3....... .......... .

A/T does not shift to ªD

4º when driving with over-

drive control switch ªONº.. .213..864...57..... ......q10..q9.

Engine is stopped at ªRº, ªDº, ª2º and ª1º positions. 1.......543.2....... .......... .

TROUBLE DIAGNOSIS Ð General Description

Symptom Chart (Cont'd)

AT-45

Page 49 of 1767

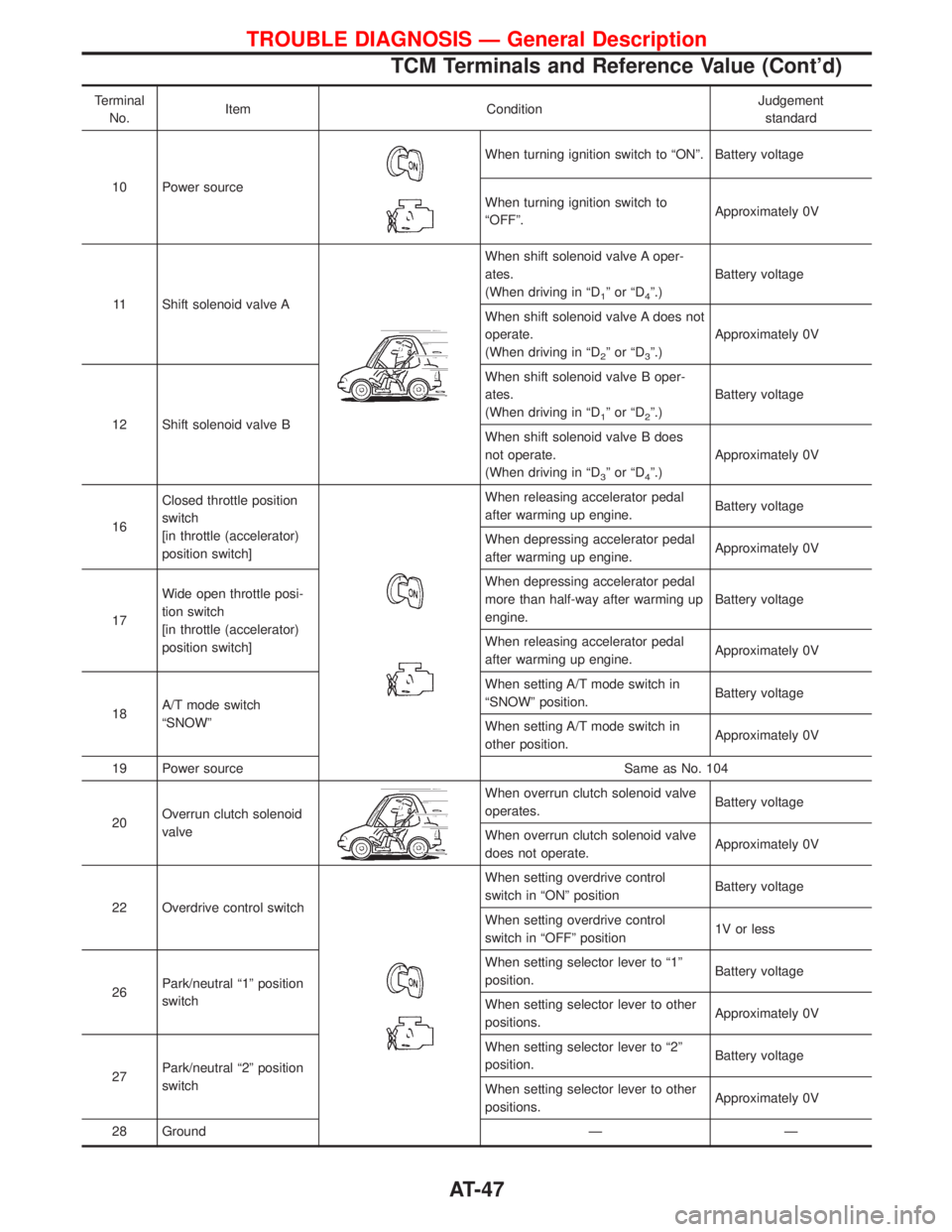

Terminal

No.Item ConditionJudgement

standard

10 Power source

When turning ignition switch to ªONº. Battery voltage

When turning ignition switch to

ªOFFº.Approximately 0V

11 Shift solenoid valve A

When shift solenoid valve A oper-

ates.

(When driving in ªD

1ºorªD4º.)Battery voltage

When shift solenoid valve A does not

operate.

(When driving in ªD

2ºorªD3º.)Approximately 0V

12 Shift solenoid valve BWhen shift solenoid valve B oper-

ates.

(When driving in ªD

1ºorªD2º.)Battery voltage

When shift solenoid valve B does

not operate.

