Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1429 of 1767

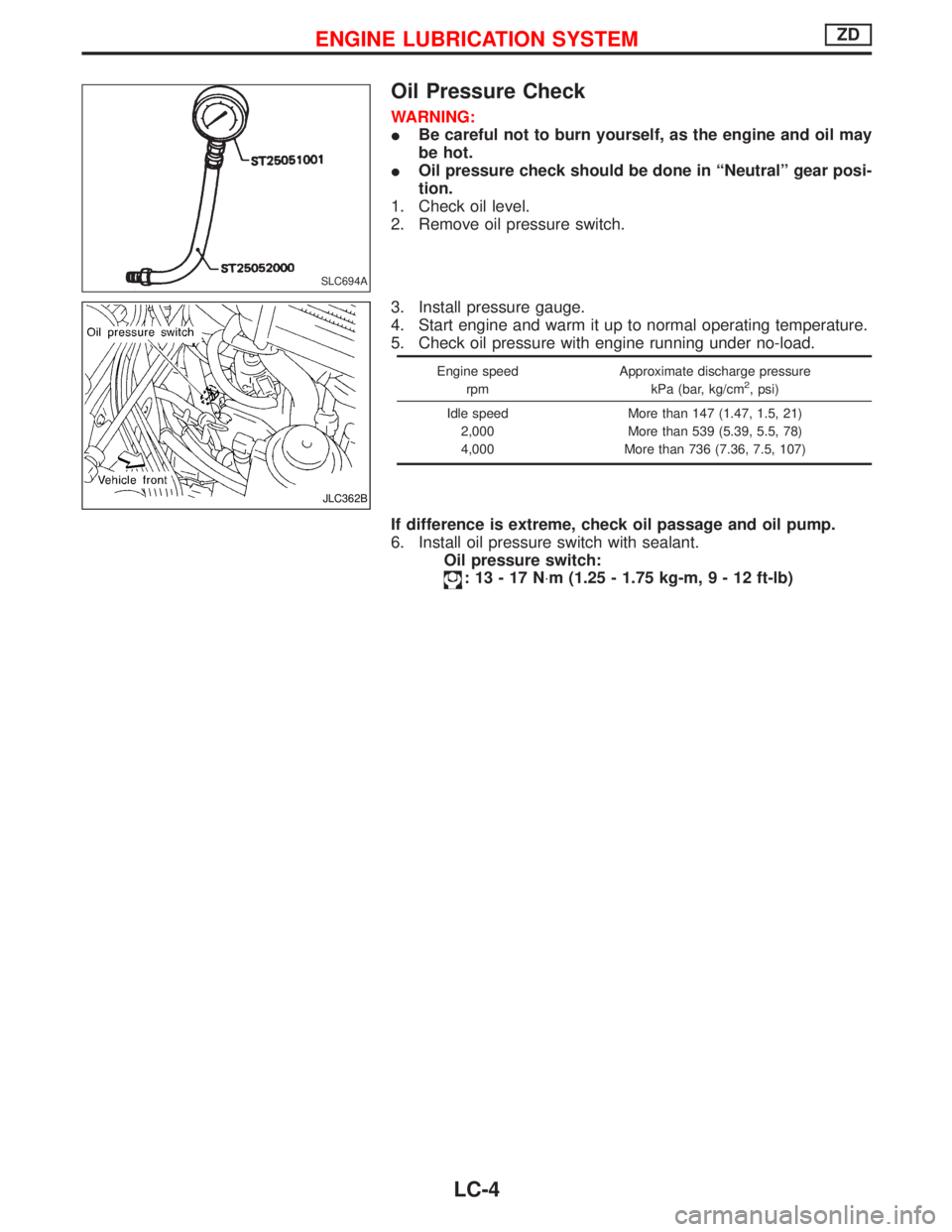

Oil Pressure Check

WARNING:

IBe careful not to burn yourself, as the engine and oil may

be hot.

IOil pressure check should be done in ªNeutralº gear posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed

2,000

4,000More than 147 (1.47, 1.5, 21)

More than 539 (5.39, 5.5, 78)

More than 736 (7.36, 7.5, 107)

If difference is extreme, check oil passage and oil pump.

6. Install oil pressure switch with sealant.

Oil pressure switch:

:13-17N×m (1.25 - 1.75 kg-m,9-12ft-lb)

