Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1339 of 1767

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

IConnectors not fully seated.

IWiring harness not long enough and is being stressed due to

engine vibrations or rocking.

IWires laying across brackets or moving components.

ILoose, dirty or corroded ground wires.

IWires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection bygently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

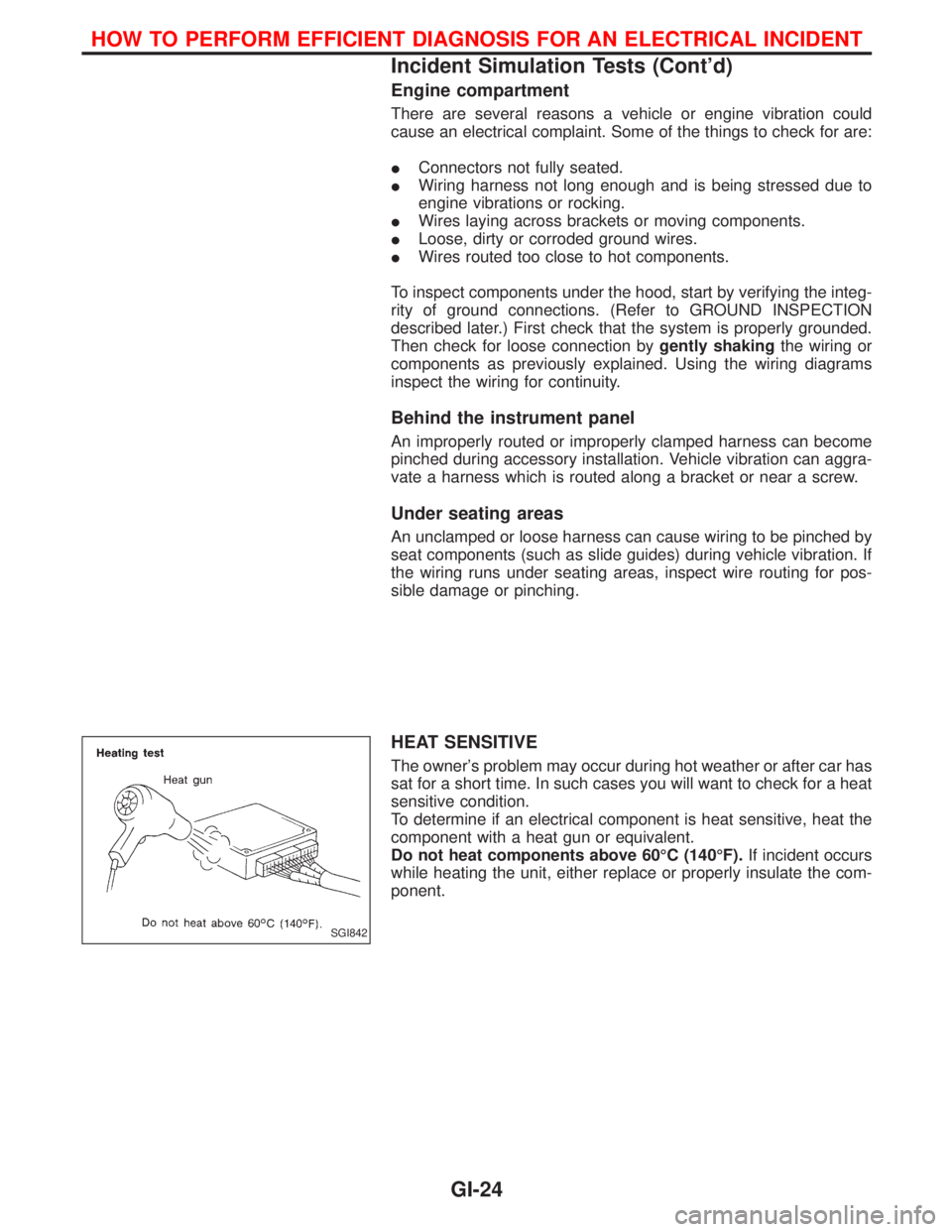

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

Page 1340 of 1767

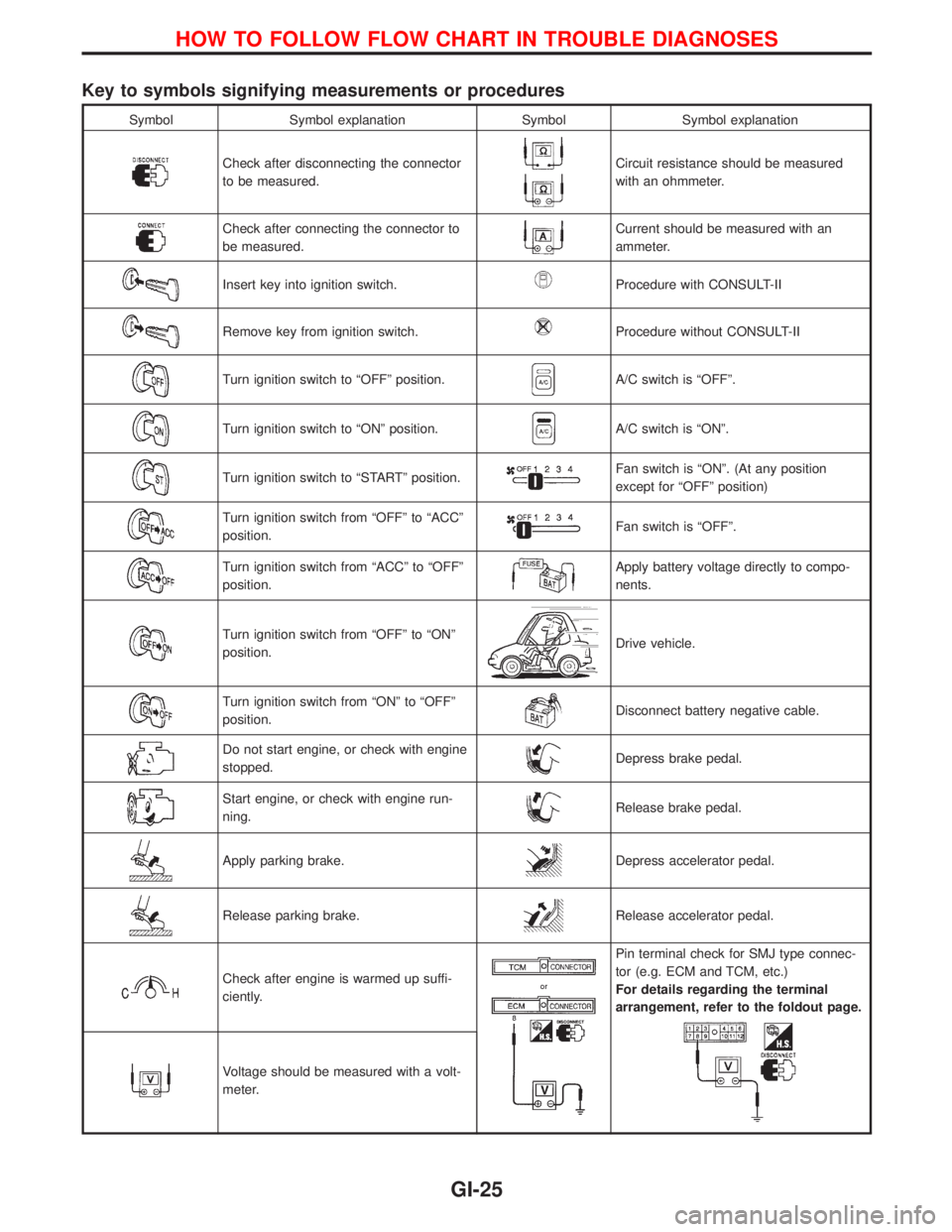

Key to symbols signifying measurements or procedures

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connector

to be measured.Circuit resistance should be measured

with an ohmmeter.

Check after connecting the connector to

be measured.Current should be measured with an

ammeter.

Insert key into ignition switch.Procedure with CONSULT-II

Remove key from ignition switch.Procedure without CONSULT-II

Turn ignition switch to ªOFFº position.A/C switch is ªOFFº.

Turn ignition switch to ªONº position.A/C switch is ªONº.

Turn ignition switch to ªSTARTº position.Fan switch is ªONº. (At any position

except for ªOFFº position)

Turn ignition switch from ªOFFº to ªACCº

position.Fan switch is ªOFFº.

Turn ignition switch from ªACCº to ªOFFº

position.Apply battery voltage directly to compo-

nents.

Turn ignition switch from ªOFFº to ªONº

position.Drive vehicle.

Turn ignition switch from ªONº to ªOFFº

position.Disconnect battery negative cable.

Do not start engine, or check with engine

stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake.Depress accelerator pedal.

Release parking brake.Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.

Pin terminal check for SMJ type connec-

tor (e.g. ECM and TCM, etc.)

For details regarding the terminal

arrangement, refer to the foldout page.