(When driving in ªD

3ºorªD4º.)Approximately 0V

16Closed throttle position

switch

[in throttle (accelerator)

position switch]

When releasing accelerator pedal

after warming up engine.Battery voltage

When depressing accelerator pedal

after warming up engine.Approximately 0V

17Wide open throttle posi-

tion switch

[in throttle (accelerator)

position switch]When depressing accelerator pedal

more than half-way after warming up

engine.Battery voltage

When releasing accelerator pedal

after warming up engine.Approximately 0V

18A/T mode switch

ªSNOWºWhen setting A/T mode switch in

ªSNOWº position.Battery voltage

When setting A/T mode switch in

other position.Approximately 0V

19 Power source Same as No. 104

20Overrun clutch solenoid

valve

When overrun clutch solenoid valve

operates.Battery voltage

When overrun clutch solenoid valve

does not operate.Approximately 0V

22 Overdrive control switch

When setting overdrive control

switch in ªONº positionBattery voltage

When setting overdrive control

switch in ªOFFº position1V or less

26Park/neutral ª1º position

switchWhen setting selector lever to ª1º

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

27Park/neutral ª2º position

switchWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

28 Ground Ð Ð

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-47

Page 50 of 1767

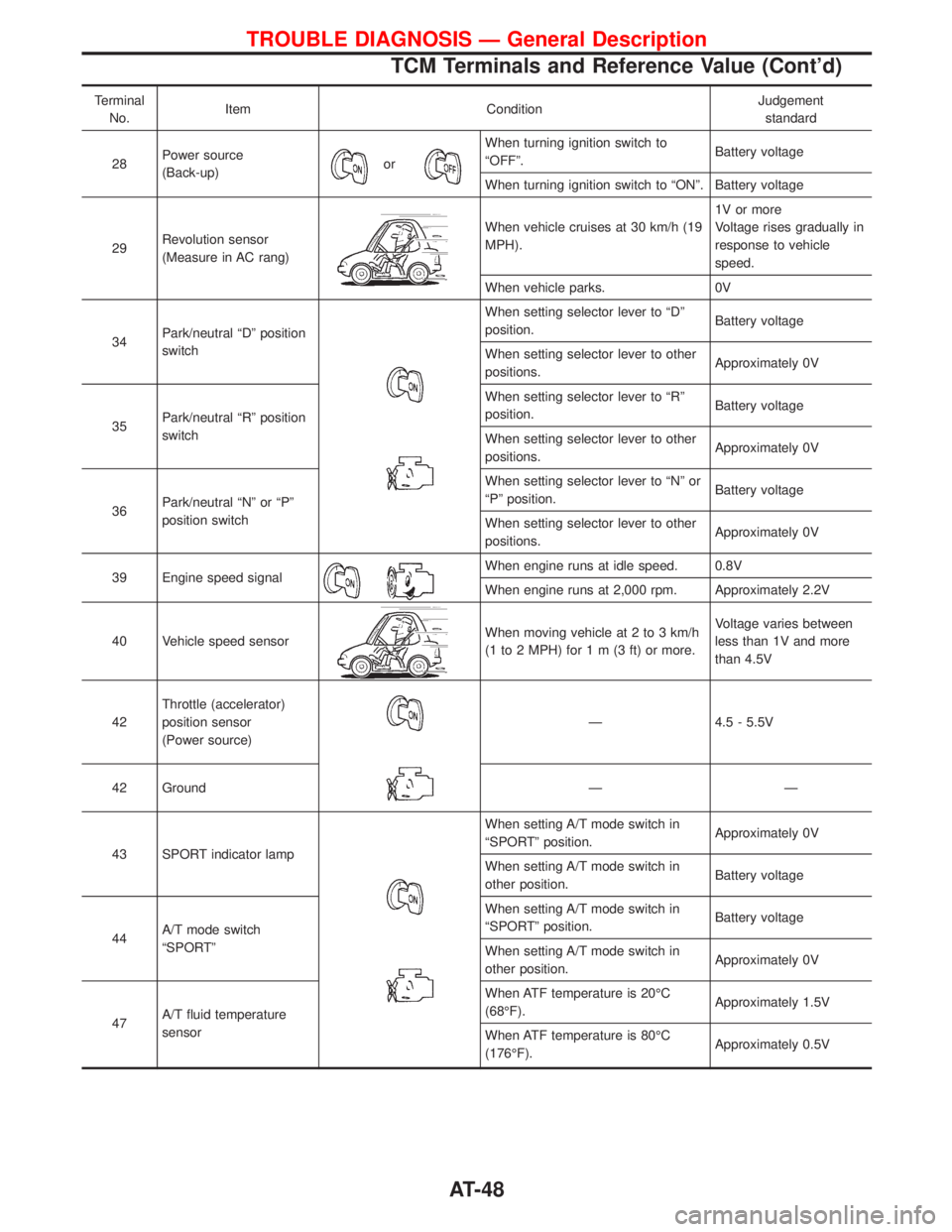

Terminal

No.Item ConditionJudgement

standard

28Power source

(Back-up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to ªONº. Battery voltage

29Revolution sensor

(Measure in AC rang)

When vehicle cruises at 30 km/h (19

MPH).1V or more

Voltage rises gradually in

response to vehicle

speed.

