torque NISSAN TERRANO 2002 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1172 of 1767

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor and

inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix it

to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move har-

nesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mounting

bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to trans-

mission.

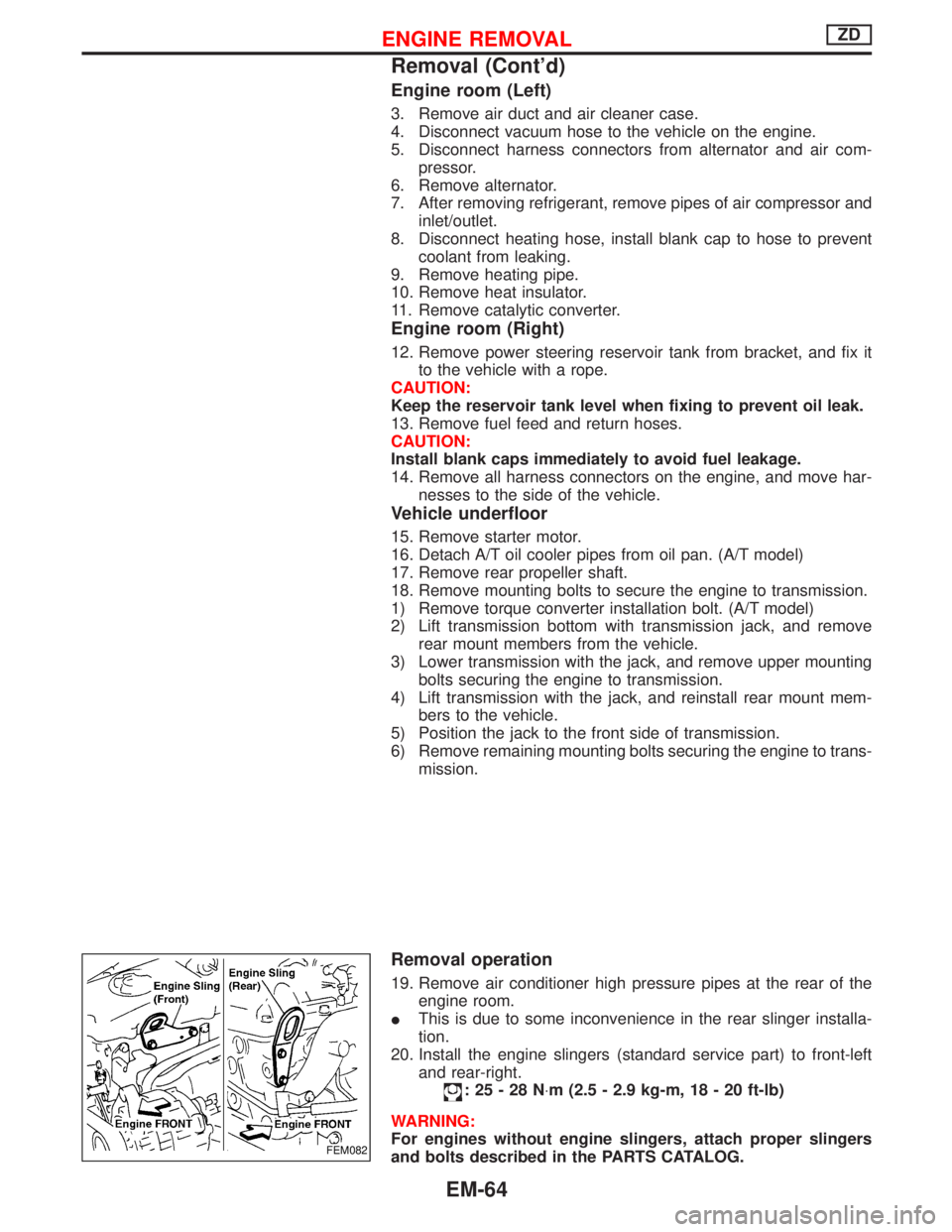

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

IThis is due to some inconvenience in the rear slinger installa-

tion.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28N×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-64