Voltage should be measured with a volt-

meter.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-25

Page 1347 of 1767

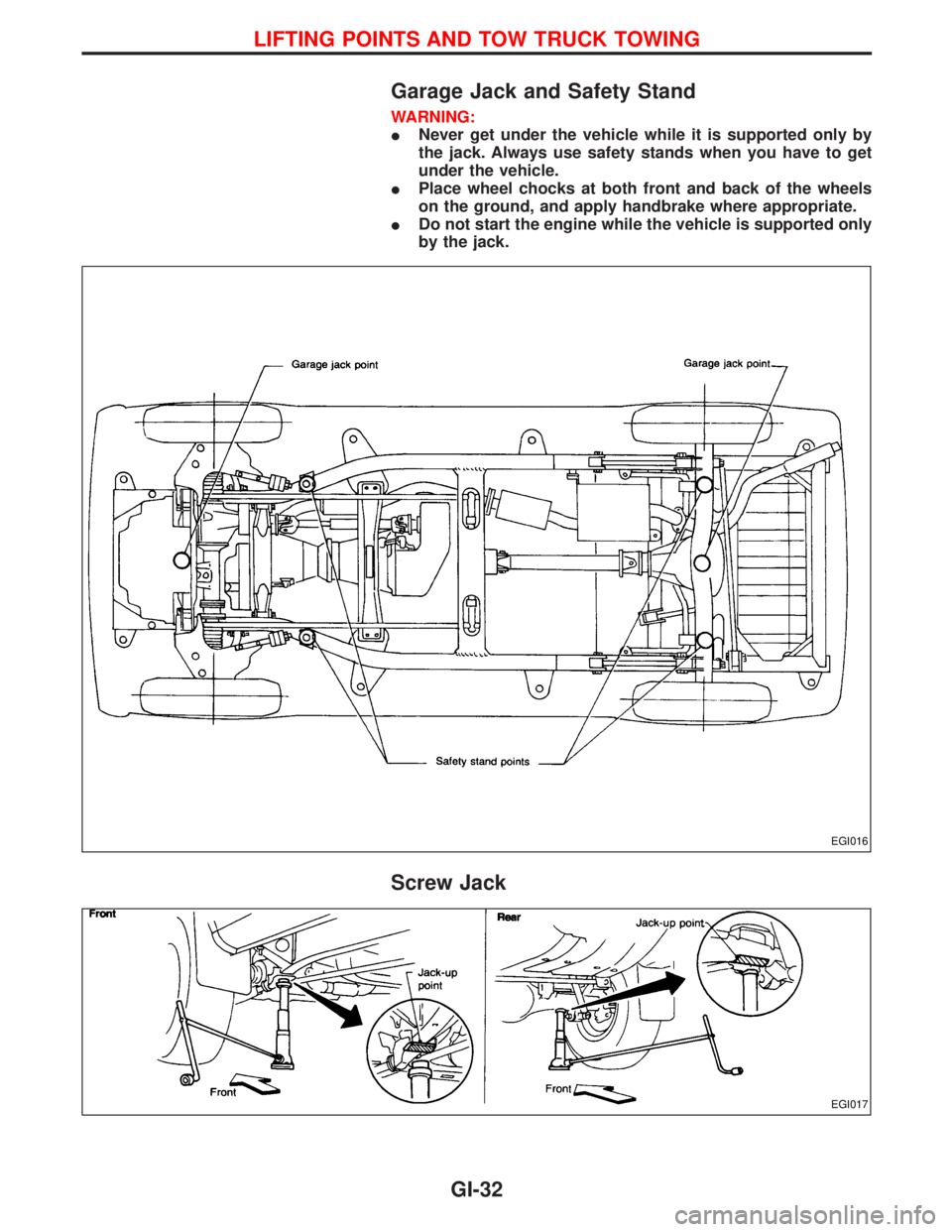

Garage Jack and Safety Stand

WARNING:

INever get under the vehicle while it is supported only by

the jack. Always use safety stands when you have to get

under the vehicle.

IPlace wheel chocks at both front and back of the wheels

on the ground, and apply handbrake where appropriate.

IDo not start the engine while the vehicle is supported only

by the jack.

Screw Jack

EGI016

EGI017

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

Page 1359 of 1767

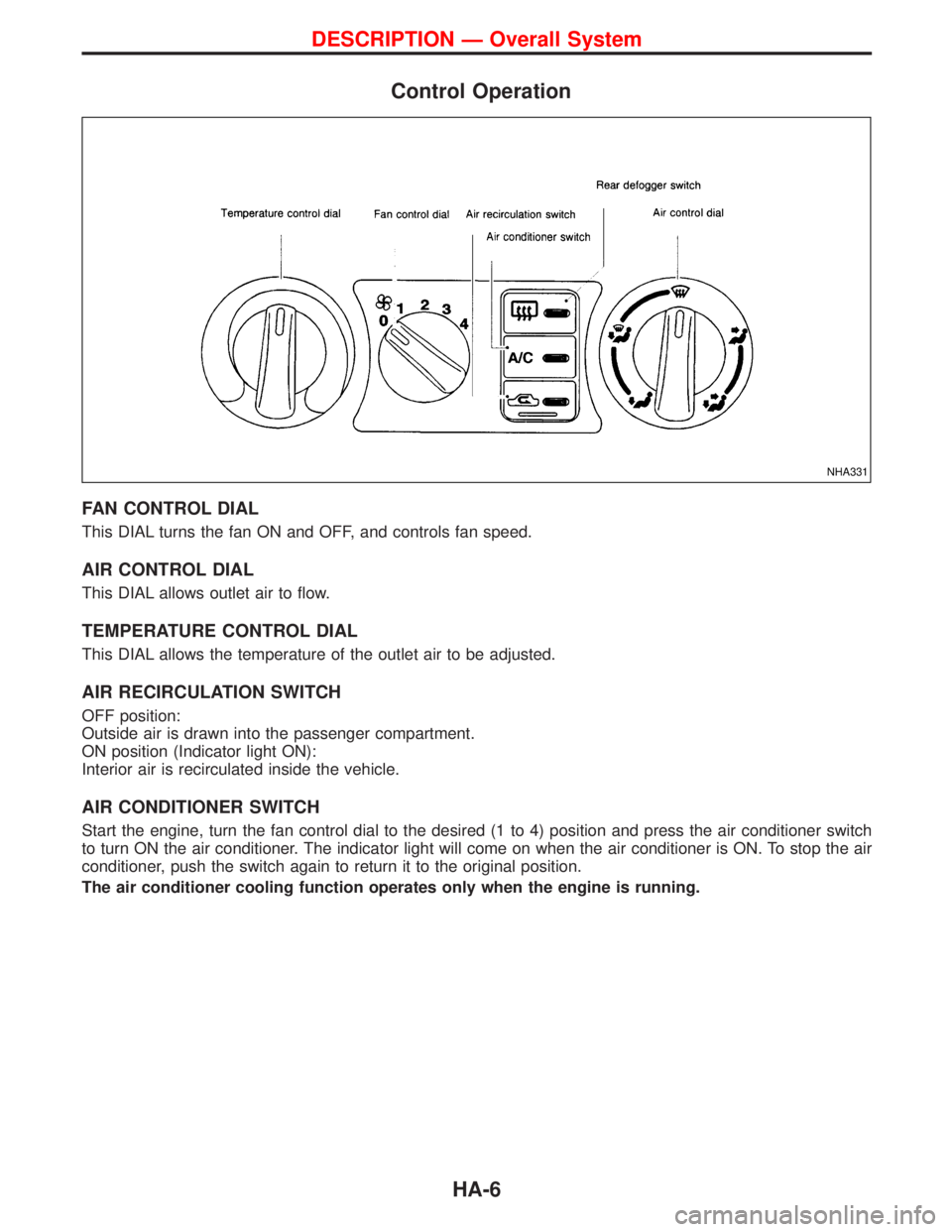

Control Operation

FAN CONTROL DIAL

This DIAL turns the fan ON and OFF, and controls fan speed.

AIR CONTROL DIAL

This DIAL allows outlet air to flow.

TEMPERATURE CONTROL DIAL

This DIAL allows the temperature of the outlet air to be adjusted.

AIR RECIRCULATION SWITCH

OFF position:

Outside air is drawn into the passenger compartment.

ON position (Indicator light ON):

Interior air is recirculated inside the vehicle.

AIR CONDITIONER SWITCH

Start the engine, turn the fan control dial to the desired (1 to 4) position and press the air conditioner switch

to turn ON the air conditioner. The indicator light will come on when the air conditioner is ON. To stop the air

conditioner, push the switch again to return it to the original position.

The air conditioner cooling function operates only when the engine is running.