When vehicle parks. 0V

34Park/neutral ªDº position

switch

When setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

35Park/neutral ªRº position

switchWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

36Park/neutral ªNº or ªPº

position switchWhen setting selector lever to ªNº or

ªPº position.Battery voltage

When setting selector lever to other

positions.Approximately 0V

39 Engine speed signal

When engine runs at idle speed. 0.8V

When engine runs at 2,000 rpm. Approximately 2.2V

40 Vehicle speed sensor

When moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for1m(3ft)ormore.Voltage varies between

less than 1V and more

than 4.5V

42Throttle (accelerator)

position sensor

(Power source)

Ð 4.5 - 5.5V

42 Ground Ð Ð

43 SPORT indicator lamp

When setting A/T mode switch in

ªSPORTº position.Approximately 0V

When setting A/T mode switch in

other position.Battery voltage

44A/T mode switch

ªSPORTºWhen setting A/T mode switch in

ªSPORTº position.Battery voltage

When setting A/T mode switch in

other position.Approximately 0V

47A/T fluid temperature

sensorWhen ATF temperature is 20ÉC

(68ÉF).Approximately 1.5V

When ATF temperature is 80ÉC

(176ÉF).Approximately 0.5V

TROUBLE DIAGNOSIS Ð General Description

TCM Terminals and Reference Value (Cont'd)

AT-48

Page 63 of 1767

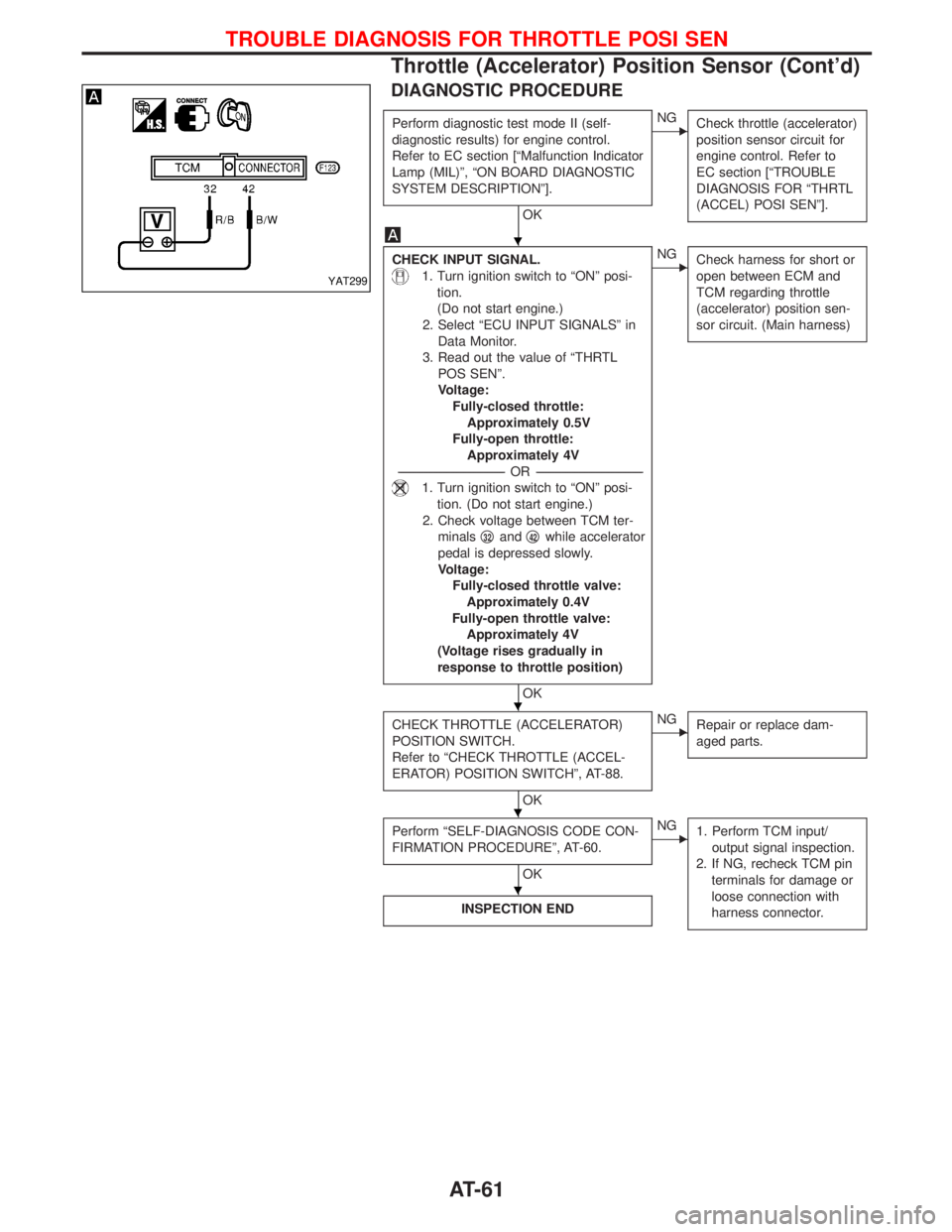

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indicator

Lamp (MIL)º, ªON BOARD DIAGNOSTIC

SYSTEM DESCRIPTIONº].

OK

ENG

Check throttle (accelerator)

position sensor circuit for

engine control. Refer to

EC section [ªTROUBLE

DIAGNOSIS FOR ªTHRTL

(ACCEL) POSI SENº].

CHECK INPUT SIGNAL.

1. Turn ignition switch to ªONº posi-

tion.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªTHRTL

POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªONº posi-

tion. (Do not start engine.)

2. Check voltage between TCM ter-

minalsq

32andq42while accelerator

pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.4V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in

response to throttle position)

OK

ENG

Check harness for short or

open between ECM and

TCM regarding throttle

(accelerator) position sen-

sor circuit. (Main harness)

CHECK THROTTLE (ACCELERATOR)

POSITION SWITCH.

Refer to ªCHECK THROTTLE (ACCEL-

ERATOR) POSITION SWITCHº, AT-88.