SLC694A

JLC362B

ENGINE LUBRICATION SYSTEMZD

LC-4

Page 1446 of 1767

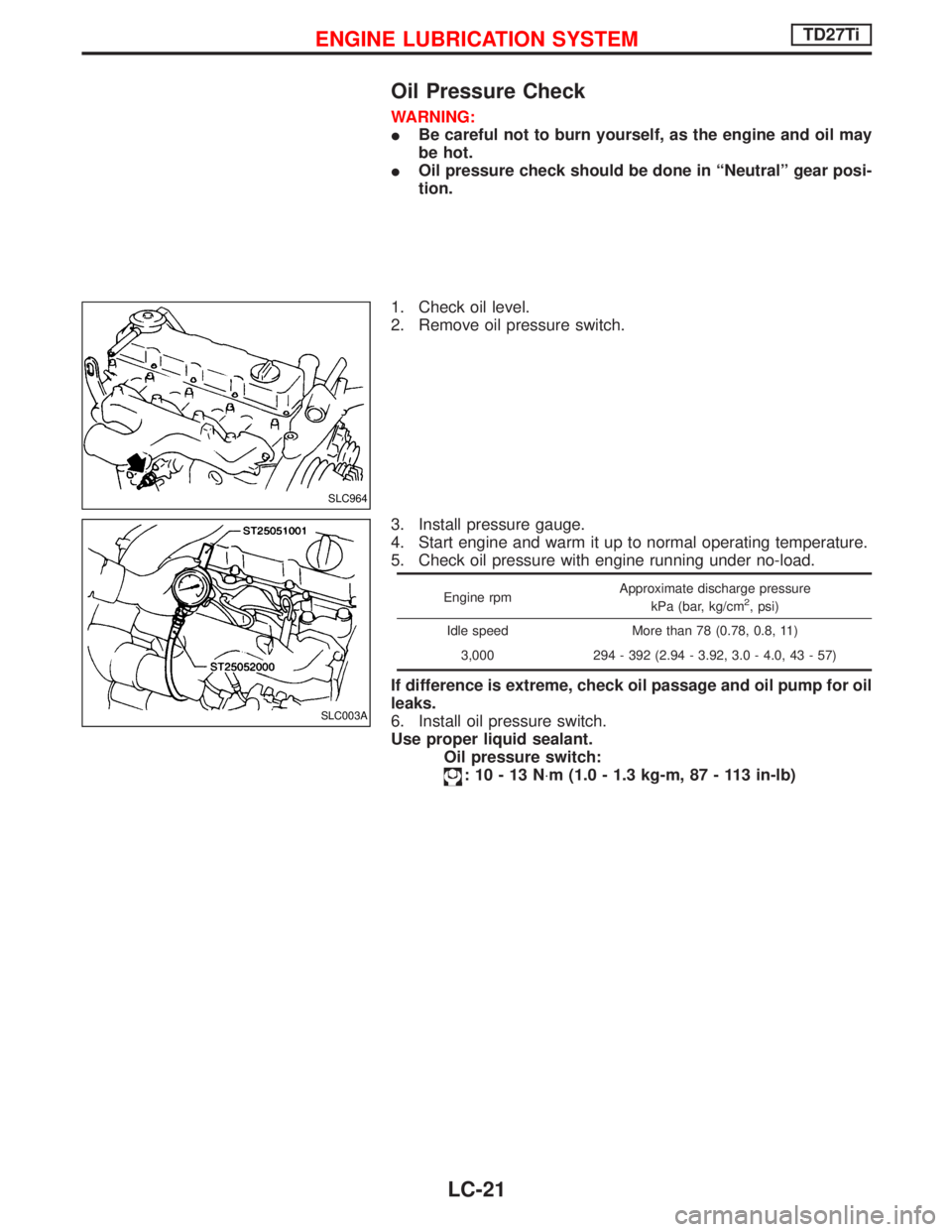

Oil Pressure Check

WARNING:

IBe careful not to burn yourself, as the engine and oil may

be hot.

IOil pressure check should be done in ªNeutralº gear posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 78 (0.78, 0.8, 11)

3,000 294 - 392 (2.94 - 3.92, 3.0 - 4.0, 43 - 57)

If difference is extreme, check oil passage and oil pump for oil

leaks.

6. Install oil pressure switch.

Use proper liquid sealant.

Oil pressure switch:

:10-13N×m (1.0 - 1.3 kg-m, 87 - 113 in-lb)