NHA331

DESCRIPTION Ð Overall System

HA-6

Page 1369 of 1767

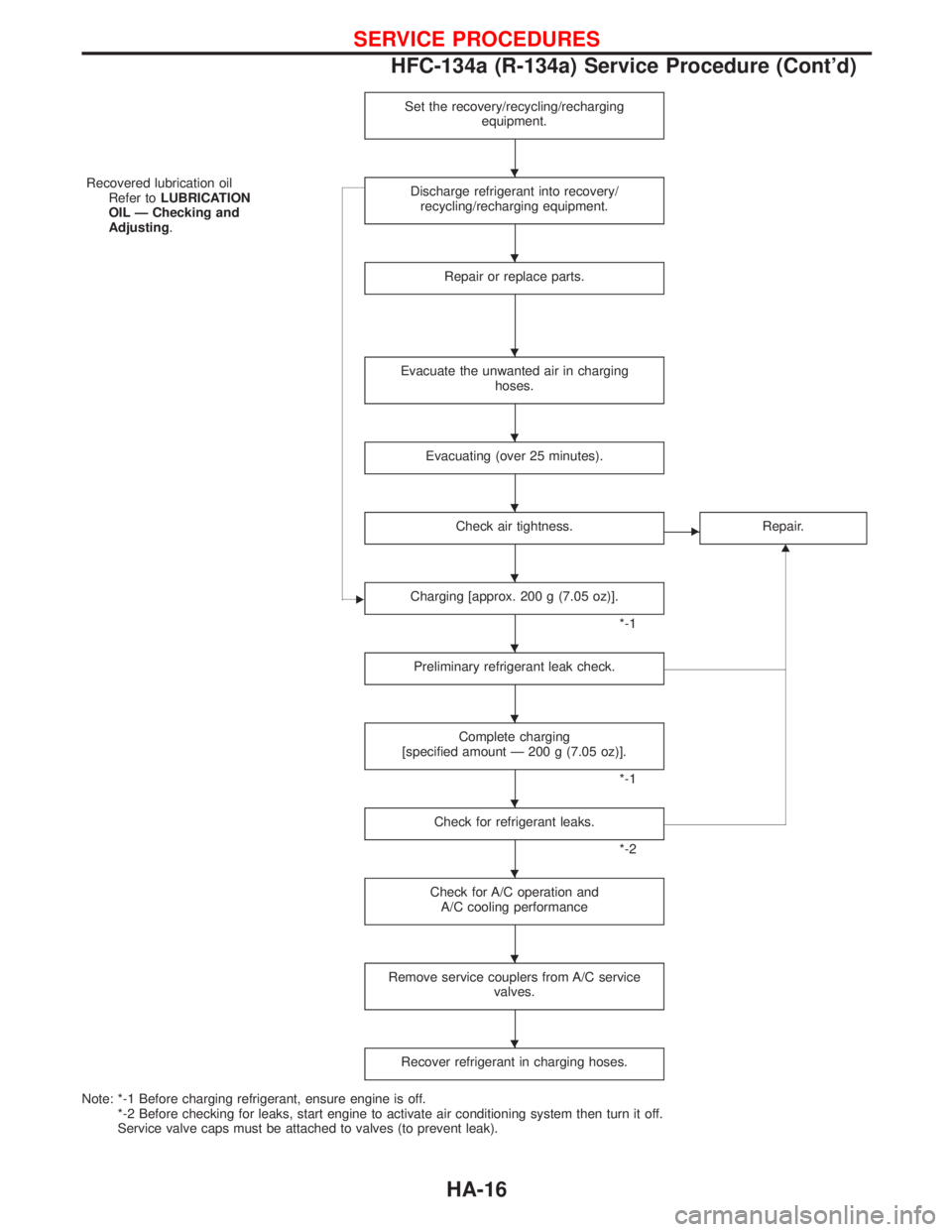

Set the recovery/recycling/recharging

equipment.

Recovered lubrication oil

Refer toLUBRICATION

OIL Ð Checking and

Adjusting.Discharge refrigerant into recovery/

recycling/recharging equipment.

Repair or replace parts.

Evacuate the unwanted air in charging

hoses.

Evacuating (over 25 minutes).

Check air tightness.ERepair.

G

ECharging [approx. 200 g (7.05 oz)].

*-1

Preliminary refrigerant leak check.

Complete charging

[specified amount Ð 200 g (7.05 oz)].

*-1

Check for refrigerant leaks.

*-2

Check for A/C operation and

A/C cooling performance

Remove service couplers from A/C service

valves.

Recover refrigerant in charging hoses.

Note: *-1 Before charging refrigerant, ensure engine is off.

*-2 Before checking for leaks, start engine to activate air conditioning system then turn it off.

Service valve caps must be attached to valves (to prevent leak).

H

H

H

H

H

H

H

H

H

H

H

H

SERVICE PROCEDURES

HFC-134a (R-134a) Service Procedure (Cont'd)