OK

ENG

Repair or replace dam-

aged parts.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-60.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT299

H

H

H

H

TROUBLE DIAGNOSIS FOR THROTTLE POSI SEN

Throttle (Accelerator) Position Sensor (Cont'd)

AT-61

Page 66 of 1767

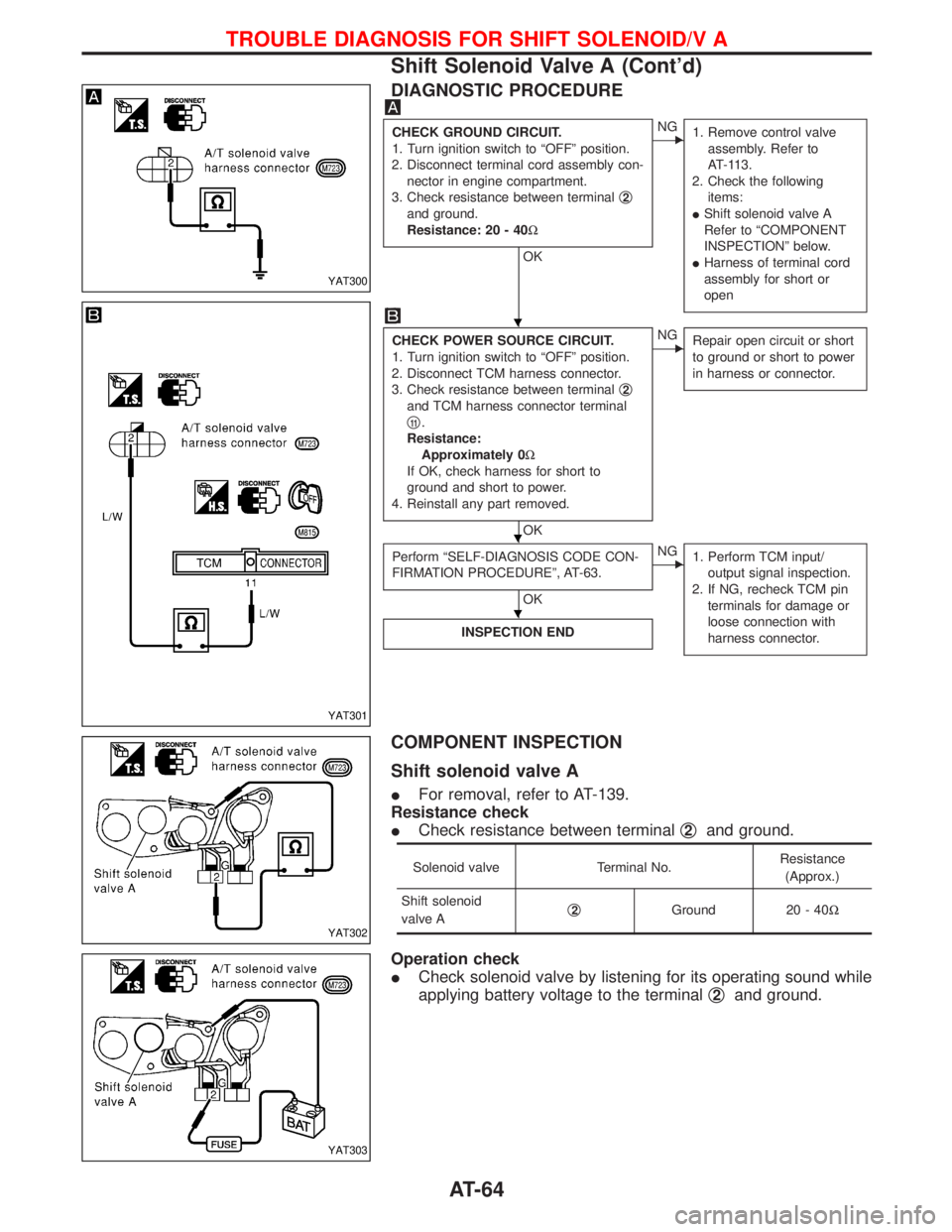

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly con-

nector in engine compartment.

3. Check resistance between terminalq

2

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following

items:

IShift solenoid valve A

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

2

and TCM harness connector terminal

q

11.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-63.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve A

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

2and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve Aq

2Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

2and ground.

YAT300

YAT301

YAT302

YAT303

H

H

H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V A

Shift Solenoid Valve A (Cont'd)