Page 1181 of 1767

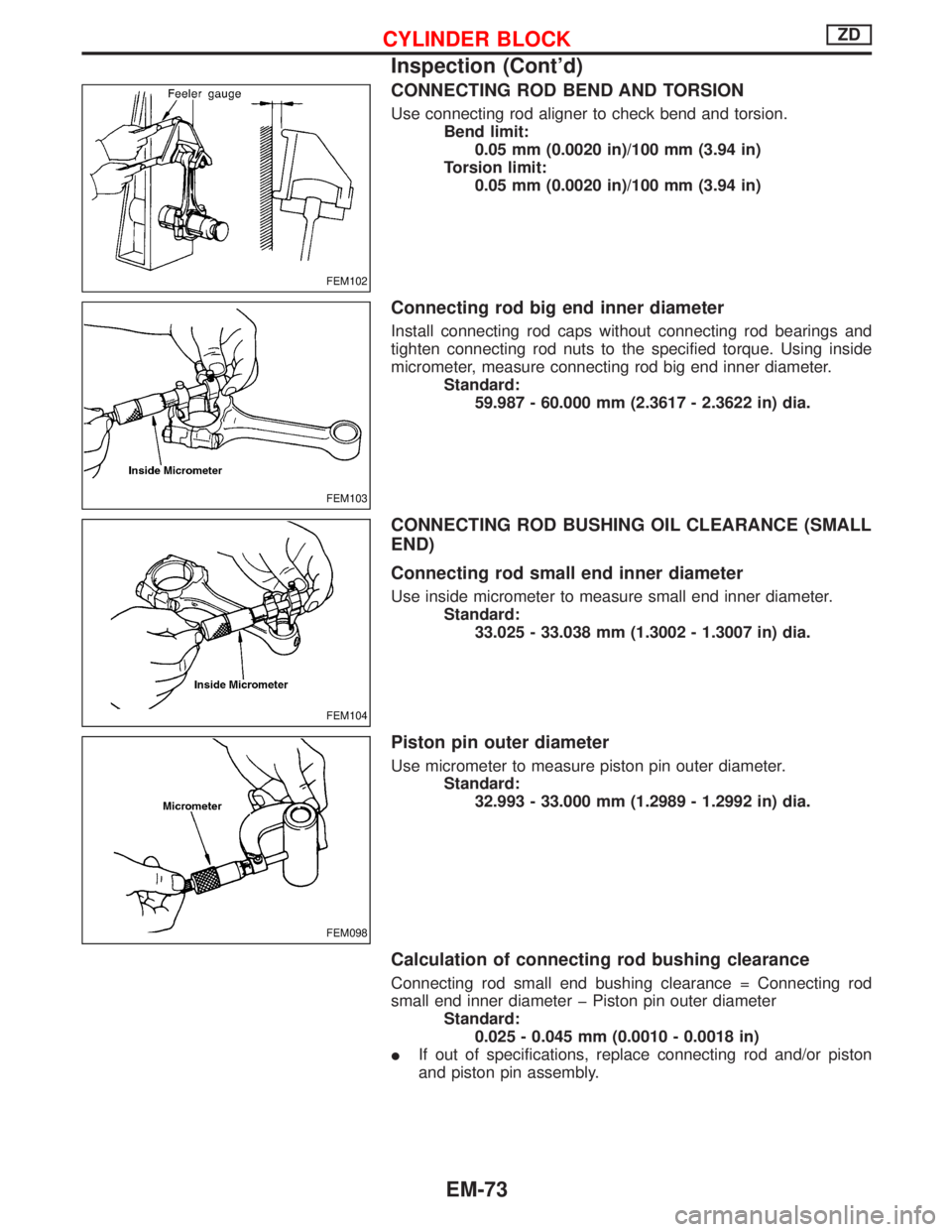

CONNECTING ROD BEND AND TORSION

Use connecting rod aligner to check bend and torsion.

Bend limit:

0.05 mm (0.0020 in)/100 mm (3.94 in)

Torsion limit:

0.05 mm (0.0020 in)/100 mm (3.94 in)

Connecting rod big end inner diameter

Install connecting rod caps without connecting rod bearings and

tighten connecting rod nuts to the specified torque. Using inside

micrometer, measure connecting rod big end inner diameter.

Standard:

59.987 - 60.000 mm (2.3617 - 2.3622 in) dia.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL

END)

Connecting rod small end inner diameter

Use inside micrometer to measure small end inner diameter.

Standard:

33.025 - 33.038 mm (1.3002 - 1.3007 in) dia.

Piston pin outer diameter

Use micrometer to measure piston pin outer diameter.

Standard:

32.993 - 33.000 mm (1.2989 - 1.2992 in) dia.

Calculation of connecting rod bushing clearance

Connecting rod small end bushing clearance = Connecting rod

small end inner diameter þ Piston pin outer diameter

Standard:

0.025 - 0.045 mm (0.0010 - 0.0018 in)

IIf out of specifications, replace connecting rod and/or piston

and piston pin assembly.

FEM102

FEM103

FEM104

FEM098

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-73

Page 1182 of 1767

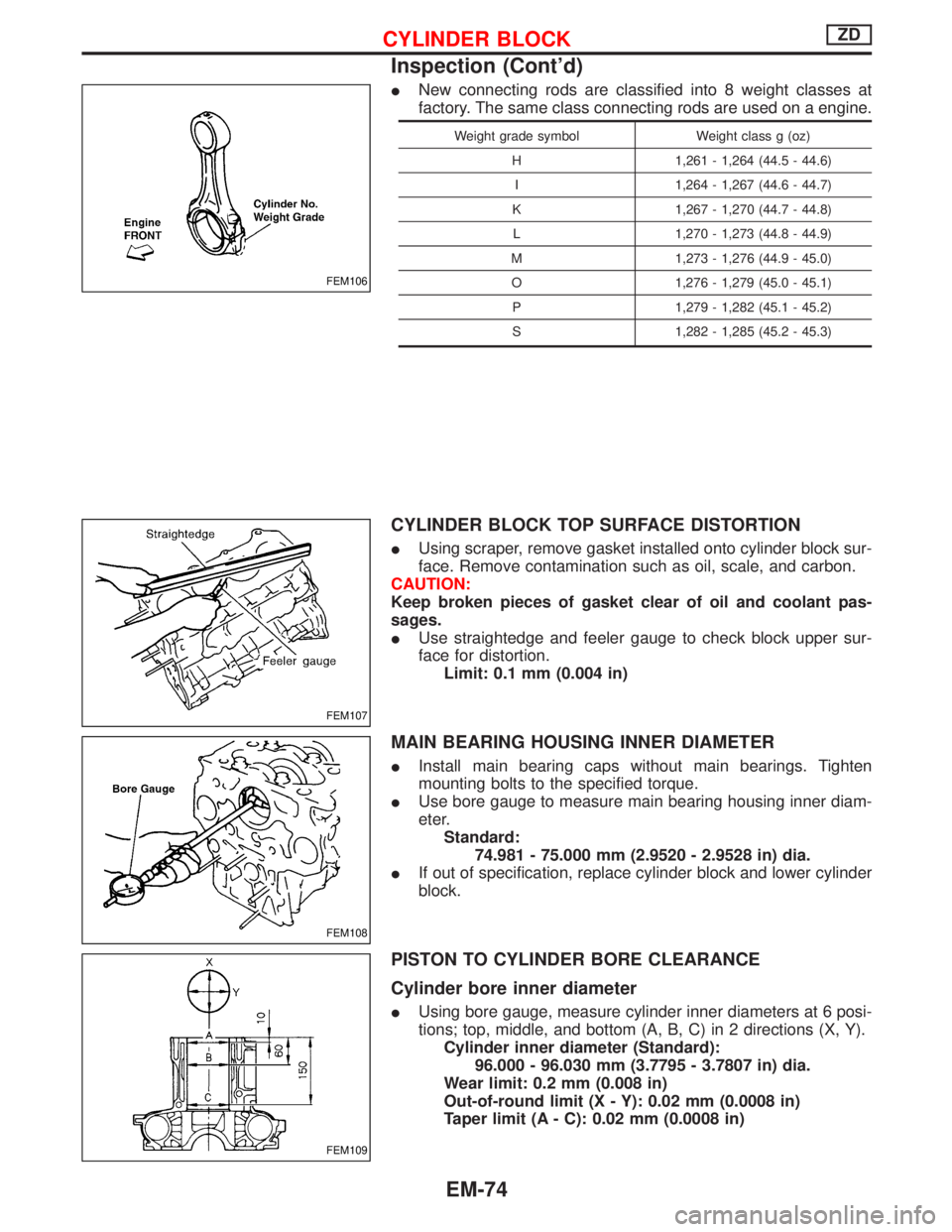

INew connecting rods are classified into 8 weight classes at

factory. The same class connecting rods are used on a engine.