HA-16

Page 1375 of 1767

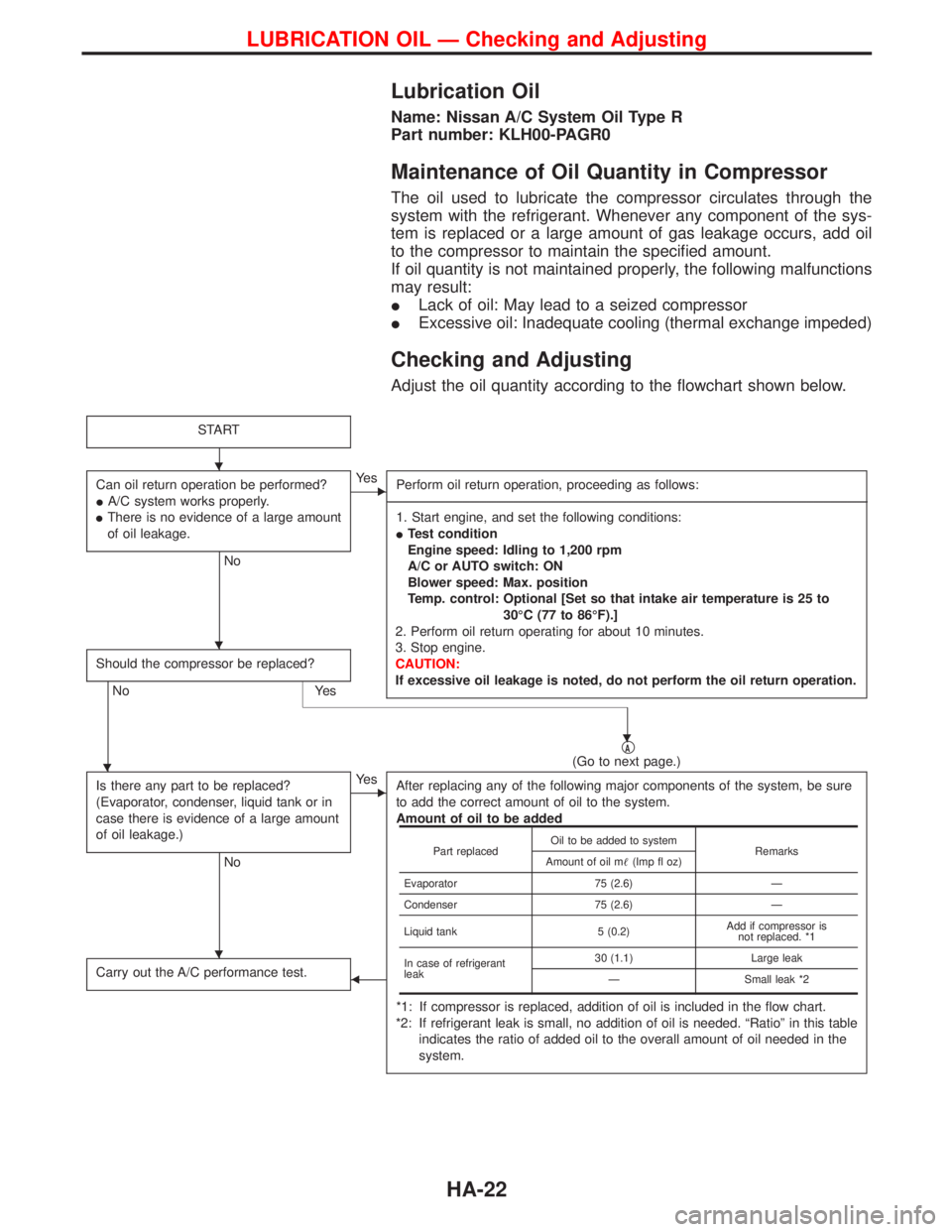

Lubrication Oil

Name: Nissan A/C System Oil Type R

Part number: KLH00-PAGR0

Maintenance of Oil Quantity in Compressor

The oil used to lubricate the compressor circulates through the

system with the refrigerant. Whenever any component of the sys-

tem is replaced or a large amount of gas leakage occurs, add oil

to the compressor to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions

may result:

ILack of oil: May lead to a seized compressor

IExcessive oil: Inadequate cooling (thermal exchange impeded)

Checking and Adjusting

Adjust the oil quantity according to the flowchart shown below.

START

Can oil return operation be performed?

IA/C system works properly.

IThere is no evidence of a large amount

of oil leakage.

No

EYe s

Perform oil return operation, proceeding as follows:

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

ITest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to

30ÉC (77 to 86ÉF).]

2. Perform oil return operating for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Should the compressor be replaced?

No Yes

qA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount

of oil leakage.)

No

EYe s

After replacing any of the following major components of the system, be sure

to add the correct amount of oil to the system.

Amount of oil to be added

*1: If compressor is replaced, addition of oil is included in the flow chart.

*2: If refrigerant leak is small, no addition of oil is needed. ªRatioº in this table

indicates the ratio of added oil to the overall amount of oil needed in the

system.