SLC964

SLC003A

ENGINE LUBRICATION SYSTEMTD27Ti

LC-21

Page 1464 of 1767

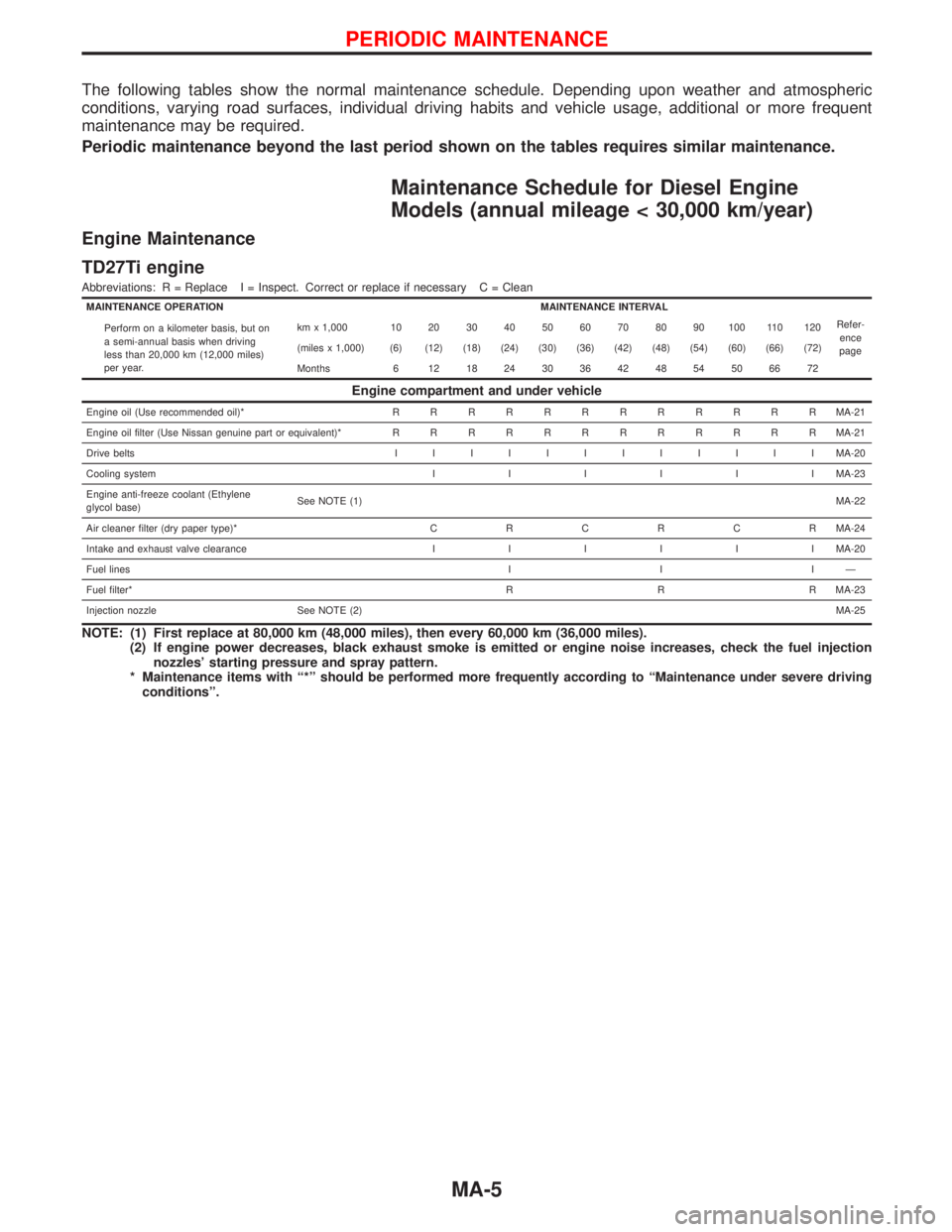

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric

conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent

maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

Maintenance Schedule for Diesel Engine

Models (annual mileage < 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on

a semi-annual basis when driving

less than 20,000 km (12,000 miles)

per year.km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Months 6 12 18 24 30 36 42 48 54 50 66 72

Engine compartment and under vehicle

Engine oil (Use recommended oil)*RRRRRRRRRRRRMA-21

Engine oil filter (Use Nissan genuine part or equivalent)*RRRRRRRRRRRRMA-21

Drive beltsIIIIIIIIIIIIMA-20

Cooling systemIIIIIIMA-23

Engine anti-freeze coolant (Ethylene

glycol base)See NOTE (1)MA-22

Air cleaner filter (dry paper type)*CRCRCRMA-24

Intake and exhaust valve clearanceIIIIIIMA-20

Fuel linesIIIÐ

Fuel filter*R R R MA-23

Injection nozzle See NOTE (2)MA-25

NOTE: (1) First replace at 80,000 km (48,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injection

nozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving

conditionsº.

PERIODIC MAINTENANCE

MA-5

Page 1467 of 1767

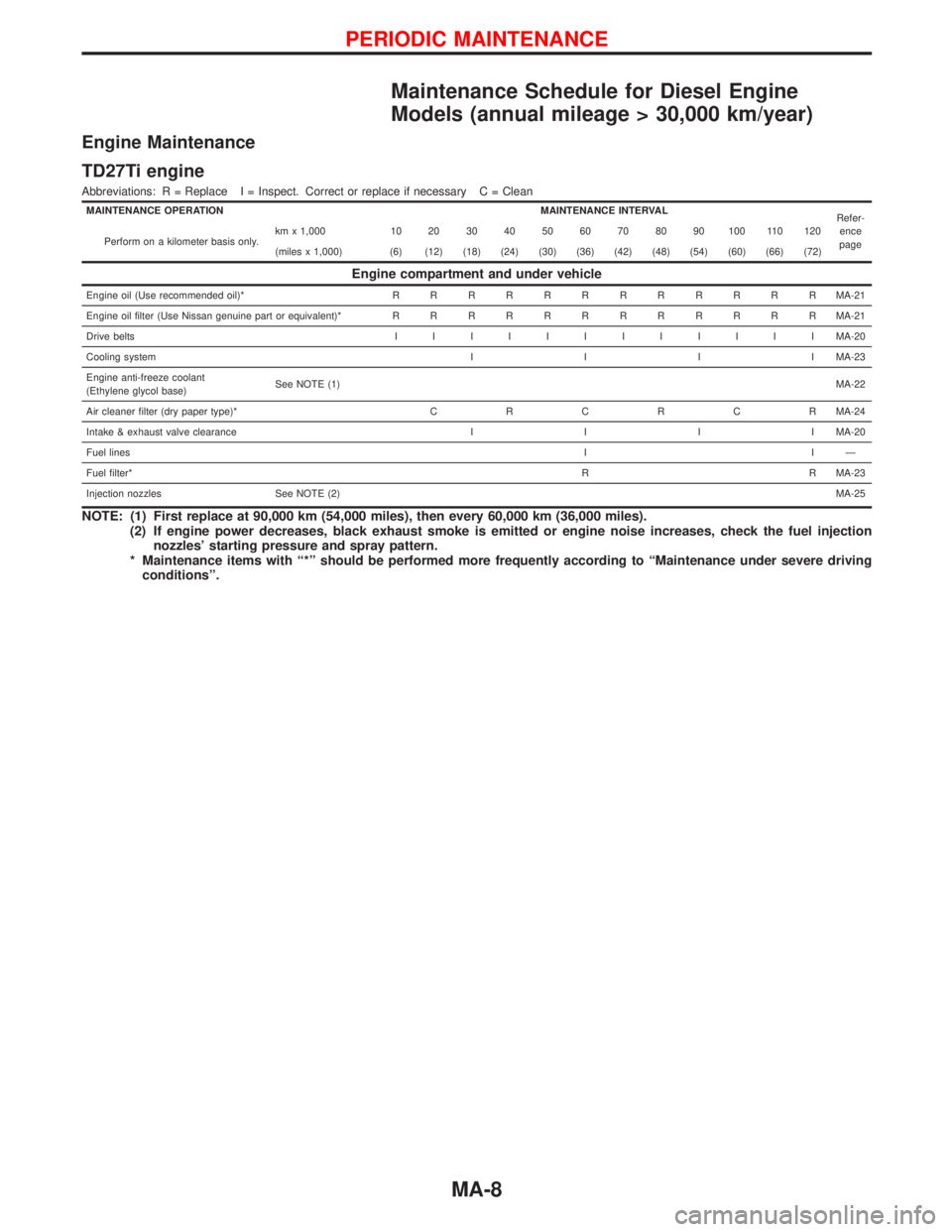

Maintenance Schedule for Diesel Engine

Models (annual mileage > 30,000 km/year)