Weight grade symbol Weight class g (oz)

H 1,261 - 1,264 (44.5 - 44.6)

I 1,264 - 1,267 (44.6 - 44.7)

K 1,267 - 1,270 (44.7 - 44.8)

L 1,270 - 1,273 (44.8 - 44.9)

M 1,273 - 1,276 (44.9 - 45.0)

O 1,276 - 1,279 (45.0 - 45.1)

P 1,279 - 1,282 (45.1 - 45.2)

S 1,282 - 1,285 (45.2 - 45.3)

CYLINDER BLOCK TOP SURFACE DISTORTION

IUsing scraper, remove gasket installed onto cylinder block sur-

face. Remove contamination such as oil, scale, and carbon.

CAUTION:

Keep broken pieces of gasket clear of oil and coolant pas-

sages.

IUse straightedge and feeler gauge to check block upper sur-

face for distortion.

Limit: 0.1 mm (0.004 in)

MAIN BEARING HOUSING INNER DIAMETER

IInstall main bearing caps without main bearings. Tighten

mounting bolts to the specified torque.

IUse bore gauge to measure main bearing housing inner diam-

eter.

Standard:

74.981 - 75.000 mm (2.9520 - 2.9528 in) dia.

IIf out of specification, replace cylinder block and lower cylinder

block.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder bore inner diameter

IUsing bore gauge, measure cylinder inner diameters at 6 posi-

tions; top, middle, and bottom (A, B, C) in 2 directions (X, Y).

Cylinder inner diameter (Standard):

96.000 - 96.030 mm (3.7795 - 3.7807 in) dia.

Wear limit: 0.2 mm (0.008 in)

Out-of-round limit (X - Y): 0.02 mm (0.0008 in)

Taper limit (A - C): 0.02 mm (0.0008 in)

FEM106

FEM107

FEM108

FEM109

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-74

Page 1185 of 1767

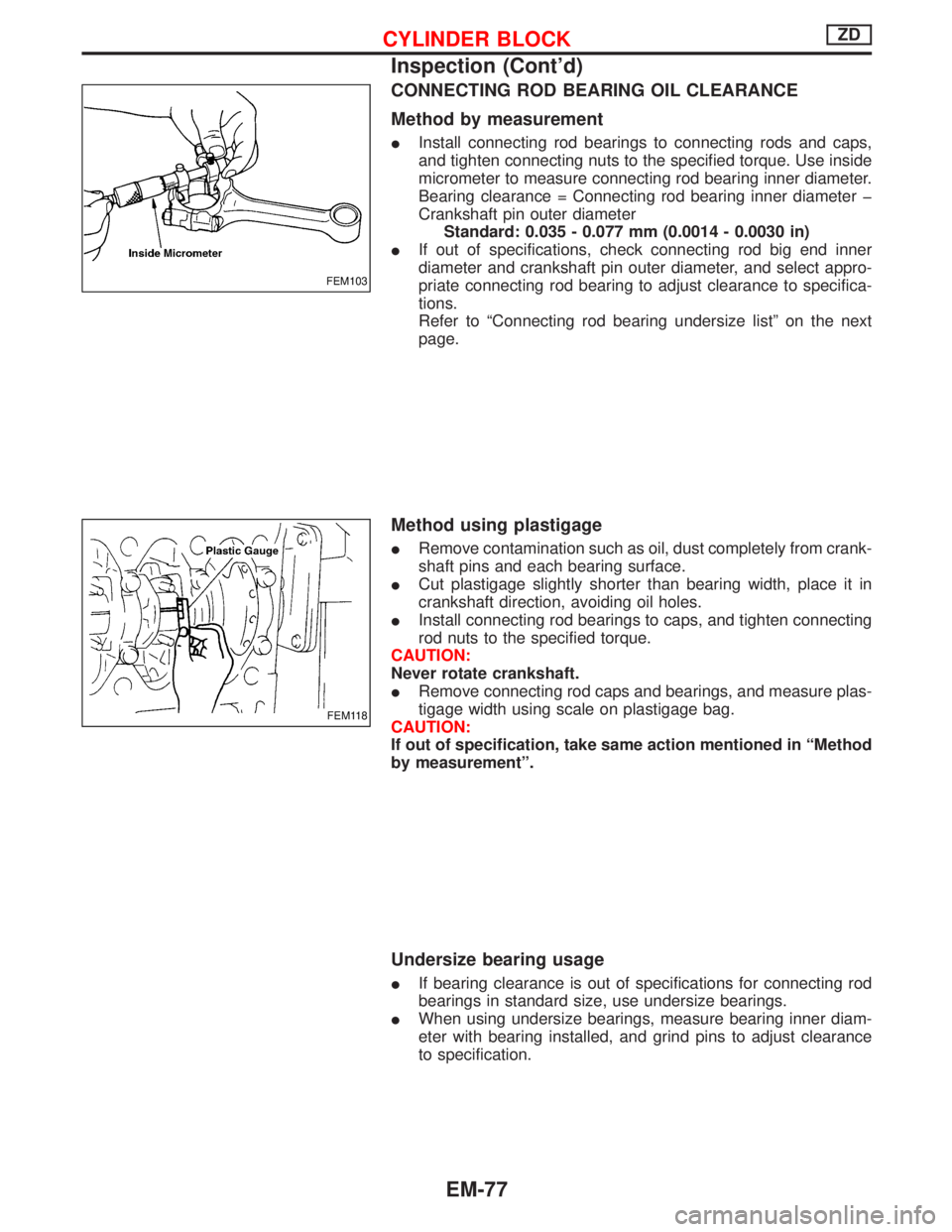

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

IInstall connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

Bearing clearance = Connecting rod bearing inner diameter þ

Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

IIf out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select appro-

priate connecting rod bearing to adjust clearance to specifica-

tions.