Carry out the A/C performance test.F

Part replacedOil to be added to system

Remarks

Amount of oil m(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is

not replaced. *1

In case of refrigerant

leak30 (1.1) Large leak

Ð Small leak *2

H

H

H

H

H

LUBRICATION OIL Ð Checking and Adjusting

HA-22

Page 1383 of 1767

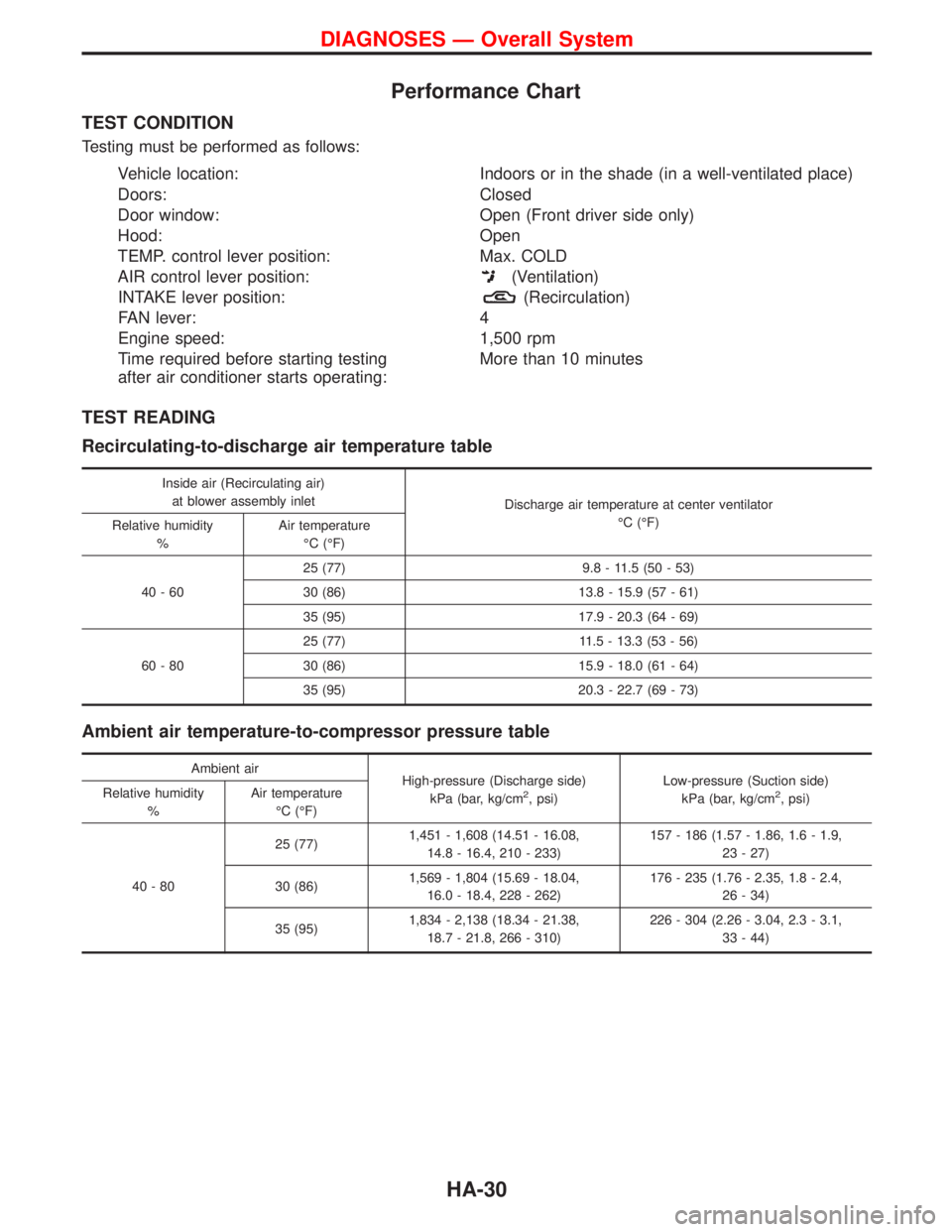

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open (Front driver side only)

Hood: Open

TEMP. control lever position: Max. COLD

AIR control lever position:

(Ventilation)

INTAKE lever position:

(Recirculation)

FAN lever: 4

Engine speed: 1,500 rpm

Time required before starting testing

after air conditioner starts operating:More than 10 minutes

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet

Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

%Air temperature

ÉC (ÉF)

40-6025 (77) 9.8 - 11.5 (50 - 53)

30 (86) 13.8 - 15.9 (57 - 61)

35 (95) 17.9 - 20.3 (64 - 69)

60-8025 (77) 11.5 - 13.3 (53 - 56)

30 (86) 15.9 - 18.0 (61 - 64)

35 (95) 20.3 - 22.7 (69 - 73)

Ambient air temperature-to-compressor pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

ÉC (ÉF)

40-8025 (77)1,451 - 1,608 (14.51 - 16.08,

14.8 - 16.4, 210 - 233)157 - 186 (1.57 - 1.86, 1.6 - 1.9,

23 - 27)

30 (86)1,569 - 1,804 (15.69 - 18.04,

16.0 - 18.4, 228 - 262)176 - 235 (1.76 - 2.35, 1.8 - 2.4,

26 - 34)

35 (95)1,834 - 2,138 (18.34 - 21.38,

18.7 - 21.8, 266 - 310)226 - 304 (2.26 - 3.04, 2.3 - 3.1,

33 - 44)