Engine Maintenance

TD27Ti engine

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary C = Clean

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis only.km x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Engine compartment and under vehicle

Engine oil (Use recommended oil)*RRRRRRRRRRRRMA-21

Engine oil filter (Use Nissan genuine part or equivalent)*RRRRRRRRRRRRMA-21

Drive beltsIIIIIIIIIIIIMA-20

Cooling systemIIIIMA-23

Engine anti-freeze coolant

(Ethylene glycol base)See NOTE (1)MA-22

Air cleaner filter (dry paper type)*CRCRCRMA-24

Intake & exhaust valve clearanceIIIIMA-20

Fuel linesIIÐ

Fuel filter*R R MA-23

Injection nozzles See NOTE (2)MA-25

NOTE: (1) First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles).

(2) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check the fuel injection

nozzles' starting pressure and spray pattern.

* Maintenance items with ª*º should be performed more frequently according to ªMaintenance under severe driving

conditionsº.

PERIODIC MAINTENANCE

MA-8

Page 1480 of 1767

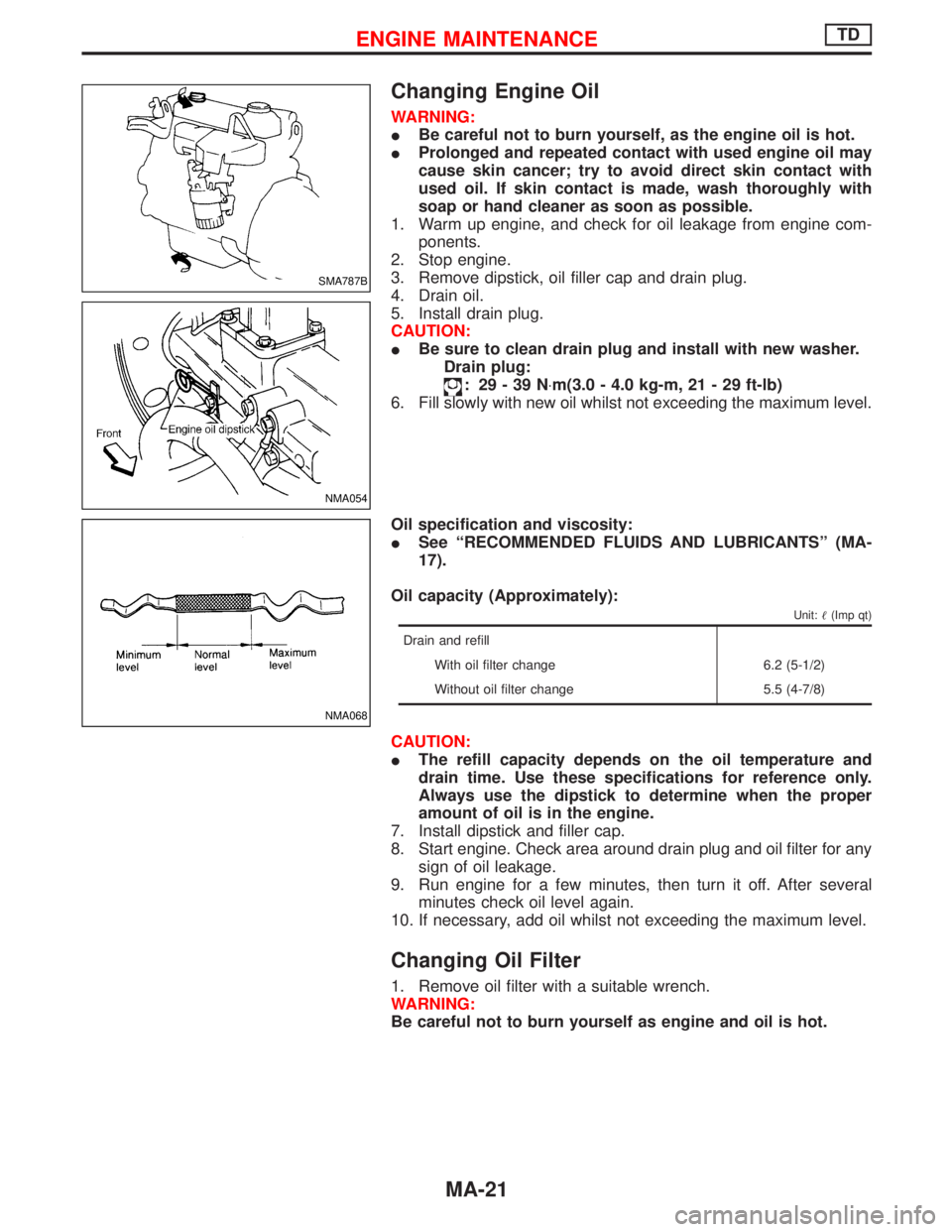

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine.

3. Remove dipstick, oil filler cap and drain plug.

4. Drain oil.

5. Install drain plug.

CAUTION:

IBe sure to clean drain plug and install with new washer.

Drain plug:

: 29-39N×m(3.0 - 4.0 kg-m, 21 - 29 ft-lb)

6. Fill slowly with new oil whilst not exceeding the maximum level.

Oil specification and viscosity:

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº (MA-

17).

Oil capacity (Approximately):

Unit:(Imp qt)

Drain and refill

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

CAUTION:

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

7. Install dipstick and filler cap.

8. Start engine. Check area around drain plug and oil filter for any

sign of oil leakage.

9. Run engine for a few minutes, then turn it off. After several

minutes check oil level again.

10. If necessary, add oil whilst not exceeding the maximum level.

Changing Oil Filter

1. Remove oil filter with a suitable wrench.

WARNING:

Be careful not to burn yourself as engine and oil is hot.