AT-64

Page 69 of 1767

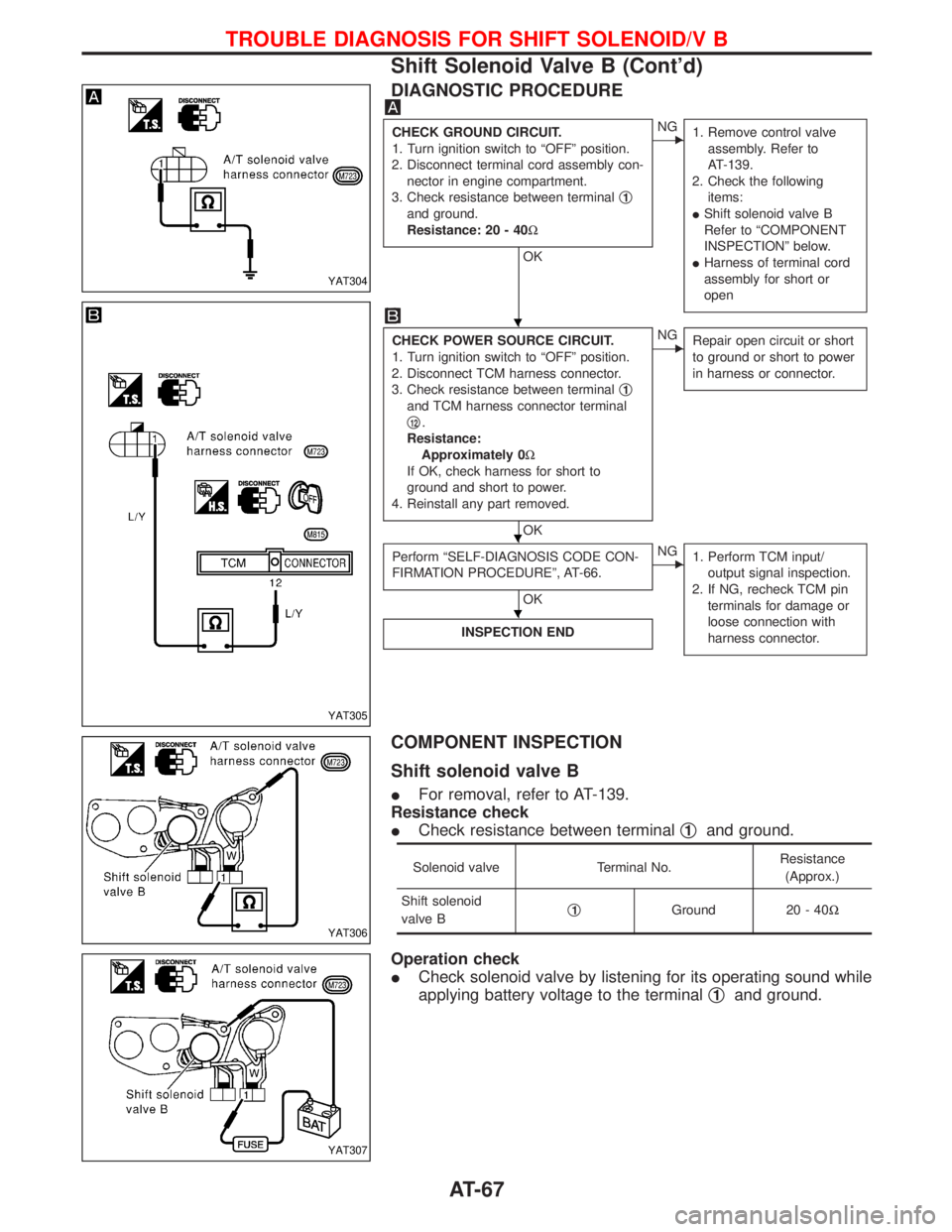

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly con-

nector in engine compartment.

3. Check resistance between terminalq

1

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-139.

2. Check the following

items:

IShift solenoid valve B

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

1

and TCM harness connector terminal

q

12.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-66.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

Shift solenoid valve B

IFor removal, refer to AT-139.

Resistance check

ICheck resistance between terminalq

1and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Shift solenoid

valve Bq

1Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

1and ground.

YAT304

YAT305

YAT306

YAT307

H

H

H

TROUBLE DIAGNOSIS FOR SHIFT SOLENOID/V B

Shift Solenoid Valve B (Cont'd)