Refer to ªConnecting rod bearing undersize listº on the next

page.

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft pins and each bearing surface.

ICut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

IInstall connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

IRemove connecting rod caps and bearings, and measure plas-

tigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

IIf bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

IWhen using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind pins to adjust clearance

to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-77

Page 1186 of 1767

Connecting rod bearing undersize list

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 1.630 - 1.638 (0.0642 - 0.0645)

US 0.50 (0.0197) 1.755 - 1.763 (0.0691 - 0.0694)

US 0.75 (0.0295) 1.880 - 1.888 (0.0740 - 0.0743)

US 1.00 (0.0394) 2.005 - 2.013 (0.0789 - 0.0793)

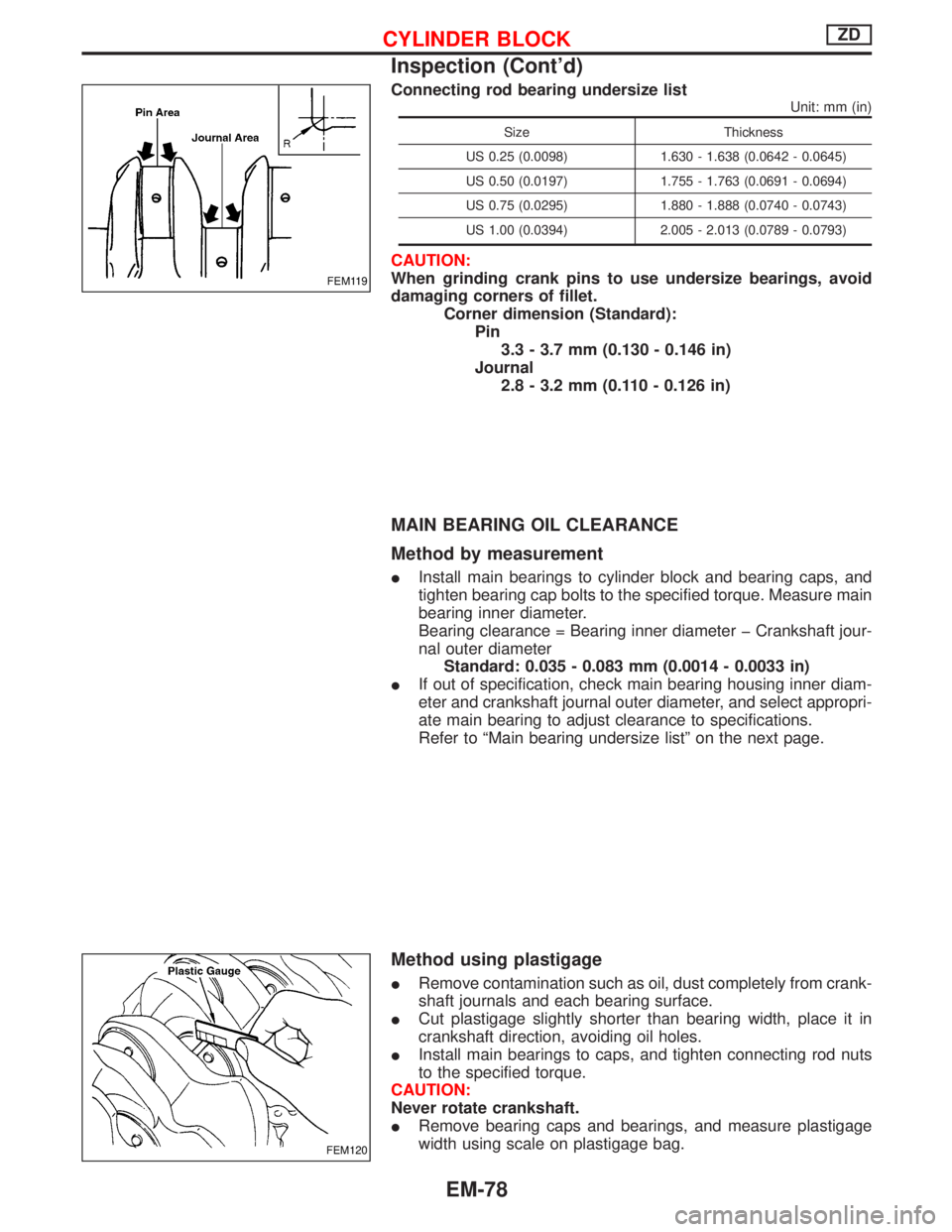

CAUTION:

When grinding crank pins to use undersize bearings, avoid

damaging corners of fillet.

Corner dimension (Standard):

Pin

3.3 - 3.7 mm (0.130 - 0.146 in)

Journal

2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING OIL CLEARANCE

Method by measurement

IInstall main bearings to cylinder block and bearing caps, and

tighten bearing cap bolts to the specified torque. Measure main

bearing inner diameter.

Bearing clearance = Bearing inner diameter þ Crankshaft jour-

nal outer diameter

Standard: 0.035 - 0.083 mm (0.0014 - 0.0033 in)

IIf out of specification, check main bearing housing inner diam-

eter and crankshaft journal outer diameter, and select appropri-

ate main bearing to adjust clearance to specifications.

Refer to ªMain bearing undersize listº on the next page.