SMA787B

NMA054

NMA068

ENGINE MAINTENANCETD

MA-21

Page 1483 of 1767

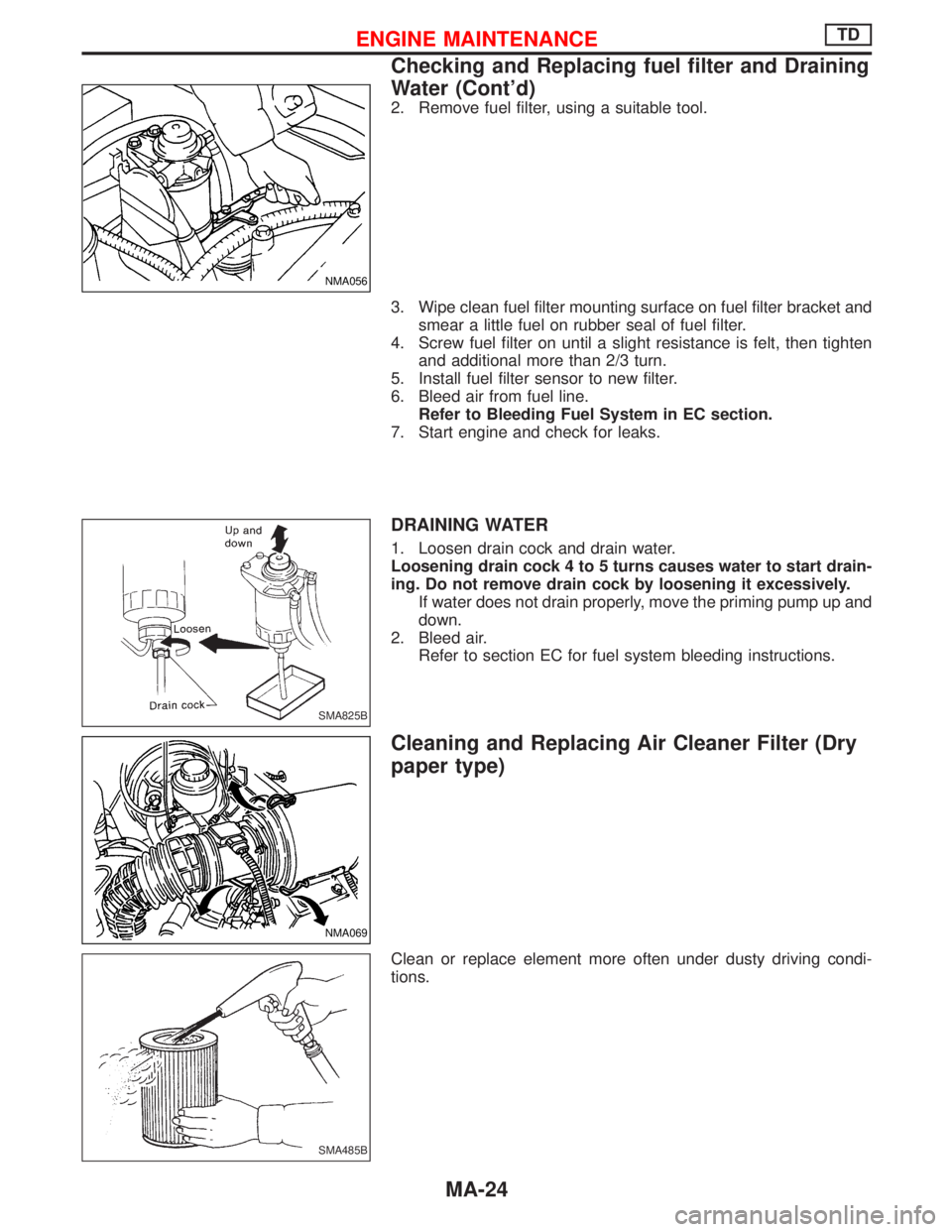

2. Remove fuel filter, using a suitable tool.

3. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

4. Screw fuel filter on until a slight resistance is felt, then tighten

and additional more than 2/3 turn.

5. Install fuel filter sensor to new filter.

6. Bleed air from fuel line.

Refer to Bleeding Fuel System in EC section.

7. Start engine and check for leaks.

DRAINING WATER

1. Loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start drain-

ing. Do not remove drain cock by loosening it excessively.

If water does not drain properly, move the priming pump up and

down.

2. Bleed air.

Refer to section EC for fuel system bleeding instructions.

Cleaning and Replacing Air Cleaner Filter (Dry

paper type)

Clean or replace element more often under dusty driving condi-

tions.

NMA056

SMA825B

NMA069

SMA485B

ENGINE MAINTENANCETD

Checking and Replacing fuel filter and Draining

Water (Cont'd)