AT-67

Page 72 of 1767

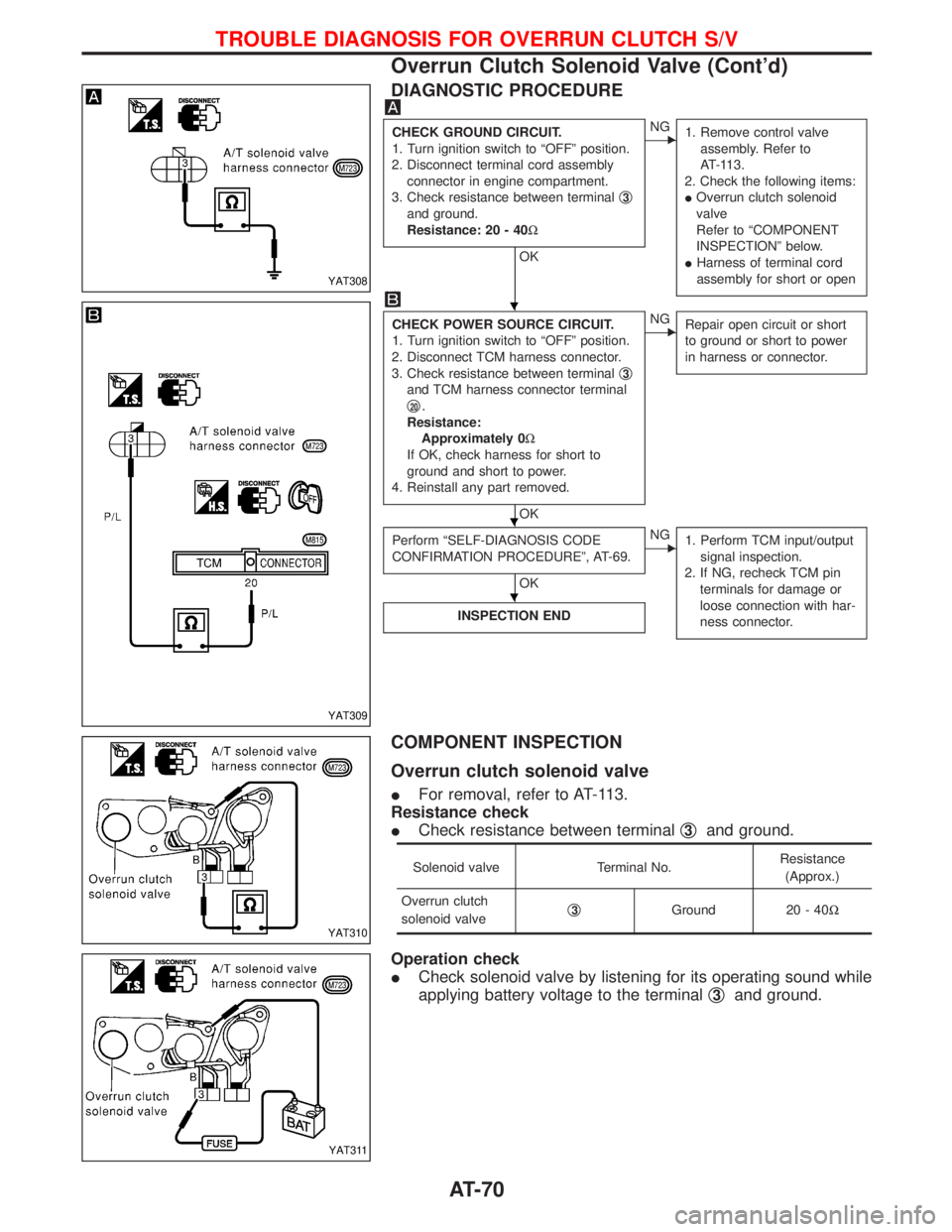

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

3

and ground.

Resistance: 20 - 40W

OK

ENG

1. Remove control valve

assembly. Refer to

AT-113.

2. Check the following items:

IOverrun clutch solenoid

valve

Refer to ªCOMPONENT

INSPECTIONº below.

IHarness of terminal cord

assembly for short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

3

and TCM harness connector terminal

q

20.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to power

in harness or connector.

Perform ªSELF-DIAGNOSIS CODE

CONFIRMATION PROCEDUREº, AT-69.

OK

ENG

1. Perform TCM input/output

signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with har-

ness connector.

INSPECTION END

COMPONENT INSPECTION

Overrun clutch solenoid valve

IFor removal, refer to AT-113.

Resistance check

ICheck resistance between terminalq

3and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Overrun clutch

solenoid valveq

3Ground 20 - 40W

Operation check

ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminalq

3and ground.

YAT308

YAT309

YAT310

YAT311

H

H

H

TROUBLE DIAGNOSIS FOR OVERRUN CLUTCH S/V

Overrun Clutch Solenoid Valve (Cont'd)