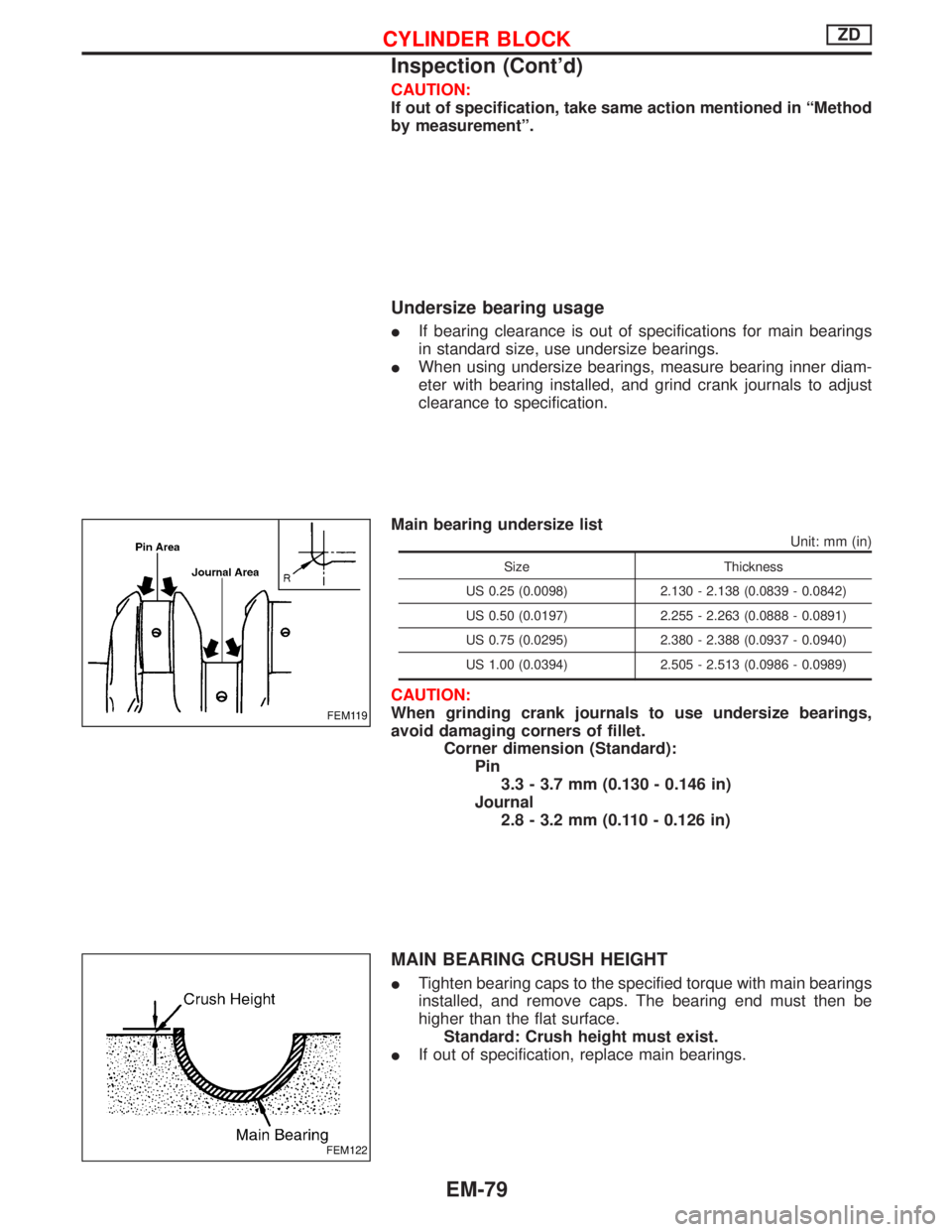

Method using plastigage

IRemove contamination such as oil, dust completely from crank-

shaft journals and each bearing surface.

ICut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

IInstall main bearings to caps, and tighten connecting rod nuts

to the specified torque.

CAUTION:

Never rotate crankshaft.

IRemove bearing caps and bearings, and measure plastigage

width using scale on plastigage bag.

FEM119

FEM120

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-78

Page 1187 of 1767

CAUTION:

If out of specification, take same action mentioned in ªMethod

by measurementº.

Undersize bearing usage

IIf bearing clearance is out of specifications for main bearings

in standard size, use undersize bearings.

IWhen using undersize bearings, measure bearing inner diam-

eter with bearing installed, and grind crank journals to adjust

clearance to specification.

Main bearing undersize list

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 2.130 - 2.138 (0.0839 - 0.0842)

US 0.50 (0.0197) 2.255 - 2.263 (0.0888 - 0.0891)

US 0.75 (0.0295) 2.380 - 2.388 (0.0937 - 0.0940)

US 1.00 (0.0394) 2.505 - 2.513 (0.0986 - 0.0989)

CAUTION:

When grinding crank journals to use undersize bearings,

avoid damaging corners of fillet.

Corner dimension (Standard):

Pin

3.3 - 3.7 mm (0.130 - 0.146 in)

Journal

2.8 - 3.2 mm (0.110 - 0.126 in)