MA-24

Page 1485 of 1767

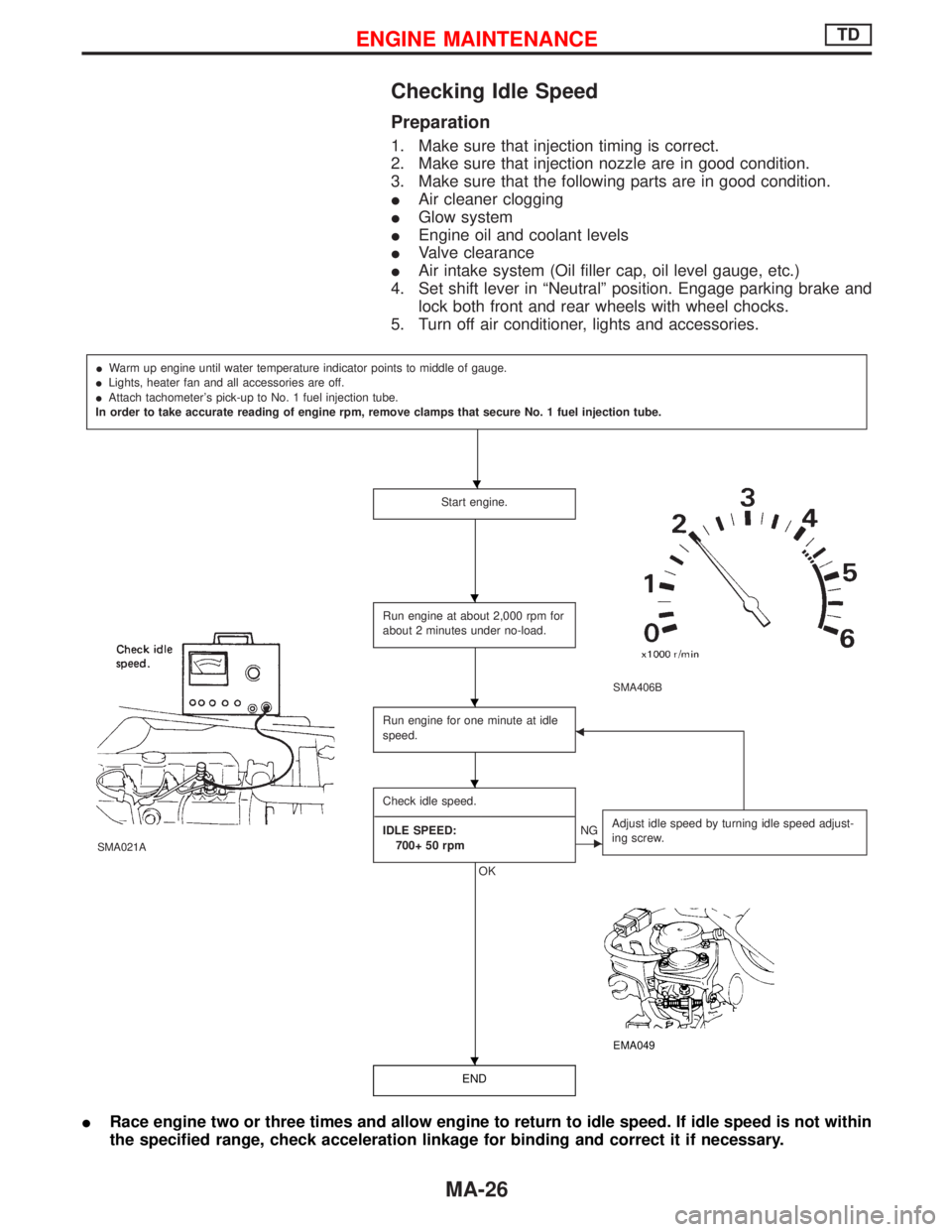

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

IGlow system

IEngine oil and coolant levels

IValve clearance

IAir intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and

lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

IWarm up engine until water temperature indicator points to middle of gauge.

ILights, heater fan and all accessories are off.

IAttach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

IDLE SPEED:

700+ 50 rpm

OK

ENGAdjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

IRace engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

Page 1488 of 1767

Removal

WATER PUMP, ALTERNATOR AND AIR CONDITIONER

BELT

1. Remove radiator shroud.

2. Contract and hold the auto tensioner using the following proce-

dure.

a. Securely hold the 19 mm (0.75 in) hexagonal portion A of auto

tensioner with a closed wrench.

IPreferably use a tool with a handhold of 500 mm (19.69 in) or

more in length.

INo bolts or nuts are required to be loosened during the opera-

tion.

b. Turn the hexagonal portion A in the direction shown by the

arrow to contract the damper unit of the auto tensioner.

CAUTION:

IBecause the tensioner has a high tension, it shall be

securely held and turned with a closed wrench.

IBecause the hexagonal portion A of the tensioner is made

of aluminum and may be damaged by sudden input, turn

it slowly according to the contraction of the damper unit.

3. Remove the belt from the alternator pulley first, and then

remove it from the other pulleys.

IIf the tensioner is not held firmly, your finger may get caught

between the belt and the pulleys. Confirm the holding of the

tensioner, and then hold the belt side in the place away from

the pulleys to attach or remove the belt, paying attention to

prevent your finger from being caught.

CAUTION:

IWhen handling the belt, pay attention to prevent the oil or

coolant from adhering to the belt.

IDo not distort or bend the belt intensively.

Installation

IInstall the belt in the reverse order of removal.

IAfter installation of the belt, confirm that the belt engages the

pulleys securely.

IDepending on the engagement between the belt and the idler

pulley, noise (belt noise) may be heard when the engine is

started just after installation. This noise will stop with time.