AT-70

Page 75 of 1767

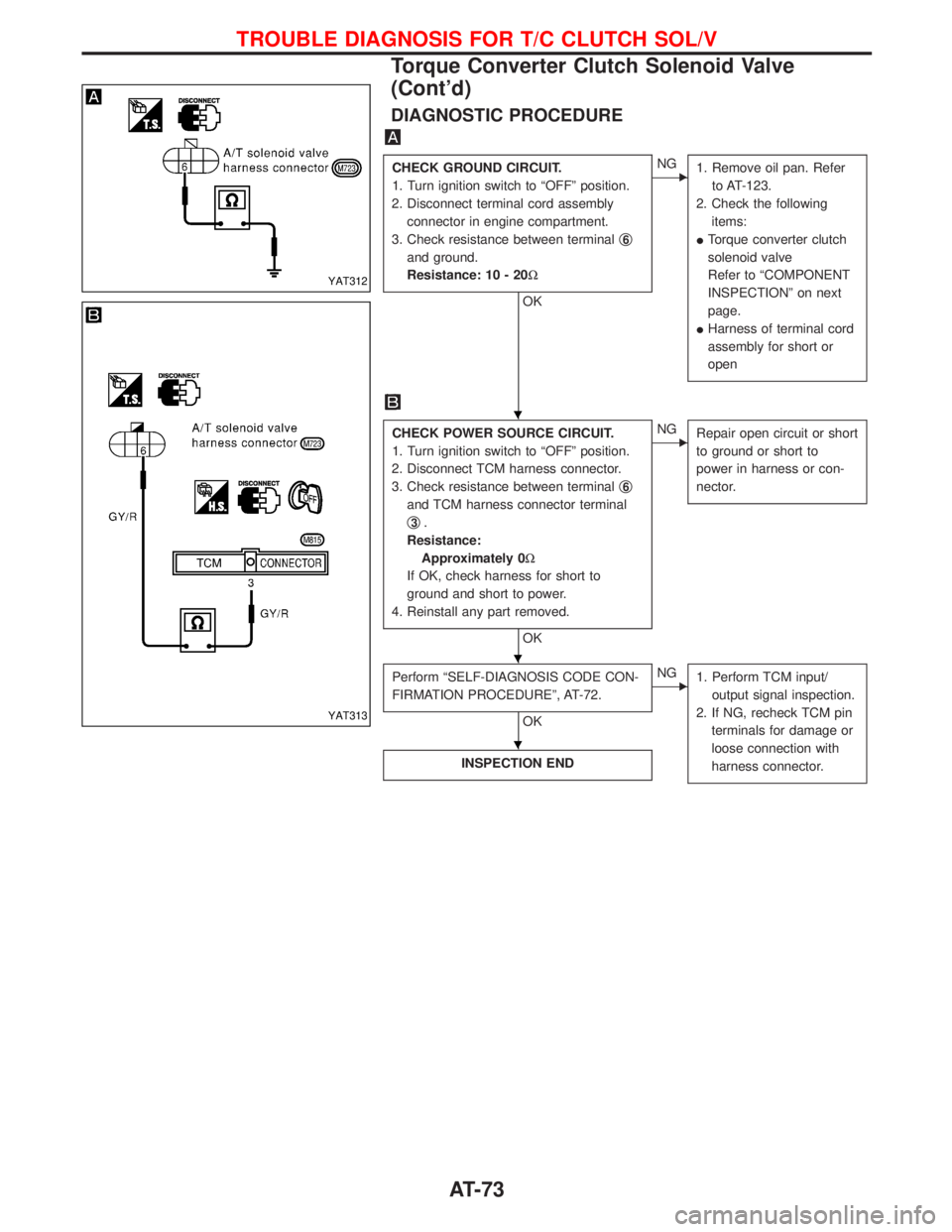

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalq

6

and ground.

Resistance: 10 - 20W

OK

ENG

1. Remove oil pan. Refer

to AT-123.

2. Check the following

items:

ITorque converter clutch

solenoid valve

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminalq

6

and TCM harness connector terminal

q

3.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

4. Reinstall any part removed.

OK

ENG

Repair open circuit or short

to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-72.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT312

YAT313

H

H

H

TROUBLE DIAGNOSIS FOR T/C CLUTCH SOL/V

Torque Converter Clutch Solenoid Valve

(Cont'd)

AT-73

Page 79 of 1767

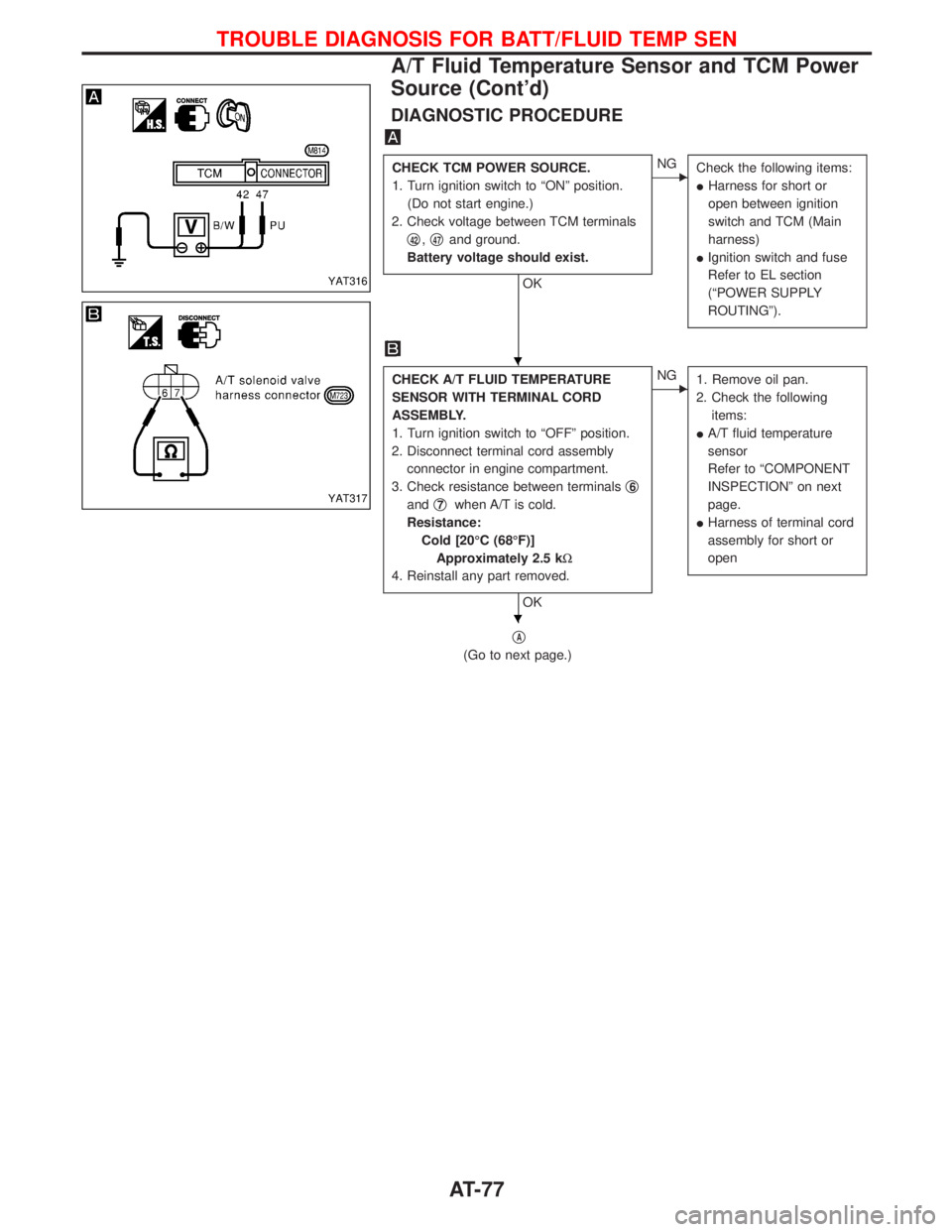

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

42,q47and ground.