DIAGNOSES Ð Overall System

HA-30

Page 1387 of 1767

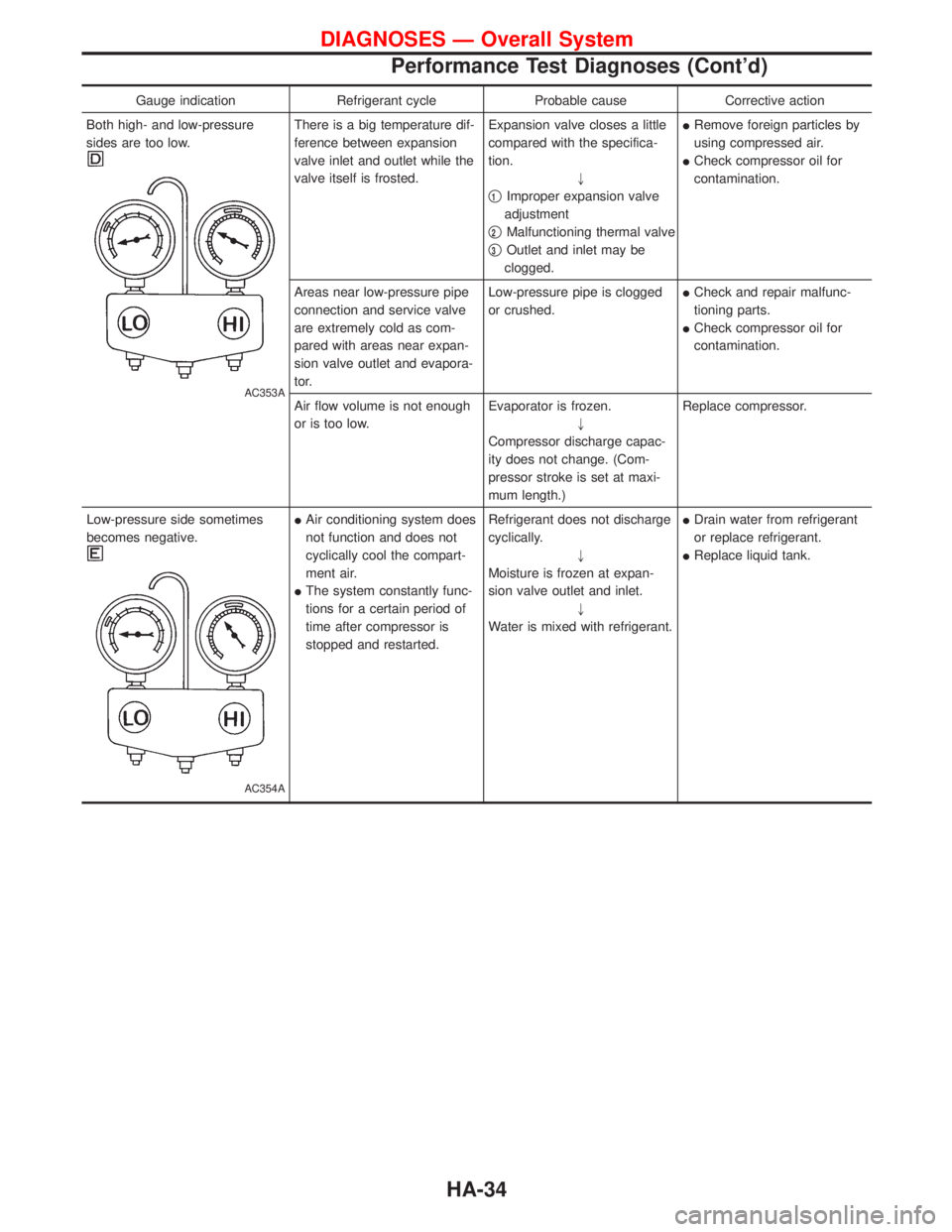

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too low.

AC353A

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

"

q

1Improper expansion valve

adjustment

q

2Malfunctioning thermal valve

q

3Outlet and inlet may be

clogged.IRemove foreign particles by

using compressed air.

ICheck compressor oil for

contamination.

Areas near low-pressure pipe

connection and service valve

are extremely cold as com-

pared with areas near expan-

sion valve outlet and evapora-

tor.Low-pressure pipe is clogged

or crushed.ICheck and repair malfunc-

tioning parts.

ICheck compressor oil for

contamination.

Air flow volume is not enough

or is too low.Evaporator is frozen.

"

Compressor discharge capac-

ity does not change. (Com-

pressor stroke is set at maxi-

mum length.)Replace compressor.

Low-pressure side sometimes

becomes negative.

AC354A

IAir conditioning system does

not function and does not

cyclically cool the compart-

ment air.

IThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not discharge

cyclically.

"

Moisture is frozen at expan-

sion valve outlet and inlet.

"

Water is mixed with refrigerant.IDrain water from refrigerant

or replace refrigerant.

IReplace liquid tank.

DIAGNOSES Ð Overall System

Performance Test Diagnoses (Cont'd)

HA-34

Page 1388 of 1767

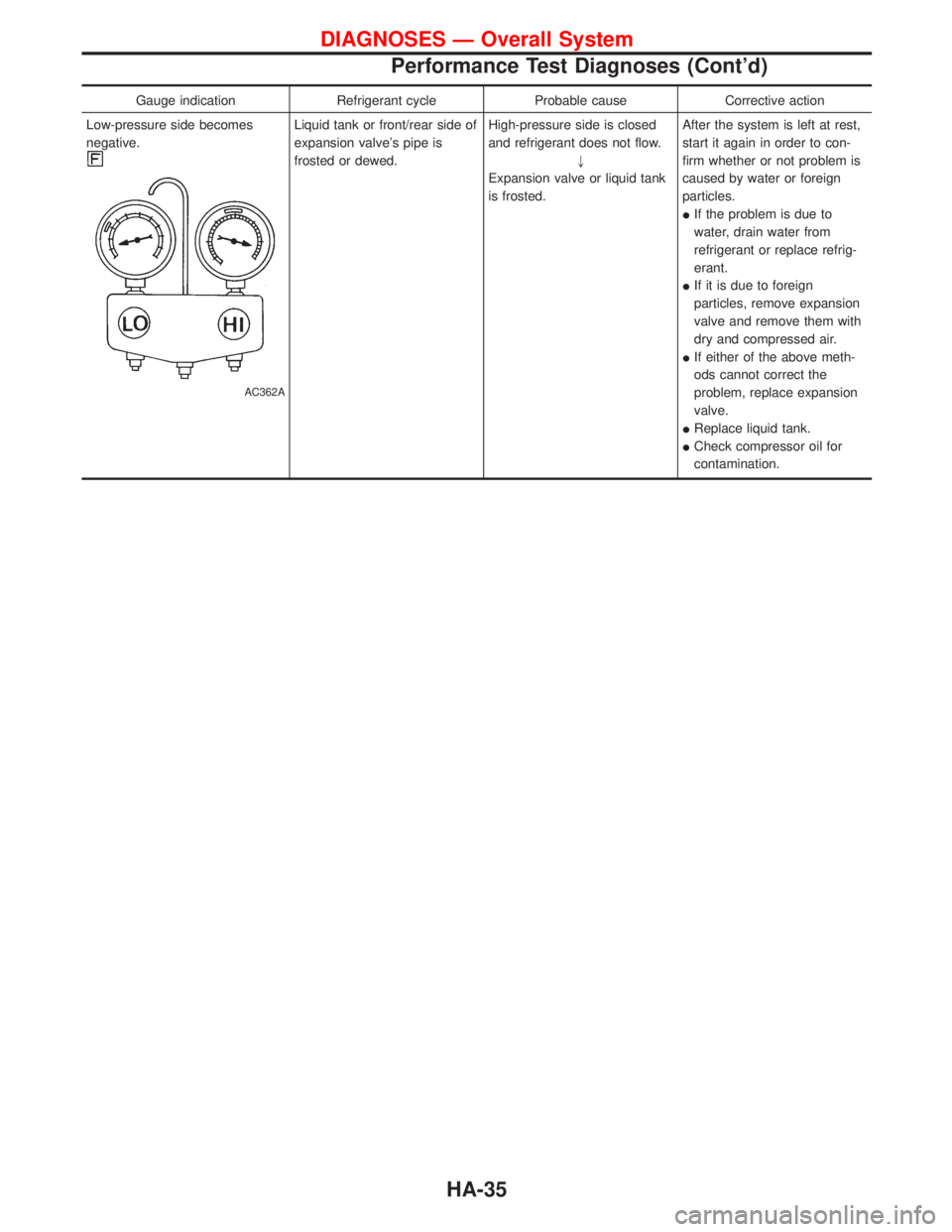

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes

negative.