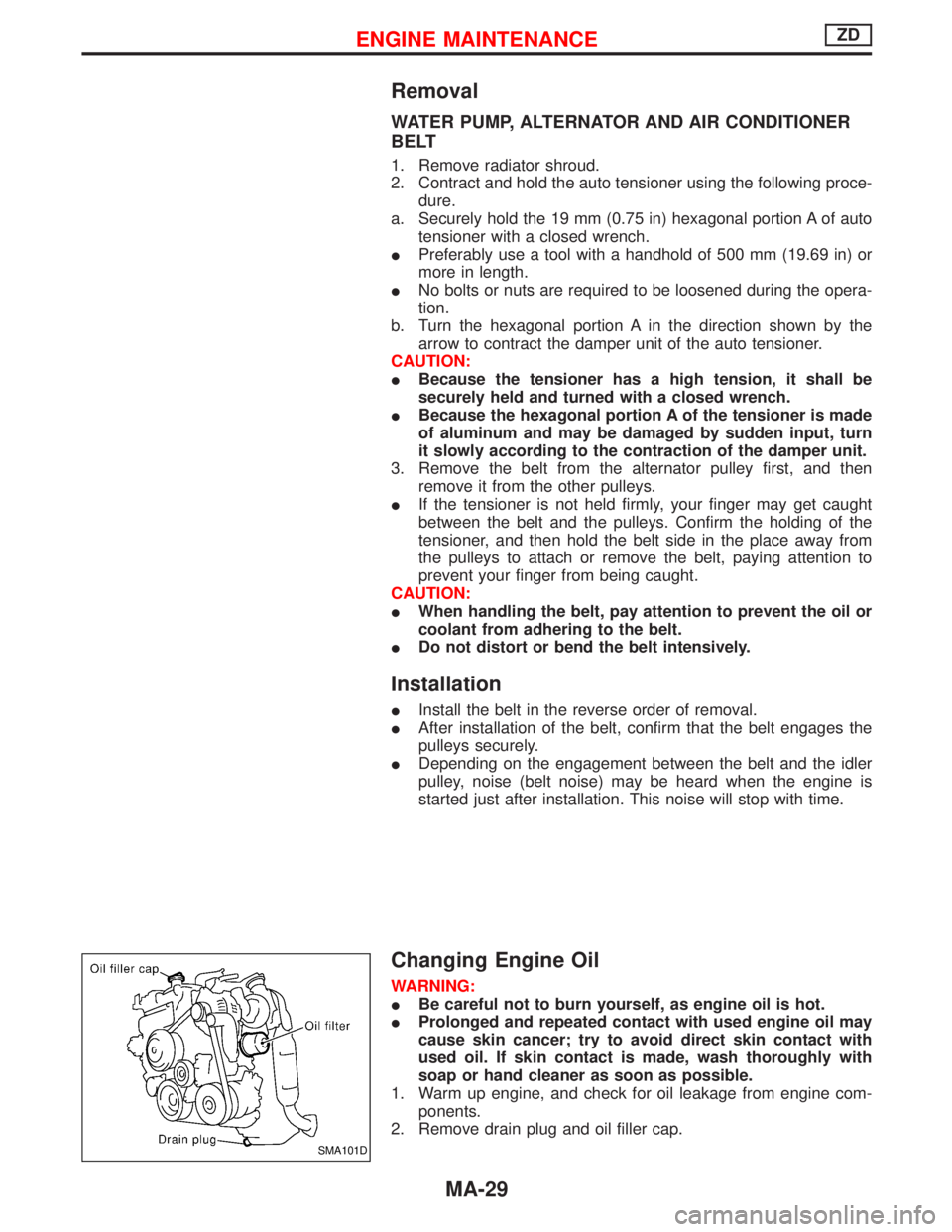

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Remove drain plug and oil filler cap.

SMA101D

ENGINE MAINTENANCEZD

MA-29

Page 1489 of 1767

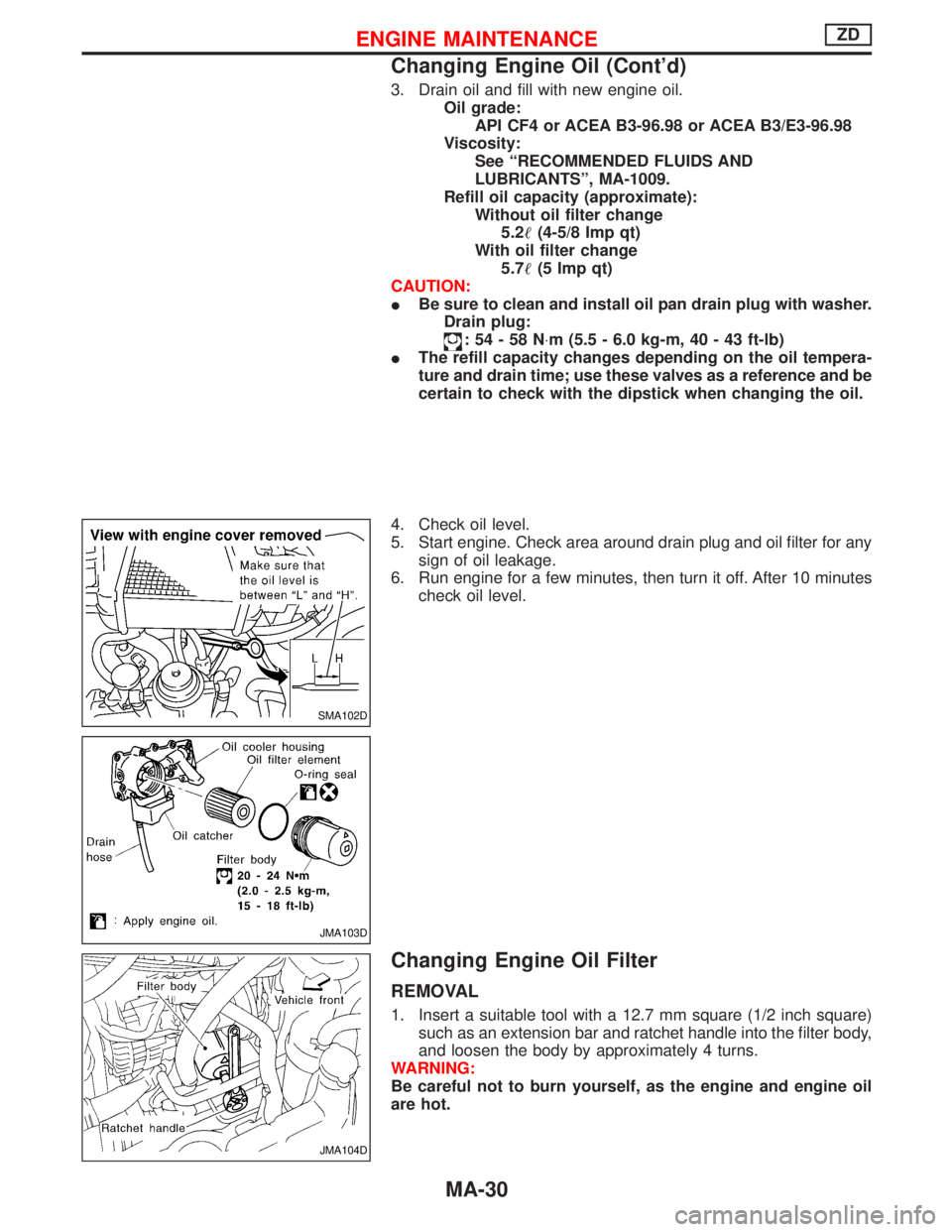

3. Drain oil and fill with new engine oil.

Oil grade:

API CF4 or ACEA B3-96.98 or ACEA B3/E3-96.98

Viscosity:

See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-1009.

Refill oil capacity (approximate):

Without oil filter change

5.2(4-5/8 Imp qt)

With oil filter change

5.7(5 Imp qt)

CAUTION:

IBe sure to clean and install oil pan drain plug with washer.

Drain plug:

:54-58N×m (5.5 - 6.0 kg-m, 40 - 43 ft-lb)

IThe refill capacity changes depending on the oil tempera-

ture and drain time; use these valves as a reference and be

certain to check with the dipstick when changing the oil.

4. Check oil level.

5. Start engine. Check area around drain plug and oil filter for any

sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After 10 minutes

check oil level.

Changing Engine Oil Filter

REMOVAL

1. Insert a suitable tool with a 12.7 mm square (1/2 inch square)

such as an extension bar and ratchet handle into the filter body,

and loosen the body by approximately 4 turns.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

SMA102D

JMA103D

JMA104D

ENGINE MAINTENANCEZD

Changing Engine Oil (Cont'd)

MA-30

Page 1493 of 1767

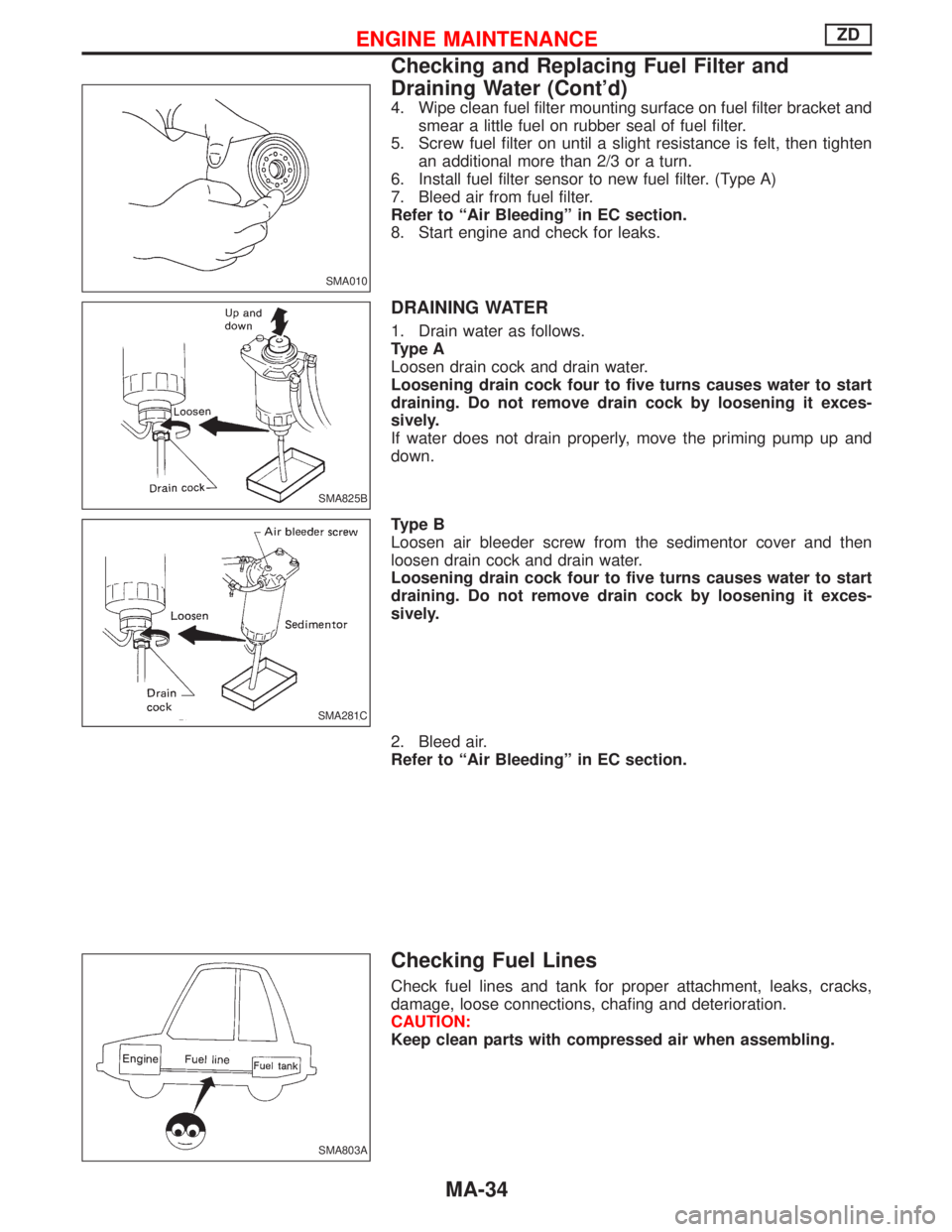

4. Wipe clean fuel filter mounting surface on fuel filter bracket and

smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 or a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-34