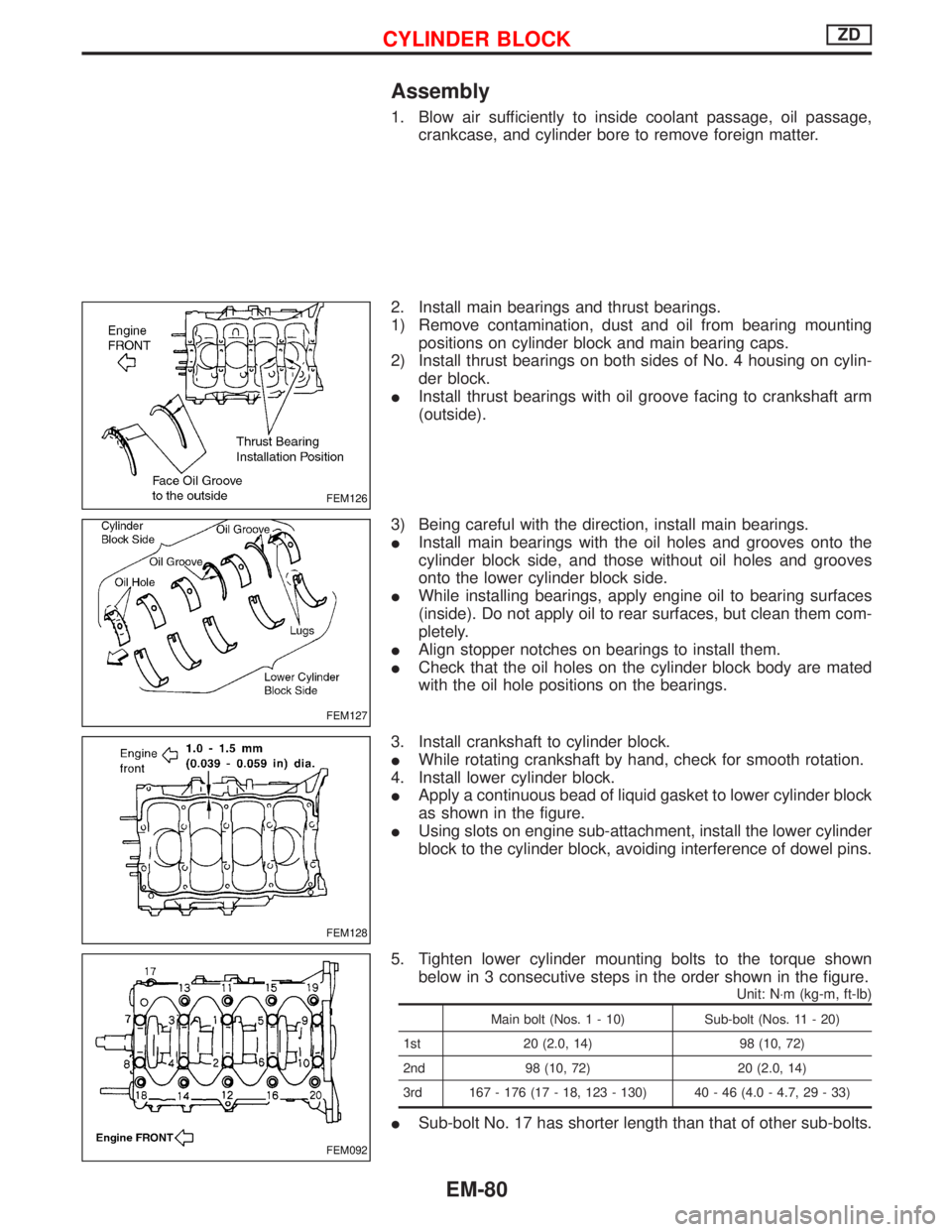

MAIN BEARING CRUSH HEIGHT

ITighten bearing caps to the specified torque with main bearings

installed, and remove caps. The bearing end must then be

higher than the flat surface.

Standard: Crush height must exist.

IIf out of specification, replace main bearings.

FEM119

FEM122

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-79

Page 1188 of 1767

Assembly

1. Blow air sufficiently to inside coolant passage, oil passage,

crankcase, and cylinder bore to remove foreign matter.

2. Install main bearings and thrust bearings.

1) Remove contamination, dust and oil from bearing mounting

positions on cylinder block and main bearing caps.

2) Install thrust bearings on both sides of No. 4 housing on cylin-

der block.

IInstall thrust bearings with oil groove facing to crankshaft arm

(outside).

3) Being careful with the direction, install main bearings.

IInstall main bearings with the oil holes and grooves onto the

cylinder block side, and those without oil holes and grooves

onto the lower cylinder block side.

IWhile installing bearings, apply engine oil to bearing surfaces

(inside). Do not apply oil to rear surfaces, but clean them com-

pletely.

IAlign stopper notches on bearings to install them.

ICheck that the oil holes on the cylinder block body are mated

with the oil hole positions on the bearings.

3. Install crankshaft to cylinder block.

IWhile rotating crankshaft by hand, check for smooth rotation.

4. Install lower cylinder block.

IApply a continuous bead of liquid gasket to lower cylinder block

as shown in the figure.

IUsing slots on engine sub-attachment, install the lower cylinder

block to the cylinder block, avoiding interference of dowel pins.

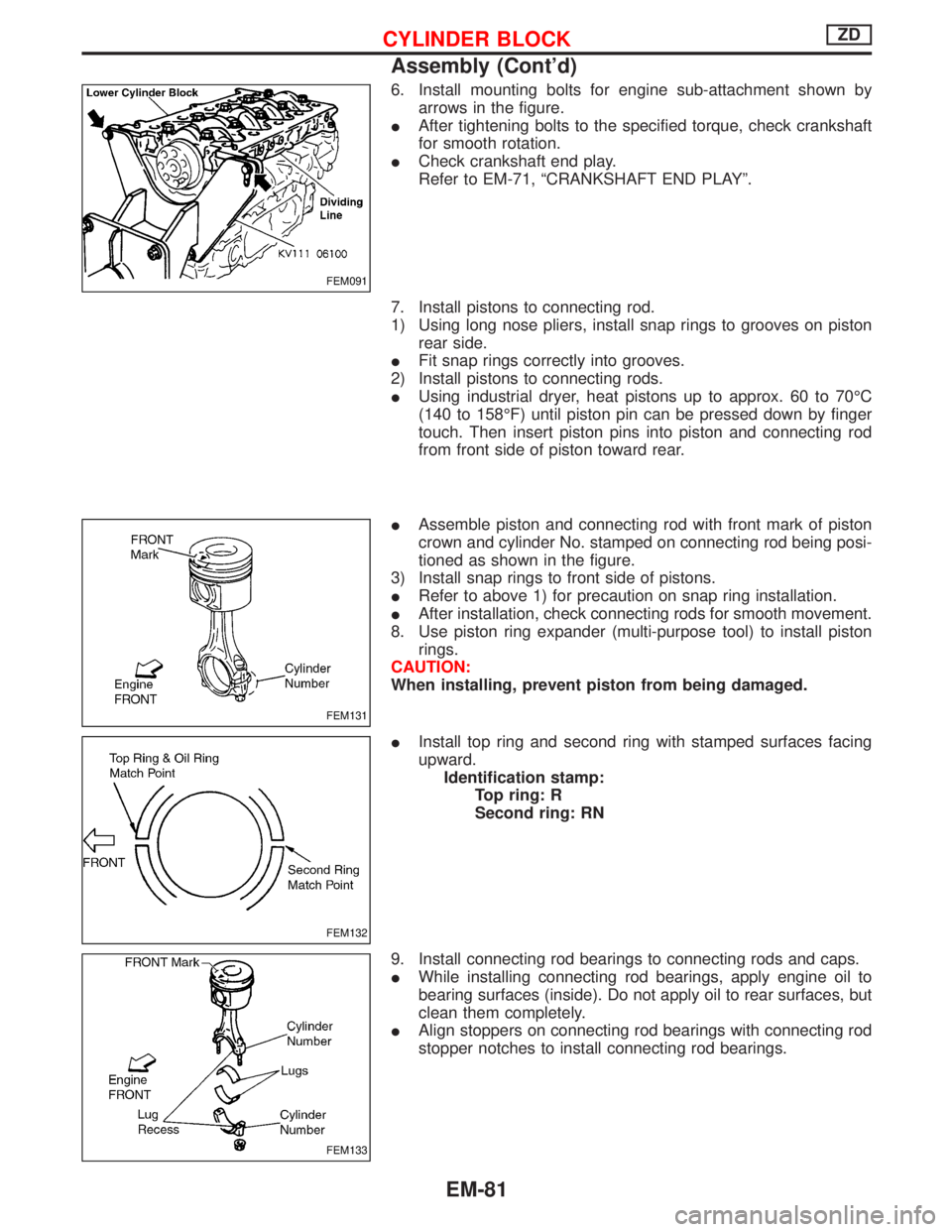

5. Tighten lower cylinder mounting bolts to the torque shown

below in 3 consecutive steps in the order shown in the figure.