Battery voltage should exist.

OK

ENG

Check the following items:

IHarness for short or

open between ignition

switch and TCM (Main

harness)

IIgnition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminalsq

6

andq7when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

ENG

1. Remove oil pan.

2. Check the following

items:

IA/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

IHarness of terminal cord

assembly for short or

open

qA

(Go to next page.)

YAT316

YAT317

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont'd)

AT-77

Page 83 of 1767

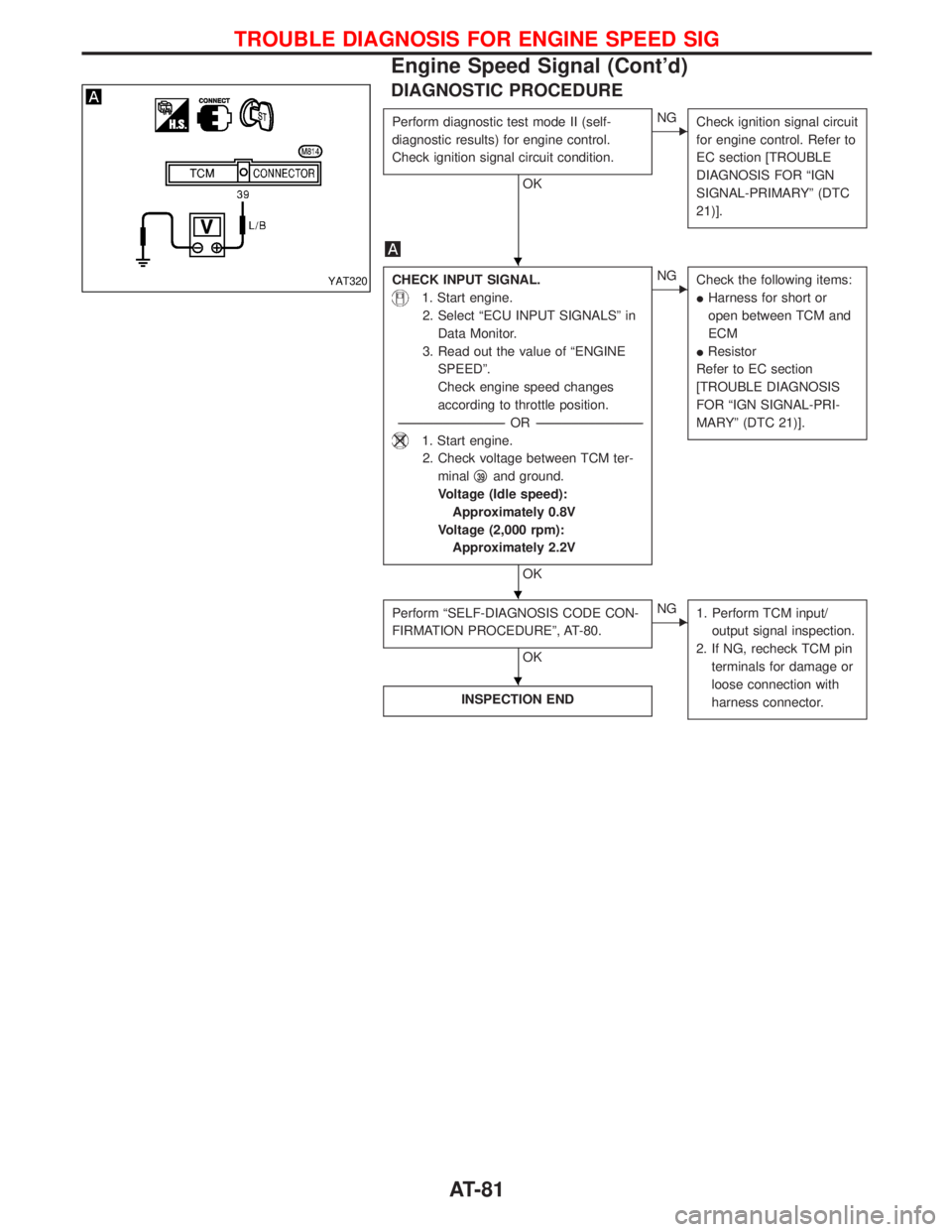

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Check ignition signal circuit condition.

OK

ENG

Check ignition signal circuit

for engine control. Refer to

EC section [TROUBLE

DIAGNOSIS FOR ªIGN

SIGNAL-PRIMARYº (DTC

21)].

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªECU INPUT SIGNALSº in

Data Monitor.

3. Read out the value of ªENGINE

SPEEDº.

Check engine speed changes

according to throttle position.

-----------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM ter-

minalq

39and ground.

Voltage (Idle speed):

Approximately 0.8V

Voltage (2,000 rpm):

Approximately 2.2V

OK

ENG

Check the following items:

IHarness for short or

open between TCM and

ECM

IResistor

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-80.

OK

ENG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

YAT320

H

H

H

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

Engine Speed Signal (Cont'd)

AT-81