AC362A

Liquid tank or front/rear side of

expansion valve's pipe is

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

"

Expansion valve or liquid tank

is frosted.After the system is left at rest,

start it again in order to con-

firm whether or not problem is

caused by water or foreign

particles.

IIf the problem is due to

water, drain water from

refrigerant or replace refrig-

erant.

IIf it is due to foreign

particles, remove expansion

valve and remove them with

dry and compressed air.

IIf either of the above meth-

ods cannot correct the

problem, replace expansion

valve.

IReplace liquid tank.

ICheck compressor oil for

contamination.

DIAGNOSES Ð Overall System

Performance Test Diagnoses (Cont'd)

HA-35

Page 1423 of 1767

Pre-delivery inspection.....................................MA-3

Priming pump .................................................EC-50

Propeller shaft ............................................PD-5, 57

Propeller shaft greasing...........................MA-36, 38

Propeller shaft inspection ........................MA-36, 38

Propeller shaft on vehicle service ....................PD-6

Pump communication line (Electronic

Fuel Injection Pump) ................................EC-175

Pump control module (Electronic Fuel

Injection Pump).........................................EC-189

R

Radiator ....................................................LC-14, 32

Rear axle................................................RA-4, 6, 12

Rear bumper .....................................................BT-8

Rear case (Transfer)...................................TF-9, 24

Rear combination lamp removal and

installation .....................................................BT-8

Rear door ........................................................BT-12

Rear door trim...........................................BT-18, 19

Rear drum brake ............................................BR-31

Rear fog lamp .................................................EL-54

Rear side window .....................................BT-21, 43

Rear suspension ........................................RA-4, 12

Rear window defogger..................EL-107, 109, 110

Refrigerant connection precaution ...................HA-4

Refrigerant general precaution.........................HA-3

Refrigerant lines .............................................HA-17

Refrigeration cycle............................................HA-9

REMOTE - Wiring diagram ...........................EL-122

Removal and installation (A/T) ......................AT-116

Removal and installation (Transfer) ..................TF-7

Reverse clutch ..............................................AT-151

Reverse idler shaft (M/T)................................MT-11

Reverse main gear (M/T) ...............................MT-11

Revolution sensor (A/T) ..........................AT-50, 114

R/FOG - Wiring diagram .................................EL-54

Ring gear diff. inspection .........................PD-20, 42

Rocker cover ..................................................EM-20

Roof trim .........................................................BT-20

Rotor disc (front) .............................................FA-18

S

Screw jack .......................................................GI-32

Seal - See Exterior .........................................BT-21

Seat belt inspection .................................MA-36, 45

Seat belt pre-tensioner.................................RS-2, 9

Seat belt pre-tensioner disposal ....................RS-20

Seat belt, front ..................................................RS-4

Seat, front .......................................................BT-34

Seat, second (2nd) .........................................BT-37

Seat, third (3rd) ...............................................BT-39

Second (2nd) seat ..........................................BT-37

Self-diagnostic results ............................EC-35, 324

Shift control (Transfer) ..............................TF-11, 24Shift control components

(M/T) ............................MT-13, 14, 15, 21, 23, 31

Shift fork (M/T) ...............................................MT-13

Shift schedule................................................AT-196

Shift solenoid valve A (A/T).............................AT-63

Shift solenoid valve B (A/T) ............................AT-66

Shock absorber (front) ....................................FA-30

Shock absorber (rear) ..............................RA-14, 16

Side air bag ....................................................RS-18

Side air bag (satellite) sensor ........................RS-13

Side bearing preload diff. ...............................PD-24

Side trim....................................................BT-18, 21

Side window - See Rear side window ............BT-21

S/LOCK - Wiring diagram .............................EL-150

SMJ (super multiple junction) .......................Foldout

Speedometer...................................................EL-72

Spill valve .....................................................EC-182

Spiral cable.....................................................RS-14

SROOF - Wiring diagram .............................EL-130

SRS - See Supplemental Restraint

System ..........................................................RS-6

SRS - Wiring diagram ....................................RS-32

SRS Trouble diagnoses .................................RS-26

S/SIG - Wiring diagram ................................EC-248

Stabilizer bar (front) ....................................FA-4, 33

Stabilizer bar (rear) ..................................RA-15, 16

Stall test (A/T) .........................................AT-27, 196

Standardized relay ............................................EL-4

START - Wiring diagram ................................SC-14

Start signal ...................................................EC-248

Starter .............................................................SC-17

Starting system...............................................SC-13

Steering gear and linkage inspection ......MA-36, 43

Steering gear oil level ..............................MA-36, 44

Steering gear, linkage and transfer

gear inspection ..............................MA-36, 43, 44

Steering linkage ........................................ST-17, 22

Steering switch................................................EL-25

Steering wheel and column ........................ST-8, 22

Steering wheel play ..........................................ST-4

Steering wheel turning force .............................ST-6

Stop lamp ........................................................EL-48

Stop lamp switch ..................................EC-204, 403

STOP/L - Wiring diagram................................EL-48

Striking rod (M/T) ...........................................MT-13

Sub-gear (M/T) ...............................................MT-11

Sun roof, electric ...........................................EL-130

Sunroof............................................................BT-40

Super lock ............................EL-145, 146, 148, 158

Supplemental Restraint System .......................RS-6

Swirl control valve control solenoid

valve .........................................................EC-263

SWL/V - Wiring diagram ..............................EC-265

Symptom matrix chart ............................EC-56, 340

T

Tachometer .....................................................EL-72

Tail lamp ..........................................................EL-45

ALPHABETICAL INDEX

IDX-6