Unit: N×m (kg-m, ft-lb)

Main bolt (Nos. 1 - 10) Sub-bolt (Nos. 11 - 20)

1st 20 (2.0, 14) 98 (10, 72)

2nd 98 (10, 72) 20 (2.0, 14)

3rd 167 - 176 (17 - 18, 123 - 130) 40 - 46 (4.0 - 4.7, 29 - 33)

ISub-bolt No. 17 has shorter length than that of other sub-bolts.

FEM126

FEM127

FEM128

FEM092

CYLINDER BLOCKZD

EM-80

Page 1189 of 1767

6. Install mounting bolts for engine sub-attachment shown by

arrows in the figure.

IAfter tightening bolts to the specified torque, check crankshaft

for smooth rotation.

ICheck crankshaft end play.

Refer to EM-71, ªCRANKSHAFT END PLAYº.

7. Install pistons to connecting rod.

1) Using long nose pliers, install snap rings to grooves on piston

rear side.

IFit snap rings correctly into grooves.

2) Install pistons to connecting rods.

IUsing industrial dryer, heat pistons up to approx. 60 to 70ÉC

(140 to 158ÉF) until piston pin can be pressed down by finger

touch. Then insert piston pins into piston and connecting rod

from front side of piston toward rear.

IAssemble piston and connecting rod with front mark of piston

crown and cylinder No. stamped on connecting rod being posi-

tioned as shown in the figure.

3) Install snap rings to front side of pistons.

IRefer to above 1) for precaution on snap ring installation.

IAfter installation, check connecting rods for smooth movement.

8. Use piston ring expander (multi-purpose tool) to install piston

rings.

CAUTION:

When installing, prevent piston from being damaged.

IInstall top ring and second ring with stamped surfaces facing

upward.

Identification stamp:

Top ring: R

Second ring: RN

9. Install connecting rod bearings to connecting rods and caps.

IWhile installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do not apply oil to rear surfaces, but

clean them completely.

IAlign stoppers on connecting rod bearings with connecting rod

stopper notches to install connecting rod bearings.

FEM091

FEM131

FEM132

FEM133

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-81

Page 1203 of 1767

Parts Requiring Angular Tightening

ISome important engine parts are tightened using an angular-

tightening method rather than a torque setting method.

IIf these parts are tightened using a torque setting method, dis-

persal of the tightening force (axial bolt force) will be two or

three times that of the dispersal produced by using the correct

angular-tightening method.

IAlthough the torque setting values (described in this manual)

are equivalent to those used when bolts and nuts are tightened

with an angular-tightening method, they should be used for

reference only.

ITo assure the satisfactory maintenance of the engine, bolts and

nuts must be tightened using an angular-tightening method.

IBefore tightening the bolts and nuts, ensure that the thread and

seating surfaces are clean and then coated with engine oil.

IThe bolts and nuts which require the angular-tightening method

are as follows:

(1) Cylinder head bolts

(2) Connecting rod cap nuts

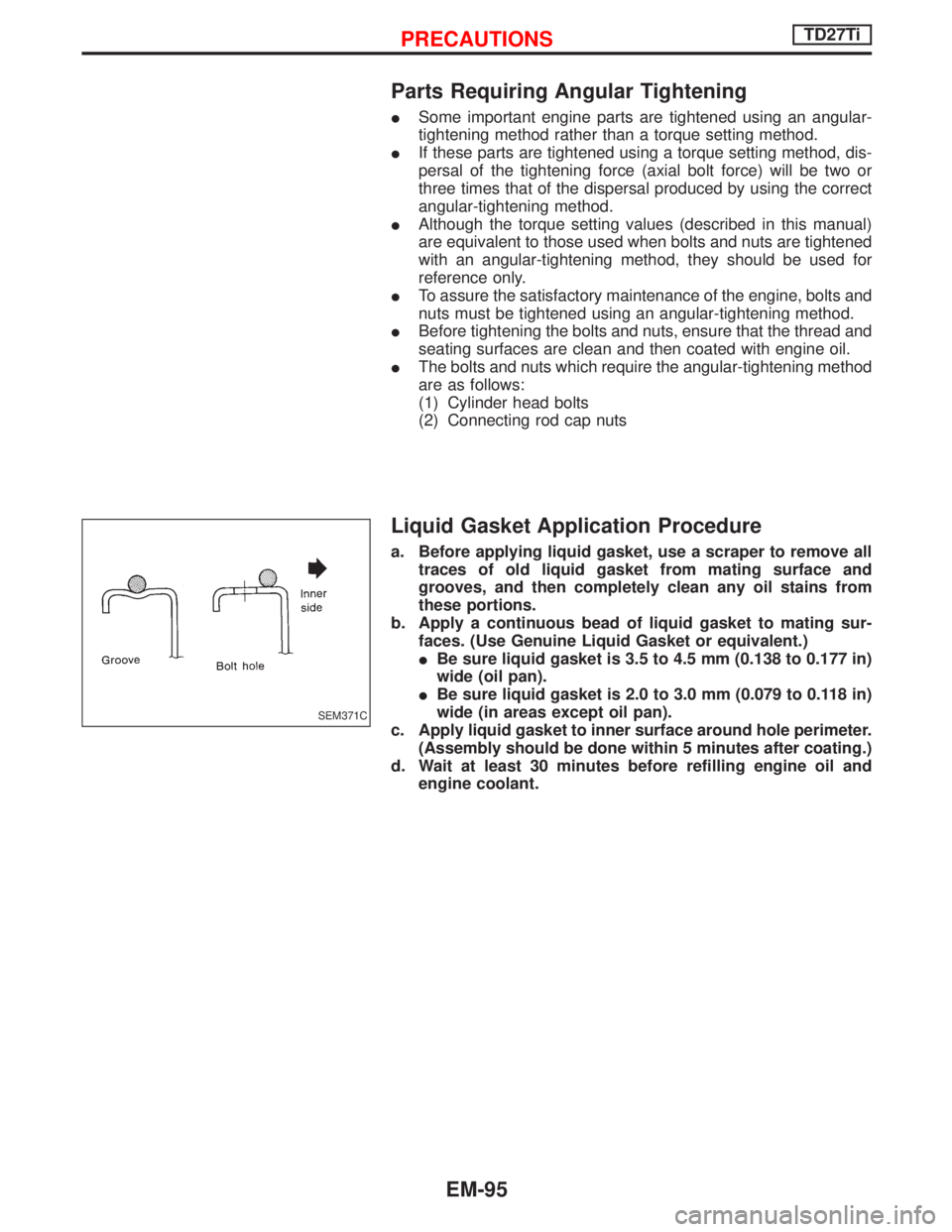

Liquid Gasket Application Procedure

a. Before applying liquid gasket, use a scraper to remove all

traces of old liquid gasket from mating surface and

grooves, and then completely clean any oil stains from

these portions.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

IBe sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in)

wide (oil pan).

IBe sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118 in)

wide (in areas except oil pan).

c. Apply liquid gasket to inner surface around hole perimeter.

(Assembly should be done within 5 minutes after coating.)

d. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM371C

PRECAUTIONSTD27Ti

EM-95

Page 1261 of 1767

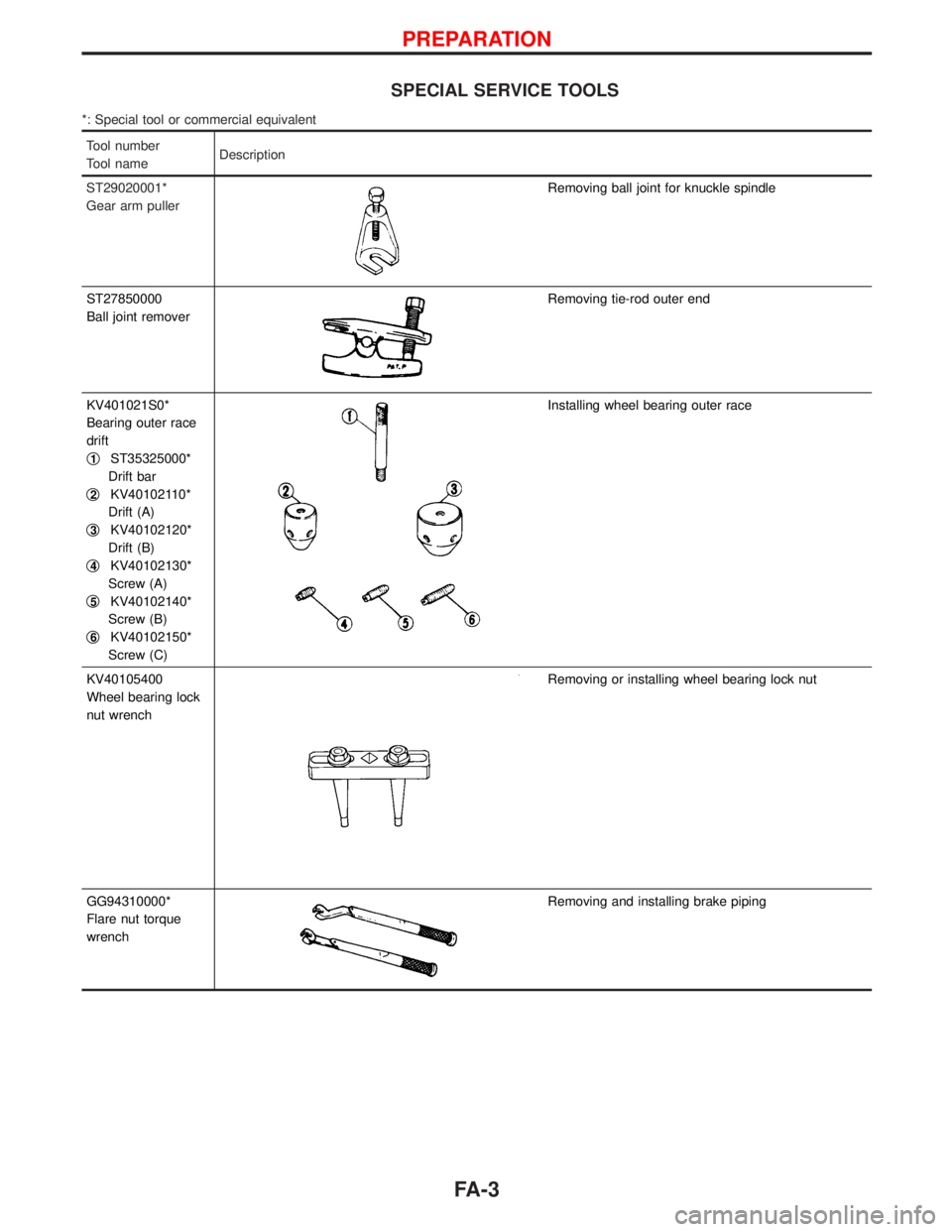

SPECIAL SERVICE TOOLS

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

ST29020001*

Gear arm puller

Removing ball joint for knuckle spindle

ST27850000

Ball joint remover

Removing tie-rod outer end

KV401021S0*

Bearing outer race

drift

q

1ST35325000*

Drift bar

q

2KV40102110*

Drift (A)

q

3KV40102120*

Drift (B)

q

4KV40102130*

Screw (A)

q

5KV40102140*

Screw (B)

q

6KV40102150*

Screw (C)

Installing wheel bearing outer race

KV40105400

Wheel bearing lock

nut wrench

Removing or installing wheel bearing lock nut

GG94310000*

Flare nut torque

wrench

Removing and installing brake piping

PREPARATION

FA-3